Three-dimensional memory and its manufacturing method

A manufacturing method and memory technology, which are applied to semiconductor devices, electrical solid-state devices, electrical components, etc., can solve the problems of complex circuit design and layout, and achieve the effects of avoiding connection reliability problems, simple layout, and avoiding deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

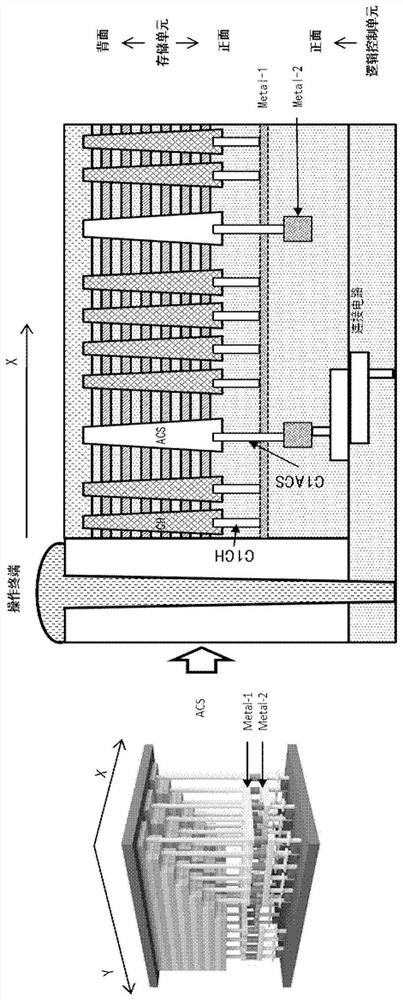

[0059] In a first exemplary embodiment of the present disclosure, a three-dimensional memory is provided.

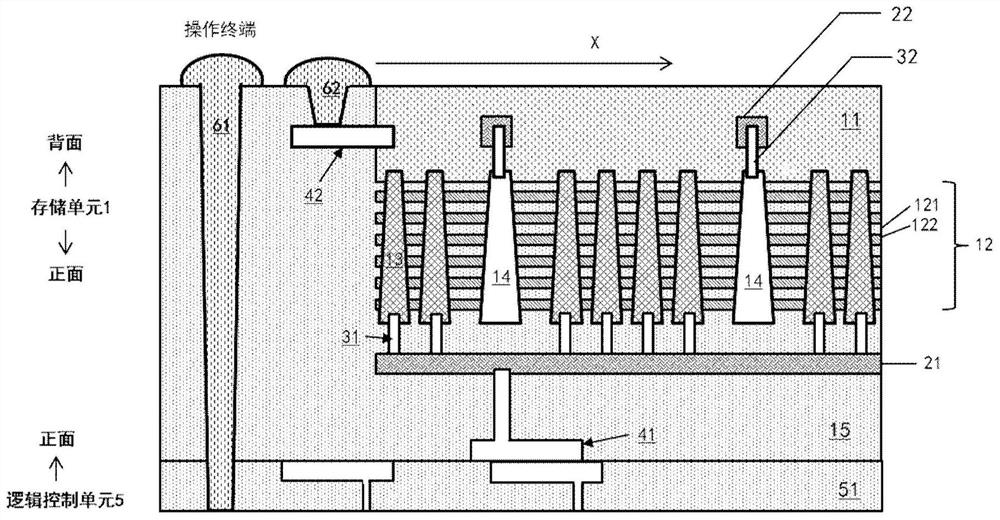

[0060] figure 2 It is a schematic cross-sectional view of the three-dimensional memory according to the first embodiment of the present disclosure.

[0061] refer to figure 2 As shown, the three-dimensional memory of the present disclosure includes: a storage unit 1 and a logic control unit 5 that are bonded to each other on the front side, and the logic control unit 5 is connected to the control circuit. It is characterized in that the second metal wire 22 of the storage unit 1 The first metal line 21 and the first metal line 21 are respectively arranged on the upper and lower sides of the channel layer 12 in the memory cell 1 , and both the first metal line 21 and the second metal line 22 are electrically connected to the control circuit.

[0062] Figure 2-Figure 3 Among them, the first metal wire 21 and the second metal wire 22 are directly or indirectly led out...

no. 2 example

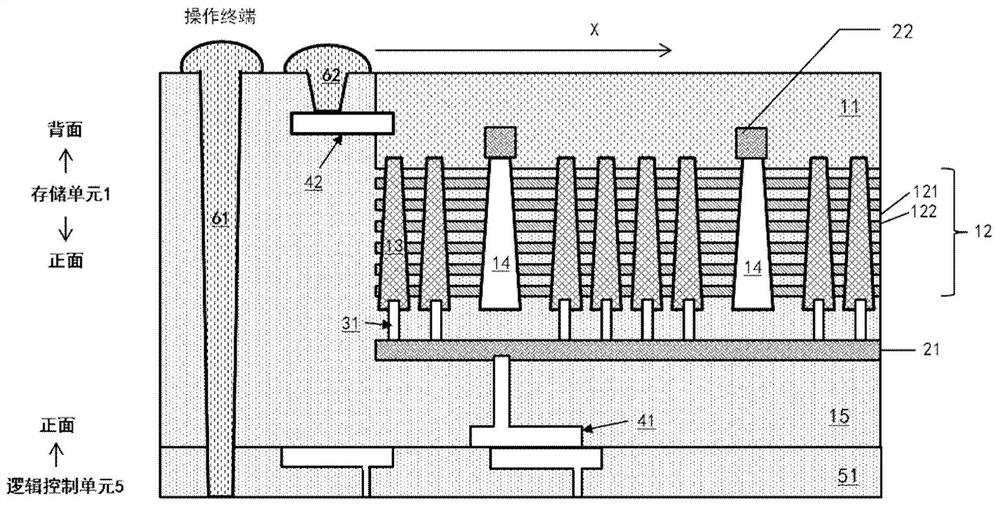

[0075] In a second exemplary embodiment of the present disclosure, a three-dimensional memory is provided.

[0076] image 3 It is a schematic cross-sectional view of a three-dimensional memory according to a second embodiment of the present disclosure. Components in this embodiment that are the same as those in the first embodiment are denoted by the same reference numerals.

[0077] refer to image 3 As shown, the difference between the three-dimensional memory of this embodiment and the three-dimensional memory of the first embodiment is that the bottom of the common selection line 14 in the three-dimensional memory of this embodiment is directly electrically connected to the second metal line 22, The second connection hole 32 in the first embodiment does not exist.

no. 3 example

[0079] In a third exemplary embodiment of the present disclosure, a method for fabricating a three-dimensional memory is provided.

[0080] Figure 4 It is a flowchart of a manufacturing method for manufacturing the three-dimensional memory shown in the first embodiment according to the third embodiment of the present disclosure.

[0081] refer to Figure 4 As shown, the manufacturing method of the three-dimensional memory of the present disclosure includes:

[0082] Step S31: arranging the second metal line and the first metal line respectively on the upper and lower sides of the channel layer in the memory cell;

[0083] In this embodiment, step S31 includes:

[0084] Sub-step S31a: preparing a substrate 11;

[0085] Sub-step S31b: arranging a second metal wire 22 in the substrate 11 and insulating it from the substrate 11;

[0086] Sub-step S31c: Continue to epitaxially grow the substrate material on the substrate 11 on which the second metal line 22 has been laid, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com