Patents

Literature

31results about How to "Eliminate structural defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for polystyrene/polyvinylidene fluoride cation exchange membrane

ActiveCN102814125AEliminate structural defectsLow film resistanceSemi-permeable membranesPolyvinylidene fluorideIon-exchange membranes

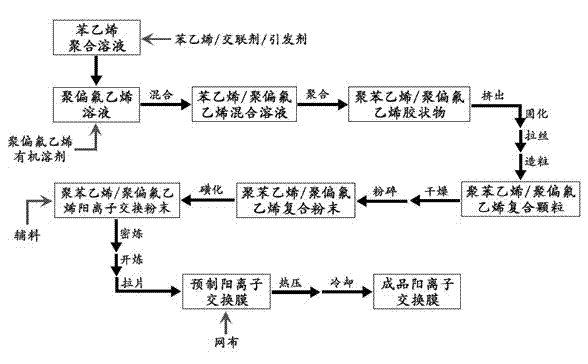

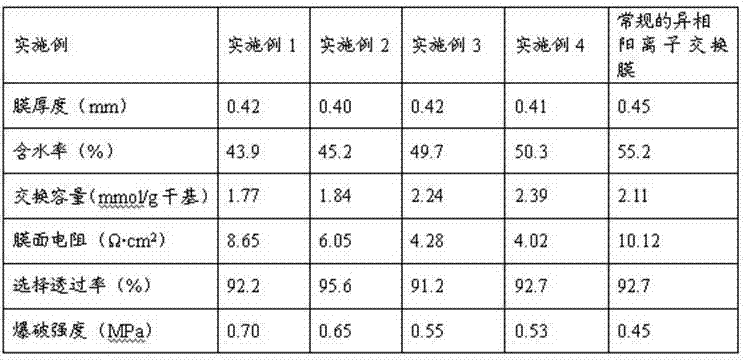

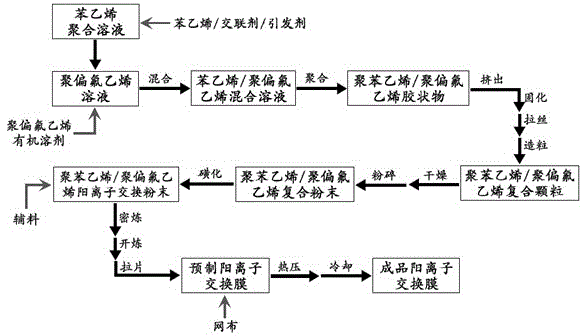

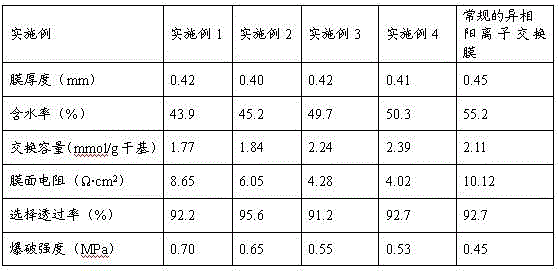

The invention discloses a preparation method for a polystyrene / polyvinylidene fluoride cation exchange membrane. According to the method, polyvinylidene fluoride is used as a matrix material for the membrane. The method comprises the following steps: dissolving polyvinylidene fluoride and then fully mixing dissolved polyvinylidene fluoride with styrene and a cross-linking agent so as to obtain a homogeneous polymer solution; carrying out heat-initiated crosslinking copolymerization so as to obtain gelatinoid with an interpenetrating network structure; subjecting the gelatinoid to polymer physical processing so as to obtain polystyrene / polyvinylidene composite powder; then preparing cation exchange powder by using a sulfonation method for a storng-acid cation exchange resin as reference; and finally preparing the cation exchange membrane by using a hot pressing molding method for a heterogeneous cation exchange membrane. The polystyrene / polyvinylidene fluoride cation exchange composite high polymer membrane prepared in the invention has the interpenetrating network structure, so the structural defect of incompatibility between cation exchange resin powder and a high polymer binder in conventional heterogeneous cation exchange membranes is eradicated, membrane resistance is substantially reduced, and comprehensive properties of the polystyrene / polyvinylidene fluoride cation exchange membrane in the invention are closer to comprehensive properties of cation exchange membranes.

