Patents

Literature

30results about How to "Reduce or avoid deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

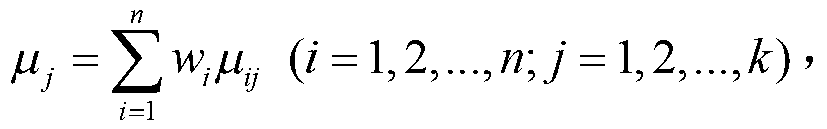

Method for evaluating risks of high rock slope

InactiveCN103268420AImprove digging effectEliminate one-sidednessSpecial data processing applicationsIndex systemSafety coefficient

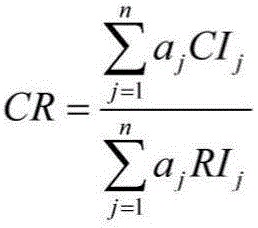

The invention discloses a method for evaluating risks of a high rock slope. The method for evaluating the risks of the high rock slope comprises the following steps: (1) constructing a risk evaluation index system, (2) defining classification levels, (3) carrying out dimensionless processing on indexes, (4) determining comprehensive weight of evaluation indexes, and (5) evaluating risk states of the slope. By means of the method for evaluating the risks of the high rock slope, factors which influence stability of the slope are comprehensively analyzed and identified, a subjective weighting method and an objective weighting method are combined, and the attribute recognition theory and the maximum attribute measure principle are adopted to indentify the risk states of the slope. Compared with other methods in the prior art, the method for evaluating the risks of the high rock slope overcomes the defects that a safety factor method can not express the change degree of the risks of the slope and reflect uncertainty and randomness of the risks of the slope, subjective preference and objective laws are comprehensively measured, evaluation and judgment are more reasonable, and high engineering significance and practical values are possessed.

