LiMn2O4/Al<3+> doped Li7La3Zr2O12/Li4TiO5O12 all-solid-state thin film battery and preparation method

A thin-film battery, all-solid-state technology, applied in the manufacture of electrolyte batteries, secondary batteries, non-aqueous electrolyte batteries, etc., can solve the problems of poor particle matching, under-burning, and high interface grain boundary resistance, and improve the comprehensive electrochemical performance. performance, the effect of avoiding under-burning or over-burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

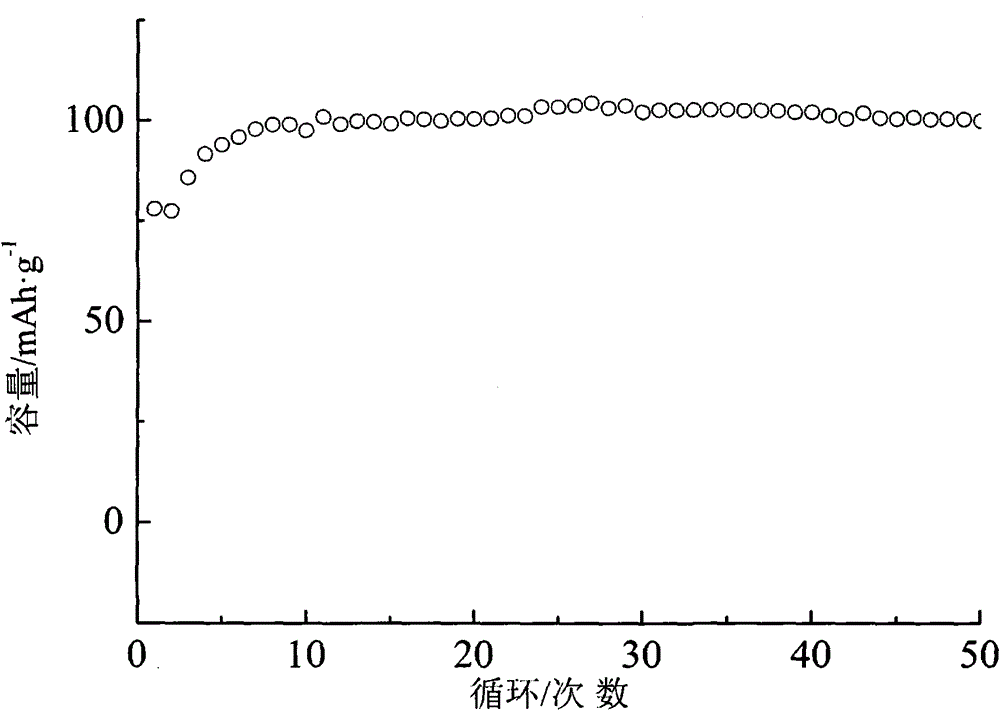

Image

Examples

Embodiment 1

[0026] Embodiment 1: 3.55molLi 2 CO 3 , 1.5molLa 2 o 3 , 0.05molAl 2 o 3 , 1.9molZrO 2 Mix evenly, add 2% 95% 7-alcohol, ball mill with 250 revolutions per minute in a ball mill for 10 hours, dry in a 60°C vacuum oven (vacuum degree 20Pa) for 10 hours after ball milling, take it out and put it in an agate mortar Regrind for 30 minutes in the medium, and the ground powder is heated at a rate of 5°C / min to 700°C for 6 hours, and then heated at a rate of 8°C / min to 1120°C for 10 hours to make a solid electrolyte powder; The chip is placed on the surface of the working plate heated at a constant temperature of 250°C, the substrate surface is grounded, and the liquid spray gun A is connected to the precursor solution I. The solution composition is: manganese oxalate with a concentration of 0.2mol / L, lithium acetate Li with a concentration of 0.1mol / L ( CH 3 COO) and the mass percentage concentration are the aqueous solution of ethylene glycol methyl ether of 0.2wt%, spray gu...

Embodiment 2

[0027] Embodiment 2: 3.55molLi 2 CO 3 , 1.5molLa 2 o 3 , 0.05molAl 2 o 3 , 1.9molZrO 2 Mix evenly, add 6% of 95% ethanol, ball mill for 10 hours at a speed of 200 rpm in a ball mill, dry in a 70°C vacuum oven (vacuum degree 50Pa) for 15 hours after ball milling, take it out and put it in an agate mortar Re-grind for 10 minutes, heat the ground powder at a rate of 7°C / min to 700°C for 10 hours, then heat at a rate of 2°C / min to 1180°C for 30 hours to make a solid electrolyte powder; Place it on a constant temperature of 500°C to heat the surface of the working plate, ground the substrate surface, connect the liquid spray gun A to the precursor solution I, and the solution composition is: manganese oxalate with a concentration of 2mol / L, lithium acetate Li(CH 3 COO) and mass percentage concentration are the aqueous solution of polyvinyl alcohol PVA of the average molecular weight of 2wt%3 COO), n-butyl titanate Ti(OC with a concentration of 2.0mol / L 4 h 9 ) 4 , concentr...

Embodiment 3

[0028] Embodiment 3: 3.575molLi 2 CO 3 , 1.5molLa 2 o 3 , 0.075molAl 2 o 3 , 1.85molZrO 2 Mix evenly, add 4% of 95% ethanol, ball mill for 20 hours at a speed of 400 rpm in a ball mill, dry in a vacuum oven at 80°C (vacuum degree 100Pa) for 20 hours after ball milling, take it out and put it in an agate mortar Re-grind for 20 minutes, heat up the ground powder at a rate of 8°C / min to 800°C for 8 hours, then heat at a rate of 10°C / min to 1200°C for 10 hours to make a solid electrolyte powder; Place it on a constant temperature of 400°C to heat the surface of the working plate, ground the substrate surface, connect the liquid spray gun A to the precursor solution I, and the solution composition is: manganese oxalate with a concentration of 1mol / L, lithium acetate Li(CH 3 COO) and mass percentage concentration are the aqueous solution of the n-amyl alcohol of 1wt%, and spray gun A distances 10cm from the vertical distance of heating work plate surface, and forms 65 ° inters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com