Fuel spraying system for utilizing heat pipe technology to extract heat vaporized diesel oil from exhaust gas

A fuel injection system and heat pipe technology, applied in fuel injection devices, charging systems, cylinders, etc., to achieve the effects of avoiding manufacturing costs, simple and compact structure, and improving energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

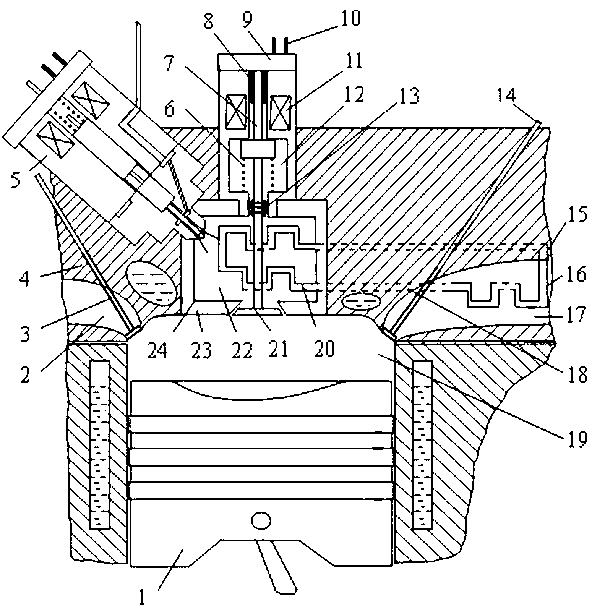

[0018] figure 1 As shown, the invention creates a specific embodiment of the fuel injection system utilizing the heat pipe technology to extract heat from the exhaust gas into the vaporized diesel fuel, which includes a cylinder block, a piston 1, a cylinder head 4, an electronically controlled fuel injector 5, and a cylinder head 4 An intake port 2 and an exhaust port 17 are arranged on the top, and an intake valve 3 and an exhaust valve 14 are installed correspondingly on the intake port 2 and the exhaust port 17. The cylinder block, the piston 1 and the cylinder head 4 form a combustion chamber 19 , the cylinder head 4 is provided with a diesel vaporization injector 9 and a diesel carburetor 24, the diesel carburetor 24 includes a heat pipe 15 and a vaporization cavity 23, and the heat pipe 15 is composed of a heat pipe evaporation section 16, a heat pipe insulation section 18 and a heat pipe condensation section 20 , the vaporization chamber 24 is installed on the cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com