Owner:HOHAI UNIV

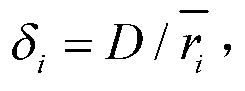

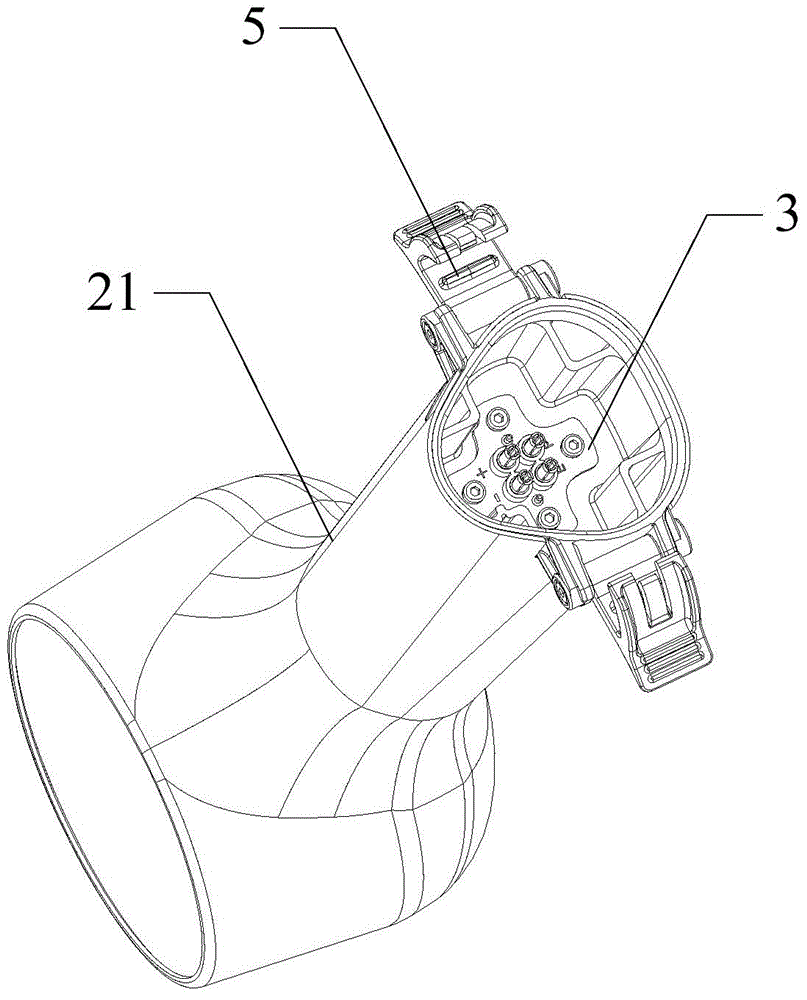

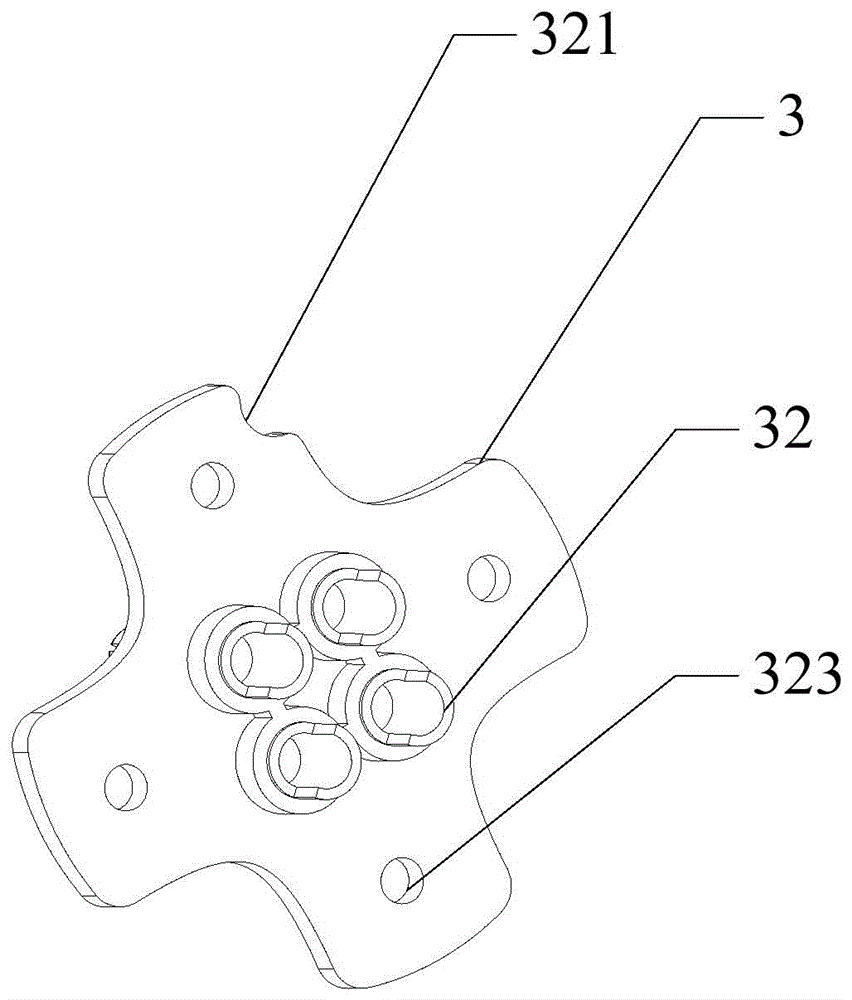

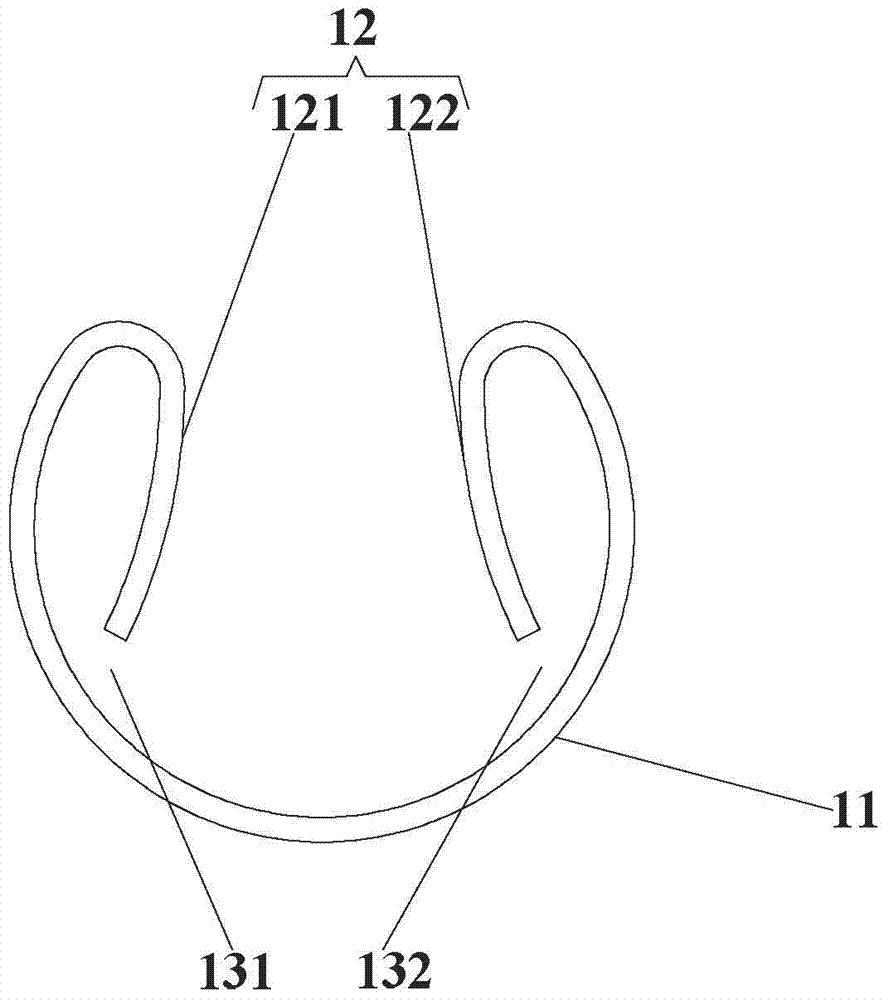

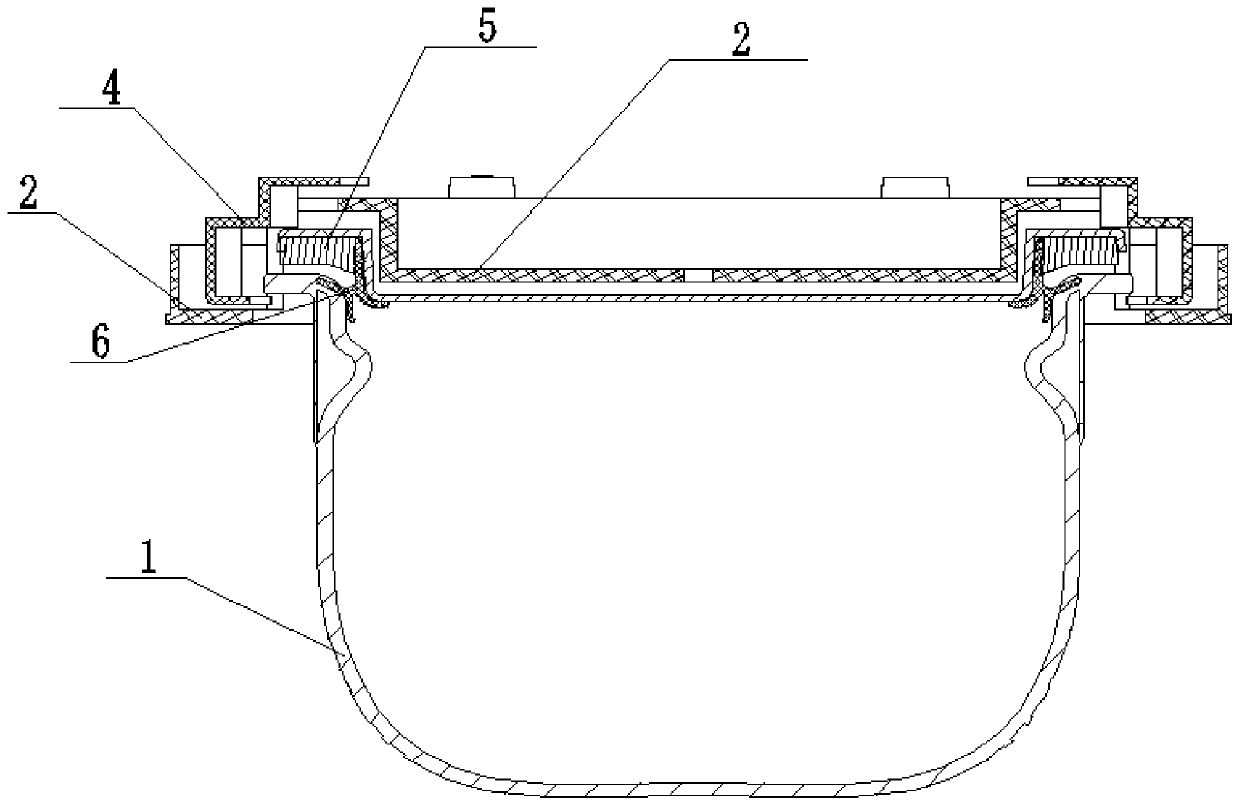

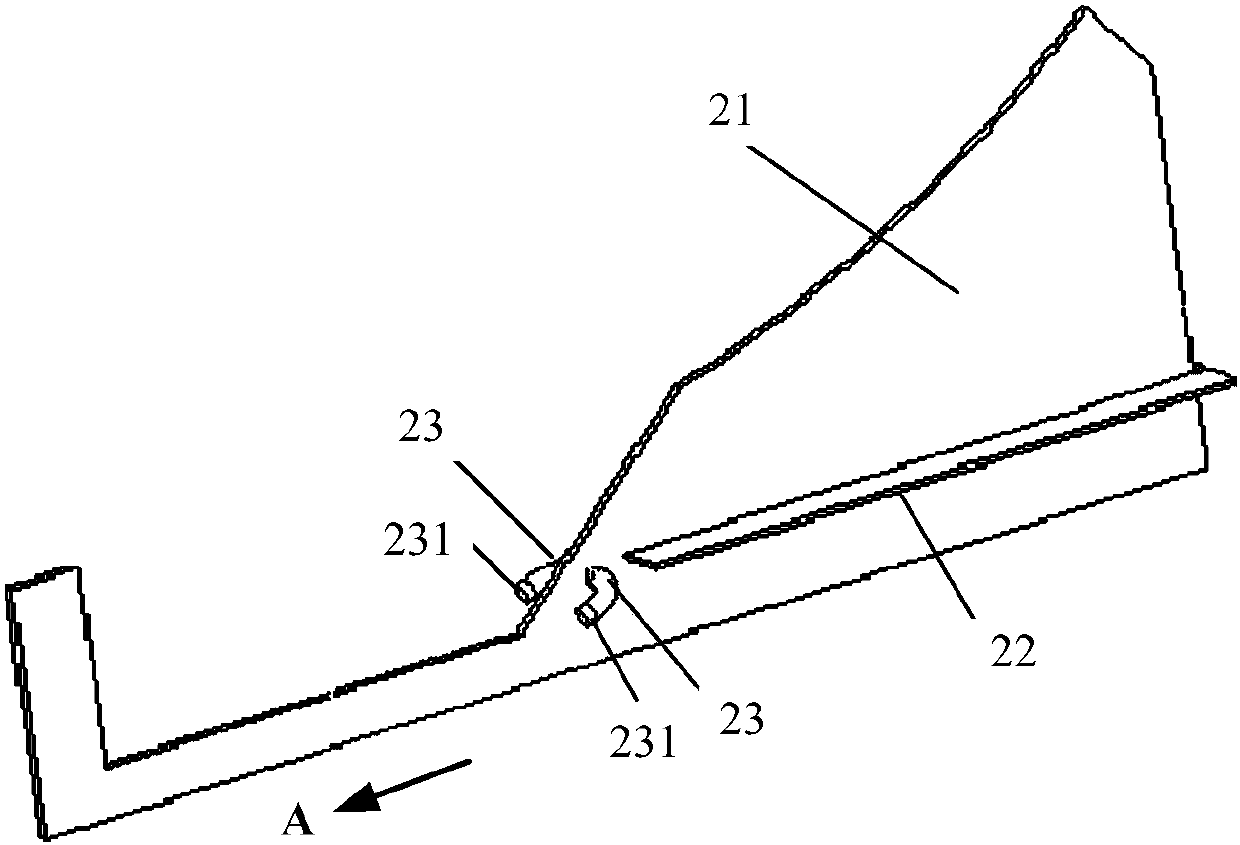

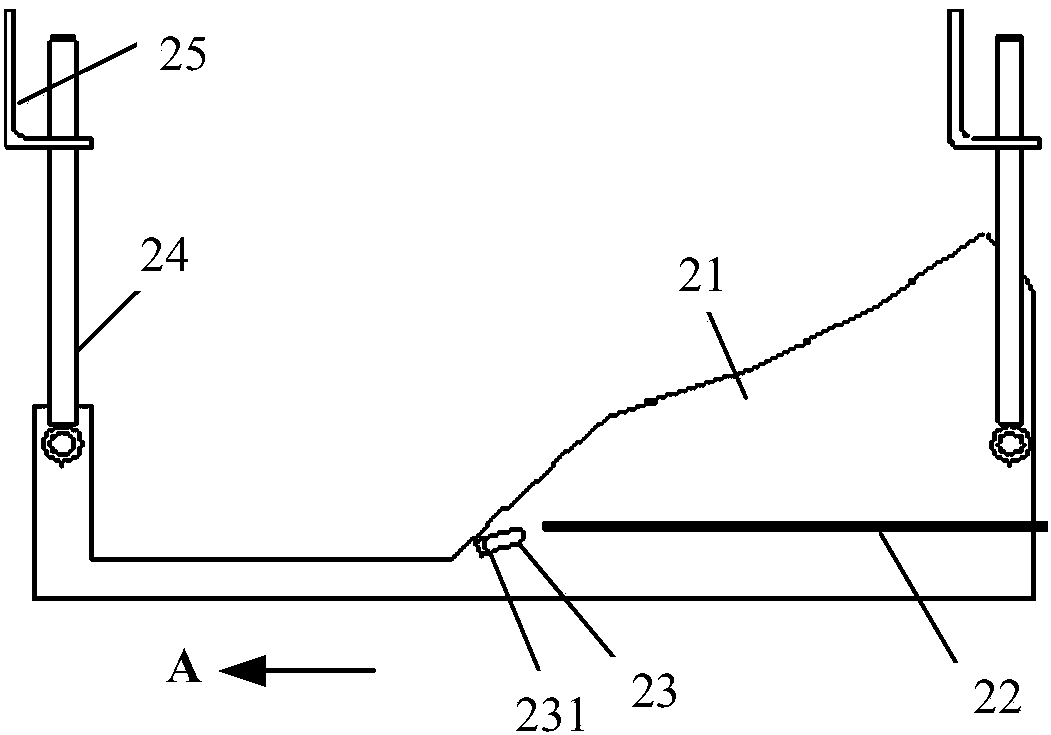

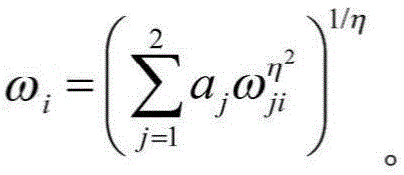

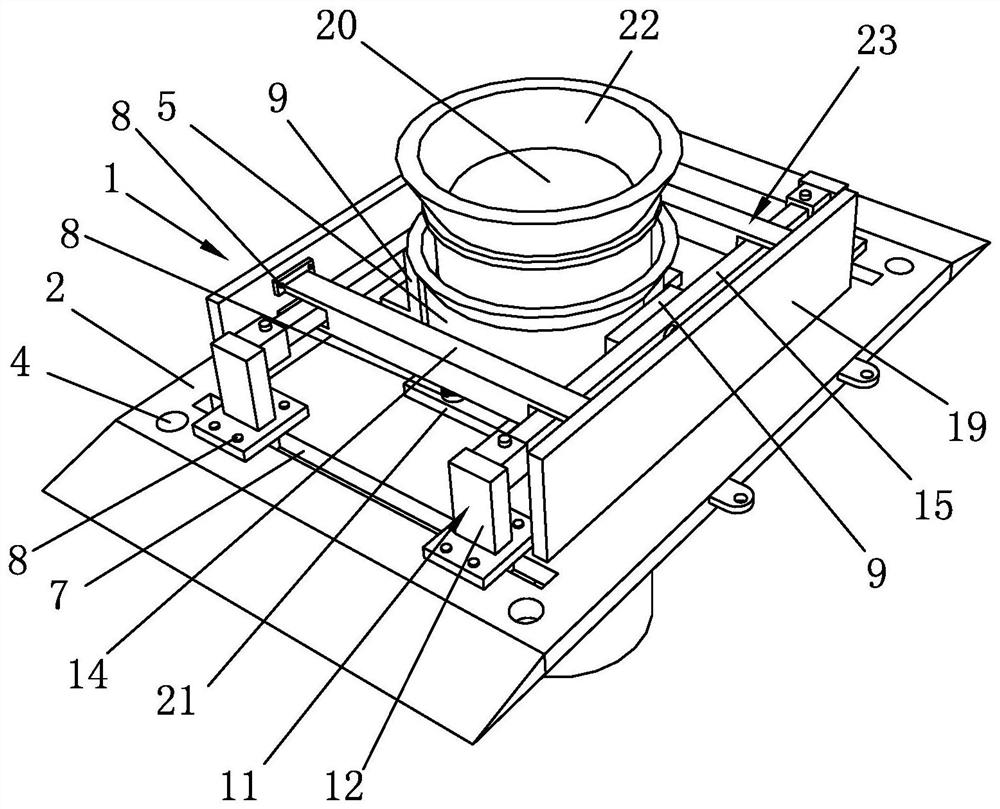

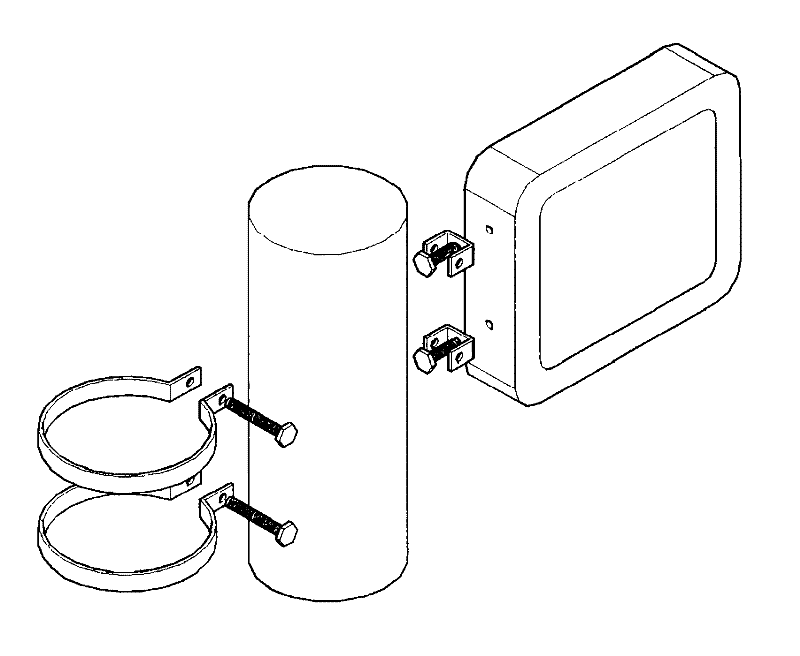

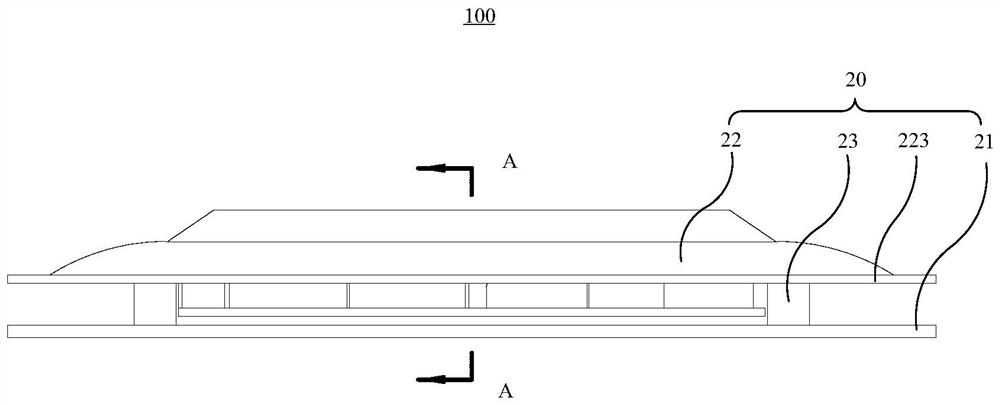

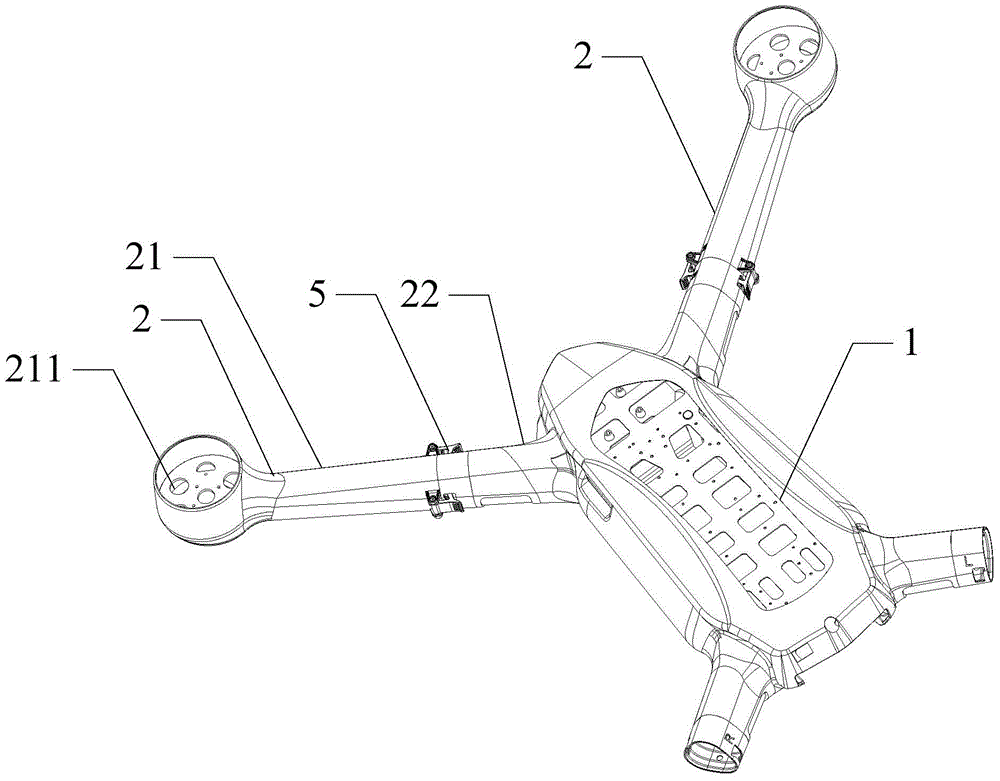

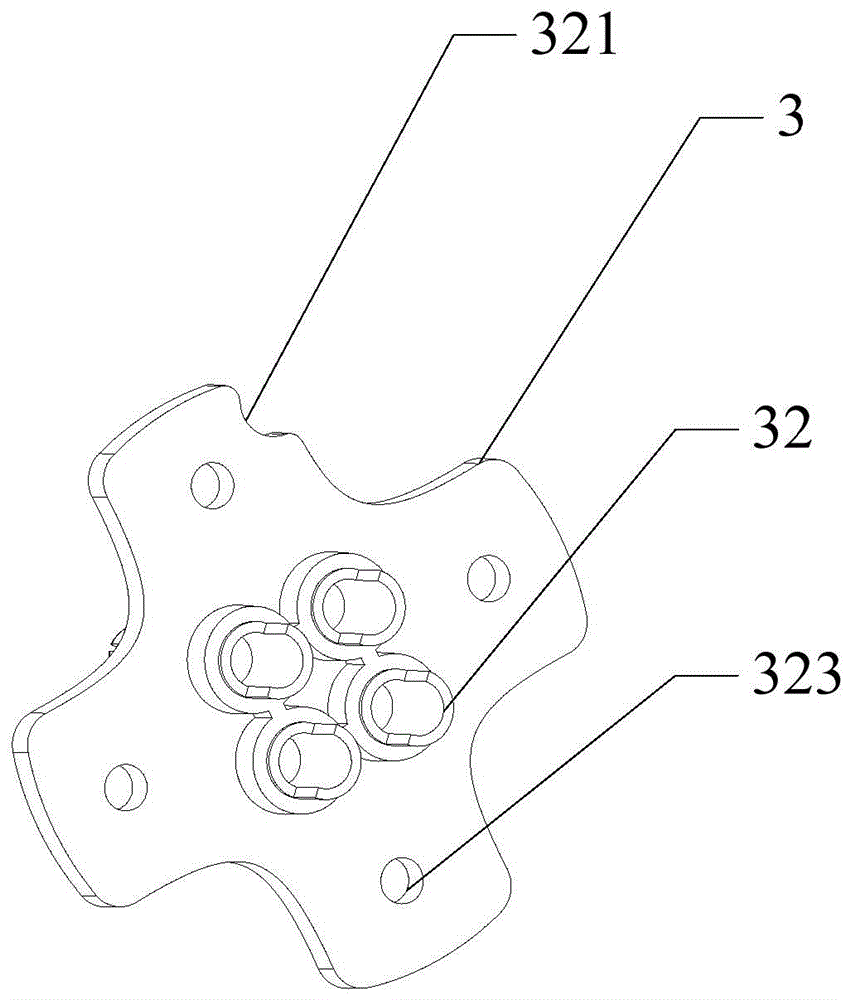

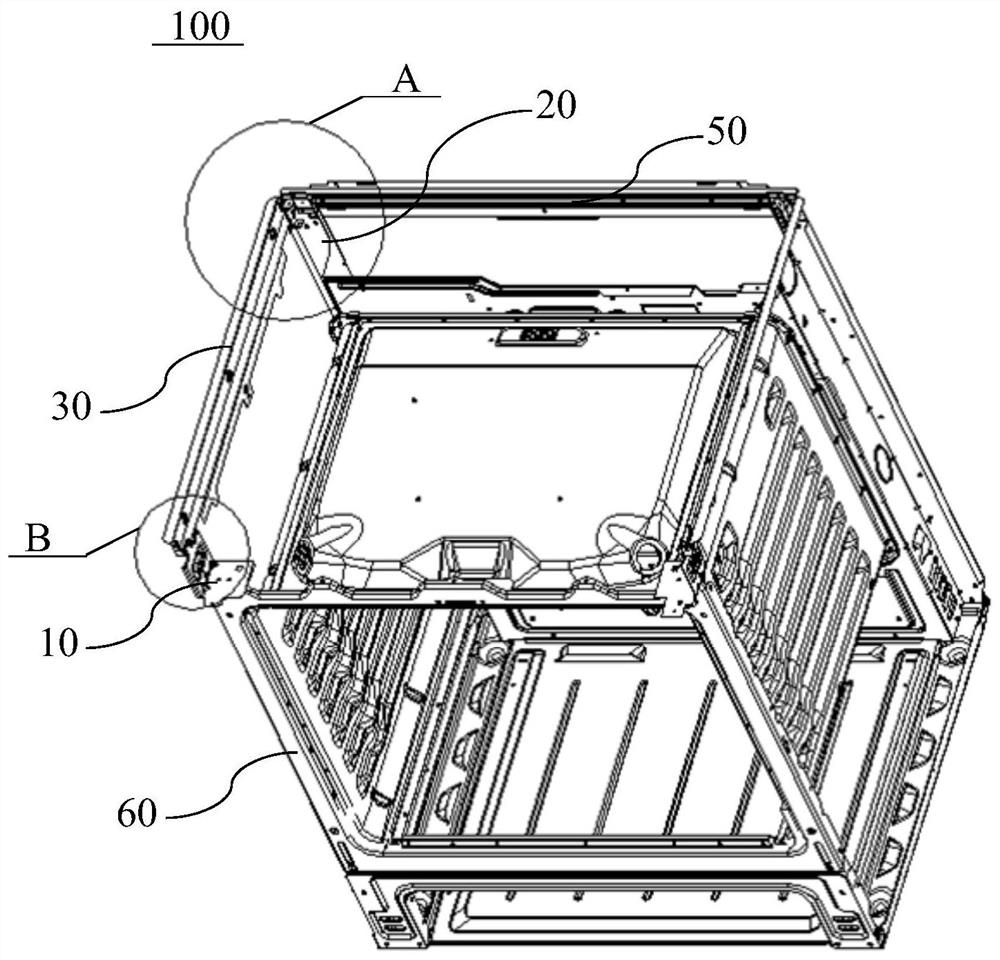

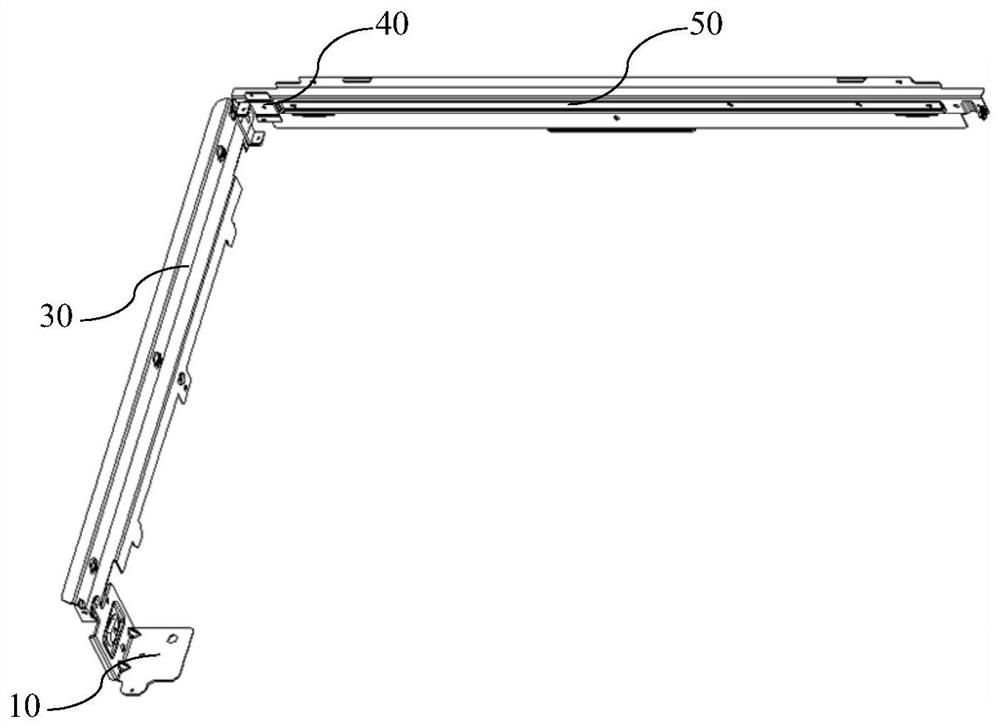

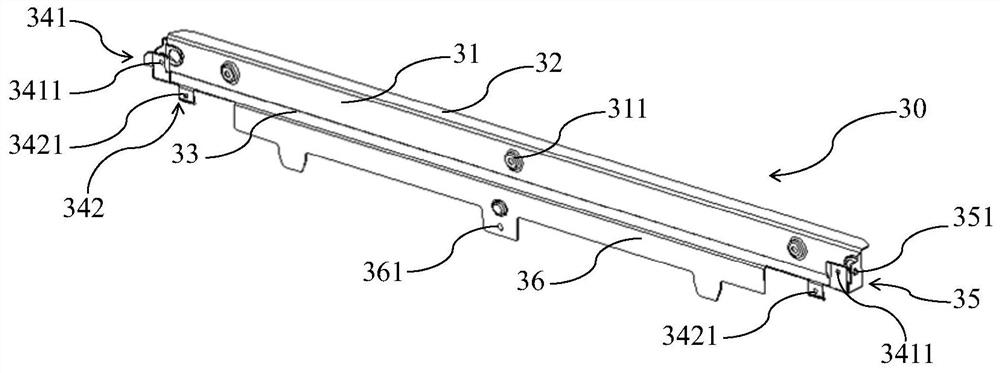

Propeller arm connection assembly and aircraft

The invention discloses a propeller arm connection assembly. Propeller arms are installed on a machine body of an aircraft. Each propeller arm comprises a propeller arm first segment and a propeller arm second segment. The propeller arm connection assembly comprises a first connecting base and a second connecting base fixedly connected with the first connecting base in a butting mode through electric connectors. The first connecting base is connected with the propeller arm first segments, and the second connecting base is connected with the propeller arm second segments. At least one of the first connecting base and the second connecting base is in non-fixed limiting connection with the corresponding propeller arm first segment or the corresponding propeller arm second segment. According to the propeller arm connection assembly, one connecting base can swing together with the other connecting base which joggles under the condition that the propeller arm segments provided with paddles joggle; deformation of the electric connectors is reduced or avoided; and therefore poor contact in the subsequent connection process is avoided, and stability and safety of the aircraft are greatly improved.

Owner:SICHUAN AEE AVIATION TECH CO LTD

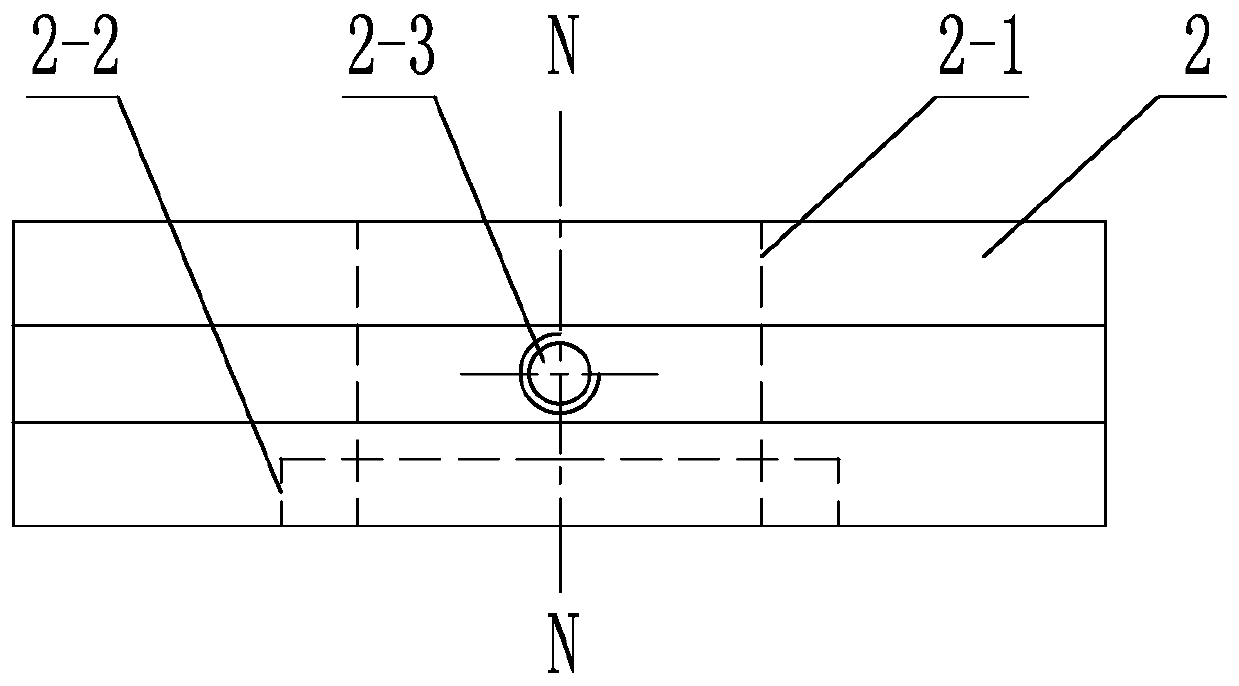

Method for machining thin-wall separation type solid retainer

ActiveCN109732293ASolve processing deformationImprove machining accuracyManufacturing technologySolid solution strengthening

The invention discloses a method for machining a thin-wall separation type solid retainer, and relates to the technical field of design and manufacture of retainers. According to the method, the problems that an existing thin-wall separation type bearing solid retainer is large in machining difficulty, easy to deform, the interior of the retainer, the outer diameter precision and the rivet hole machining precision are low, and the product machining quality is difficult to guarantee are solved; the method for machining the thin-wall separation type solid retainer is realized through the following steps that 1, finely turning is sequentially carried out on a first plane and a second plane, the outer diameter is coarsely ground and finely turning is carried out on the inner diameter; 2, solidsolution strengthening is carried out; 3, turning are both carried out on two planes ; 4, the finely turning is carried out on the outer diameter; 5, the inner diameter is finely ground; 6, a rivet hole is drilled; 7, a bolt is inserted; 8, a pocket is drilled and milled; 9, the outer diameter is finally milled; 10, final turning is carried out on the inner diameter; 11, the bolt is removed, deburring is carried out, and finishing is carried out; and 12, fluorescent permeation flaw detection is carried out. The method is used for improving the interior of the retainer, the outer diameter precision and the rivet hole machining precision of the thin-wall separation type solid retainer.

Owner:AVIC HARBIN BEARING

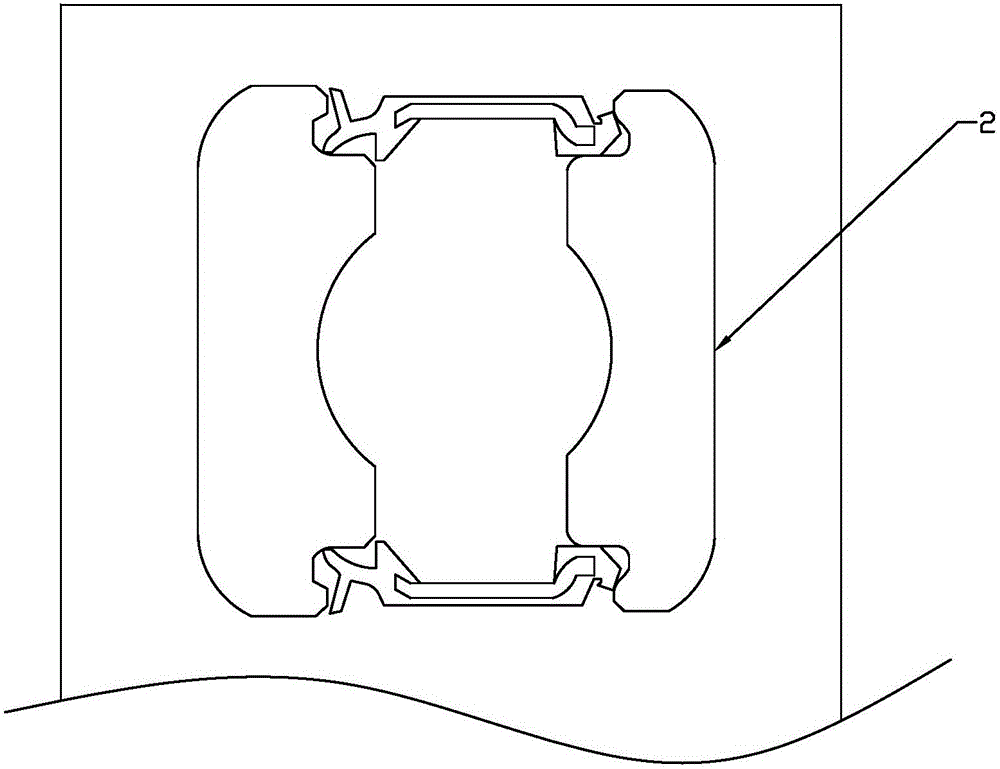

Sealed bearing sealing structure and sealing ring shape detection method thereof

The invention relates to a sealed bearing sealing structure shape detection method. An inlaid material is inlaid and solidified. The cross section is exposed through axial half-cutting. The mosaic material is polished and placed on a projection device for projection to acquire a CAD image. The invention further provides a sealing ring shape detection method. Axial half-cutting is carried out to form the cross section. The cross section is controlled to be fixed in an inlay mold. The inlay material is poured, inlaid, solidified and polished to acquire a sample. The sample is placed on the projection device. The cross section is projected to acquire the CAD image. According to the invention, a bearing sealing structure and a sealing ring structure can be directly recorded and observed, and the methods have the advantages of simple operation and convenient size and wear detection.

