Manufacturing method for backboard and target material assembly

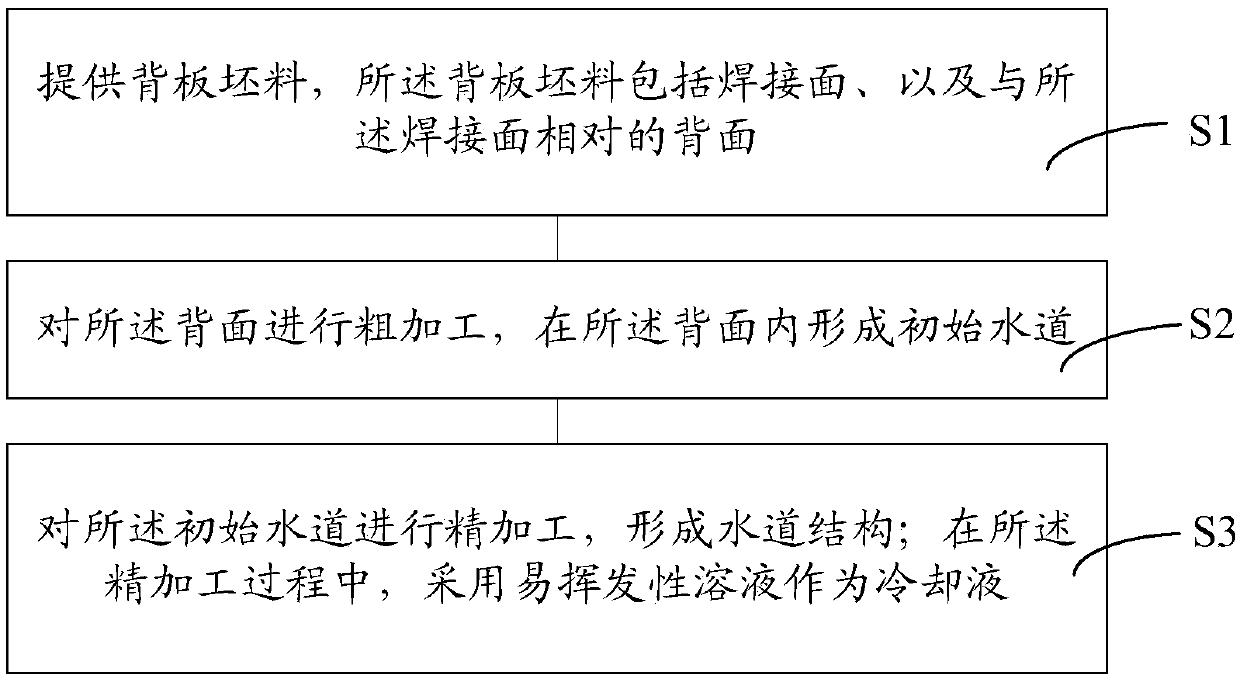

A manufacturing method and backplane technology, which are applied in the directions of manufacturing tools, milling machine equipment details, metal processing equipment, etc., can solve the problem that the performance of target components needs to be improved, and achieve the effect of improving forming quality, improving quality and high performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

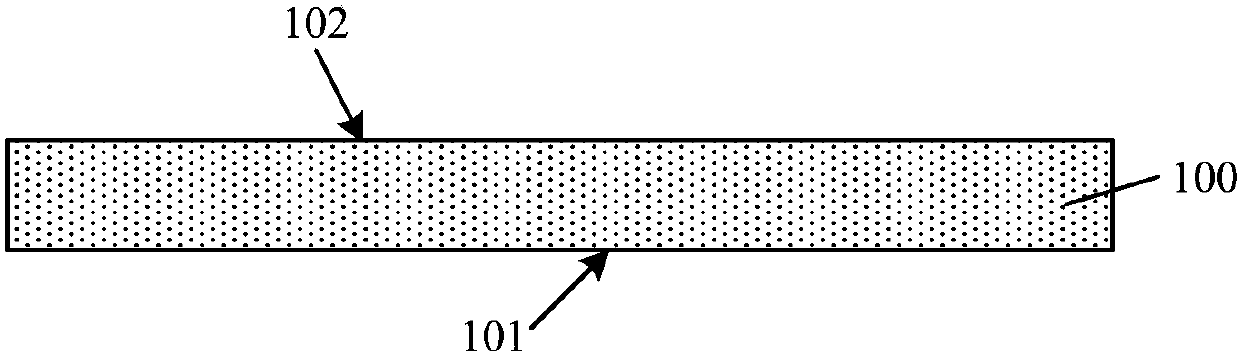

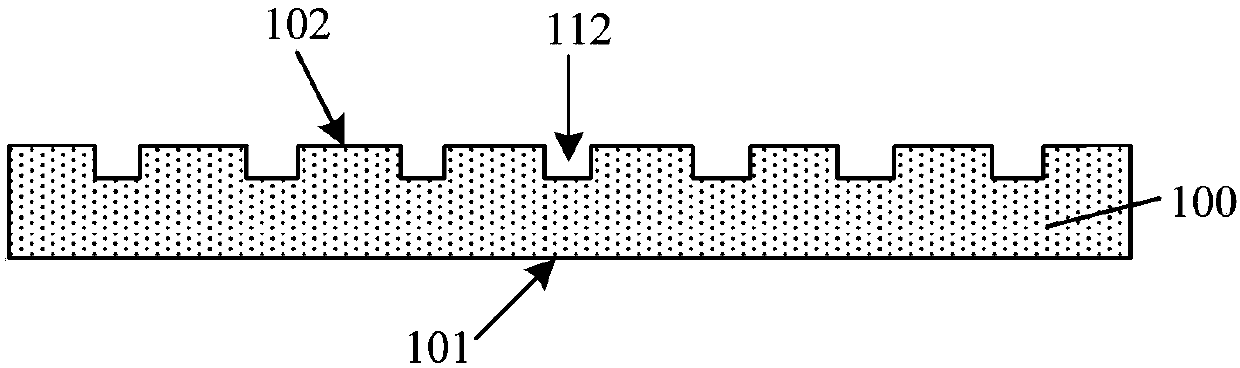

[0027] It can be seen from the background art that in order to achieve good high-temperature deformation resistance of the backboard, the interior of the backboard adopts a water channel structure design. During the use of the target assembly, continuous cooling water flows into the water channel structure, thereby taking away a large amount of heat from the surface of the target assembly.

[0028] However, the quality of the back plate still needs to be improved. The reason is that currently the milling process is mainly used to form the water channel structure. During the milling process, cutting fluid is generally used to lubricate and cool. Since the cutting fluid is an oily solution, it is difficult to completely remove the cutting fluid after the waterway structure is formed, so there is likely to be cutting fluid residue in the waterway structure, resulting in poor surface finish and color of the waterway structure. Dullness, poor visual appearance and other problems, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com