Patents

Literature

153results about How to "Improve formation quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

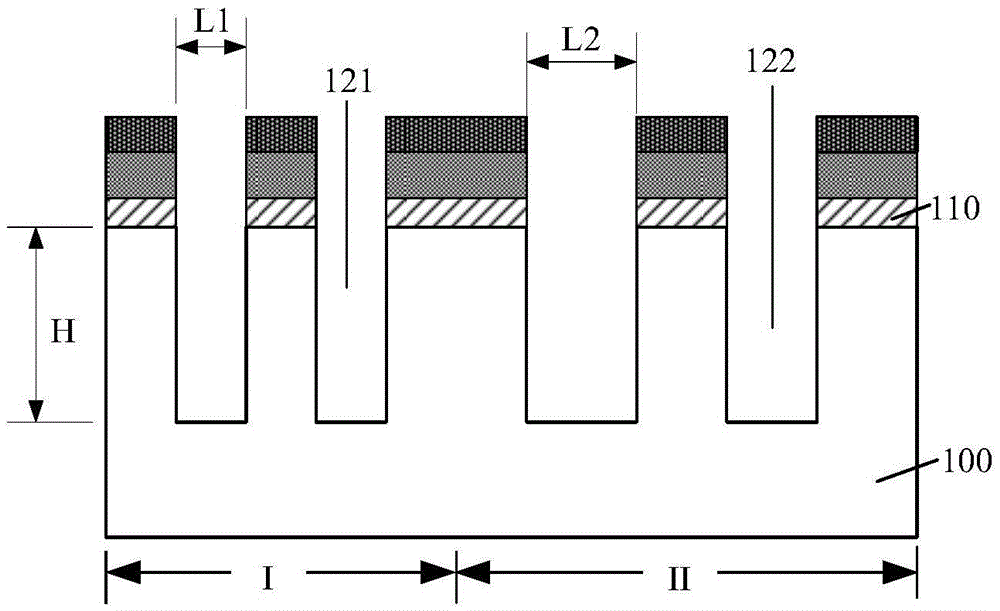

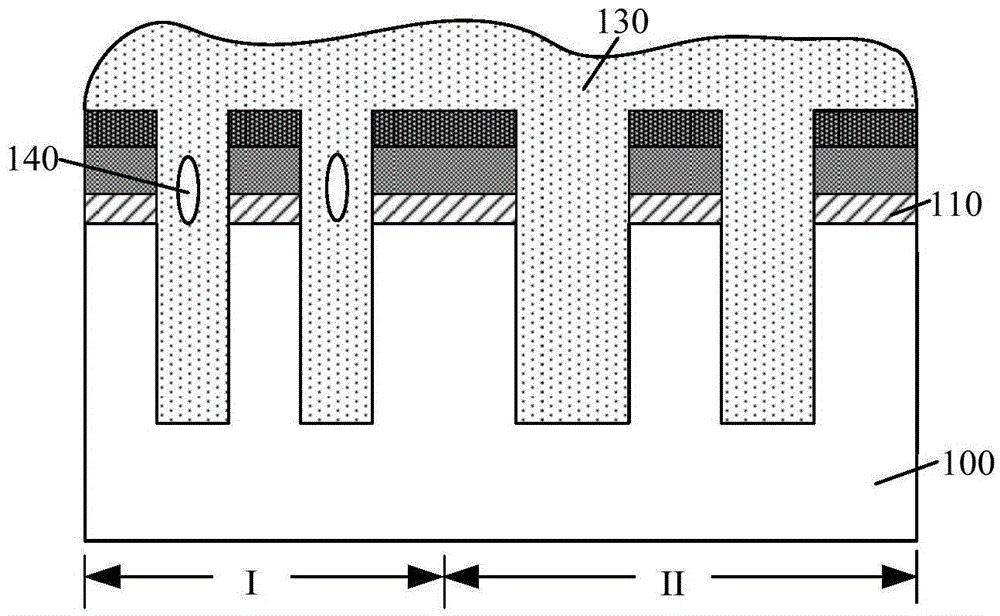

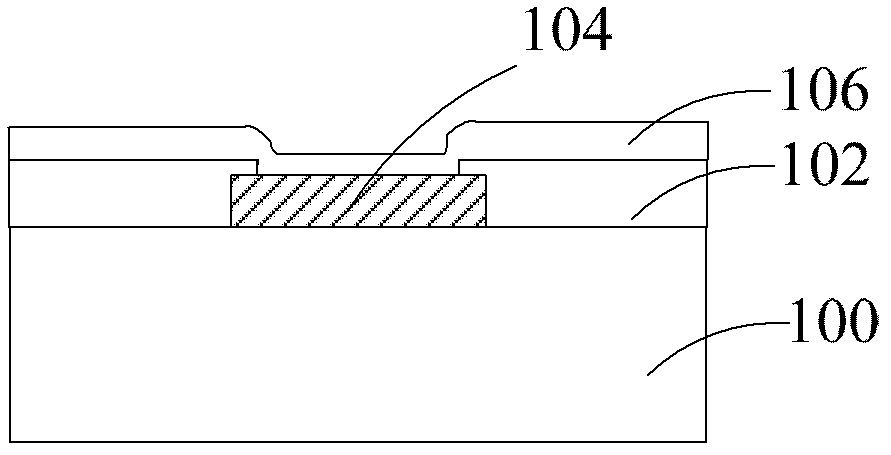

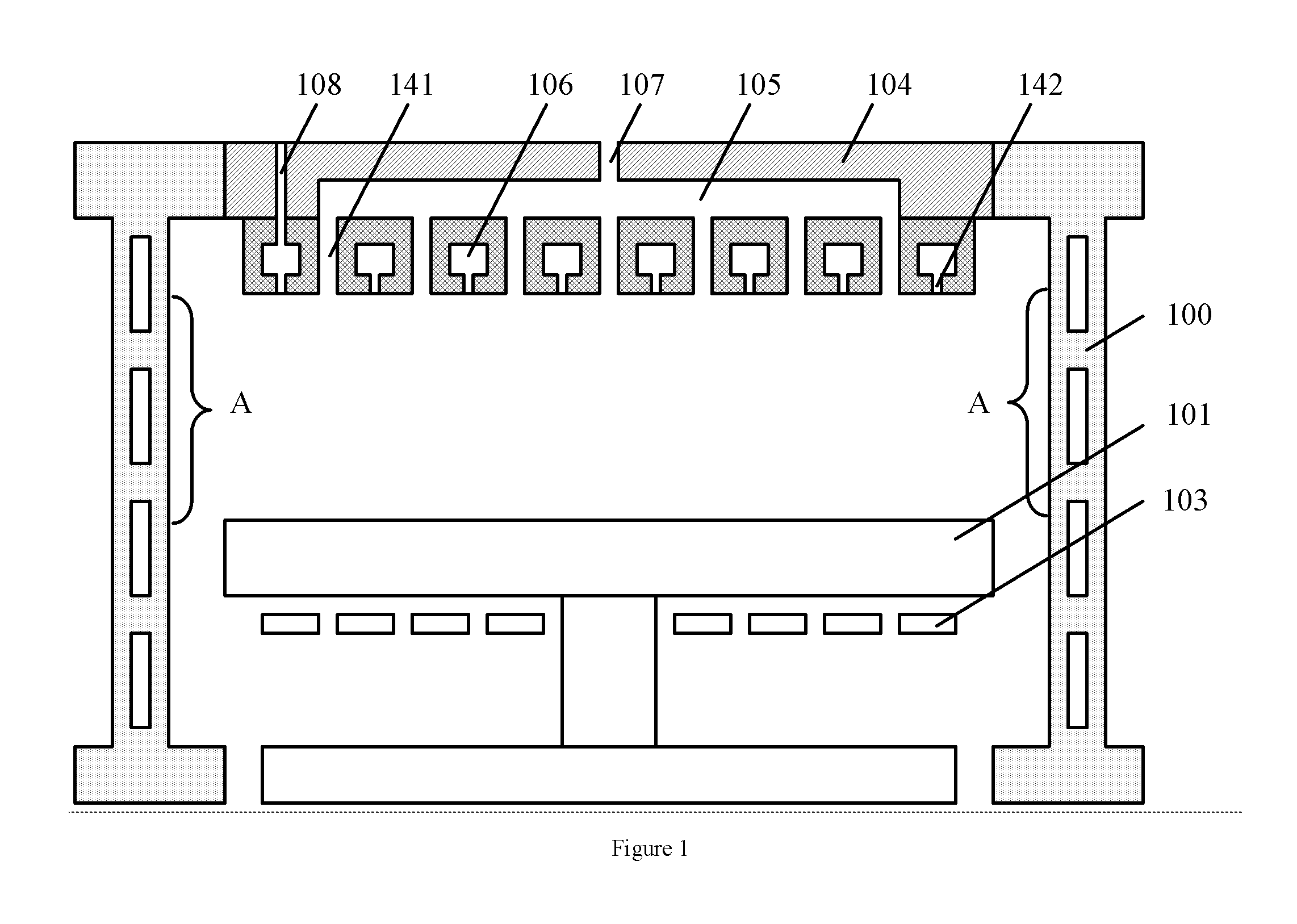

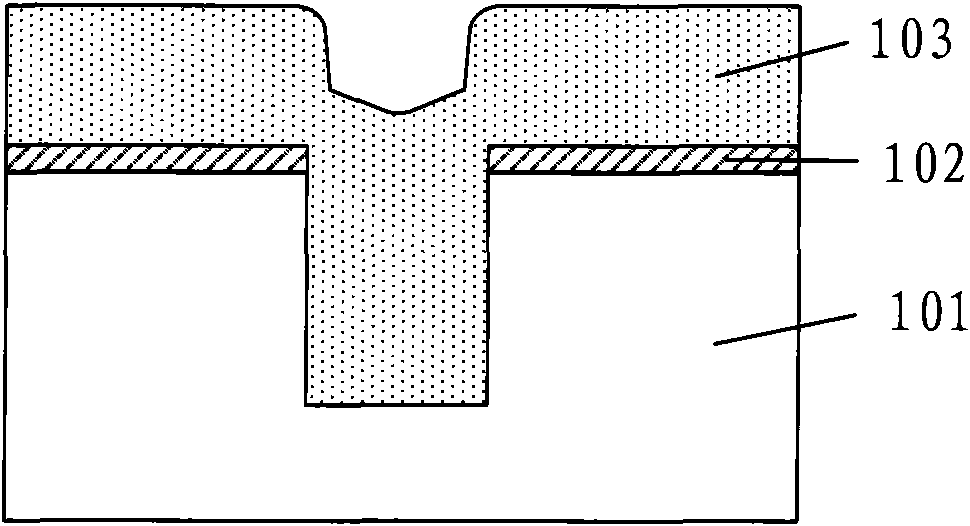

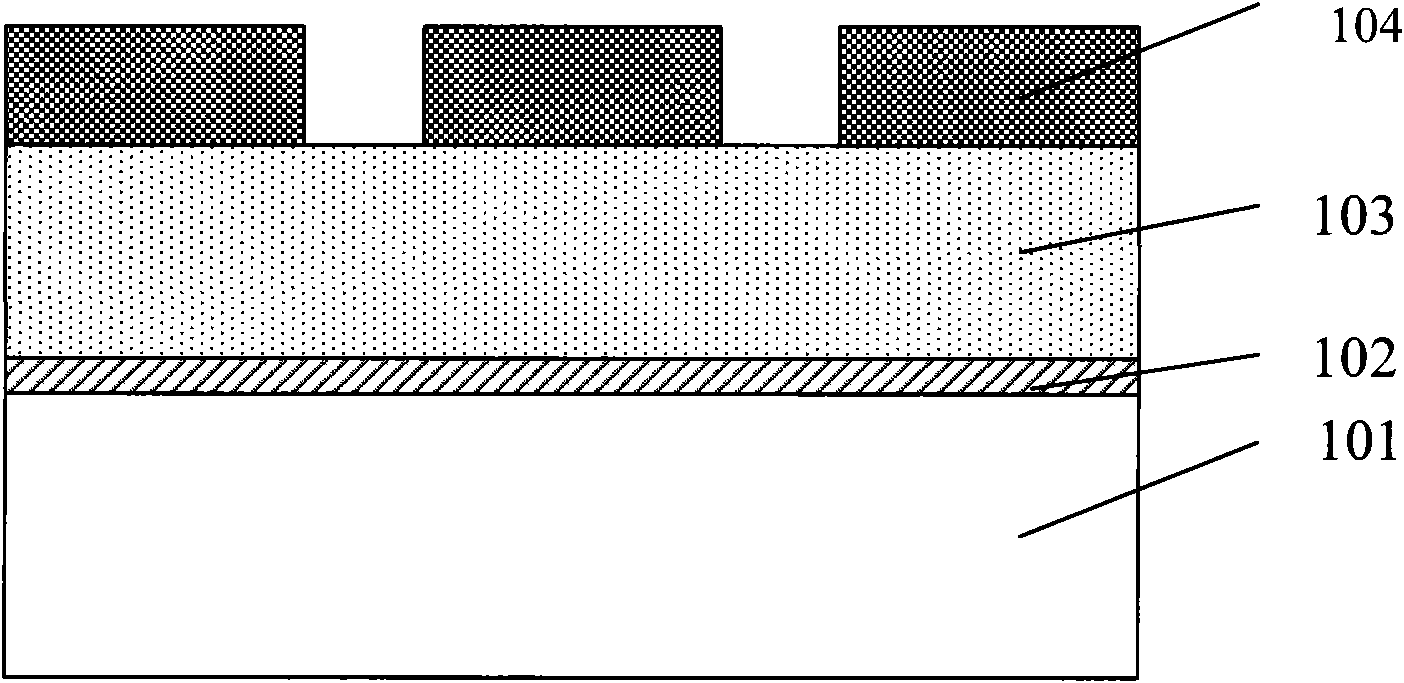

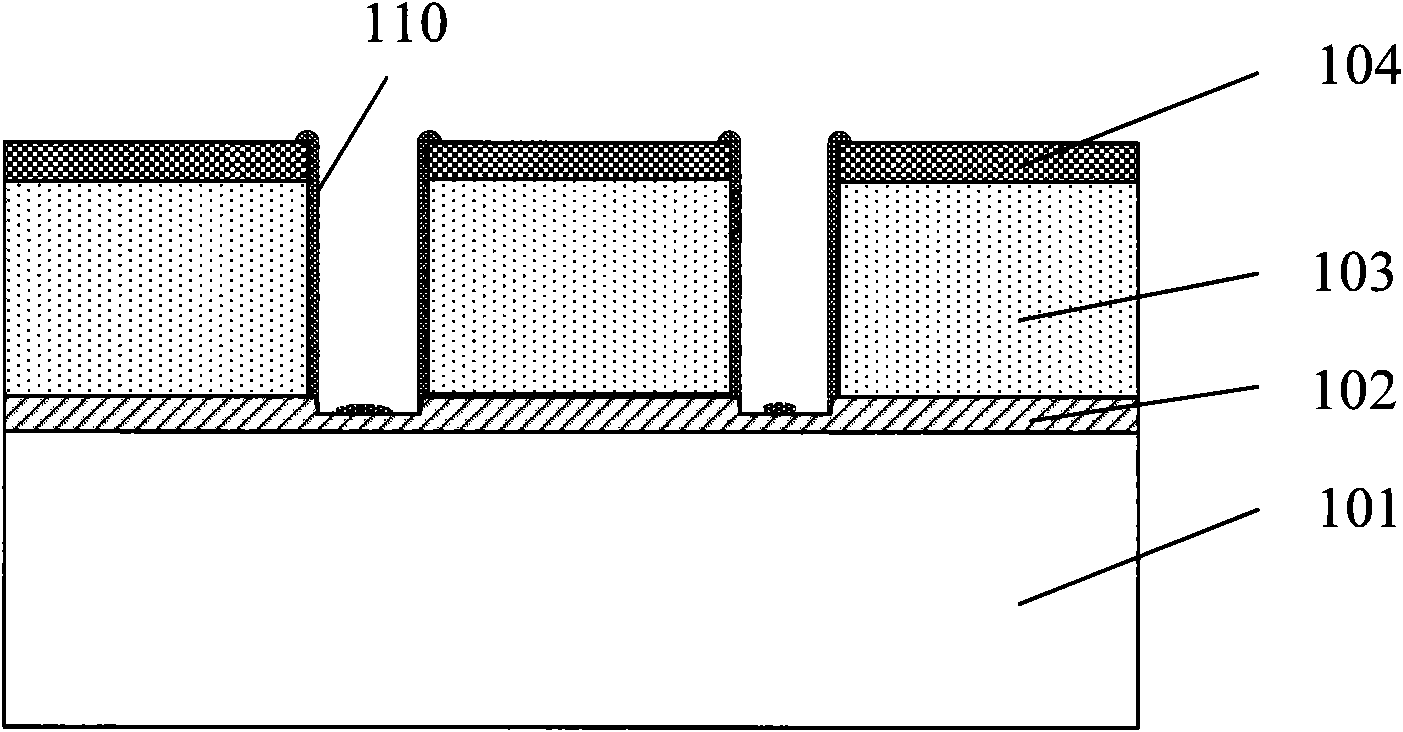

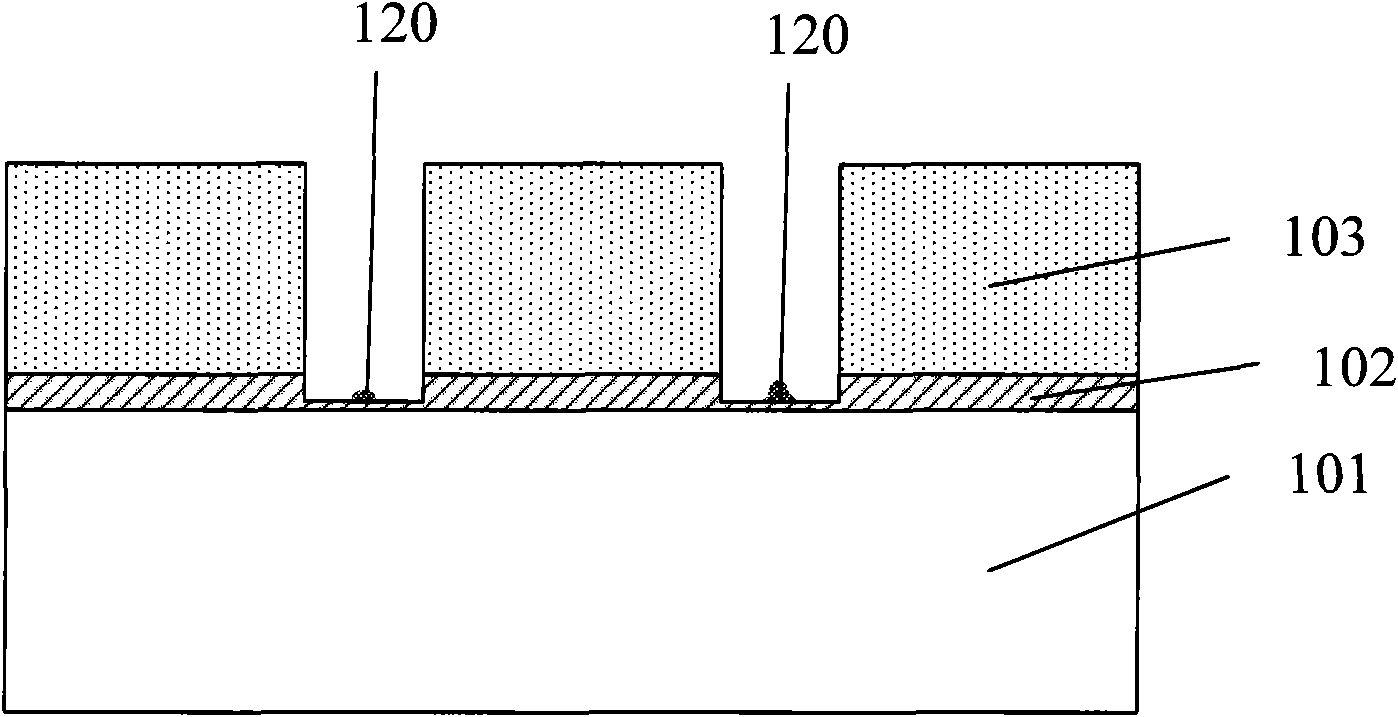

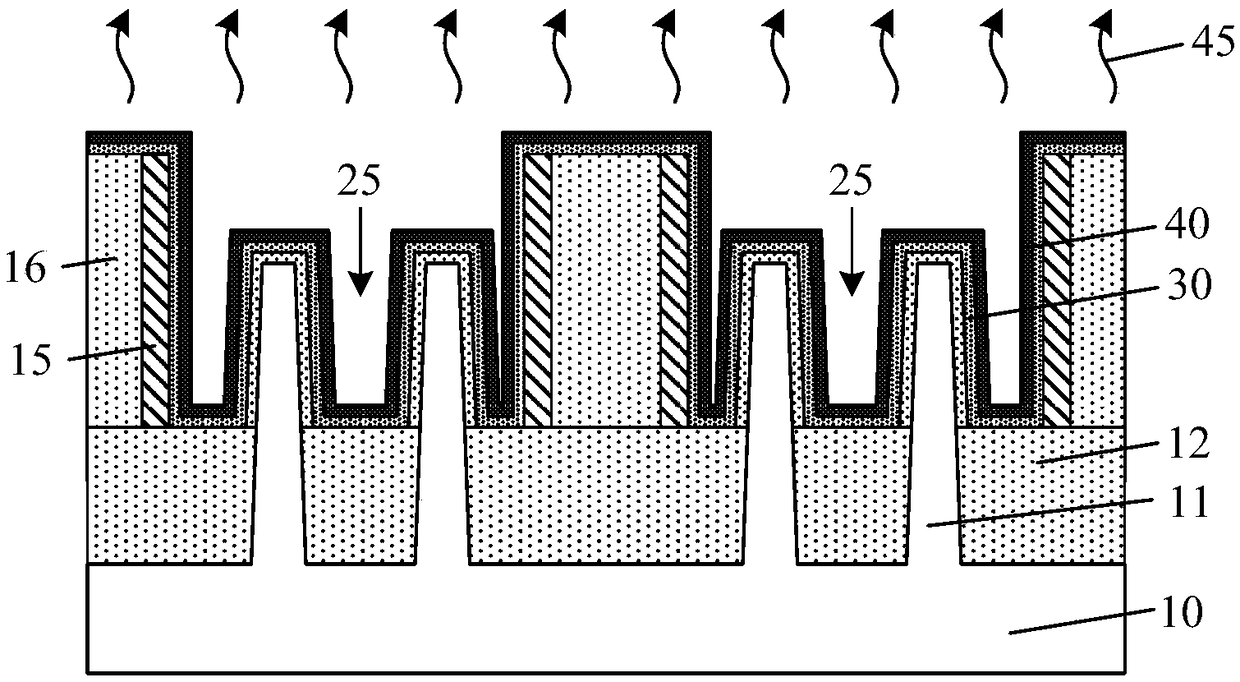

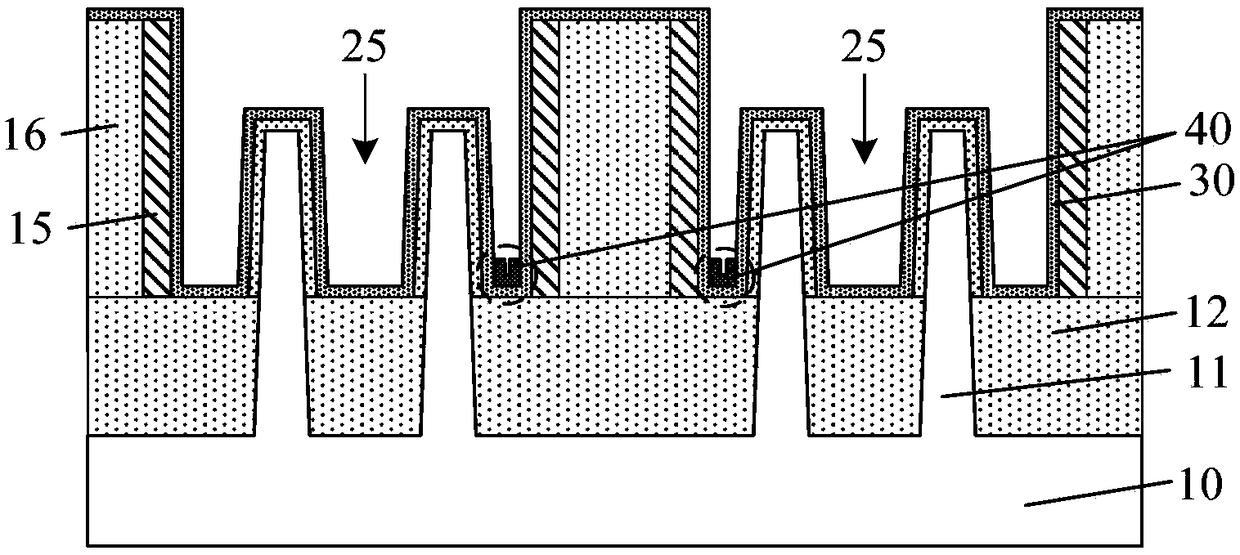

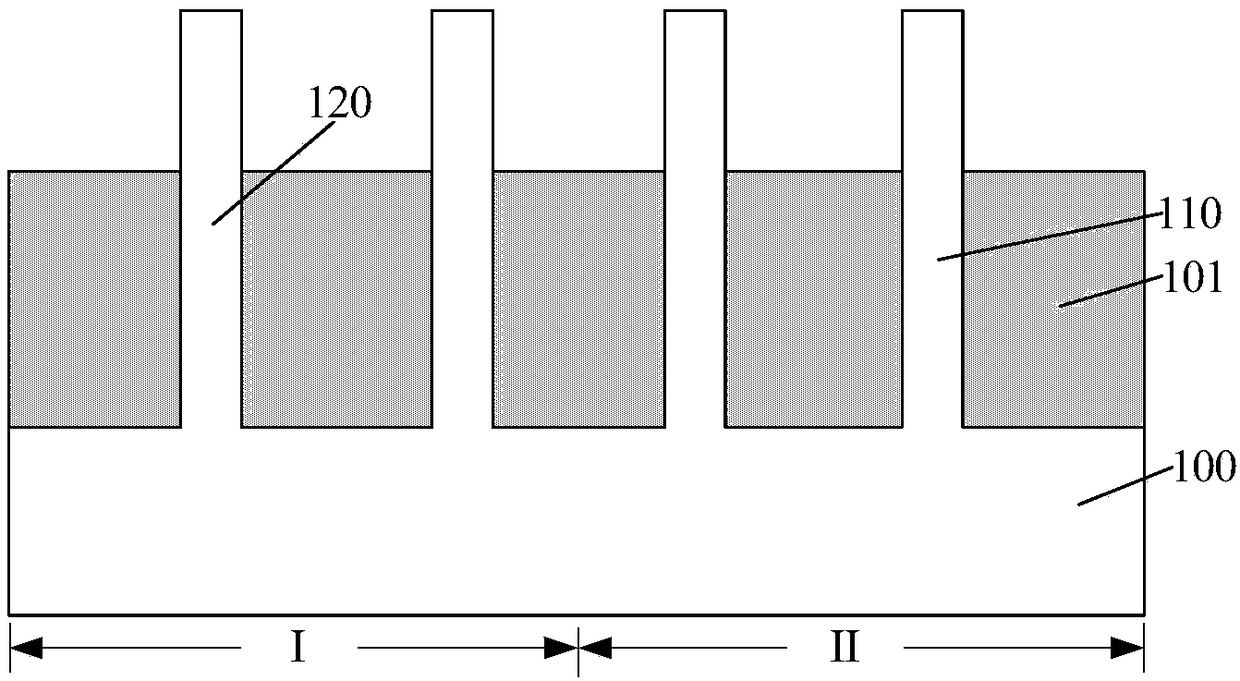

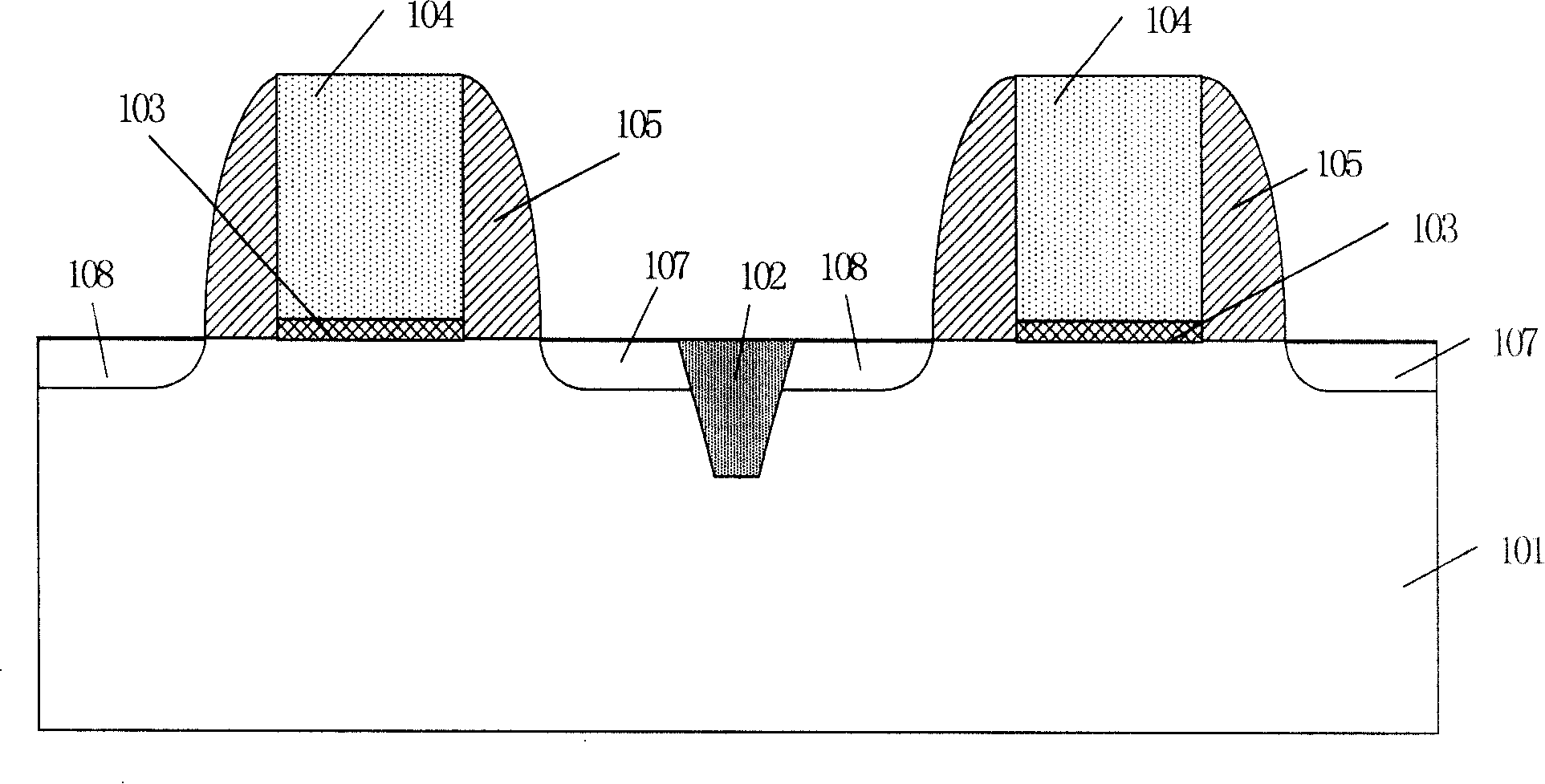

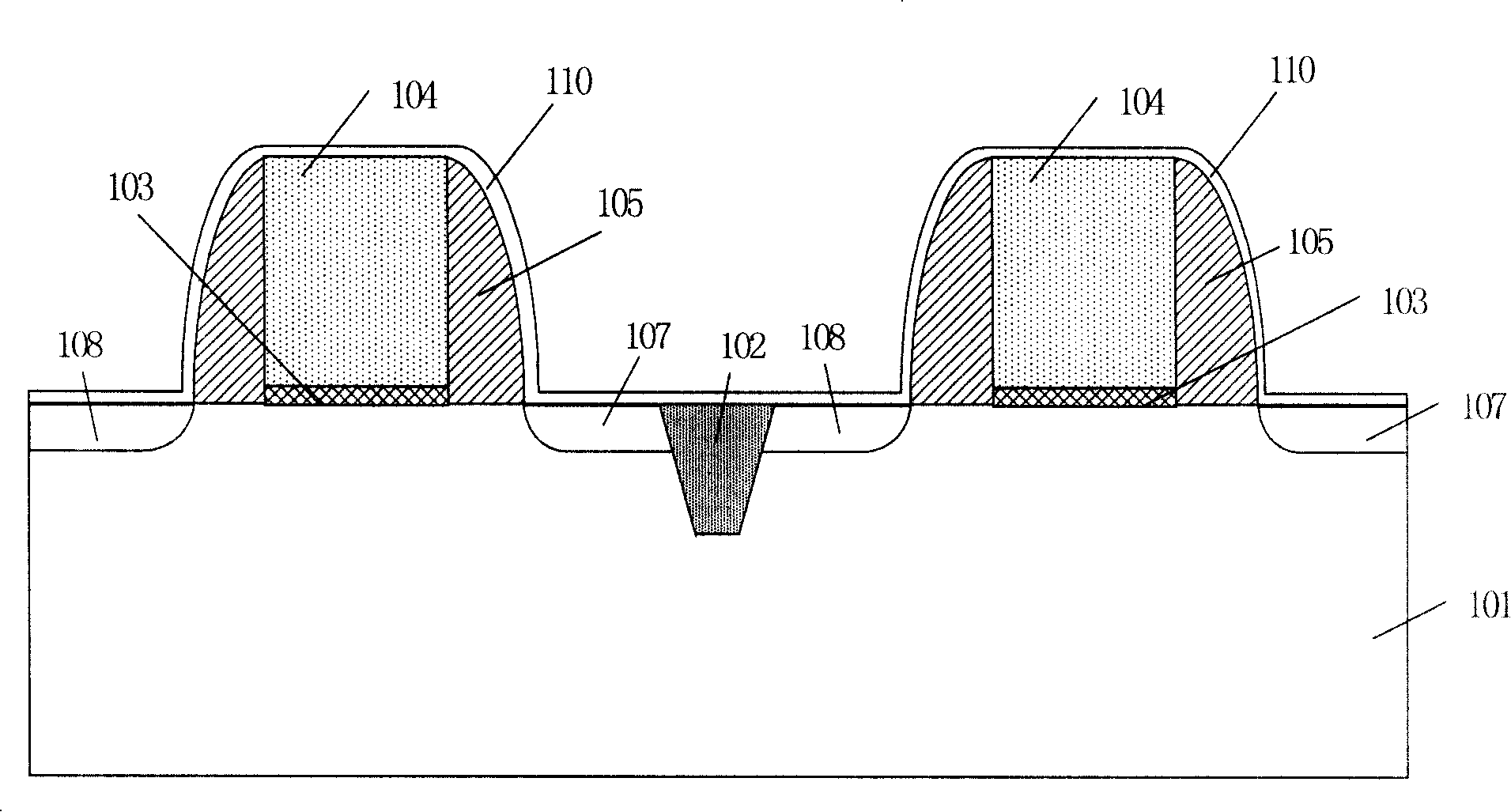

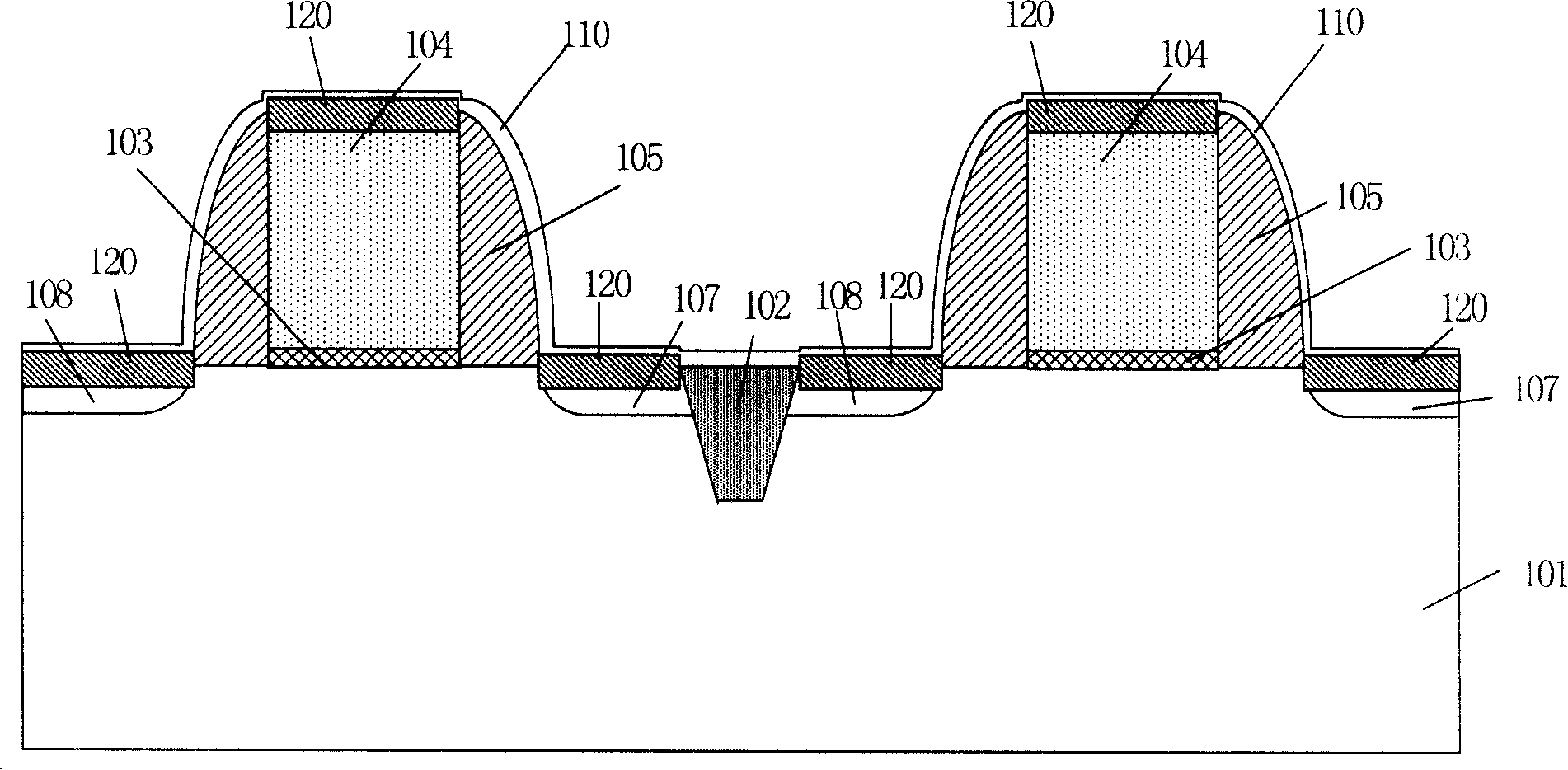

Forming method of semiconductor structure

InactiveCN105655286AReduce aspect ratioImprove formation qualitySemiconductor/solid-state device manufacturingSemiconductor structureElectric properties

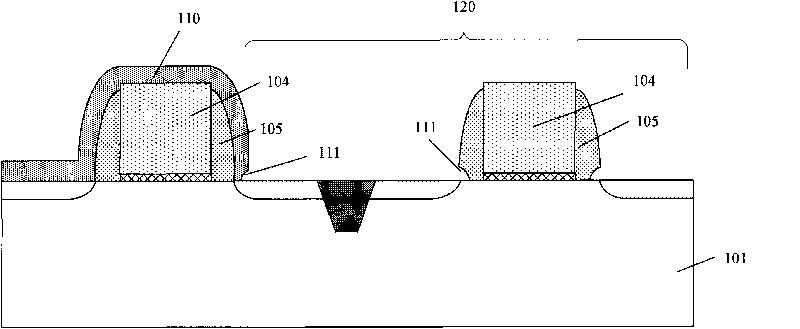

The invention discloses a forming method of a semiconductor structure. The method comprises the following steps: providing a substrate which comprises a first region for forming a core storage circuit; orderly forming a gate electrode film and an initial hard mask film on the substrate; etching the initial hard mask film by using the first etching process, forming a first opening penetrating through the initial hard mask film in the first region; filling a sacrifice layer in the first opening; etching the sacrifice layer and the substrate at the bottom of the first opening by using the second etching process, and forming a first groove in the first region substrate; and forming a first isolation structure in the first groove. The method comprises: firstly forming the first opening penetrating through the initial hard mask film in the first region, and then filling the sacrifice layer in the first opening to form the first groove, wherien the sacrifice layer is firstly etched along the first opening and then the substrate is etched, thereby acquiring the first groove with small depth so as to reduce the depth-to-width ratio of the first groove; and the condition of forming a gap in the first isolation structure is avoided, thereby improving the forming quality of the first isolation structure, and then improving the electric property of a semiconductor device.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

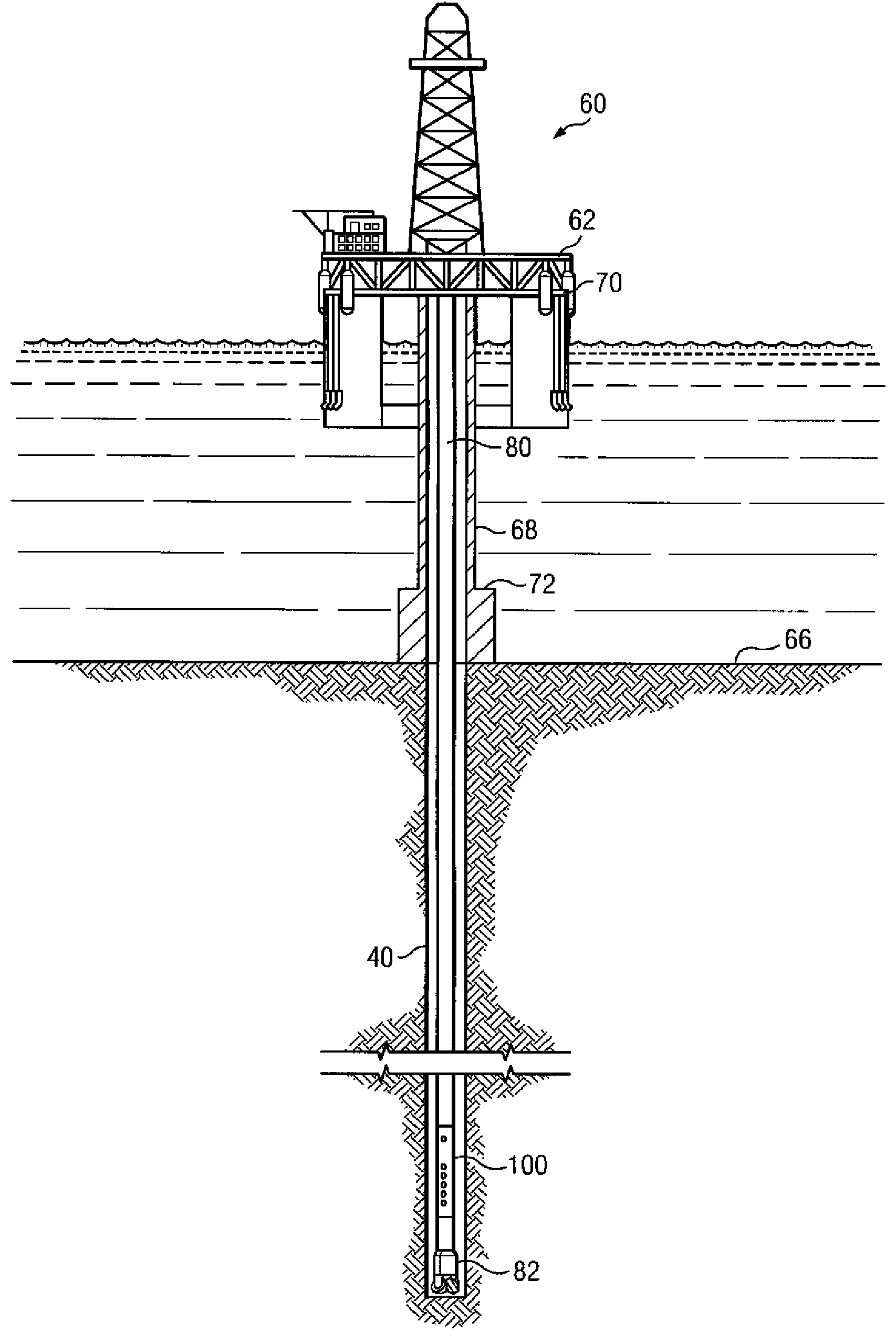

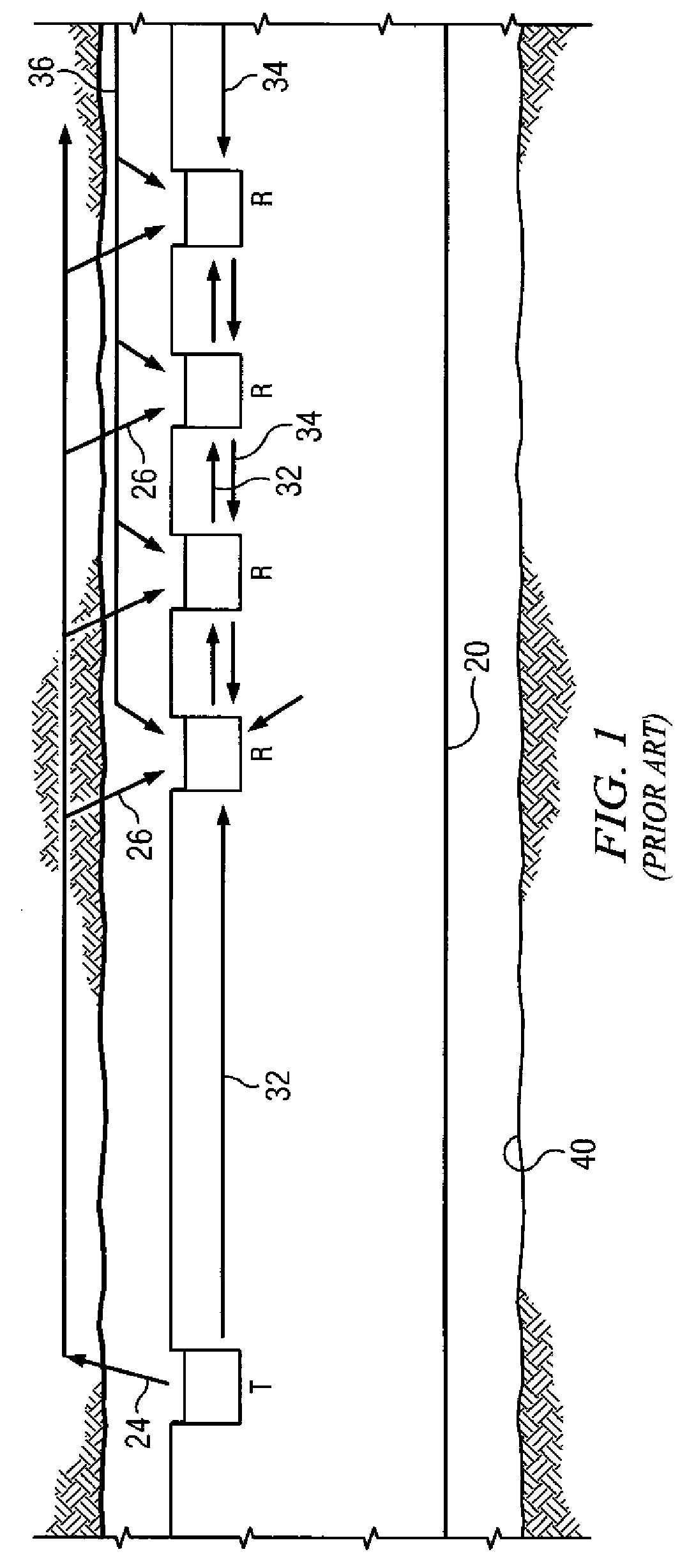

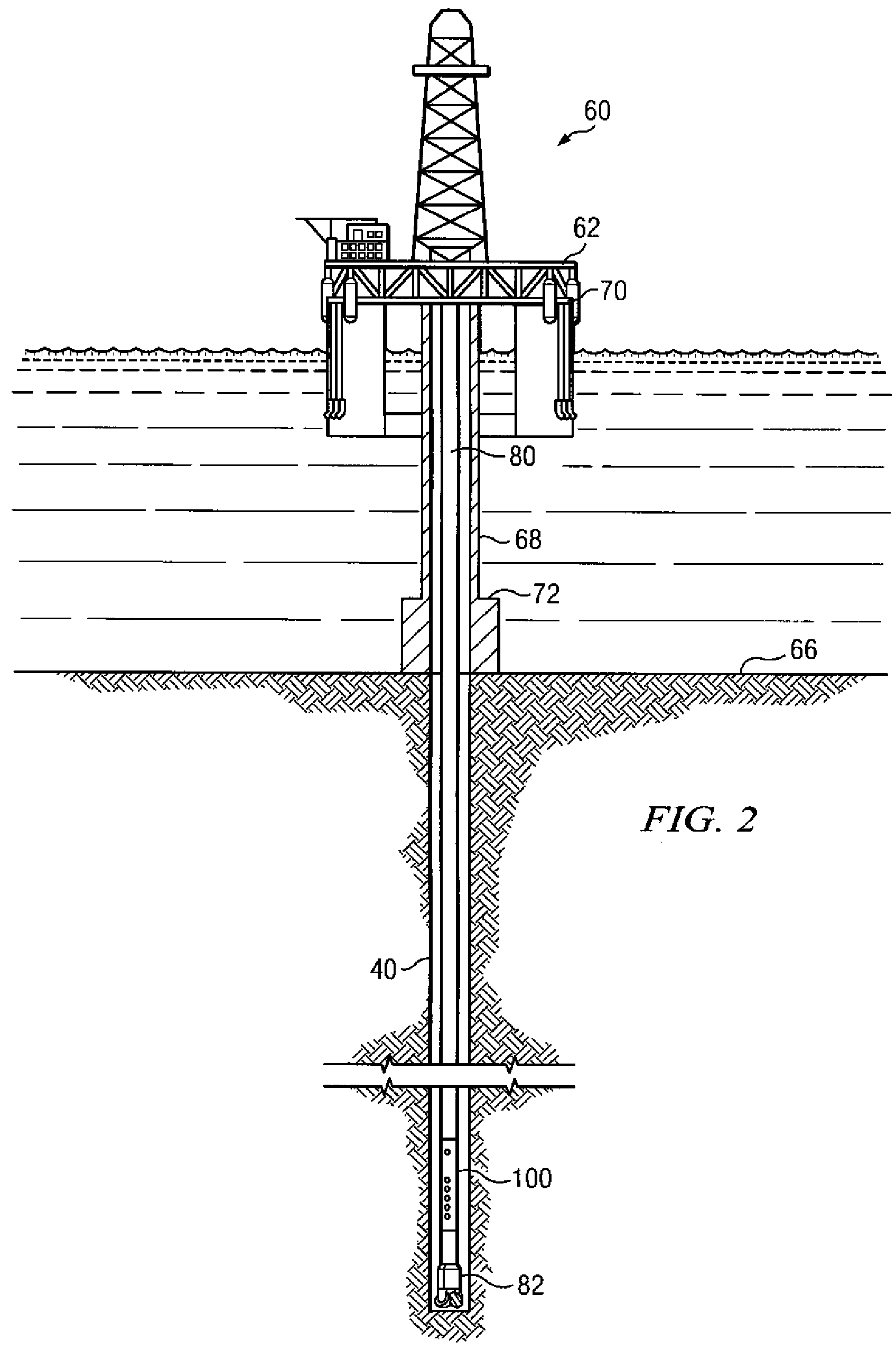

Reduction of Tool Mode and Drilling Noise In Acoustic LWD

InactiveUS20110073368A1Accurate predictionImprove formation qualitySurveySeismology for water-loggingHigh impedanceWave shape