Owner:C&U CO LTD

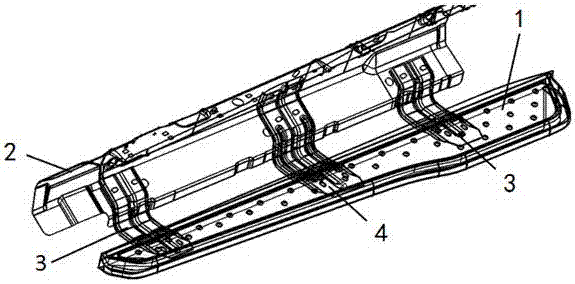

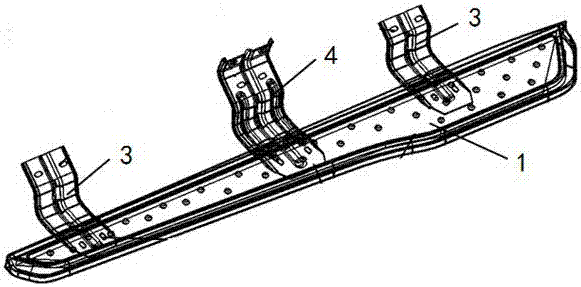

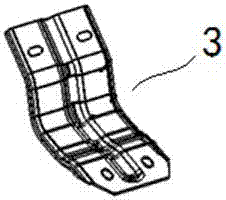

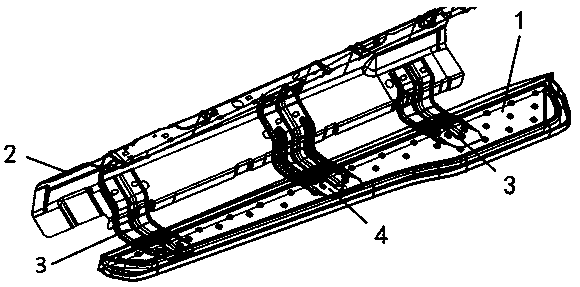

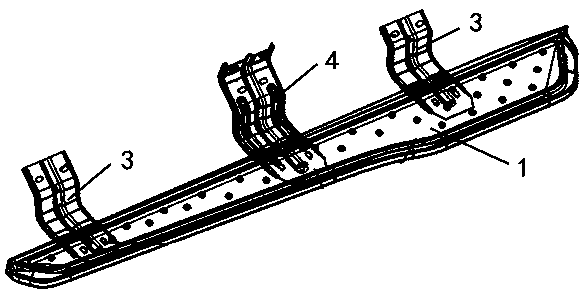

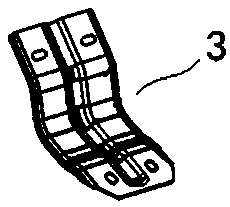

Automobile side step fixing structure

Owner:CHERY AUTOMOBILE CO LTD

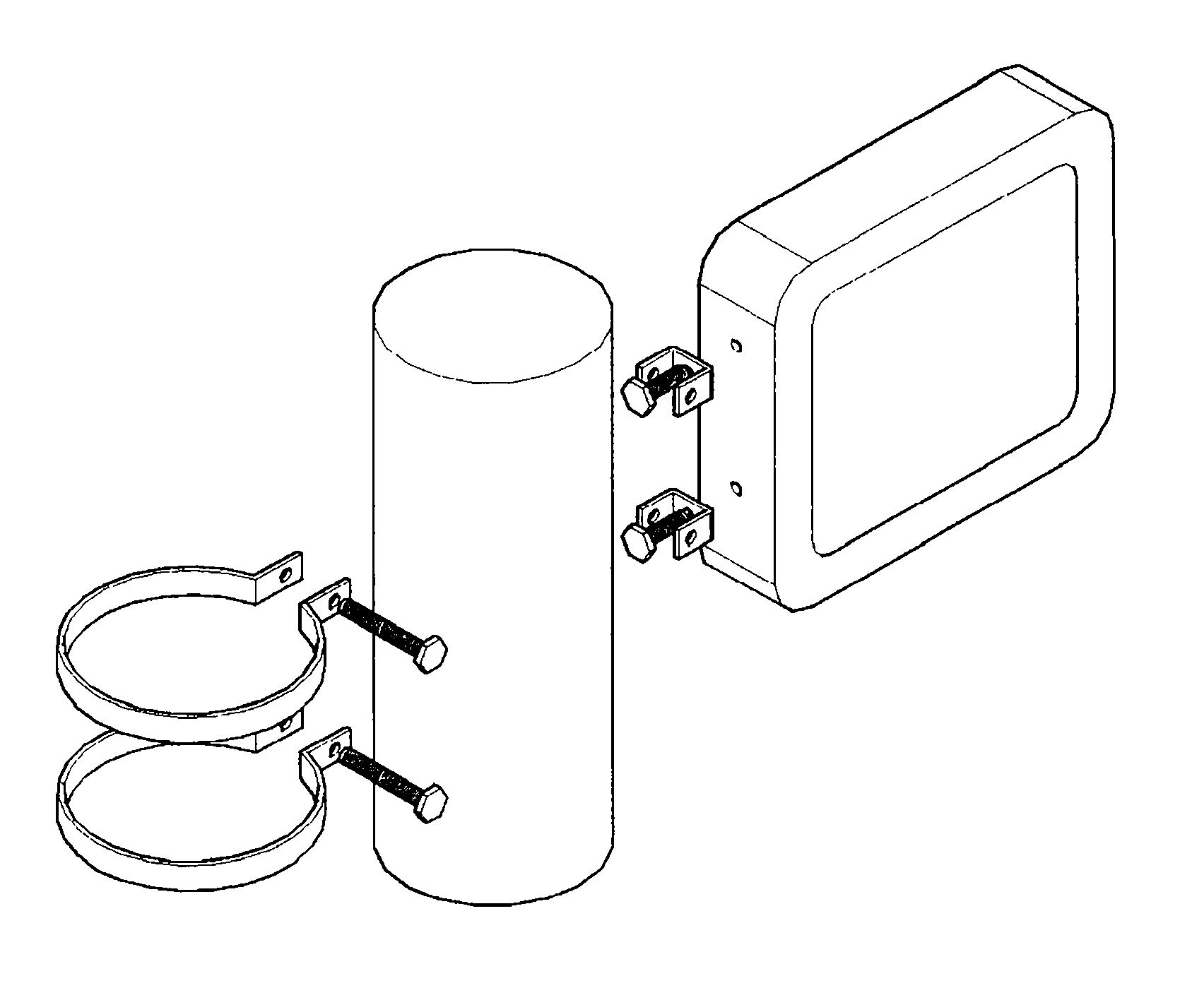

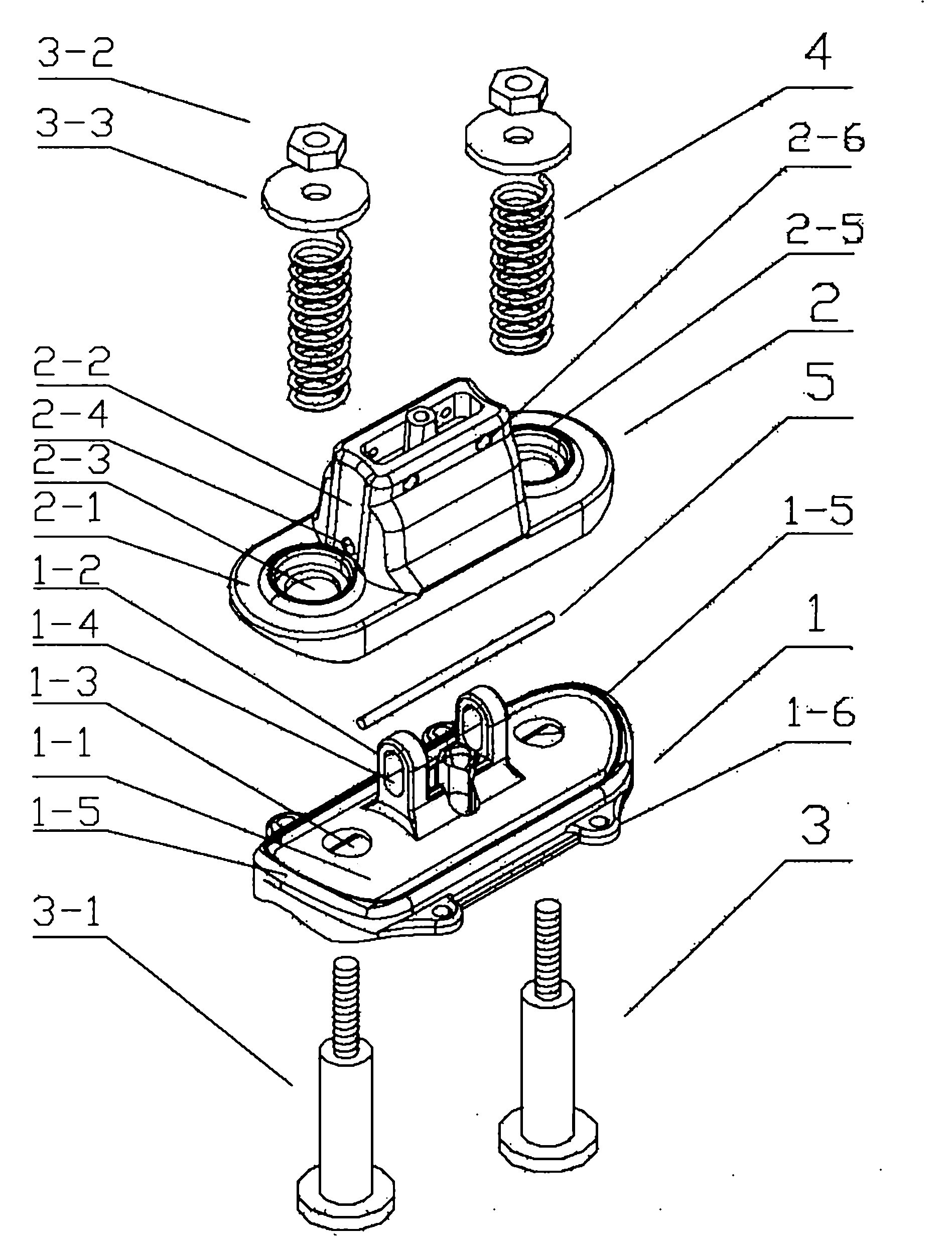

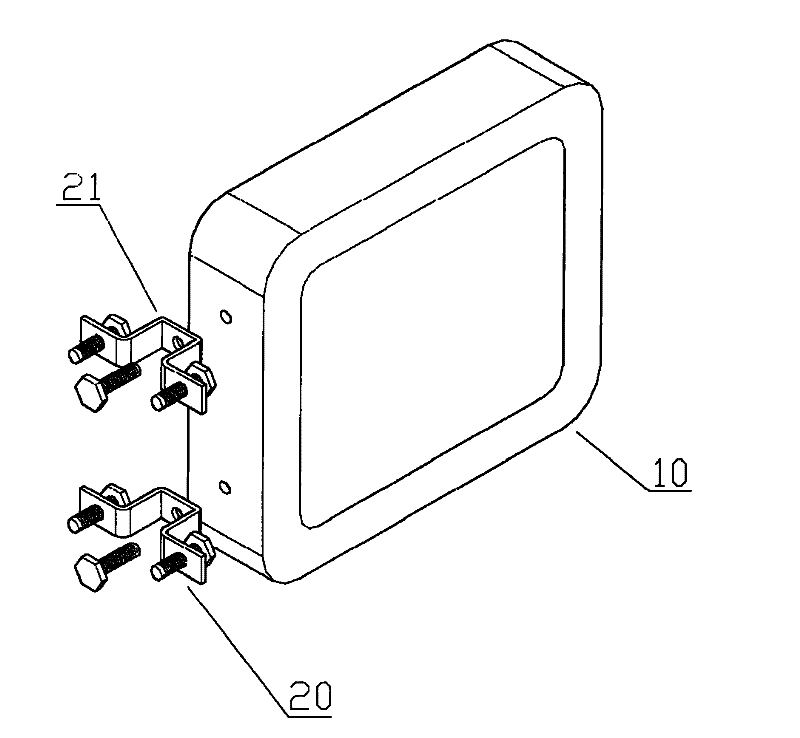

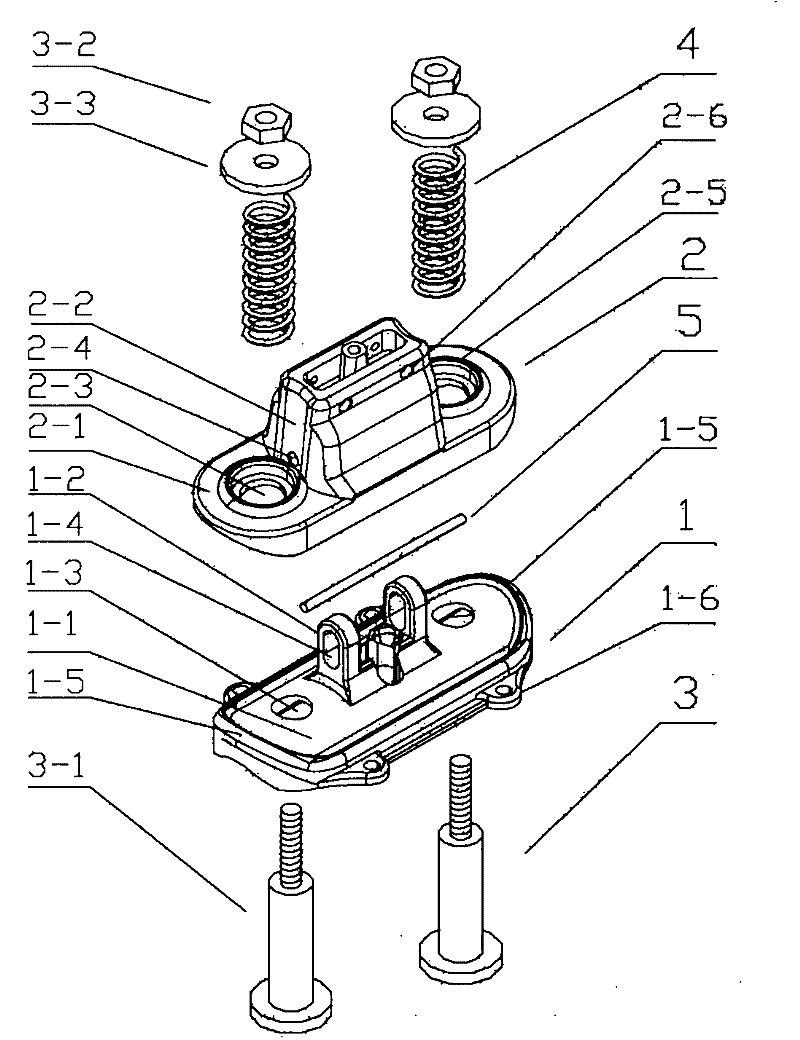

Connecting device

InactiveCN101968210AAct as a buffer against windReduce forceLighting support devicesIlluminated signsEngineeringWind power

The invention provides a connecting device. The connecting device comprises a lower base, an upper base, two connecting rods, two compression springs and a pin, wherein the lower base comprises a lower bottom plate and a bulge on the lower bottom plate; the upper base comprises an upper bottom plate and a convex shell on the upper bottom plate; the bulge is arranged in a cavity of the convex shell; two through holes into which the connecting rods are inserted are formed at the two ends of the lower bottom plate; two through holes into which the connecting rods are inserted are also formed at the two ends of the upper bottom plate; the rod parts of the connecting rods pass through the through holes of the lower bottom plate, the through holes of the upper bottom plate and the compression springs in turn; a pin hole is also formed on the bulge on the lower bottom plate; pin holes are formed on the two sides of the convex shell on the upper bottom plate; the pin passes through the pin hole on one side of the convex shell, the pin hole on the bulge, and the pin hole on the other side of the convex shell in turn; the pin hole on the bulge is strip; and the pin can relatively move in the pin hole on the bulge in the axial direction of the connecting rods. The invention has the advantage that: when outside wind power is high, the wind resistance of a light box which is arranged by the connecting device provided by the invention is improved.

Owner:HANGZHOU AOTU LIGHT TECH

Wool knitted fabrics shape-remembering finishing agent as well as preparation method and application thereof

InactiveCN101994254BReduce the temperatureConvenient careAnimal fibresRecovery performanceReaction temperature

Owner:THE HONG KONG RES INST OF TEXTILES & APPAREL

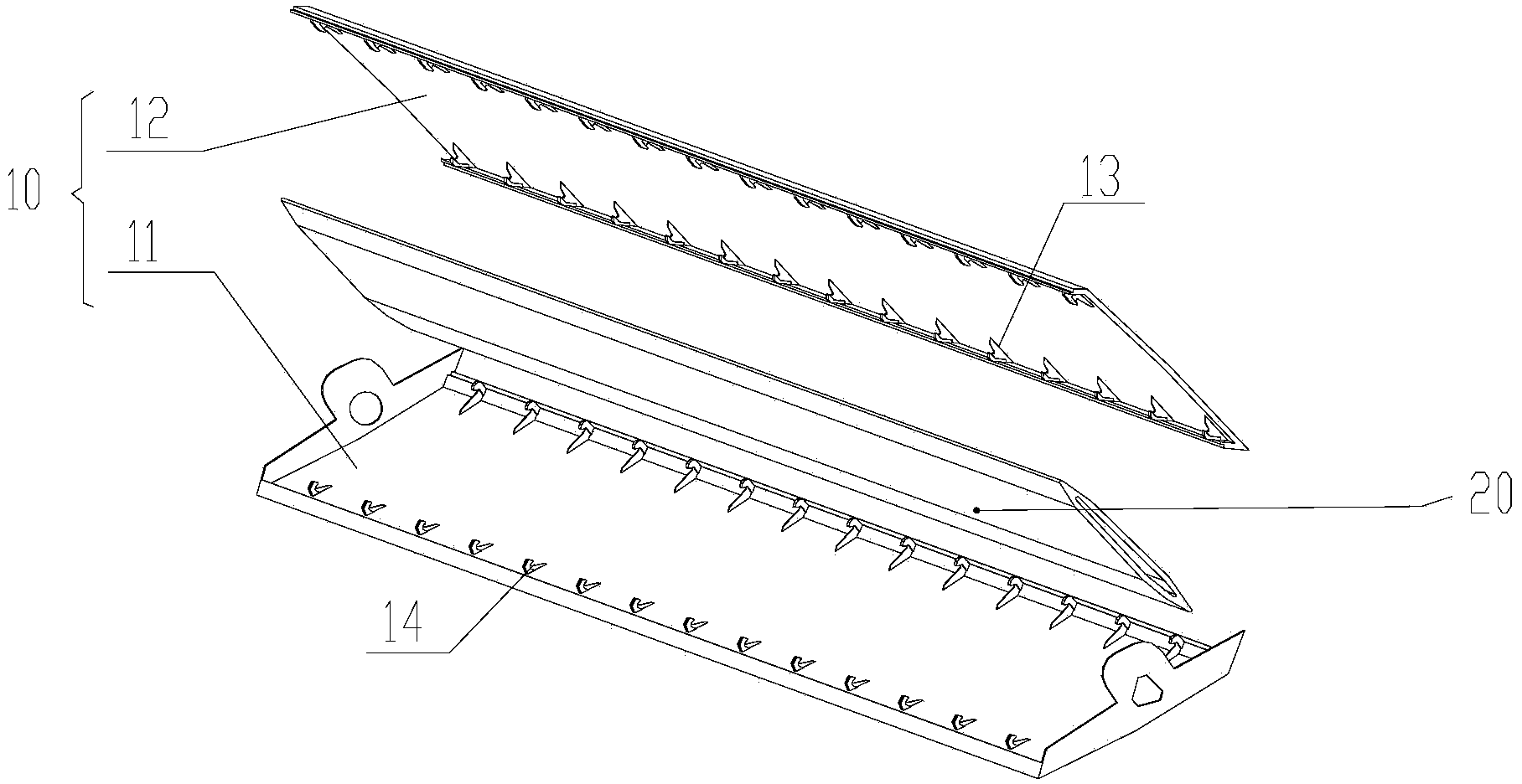

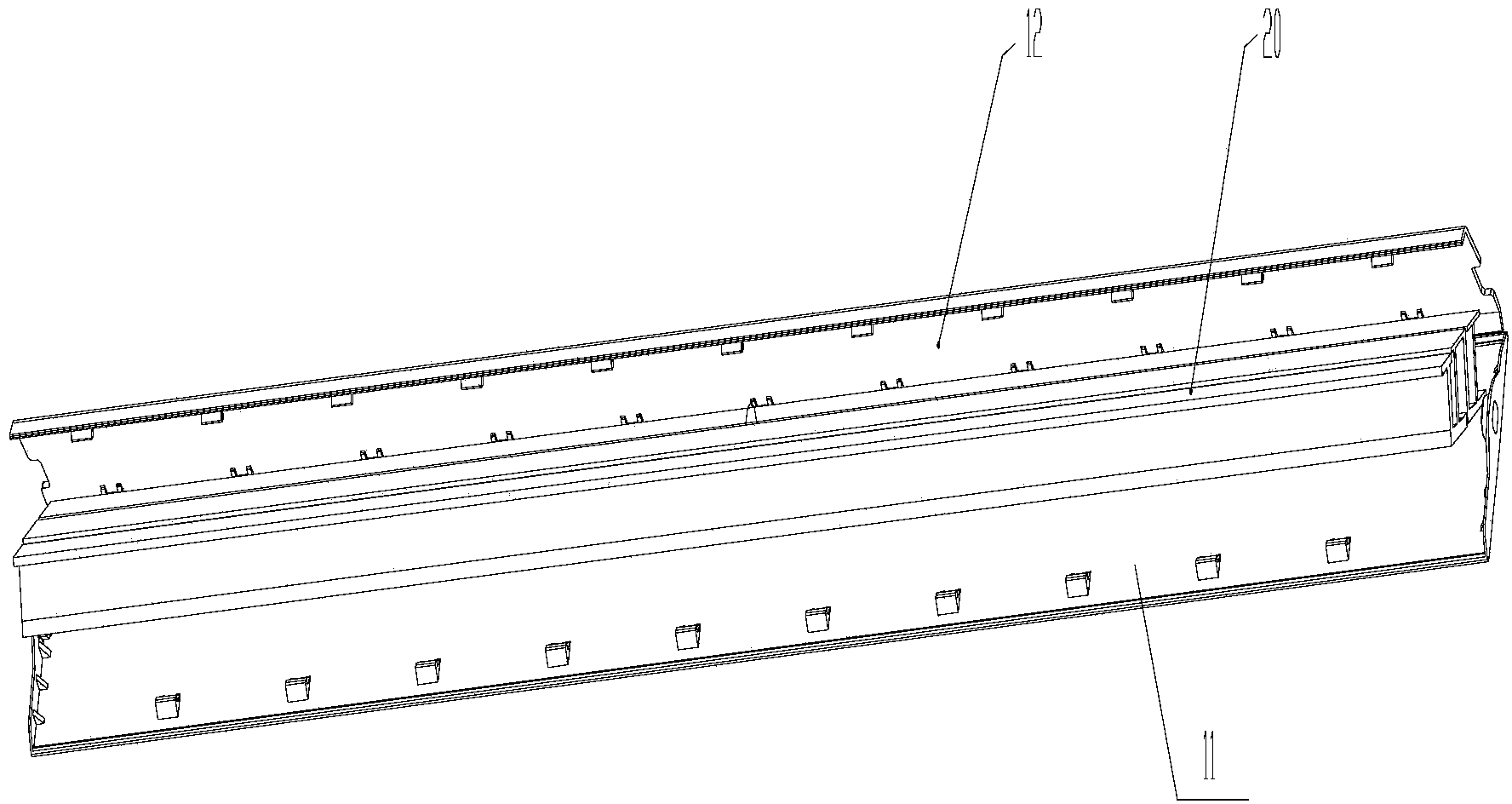

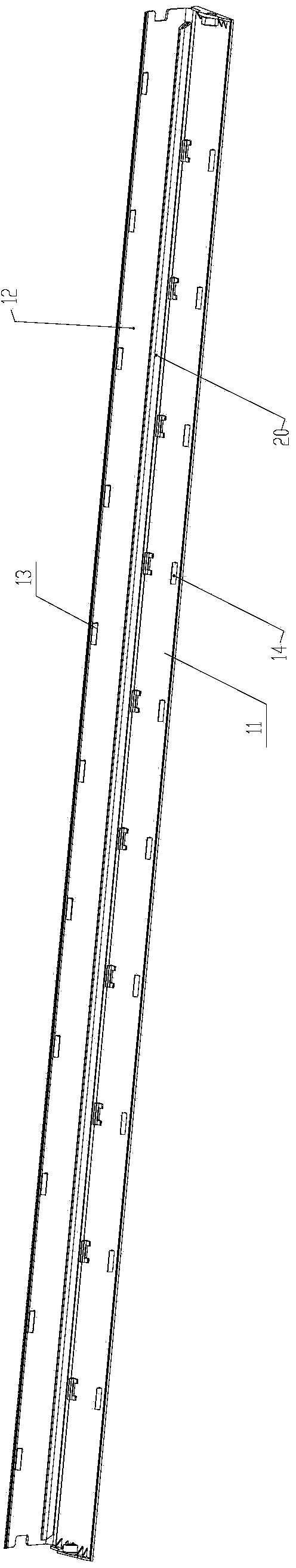

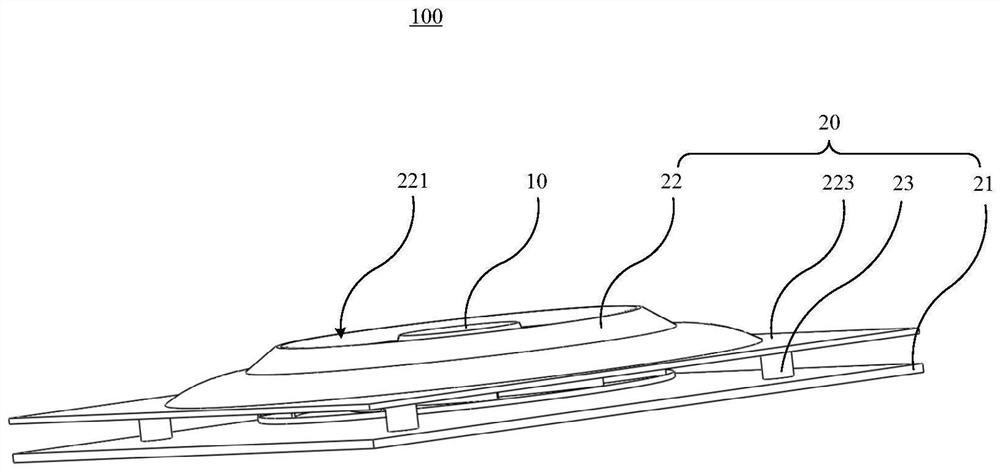

Air deflector and air conditioner comprising same

InactiveCN104315692AHigh strengthReduce or avoid deformationAir-flow control membersBoard structureElectrical and Electronics engineering

The invention provides an air deflector and an air conditioner comprising same. The air deflector comprises an external board, an internal board and a reinforcing structure which is arranged inside a hollow internal chamber to form into the air deflector; the external board is provided with the hollow internal chamber. The air conditioner comprises the air deflector which is the provided air deflector. According to the air deflector, the air deflector is arranged to be in an external board structure which is provided with a hollow portion, the internal board is arranged inside the hollow internal chamber to reinforce the air deflector structure, then a supporting base structure in the prior art is saved, meanwhile the intensity of the air deflector is increased, deformation of the air deflector is reduced or avoided, the air deflector does not generate influence to air guiding, and the integral aesthetic sense of the air conditioner is increased.

