Process for preventing anodic oxidation deformation of bolt bottom plate of DaVinci test socket

A technology of anodizing and testing sockets, used in test/measurement connectors, contact manufacturing, electrolytic coatings, etc., can solve problems affecting assembly accuracy and function, test pin damage, etc., to ensure stability, easy operation, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the purpose of the invention, technical solutions and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods;

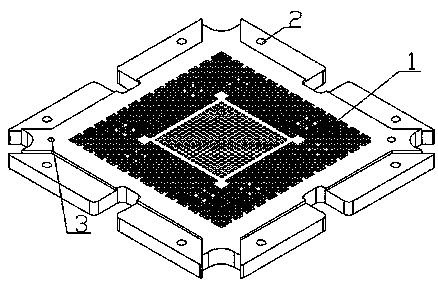

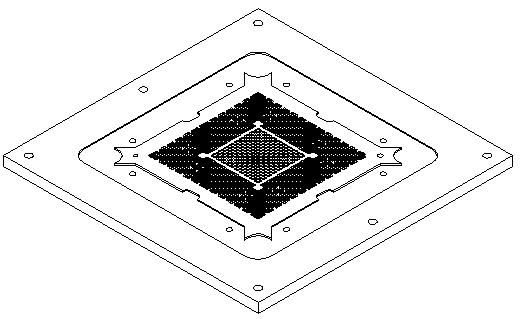

[0013] In the accompanying drawings: the anti-anodizing deformation process of the pin bottom plate of Da Vinci test socket, which is characterized in that it includes the following operation steps: Step 1, reserve a margin on the pin bottom plate before anodizing for the first time: the length and width of the cutting material are in Add 30-40mm to the maximum shape of the pin bottom plate, and increase the thickness by 1-2mm; Step 2, anodize the pin bottom plate: connect the pin bottom plate to the positive electrode, and the liquid in the oxidation tank to the negative electrode, and power on for 90-120 minutes to make it A layer of aluminum oxide film with a thickness of 40μm-60μm is forme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com