A downhole measurement tool includes at least one regular receiver and at least one reference receiver externally deployed on a tool body. The reference receiver is configured to be acoustically isolated from the borehole, for example, via an isolation structure including a high-impedance cap and a low-impedance gap. The reference receiver may be deployed in a linear array with the regular receiver(s) and may be substantially identical to the regular receiver(s) such that it has substantially the same sensitivity to tool mode signals and internal drilling noise as do the regular receivers. Received waveforms may be processed so as to remove tool mode arrivals and / or drilling noise.

Owner:SCHLUMBERGER TECH CORP

Pearl sacs processing method for cultivating nucleated pearls

InactiveCN101036449AEnhanced nucleophilicityImprove formation qualityClimate change adaptationPisciculture and aquariaTropismBiological activation

The present invention discloses a pearl nucleus processing method for culturing nucleated pearl which comprise the following steps: (1)Choosing pearl nucleus of 12-17mm diameter, (2) purifying pearl nucleus, washing pearl nucleus with 5-10% dilute hydrochloric acid, then washing repeatedly with limewater until the pearl nucleus is neutral in pH, placing pearl nucleus in boiled water for disinfection; (3) activating the immersed pearl nuleus, placing pearl nucleus in activation liquor and processed pearl nucleus is obtained. The present invention purifies the pearl nucleus and activate the pearl nucleus before transplanting that effectively promote the tropism of pearl oyster to pearl nuclus reduce the cut infection probability of nucleus-transplanting tissue quick the healing rate of wound, promote the forming quality of pearl sac, reduce the surface blemish forming rate of nucleated pearl, promote the yield of nucleated pearl.

Owner:ZHEJIANG GRACE PEARL JEWELRY +1

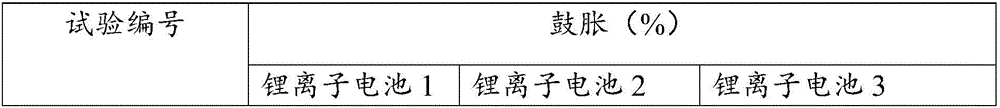

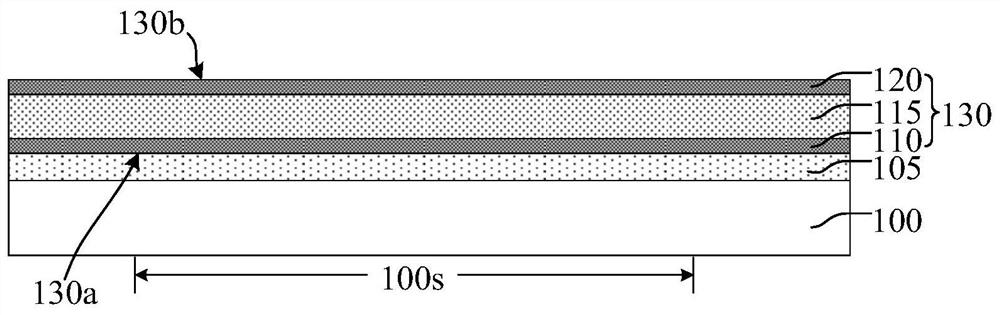

Formation method and lithium-ion secondary battery

ActiveCN106785148AImprove comprehensive electrochemical performanceImprove formation qualitySecondary cells charging/dischargingLithium electrodeEngineering

The invention provides a formation method and a lithium-ion secondary battery, and relates to the technical field of lithium-ion batteries. The invention provides a formation method. The lithium-ion battery is formed through four formation stages which are sequentially carried out. The formation current of the four formation stages is gradually increased, and negative pressure extracted for four times is also linearly increased. According to the formation method, the formation quality of an SEI film can be effectively improved and the bulging rate of the lithium-ion battery is reduced, so that the comprehensive electrochemical properties of the lithium-ion battery are improved. According to the lithium-ion secondary battery, an electrolyte of the lithium-ion secondary battery is a non-aqueous system and formation treatment is carried out by using the formation method. The lithium-ion secondary battery does not easily bulge in the using process and has good comprehensive electrochemical properties.

