Winding battery

A battery and electrode technology, applied in secondary batteries, battery electrodes, non-aqueous electrolyte battery electrodes, etc., can solve the problems of high productivity, unavailability, and difficulty in practical application, and achieve high productivity and shorten the effect of pre-doping time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

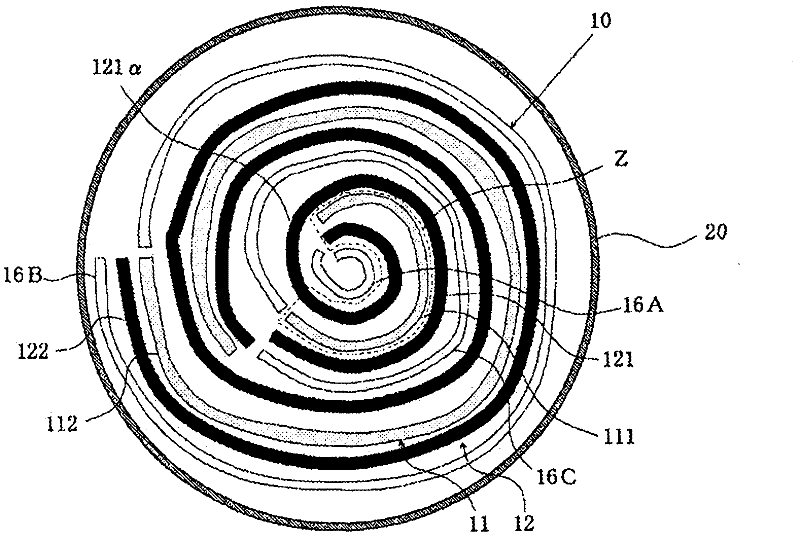

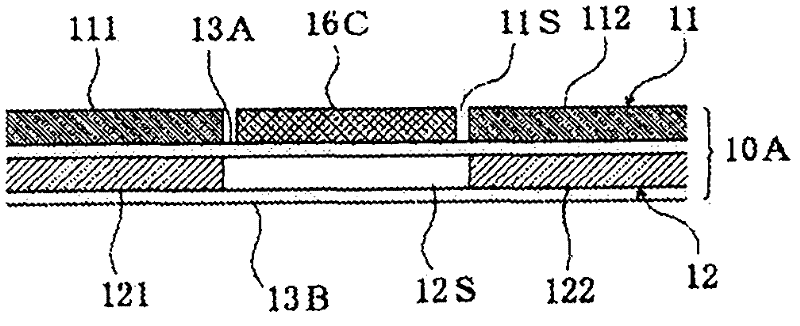

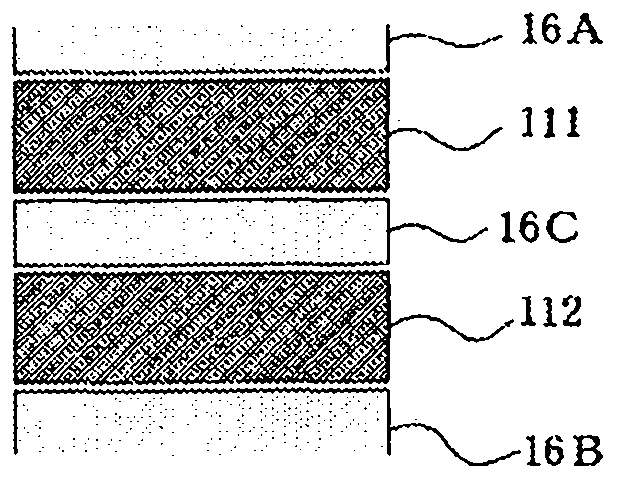

[0140] figure 1 It is an explanatory sectional view schematically showing the configuration of the wound LIC according to the first embodiment of the present invention. figure 2 is schematically shown figure 1 A cross-sectional view for explaining a state of a cross-section of an electrode laminate in a wound state of the wound electrode unit of the wound-type LIC.

[0141] The winding type LIC of this example has a cylindrical electrode winding unit 10, and the cylindrical electrode winding unit 10 is configured as follows: a strip-shaped positive electrode 11 having a positive electrode gap portion 11S and a strip-shaped positive electrode 11 having a negative electrode gap portion 12S. The negative electrode 12 is laminated with the separator interposed therebetween, specifically, the negative electrode 12, the separator 13A, and the positive electrode 11 are sequentially laminated on the separator 13B to form an electrode laminate 10A, and the electrode laminate 10A is w...

no. 2 approach

[0253] Such as Figure 16 and Figure 17 As shown, in the wound-type LIC of the second embodiment, the electrode winding unit 50 is a cylindrical member, and is configured as follows: a strip-shaped positive electrode 51 having a positive electrode gap 51S and a strip-shaped negative electrode 52 having a negative electrode gap 52S. The electrode laminate 50A is formed by laminating, specifically, the negative electrode 52 , the separator 53A, and the positive electrode 51 are sequentially laminated on the separator 53B, and the electrode laminate 50A is wound from one end thereof to form a wound electrode. The unit 50 has the same structure as that of the first embodiment except for this. In addition, in Figure 16 and Figure 17 In , the same reference numerals as those of the first embodiment denote the same components.

[0254] In wound electrode unit 50 in which positive electrode 51 , negative electrode 52 , and lithium ion supply sources 16A to 16C are laminated and w...

no. 3 approach

[0266] Figure 20 It is an explanatory cross-sectional view schematically showing the structure of a wound-type LIC according to a third embodiment of the present invention.

[0267] In this wound type LIC, an electrode wound unit 10 is provided in a packaging container 20 . Such as Figure 21 As shown, the electrode winding unit 10 sequentially stacks the negative electrode 12, the second separator 14B, and the positive electrode 11 on one side of the first separator 14A to form an electrode laminate 10A, and the electrode laminate 10A is wound in a cylindrical shape from one end thereof. The electrode winding unit 10 is formed by winding around the mandrel 19 . Here, electrode layers of the positive electrode 11 and the negative electrode 12 , which will be described later, are arranged to face each other with the second separator 14B interposed therebetween. In the illustrated example, the electrode laminate 10A is wound with the first separator 14A on the inside, whereb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com