Method for machining thin-wall separation type solid retainer

A technology of a solid cage and a processing method, which is applied in the field of thin-walled separation-type solid cage processing, can solve the problems of low machining precision of the rivet holes of the cage, difficulty in ensuring product processing quality, and difficulty in machining the cage, and achieves guaranteed machining. Consistency of accuracy and size, improvement of machining accuracy, reduction of turning stress and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

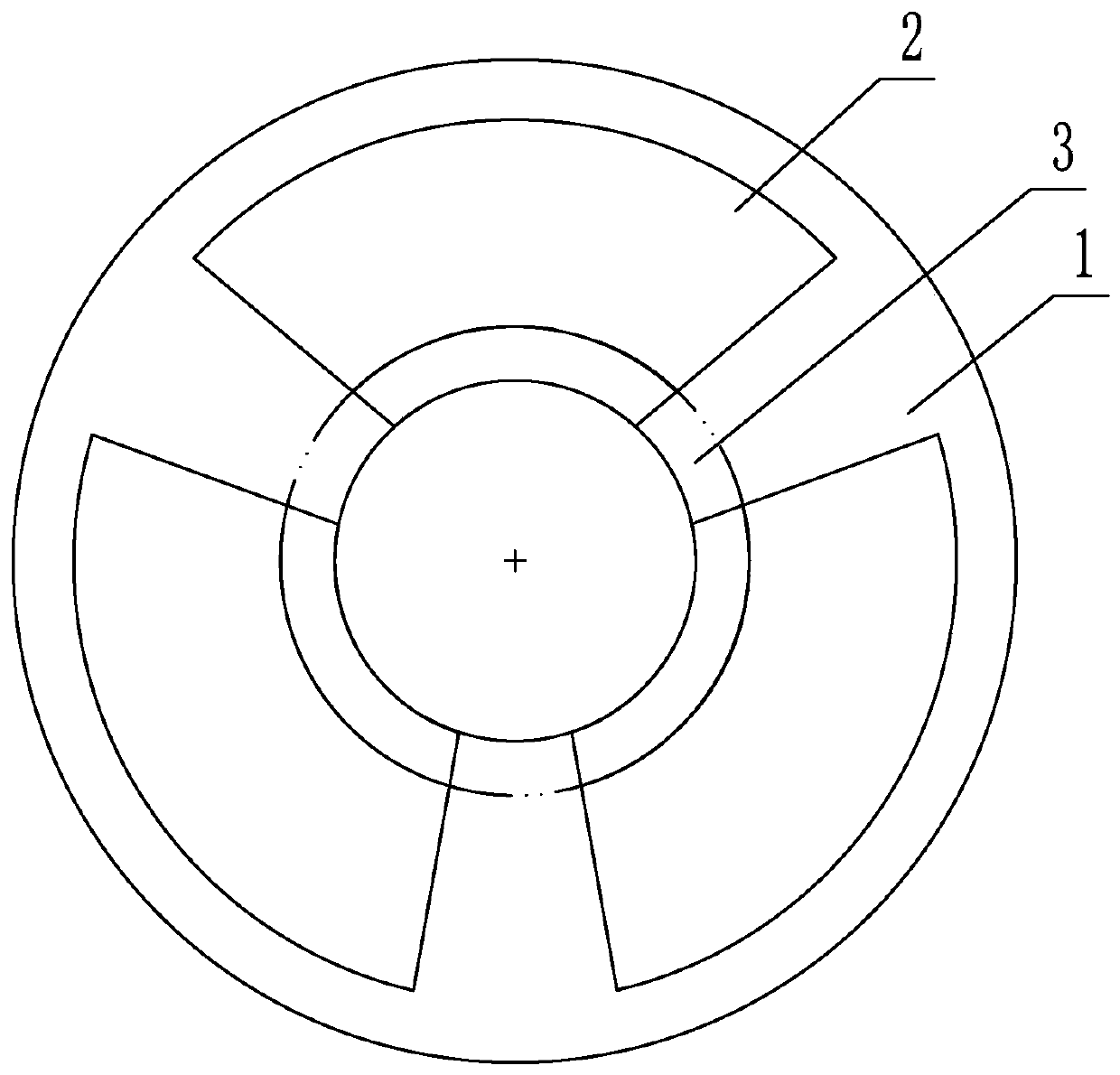

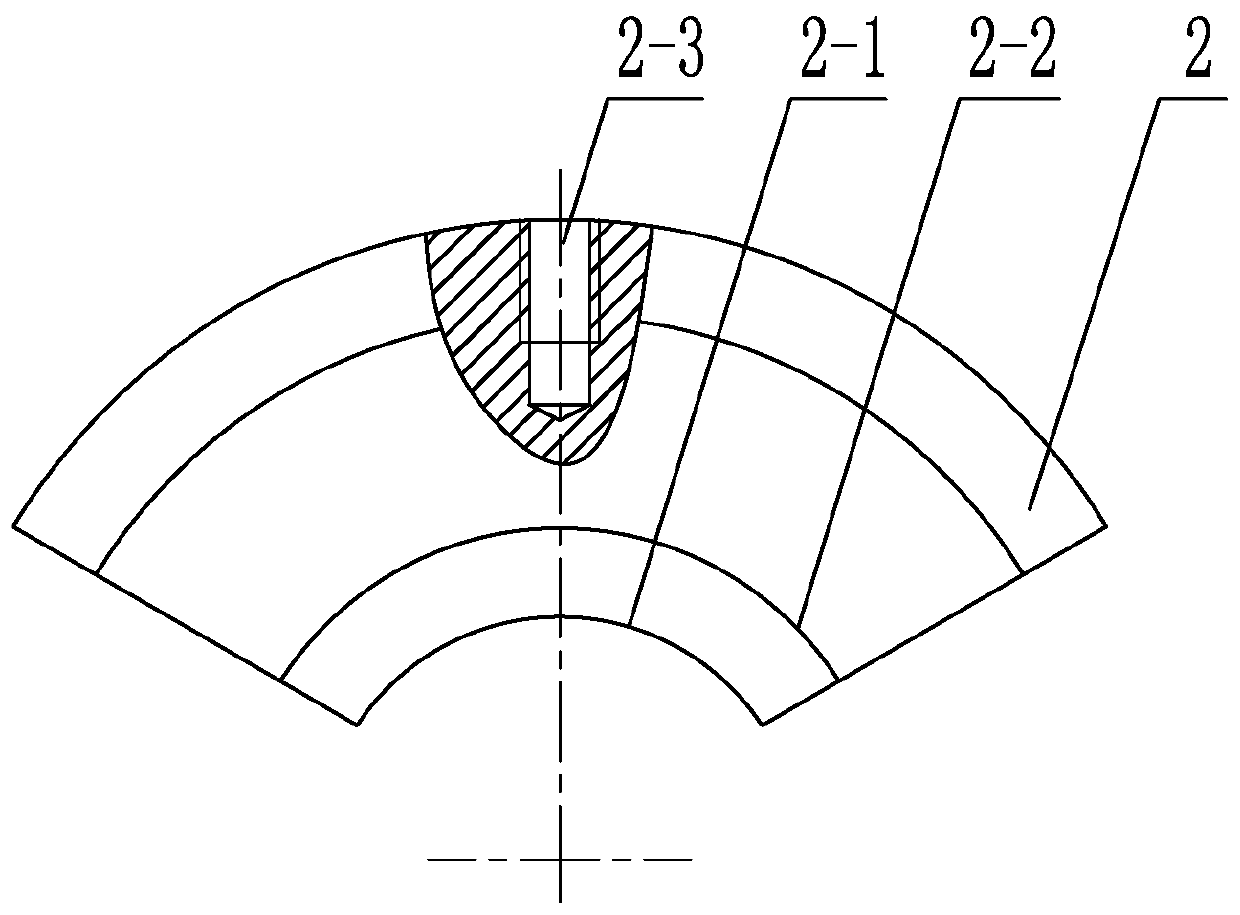

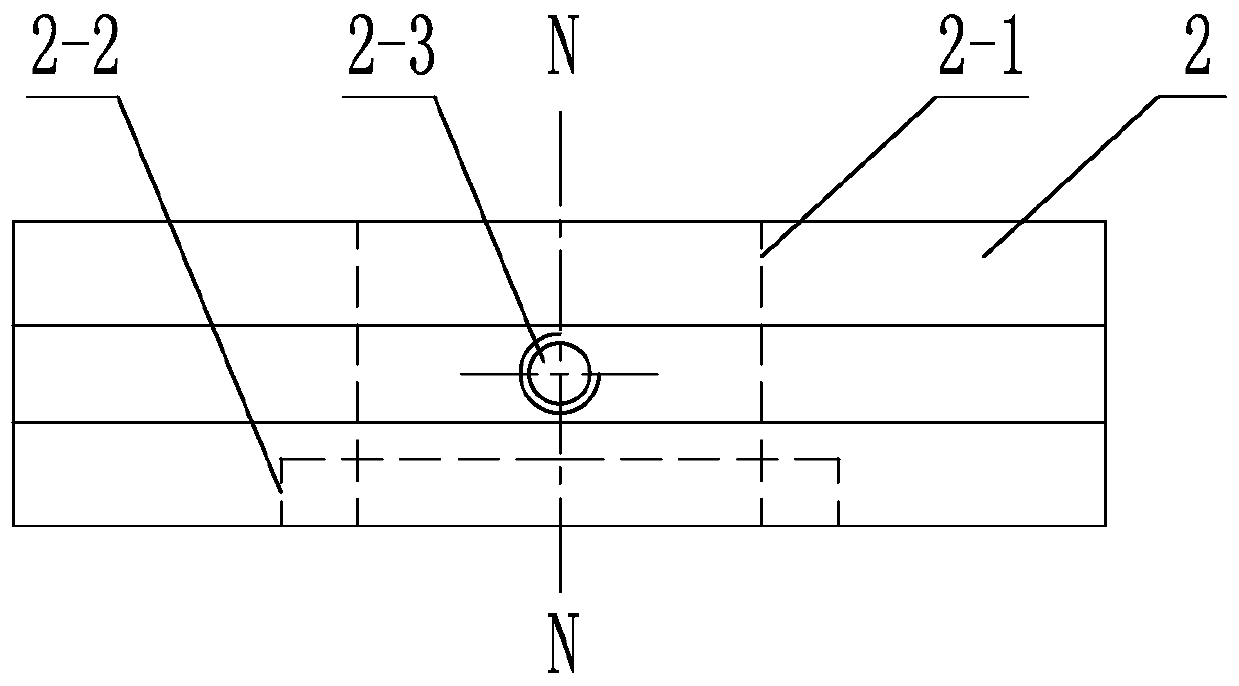

[0065] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, a thin-wall separation type solid cage processing method in this embodiment, the thin-wall separation type solid cage processing method is realized by the following steps,