Owner:深圳一特科技有限公司

Method for cleaning chemical vapour deposition chamber

InactiveCN101139703AClean thoroughlyReduce idle timeCleaning using gasesCleaning using liquidsCompound (substance)Engineering

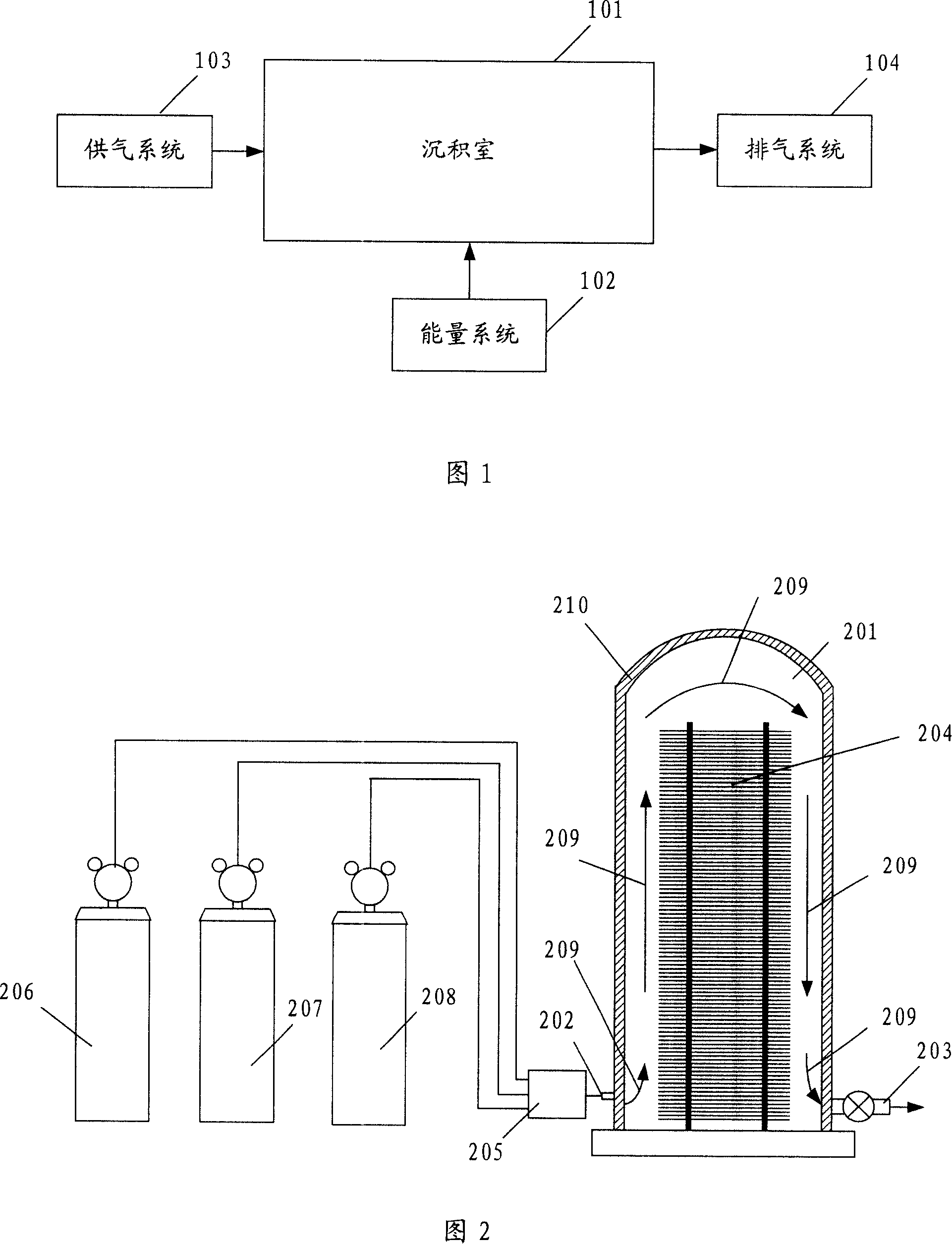

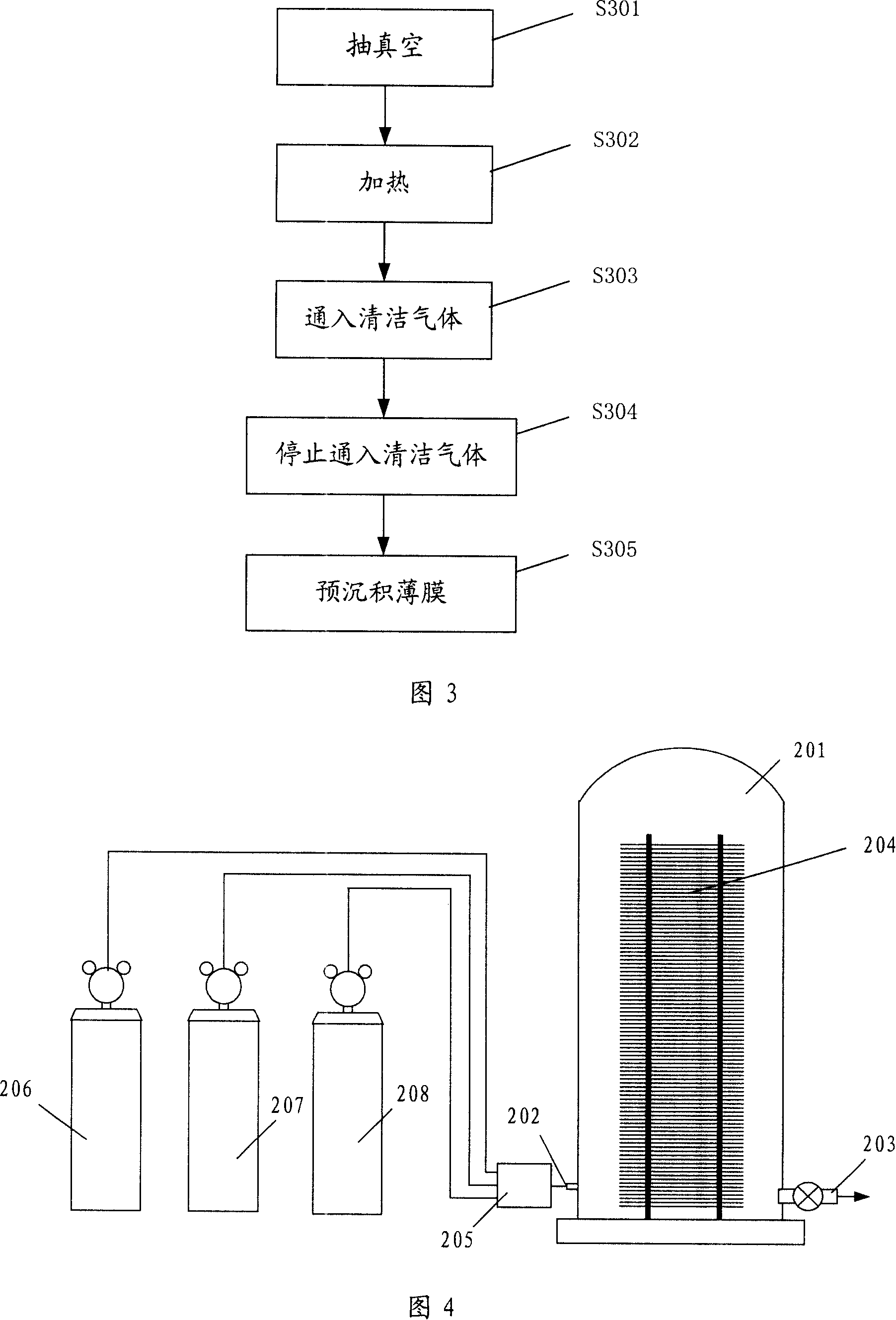

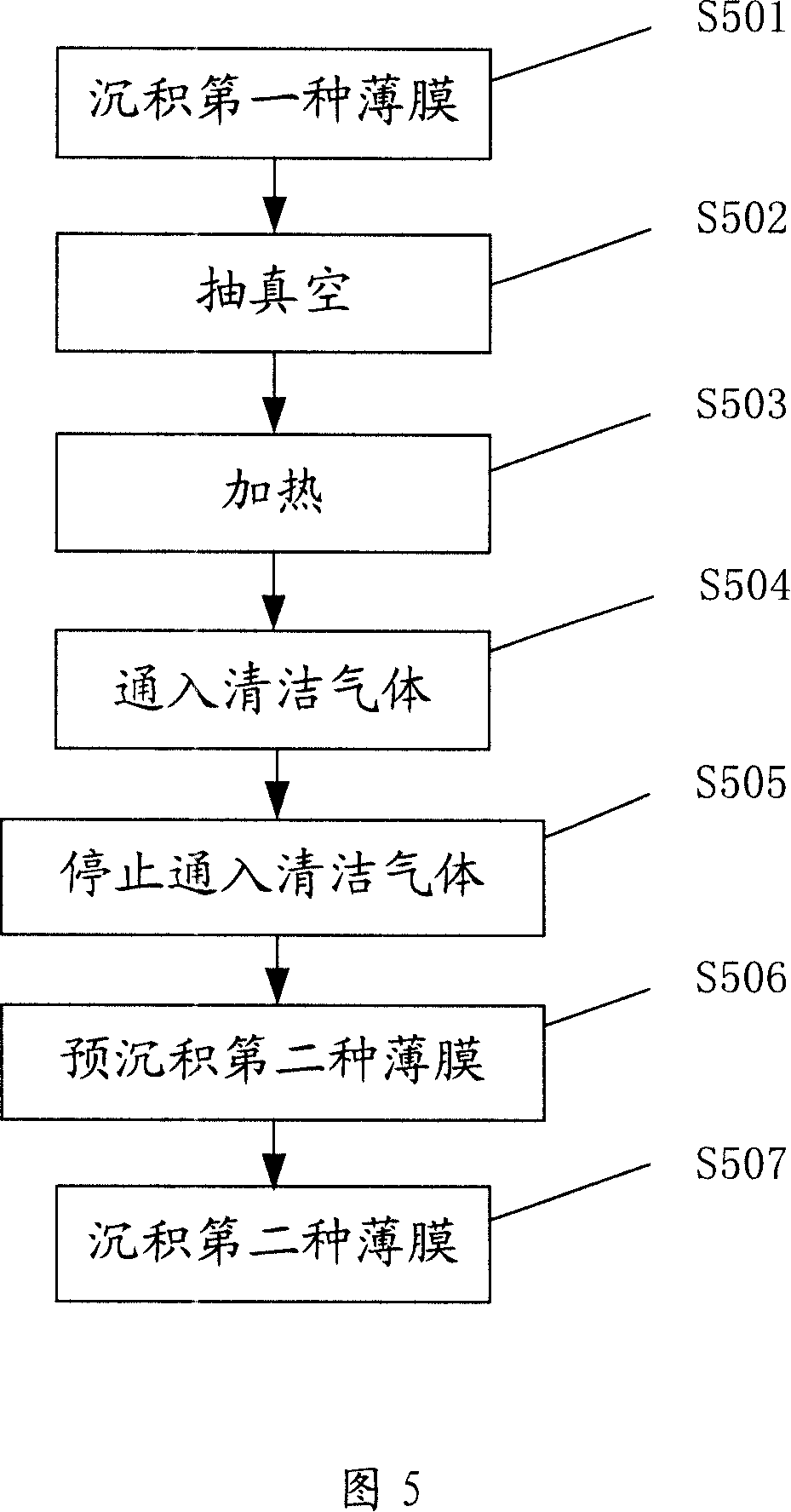

The invention discloses a method for cleaning a chemical vapor phase deposition chamber, which comprises such procedures as vacuuming the deposition chamber, heating the deposition chamber, inputting clean air to remove any attachment in the deposition chamber, and turning off the clean air. The method can substitute a wet cleaning method to clean completely the deposition chamber, is easy and rapid to operate, can reduce the idle time of equipment and improve the productivity.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Method for removing film

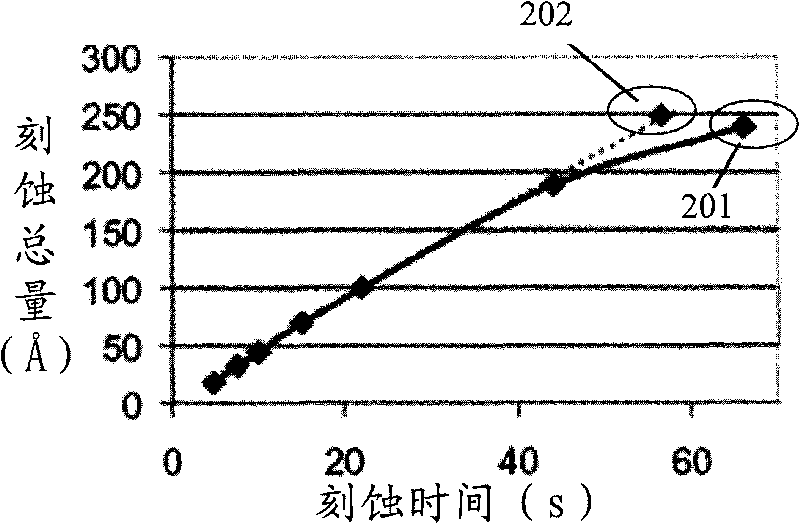

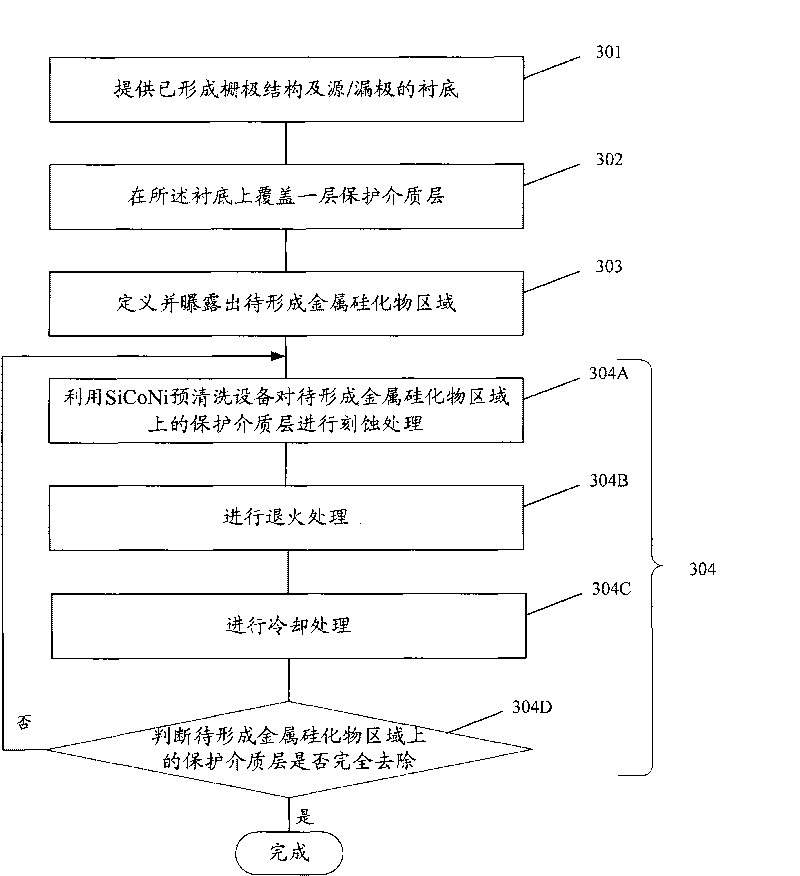

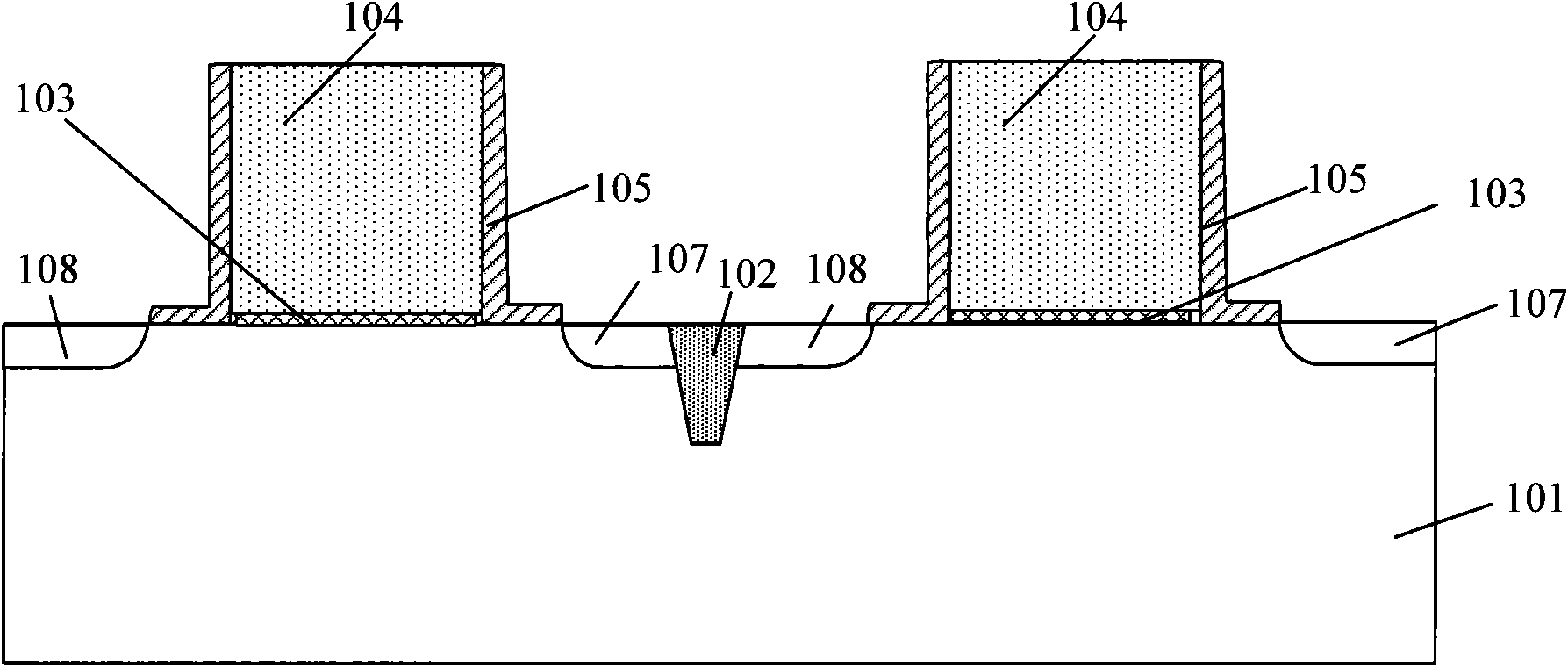

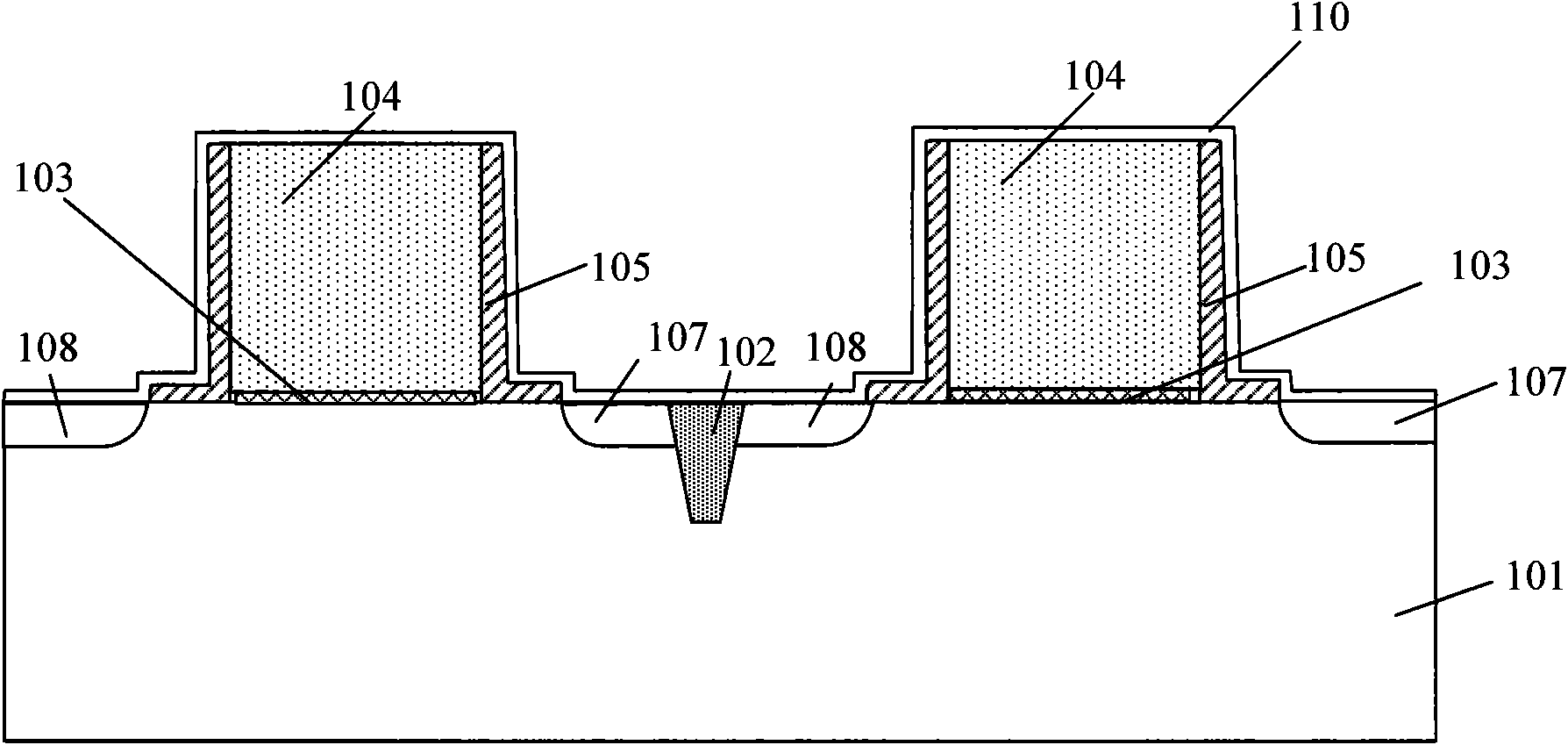

InactiveCN101740338AAvoid damageAchieve removalSemiconductor/solid-state device manufacturingMetal silicidePlasma activation

The invention discloses a method for removing a film. The method comprises the following steps of: providing a substrate the surface of which is provided with a film; transmitting the substrate to a treating room; carrying out the plasma activation on reactant gas outside the treating room by using a low-powered radio-frequency power supply; introducing the reactant gas after being subjected to the plasma activation to the treating room; and carrying out etching treatment by using the reactant gas after being subjected the plasma activation to remove the film, and removing resultants produced in the etching treatment process by using the annealing treatment. The invention also discloses specific implementation steps for forming a local metal silicide and forming the opening of a contact hole by using the method correspondingly. By using the method for removing a film, the damage to the understructure by a traditional dry etching method can be avoided, and the damage to the side-wall structure by an isotropic wet corrosion method can be also avoided.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

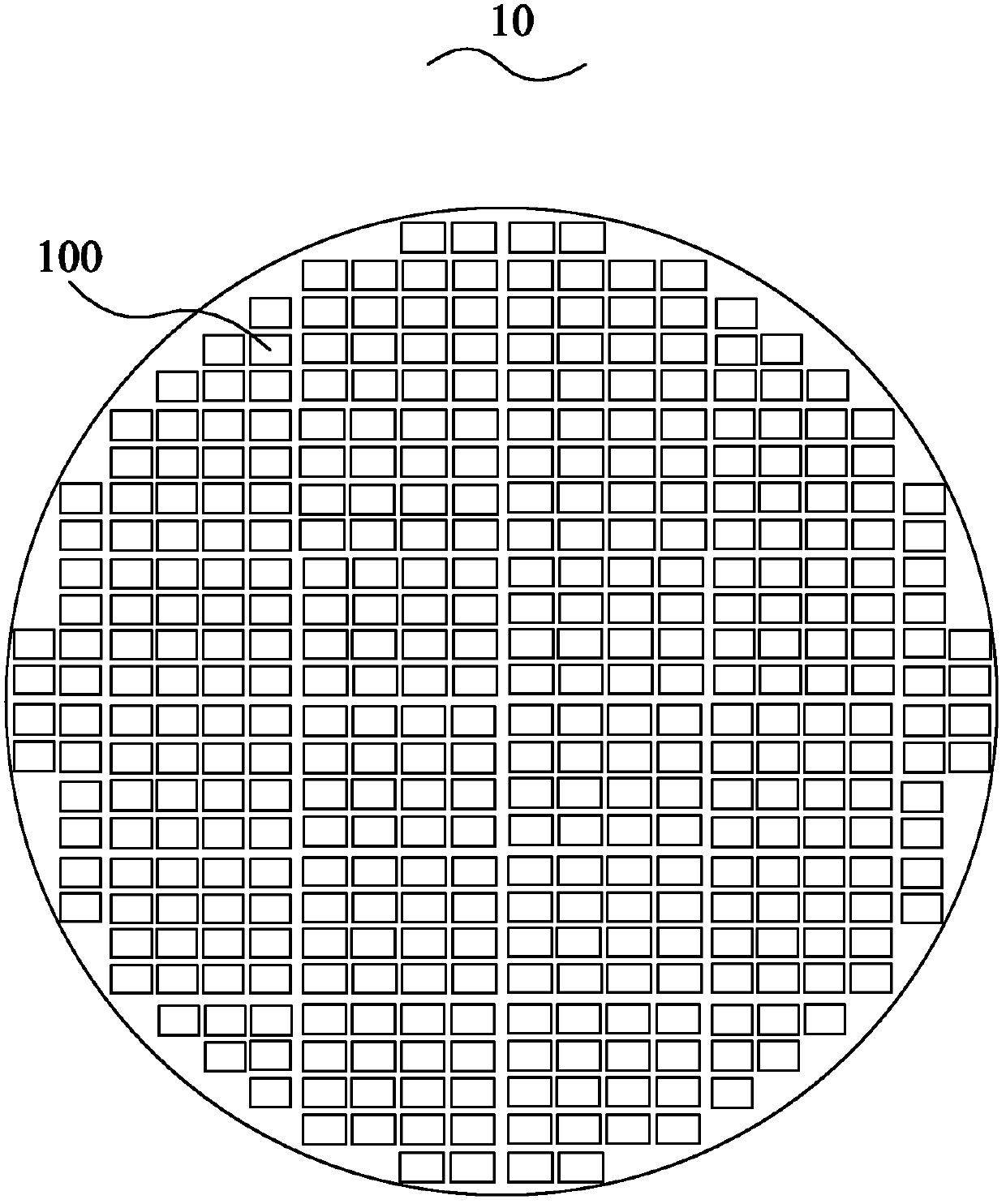

Flattening method of interlayer medium layer and forming method of contact hole

InactiveCN101577244AImprove flatnessMeet filling requirementsSemiconductor/solid-state device manufacturingHigh densityMedia layer

The invention discloses a flattening method of an interlayer medium layer, comprising the following steps: proving a substrate provided with a grid structure; performing high-density plasma chemical vapor deposition on the substrate to form a first interlayer medium layer, wherein the thickness of the first interlayer medium layer is larger than the height of the grid structure; flattening the first interlayer medium layer; and performing plasma enhanced chemical vapor deposition on the substrate which is flattened to form a second interlayer medium layer. The invention also discloses a forming method of a contact hole. Due to the adoption of the flattening method of the interlayer medium layer and the forming method of the contact hole, the planeness of the interlayer medium layers in a wafer can be improved, furthermore, the forming quality and the consistency of each contact hole in the wafer are obviously improved, and the rate of finished products is improved.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

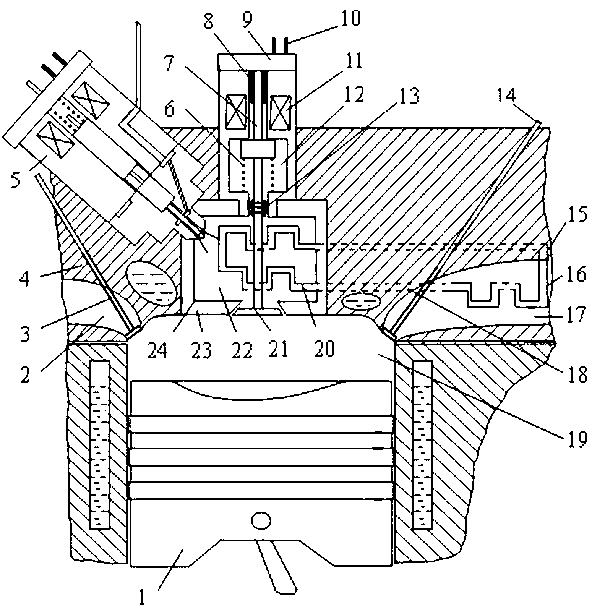

Fuel spraying system for utilizing heat pipe technology to extract heat vaporized diesel oil from exhaust gas

InactiveCN102865172AImprove utilization efficiencyIncrease manufacturing costInternal combustion piston enginesCylinder headsExhaust valveInlet channel

The invention discloses a fuel spraying system for utilizing a heat pipe technology to extract heat vaporized diesel oil from exhaust gas. The fuel spraying system comprises a cylinder, a piston (1), a cylinder cover (4), an electric control oil sprayer (5), a gas inlet channel (2), an exhaust channel (17), a gas inlet valve (3) and an exhaust valve (14), wherein a diesel oil vaporizing sprayer (9) and a diesel oil vaporizer (24) are arranged on the cylinder cover (4); the diesel oil vaporizer (24) comprises a heat pipe (15) and a vaporizing cavity (23); the heat pipe (15) is composed of a heat pipe vaporizing section (16), a heat pipe heat-insulating section (18) and a heat pipe condensing section (20); the diesel oil vaporizer (24) is mounted on the cylinder cover (4); the heat pipe vaporizing section (16) is arranged on the exhaust channel (17); the heat pipe condensing section (20) is arranged in a vaporizing chamber (22); the heat pipe heat-insulating section (18) is arranged on the cylinder cover (4); and the electric control oil sprayer (5) is communicated with the vaporizing cavity (23). With such a structure, the fuel spraying system provided by the invention has the advantages that the structure is simple and compact, the heat of the exhaust gas is utilized to vaporize the diesel oil, the forming quality of the mixed gas in the cylinder is good, the burning efficiency is high and the effects of energy conservation and emission reduction are obvious.

Owner:金华三人科技有限公司

High-reliability chip scale packaging method

InactiveCN102437065ABlocking poresPrevent disappearingSolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveProtection layer

The invention discloses a high-reliability chip scale packaging method. The method comprises the following steps: forming a heat-resisting metal layer and a metal wetting layer sequentially on a welding pad and a passivation layer on a chip; forming a photoresist on the metal wetting layer, wherein the photoresist is provided with the metal wetting layer with an opening exposed above the welding pad of the chip; forming a blocking layer and a welding flux protection layer sequentially on the metal wetting layer in the opening; removing the photoresist; etching the heat-resisting metal layer and the metal wetting layer which are positioned on the passivation layer until the passivation layer is uncovered; forming a protection adhesive layer on the chip, wherein the welding flux protection layer is covered by a protection adhesive; exposing the protection adhesive above a connection layer so as to form an opening, and uncovering the upper surface of the welding flux protection layer; and forming a welding flux bump on the welding flux protection layer and reflowing. According to the invention, the electric property and reliability of products are improved.

