Formation method and lithium-ion secondary battery

A lithium ion battery and a technology for a formation method, which are applied in the fields of formation methods and lithium ion secondary batteries, can solve the problems of low capacity of lithium ion batteries, poor appearance of lithium ion batteries, bulging of lithium ion batteries, etc., so as to improve the formation quality and reduce the Production cost, effect of improving overall electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

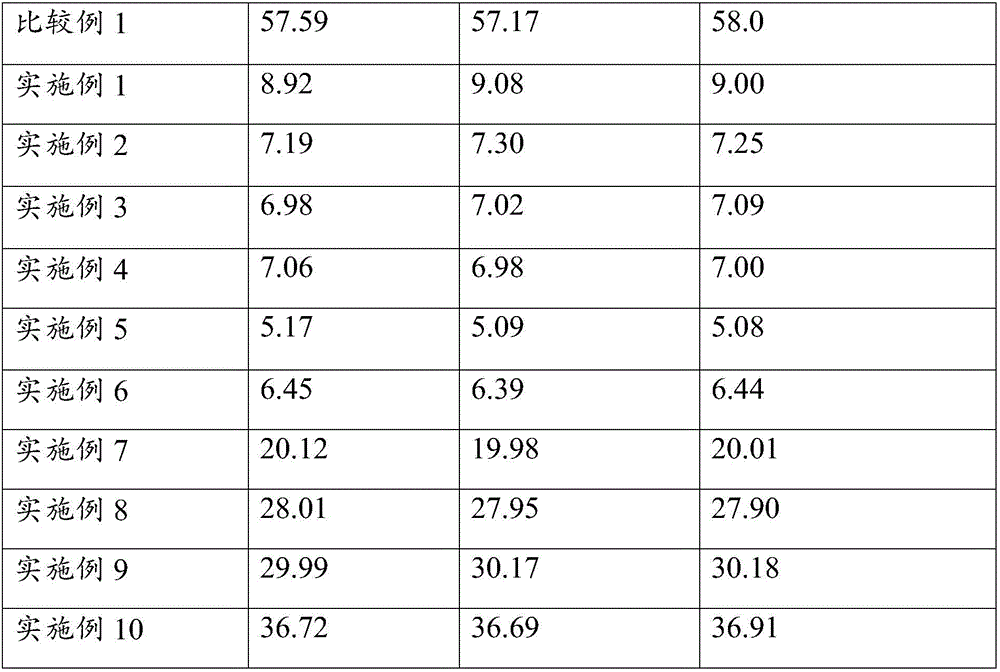

Embodiment 1

[0025] This embodiment provides a chemical formation method, including a first chemical formation stage, a second chemical formation stage, a third chemical formation stage, and a fourth chemical formation stage, which are performed sequentially.

[0026] The first formation stage is to charge the lithium-ion battery to a 2% state of charge at a constant current of 0.01C at a temperature of 15°C, and perform the first charge under the conditions of a 2% state of charge and a vacuum of -0.005MPa. Pumping for 0.5h.

[0027] The second formation stage is to charge the lithium-ion battery to a 30% state of charge at a constant current of 0.03C at a temperature of 30°C, and conduct the second charge at a state of charge of 30% and a vacuum of -0.01MPa. Pumping for 1h.

[0028] The third formation stage is to charge the lithium-ion battery to a 75% state of charge at a constant current of 0.06C at a temperature of 60°C, and perform the third charge under the conditions of a state o...

Embodiment 2

[0032] The difference between a kind of formation method provided in this embodiment and the formation method provided in Example 1 is:

[0033] In the fourth formation stage, after the lithium-ion battery is charged to full charge with a constant current, the lithium-ion battery is also stored at the temperature of the fourth formation stage for 24 hours before the fourth pumping.

[0034] For simplicity, please refer to the corresponding content in Embodiment 2 for the parts not mentioned in this embodiment.

Embodiment 3

[0036] The difference between a kind of formation method provided in this embodiment and the formation method provided in Example 2 is:

[0037] In the fourth formation stage, after the lithium-ion battery is charged to full charge with a constant current, the lithium-ion battery is also stored at the temperature of the fourth formation stage for 48 hours before the fourth pumping.

[0038] For simplicity, please refer to the corresponding content in Embodiment 2 for the parts not mentioned in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com