Semiconductor structure and formation method thereof

A semiconductor and fin technology, applied in the field of semiconductor structure and its formation, can solve the problems that the performance of semiconductor structure needs to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It can be seen from the background art that the performance of existing semiconductor structures still needs to be improved.

[0034] Now combined with a method of forming a semiconductor structure for analysis, Figure 1 to Figure 5 It is a structural diagram corresponding to each step in a method for forming a semiconductor structure. The process steps for forming a semiconductor structure mainly include:

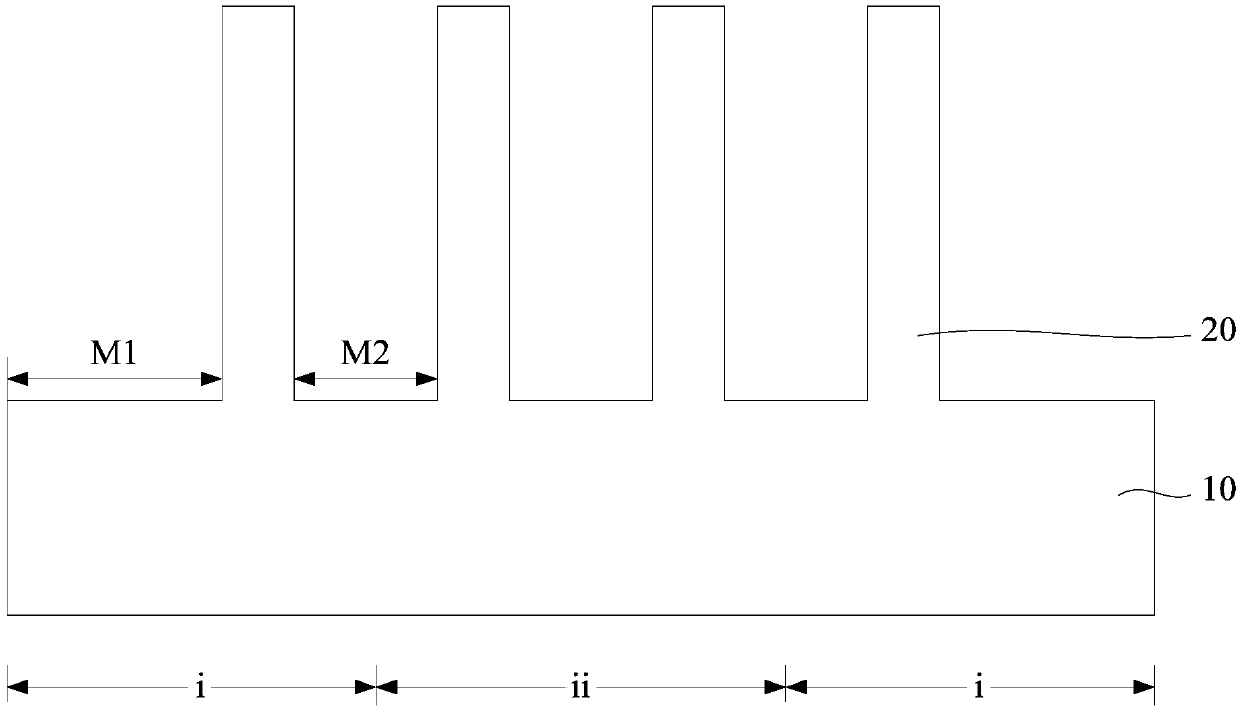

[0035] refer to figure 1 , providing a substrate 10 and fins 20 protruding from the substrate 10 .

[0036] The substrate 10 includes an edge region i and a central region ii between adjacent edge regions i.

[0037] There are multiple fins 20 , and the multiple fins 20 are arranged at equal intervals on the substrate 10 . The distance between the fin 20 in the edge region i and the sidewall of the substrate 10 is a first distance M1, and the distance between the fin 20 in the edge region i and an adjacent fin 20 is a second distance M2 , M1≠M2.