Owner:NANTONG FUJITSU MICROELECTRONICS

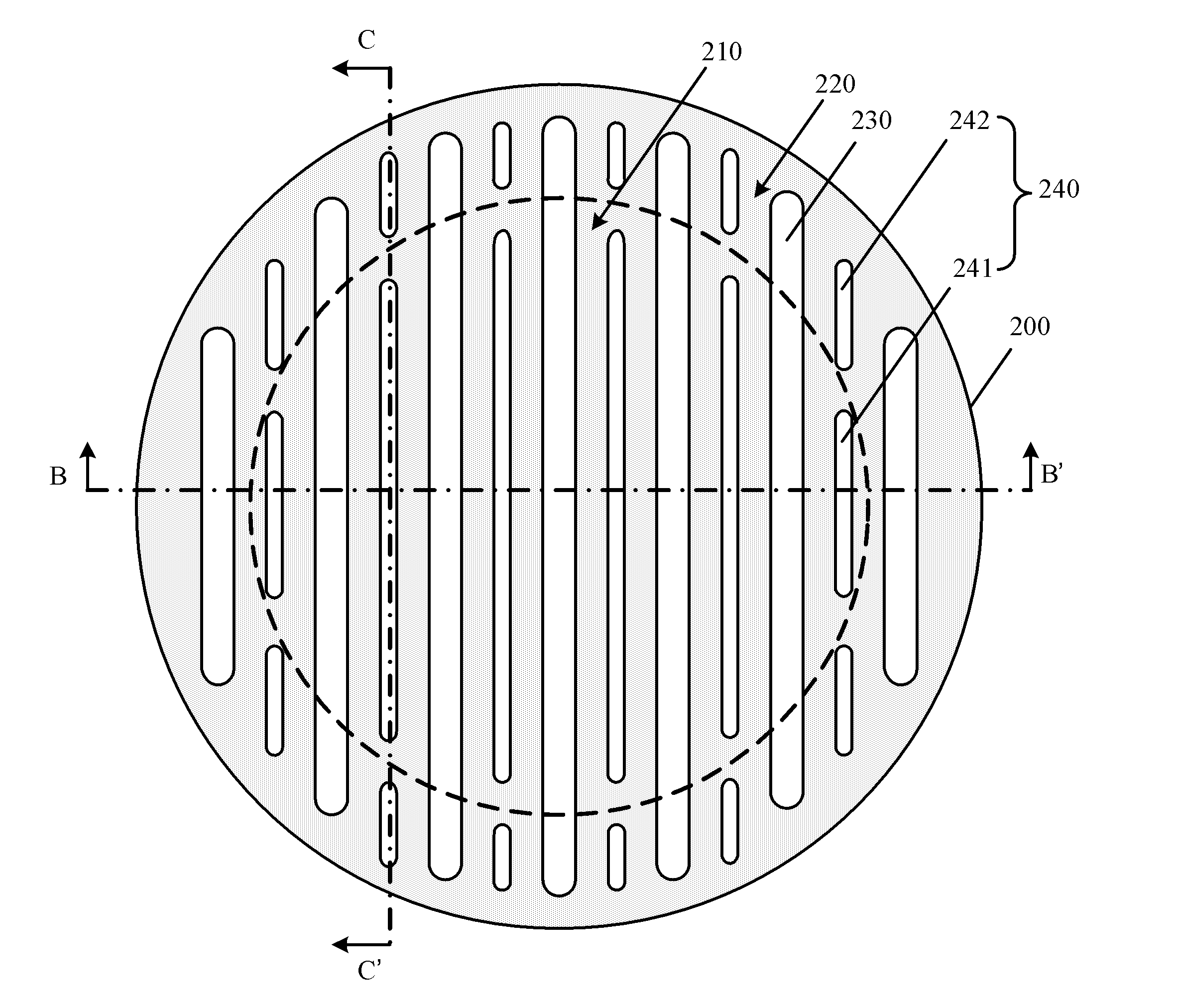

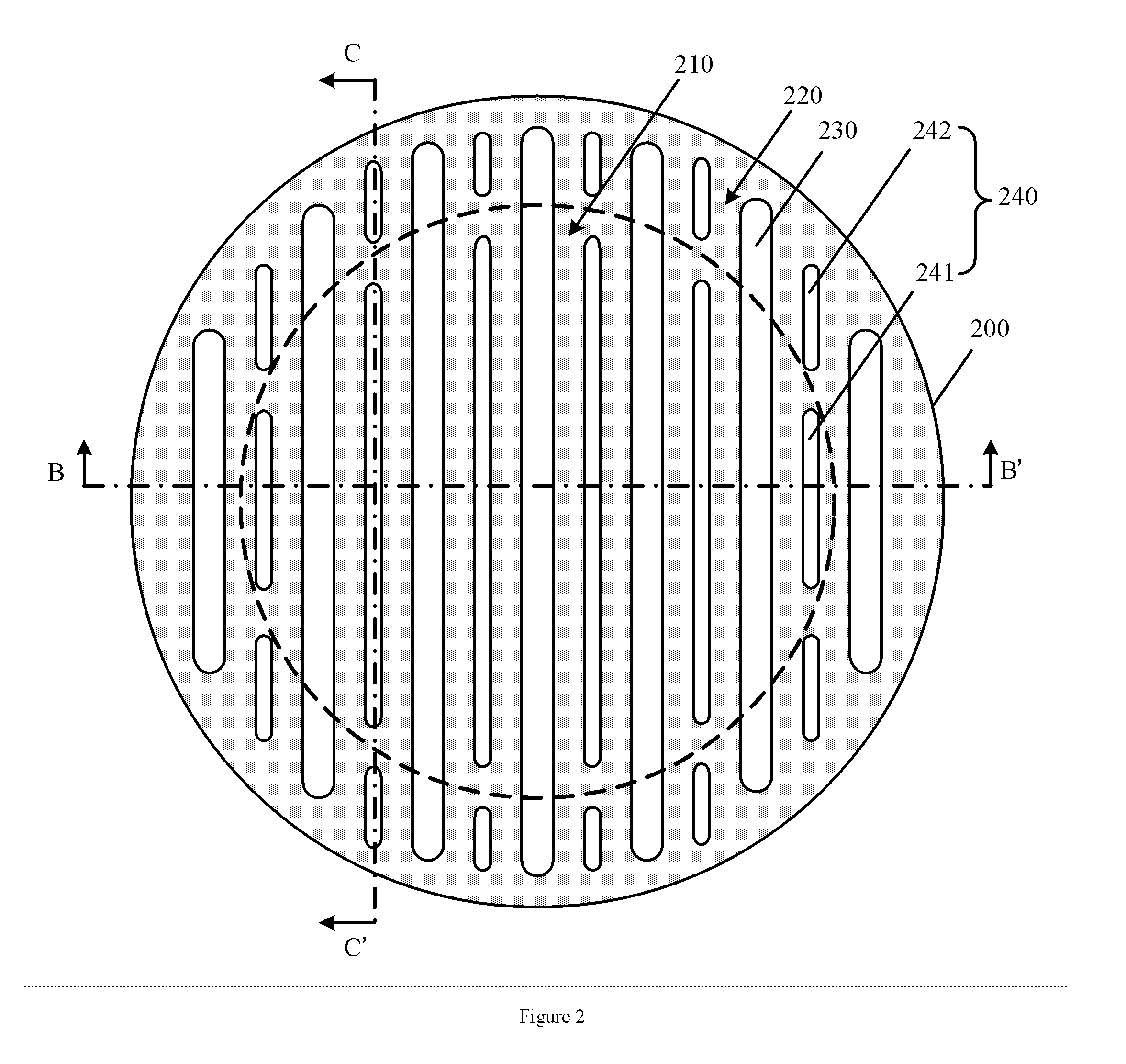

Gas shower device, chemical vapor deposition device and method

ActiveUS20150368799A1Stable propertyStrongly protectSpray nozzlesChemical vapor deposition coatingEngineeringElectrical and Electronics engineering

A gas shower device, a device and a method for chemical vapor deposition. A gas shower device has a showerhead. The showerhead includes a center region and a periphery region surrounding the center region; the center region and periphery region of the showerhead have a plurality of second gas-outlets which are arranged in parallel; the second gas-outlets are used to output the second gas; a first gas-outlet arranged between two adjacent second gas-outlets, includes the first sub-gas-outlet located in the center region and the second sub-gas-outlet located in the periphery region; the first sub-gas-outlet and the second sub-gas-outlet are mutually isolated, the first sub-gas-outlet is used to output the first gas and the second sub-gas-outlet is used to output the second gas; a first gas channel is connected to the first sub-gas-outlet; a second gas channel is connected to the second gas-outlet and the second sub-gas-outlet. The film formation quality is improved by using the chemical vapor deposition device with the gas shower device.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