Owner:辽宁易辰膜科技有限公司

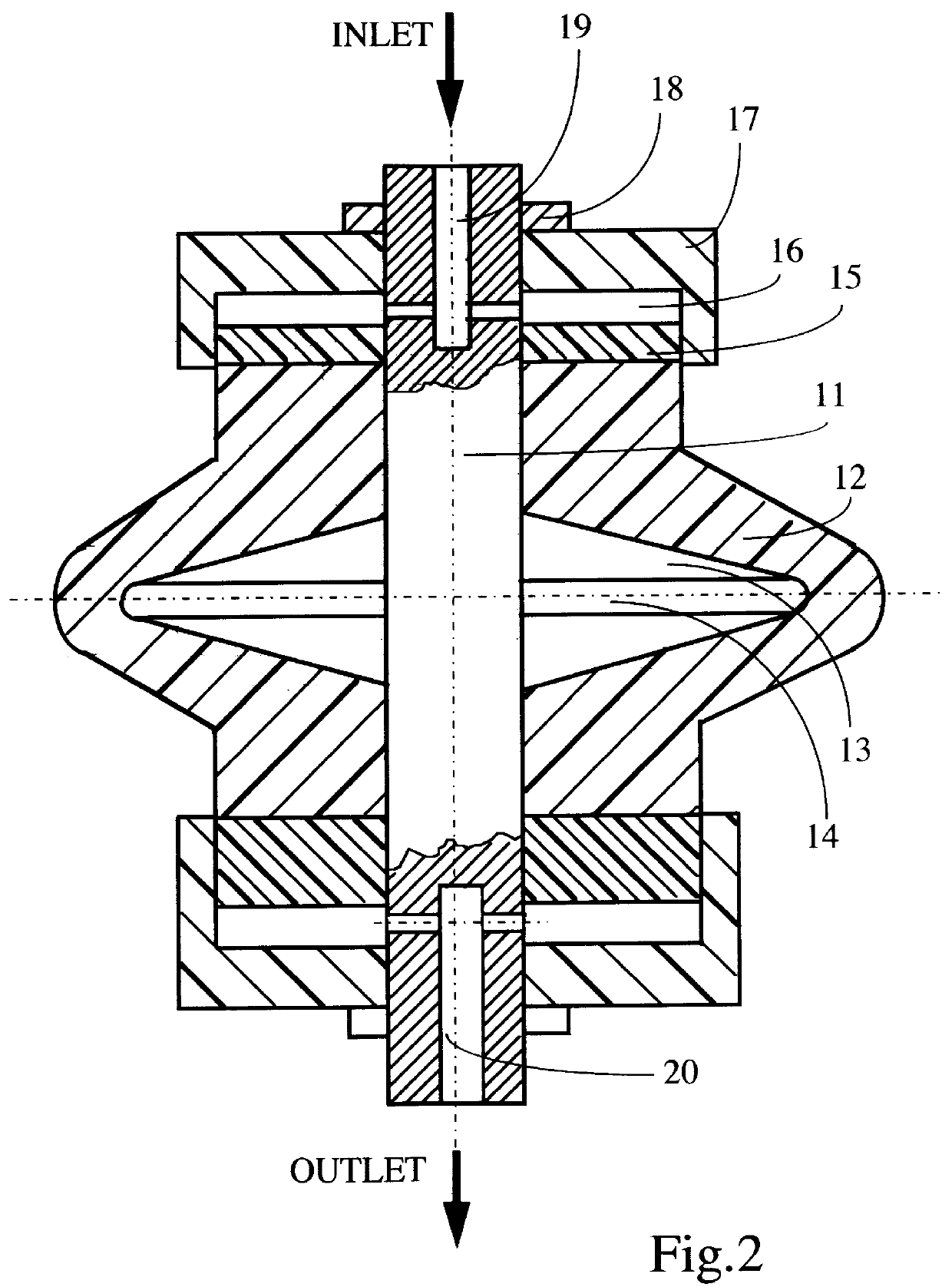

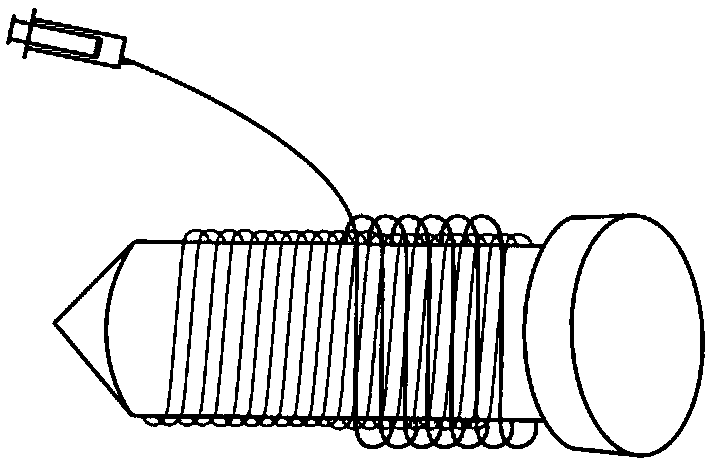

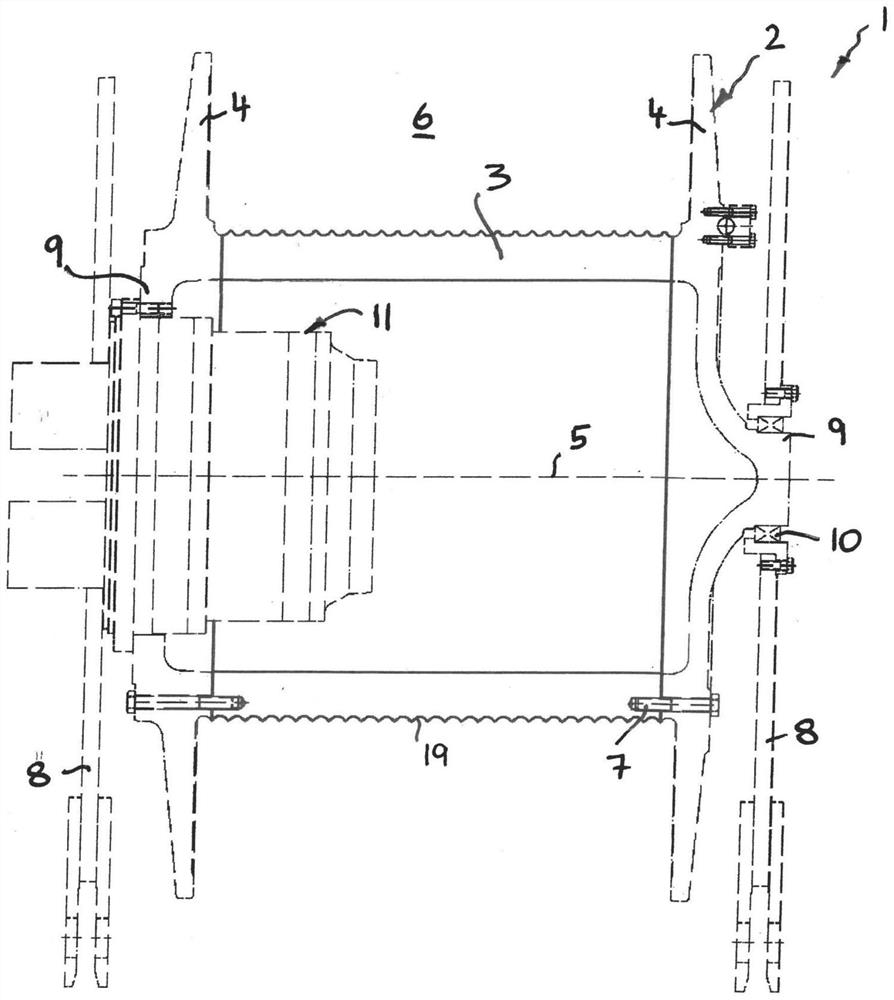

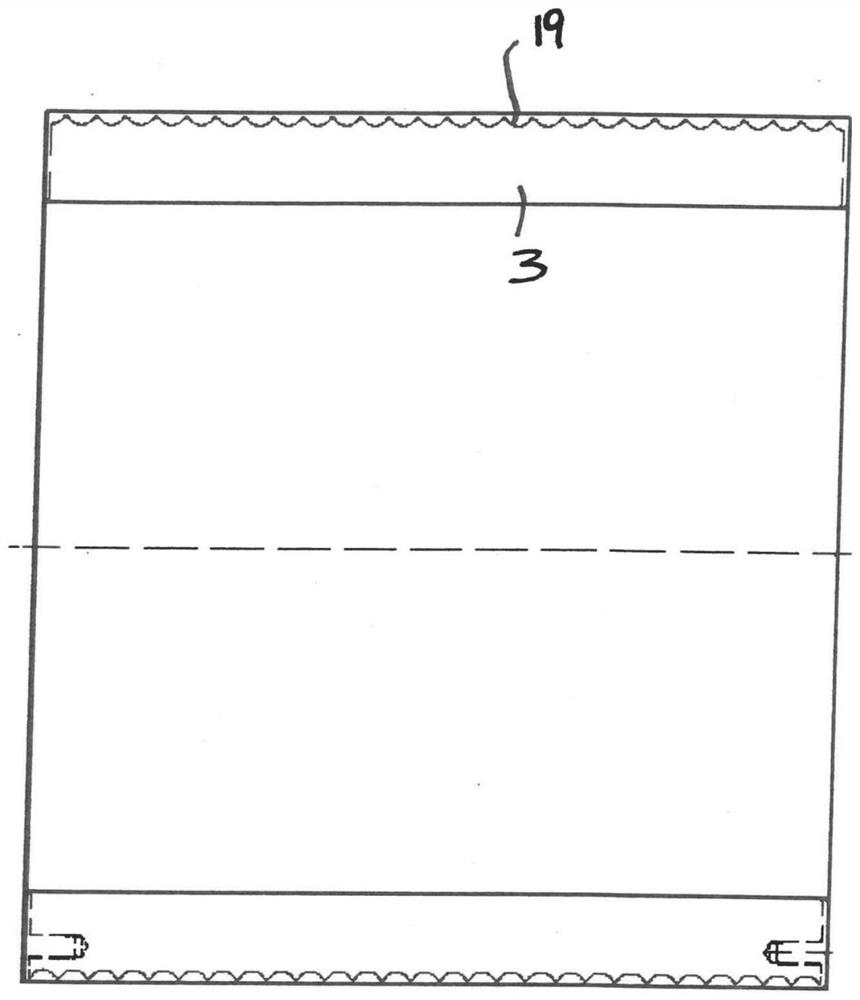

