Method for extracting polyphenol from canna edulis ker waste residue

A kind of canna, waste residue technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

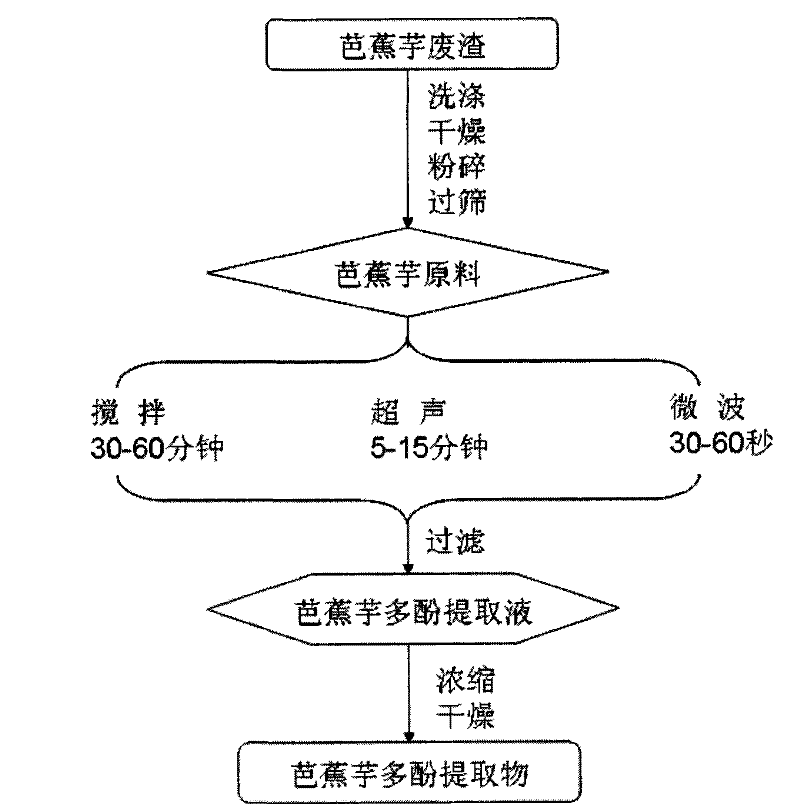

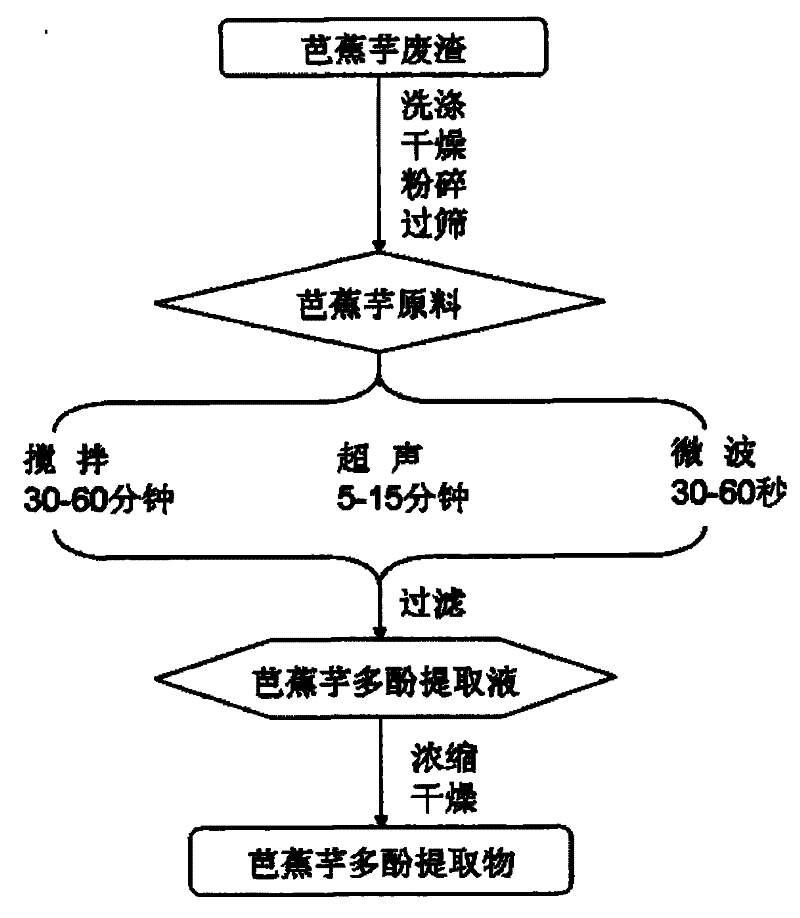

Method used

Image

Examples

Embodiment 1

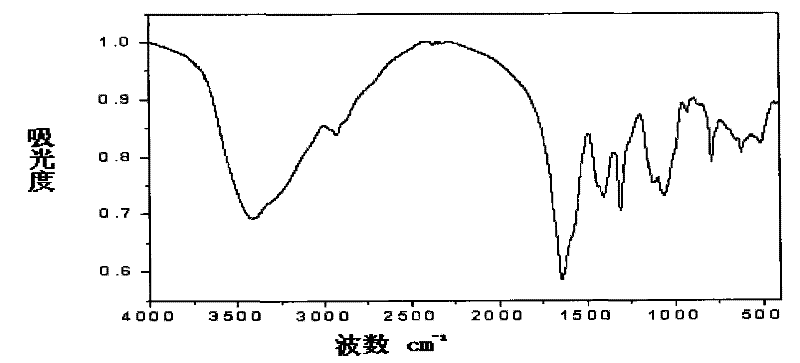

[0021] Be that 70% ethanol washes canna waste residue with the volume fraction, until with phenol-sulfuric acid method (see Liu Lichao, Huang Honglin, Lai Zhengquan, Liao Huijun. Phenol sulfuric acid method is measured gardenia water-soluble polysaccharide content. Anhui Medicine, 2005, 9 (11 ): 831-832) to detect the waste residue as negative; then the filter residue was dried at 20°C, pulverized, and passed through a 30-mesh sieve to obtain the pulverized filter residue; 10g of the filter residue was weighed, and 500ml mass fraction was added to be an aqueous solution of 2.5% sodium sulfite , stirring and extracting at 800 rpm at 2°C for 30 minutes, filtering, re-extracting the residue once, and combining the filtrates to obtain a polyphenol extract from canna polyphenols; after concentrating the polyphenol extract from canna polyphenols under reduced pressure, vacuum drying at 40°C to obtain polyphenols from canna polyphenols phenol. Use infrared spectrum to identify the pr...

Embodiment 2

[0023] Wash the canna waste residue repeatedly with ethanol with a volume fraction of 75%, until the waste residue detected by the phenol-sulfuric acid method is negative; then the filter residue is dried at 25°C, crushed, and passed through a 60-mesh sieve to obtain the crushed filter residue; 10g filter residue, add 400ml mass fraction and be the aqueous solution of 1% sodium sulfite, power is 1000W microwave treatment 30 seconds, filter, residue is extracted once again, merge filtrate, obtain canna polyphenol extract; After concentrated under pressure, freeze-dried to obtain the polyphenols of canna taro.

Embodiment 3

[0025] Wash the canna waste residue repeatedly with ethanol with a volume fraction of 80%, until the waste residue detected by the phenol-sulfuric acid method is negative; then the filter residue is dried at 30°C, crushed, and passed through an 80-mesh sieve to obtain the crushed filter residue; 10g filter residue, add 500ml mass fraction and be the aqueous solution of 5% ascorbic acid, frequency is 40000Hz, power is the ultrasonic extraction of 100W 10 minutes, filter, residue is extracted again, merge filtrate, obtain canna polyphenol extract; After the polyphenol extract is concentrated under reduced pressure, it is freeze-dried to obtain the polyphenol of canna taro.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com