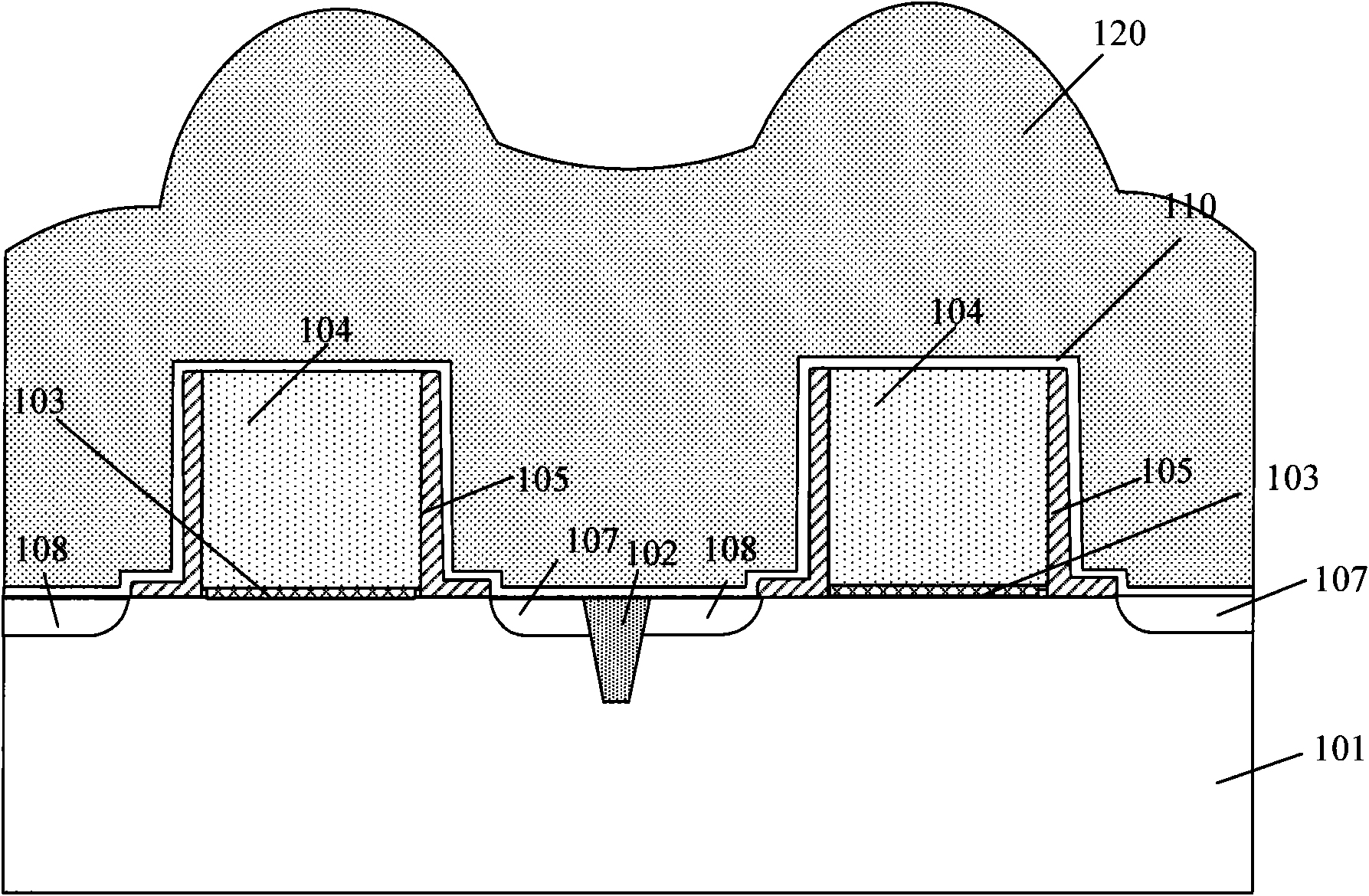

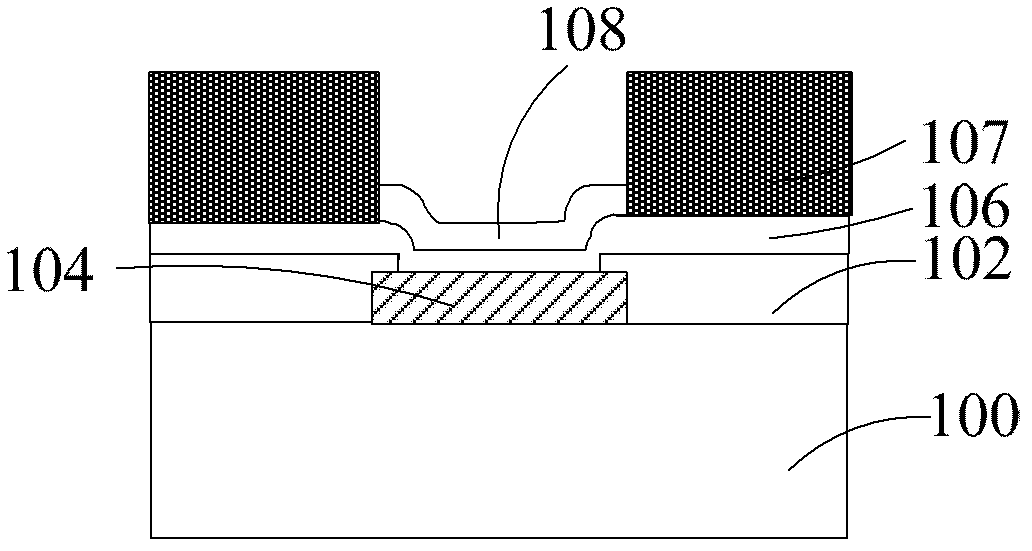

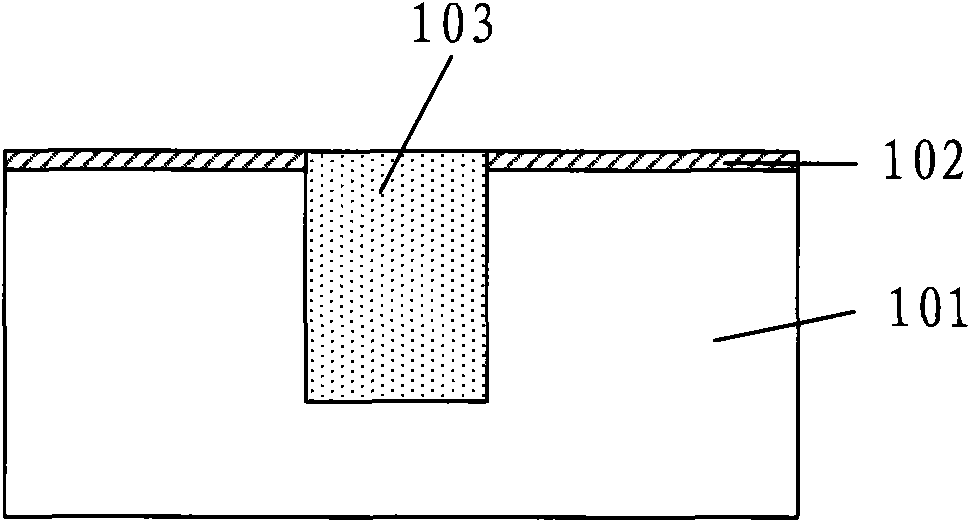

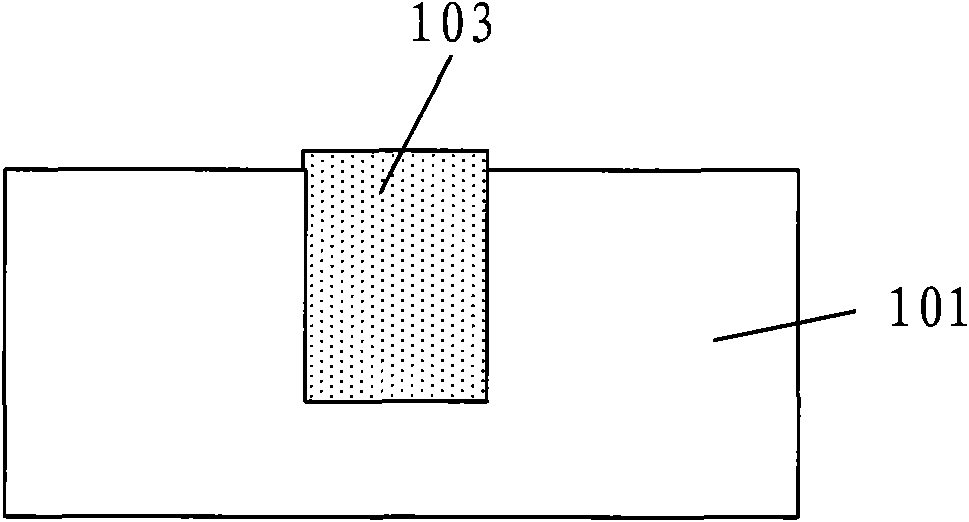

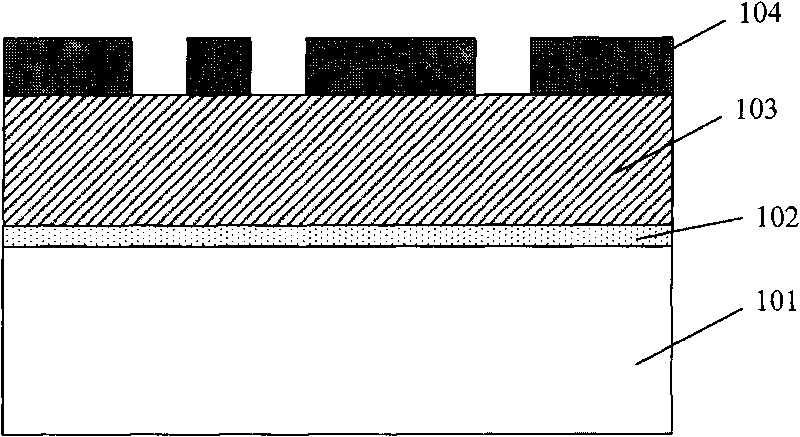

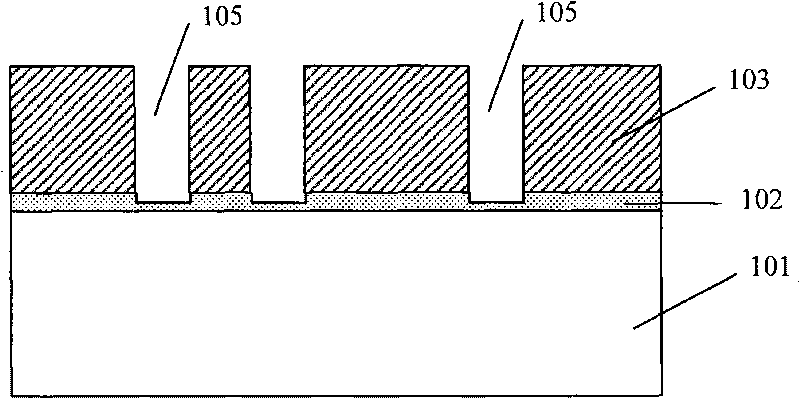

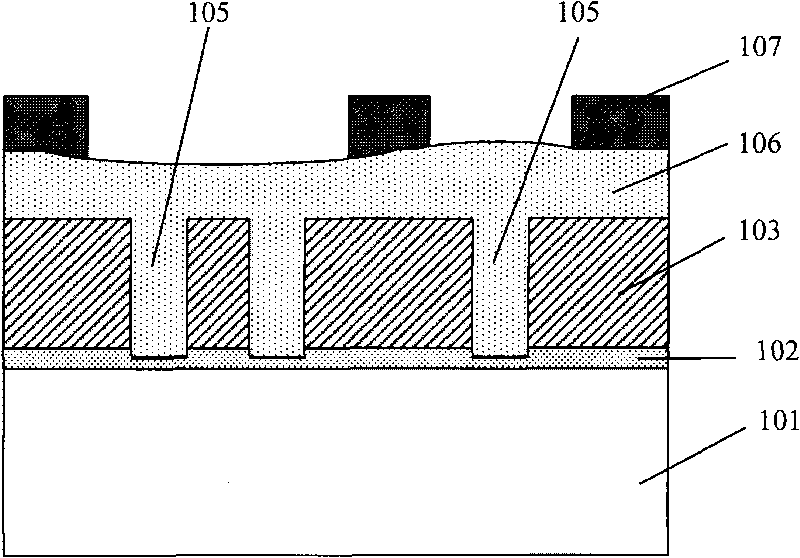

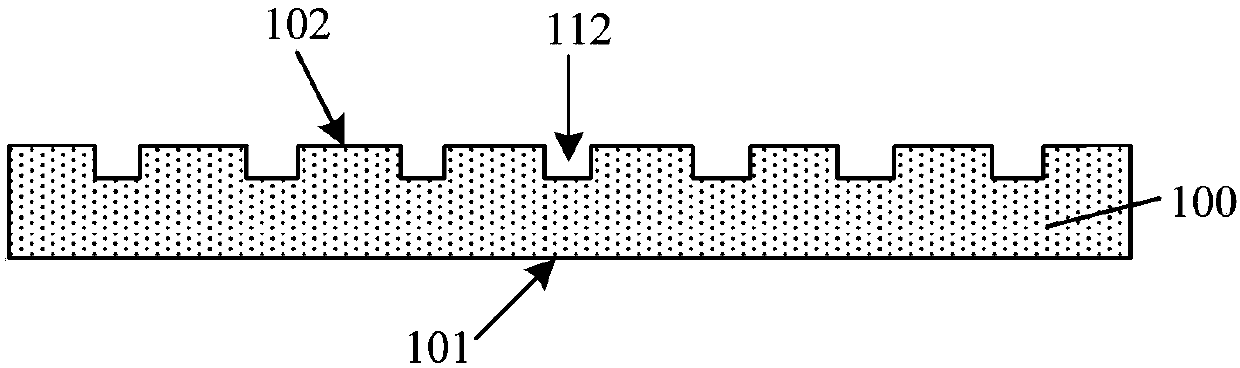

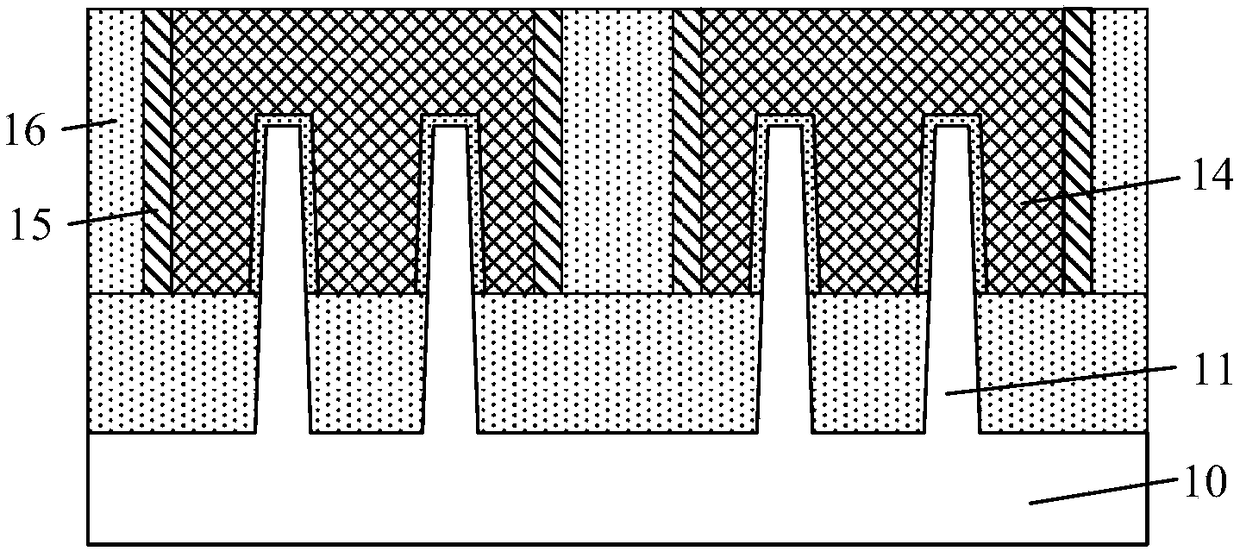

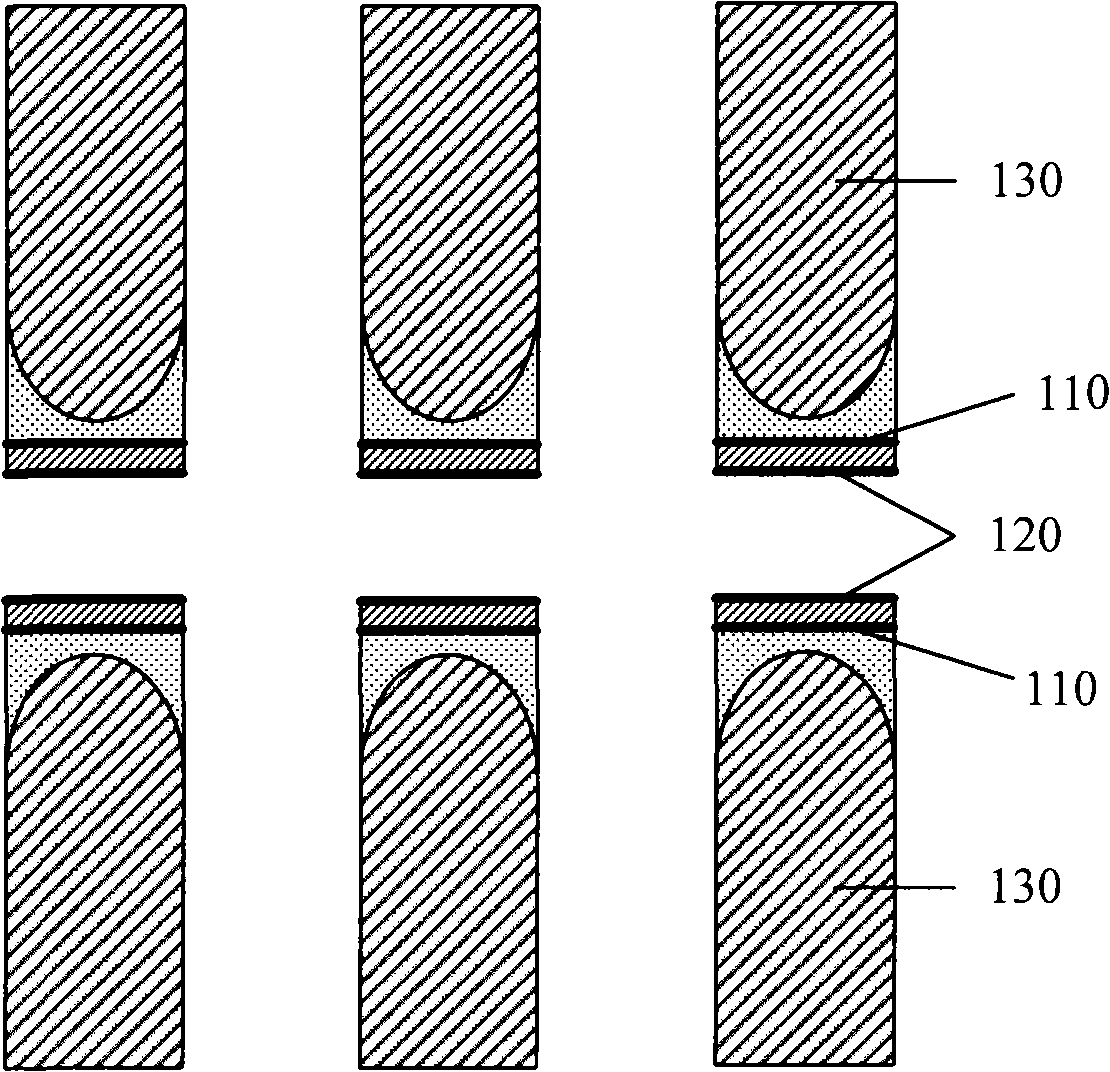

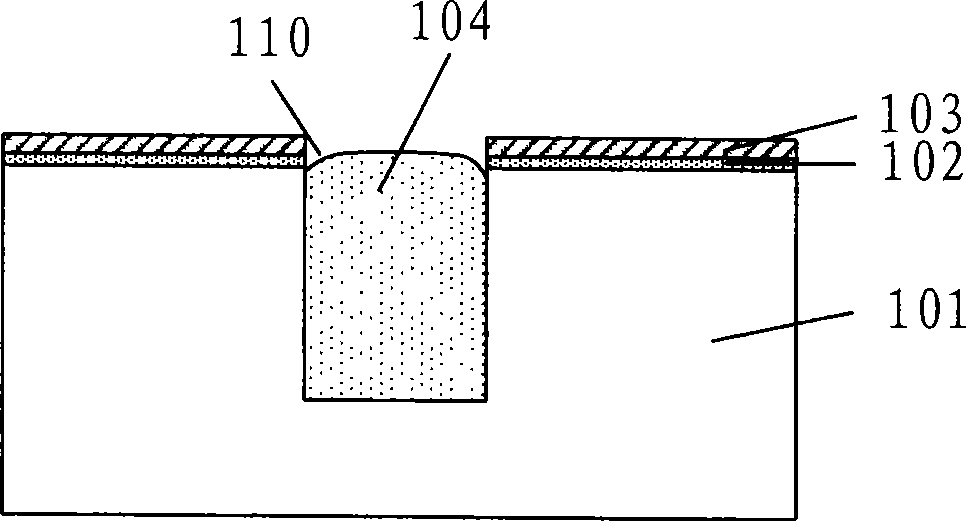

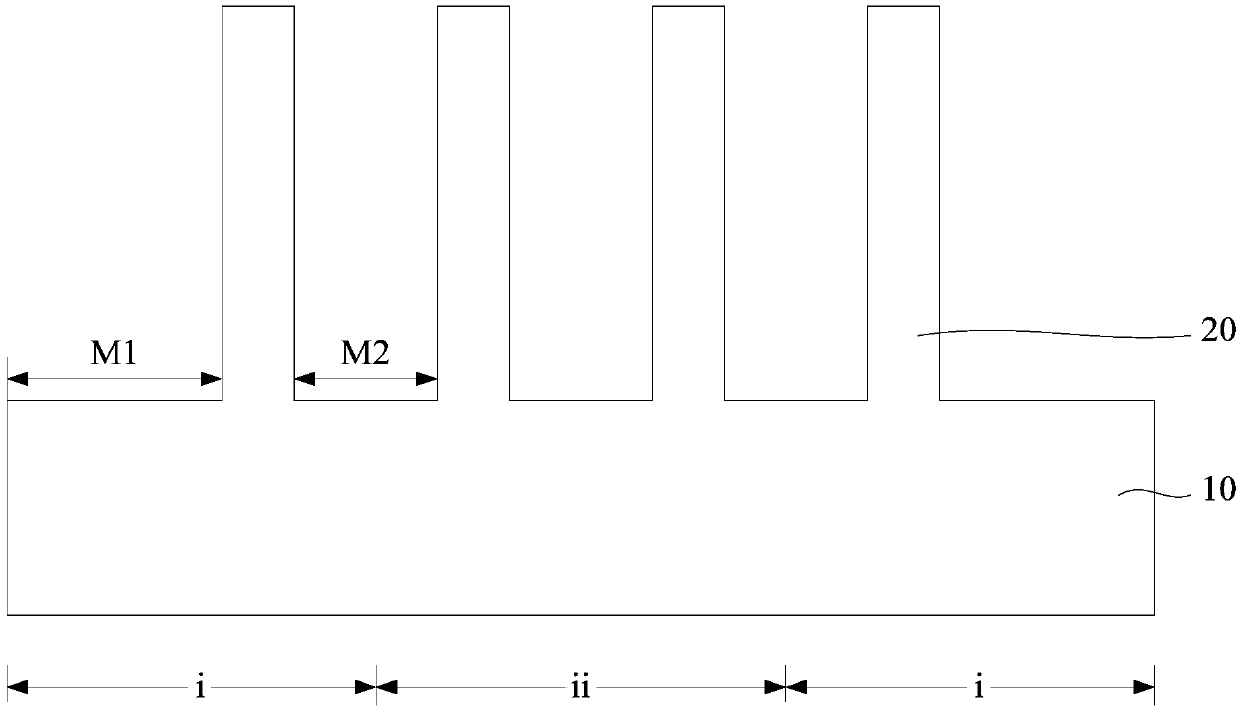

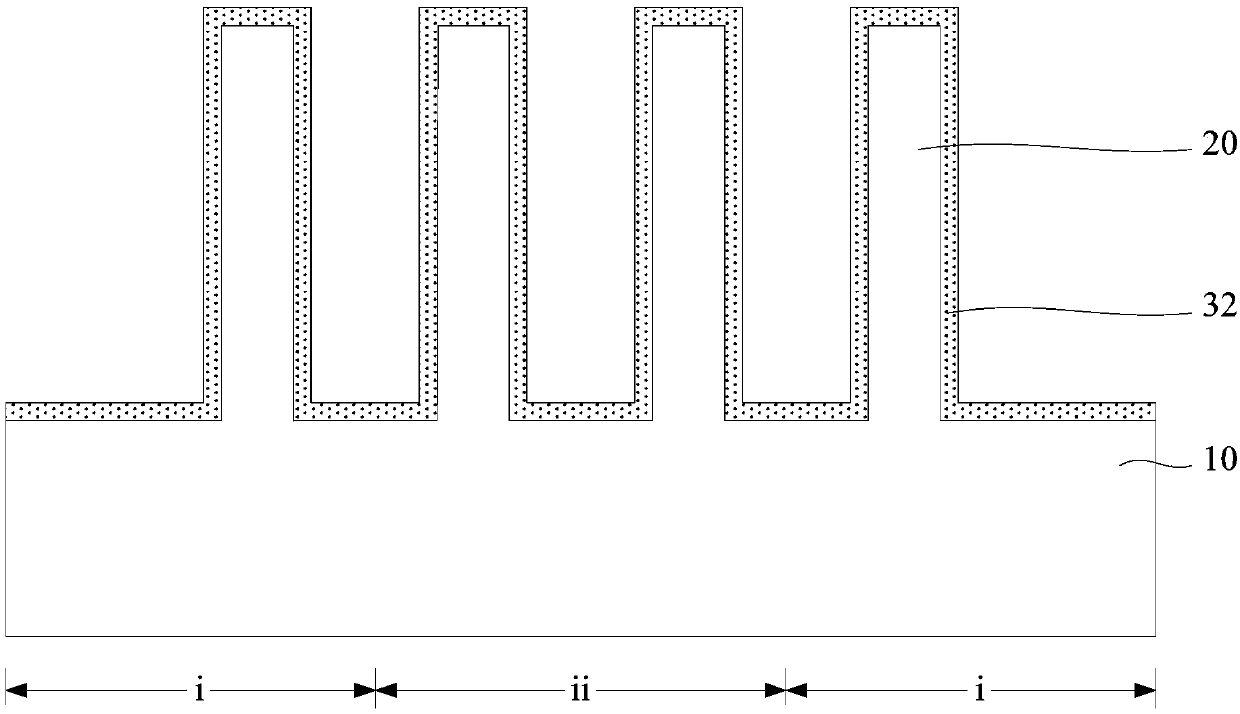

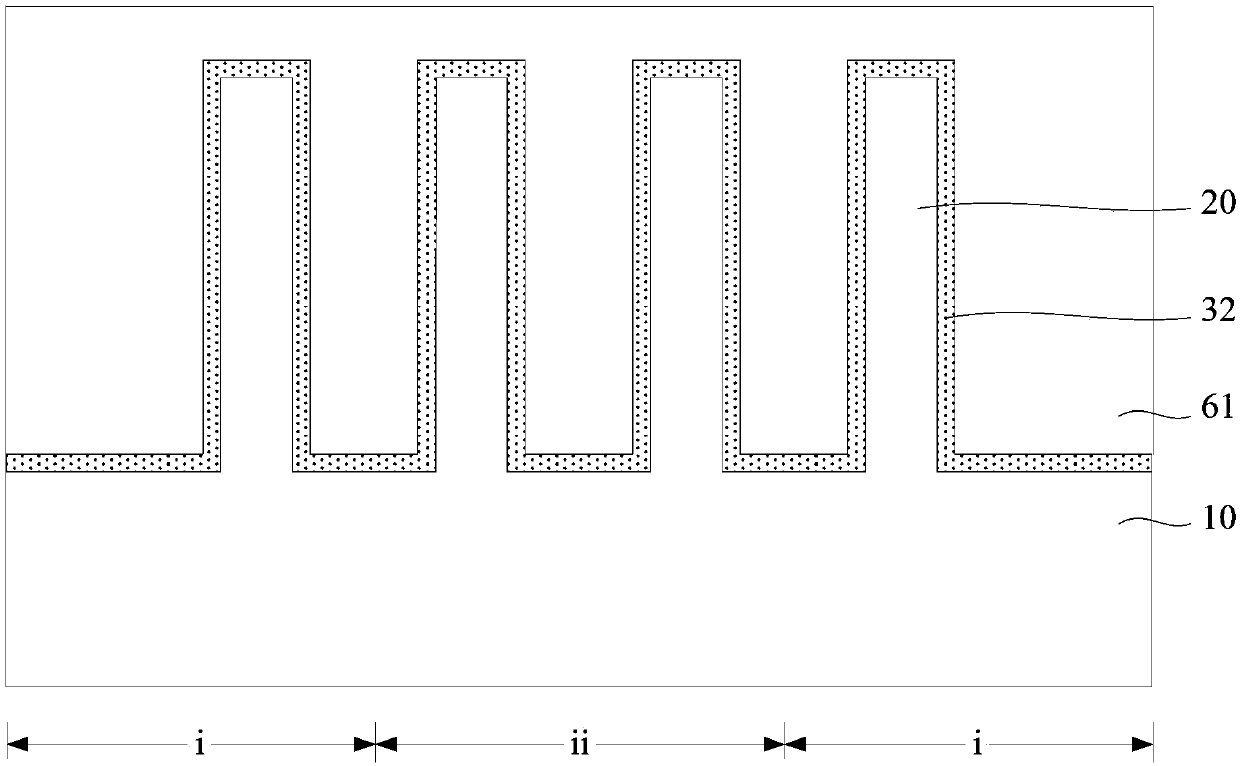

Shallow trench isolation structure and forming method thereof

ActiveCN101577242AImprove formation qualityImprove yieldSolid-state devicesSemiconductor/solid-state device manufacturingEtchingEngineering

The invention discloses a forming method of a shallow trench isolation structure, comprising the steps: providing an substrate; forming a stop layer on the substrate; defining a shallow trench graph on the substrate; forming a trench in the substrate on which the stop layer is formed; depositing protective dielectric layers on the stop layer and the trench; corroding the protective dielectric layers until the protective dielectric layer on the stop layer is removed; depositing filler on the stop layer and in the trench; performing planarization process on the substrate where the filler is deposited; eliminating the stop layer on the substrate; and processing the filler by a method of wet etching. The invention also discloses the corresponding shallow trench isolation structure. The shallow trench isolation structure and the forming method thereof can prevent pits occurring at the edges of the shallow trench isolation structure, thereby the forming quality of the shallow trench isolation structure and the yield of devices are improved.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

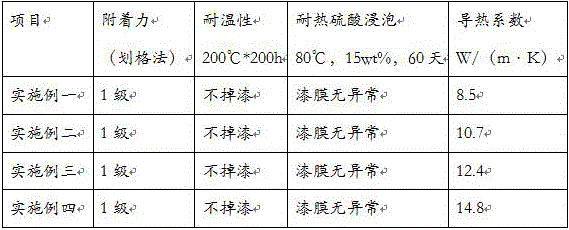

Graphene coating for corrosion prevention of thermal power plant desulfurization chimney, and preparation method of graphene coating

ActiveCN106366928AImprove toughnessImprove thermal stabilityFireproof paintsAnti-corrosive paintsFiberMetallurgy

The invention discloses graphene coating for corrosion prevention of a thermal power plant desulfurization chimney. The graphene coating consists of the following raw materials in parts by weight: 90 to 100 parts of film-forming resin, 0.5 to 3 parts of graphene, 0.5 to 2 parts of reinforced fibers, 10 to 20 parts of fillers, 10 to 20 parts of a curing agent, 15 to 30 parts of a diluents, 1 to 5 parts of polyacrylic acid, 1 to 5 parts of a polyethylenimin crosslinking agent, 1 to 3 parts of stearate and 2 to 6 parts of aids. By the mode of adding the raw materials, such as the reinforced fibers, the fillers, the polyethylenimin crosslinking agent and the polyacrylic acid, the defect that the existing corrosion-resistant coating has low durability and heat stability is overcome, the problem that the corrosion-resistant coating layer is easy to pollute and difficult to clean is solved, the developed graphene corrosion-resistant coating can completely adapt to the high-temperature strong-acid environment, the manufacturing process is simple, the practicability is high and the graphene coating is particularly suitable for thermal power plant desulfurization chimneys and flues.

Owner:CHENGDU LONGZHIQUAN SCI & TECH

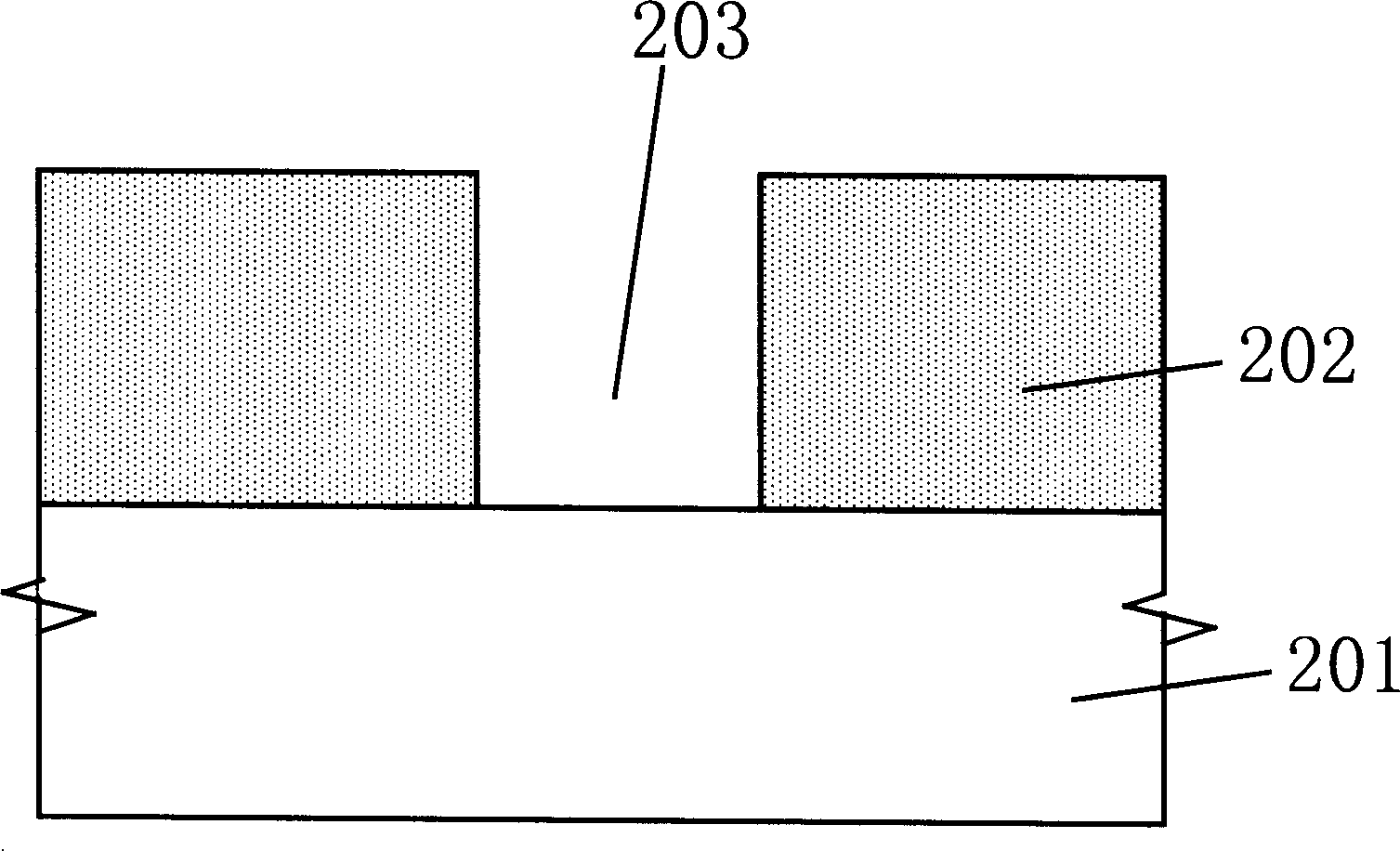

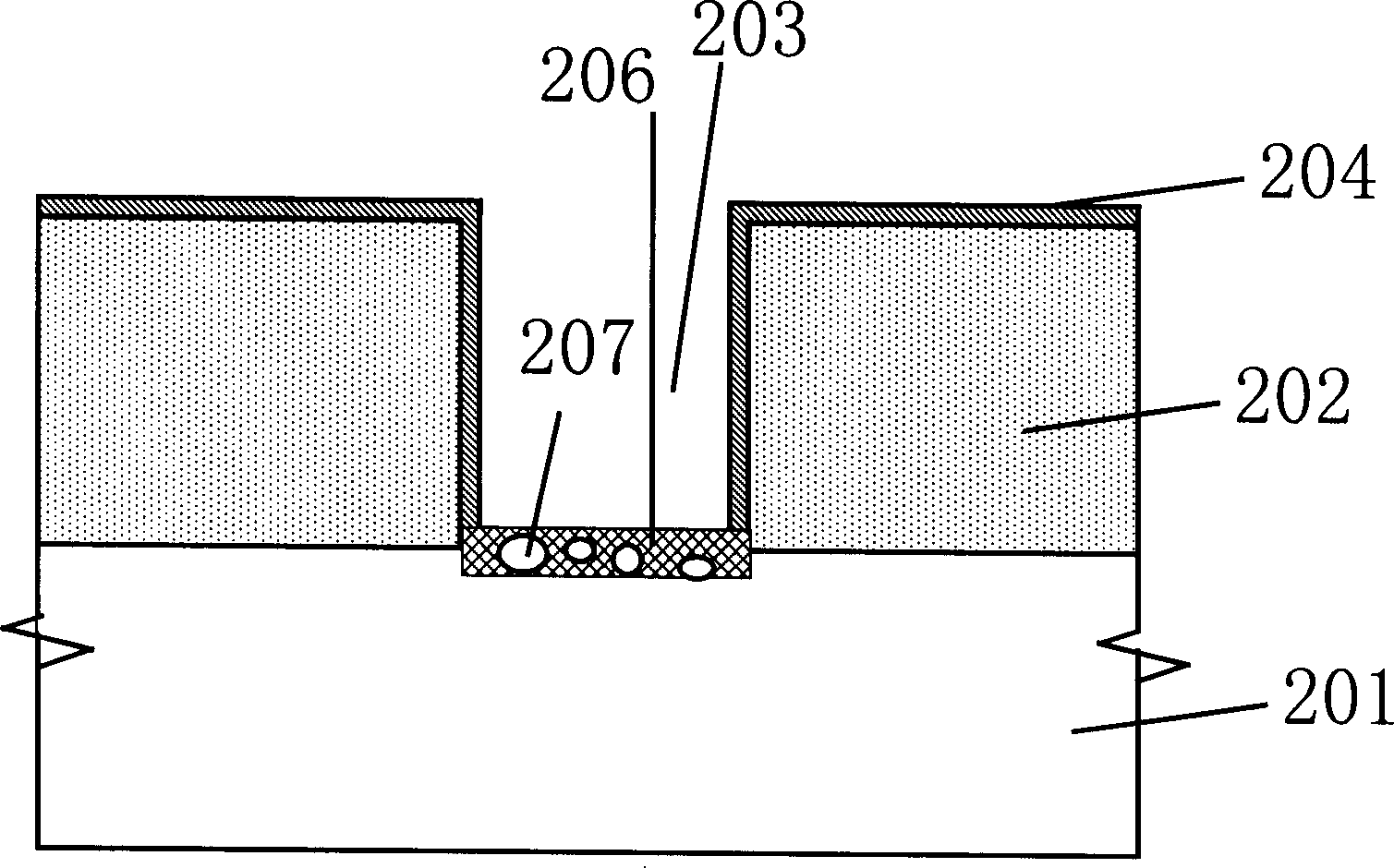

Method for forming dual mosaic structure

ActiveCN101740476AAvoid bumpingImprove formation qualitySemiconductor/solid-state device manufacturingEtchingFiller metal

The invention discloses a method for forming a dual mosaic structure, which comprises the following steps of: providing a substrate of which the surface is provided with a conductive structure; forming a first dielectric layer on the substrate; forming a through-hole pattern on the first dielectric layer; carrying out first etching by taking the through-hole pattern as a mask; covering a second dielectric layer on the substrate with a through-hole opening; carrying out second etching on the second dielectric layer; covering a third dielectric layer on the substrate after the second etching; forming a groove pattern on the third dielectric layer; carrying out third etching by taking the groove pattern as the mask to form a groove; removing the residual second dielectric layer and the third dielectric layer on the substrate after forming the groove; and filling a metal in the through-hole opening and the groove to form the dual mosaic structure. The method for forming the dual mosaic structure can solve the problems of slopes and bulges in the dual mosaic structure formed by using the conventional method, and improves the forming quality of the dual mosaic structure.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

Resonator and forming method thereof

ActiveCN112117987AImprove performanceAchieve sealingImpedence networksEngineeringMechanical engineering

The invention relates to a resonator and a forming method thereof, and the forming method of the resonator comprises the steps: forming a piezoelectric laminated structure on a first substrate, the piezoelectric laminated structure comprises a first region, and the surface, in contact with the first substrate, of the piezoelectric laminated structure is a first front surface; forming a sacrificiallayer covering the piezoelectric laminated structure on the first region; providing a second substrate; forming a bonding layer on the second substrate, the face, making contact with the second substrate, of the bonding layer is a second front face, and the face, opposite to the second front face, of the bonding layer is a second back face; attaching the second back surface of the bonding layer to the sacrificial layer and the piezoelectric laminated structure exposed out of the sacrificial layer, so that the bonding layer covers the side wall of the sacrificial layer and fills between the second substrate and the piezoelectric laminated structure; removing the first substrate to expose the first front surface of the piezoelectric laminated structure; forming a release hole penetrating through the piezoelectric laminated structure or forming a release hole penetrating through the second substrate, wherein the release hole exposes the sacrificial layer; and removing the sacrificial layer through the release hole to form a cavity. The method of the invention is beneficial to improving the performance of the resonator.

Owner:NINGBO SEMICON INT CORP

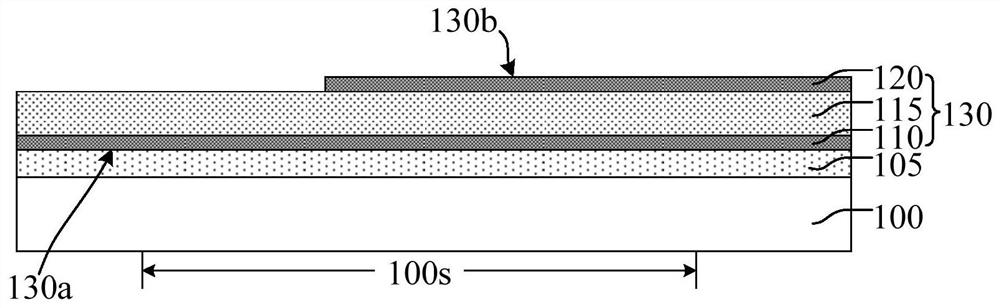

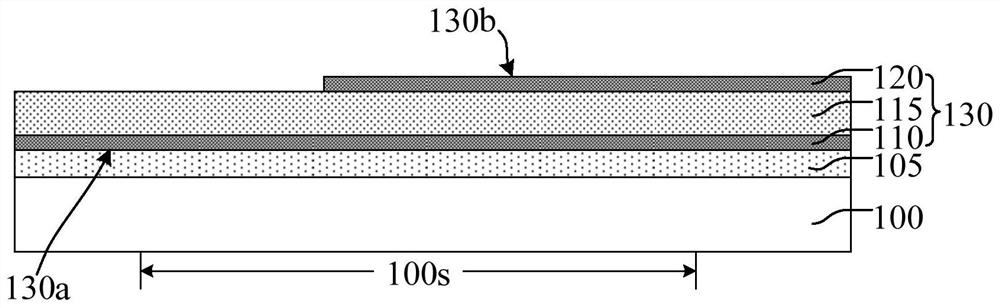

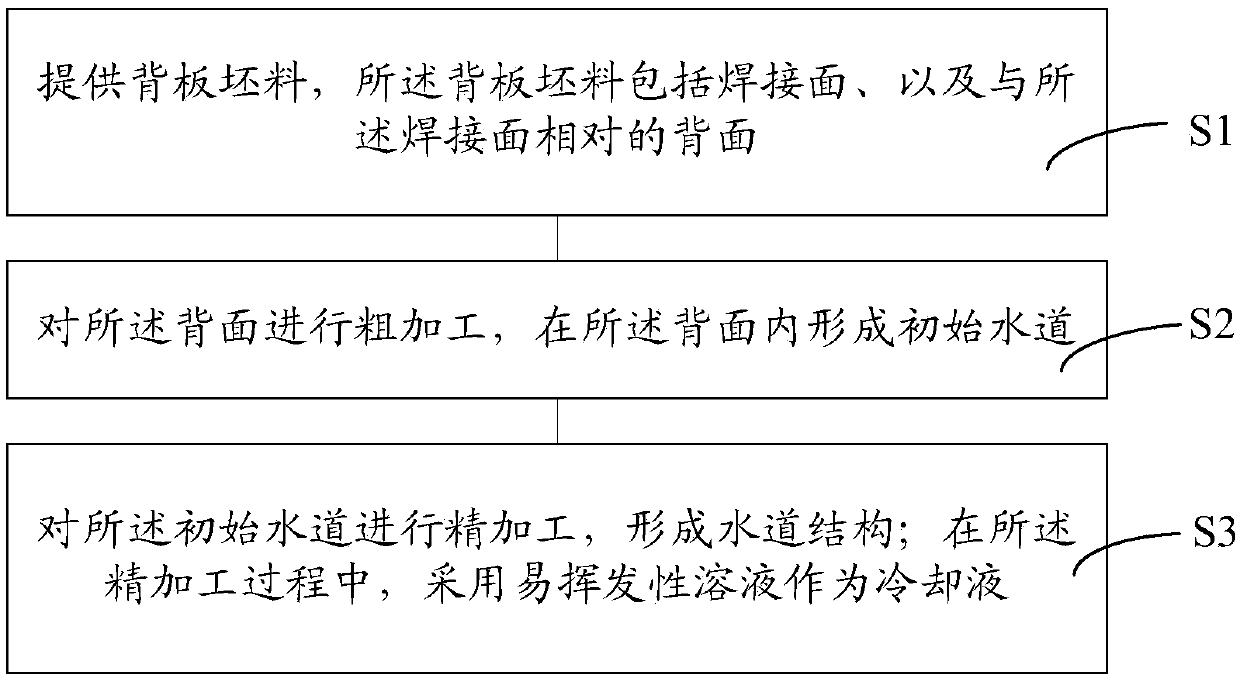

Manufacturing method for backboard and target material assembly

InactiveCN107717024AImprove surface cleanlinessHigh lusterVacuum evaporation coatingSputtering coatingEngineeringMachining process

The invention provides a manufacturing method for a backboard and a target material assembly. The manufacturing method includes the steps that a backboard blank material is provided, and comprises a welding face and a back face opposite to the welding face; the back face is subjected to rough machining, and an initial water channel is formed in the back face; the initial water channel is subjectedto finish machining to form a water channel structure; and in the finish machining process, an easy volatile solution is adopted to serve as cooling liquid. According to the manufacturing method forthe backboard, in the finish machining process on the initial water channel, the easy volatile solution is adopted to serve as the cooling liquid, the cooling liquid is not likely to form residues inthe water channel structure after volatizing of the cooling liquid, and therefore the surface cleanness degree and the luster degree of the water channel structure can be improved, remaining impurities in the water channel structure can be reduced or avoided, and therefore the forming quality of the water channel structure is improved, and therefore the quality of the backboard is improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

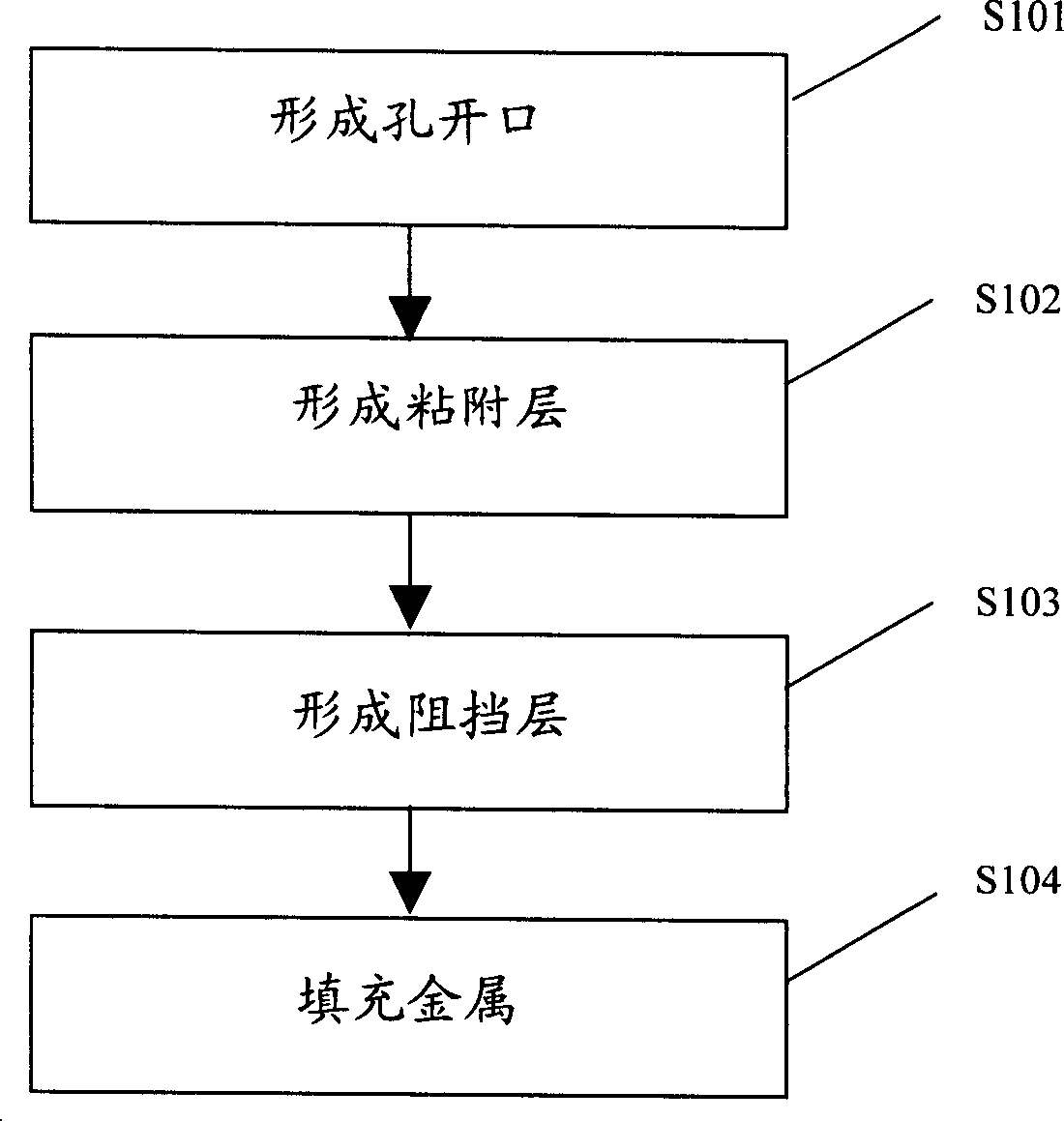

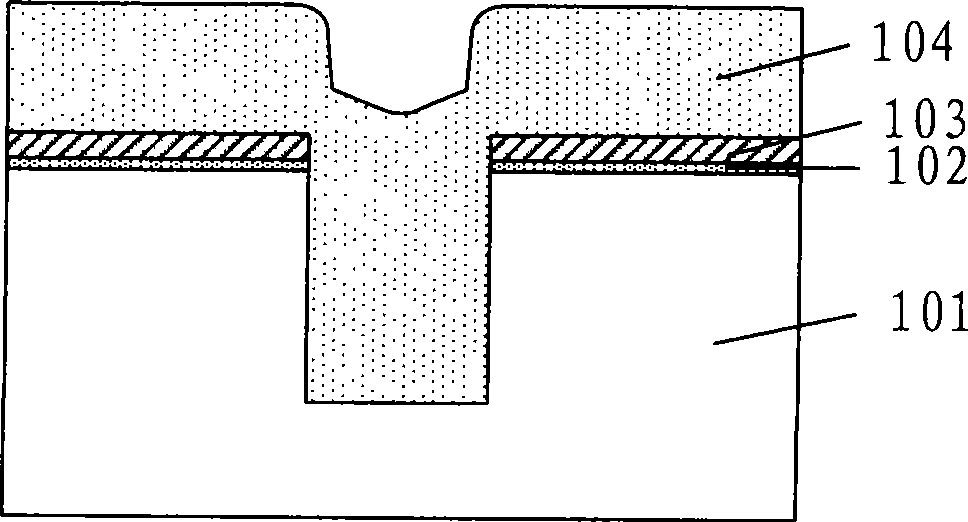

Contact hole filling method

InactiveCN101192560AReduce contact resistanceImprove formation qualitySemiconductor/solid-state device manufacturingPoor qualityMicrometer

The invention discloses a method for filling a contact hole, which includes the following steps: a silicon substrate, the surface of which has a contact hole opening, is provided; an adhere layer is formed inside the contact hole opening; the silicon wafer is processed by rapid thermal annealing; a barrier layer is formed on the adhere layer; metal is filled on the barrier layer in the contact hole opening. The filling method provided by the invention can be applied to the field of semiconductor manufacture and can solve the problem of forming the contact hole with relatively poor quality in the prior process below 0.25 micrometer through improving the process of filling the contact hole.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Method for incinerating etched substrate and method for forming etched structure

ActiveCN101572217AHigh energyAvoid lossSemiconductor/solid-state device manufacturingPhotosensitive material processingOptoelectronicsPlasma Gases

The invention discloses a method for incinerating an etched substrate, comprising the following steps: providing an etched substrate; putting the etched substrate in a processing chamber; guiding plasma gas into the processing chamber; incinerating the substrate for the first time by high radio frequency power supply; incinerating the substrate for the second time by low radio frequency power supply; and taking out the substrate. The invention also discloses a method for forming an etched structure with the method for incinerating the etched substrate. The method for incinerating an etched substrate and the method for forming an etched structure can ensure that the next layer of incinerated material is kept thick enough without thickening the next layer of material and narrowing an etching process window, thereby improving the quality of forming the etched structure.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