[0066] Step 1. Fine turning the first plane, second plane, rough grinding outer diameter, and fine turning inner diameter in turn:

[0067] Install the molded cage on the lathe, finely process the first plane and the second plane of the cage, install the cage after fine turning two planes on the grinding machine, rough grind the outer diameter of the cage, and then Install the cage after rough grinding the outer diameter on the lathe, and finely process the inner diameter of the cage. The rough grinding outer diameter is 0.2-0.3 mm for the fine grinding outer diameter, and the fine turning inner diameter is 0.3-0.4 mm for the fine turning inner diameter. mm;

[0068] Step two, solid solution strengthening:

...

specific Embodiment approach 2

[0091] In this embodiment, when the outer diameter is finally ground, the dispersion of the outer diameter is controlled at 0~+0.02mm, and the ellipticity of the outer diameter VDcp0.006~0.01mm. The outer diameter is the guide surface of the cage and is also a relatively important part of the cage. , the required processing accuracy is relatively high, so the processing accuracy must be guaranteed during processing. Embodiment 2: The machining tolerance of the rivet holes described in step 6 of this embodiment is reduced to 0-+0.05 mm. In this way, the finished product drawing requires the processing tolerance of the rivet hole to be ±0.05mm. In order to achieve the universal assembly of the rivet hole processing, the processing tolerance of the rivet hole is compressed to +0.05mm, and the carbide drill bit is selected, which has high hardness and is durable. Wear and tear, the diameter and size of the processed rivet holes are stable, so that two and a half cages can be rivet...

specific Embodiment approach 3

[0092] Embodiment 3: The minimum processing size of the rivet hole described in step 6 of this embodiment is Φ0.8 mm. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com