Shallow groove isolation construction, forming method and grinding method

A technology of isolation structure and grinding method, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve problems such as edge depressions, achieve low turntable speed, reduce damage, and improve uniformity and consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

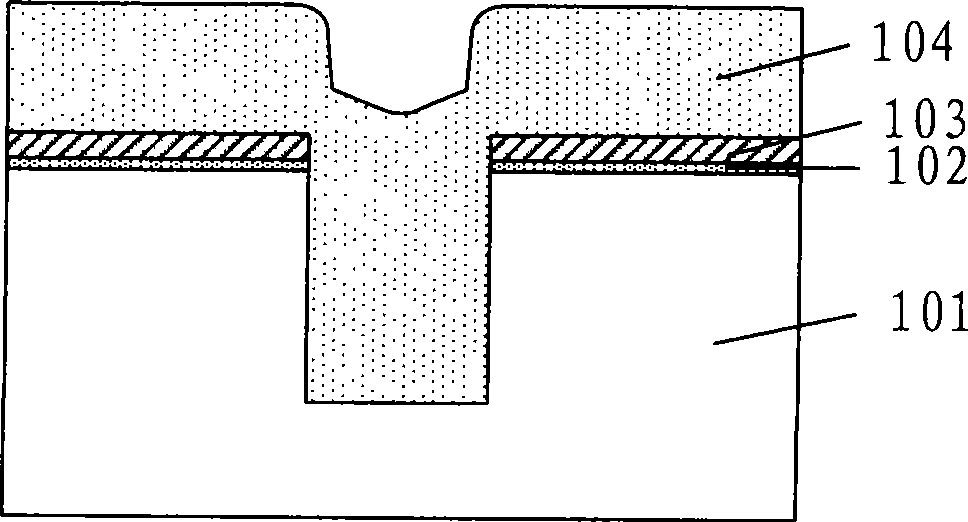

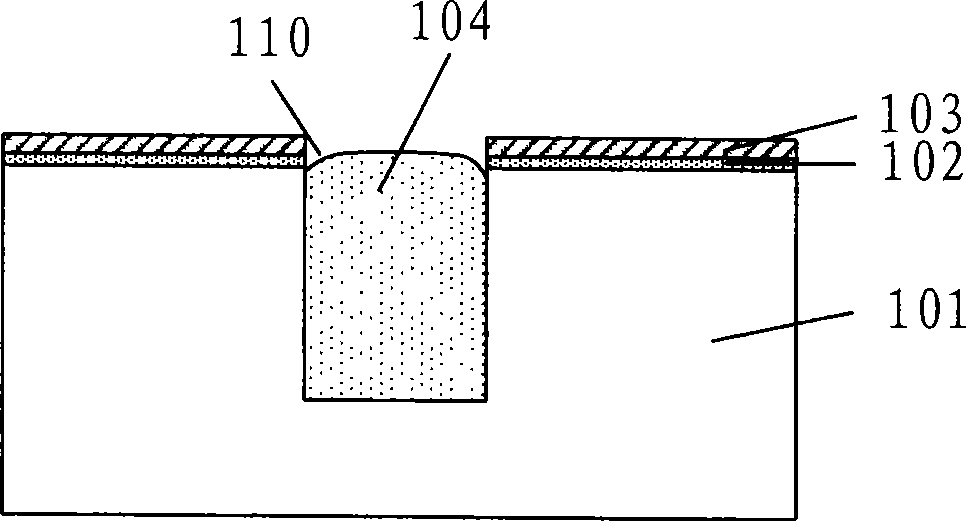

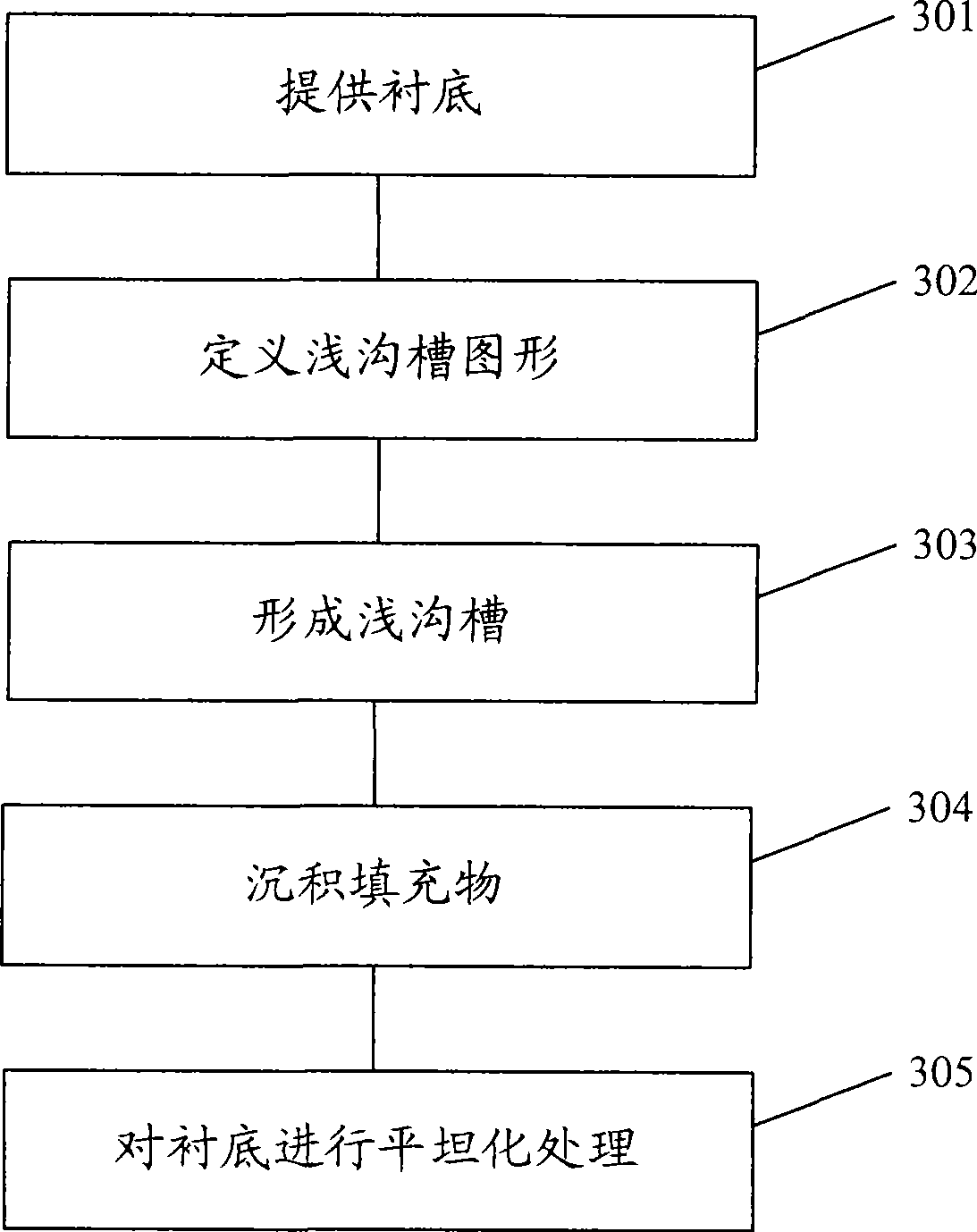

[0078] This embodiment introduces a method for forming a shallow trench isolation structure, image 3 is a flow chart of the method for forming the shallow trench isolation structure according to the first embodiment of the present invention, Figure 4 to Figure 8 In order to illustrate the device cross-sectional schematic diagram of the method for forming the shallow trench isolation structure in the first embodiment of the present invention, the following is combined with Figure 3 to Figure 8 The first embodiment of the present invention will be described in detail.

[0079] The method for forming the shallow trench isolation structure of this embodiment includes the steps of:

[0080] Step 301: providing a substrate on which a stop layer has been formed.

[0081] Figure 4 is a schematic cross-sectional view of the substrate in the first embodiment of the present invention, as Figure 4 As shown, the substrate provided in this embodiment is a silicon substrate 401 on w...

no. 2 example

[0117] This embodiment introduces a polishing method, which improves the formation quality of the shallow trench isolation structure after polishing by adjusting the polishing end point and process conditions of the shallow trench isolation structure.

[0118] Figure 11 A schematic diagram of the chemical mechanical grinding device used in the grinding method of the second embodiment of the present invention, such as Figure 11 As shown, the device includes: a housing 1101, a turntable (platen) 1102 with a polishing pad (polish pad) attached to the surface, polishing heads 1103a, 1103b and a polishing liquid supply pipe (tube) 1104 for transporting a polishing liquid (slurry) 1105 .

[0119] When grinding, the substrate to be polished is first attached to the grinding head 1103, and the substrate is pressed against the grinding pad by applying downward pressure on the grinding head 1103; then, the turntable 1102 with the grinding pad attached to the surface is driven by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com