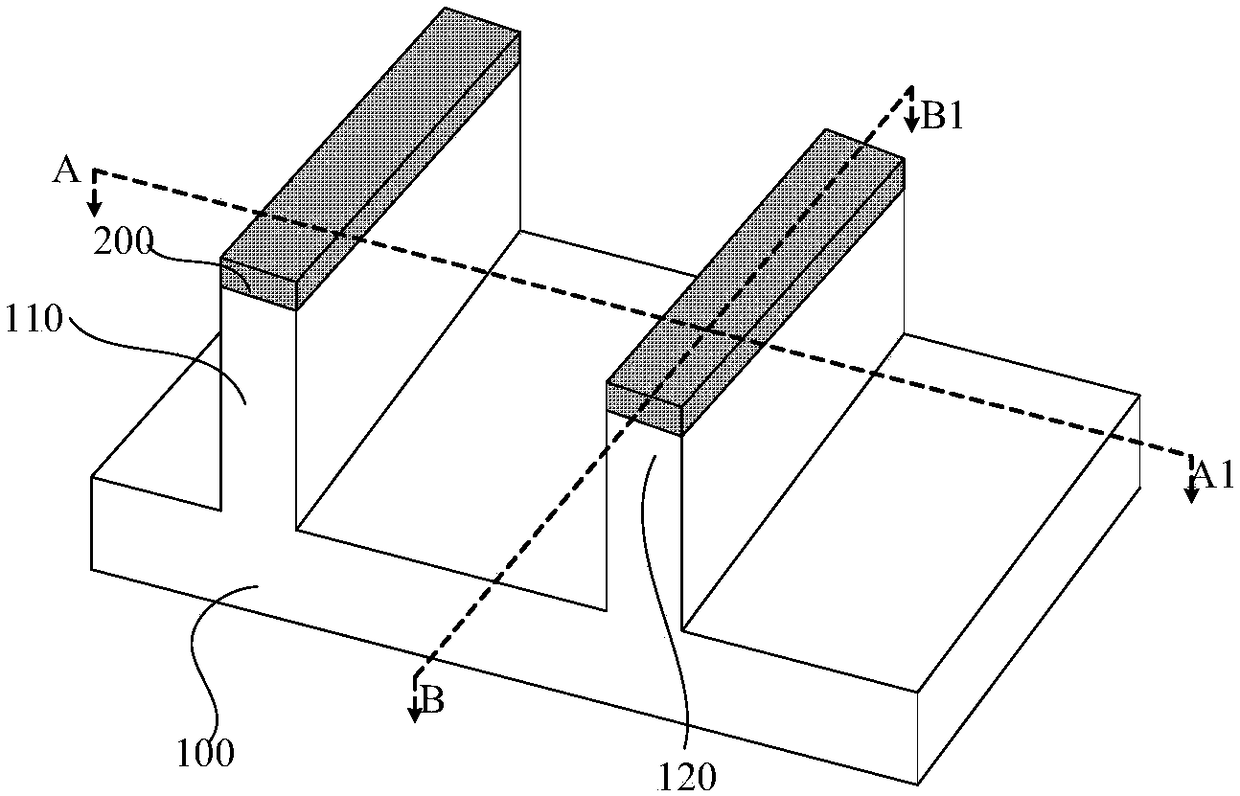

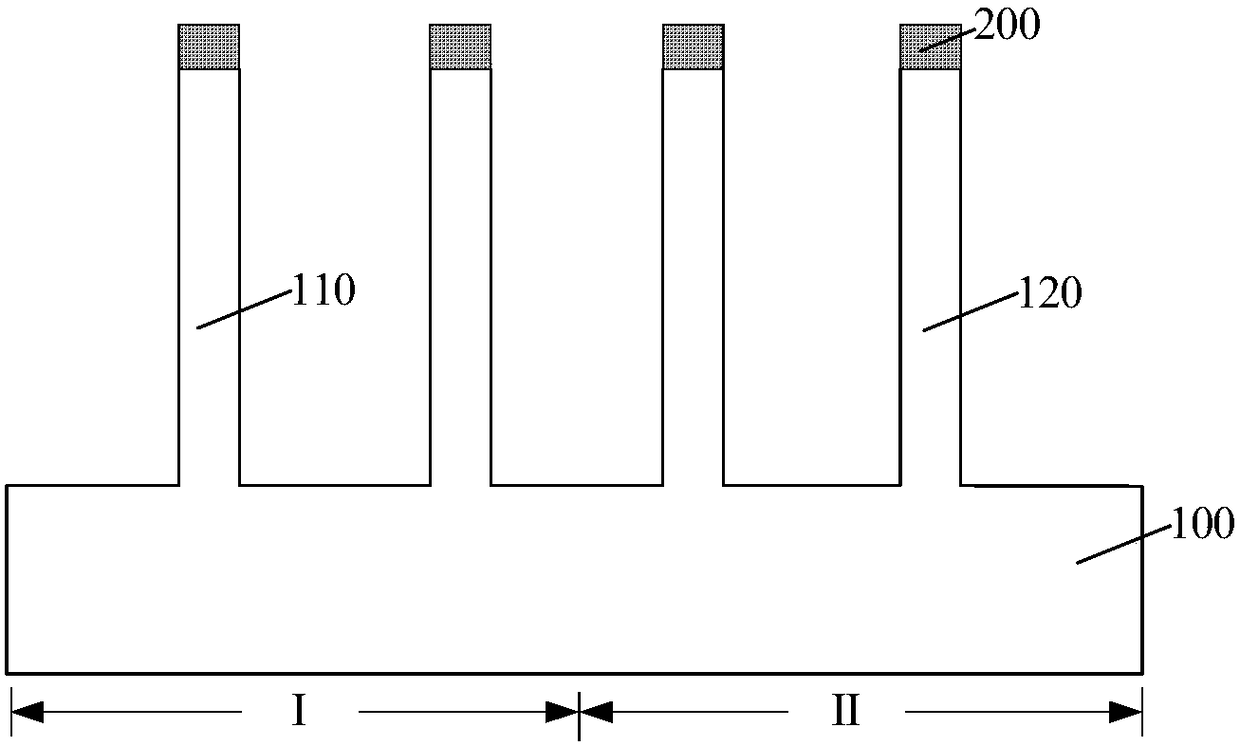

Semiconductor structure and forming method

ActiveCN109427664AIncrease space sizeReduce process difficultyTransistorSolid-state devicesEngineeringSemiconductor structure

The present invention discloses a semiconductor structure and forming method of the semiconductor structure, the method comprises: providing a substrate, including a substrate and a fin on the substrate, wherein the substrate is formed with an interlayer dielectric layer, within the interlayer dielectric layer is formed with a gate opening exposing a portion of the substrate, and sidewall of the gate opening is formed a side wall; thinning a sidewall of the side wall that is away from a side of the substrate, wherein top of the side wall that is not thinned is at most flush with top of the fin; after the thinning process, forming a gate dielectric layer at bottom and the sidewall of the gate opening; forming an amorphous silicon layer on the gate dielectric layer; after the amorphous silicon layer is formed, annealing the substrate; and after the annealing process, removing the amorphous silicon layer. The method thins portion of height of the sidewall of the side wall that is away from the side of the substrate, and the top of the side wall which is not thinned is at most flush with the top of the fin, thereby reducing the probability of occurrence of an amorphous silicon layer residue problem after removal of the amorphous silicon layer.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Semiconductor structure and formation method thereof

ActiveCN108257916AReduce manufacturing costReduce the impactTransistorSolid-state devicesDopantSemiconductor structure

Disclosed are a semiconductor structure and a formation method thereof. The formation method comprises the steps of forming a base, wherein the base comprises a substrate, a gate structure positionedon the substrate, source and drain doped regions positioned in the base on the two sides of the gate structure, and an interlayer dielectric layer positioned on the base and for covering the top of the gate structure, and the substrate comprises a first region for forming a P type device and a second region for forming an N type device; forming a first contact opening for exposing the source and drain doped regions in the interlayer dielectric layer on the two sides of the gate structure; performing a P type dopant segregated schottky doping process on the source and drain doped regions exposed from the first contact opening in the first region and the second region; forming a metal silicide layer at the bottom of the first contact opening; and forming a first contact hole inserting plug in the first contact opening. By adjusting the doping concentration of the source and drain doped regions in the second region, use of a photomask can be avoided when the P type dopant segregated schottky doping process is performed, so that lowering of the process cost is realized, and the N type device suffers from relatively low influence.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

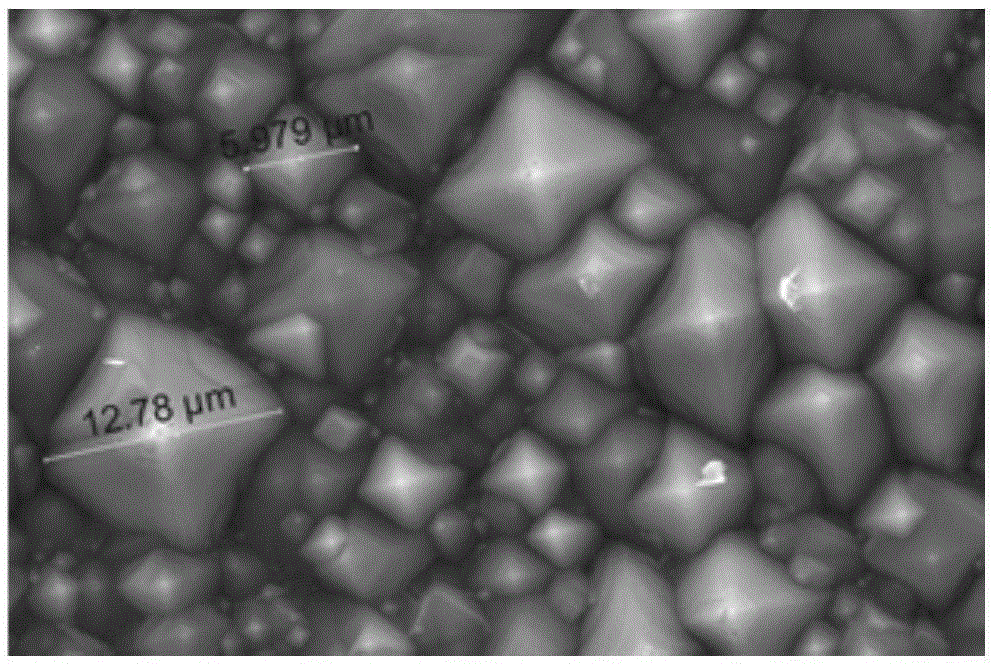

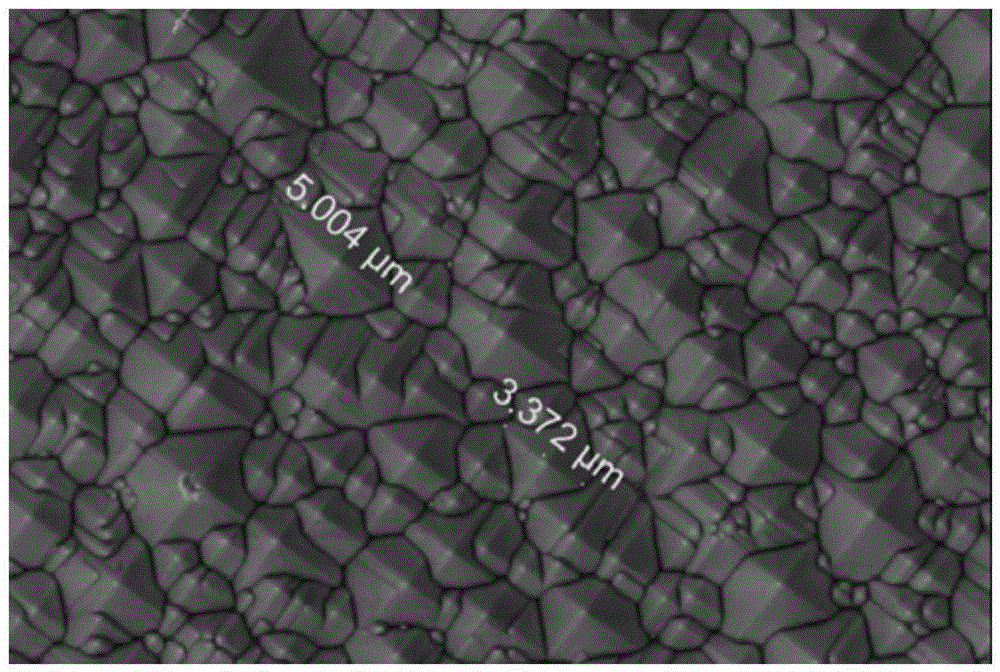

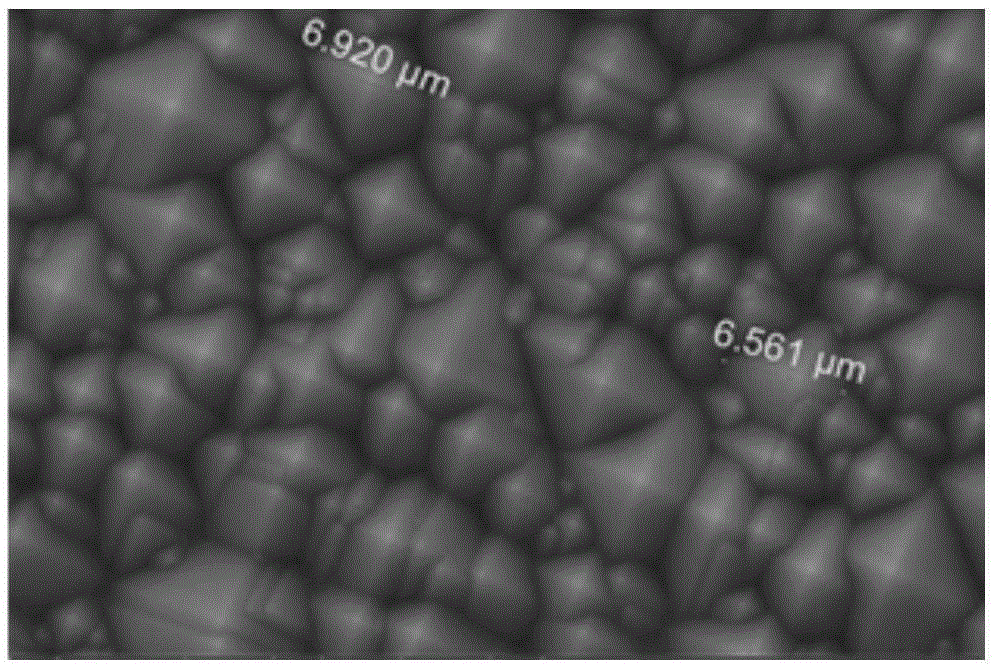

Control method for controlling suede dimension of monocrystalline silicon heterojunction solar battery cell

InactiveCN106601835AImprove uniformityImprove formation qualityFinal product manufacturePhotovoltaic energy generationHeterojunctionHydrofluoric acid

The invention discloses a control method for controlling the suede dimension of a monocrystalline silicon heterojunction solar battery cell. The method comprises the steps of conducting the damage layer removing treatment on the surface of a silicon wafer by using a strong alkaline solution; cleaning the silicon wafer by using a mixed solution of ammonia water and hydrogen peroxide; texturing by using a mixed solution of KOH / NaOH and a texturing additive so as to form pyramids on the surface of the silicon wafer, wherein the dimension of the pyramids is controlled through controlling the concentration of KOH / NaOH and the texturing time, and the concentration of KOH / NaOH and the texturing time are in directly proportional relationship with the dimension of the pyramid; cleaning the textured silicon wafer by using a mixed solution of hydrochloric acid and hydrogen peroxide; subjecting the textured silicon wafer to dehydration treatment by using a hydrofluoric acid solution, slowly pulling out the silicon wafer and drying the silicon wafer. According to the technical scheme of the invention, through controlling the concentration of KOH / NaOH, the texturing time and the texturing temperature, the range of the suede dimension can be controlled. In this way, the dimension of texturing pyramids on the silicon wafer is controlled within a certain range. Therefore, the suede uniformity of the silicon wafer is improved.

Owner:GOLD STONE (FUJIAN) ENERGY CO LTD

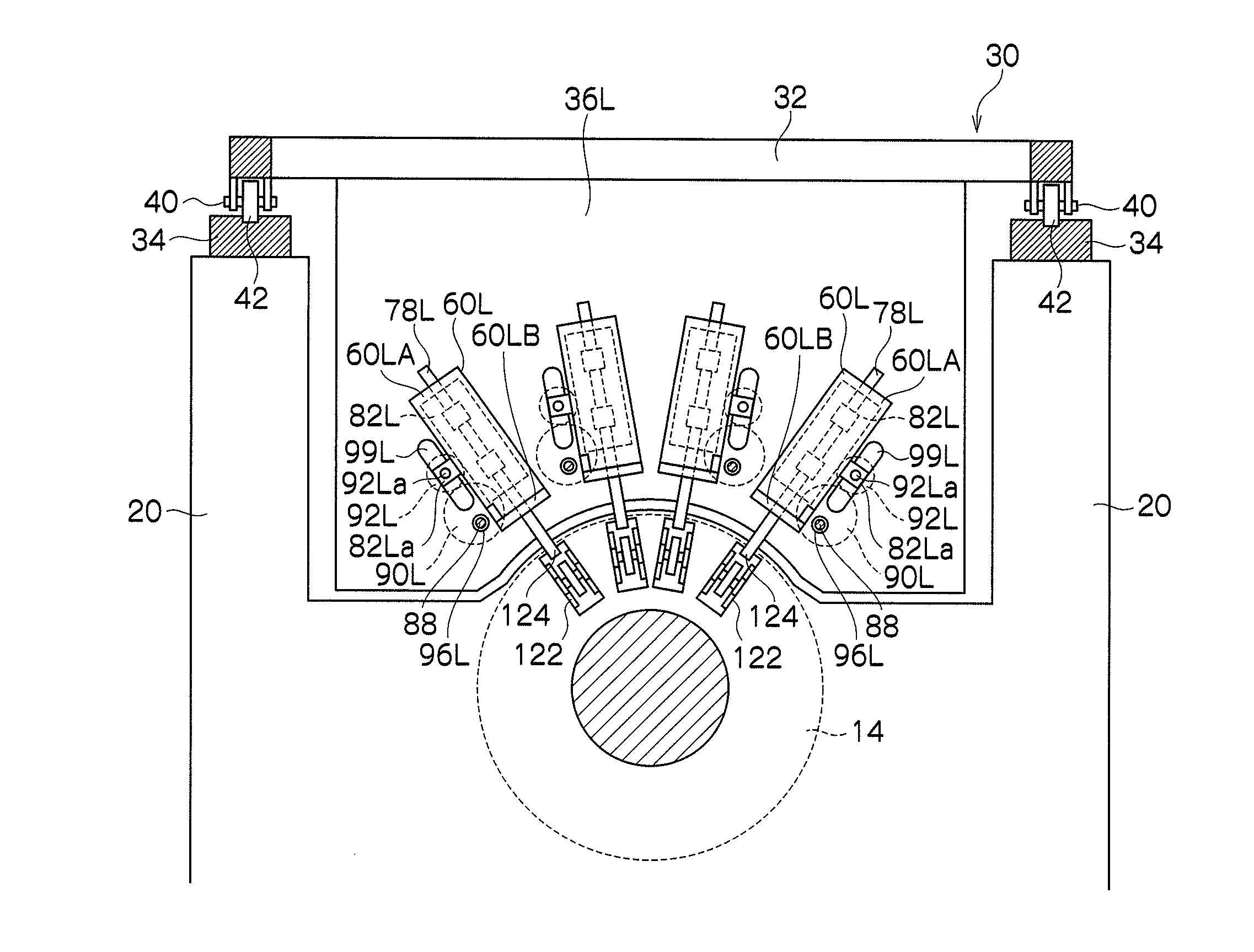

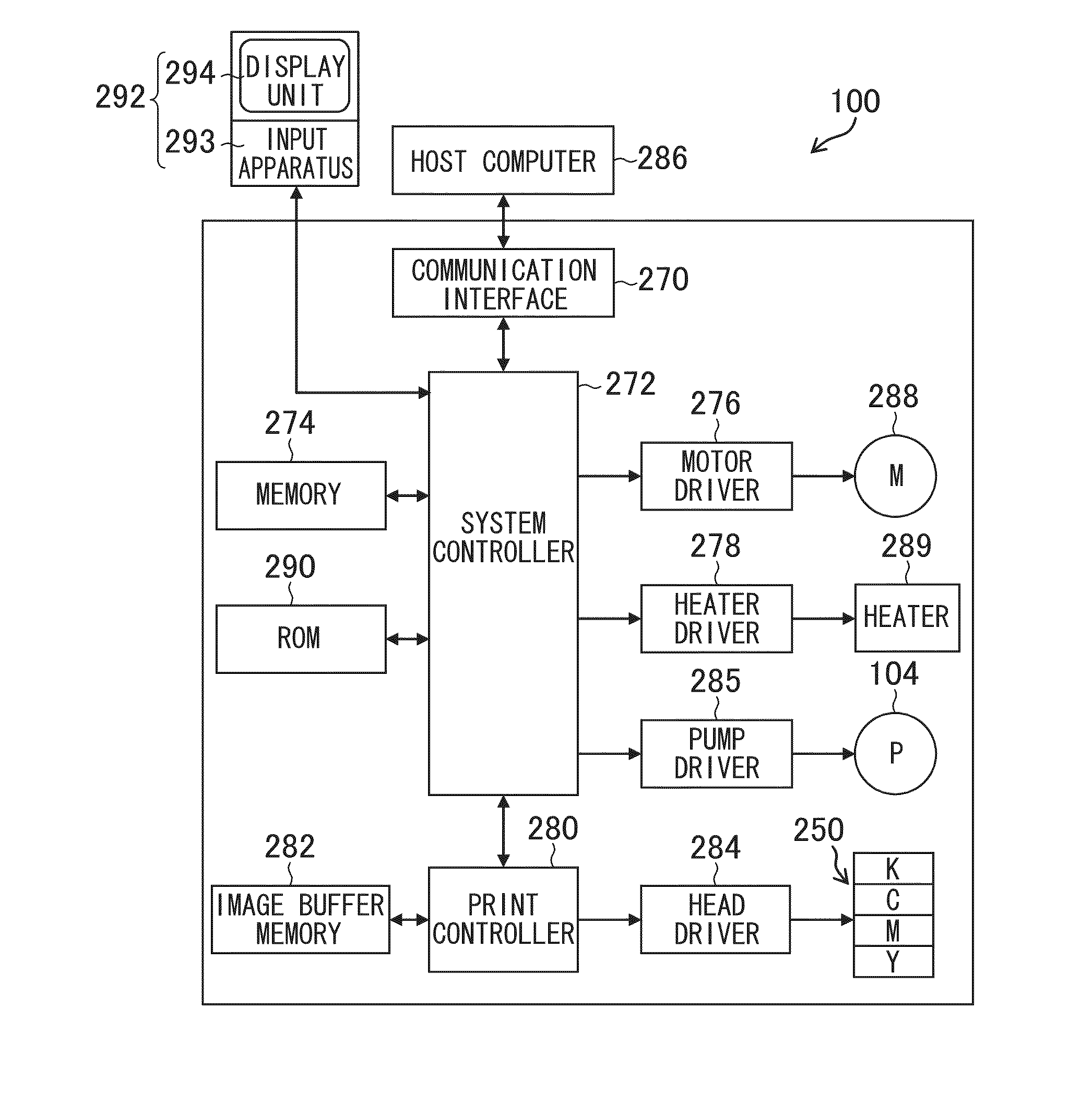

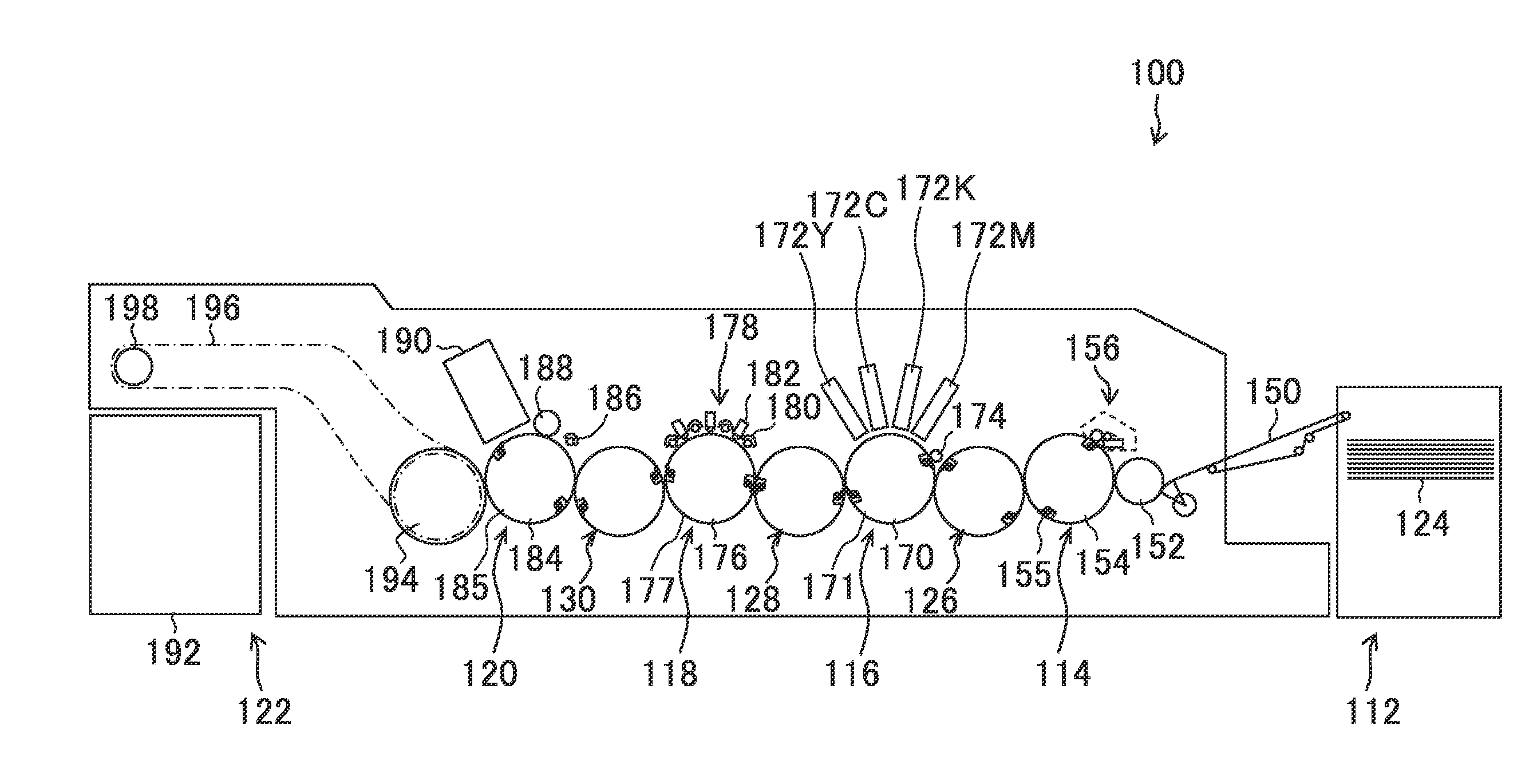

Image forming apparatus

ActiveUS20120075382A1Improve formation qualityImprove productivityInking apparatusPower drive mechanismsEngineeringNozzle

An image forming apparatus which includes a line head having a nozzle group in a two-dimensional matrix configuration, or a line head in which a plurality of head modules are joined together in a staggered matrix arrangement.