Owner:GREE ELECTRIC APPLIANCES INC

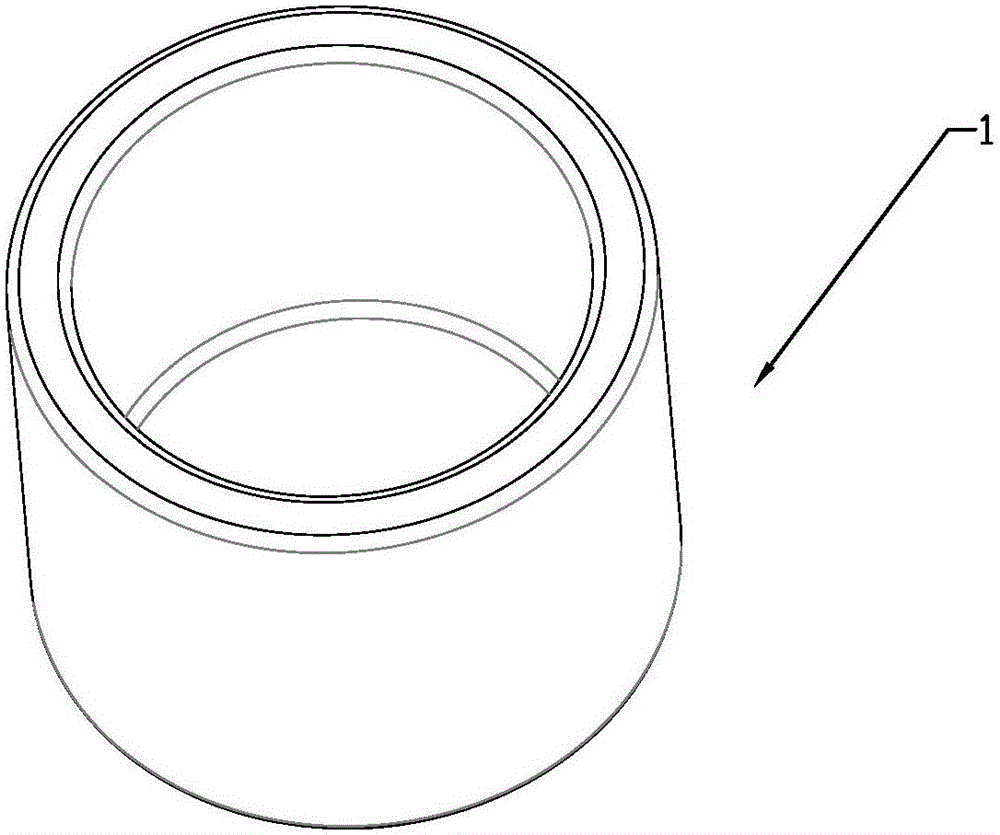

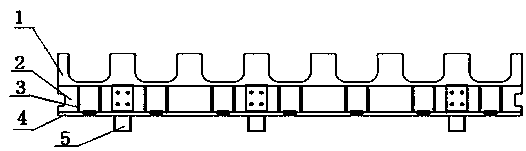

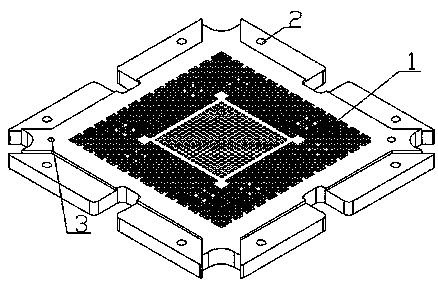

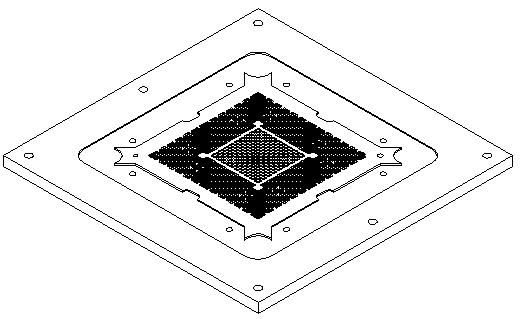

Thin-wall round tube inner hole honing fixture

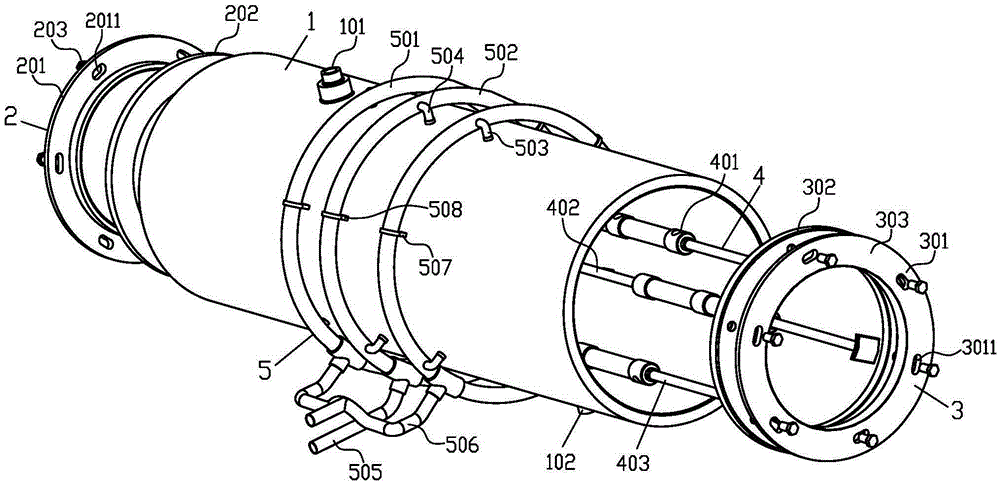

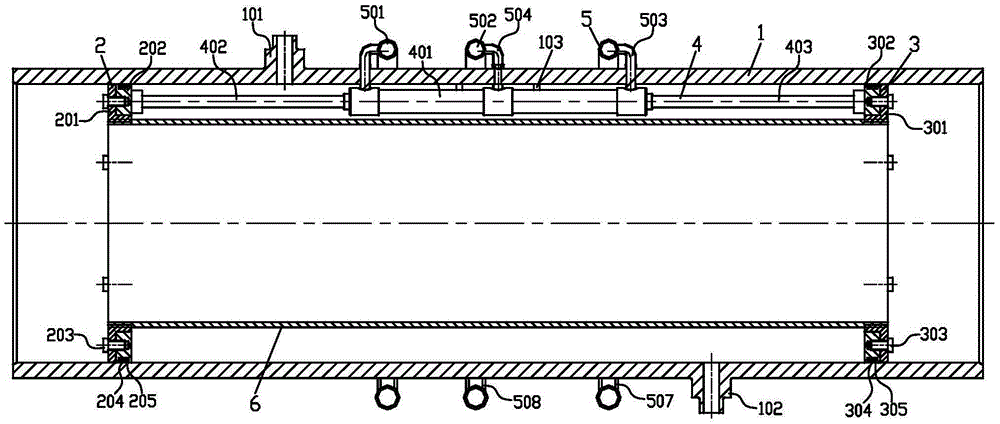

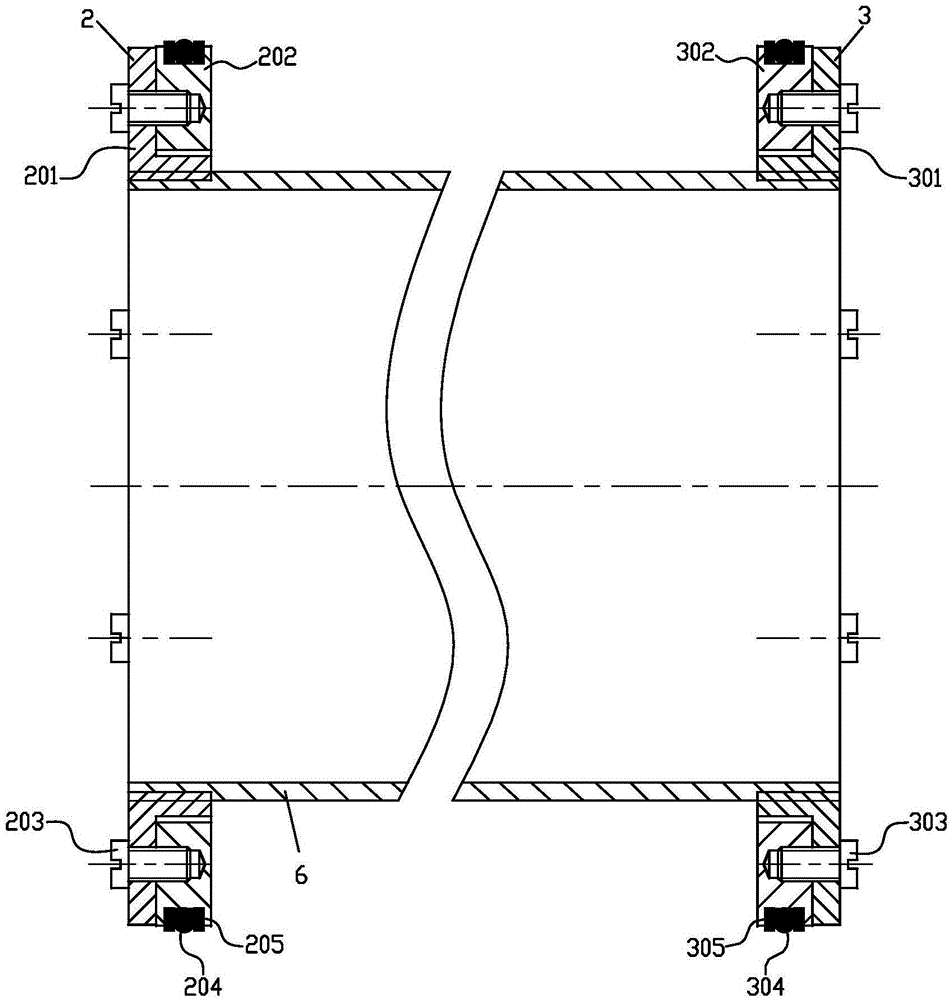

ActiveCN105290967AHigh compressive strengthReduce or avoid deformationHoning machinesGrinding work supportsHydraulic cylinderCompressive strength

The invention discloses a thin-wall round tube inner hole honing fixture which comprises a fixture body, a left end cover, a right end cover, three driving hydraulic cylinders and a pipeline system, wherein the left end cover and the right end cover are connected with the two ends of a thin-wall round tube through threads, and the pipeline system injects or discharges hydraulic oil in or out of the driving hydraulic cylinders. The three symmetrically arranged driving hydraulic cylinders drive the left end cover and the right end cover to move in the fixture body, thereby realizing axial mechanical tensioning of a workpiece. Emulsified liquid at given pressure is injected in a sealed space formed by the workpiece and the fixture body to improve the compressive strength of the workpiece, so that a situation that no workpiece deforms in a processing procedure can be ensured to the full extent, a rejection rate is reduced, the processing precision is improved, and the defects of the conventional thin-wall round tube inner hole processing fixture can be overcome. The thin-wall round tube inner hole honing fixture has the characteristics of simple structure, convenience in mounting and operation, wide processing range, high adaptability, long service life, low equipment cost, low operation power consumption, etc., and can also be used for boring, turning and milling of a thin-wall round tube workpiece.

