Sealed bearing sealing structure and sealing ring shape detection method thereof

A technology for shape detection and sealing of bearings, used in measuring devices, instruments, optical devices, etc., can solve the problem of bearing sealing ring rubber lip wear without accurate detection and analysis, the size of the bearing sealing ring cannot be well detected, and the detection method cannot be achieved. requirements and other issues, to achieve the effect of convenient detection and analysis, ease of structural integrity, and improvement of the quality of cross-section formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

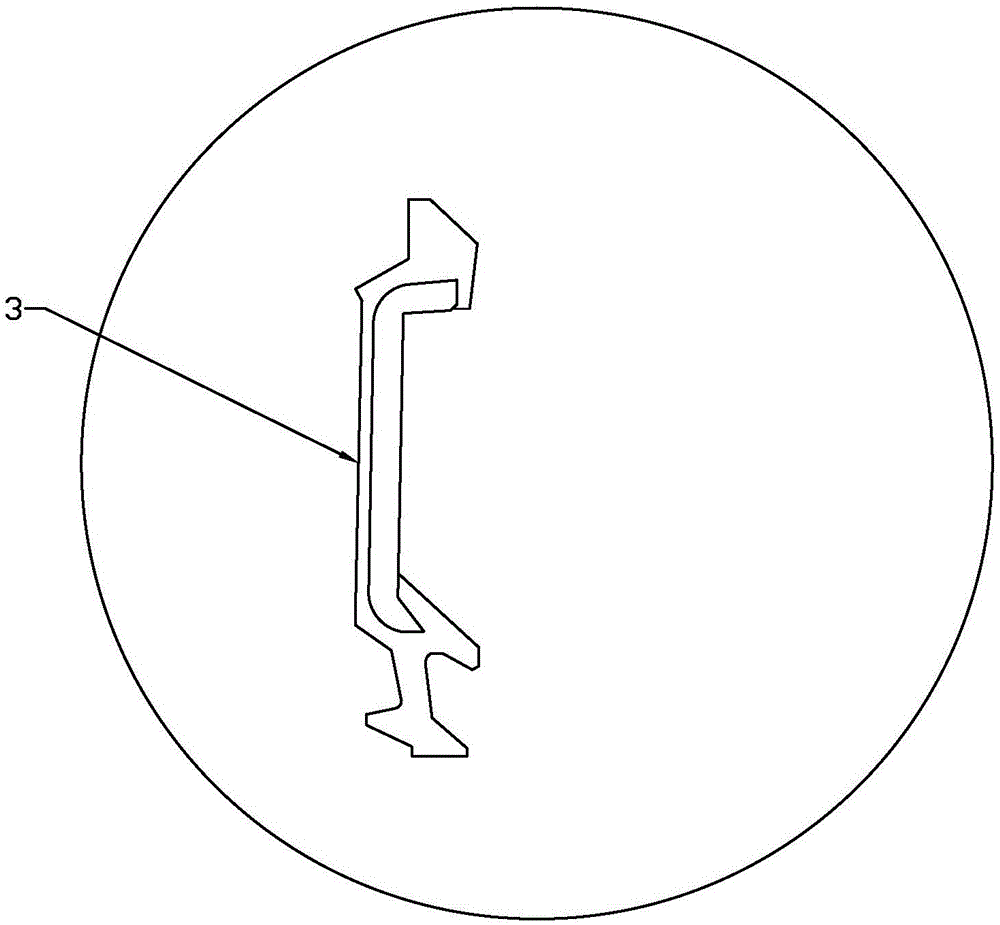

[0024] like figure 1 and image 3 , a method for detecting the shape of a sealed bearing sealing structure disclosed in the present invention is carried out according to the following steps:

[0025] (1) Sample preparation, a. Mix and stir the liquid resin and its curing agent evenly to form a flowable paste mosaic; the mosaic can choose "Crystal King" CM2, which can be purchased directly in the market, such as Naibo Other similar mosaic materials, such as "Crystal King" CM1, "Quick Epoxy King" CM3, etc., can also be used for those produced by Detection Technology (Shanghai) Co., Ltd.

