Manufacturing method of roller table frame blank in continuous rolling production line

A manufacturing method and technology of a roller table frame, applied in the field of metallurgical machinery, can solve the problems of high manufacturing cost, low material utilization rate, and inability to process the machined surface, so as to eliminate repairing or scrapping, reduce manufacturing cost and improve utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

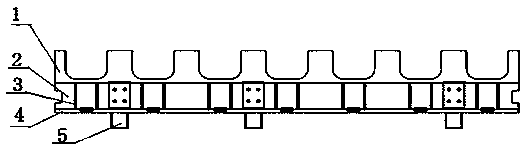

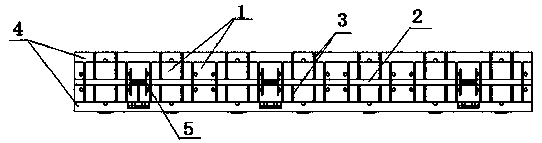

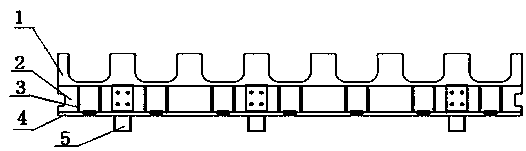

[0030] Query 1, figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , The roller frame is divided into the transmission side roller frame and the operation side roller frame. The structural characteristics of the roller frame are: slender riveting structure, the transmission side roller frame and the operation side roller frame are basically the same structure, which is left and right symmetrical Structural form; the size of the thick plate 1 of the commonly used continuous casting machine roller frame is 300mm (width) X412mm (height) X5550 (length). Regardless of the drive side or the operation side roller frame, it is necessary to cut several grooves on the thick plate, so the key to the utilization rate of the material lies in the production method of the thick part 1. The manufacturing process of the roller frame blank is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com