Owner:ANHUI UNIV OF SCI & TECH

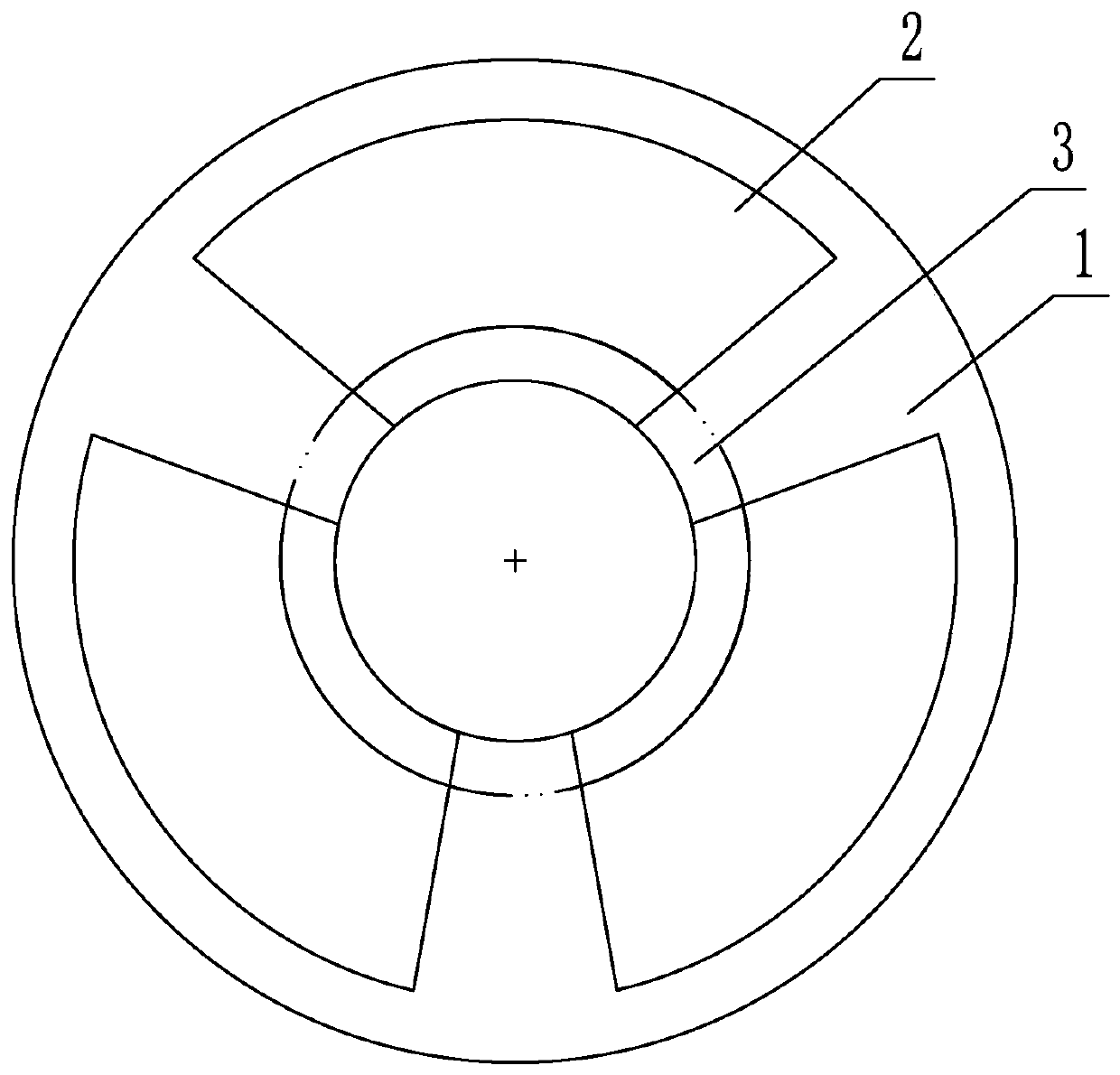

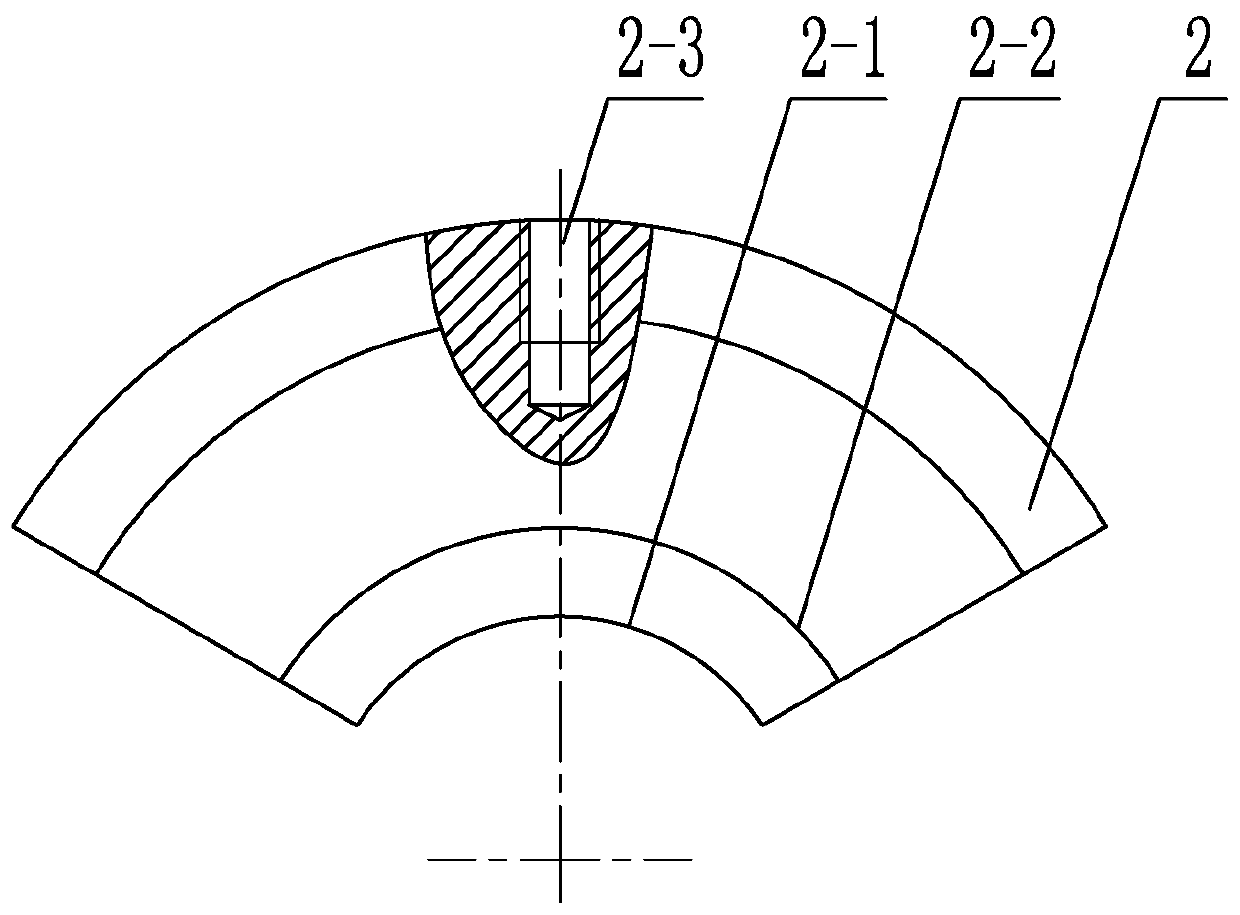

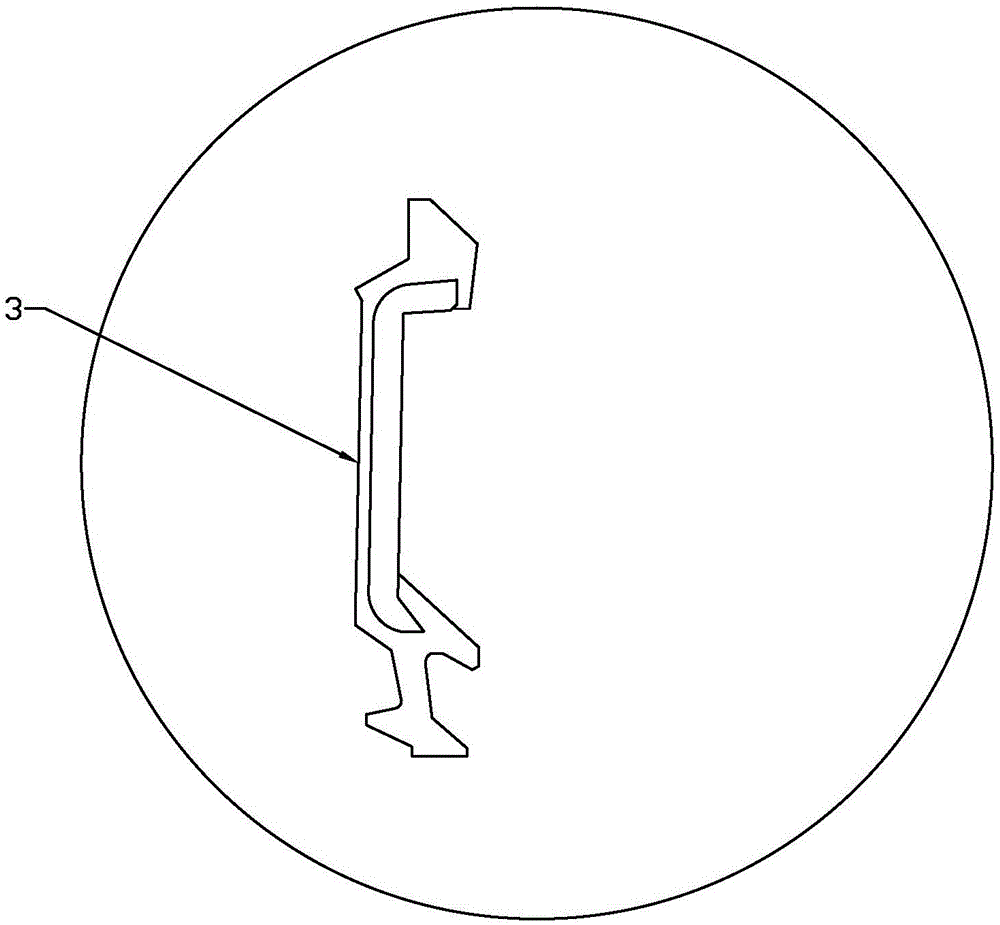

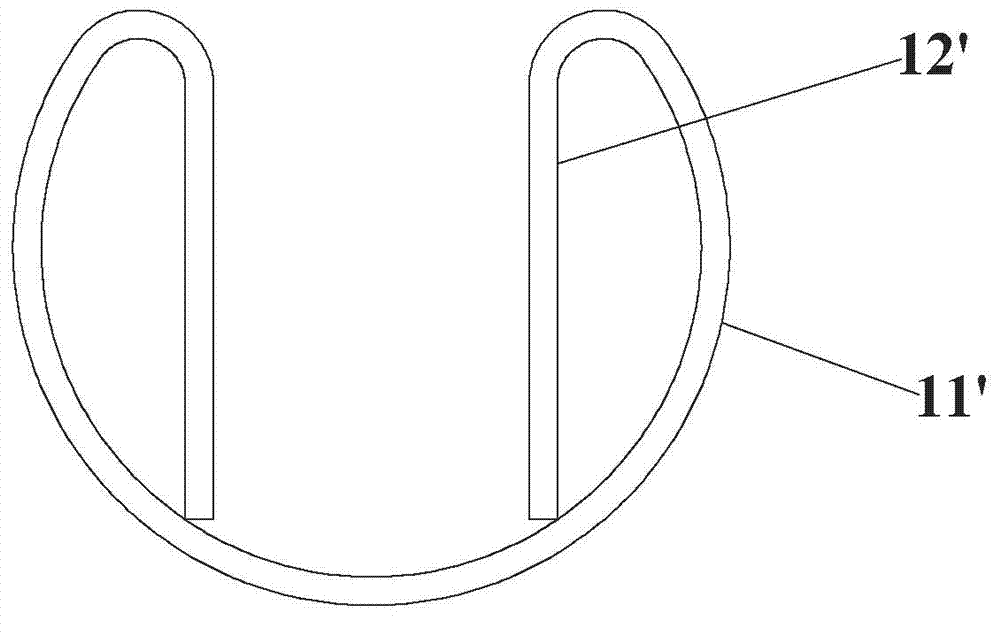

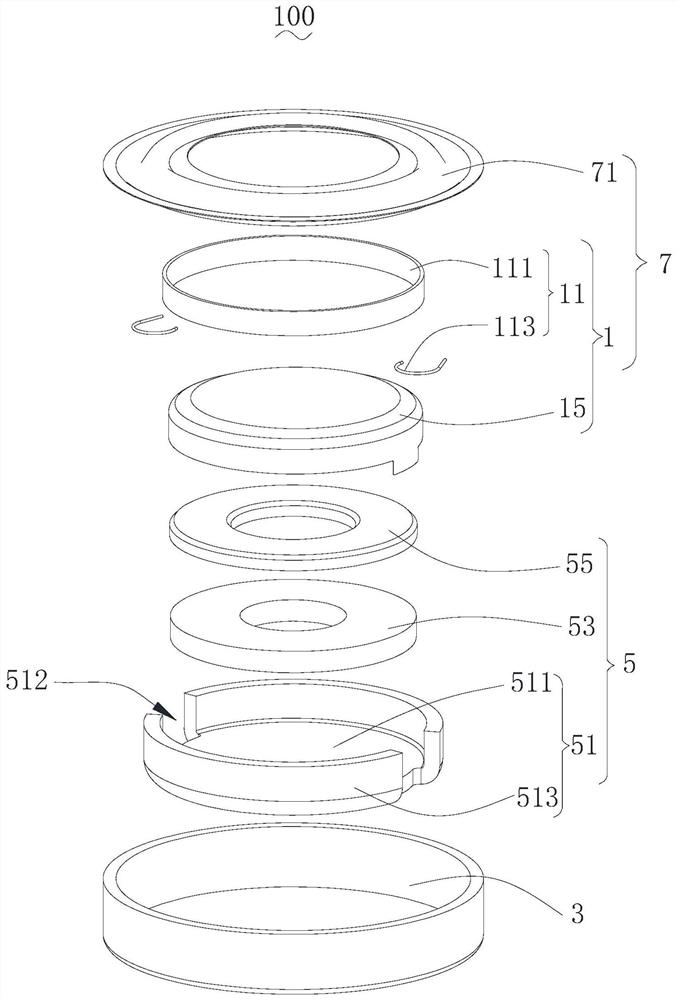

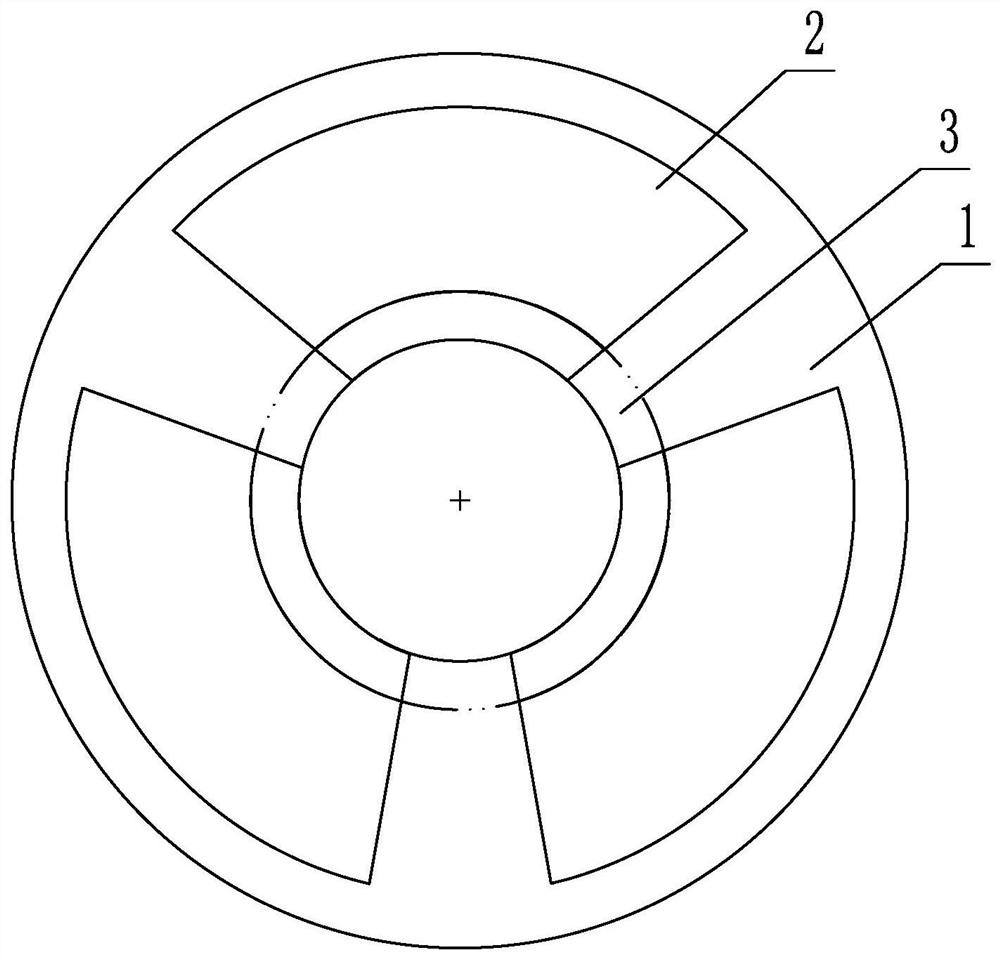

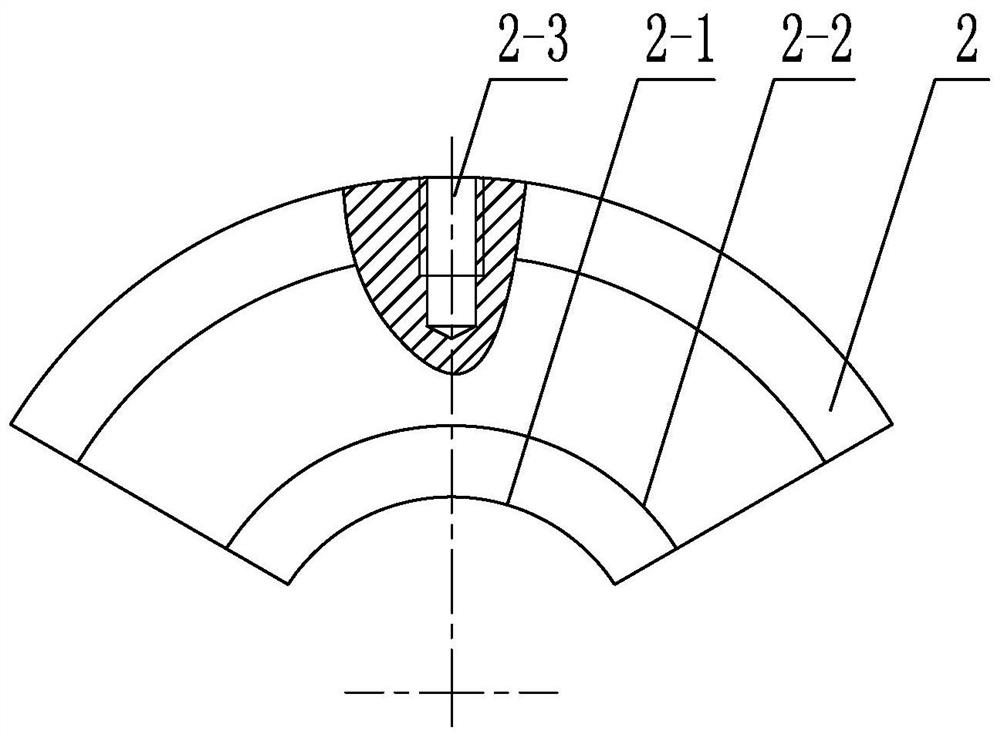

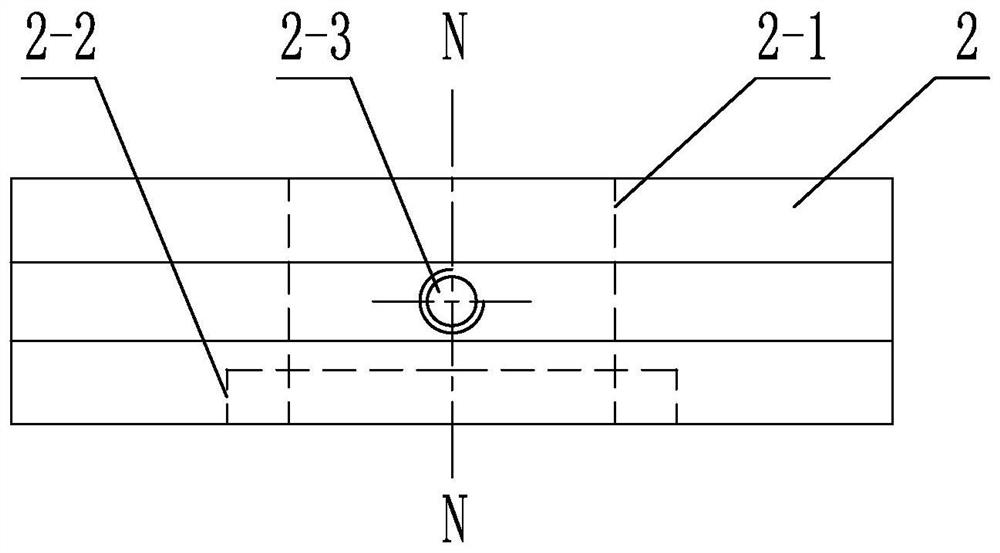

Snap spring, pressure limit valve and home appliance

InactiveCN104728319AHigh resilienceImprove structural strengthSpringsEqualizing valvesConvex sideHome appliance

The invention provides a snap spring, a pressure limit valve and a home appliance. The snap spring comprises an outer ring portion and two fastening portions, the outer ring portion is provided with notches, and the two fastening portions are connected at two notch ends of the outer ring portion and extend closely to the outer ring portion. The fastening portions are of convex arc-shaped structures, and one side of each convex arc-shaped structure facing the notches is a convex side. By the snap spring, the fastening portions are of convex arc-shaped structures, the convex sides of the convex arc-shaped structures are fastened with an object to be fastened via a point-side stress way, so as to reduce stress area of the fastening portions and achieve the purpose for reducing or avoiding deformation and falling of the snap spring.