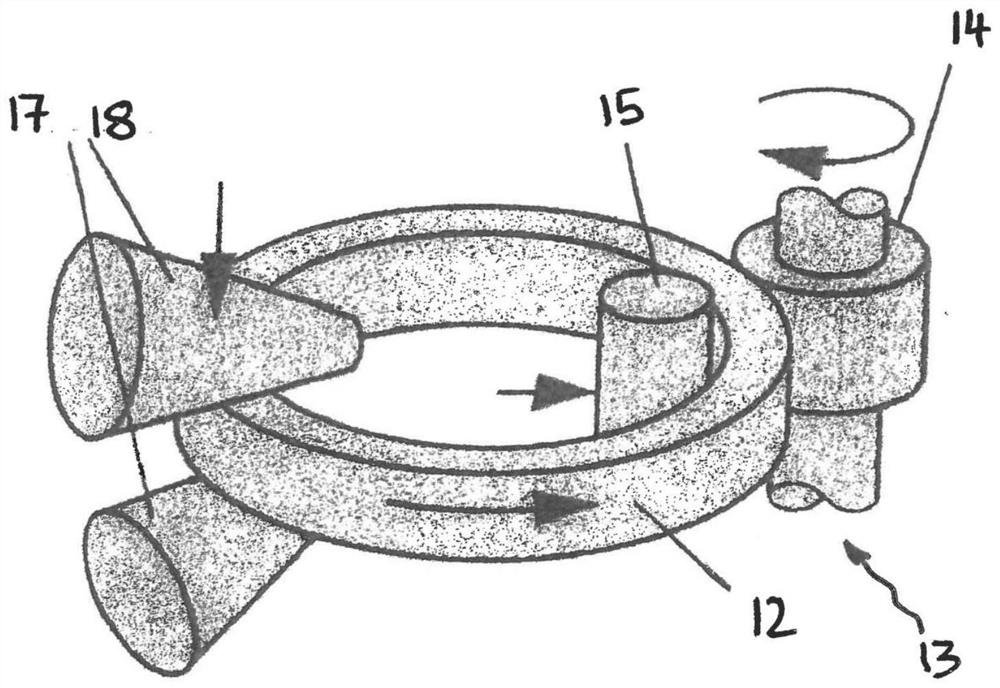

Apparatus for producing a gas mixture for hypoxia training

InactiveUS6009870AIncrease productivityGood serviceRespiratorsMembranesHollow fibreAutomatic control

