Method for improving uvioresistant laser damage for fused quartz optical element

A technology for optical components and laser damage, which is applied in the field of optical components, can solve the problems of small effect and low processing efficiency, and achieve the effect of improving surface cleanliness and anti-ultraviolet laser damage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

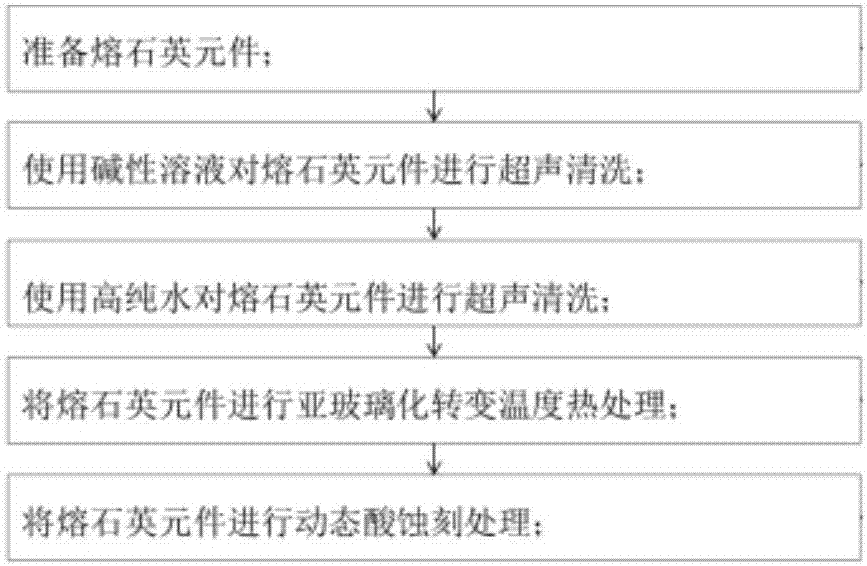

Image

Examples

Embodiment 1

[0031] A method for improving the resistance to ultraviolet laser damage of fused silica optical elements, comprising the following steps:

[0032] Step 1. Ultrasonic cleaning of the fused quartz element with an alkaline solution; the alkaline solution is a KOH solution with a mass fraction of 2%, the ultrasonic frequency of ultrasonic cleaning is 100KHz, and the ultrasonic time is 30min; the fused quartz element is 40*40 *4mm 3 fused silica element (Coring 7980);

[0033] Step 2: Ultrasonic cleaning and drying of the fused silica element after cleaning with the alkaline solution; the resistivity of the high-purity water is 15MΩ.cm, the ultrasonic frequency of ultrasonic cleaning is 100KHz, and the ultrasonic time is 5 minutes;

[0034] Step 3. Put the fused silica element cleaned with high-purity water into the annealing furnace for sub-glass transition temperature heat treatment; set the temperature of the annealing furnace to 900°C, the heating rate to 200°C / h, the heat tr...

Embodiment 2

[0038] A method for improving the resistance to ultraviolet laser damage of fused silica optical elements, comprising the following steps:

[0039]Step 1. Use alkaline solution to ultrasonically clean the fused quartz element; the alkaline solution is a KOH solution with a mass fraction of 5%, the ultrasonic frequency of ultrasonic cleaning is 150KHz, and the ultrasonic time is 60min; the fused quartz element is 40*40 *4mm 3 fused silica element (Coring 7980);

[0040] Step 2. Ultrasonic cleaning and drying of the fused silica element after cleaning with the alkaline solution; the resistivity of the high-purity water is 15MΩ.cm, the ultrasonic frequency of ultrasonic cleaning is 150KHz, and the ultrasonic time is 10min;

[0041] Step 3. Put the fused silica element cleaned with high-purity water into the annealing furnace for sub-glass transition temperature heat treatment; set the temperature of the annealing furnace to 900°C, the heating rate to 400°C / h, the heat treatment ...

Embodiment 3

[0045] A method for improving the resistance to ultraviolet laser damage of fused silica optical elements, comprising the following steps:

[0046] Step 1. Use alkaline solution to ultrasonically clean the fused quartz element; the alkaline solution is a KOH solution with a mass fraction of 3%, the ultrasonic frequency of ultrasonic cleaning is 120KHz, and the ultrasonic time is 30min; the fused quartz element is 40*40 *4mm 3 fused silica element (Coring 7980);

[0047] Step 2: The fused silica element cleaned by the alkaline solution is ultrasonically cleaned with high-purity water, and dried; the resistivity of the high-purity water is 15MΩ.cm, the ultrasonic frequency of ultrasonic cleaning is 120KHz, and the ultrasonic time is 5min;

[0048] Step 3. Put the fused silica element cleaned with high-purity water into the annealing furnace for sub-glass transition temperature heat treatment; set the temperature of the annealing furnace to 900°C, the heating rate to 600°C / h, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Damage threshold | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com