Owner:GREE ELECTRIC APPLIANCES ZHONGSHAN SMALL HOUSEHOLD APPLIANCES MFG +1

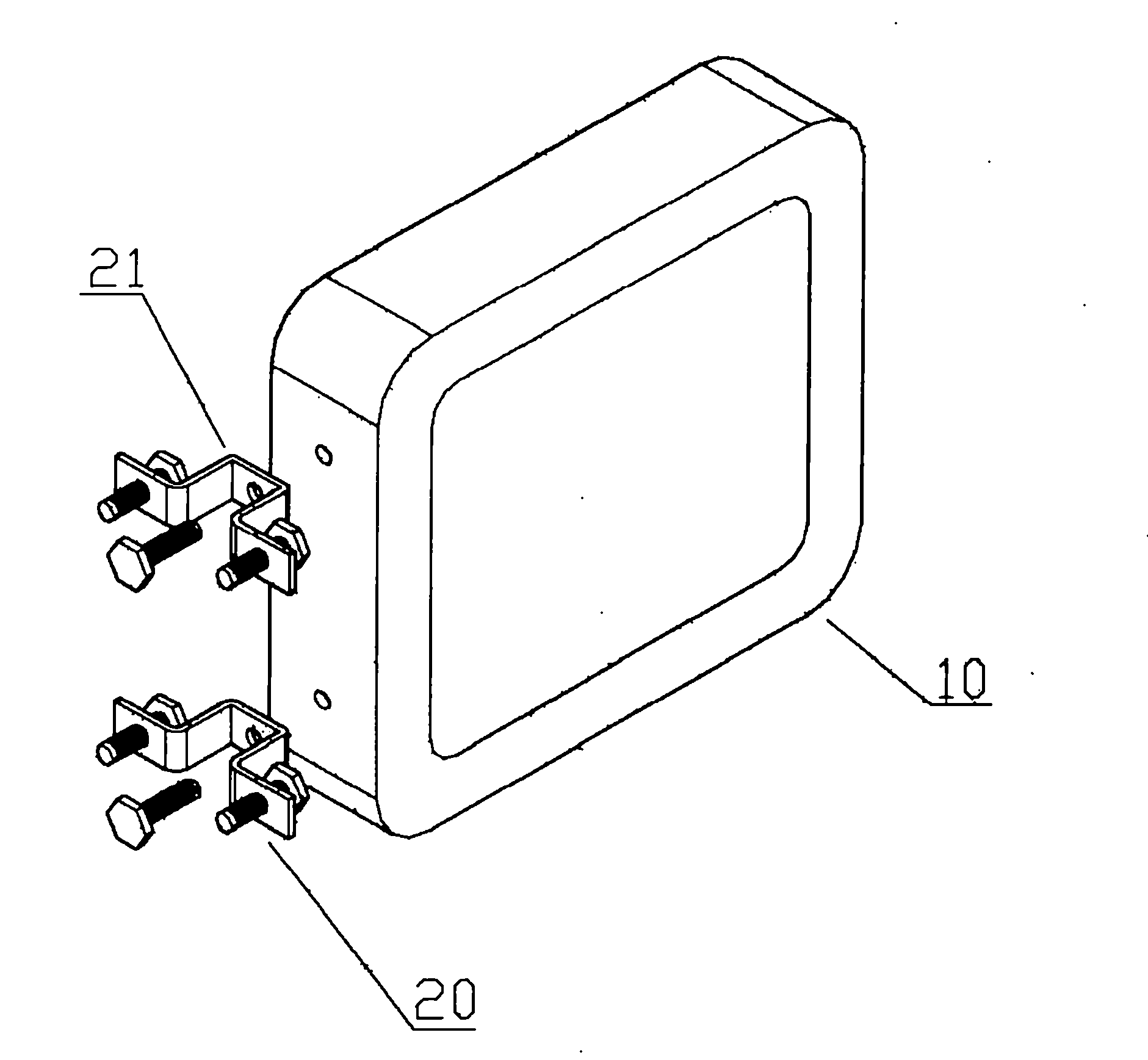

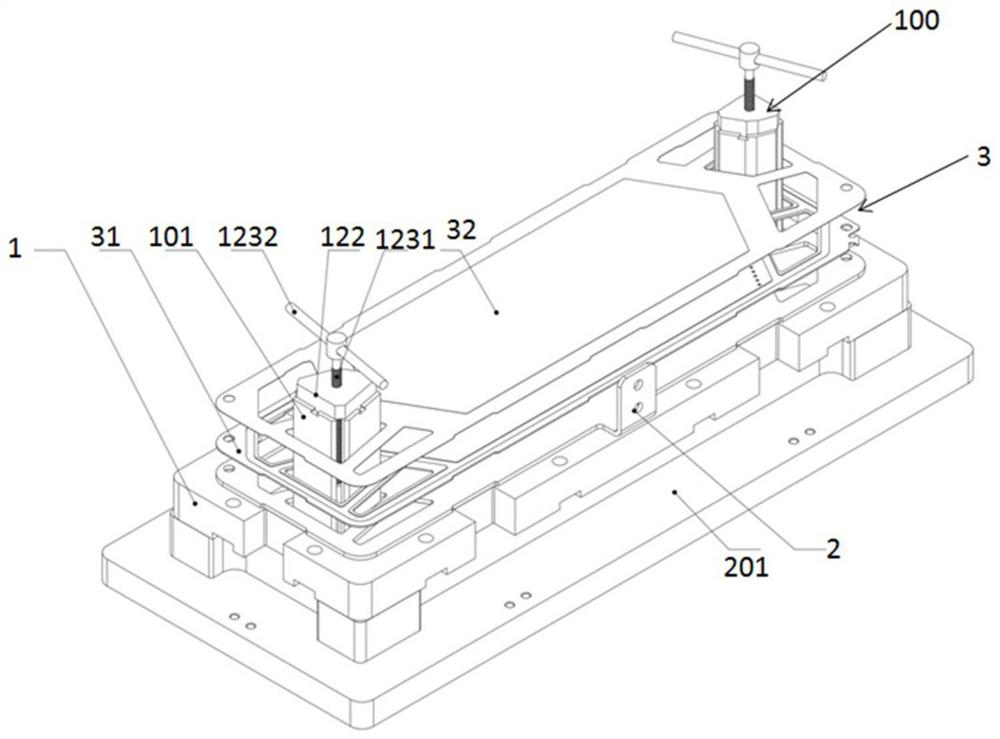

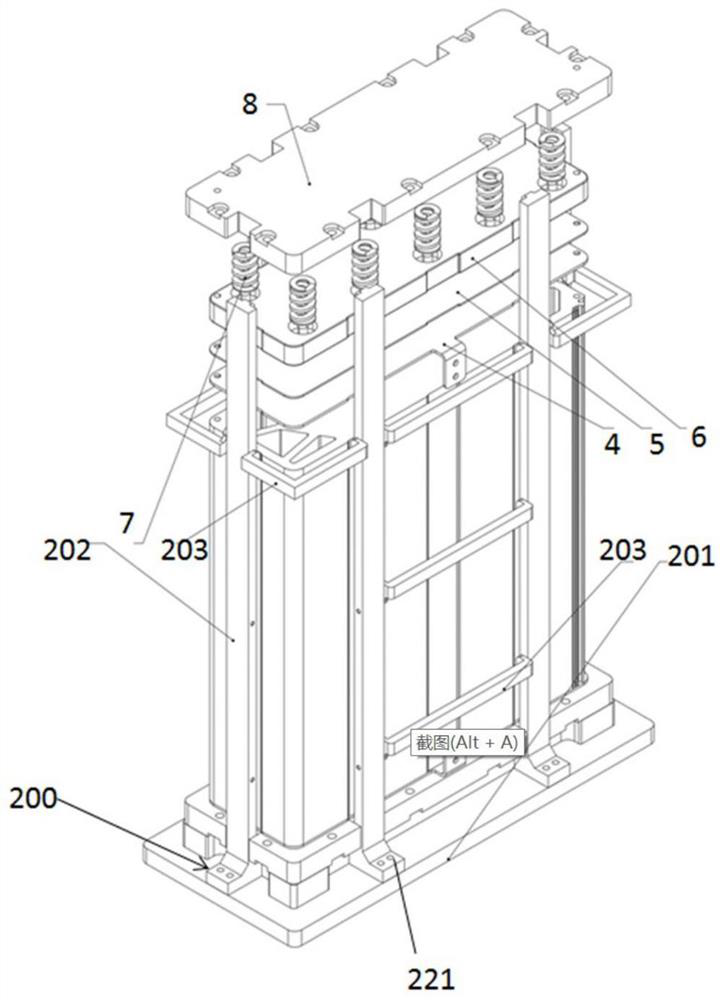

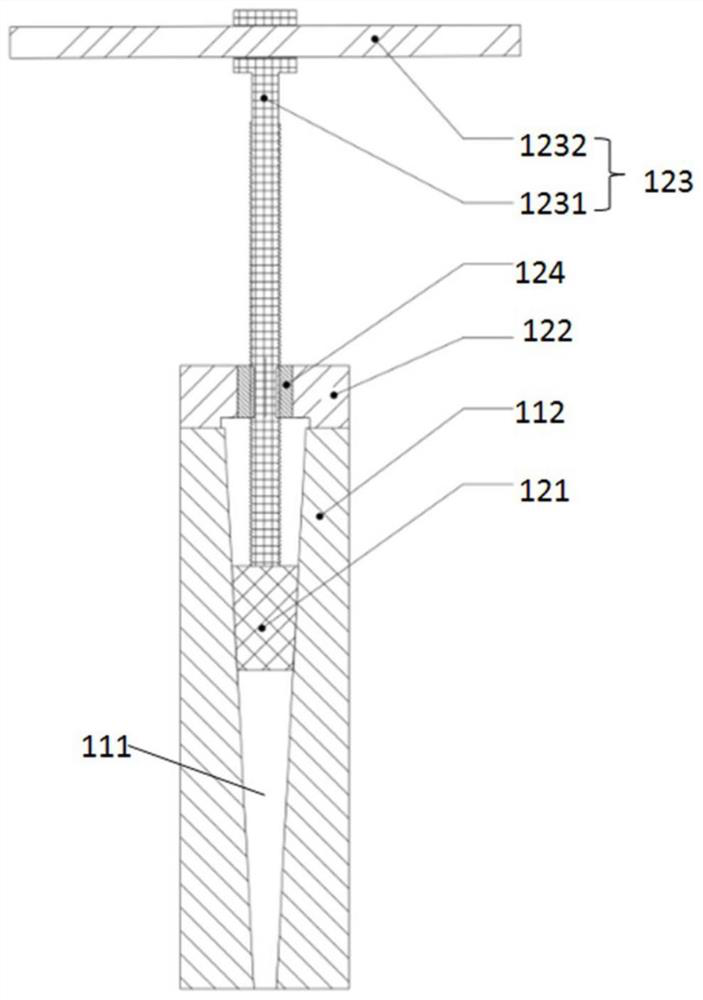

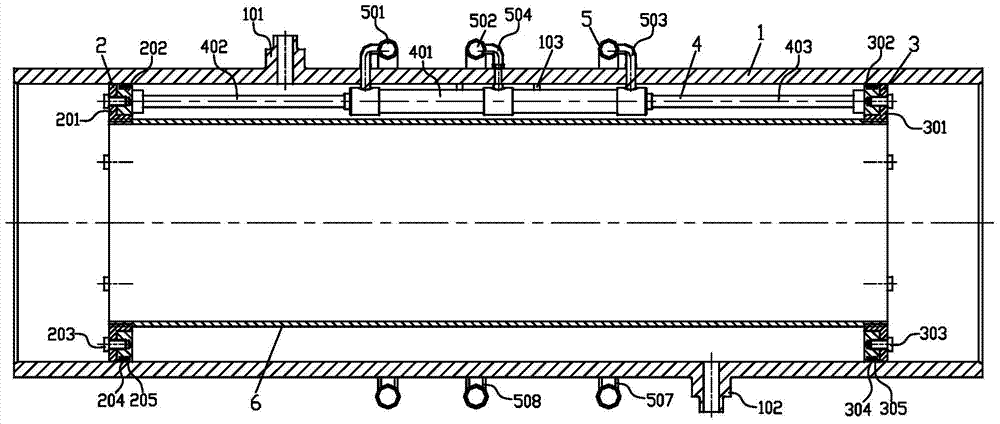

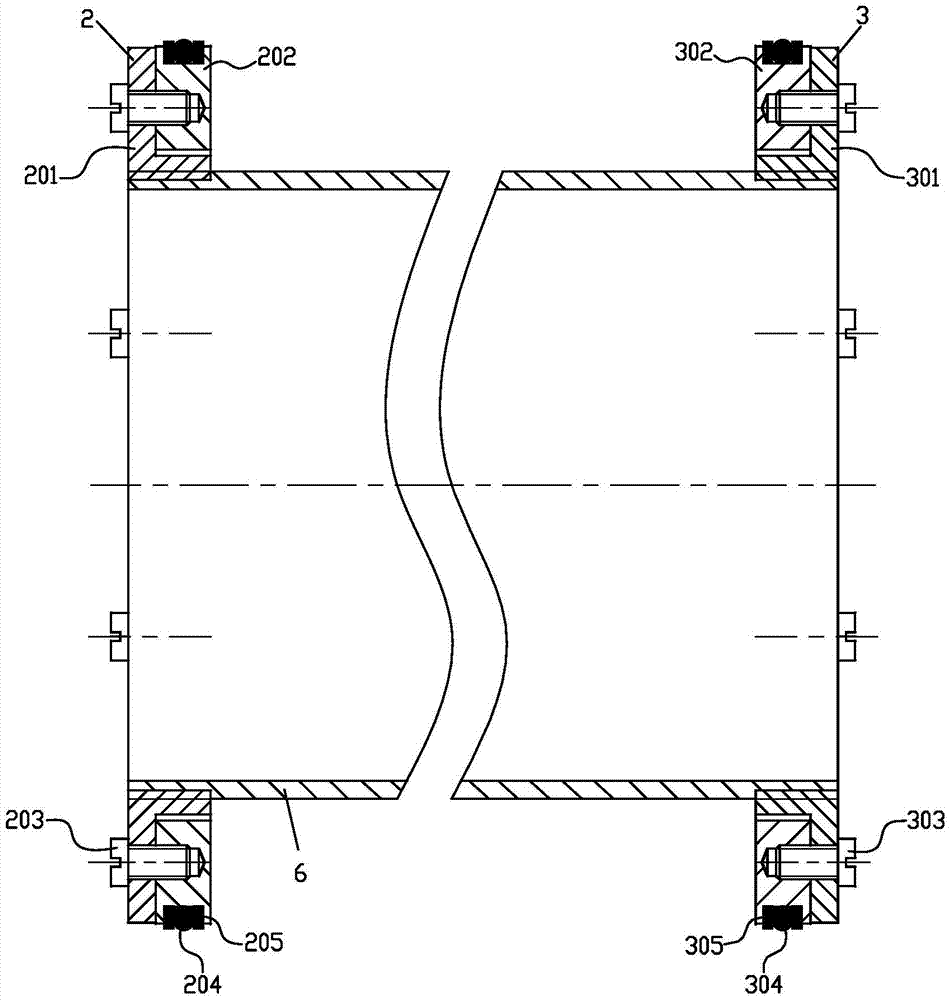

Positioning device and fuel cell stack assembling method

PendingCN114843570APrecise Assembly AlignmentImprove assembly accuracyFuel cellsFuel cellsStructural engineering

The invention discloses a positioning device and an assembling method of a fuel cell stack, and belongs to the technical field of fuel cells. A positioning device is used for assembling a fuel cell stack, the fuel cell stack comprises a first end plate, a first collector plate, a stack main body, a second collector plate and a second end plate, the first end plate, the first collector plate and the stack main body are provided with a common cavity, the positioning device comprises: an inner positioning assembly, the inner positioning assembly comprises a support body and a motion connection mechanism, the movement connecting mechanism is suitable for moving in the channel of the support body, so that the support body expands outwards in the radial direction to be in an expansion state, and the support body in the expansion state is matched with the public cavity and is used for positioning the first end plate, the first collector plate and the electric pile main body; and the outer positioning assembly comprises a base, a limiting frame and a plurality of positioning rods and is used for positioning the second collector plate and the second end plate. The assembly precision of the fuel cell stack can be improved, and the safety of the fuel cell is improved.

Owner:上海安池科技有限公司

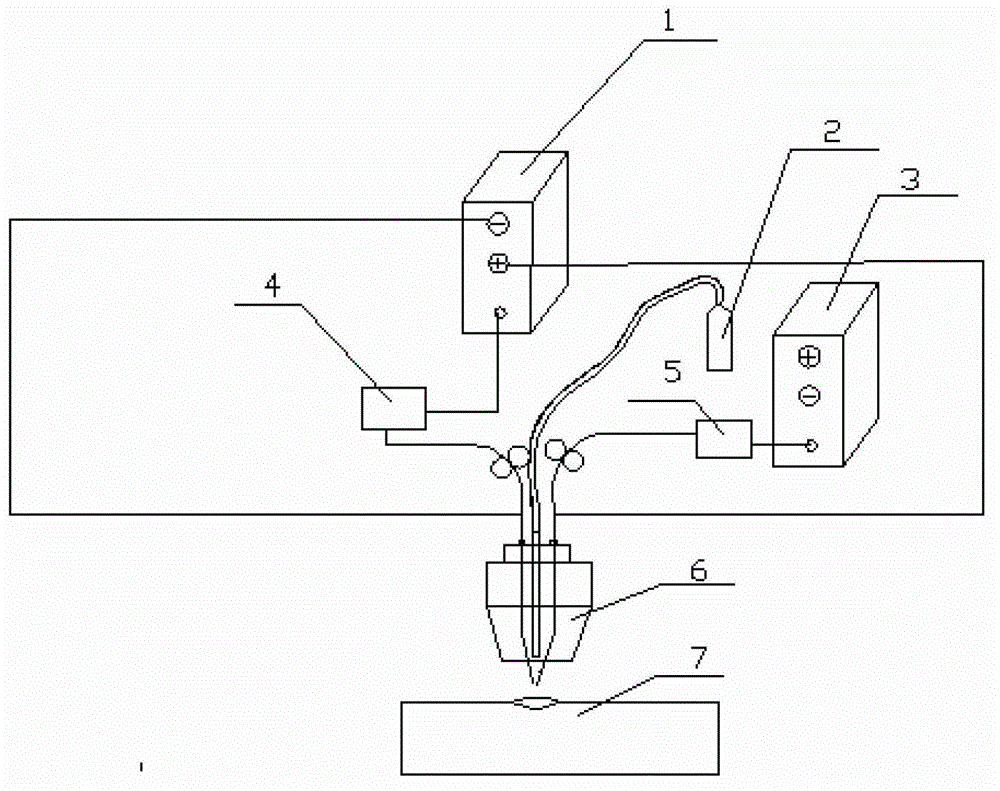

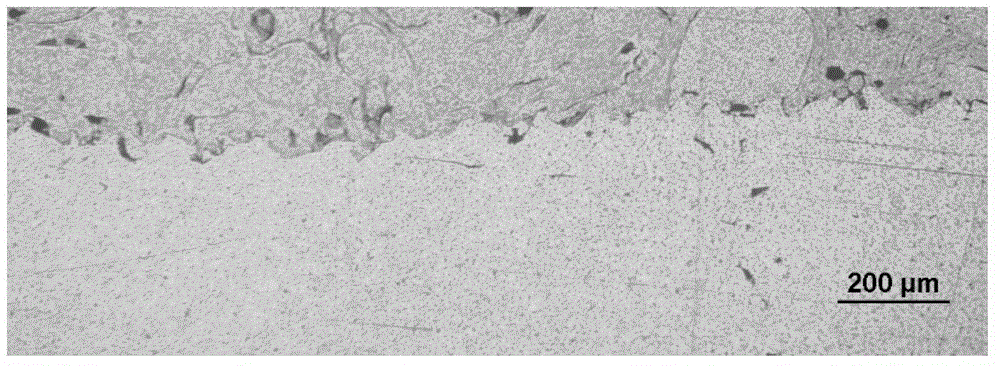

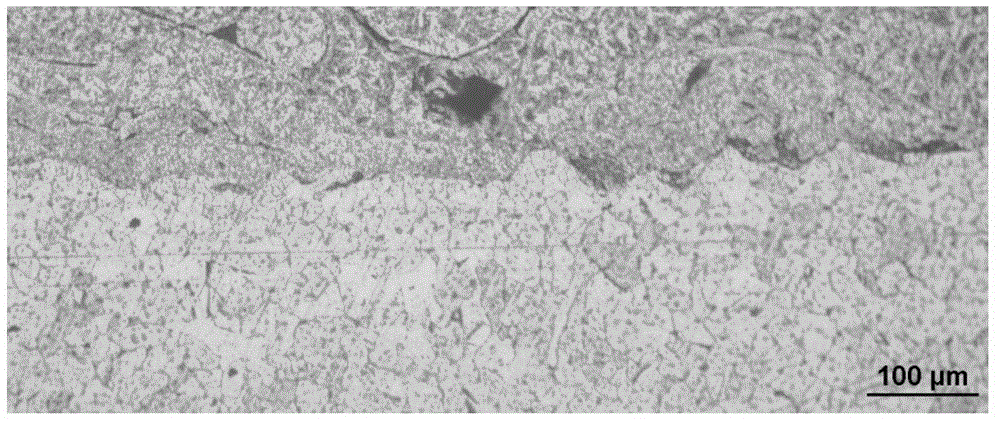

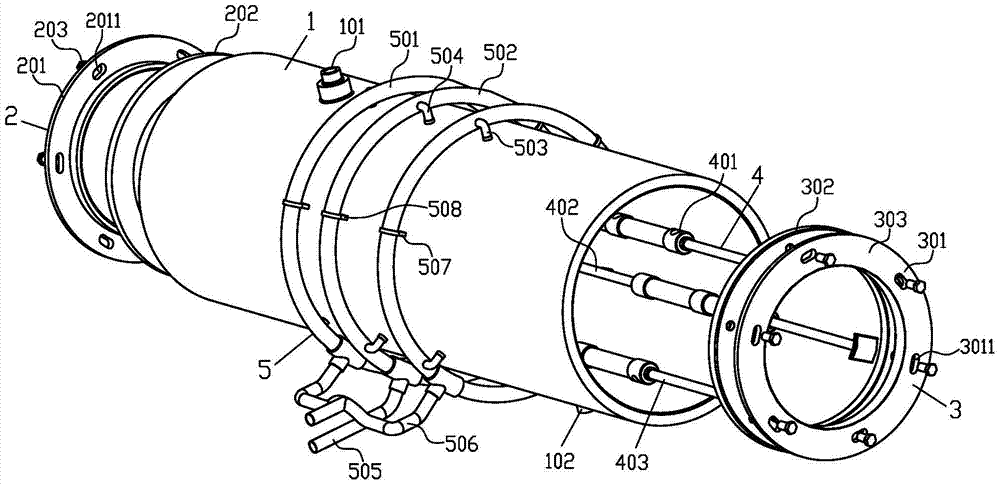

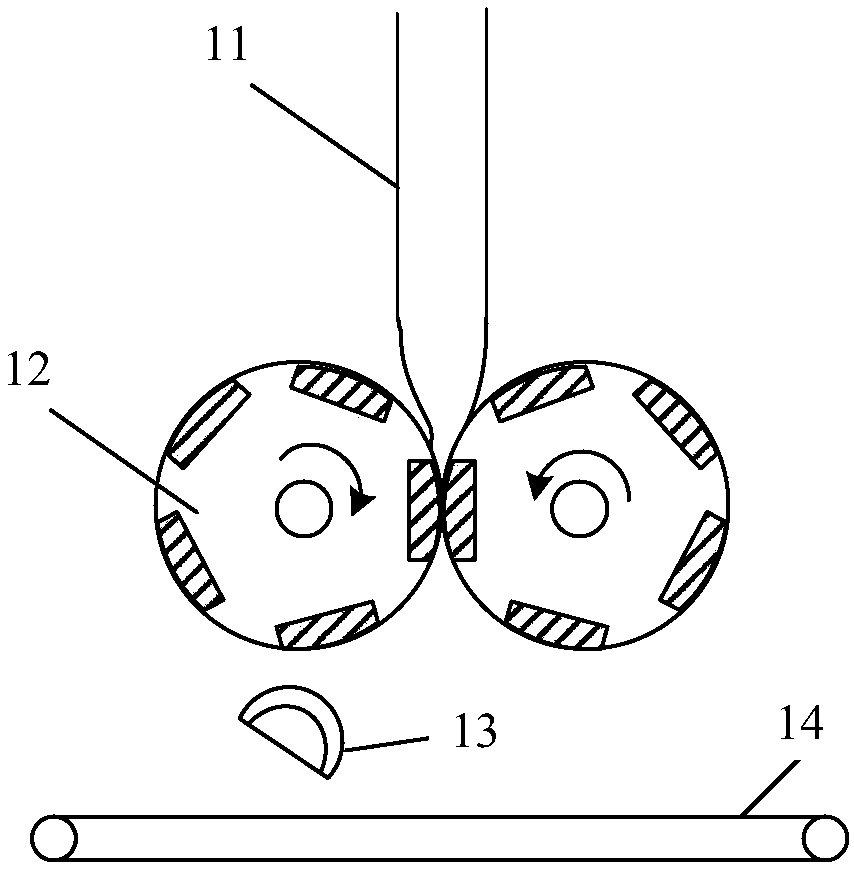

Electric arc spraying system and method for preparing micro metallurgically bonded spraying coating

InactiveCN102719781AHigh bonding strengthReduce or avoid deformationMolten spray coatingSpray coatingEngineering

The invention discloses an electric arc spraying system and a method for preparing a micro metallurgically bonded spraying coating. The method comprises the steps of: firstly connecting to form the electric arc spraying system, wherein the anode and the cathode of a first power supply are respectively connected with two spraying wires, the first power supply is connected with a first wire feeding machine, a second power supply is connected with a second wire feeding machine, a gas device is connected with an arc pistol and located at the center of the arc pistol, the two spraying wires are connected with the arc pistol, the accurate alignment of two polar wires is ensured through an alignment device and included angles of the two wires are adjusted; then fixing a workpiece on a clamp; and starting a spraying power supply and adjusting proper technological parameters to carry out spraying.. By using the technical scheme of the invention, the preparation method of the spraying coating also can be used for spraying priming layers and mass micro metallurgic bonding areas are formed between the coatings, so that matrixes can be micro metallurgically bonded with the coatings under non-overheating condition so as to improve the bonding strength.

Owner:TIANJIN UNIV

Thin-walled circular tube inner hole honing fixture

ActiveCN105290967BHigh compressive strengthReduce or avoid deformationHoning machinesGrinding work supportsHydraulic cylinderEngineering

The invention discloses a thin-wall round tube inner hole honing fixture which comprises a fixture body, a left end cover, a right end cover, three driving hydraulic cylinders and a pipeline system, wherein the left end cover and the right end cover are connected with the two ends of a thin-wall round tube through threads, and the pipeline system injects or discharges hydraulic oil in or out of the driving hydraulic cylinders. The three symmetrically arranged driving hydraulic cylinders drive the left end cover and the right end cover to move in the fixture body, thereby realizing axial mechanical tensioning of a workpiece. Emulsified liquid at given pressure is injected in a sealed space formed by the workpiece and the fixture body to improve the compressive strength of the workpiece, so that a situation that no workpiece deforms in a processing procedure can be ensured to the full extent, a rejection rate is reduced, the processing precision is improved, and the defects of the conventional thin-wall round tube inner hole processing fixture can be overcome. The thin-wall round tube inner hole honing fixture has the characteristics of simple structure, convenience in mounting and operation, wide processing range, high adaptability, long service life, low equipment cost, low operation power consumption, etc., and can also be used for boring, turning and milling of a thin-wall round tube workpiece.

Owner:ANHUI UNIV OF SCI & TECH

Voice coil assembly and sound production device

The invention discloses a voice coil assembly and a sound production device, the voice coil assembly comprises a voice coil and a voice coil skeleton, the voice coil comprises a voice coil body and avoice coil lead, and the voice coil body is formed by winding an amorphous metal wire; and the voice coil framework is arranged at the inner side of the voice coil. The voice coil assembly is small inunit resistance, and in a sound production device provided with the voice coil assembly, when a current signal is converted and output to sound wave energy, the voice coil loss is small.

Owner:GOERTEK INC

Lifting horse for lifting thin plate segment

The invention discloses a lifting horse for lifting a thin plate segment. The lifting horse comprises a main plate and a connecting plate, wherein the main plate is provided with a lifting end and a connecting end along an extending direction; the lifting end is provided with a lifting hole; the connecting plate is connected with the connecting end along the extending direction; and one end, far away from the main plate, of the connecting plate is used for connecting a mother plate of the thin plate segment. The thickness of the main plate is first thickness, the thickness of the connecting plate is second thickness, the range of the first thickness is 20 to 30 mm, and the range of the second thickness is 8 to 12 mm. The main plate and the connecting plate are spliced together along the extending direction; and relative to the prior art, the lifting horse has the following advantages that a web plate is omitted, assembling and welding of lifting horse assembling are reduced, the thin connecting plate is used for connecting the mother plate, and the influence on the mother plate of the thin plate segment by lifting horse mounting, welding and dismounting is reduced, so that deformation of the thin plate segment is reduced or avoided.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