Owner:FUJIFILM CORP

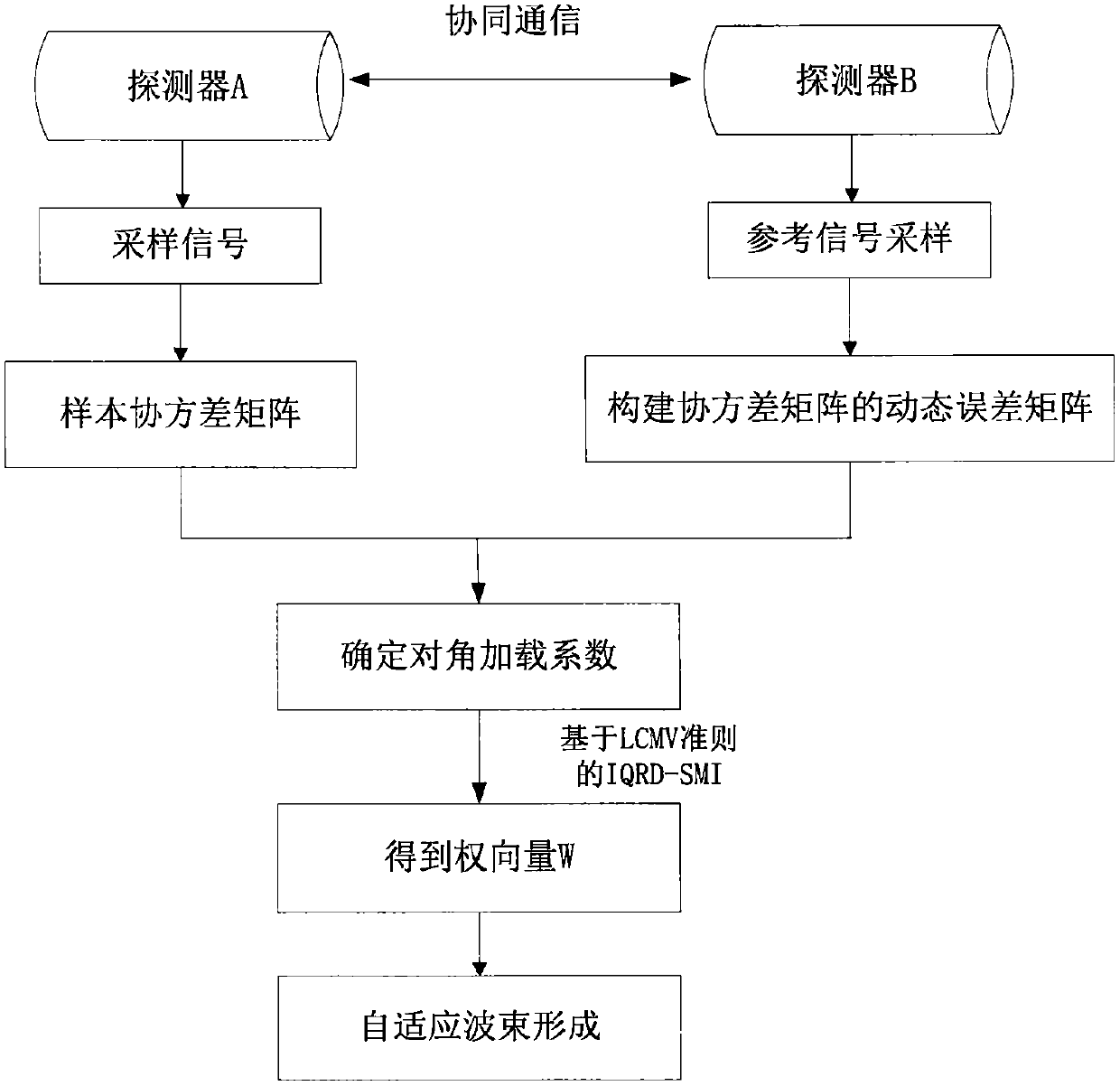

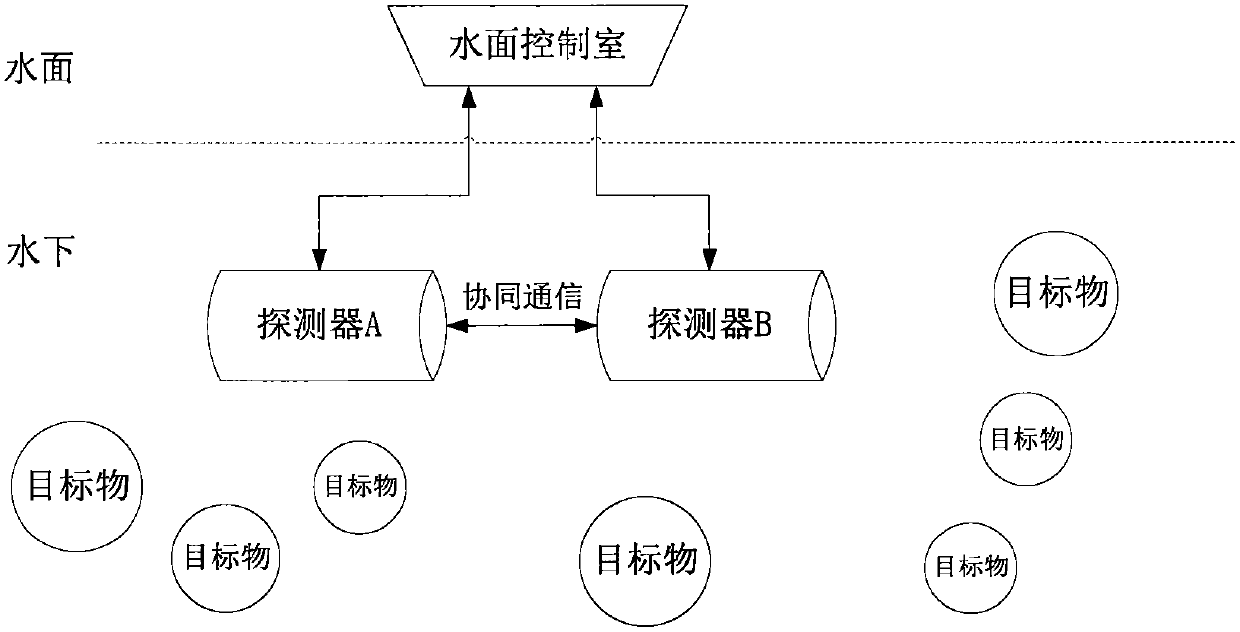

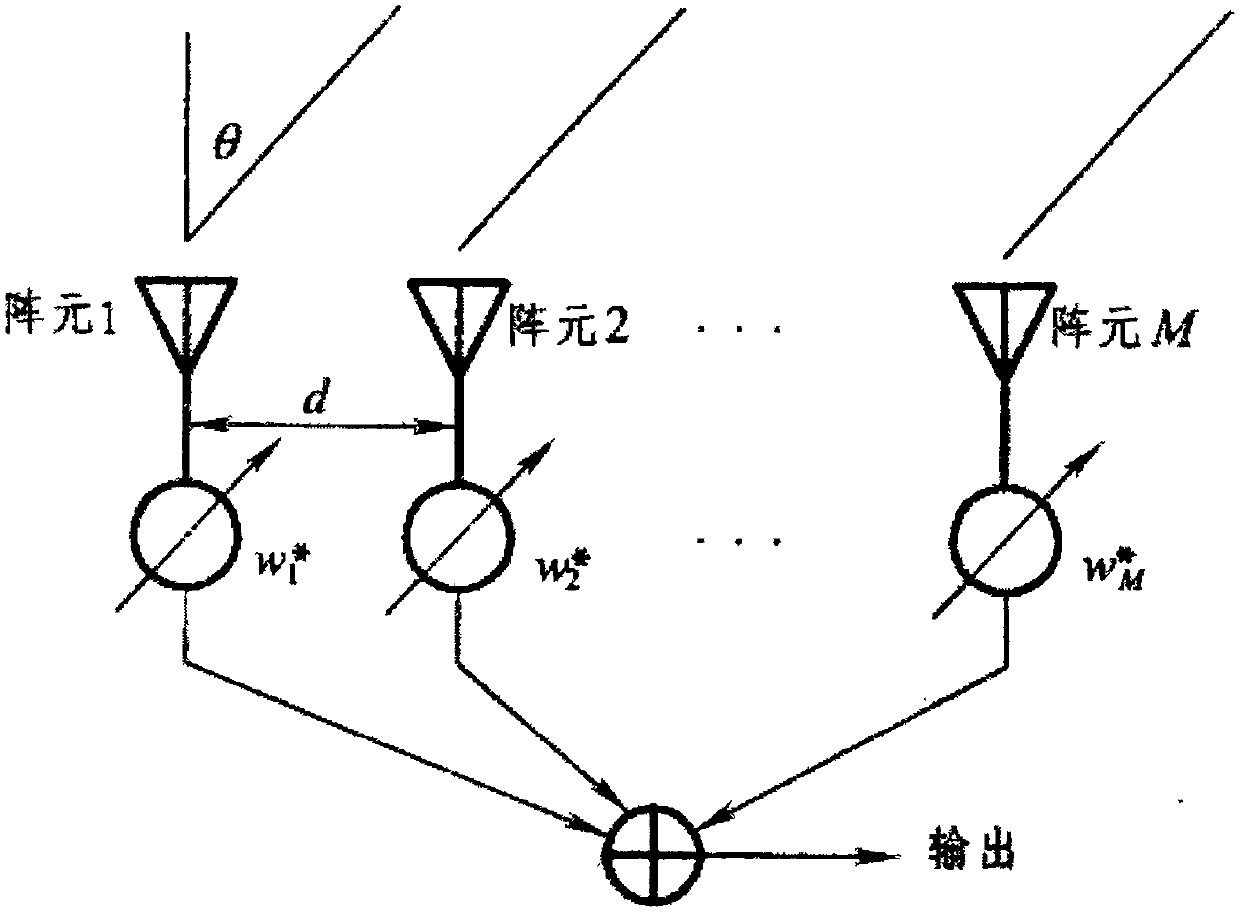

Adaptive wave beam formation method based on dynamic re-correction and system

InactiveCN105372644AImprove formation qualityReduce distractionsAcoustic wave reradiationArray elementSelf adaptive

The invention discloses an adaptive wave beam formation method and an adaptive wave beam formation system. An actual input vector covariance matrix is dynamically evaluated according to cooperation communication between reception equipment and a sampling covariance matrix, a dispersion situation of characteristic values is minimized; performance of an adaptive wave beam is improved, influence of environment interference change on signal reception is reduced, and wave beam formation accuracy and wave beam formation robustness are improved. The method comprises steps that, 1), a sample is acquired through receiving end array elements, a covariance matrix of the sample data is calculated and is taken as an estimate of an interference noise addition covariance matrix; 2), an error matrix of the covariance matrix is constructed according to a reference signal sent by cooperation equipment and a pre-stored reference signal of the equipment; 3), the covariance matrix of the sample data acquired in the step 1) is dynamically adjusted by the error matrix acquired in the step 2), and the improved sample covariance matrix is acquired; 4), a diagonal loading coefficient is determined; and 5), weight vector solution is carried out by employing an IQRD-SMI algorithm based on LCMV, and adaptive wave beams are generated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Forming method of metal silicide

InactiveCN101197280AAvoid condensationInhibited DiffusionMetal silicidesSemiconductor/solid-state device manufacturingSalicideMetal silicide

The invention discloses a forming method for metal silicide, which comprises the following steps of: providing a substrate with the surface having silicon material; forming a metal layer on the substrate; performing the first heat annealing treatment for the substrate; removing the unreacted metal layer on the substrate; forming a stress layer on the substrate; performing the second heat annealing treatment for the substrate. The forming method for metal silicide in the invention forms a low-resistance metal silicide with smooth surface and regular shape by adding the stress layer, thus improving the performance of the device and enhancing the final product rate of products.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Semiconductor structure and formation method thereof

InactiveCN108022882AWork function value influenceEasy to spreadTransistorSolid-state devicesGate dielectricSemiconductor structure

The invention relates to a semiconductor structure and a formation method thereof. The formation method comprises the steps of providing a substrate; forming a gate dielectric layer on the substrate;forming a work function layer on the gate dielectric layer; forming a cap layer on the work function layer, wherein the cap layer comprise a Ti layer; and forming a metal layer on the cap layer, wherein the gate dielectric layer, the work function layer, the cap layer and the metal layer are used for forming a gate structure. According to the invention, the cap layer is formed o the work functionlayer before the metal layer is formed, the cap layer comprises the Ti layer, the metal layer generally contains easily diffused F ions, and the F ion is high in electronegativity and easy to be boundwith a Ti ion to form a titanium-fluorine bond. Correspondingly, the Ti ions can well adsorb the F ions. Therefore, the Ti layer can effectively play a role of preventing diffusion of the F ions, sothat the F ions are avoided from being diffused to the work function layer, and thus influences imposed on a work function value of the work function layer are avoided.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

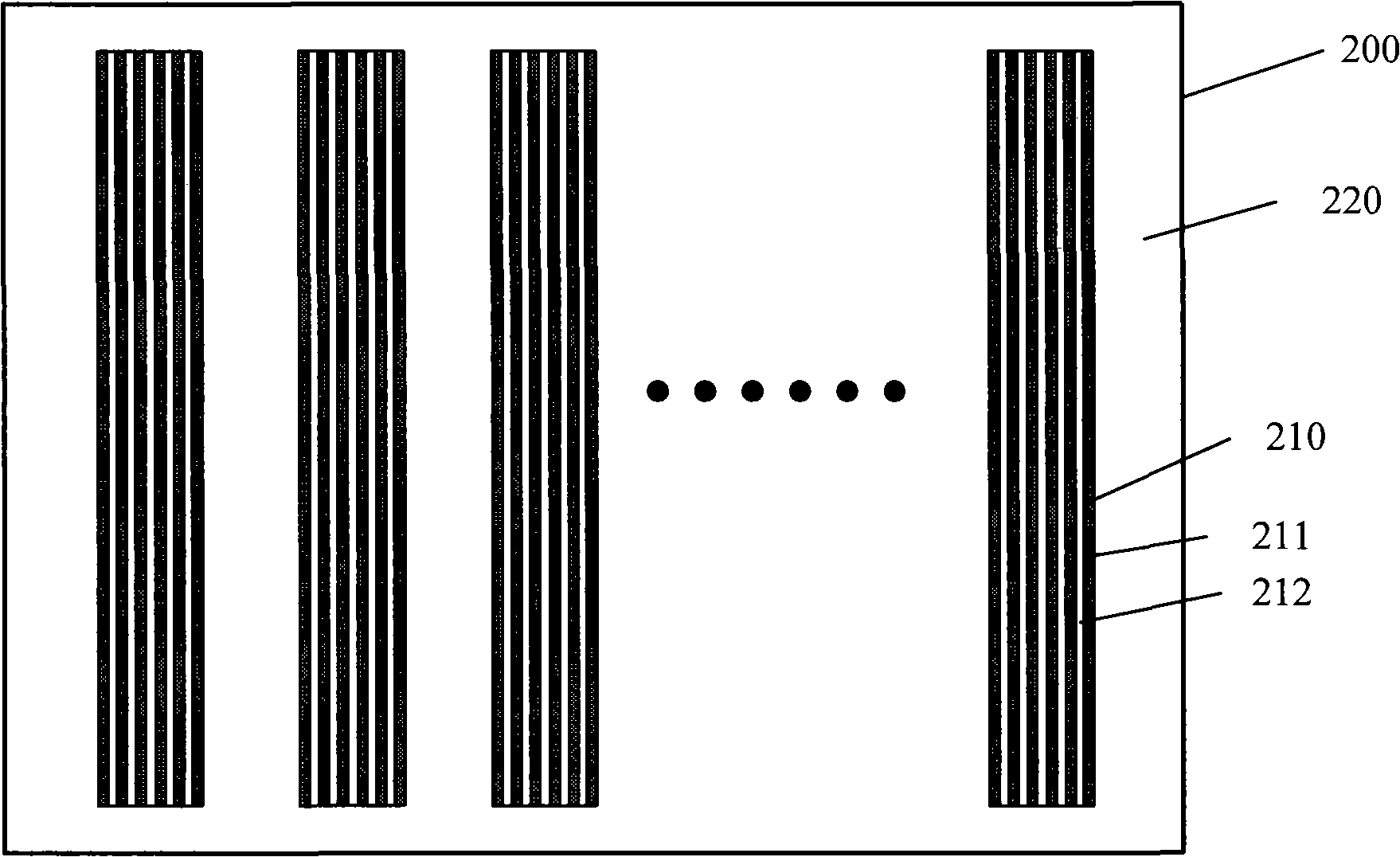

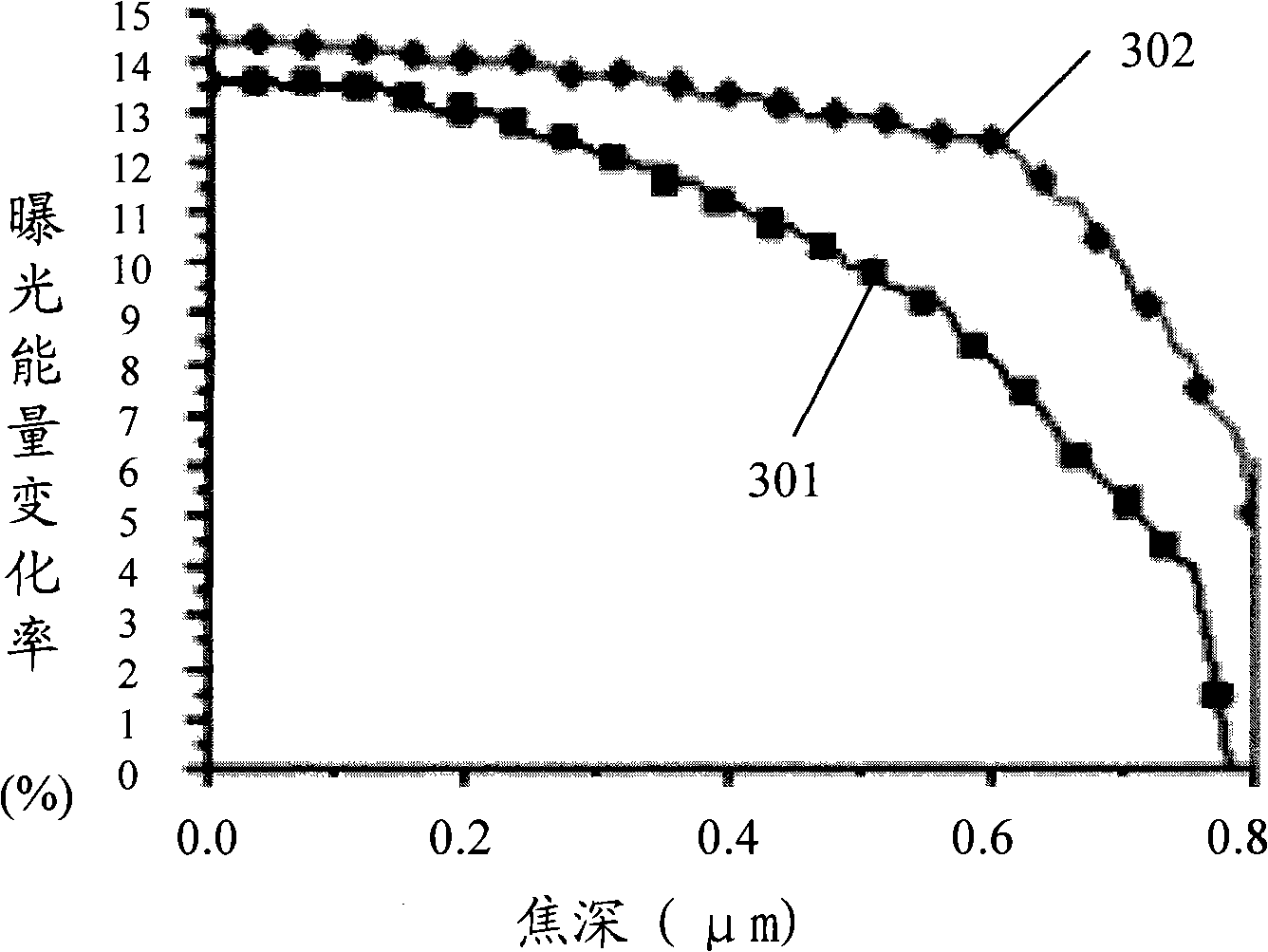

Mask plate and forming method of the mask plate

InactiveCN101359167AHigh-resolutionImprove the problem of small process windowOriginals for photomechanical treatmentGraphicsPhase shifted

The invention discloses a masking board which comprises a light transmission substrate; the light transmission substrate is provided with at least a graphics area which can shade the exposure light; wherein, a notch of a phase shift grating is arranged on the light transmission substrate in at least a graphics area; and the notch is provided with light transmittance to the exposure light. The invention also discloses a corresponding forming method of the masking board. The application of the masking board can improve the resolution, focal depth and graphics contrast in the lithography process, and increase the process window.

Owner:SEMICON MFG INT (SHANGHAI) CORP

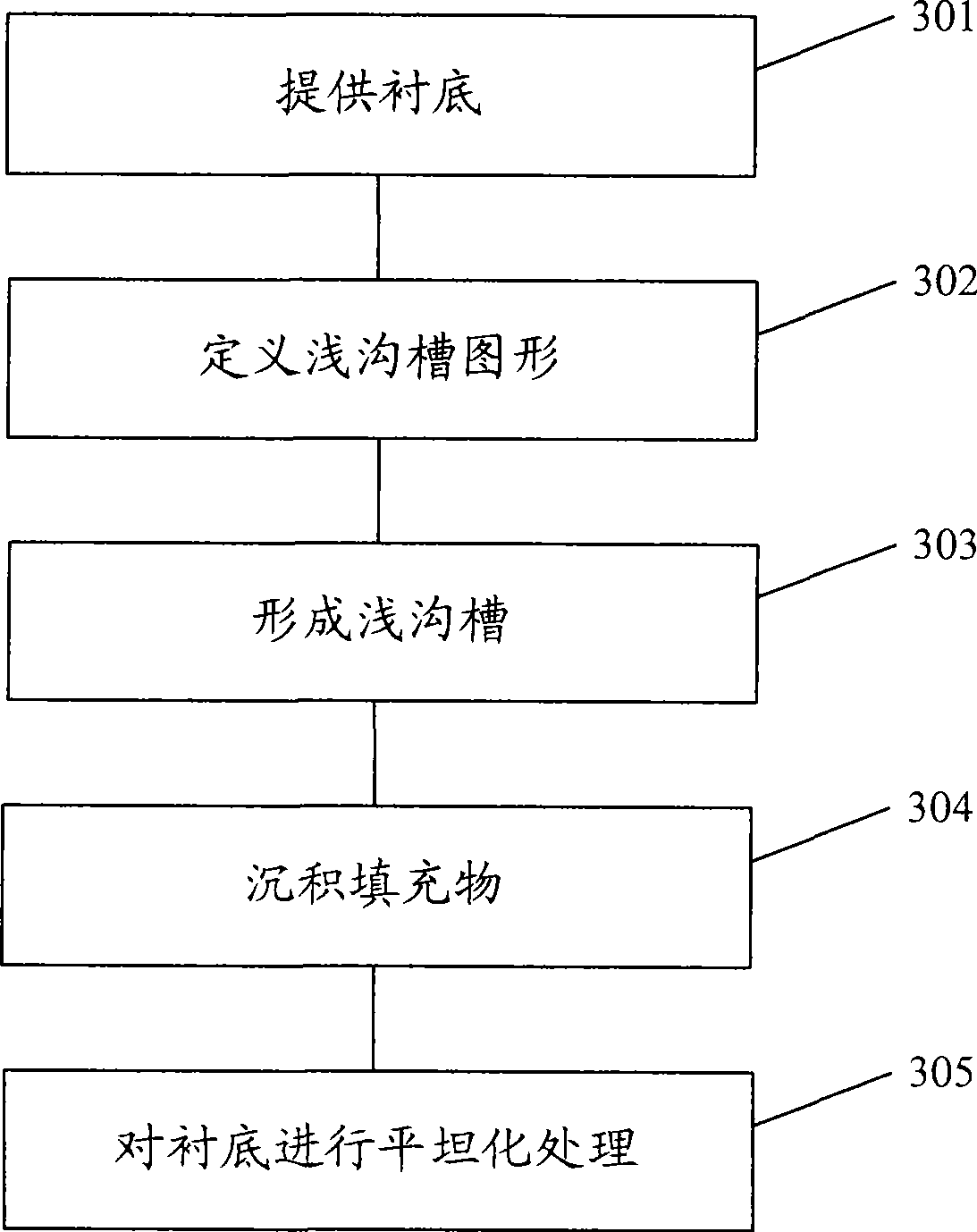

Shallow groove isolation construction, forming method and grinding method

InactiveCN101459114AGuaranteed smoothWon't dentSolid-state devicesSemiconductor/solid-state device manufacturingFilling materialsEngineering

The invention discloses a forming method of a shallow trench isolation structure, which comprises steps of providing a substrate with a shaped stop layer, defining a shallow trench pattern on the substrate, forming a shallow trench in the substrate with the shaped stop layer, depositing filling materials in the shallow trench and on the stop layer, flattening the substrate after the filling materials are deposited, wherein dishing of the filling materials in the shallow trench can be prevented by controlling the attitude difference between the filling materials in the shallow trench and the stop layer in the flattening process. The invention further provides a relative shallow trench isolation structure and a polishing method thereof. After utilizing the polishing method, the shallow trench isolation structure and the forming method thereof, flattening of the filling materials in the shallow trench can be maintained, and forming quality of the shallow trench isolation structure is increased.

Owner:SEMICON MFG INT (SHANGHAI) CORP

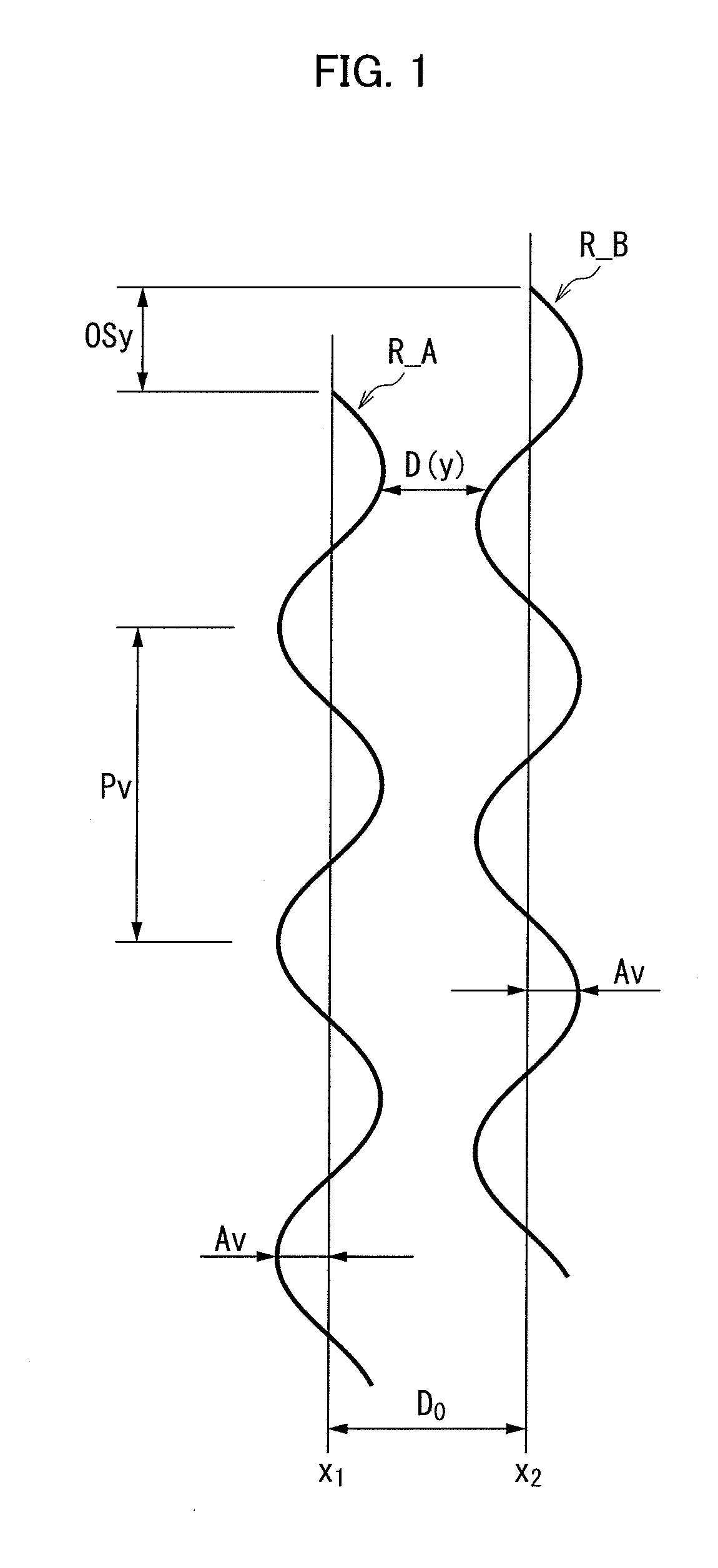

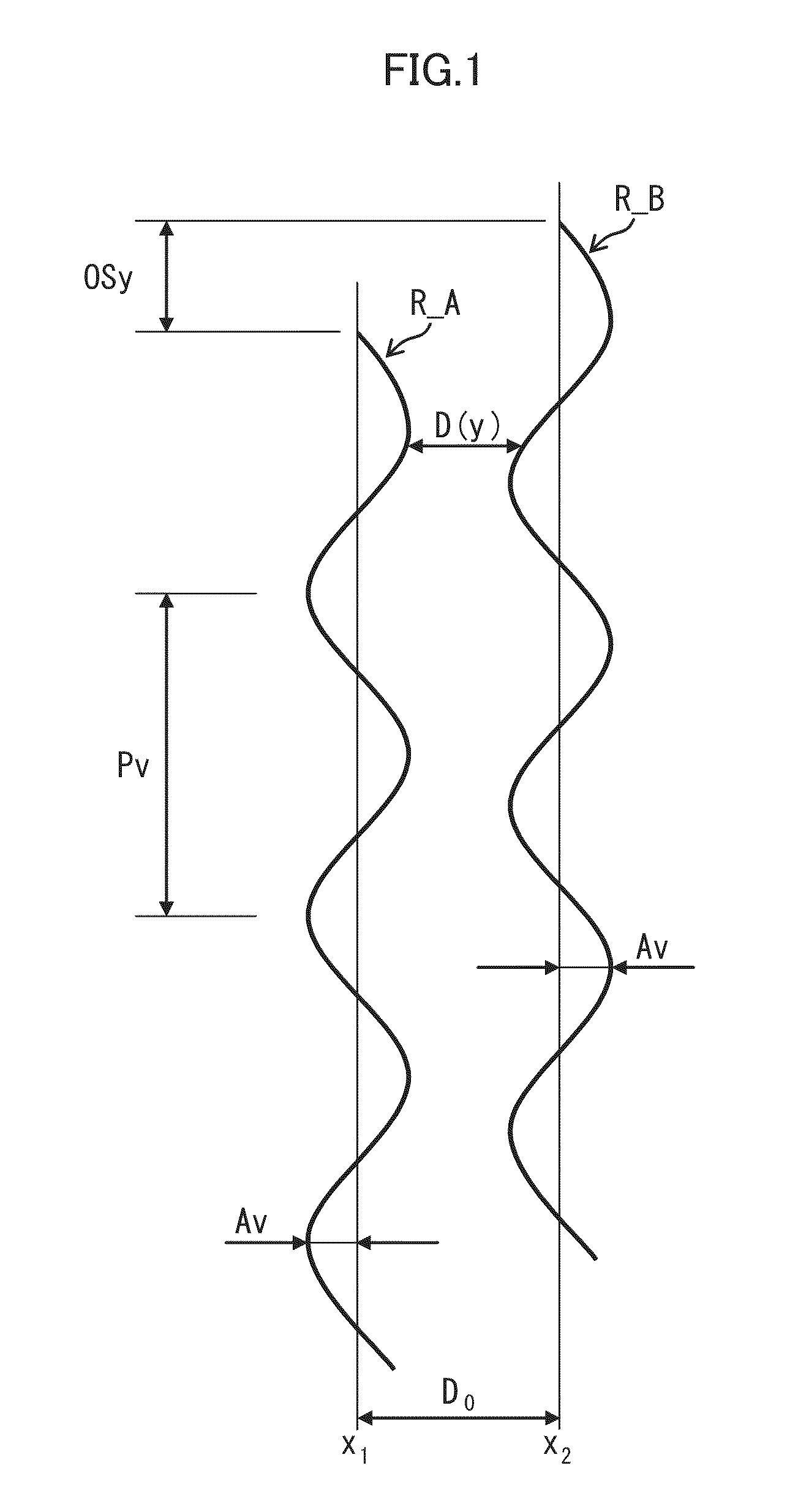

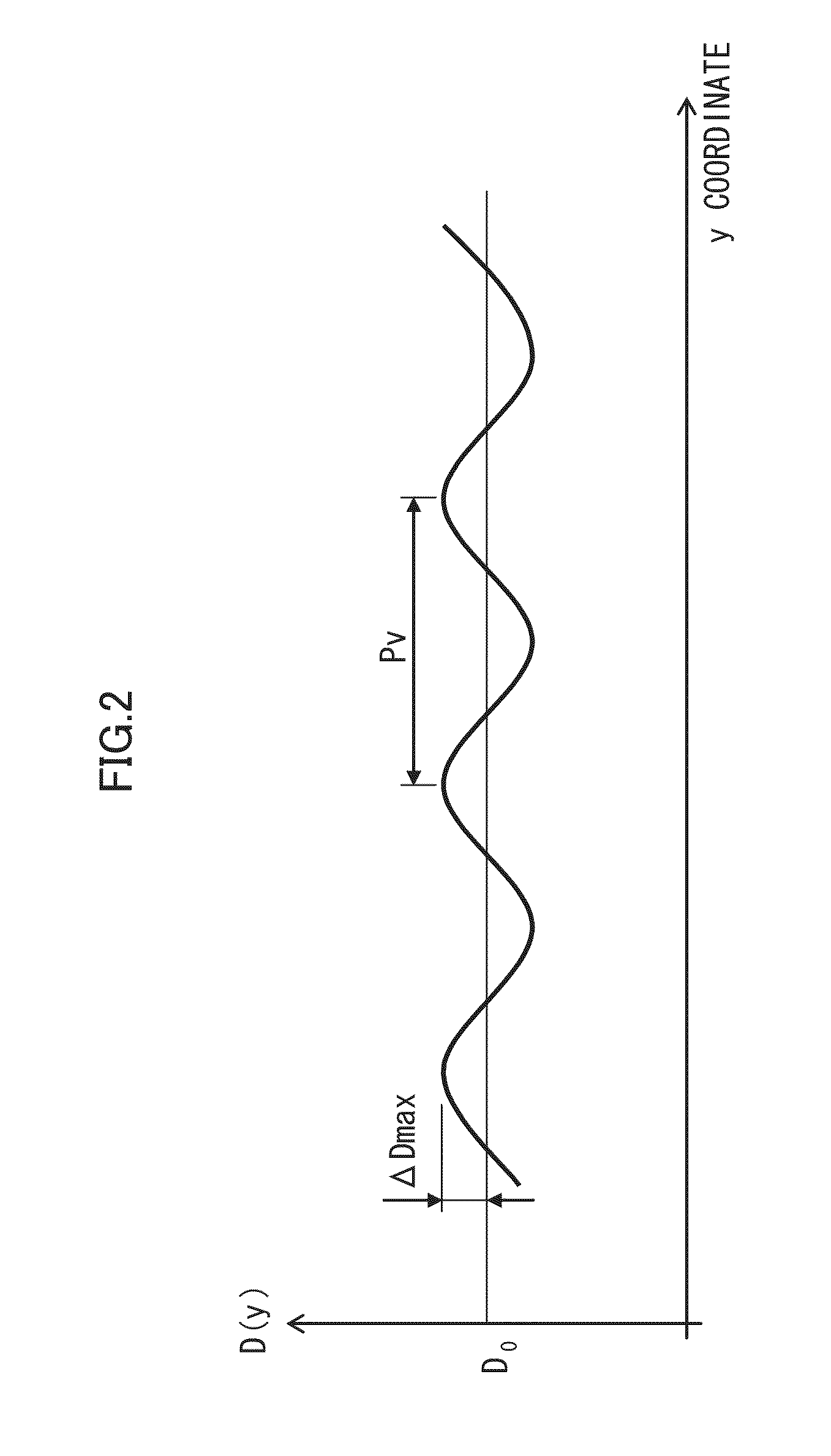

Inkjet image forming apparatus, method of designing same and method of improving image formation quality

