Method for incinerating etched substrate and method for forming etched structure

A technology of ashing and ashing treatment, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as the etch stop layer that is easy to damage the lower layer, and achieve the effect of avoiding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

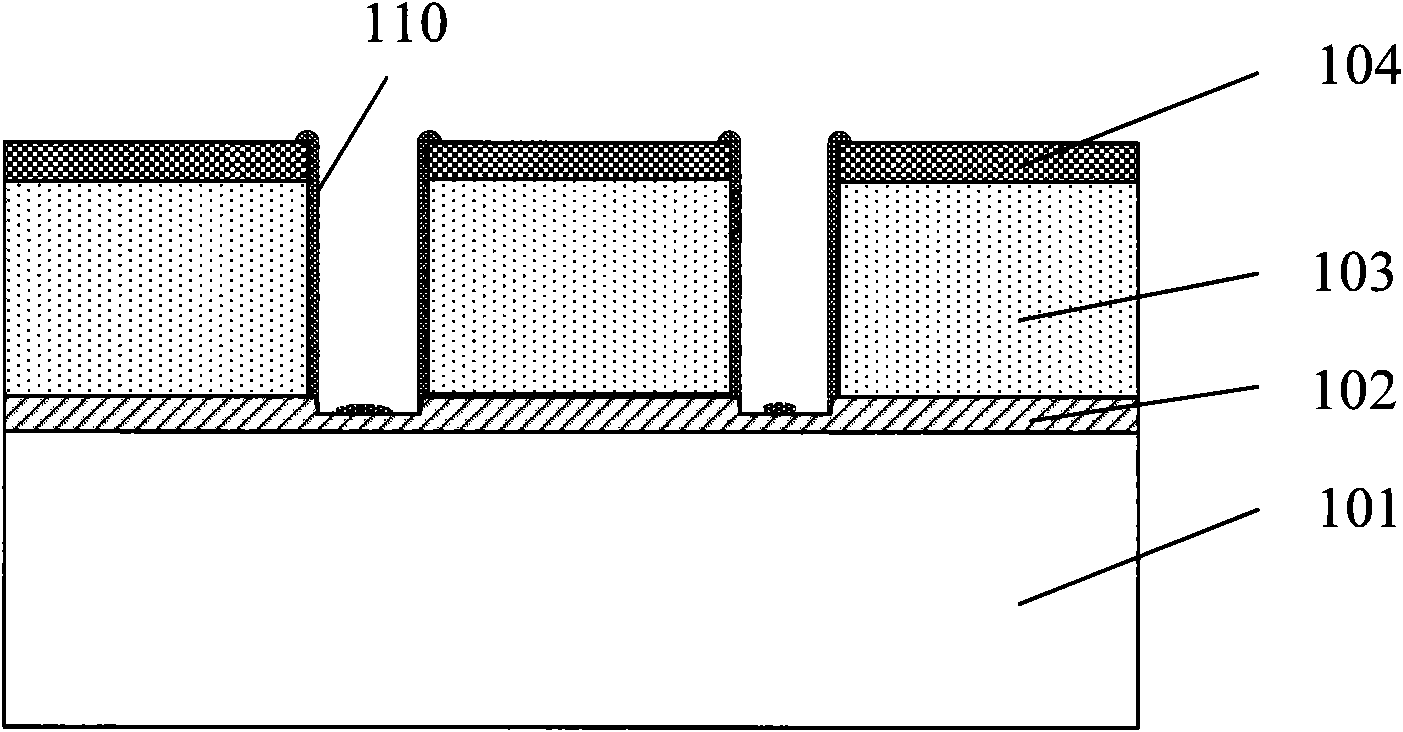

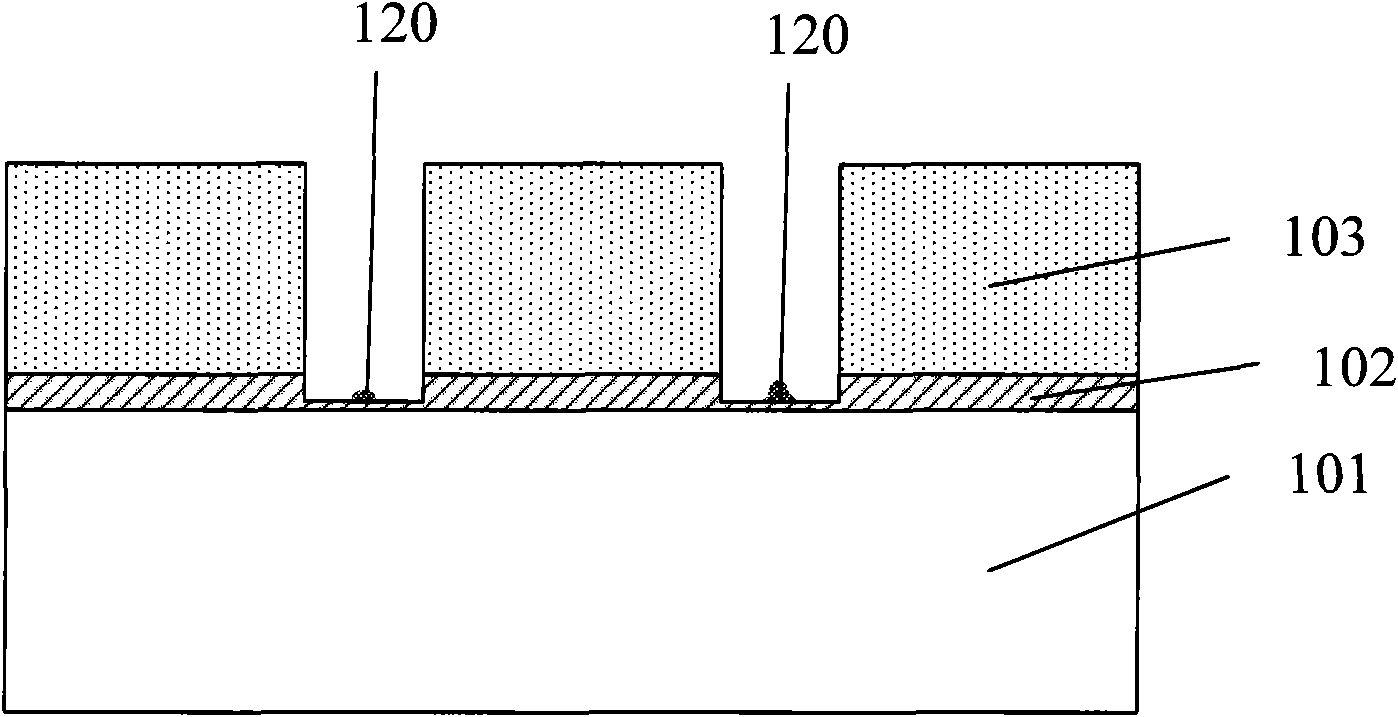

[0084] The first embodiment of the present invention introduces a post-etching ashing method, Figure 4 is a flow chart of the post-etching ashing method according to the first embodiment of the present invention, Figure 5 to Figure 7 In order to illustrate the cross-sectional view of the device of the post-etch ashing method of the first embodiment of the present invention, the following is combined with Figure 4 to Figure 7 The first embodiment of the present invention will be described in detail.

[0085] Step 401: providing an etched substrate.

[0086] The etched substrate provided in this embodiment may be a substrate that has just been etched to form various etched structures (such as contact holes, through holes, dual damascene structures, etc.), and residual photoresist is still attached to its surface. and polymers.