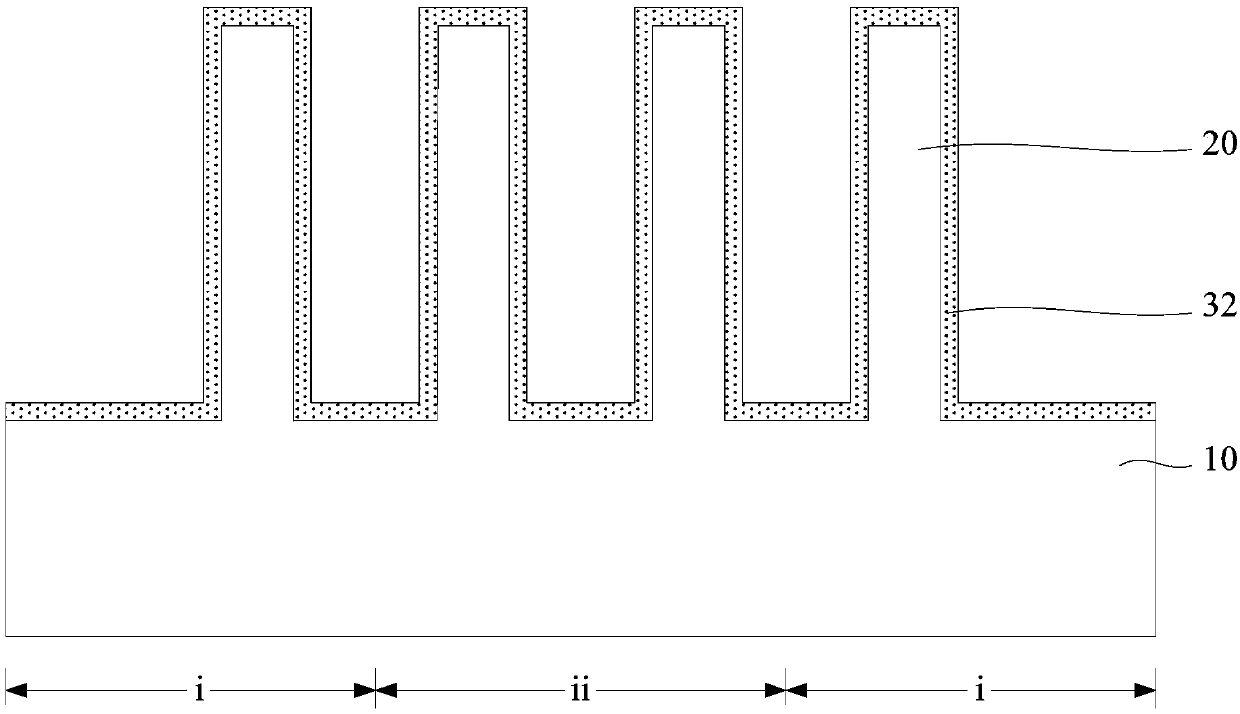

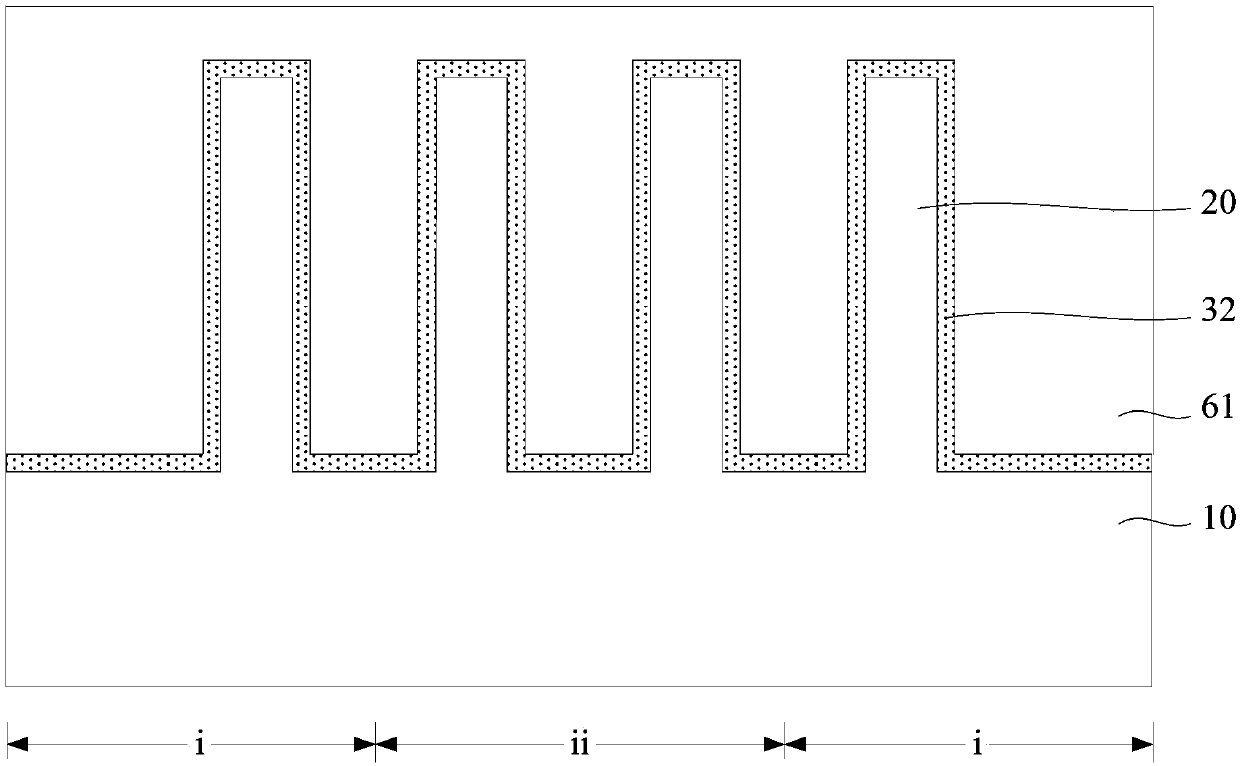

[0038] refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com