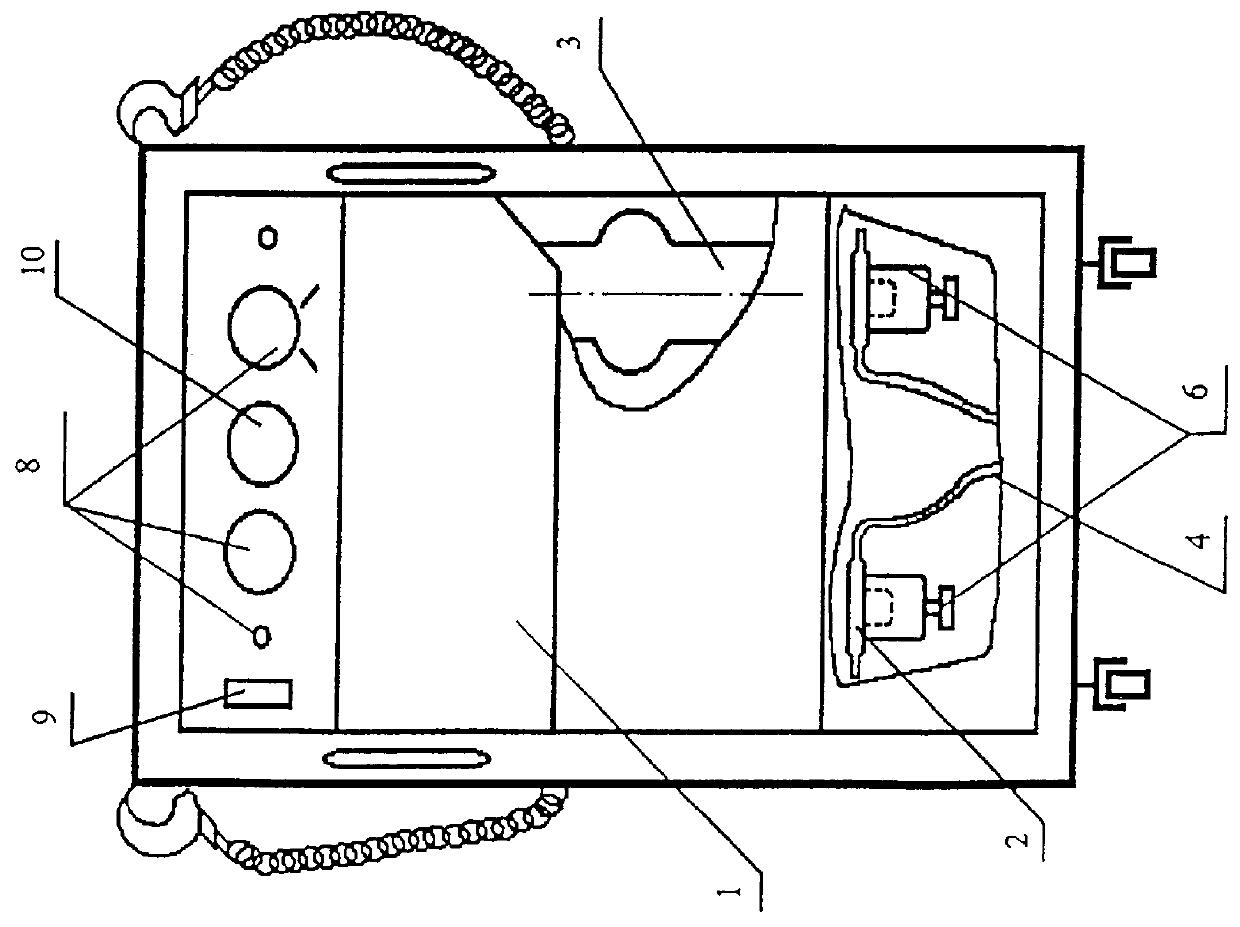

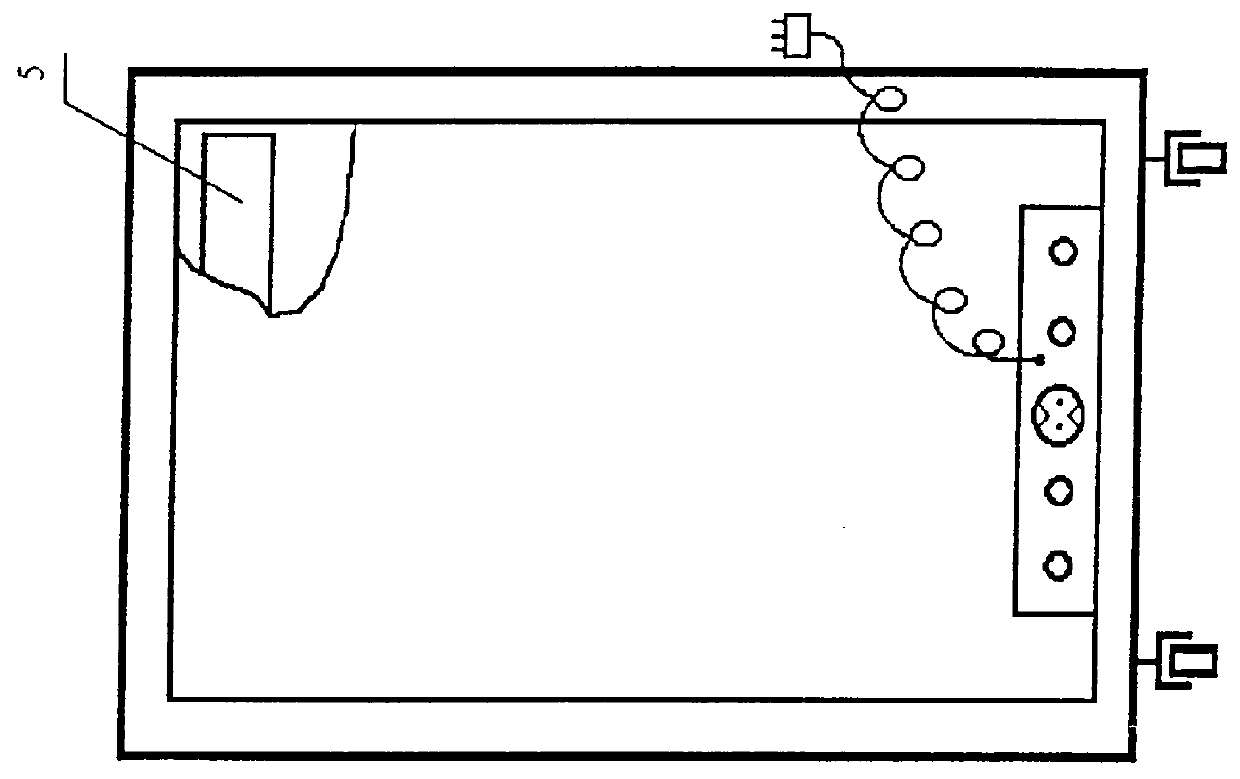

PCT No. PCT / RU96 / 00249 Sec. 371 Date Aug. 31, 1998 Sec. 102(e) Date Aug. 31, 1998 PCT Filed Sep. 2, 1996 PCT Pub. No. WO98 / 09676 PCT Pub. Date Mar. 12, 1998The present invention relates to equipment for producing a hypoxia gas mixture and for use during hypoxia training at regular intervals. The present invention may be used in the field of practical medicine during a therapy involving gas mixtures with a low oxygen content. This invention essentially relates to an apparatus for producing a gas mixture for hypoxia training at regular intervals, wherein said apparatus comprises the following elements serially connected: a compressor; a gas-distribution member made of hollow polymeric fibers of poly-4-methylpentens-1; a duct with a flow-meter; a moisturising unit; a patient mask with a breathing valve; a system for automatically controlling the operation mode parameters, wherein said system comprises a patient-condition monitoring device with an oxygen indicator and a spirometer; and a drying unit mounted before the gas-distribution member. This drying unit is made in the shape of two truncated cones which are connected together at their larger bases on a single support rod, wherein said rod comprises in its central part a disc having a diameter 4 to 6 times larger than that of said rod. Hollow fibers made of mixtures of poly-4-methylpentens-1 with different melt index are wound on the last cone.

