Resonator and forming method thereof

A resonator and piezoelectric technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, piezoelectric/electrostrictive device manufacturing/assembly, impedance network, etc., can solve the problem of difficult integration of RF front-end chips, filtering The problem of large size of the device can be solved, and the effect of improving the forming quality, improving performance and saving cost can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

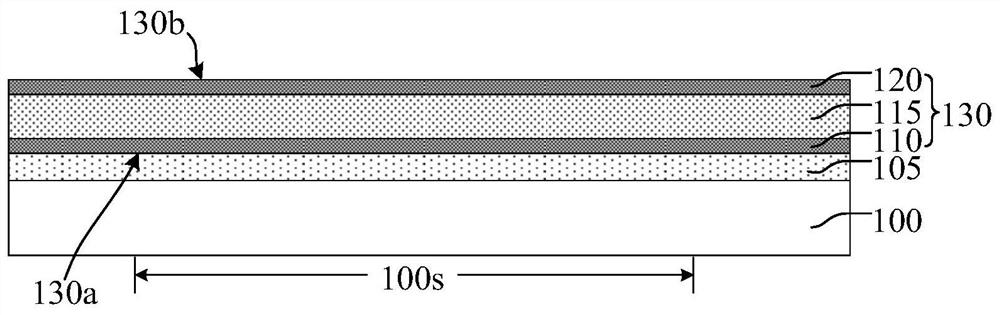

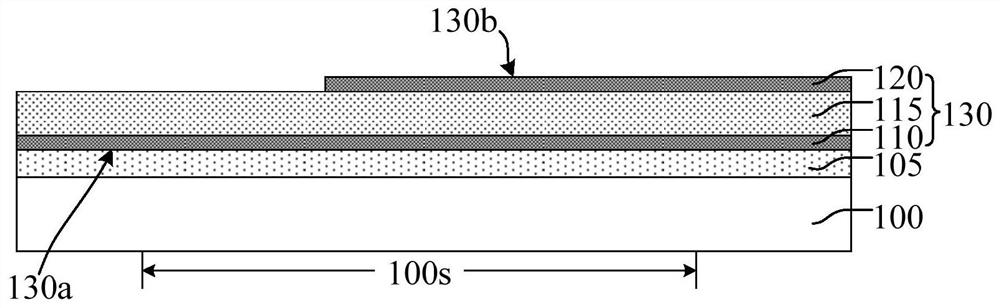

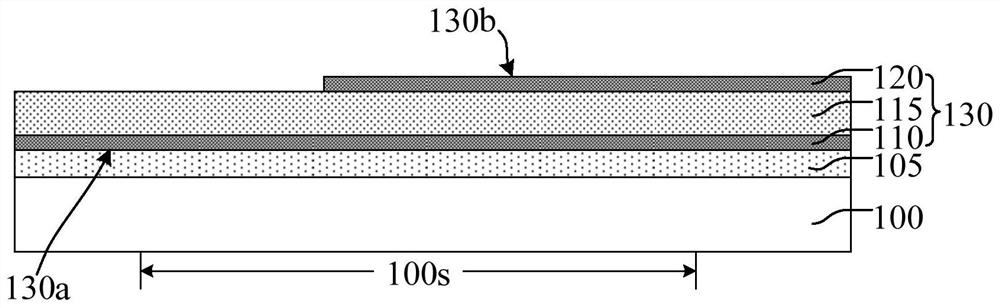

[0029] It can be seen from the background art that at present, a film bulk acoustic resonator (Film Bulk Acoustic Resonator, FBAR) is widely used. But the performance of the resonators formed so far is not good.

[0030] Specifically, the current manufacturing process of thin film bulk acoustic resonators is usually to form a groove in the substrate, form a sacrificial layer in the groove, and then sequentially form a piezoelectric stack structure on the sacrificial layer, and in order to release the For the sacrificial layer, it is usually necessary to form a release hole through the piezoelectric stack structure, and use the release hole to remove the sacrificial material layer in the groove to finally form a cavity.

[0031] Wherein, the step of forming the sacrificial layer generally includes: forming a sacrificial material layer in the groove, the sacrificial material layer is also formed on the substrate; grinding and removing the sacrificial material layer higher than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com