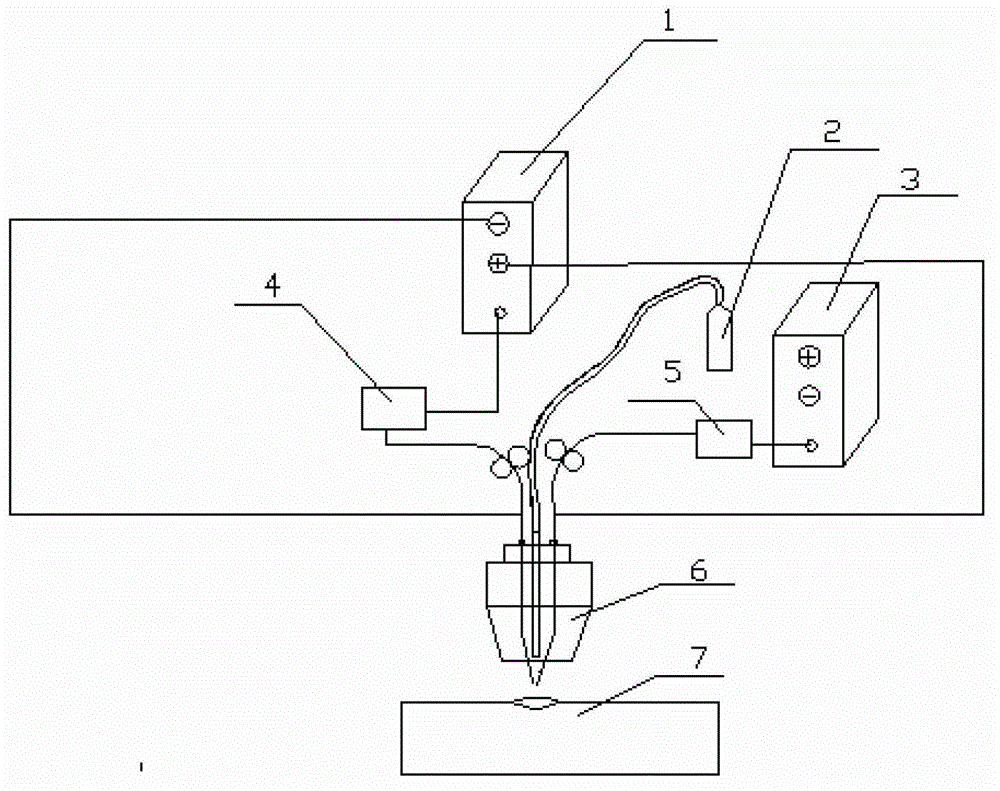

Electric arc spraying system and method for preparing micro metallurgically bonded spraying coating

An arc spraying and arc spraying gun technology, which is applied in metal material coating process, coating, melting spraying and other directions, can solve the problems of complicated operation, easy deformation and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Using Q235 as the substrate, the length, width and height are 8cm, 8cm, and 2mm respectively. Use commercially available ER50-2 welding wire, the wire diameters are 1.2mm and 1.6mm respectively, the wire diameter connected to the positive pole of the power supply is 1.6mm, and the wire diameter connected to the negative pole of the power supply is 1.2mm.

[0024] 1) Remove the oil and polish the Q235 steel plate cut according to the size, and then use a sandblasting machine to sandblast it.

[0025] 2) Fix the steel plate on the fixture to be sprayed.

[0026] 3) Keep the angle between the two wires at 30 degrees, the protruding length before the intersection of the two wires is 10mm, the plane where the two wires are located is perpendicular to the workpiece, and the distance between the intersection point of the axes of the two wires and the workpiece is kept at 15cm.

[0027] 4) Set the process parameters, adjust the wire feeding speed of the two wire feeders to mak...

