Preparation method of silver powder or doped silver powder

A silver powder and silver salt technology, applied in the chemical industry, can solve the problems of high energy consumption, harsh equipment environment requirements, and low cost performance for industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

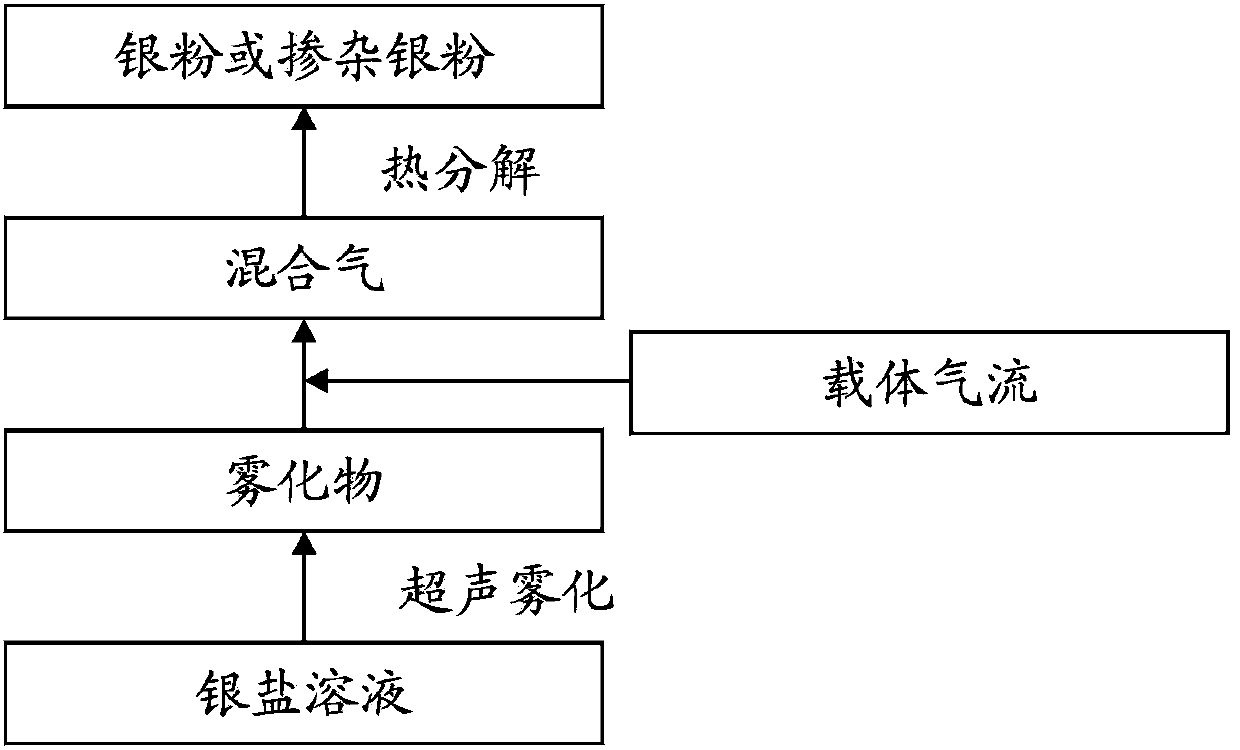

[0017] The embodiment of the present invention provides a kind of preparation method of above-mentioned silver powder or mixed silver powder, and its operation process is as follows figure 1 shown. The preparation method of the silver powder or doped silver powder comprises the following steps:

[0018] S01: Prepare silver salt atomized matter: prepare silver salt solution, and ultrasonically atomize the silver salt solution into atomized matter;

[0019] S02: thermally decompose the silver salt atomized product and the carrier airflow: mix the silver salt atomized product prepared in step S01 with the carrier airflow, then thermally decompose, and collect silver powder or doped silver powder.

[0020] Specifically, in the above step S01, the silver salt solution is a silver salt solution with a silver ion molar concentration of 0.0001 to 4 mol / L or a silver salt solution containing doped metal ions; in the silver salt solution containing doped metal ions, The ratio of the m...

Embodiment 1

[0034] A preparation method of doped silver powder, operation flow chart reference figure 1 , including the following steps:

[0035] Preparation concentration is 10L of silver nitrate aqueous solution of 2mol / L, lead nitrate, aluminum nitrate, ferric nitrate, copper nitrate, zinc nitrate are dissolved in described silver nitrate aqueous solution, obtain silver salt solution, wherein, lead ion, aluminum ion, iron ion , copper ion, zinc ion concentration are respectively 0.05mol / L, 0.003mol / L, 0.02mol / L, 0.0005mol / L, 0.0005mol / L, obtain silver salt solution;

[0036] Ultrasonic atomization is carried out on the obtained silver salt solution in the ultrasonic atomization equipment, the ultrasonic power is 500w, the frequency is 2.4MHz, the ultrasonic atomization rate is 20kg / h, and the atomized product is obtained, which is the same as normal pressure and nitrogen: hydrogen volume ratio The carrier gas flow with a flow rate of 6:4 and a flow rate of 3L / min is mixed and enters t...

Embodiment 2

[0045] A kind of preparation method of silver powder, operation flowchart is with reference to embodiment 1 figure 1 , including the following steps:

[0046] Preparation concentration is 10L of silver nitrate aqueous solution of 3mol / L, obtains silver salt solution;

[0047] Ultrasonic atomization is carried out to the obtained silver salt solution in the ultrasonic atomization equipment, the ultrasonic power is 3000w, the frequency is 2MHz, and the ultrasonic atomization rate is 150kg / h, and the atomized product is obtained, the atomized product is at normal pressure and the nitrogen: hydrogen volume ratio is 1:3, the carrier air flow with a flow rate of 800L / min is mixed and enters the sintering chamber of the microwave heater, and is heated by a microwave with a power of 30KW for 5 minutes. The generated doped silver powder gathers in the lower part of the sintering chamber and collects the silver powder.

[0048] The silver powder prepared in this embodiment was analyzed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com