ActiveUS20110234665A1Improve formation qualityEasy to changeOther printing apparatusImaging qualityImage formation

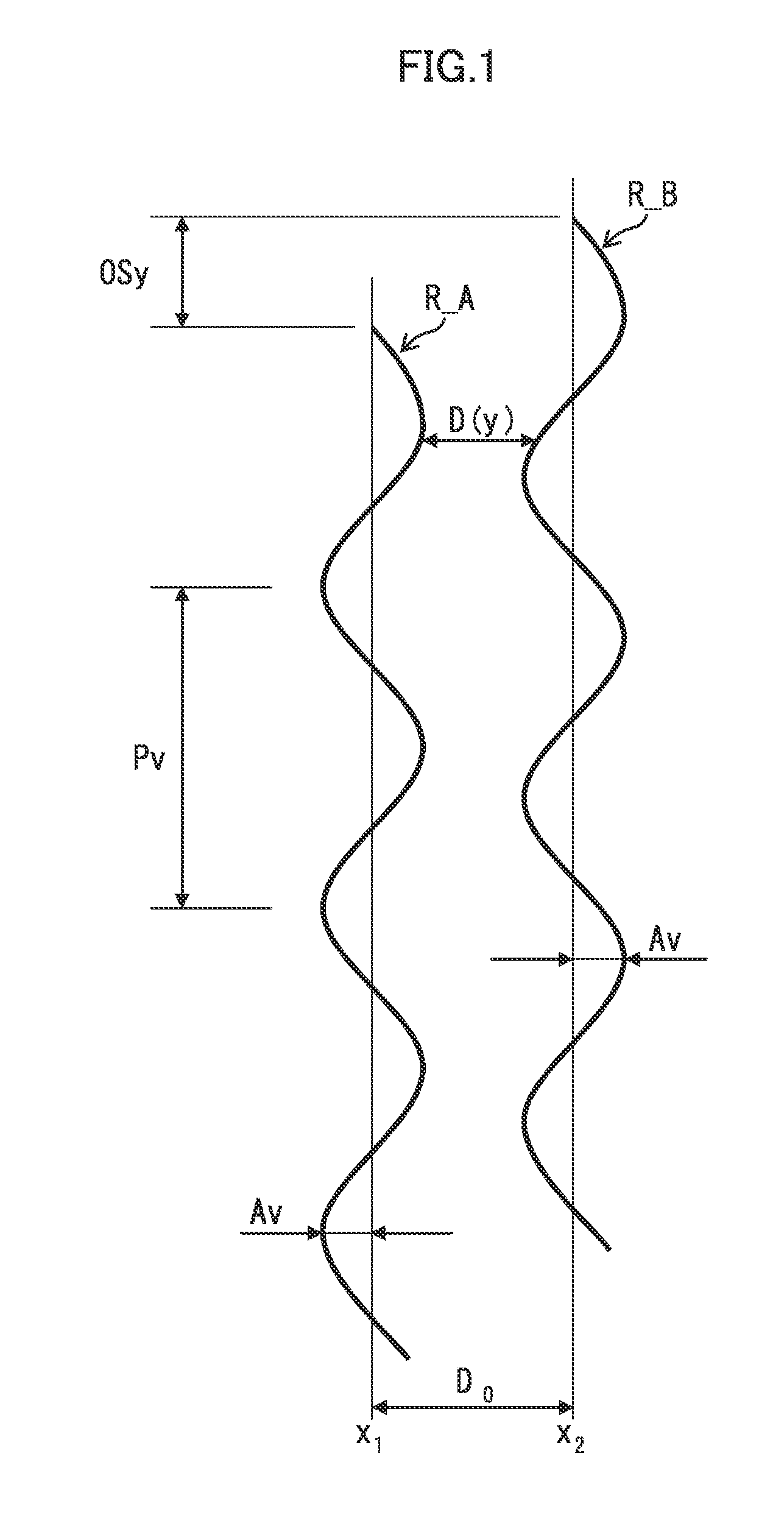

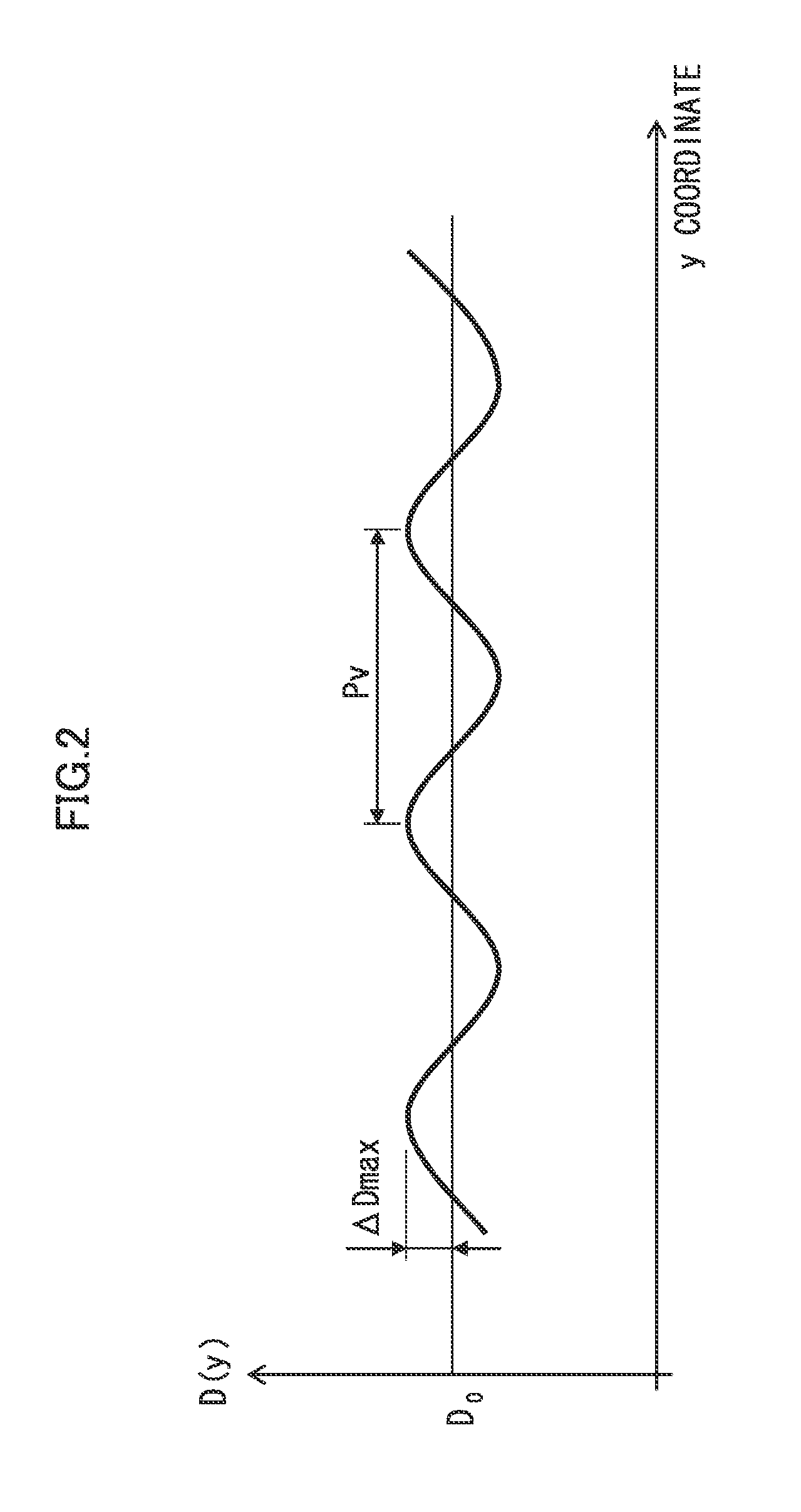

An inkjet image forming apparatus includes: a liquid ejection head having an ejection surface in which a plurality of nozzles are arranged two-dimensionally; a scanning device which conveys at least one of the liquid ejection head and an image formation receiving medium on which liquid ejected from the plurality of nozzles is deposited, to cause relative movement between the image formation receiving medium and the liquid ejection head in a first direction; and a member which vibrates at a fixed frequency that is independent of a speed of the relative movement caused by the scanning device in such a manner that relative vibration is caused between the image formation receiving medium and the plurality of nozzles, wherein when vp represents a relative scanning speed produced by the scanning device in forming an image on the image formation receiving medium by the relative movement and droplet ejection from the liquid ejection head, fv represents the fixed frequency, and OSy represents an offset distance in the first direction of a pair of nozzles which form dots that are mutually adjacent in a second direction perpendicular to the first direction on the image formation receiving medium, of the plurality of nozzles arranged two-dimensionally, then relationship of OSy≈k×vp / fv (where k is a natural number) is satisfied.

Owner:FUJIFILM CORP

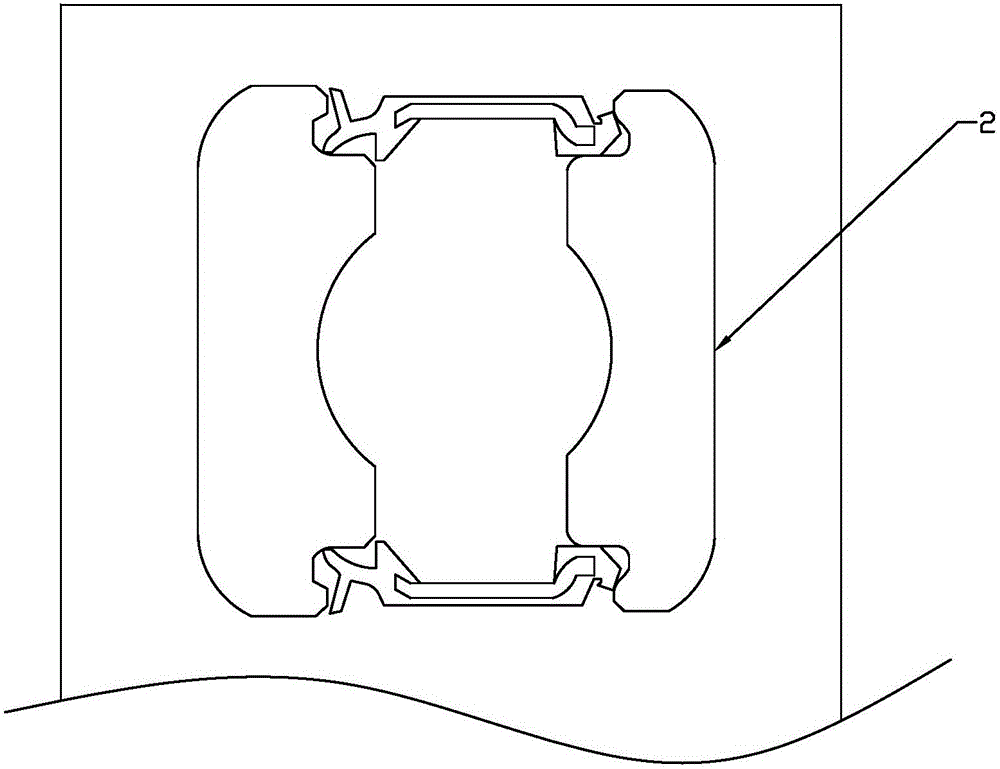

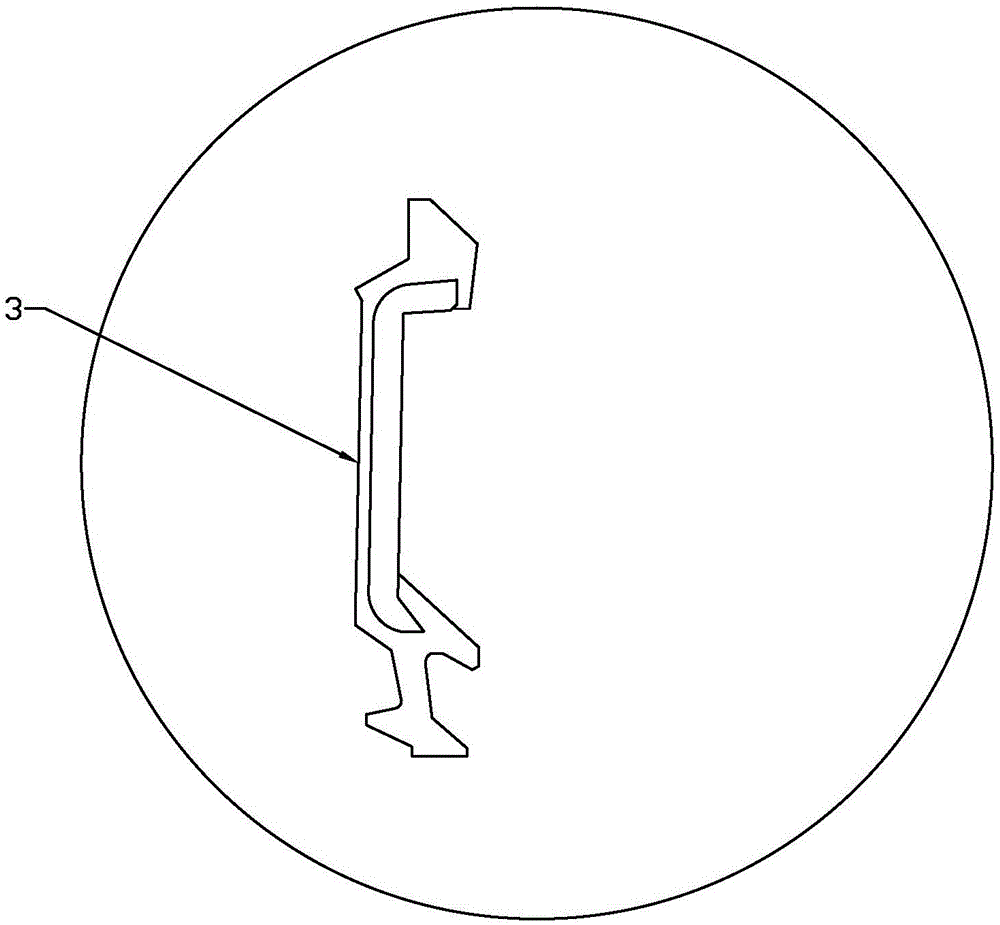

Sealed bearing sealing structure and sealing ring shape detection method thereof

The invention relates to a sealed bearing sealing structure shape detection method. An inlaid material is inlaid and solidified. The cross section is exposed through axial half-cutting. The mosaic material is polished and placed on a projection device for projection to acquire a CAD image. The invention further provides a sealing ring shape detection method. Axial half-cutting is carried out to form the cross section. The cross section is controlled to be fixed in an inlay mold. The inlay material is poured, inlaid, solidified and polished to acquire a sample. The sample is placed on the projection device. The cross section is projected to acquire the CAD image. According to the invention, a bearing sealing structure and a sealing ring structure can be directly recorded and observed, and the methods have the advantages of simple operation and convenient size and wear detection.

Owner:C&U CO LTD

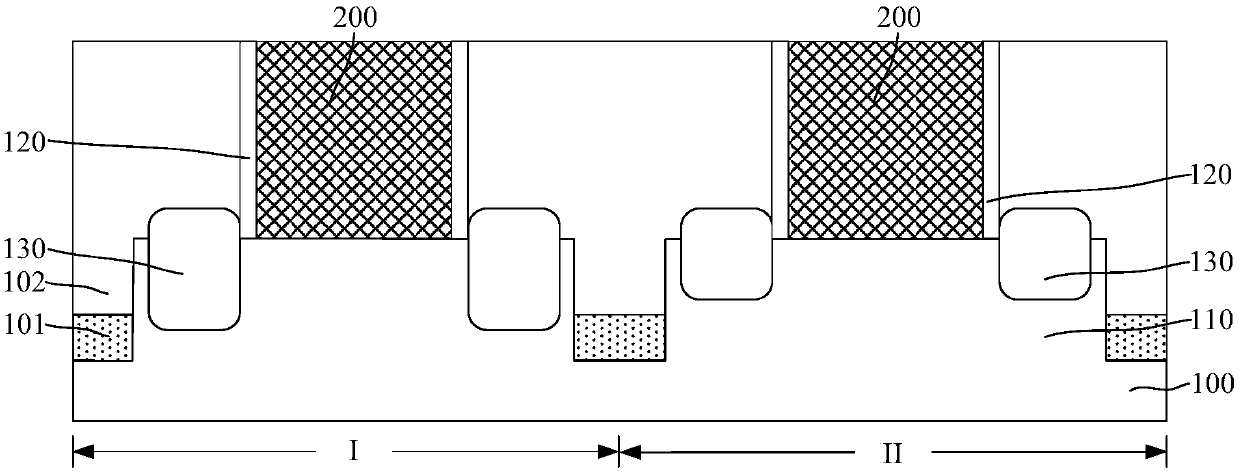

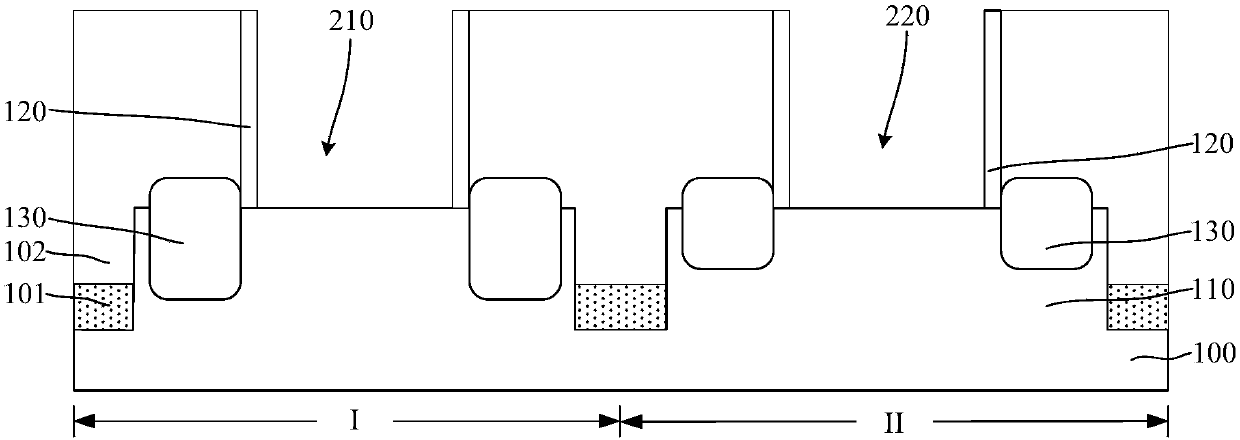

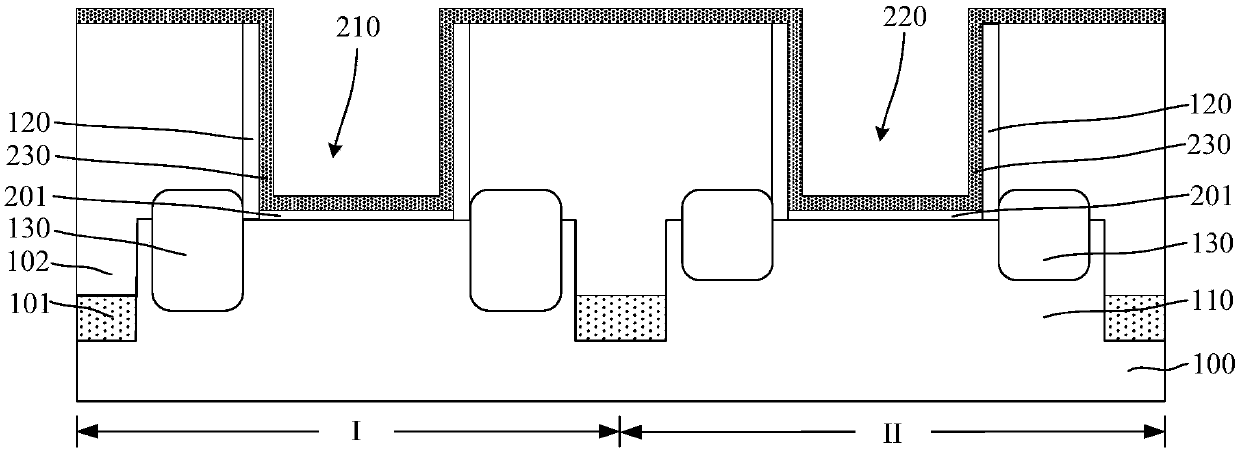

Semiconductor structure and formation method thereof

ActiveCN109860291AImprove formation qualityPrevent oxidationSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureIsolation layer

The present invention provides a semiconductor structure and a formation method thereof. The method comprises the steps of: providing a substrate and fins protruding from the substrate, wherein each fin comprises a fin first portion located at the surface of the substrate and a fin second portion located at the top portion of the fin first portion; forming first laying layers at the side walls ofthe fin first portions; forming second laying layers at the surfaces of the first laying layers and the top portions and the side walls of the fin second portions; forming isolation films covering thesecond laying layer on the substrate, wherein the top portions of the isolation films are higher than the top portions of the fins and are levelled with the top portions of the fins; removing the second laying layers and the isolation films higher than the top portions of the fin first portions, wherein the remaining isolation films form isolation layers; and forming gate oxide layers at the surfaces of the top portions and the side walls of the fins exposed on the isolation layers. In the invention, the first laying layers and the second laying layers can effectively weaken the stress applied to the side walls of the fins so as to avoid bending of the fins, and the formed process window of the isolation layers is large which facilitates improvement of the formation quality of the isolation layers.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

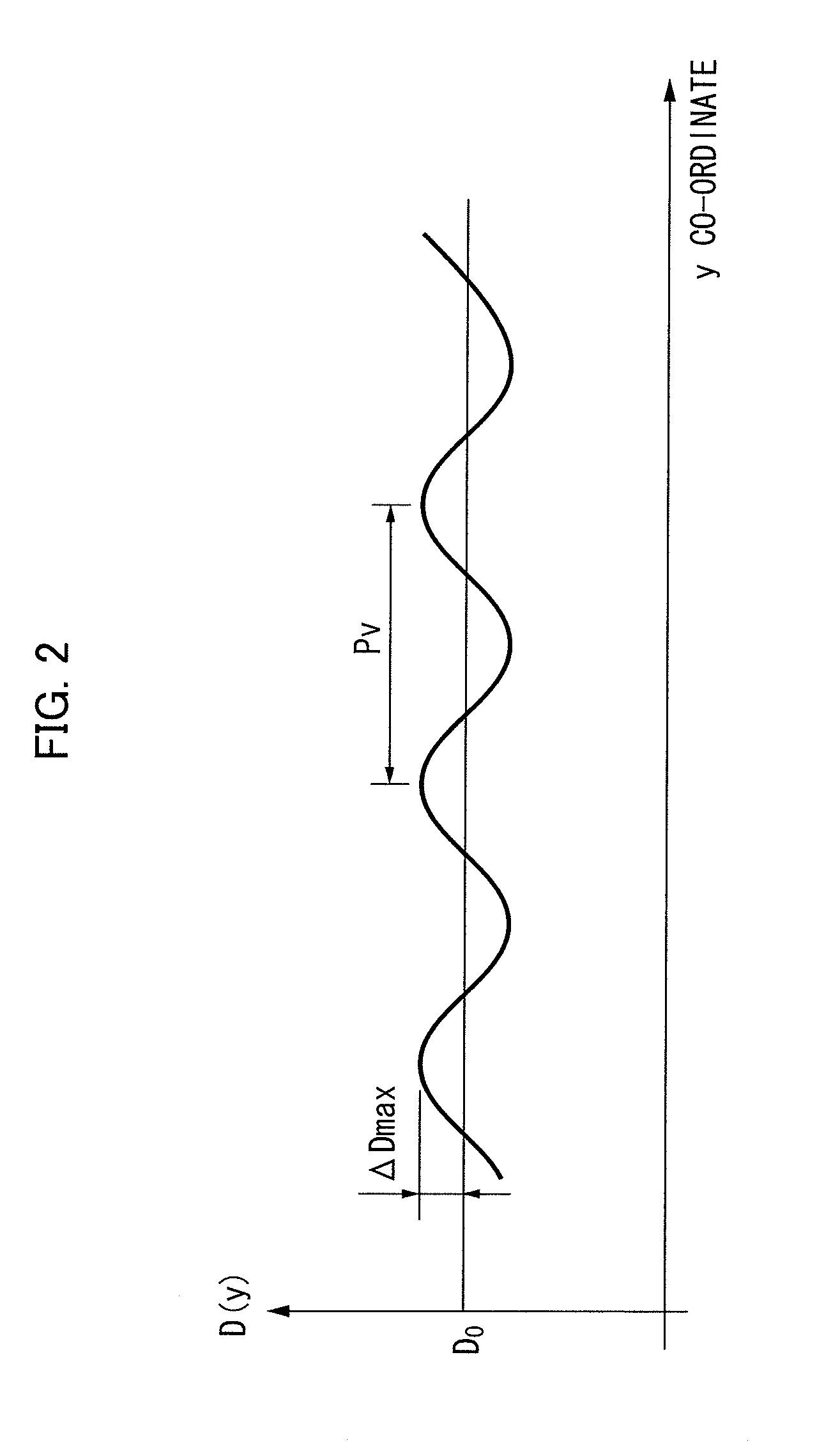

Inkjet image forming apparatus, method of designing same and method of improving image formation quality

ActiveUS20110234664A1Improve formation qualityEasy to changeOther printing apparatusOffset distanceImage formation

An inkjet image forming apparatus includes: a liquid ejection head having an ejection surface in which a plurality of nozzles are arranged two-dimensionally; a scanning device which conveys at least one of the liquid ejection head and an image formation receiving medium on which liquid ejected from the plurality of nozzles is deposited, to cause relative movement between the image formation receiving medium and the liquid ejection head in a first direction; a drive force generating device which generates drive force for driving the scanning device; and a meshing transmission mechanism which transmits the drive force generated by the drive force generating device to the scanning device by a meshing mechanism, wherein: when Pv represents a spatial period obtained by converting a pitch of meshing teeth of the meshing transmission mechanism to an amount of the relative movement in the first direction on the image formation receiving medium, and when OSy represents an offset distance in the first direction of a pair of nozzles which form dots that are mutually adjacent in a second direction perpendicular to the first direction on the image formation receiving medium, of the plurality of nozzles arranged two-dimensionally, then relationship of OSy≈k×Pv (where k is a natural number) is satisfied.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com