Air-cooleddry-type deslagging system, slag pit liner and construction method thereof

A construction method and air-cooled technology, applied in the field of slag discharge equipment, can solve the problems of complex, easy castable, falling off construction process, etc., and achieve the effect of avoiding deformation and stress, simple construction process, and loose environmental conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

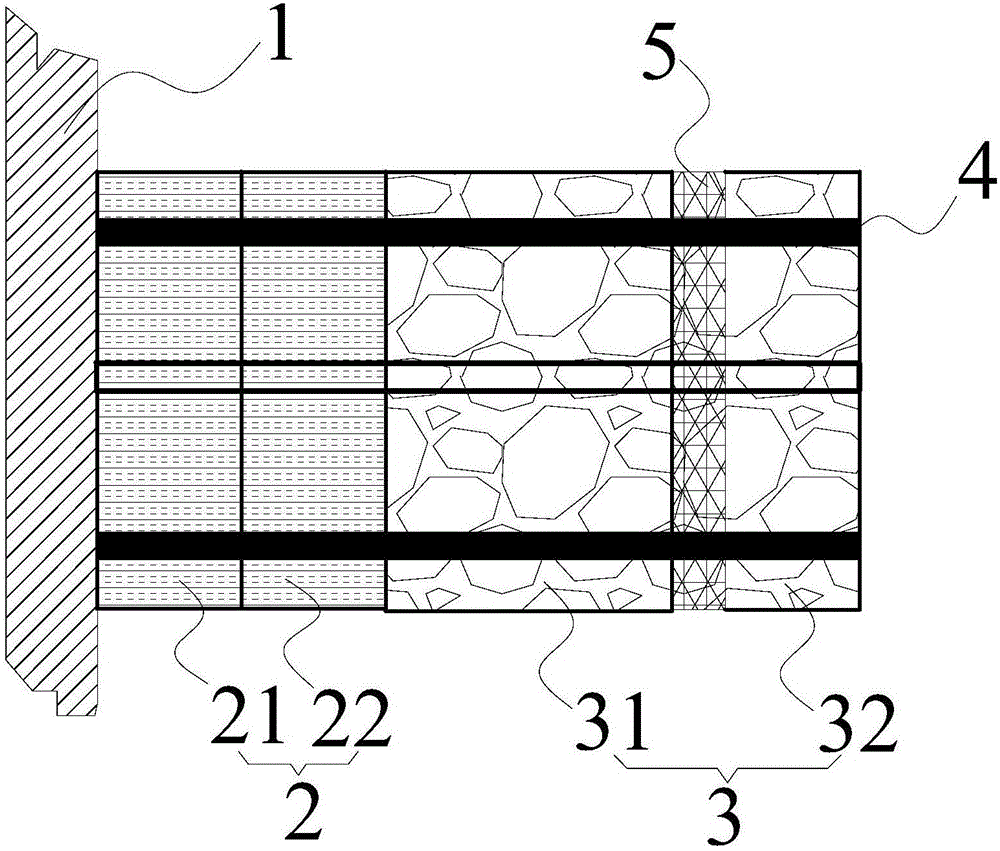

[0034] In the present invention, in the case of no contrary description, the orientation words "longitudinal" and "transverse" used generally refer to the horizontal direction along the inner surface of the slag shaft wall 1 and the direction perpendicular to the horizontal direction, for example figure 1 Perpendicular to paper orientation and vertical orientation shown in . The orientation word "thickness" used generally refers to the direction perpendicular to the inner surface of the slag shaft wall 1, for example figure 1 in the left-right direction shown in .

[0035] refer to figure 1 , shows the cross-sectional structure of the slag well lining accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com