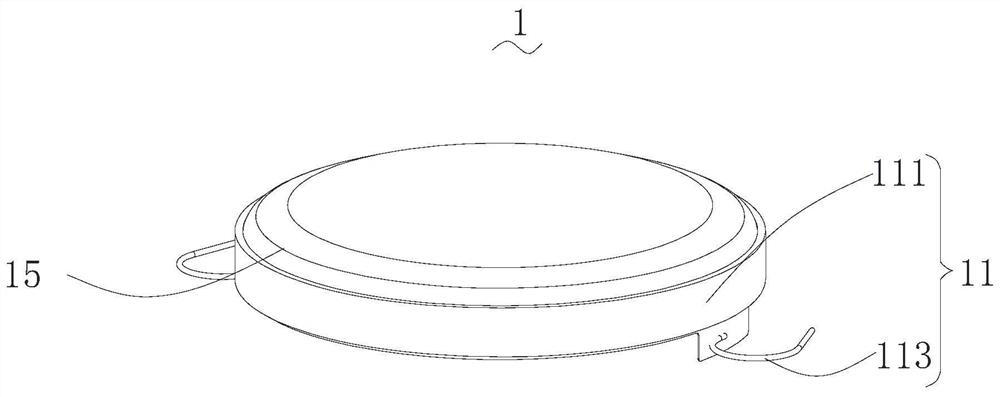

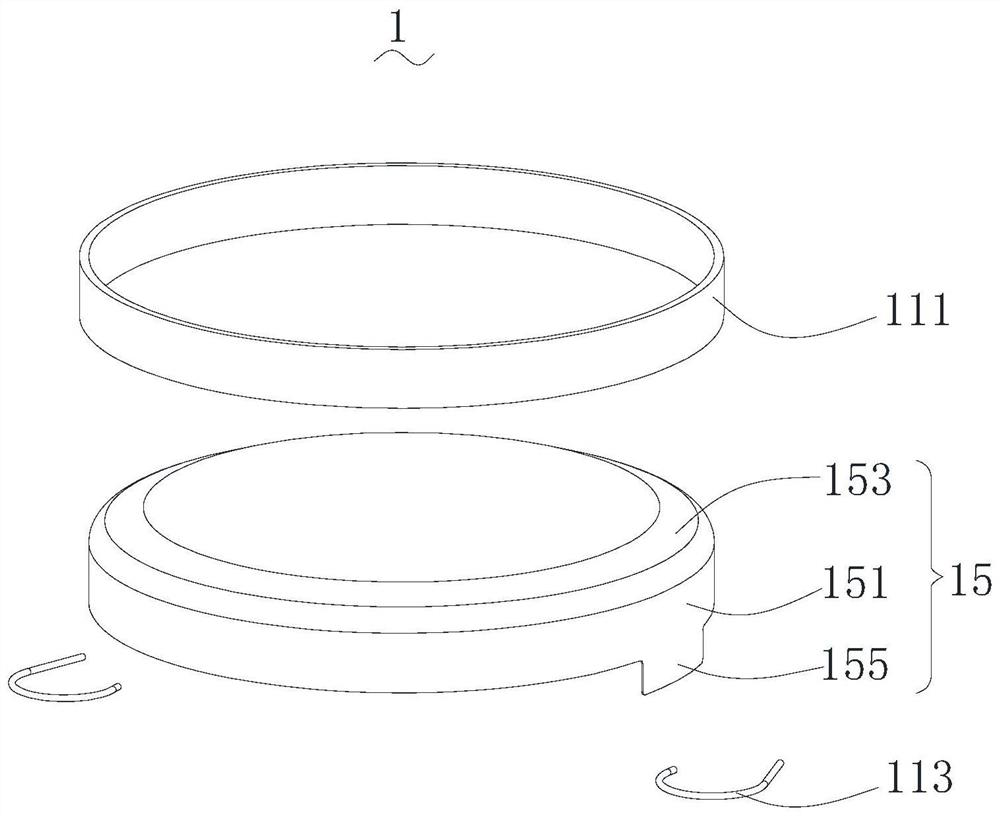

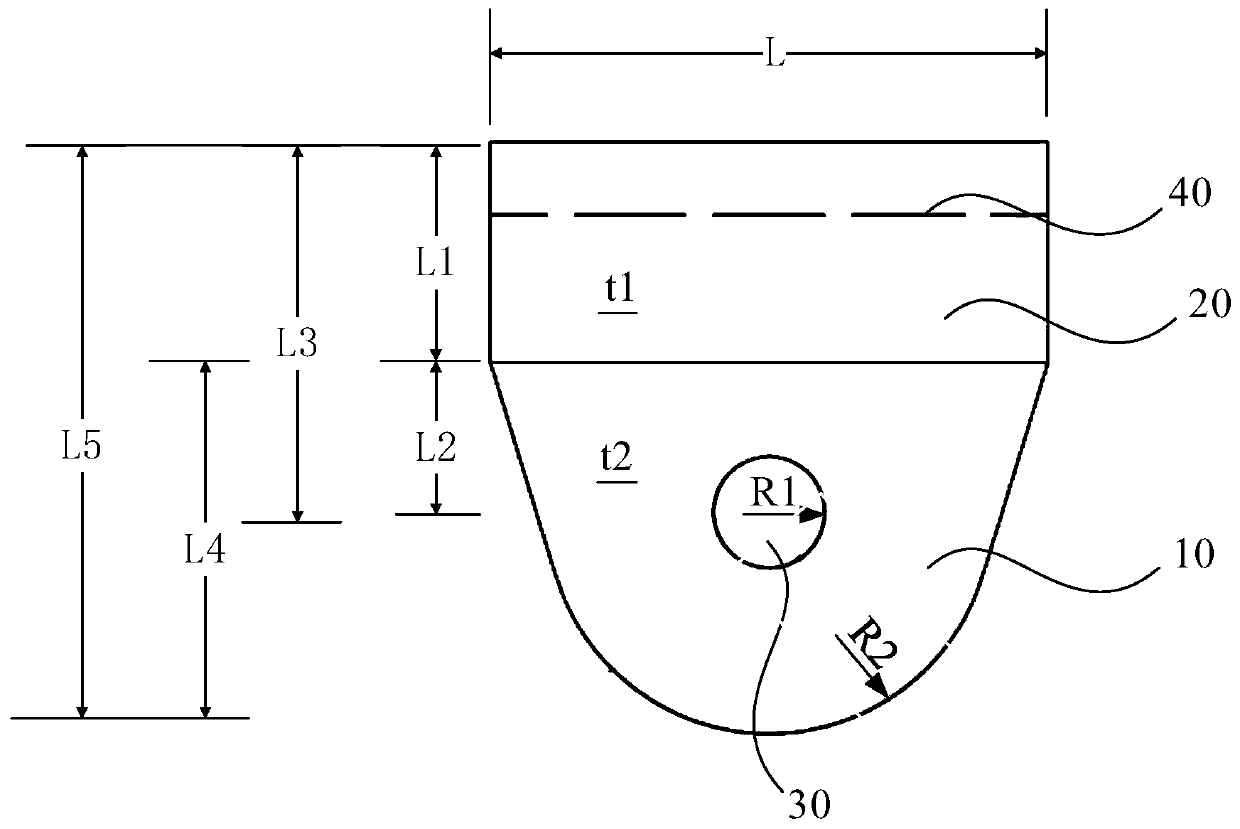

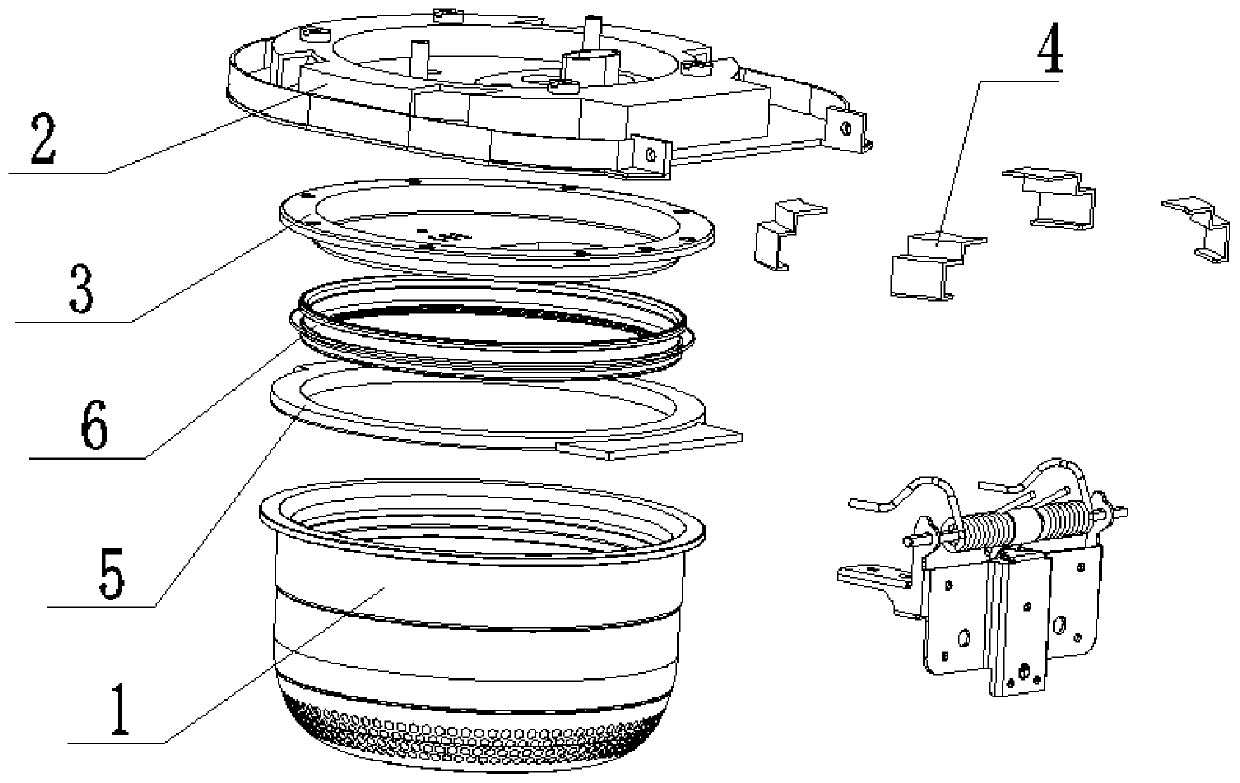

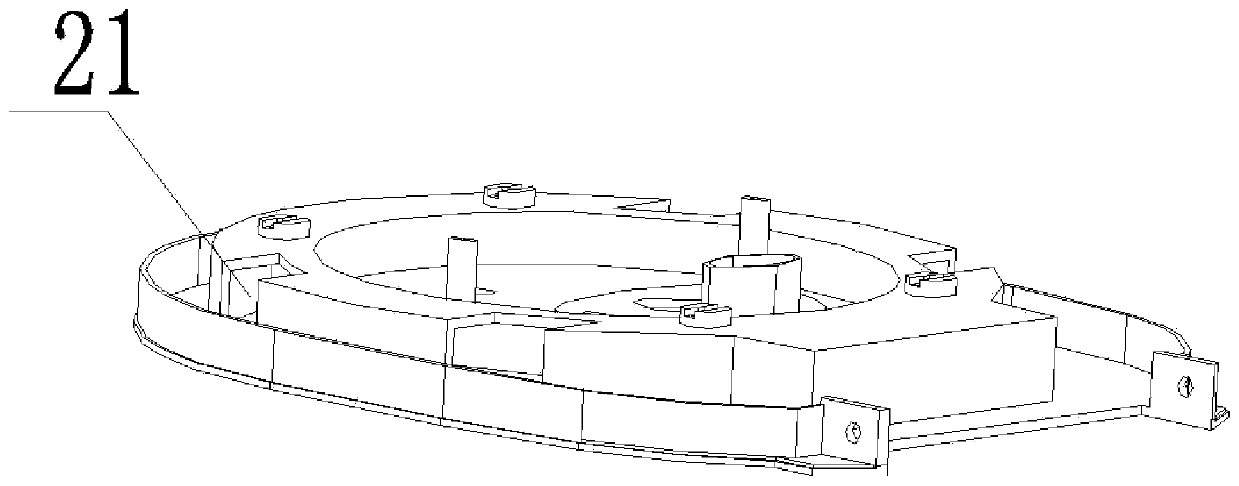

Electric cooker

PendingCN110973976AReduce or avoid deformationImprove securityCooking-vessel lids/coversCooking utensils shields/jacketsThermodynamicsEngineering

The invention provides an electric cooker. The electric cooker comprises an inner pot, an upper cover assembly which is connected with the inner pot in an openable and closable manner and comprises aninner cover, a heat preservation cover plate arranged on the inner side of the inner cover and a heat preservation cover plate support fixedly connected with the heat preservation cover plate, a gapis formed between the heat preservation cover plate and the inner cover, the upper cover assembly further comprises at least one clamping jaw, a clamping cavity is formed in each clamping jaw, and each clamping jaw is provided with a locking position enabling the heat preservation cover plate and the inner pot to be contained in the corresponding clamping cavity when the upper cover assembly is closed on the inner pot. The heat preservation cover plate and the inner pot are sealed, the heat preservation cover plate and the inner pot can be clamped and limited, the pressure in the inner pot isborne by the clamping jaw, the heat preservation cover plate and the inner pot, and a certain gap is reserved between the heat preservation cover plate and the inner cover, so that the heat preservation cover plate cannot be in contact with the inner cover in the moving process of the clamping jaw, deformation of the inner cover is effectively reduced or avoided, operation safety of the electric cooker is improved, and the service life of the electric cooker is prolonged.

Owner:GREE ELECTRIC APPLIANCES INC

Manufacturing method of roller table frame blank in continuous rolling production line

Owner:LAIWU IRON & STEEL GRP

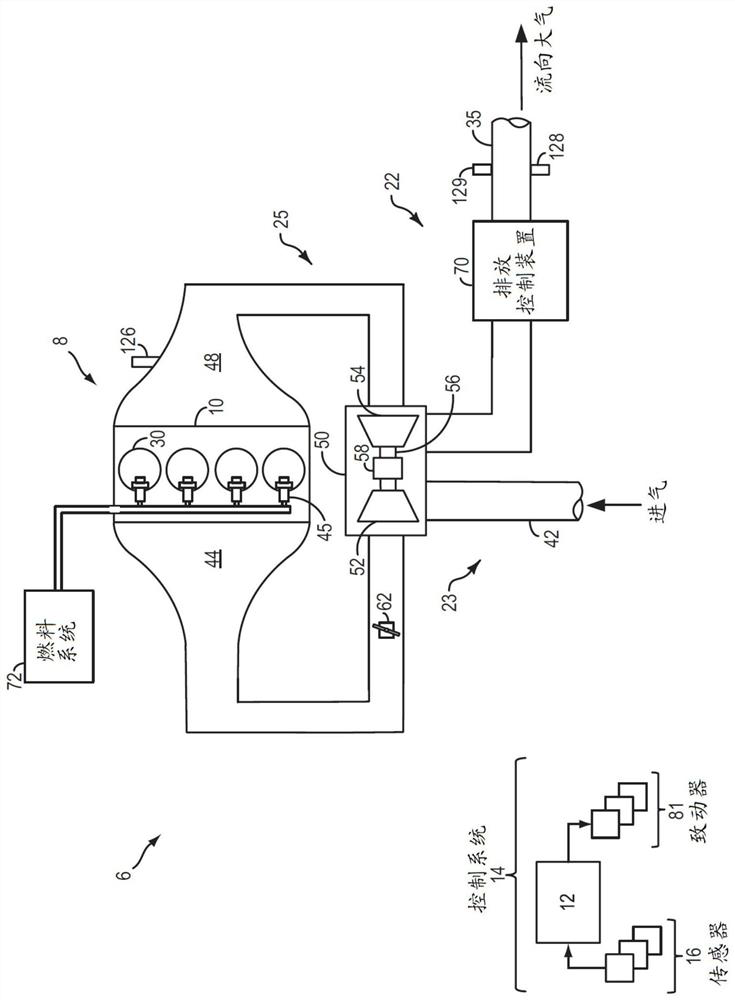

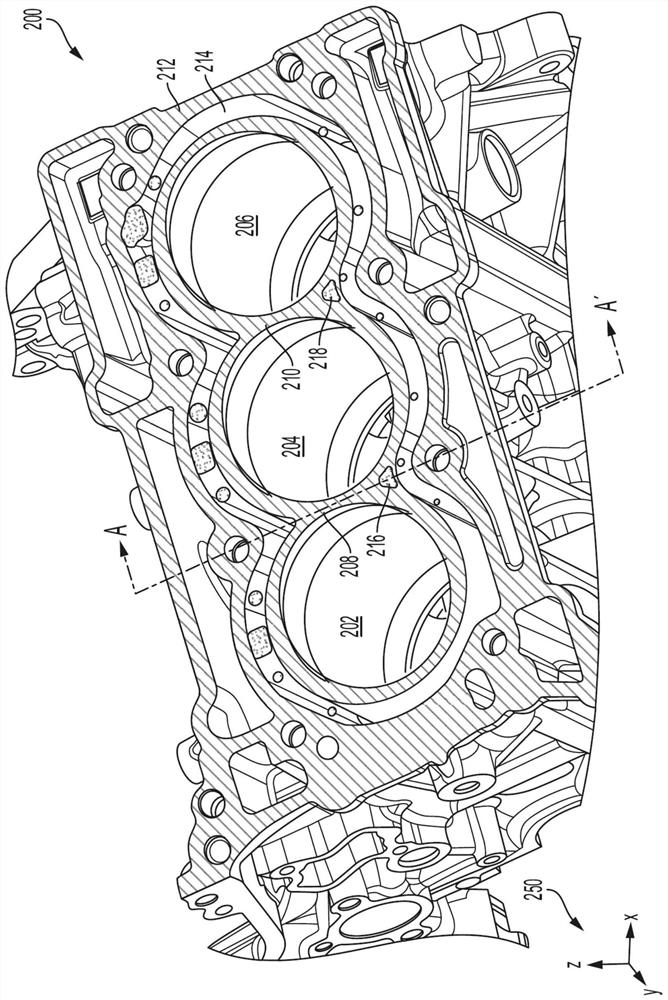

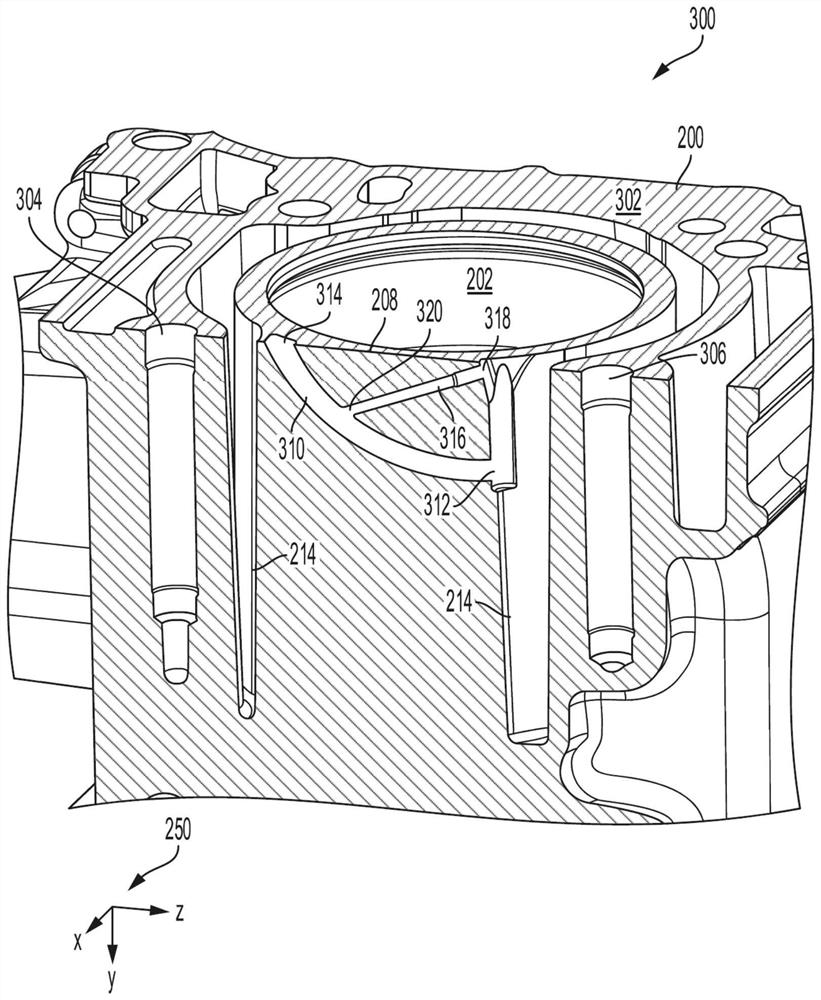

Hole bridge cooling channel

PendingCN114278452AReduce or avoid deformationIncrease surface areaLiquid coolingCasingsCylinder blockCooling channel

The present disclosure provides a "hole bridge cooling channel". The present disclosure provides a system for cooling a cylinder block via a bore bridge cooling passage. In one example, a cylinder block having a bore bridge positioned between a first cylinder and a second cylinder has at least one cooling passage positioned within the bore bridge, the cylinder block further including a coolant jacket at least partially surrounding the first cylinder and the second cylinder. An inlet of the at least one cooling channel has an area greater than an outlet of the at least one cooling channel, and at least a portion of the at least one cooling channel has a non-cylindrical geometry formed by the indwelling core.

Owner:FORD GLOBAL TECH LLC

An automobile side pedal fixing structure

ActiveCN107310481BImprove support strengthReduce or avoid deformationSteps arrangementStructural engineeringMechanical engineering

Owner:CHERY AUTOMOBILE CO LTD

Dumpling stand guide mechanism

InactiveCN107549227AImprove postureReduce or avoid deformationDough processingStructural engineeringFood engineering

The invention relates to the field of food engineering and discloses a dumpling stand guide mechanism. The dumpling stand guide mechanism comprises a vertical plate, two guide plates and two protruding parts, wherein the two guide plates and the two protruding parts are respectively and symmetrically arranged on two sides of the vertical plate; and the guide plate and the protruding part positioned on the same side of the vertical plate are sequentially arranged along the dumpling transfer direction. The invention further provides a dumpling stand guide mechanism which comprises a vertical plate and two guide plates, wherein the two guide plates are symmetrically arranged on two sides of the vertical plate; and a protruding part is formed at one end of each guide plate along the dumpling transfer direction. According to the dumpling stand guide mechanism disclosed by the invention, dumplings stand after falling, deformation of the dumplings is avoided, and the appearance is improved.

Owner:SANQUAN FOOD

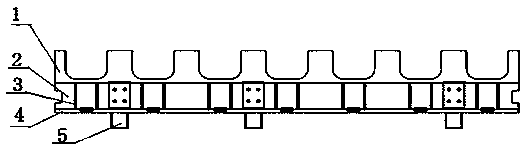

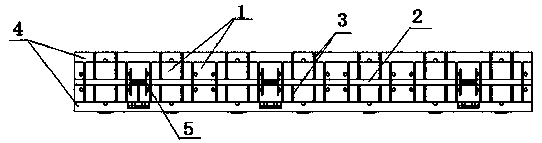

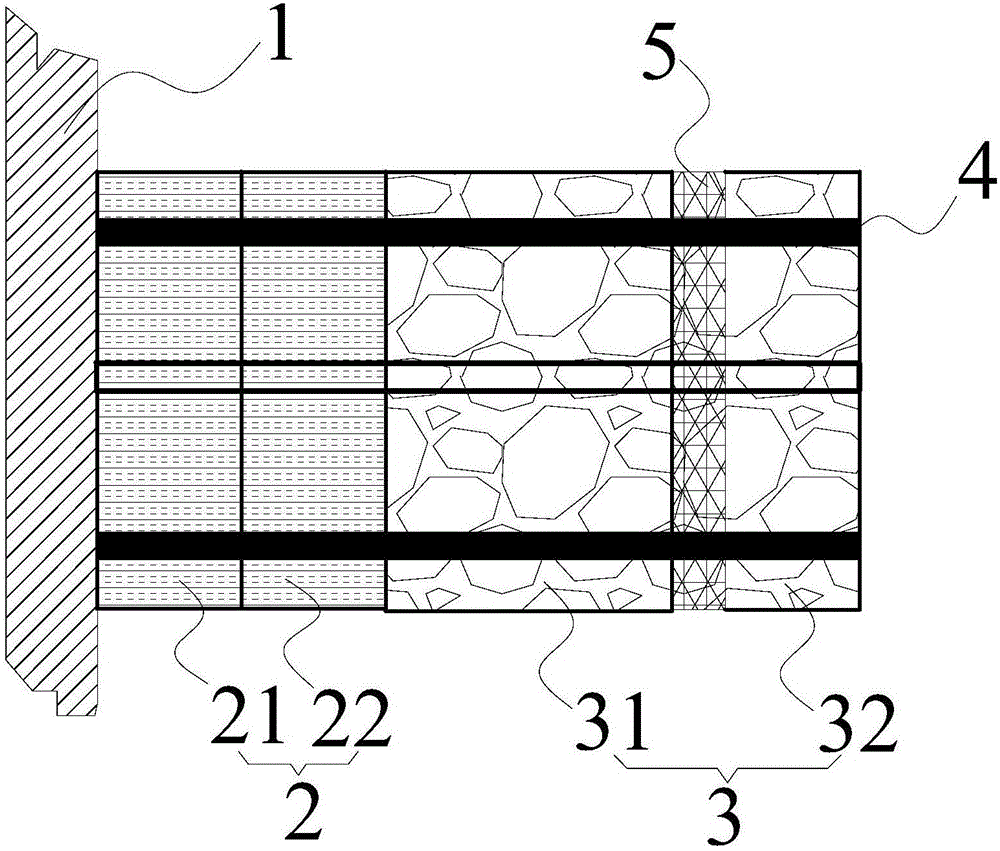

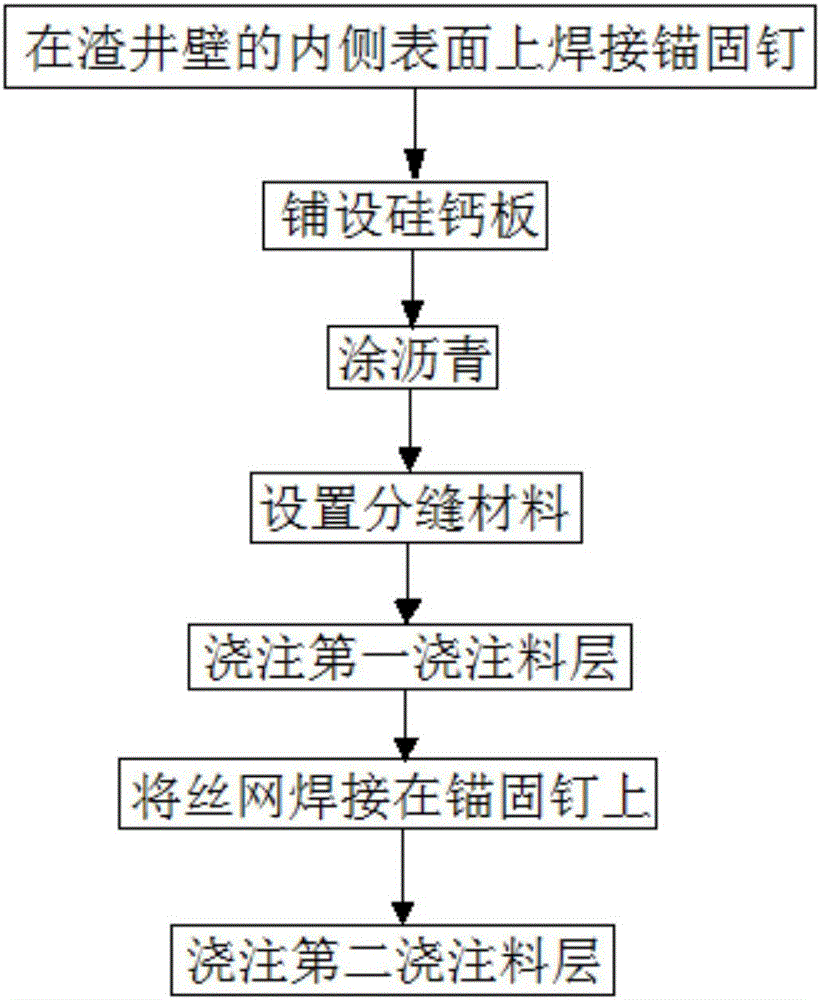

Air-cooleddry-type deslagging system, slag pit liner and construction method thereof

ActiveCN105910122AFully supportedReduce or avoid deformationLighting and heating apparatusCalcium silicateThermal insulation

The invention relates to a field of deslagging equipment and discloses an air-cooled dry-type deslagging system, a slag pit liner and a construction method thereof. The slag pit liner is arranged on the inner side surface of a slag pit wall (1) and includes a calcium silicate board layer (2) comprising a calcium silicate board; a fireproof castable layer (3) arranged on a side, away from the slag pit wall (1), of the calcium silicate board layer (2) in a fitting manner; an anchoring nail (4) connected to the inner side surface of the slag pit wall (1) and penetrates through the calcium silicate board layer (2) and the fireproof castable layer (3) and extends. According to the invention, when large blocks of slag fall onto the fireproof castable layer (3), the calcium silicate board layer (2) can provide full support and the calcium silicate board can be laid on the slag pit wall (1) so as to form the calcium silicate board layer (2) to act as a thermal insulation layer. The invention has advantages of good protection effect, simple construction technology and the like.