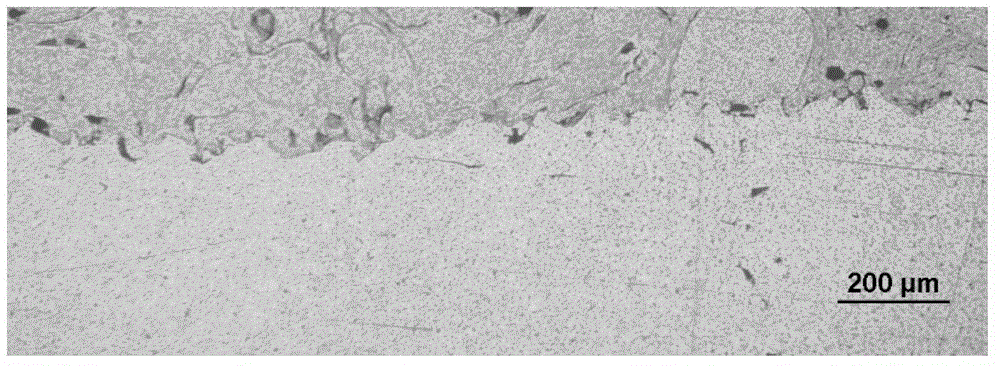

Embodiment 2

[0029] Using Q235 as the substrate, the length, width and height are 8cm, 8cm and 4mm respectively. Use commercially available ER50-2 welding wire, the wire diameters are 1.2mm and 1.6mm respectively, the wire diameter connected to the positive pole of the power supply is 1.6mm, and the wire diameter connected to the negative pole of the power supply is 1.2mm.

[0030] 1) Remove the oil and polish the Q235 steel plate cut according to the size, and then use a sandblasting machine to sandblast it.

[0031] 2) Fix the steel plate on the fixture to be sprayed.

[0032] 3) Keep the angle between the two wires at 25 degrees, the protruding length before the intersection of the two wires is 10mm, and the plane where the two wires are located is perpendicular to the workpiece. The distance between the intersection point of the two wire axes and the workpiece is kept at 12cm.

[0033] 4) Set the process parameters, adjust the wire feeding speed of the two wire feeders to make them h...

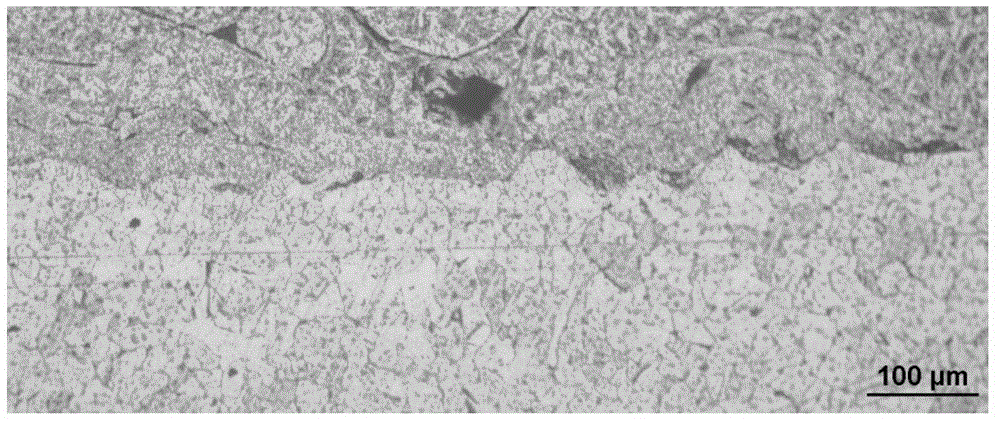

Embodiment 3

[0035] Using Q235 as the substrate, the length, width and height are 8cm, 8cm and 6mm respectively. Use commercially available ER50-2 welding wire, the wire diameters are 1.2mm and 1.6mm respectively, the wire diameter connected to the positive pole of the power supply is 1.6mm, and the wire diameter connected to the negative pole of the power supply is 1.2mm.

[0036] 1) Remove the oil and polish the Q235 steel plate cut according to the size, and then use a sandblasting machine to sandblast it.

[0037] 2) Fix the steel plate on the fixture to be sprayed.

[0038] 3) Keep the angle between the two wires at 25 degrees, the protruding length before the two wires intersect is 12mm, and the plane where the two wires are located is perpendicular to the workpiece. The distance between the intersection point of the two wire axes and the workpiece is kept at 10cm.

[0039] 4) Set the process parameters, adjust the wire feeding speed of the two wire feeders to make them have the be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com