Owner:TKATCHOUK ELENA VALERIEVNA

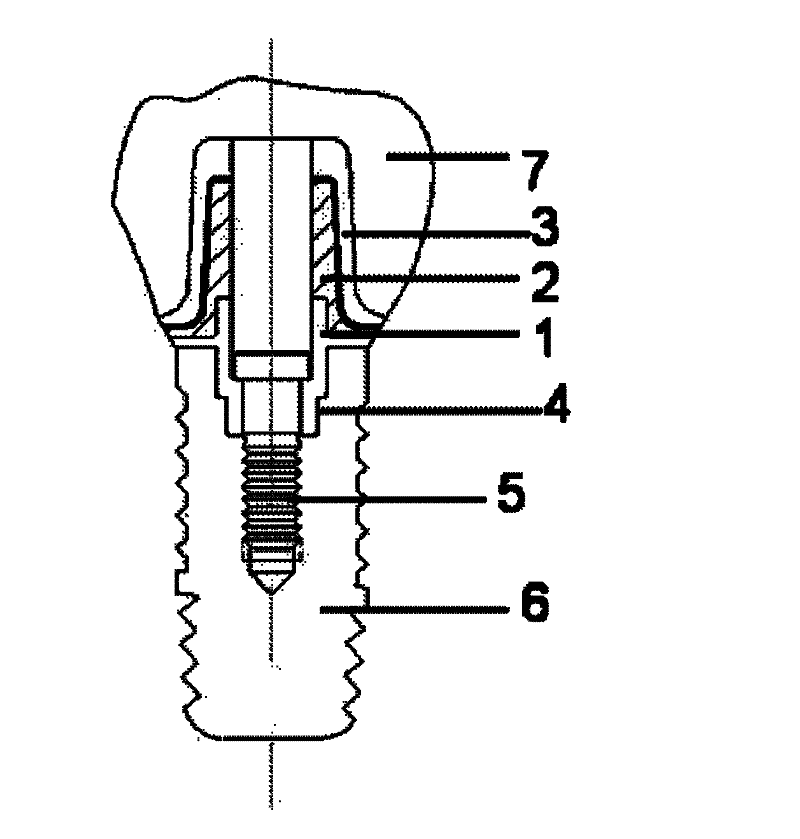

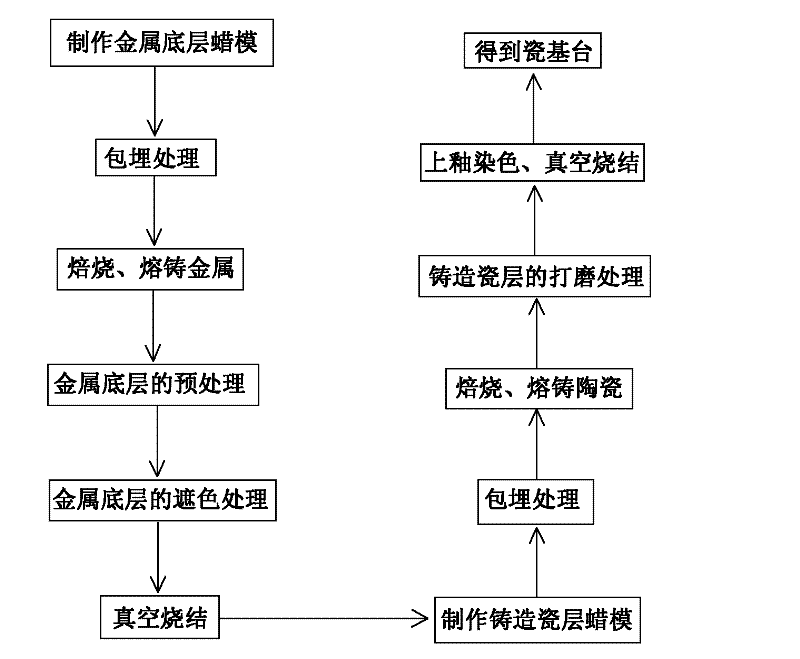

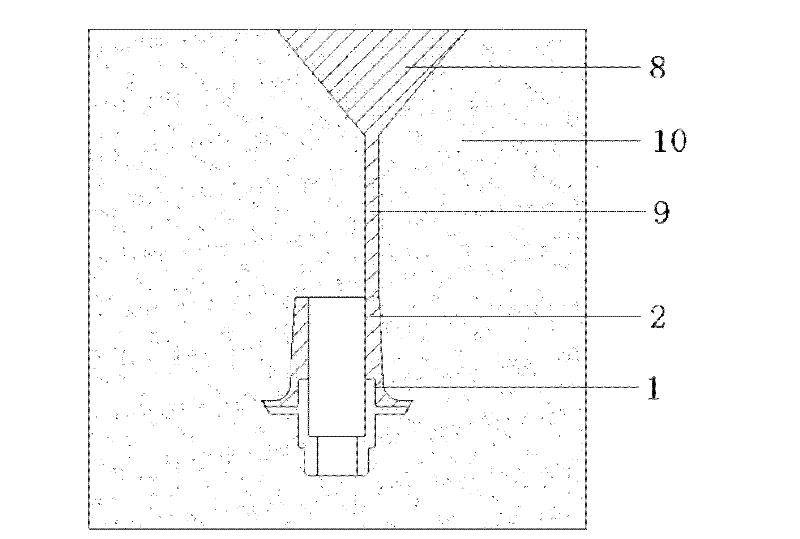

Ceramic abutment for dental implant and manufacturing method for ceramic abutment

InactiveCN102357044AEliminate structural defectsThe production process is simpleDental implantsArtificial teethWaxMetal alloy

The invention relates to a ceramic abutment for a dental implant. The ceramic abutment comprises a substrate with a countersunk head through hole, wherein a central countersunk head screw of which the external threads are matched with an implant threaded hole is formed in the countersunk head through hole; a reducer connection ring is arranged at the lower end of the substrate; a bulged edge which extends outwards is arranged on the middle part of the substrate; a metal bottom layer is wrapped on an excircle of the upper part of the substrate; the bottom end of the metal bottom layer expands outwards along the upper surface of the bulged edge; a casting ceramic layer is wrapped outside the metal bottom layer; and the appearance of the casting ceramic layer is matched with that of a concave hole at the bottom of a ceramic crown. A manufacturing method comprises the following steps of: manufacturing a metal bottom layer wax mold and a sprue on the substrate, fixing the metal bottom layer wax mold and the sprue in a casting ring, and pouring embedding material mixed liquid into the casting ring for embedding; roasting an embedding body, melting the wax mold, pouring wax liquid, melting a metal alloy, pouring the molten metal alloy into an embedding body cavity from the sprue, and clearing an embedding material after casting to obtain the substrate wrapped with the metal bottom layer; manufacturing a wax mold of which the shape is matched with that of the casting ceramic layer and a sprue, fixing the wax mold and the sprue in the casting ring, and pouring the embedding material mixed liquid into the casting ring for embedding; roasting an embedding body, melting the wax mold, pouring wax liquid, melting casting ceramic, pouring the molten casting ceramic into a cavity of the roasted embedding body from the sprue, and clearing an embedding material after casting to obtain an initial finished product; and polishing the initial finished product and modifying.