Owner:CHINA SHENHUA ENERGY CO LTD +2

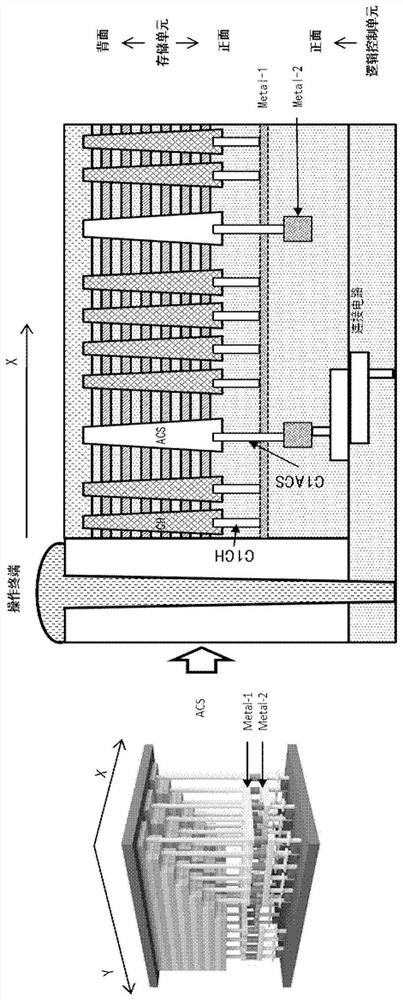

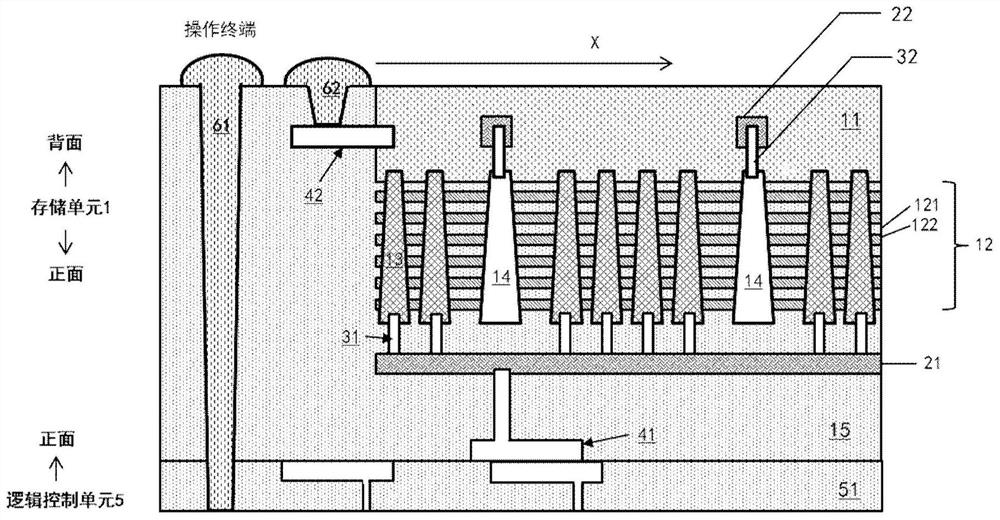

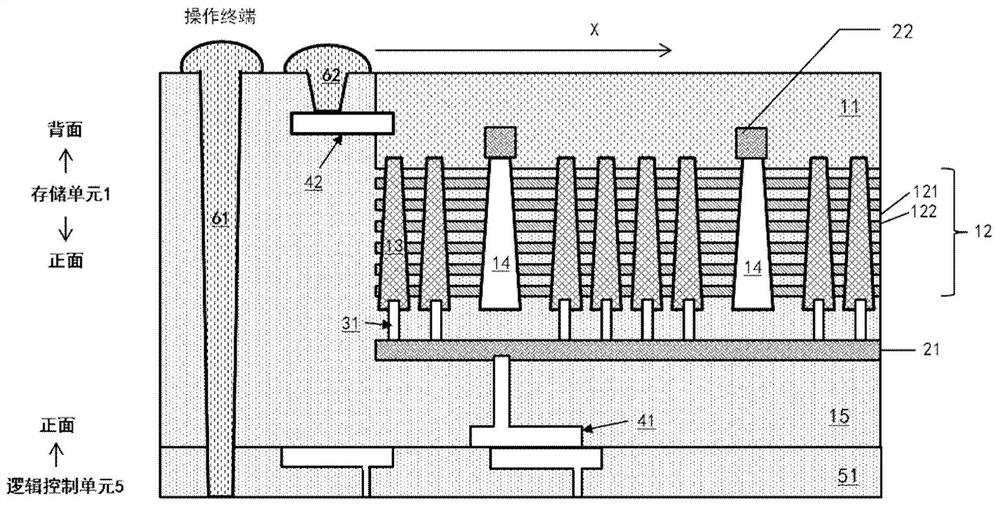

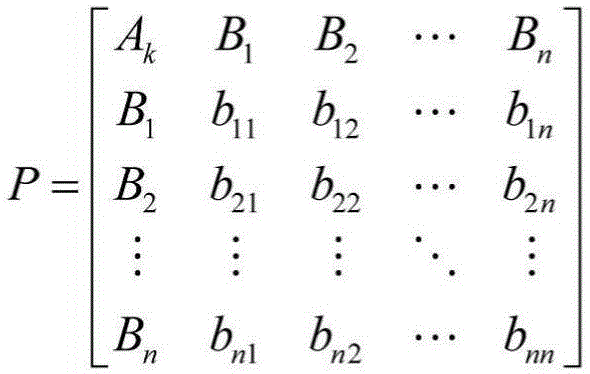

Three-dimensional memory and its manufacturing method

ActiveCN110379811BReduce or avoid deformationAvoid deformationSolid-state devicesSemiconductor devicesMemory cellEngineering

A three-dimensional memory and its manufacturing method. The three-dimensional memory includes: a storage unit and a logic control unit that are bonded to each other on the front, and the logic control unit is connected to a control circuit. It is characterized in that the second metal wire of the storage unit and the first The metal wires are respectively arranged on the upper and lower sides of the channel layer in the memory unit, and both the first metal wire and the second metal wire are electrically connected with the control circuit. By arranging the second metal wire and the first metal wire respectively on the upper and lower sides of the channel layer in the memory cell, by separately arranging the first metal wire and the second metal wire so that the distribution of the metal wire becomes balanced, reducing or The deformation of the storage unit is avoided; at the same time, the metal wiring is simplified by scattered arrangement of the first metal wire and the second metal wire, so that the layout of the connection circuit between the first metal wire and the second metal wire and the control circuit is relatively simple, and the connection is improved. Reliability, avoiding connection reliability problems in the prior art caused by complex layout and process problems.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

A Hazard Assessment Method for High Rock Slopes

InactiveCN103268420BImprove digging effectEliminate one-sidednessSpecial data processing applicationsIndex systemRisk evaluation

The invention discloses a method for evaluating risks of a high rock slope. The method for evaluating the risks of the high rock slope comprises the following steps: (1) constructing a risk evaluation index system, (2) defining classification levels, (3) carrying out dimensionless processing on indexes, (4) determining comprehensive weight of evaluation indexes, and (5) evaluating risk states of the slope. By means of the method for evaluating the risks of the high rock slope, factors which influence stability of the slope are comprehensively analyzed and identified, a subjective weighting method and an objective weighting method are combined, and the attribute recognition theory and the maximum attribute measure principle are adopted to indentify the risk states of the slope. Compared with other methods in the prior art, the method for evaluating the risks of the high rock slope overcomes the defects that a safety factor method can not express the change degree of the risks of the slope and reflect uncertainty and randomness of the risks of the slope, subjective preference and objective laws are comprehensively measured, evaluation and judgment are more reasonable, and high engineering significance and practical values are possessed.

Owner:HOHAI UNIV

Construction method of cast-in-place pile for drainage pump station

ActiveCN109440762BGuaranteed verticalityQuality assuranceBulkheads/pilesArchitectural engineeringStructural engineering

The invention discloses a construction method of a cast-in-place pile for a draining pumping station. The construction method includes the following steps that firstly, construction is prepared; secondly, measurement lofting is performed; thirdly, a positioning piece is installed; fourthly, a steel casing is embedded; and fifthly, concrete pouring is performed. The technical scheme of the construction method of the cast-in-place pile for the draining pumping station is provided, the structural design is reasonable, construction is convenient, and before embedding of the steel casing, firstly the positioning piece is installed at a constructing pile position; and due to the design of the positioning piece, the steel casing is firmly limited in a limiting guiding pipe, the perpendicularity of the steel casing during subsequent embedding is guaranteed, it is effectively avoided that the steel casing deviates, the subsequent embedding step of the steel casing is simplified, accurate positioning of the embedded position of the steel casing is improved, the positioning piece can also be used for compacting and shaping soil around a pile column hole, and deformation and collapse of a pilecolumn hole opening are effectively prevented.

Owner:浙江景昌建设有限公司

Connecting device

InactiveCN101968210BAct as a buffer against windReduce forceLighting support devicesIlluminated signsEngineeringWind power

The invention provides a connecting device. The connecting device comprises a lower base, an upper base, two connecting rods, two compression springs and a pin, wherein the lower base comprises a lower bottom plate and a bulge on the lower bottom plate; the upper base comprises an upper bottom plate and a convex shell on the upper bottom plate; the bulge is arranged in a cavity of the convex shell; two through holes into which the connecting rods are inserted are formed at the two ends of the lower bottom plate; two through holes into which the connecting rods are inserted are also formed at the two ends of the upper bottom plate; the rod parts of the connecting rods pass through the through holes of the lower bottom plate, the through holes of the upper bottom plate and the compression springs in turn; a pin hole is also formed on the bulge on the lower bottom plate; pin holes are formed on the two sides of the convex shell on the upper bottom plate; the pin passes through the pin hole on one side of the convex shell, the pin hole on the bulge, and the pin hole on the other side of the convex shell in turn; the pin hole on the bulge is strip; and the pin can relatively move in the pin hole on the bulge in the axial direction of the connecting rods. The invention has the advantage that: when outside wind power is high, the wind resistance of a light box which is arranged by the connecting device provided by the invention is improved.

Owner:HANGZHOU AOTU LIGHT TECH

A processing method for a thin-wall separated solid cage

The invention discloses a method for machining a thin-wall separation type solid retainer, and relates to the technical field of design and manufacture of retainers. According to the method, the problems that an existing thin-wall separation type bearing solid retainer is large in machining difficulty, easy to deform, the interior of the retainer, the outer diameter precision and the rivet hole machining precision are low, and the product machining quality is difficult to guarantee are solved; the method for machining the thin-wall separation type solid retainer is realized through the following steps that 1, finely turning is sequentially carried out on a first plane and a second plane, the outer diameter is coarsely ground and finely turning is carried out on the inner diameter; 2, solidsolution strengthening is carried out; 3, turning are both carried out on two planes ; 4, the finely turning is carried out on the outer diameter; 5, the inner diameter is finely ground; 6, a rivet hole is drilled; 7, a bolt is inserted; 8, a pocket is drilled and milled; 9, the outer diameter is finally milled; 10, final turning is carried out on the inner diameter; 11, the bolt is removed, deburring is carried out, and finishing is carried out; and 12, fluorescent permeation flaw detection is carried out. The method is used for improving the interior of the retainer, the outer diameter precision and the rivet hole machining precision of the thin-wall separation type solid retainer.

Owner:AVIC HARBIN BEARING

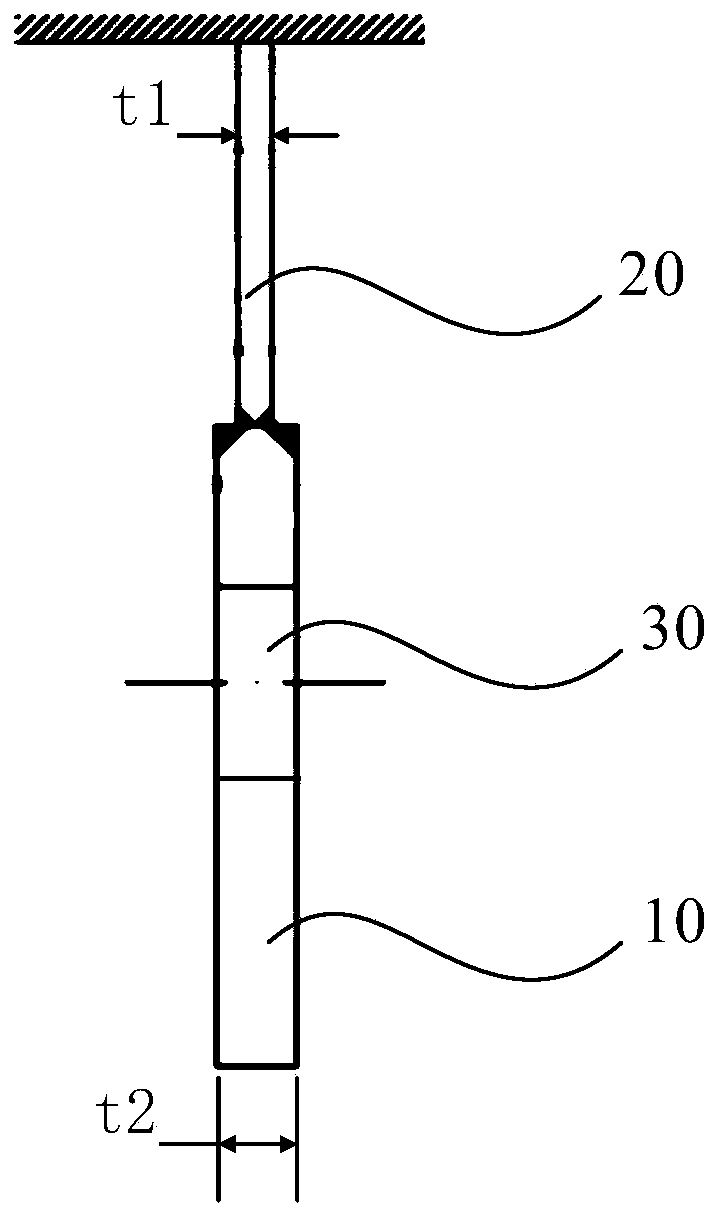

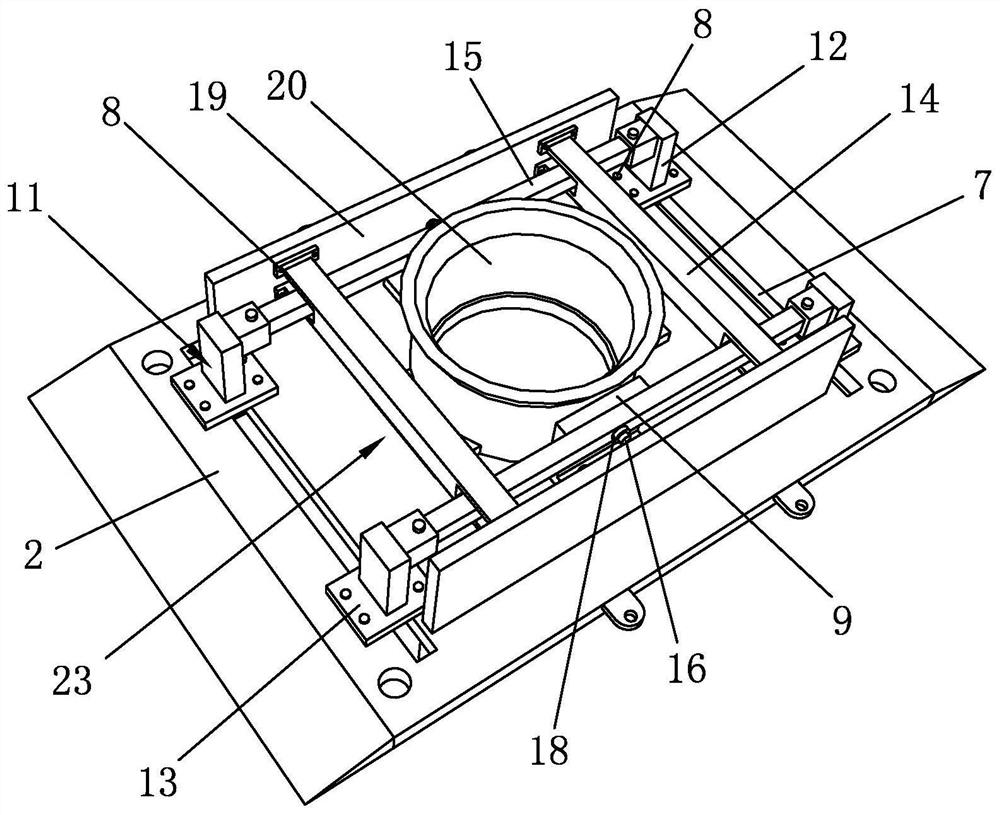

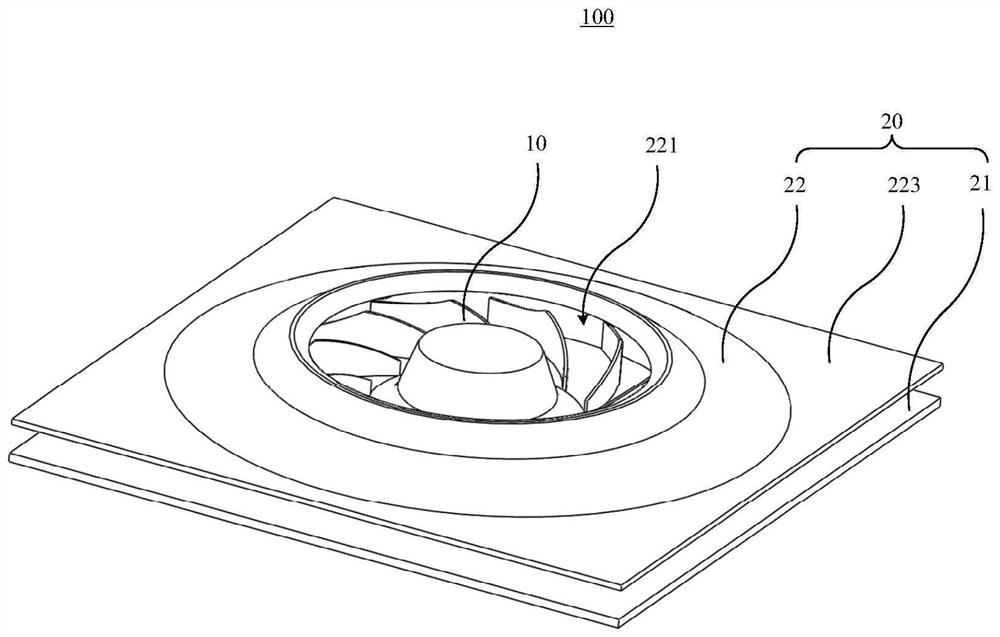

Air inlet device and refrigeration equipment

PendingCN114109912AStable gap widthIncrease gap widthPump componentsPump installationsImpellerAir volume

The invention relates to an air inlet device and refrigeration equipment, the air inlet device comprises an impeller and an air guide mechanism, the impeller comprises a mounting disc and a plurality of blades, and the blades are connected to the mounting disc in a cyclone shape; the air guide mechanism comprises a bottom plate, an air guide ring and a plurality of supporting columns, an air inlet is formed in the air guide ring, the air guide ring and the bottom plate are connected through the supporting columns, a containing space is formed between the air guide ring and the bottom plate, and an air outlet communicated with the containing space is formed in the circumferential direction of the air guide mechanism; the impeller is located in the containing space, and an airflow gap is formed between the air guide ring and the impeller. According to the air inlet device, the air guide ring and the bottom plate which are connected through the supporting columns are arranged, so that the possibility of deformation of the air guide ring is reduced or avoided, then the situation that the width of the gap between the air guide ring and the impeller is increased is avoided, and the problem that in the prior art, the air inlet amount is lost due to deformation of the air guide ring is solved.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +2

Paddle arm connecting assembly and aircraft

Owner:SICHUAN AEE AVIATION TECH CO LTD

oven

ActiveCN111671322BReduce or avoid deformationAvoid deformationRoasters/grillsMechanical engineeringPhysics

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Process for preventing anodic oxidation deformation of bolt bottom plate of DaVinci test socket

PendingCN111276859AReduce or avoid the impactAvoid influenceContact member manufacturingSurface reaction electrolytic coatingAdhesive beltAcid corrosion

The invention discloses a process for preventing anodic oxidation deformation of a bolt bottom plate of a DaVinci test socket. The process is characterized by comprising the following operation steps:step 1, reserving allowance on the bolt bottom plate before first anodic oxidation; step 2, carrying out anodic oxidation treatment on the surface of the bolt bottom plate; step 3, cutting off the allowance reserved on the bolt bottom plate, and processing the outline of the product; meanwhile, machining holes needing to be conducted; step 4, protecting all areas except the outer contour edge ofthe product by using a high-temperature-resistant and acid-corrosion-resistant adhesive tape; step 5, carrying out secondary anodic oxidation treatment; the processis simple in process and convenientto operate; the influence of heat generated by anodic oxidation treatment on the positions of the pin mounting holes is effectively reduced, the change of the shapes and the positions of the small holes can be effectively reduced or avoided, the quality stability in the product technological process is ensured, and mass production becomes possible.

Owner:江苏先锋精密科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com