Construction method of cast-in-place pile for drainage pump station

A construction method and drainage pumping station technology, applied in the direction of sheet pile wall, foundation structure engineering, building, etc., can solve the problems of increasing construction cost and construction period, adverse effects of hole verticality, and collapse at the hole of enlarged pile, etc. , to achieve the effect of ensuring verticality, reducing the probability of collapse, and avoiding serious inclination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

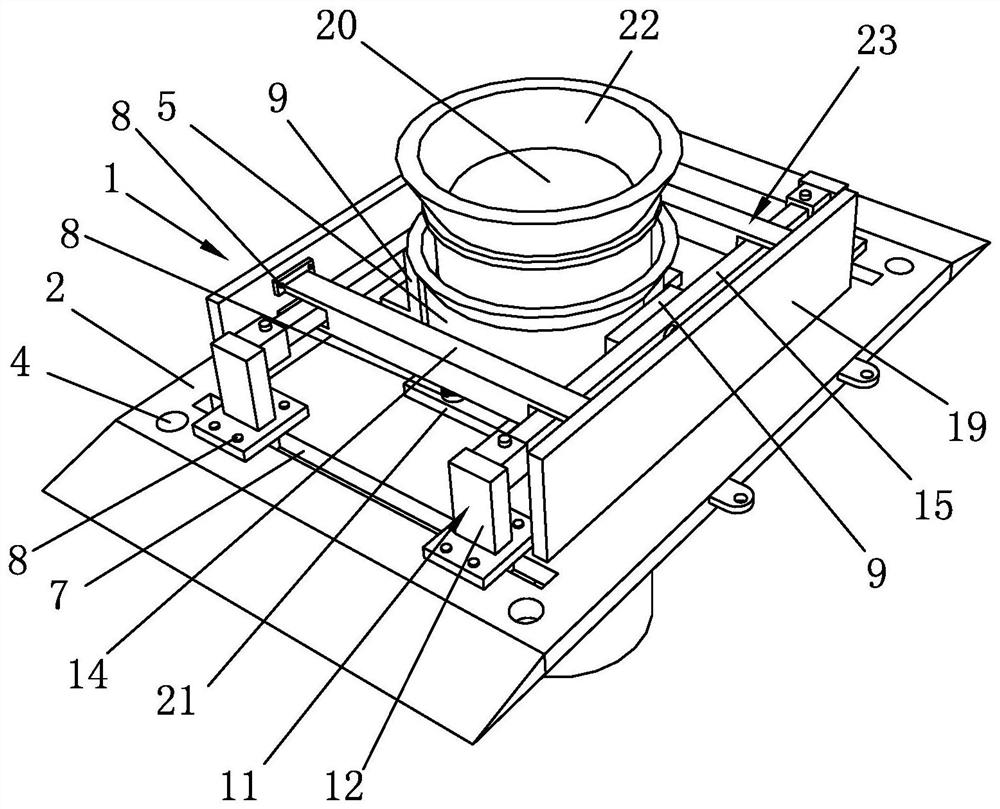

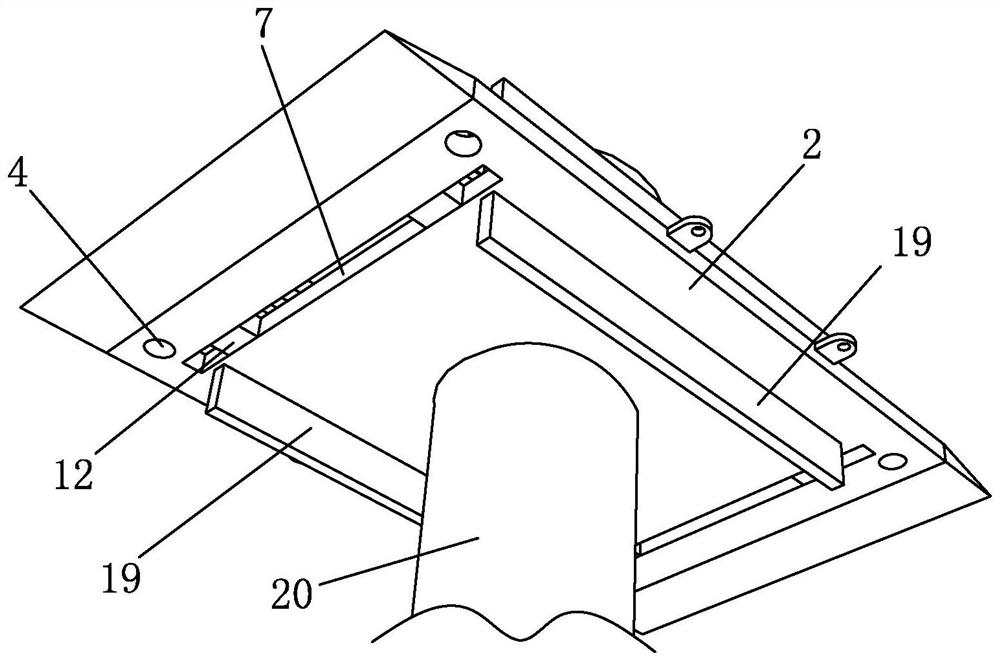

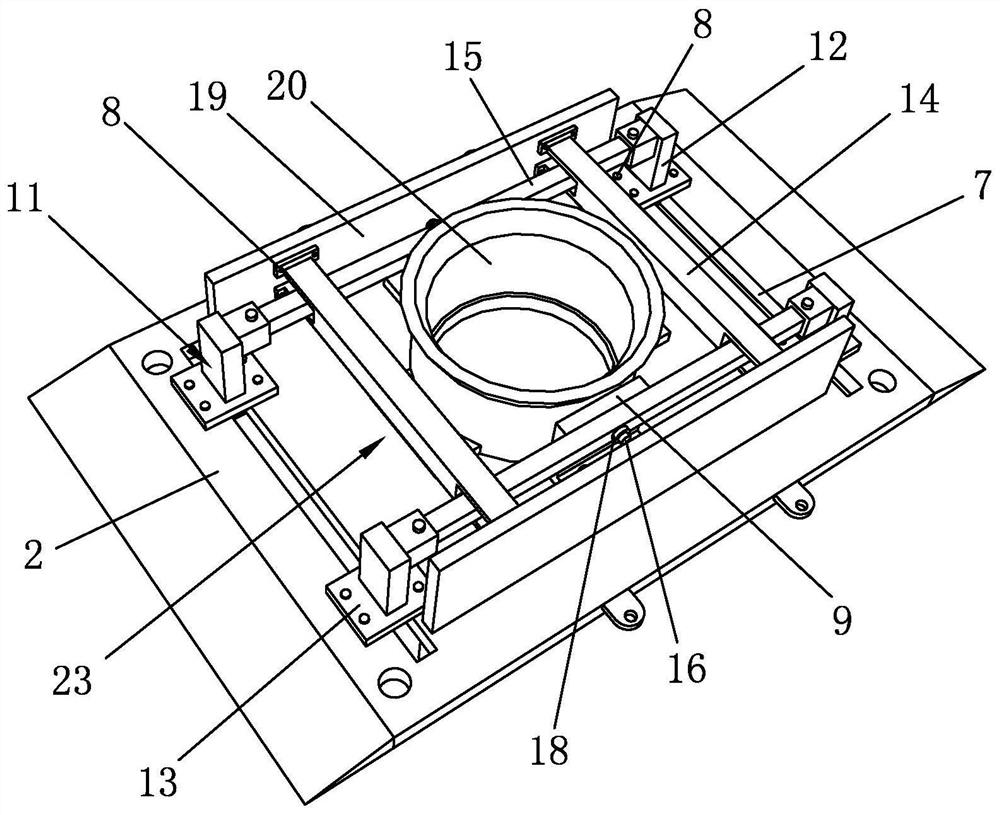

[0042] Such as Figure 1 to Figure 8 Shown, be the construction method of a kind of drainage pumping station cast-in-place pile of the present invention, it is characterized in that, comprises the following steps:

[0043] (1) Construction preparation;

[0044] (2) Measurement stakeout:

[0045] Select the measurement base point, conduct closed measurement on the construction site according to the measurement base point, measure and place the pile position according to the design drawings and the actual terrain, and mark the center position of the pile position with a bright color mark to facilitate the subsequent adjustment of the center position of the positioning hole 3;

[0046] (3) Installation of locator 1:

[0047] a. First insert a 40cm positioning rod at the center of the pile position to ensure the verticality of the positioning rod, and insert the bottom end of the positioning rod into the soil for 15-20cm;

[0048] b. Then install the positioning steel plate 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com