Owner:王培志 +4

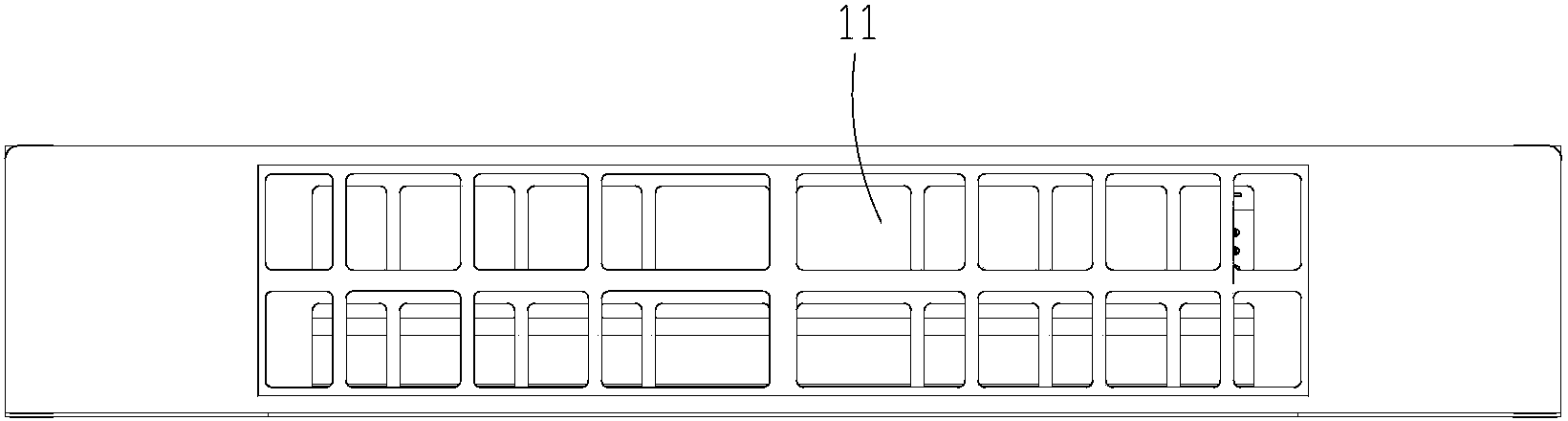

Wall-mounted air conditioner

ActiveCN104110726AEliminate structural defectsImprove satisfactionDucting arrangementsCondensate preventionCold airEngineering

The invention provides a wall-mounted air conditioner which comprises a shell, an air inlet, a first air outlet, a heat exchanger and a cross-flow fan. The air inlet is formed in the shell, the first air outlet is formed in the lower portion of the shell, the heat exchanger is arranged in the shell, and the cross-flow fan is mounted in the shell and used for enabling air flow entering from the air inlet to be discharged from the first air outlet; the wall-mounted air conditioner further comprises a second air outlet, a centrifugal fan and a driving mechanism, the second air outlet is arranged in the upper portion of the shell, the centrifugal fan is mounted in the shell and used for enabling the air flow entering from the air inlet to be discharged from the second air outlet, and the driving mechanism is used for driving the cross-flow fan and the centrifugal fan to rotate. The second air outlet is additionally arranged in the topmost of an existing wall-mounted air conditioner, so that structural defect that the air conditioner blows air obliquely and downwardly is eliminated, and cold air of the air conditioner can be completely prevented from being blown to people; in addition, good outlet airflow organizing and regulating capacities are achieved under different conditions of cooling, heating and the like, free regulation can be achieved according to preferences of users, comfortableness of indoor environment can be improved, and user's satisfaction can be improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