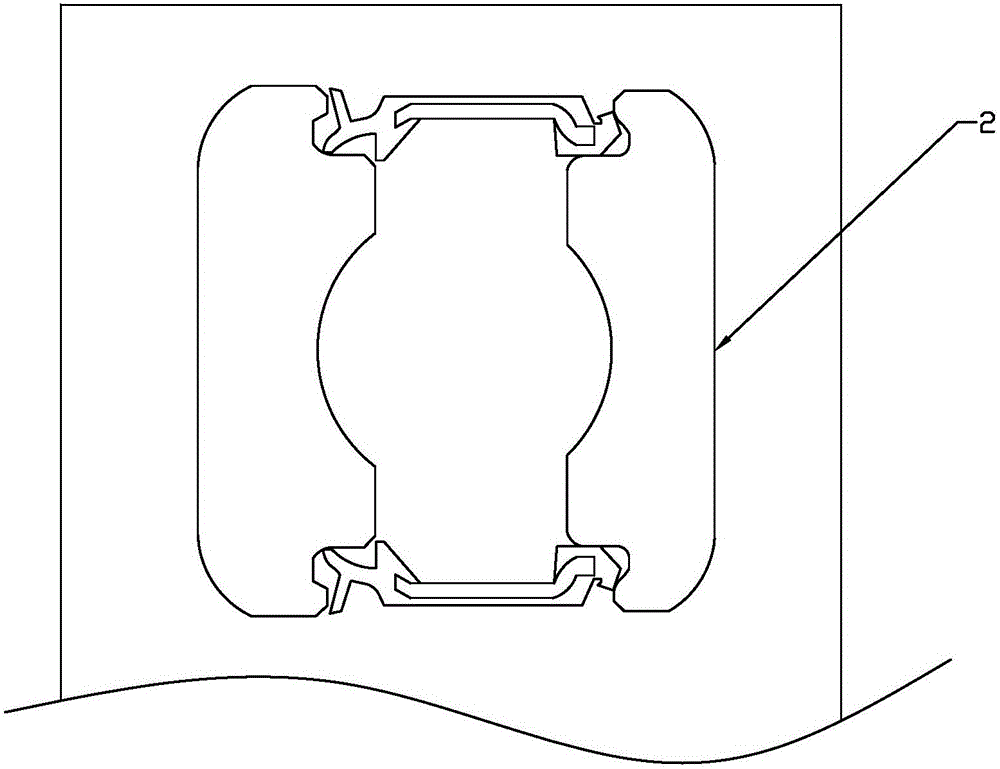

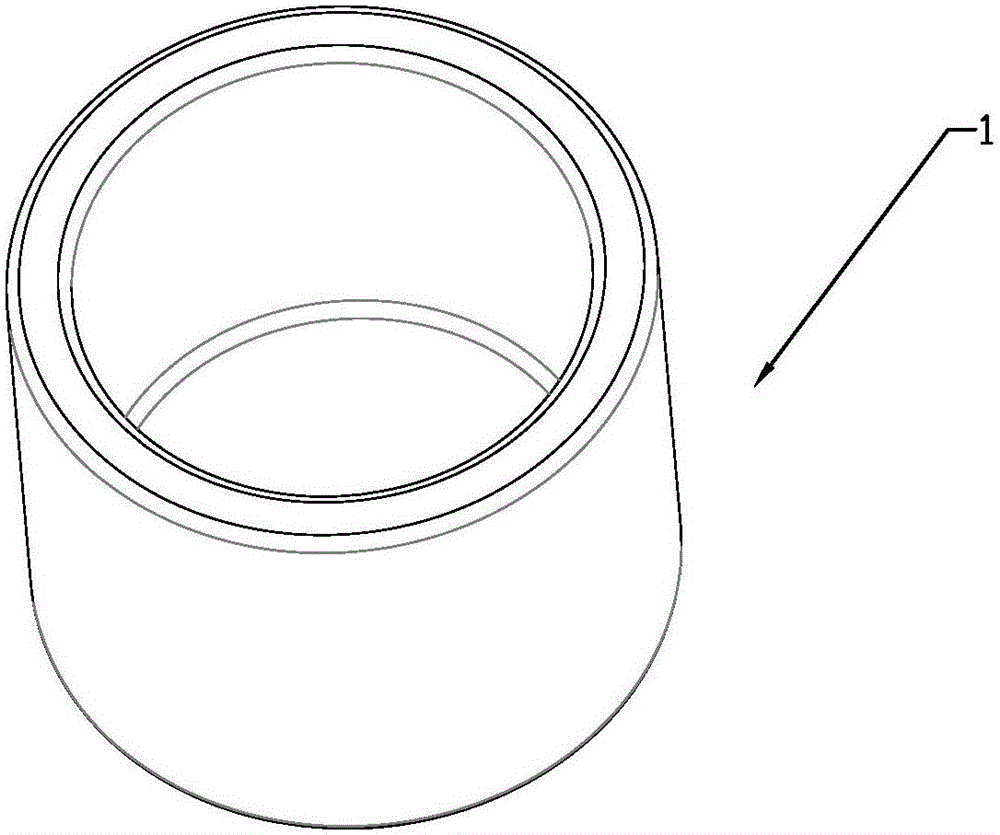

[0026] b. Put the sealed bearing 2 in the mold cavity of the mosaic mold 1, pour the mosaic material into the mold cavity of the mosaic mold 1, and the mosaic material wraps the bearing evenly by its own fluidity until it completely covers the bearing; and solidifies ; In order to facilitate demoulding after curing, the mosaic mold 1 is a barrel-shaped structure made of soft rubber (such as s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com