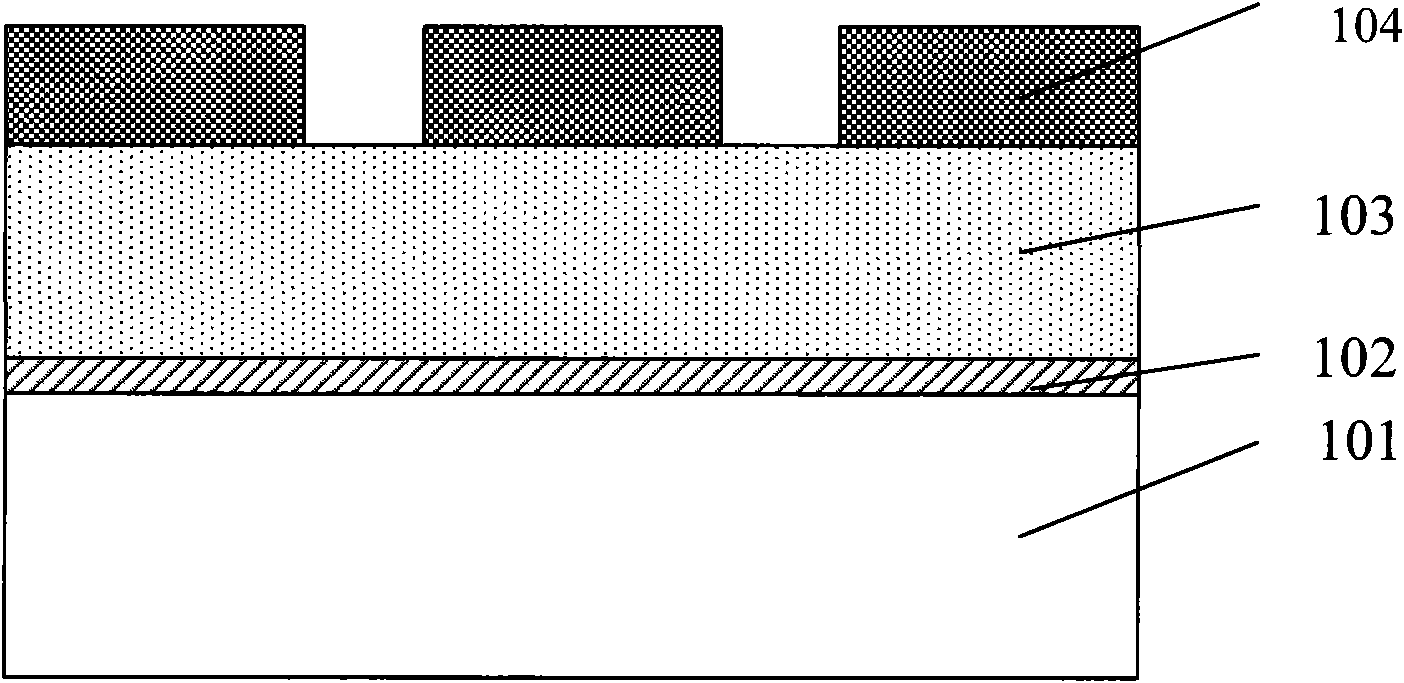

[0087] Figure 5 It is a schematic cross-sectional view of the etched substrate in the first embodiment of the present invention, as Figure 5 A...

no. 2 example

[0115] The second embodiment of the present invention introduces a method for forming an etching structure, Figure 10 It is a flow chart of the etching structure forming method according to the second embodiment of the present invention, Figure 11 to Figure 15 In order to illustrate the device cross-sectional view of the etching structure forming method of the second embodiment of the present invention, the following is combined with Figure 10 to Figure 15 The second embodiment of the present invention will be described in detail.

[0116] Step 1001: providing a substrate with a material layer to be etched on the substrate.

[0117] Figure 11 is a schematic cross-sectional view of the substrate in the second embodiment of the present invention, as Figure 11 As shown, a material layer 1104 to be etched is formed on a silicon substrate 1101. The material layer 1104 may be a silicon oxide layer, such as a phosphorus-containing silicon oxide layer, a black diamond layer, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com