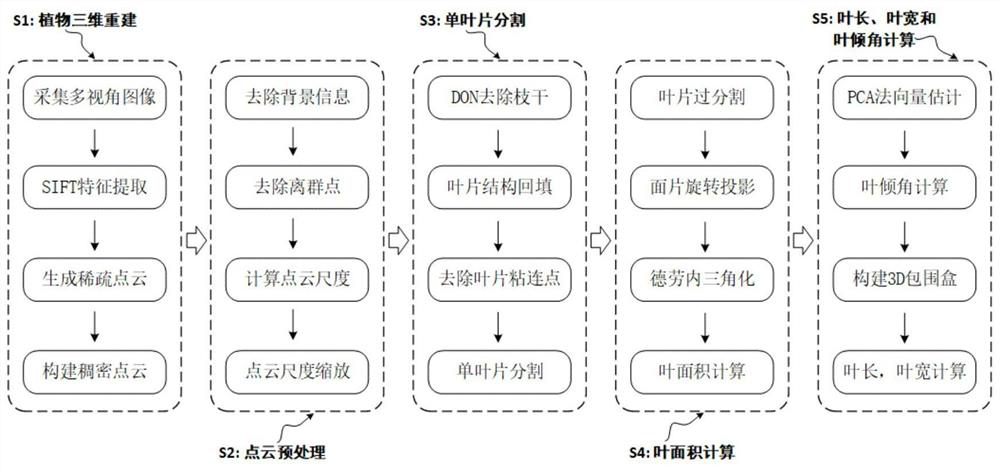

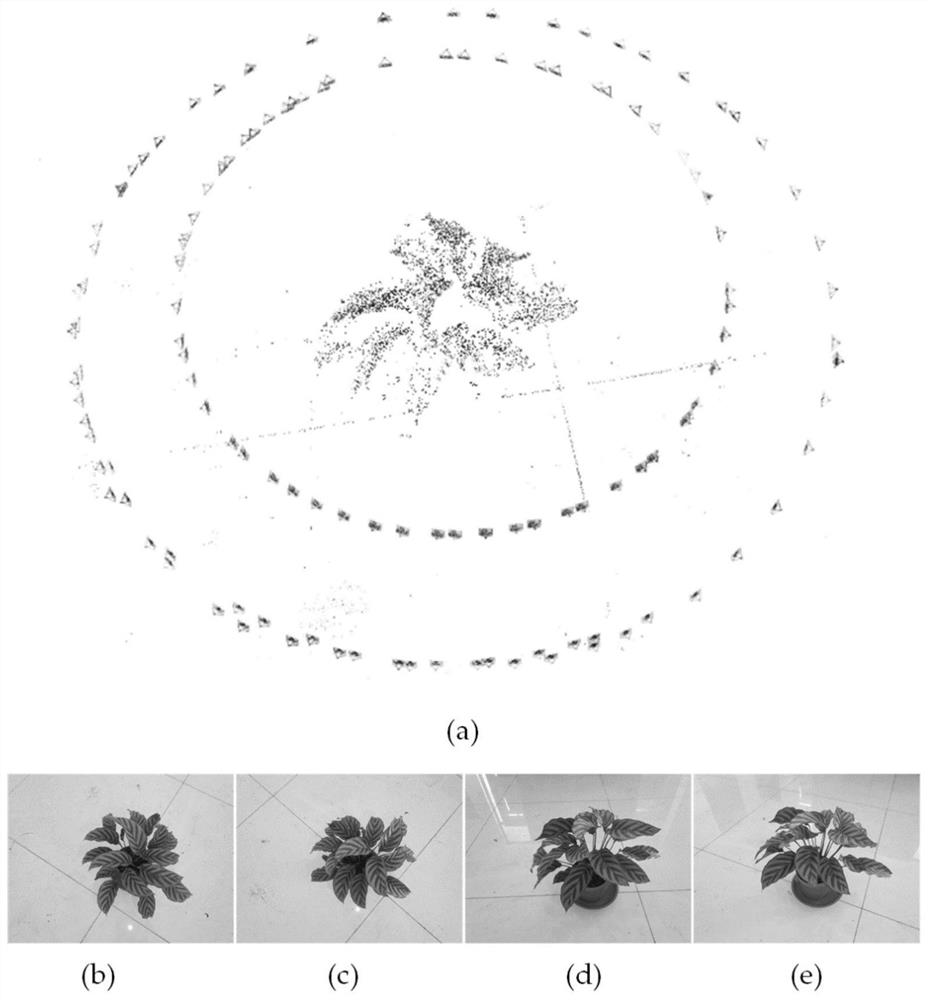

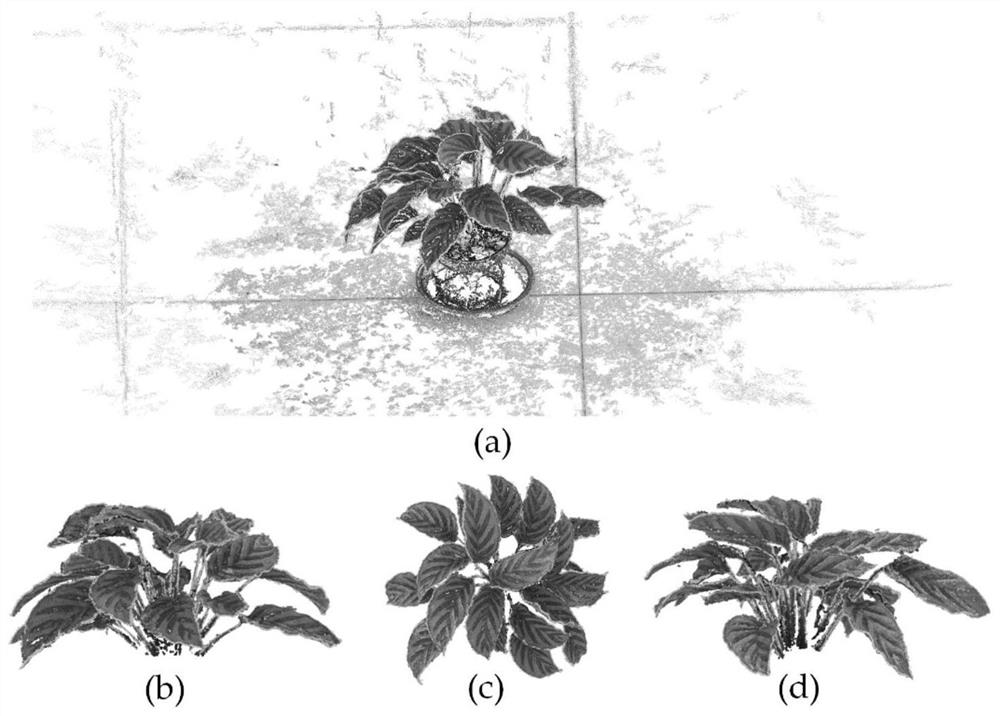

Plant point cloud blade segmentation and phenotypic characteristic measurement method

InactiveCN111667529AEliminate structural defectsHigh precisionImage enhancementImage analysisVision algorithmsEngineering

The invention provides a plant point cloud blade segmentation and phenotypic characteristic measurement method, comprising the steps: firstly, performing accurate point cloud three-dimensional reconstruction on potted plants by using a multi-view stereoscopic vision algorithm; secondly, removing non-blade parts in the plant point cloud by using a region and color-based filter and a normal vector difference algorithm; and then realizing single-blade segmentation on the canopy with the blade overlapping phenomenon by means of curvature information and a multi-feature region growth algorithm. Foreach single blade, a 3D bounding box of the blade is estimated by utilizing PCA, and the blade inclination angle can be calculated as an included angle between the height direction of the bounding box and the Z axis of a crop coordinate system, and the blade length and the blade width are the length and the width of the bounding box. The plant point cloud blade segmentation and phenotypic characteristic measurement method can realize automatic blade segmentation of potted plants with overlapped and clustered blades, has high precision and real-time performance for extracting phenotypic information such as blade area, blade length, blade width, blade inclination angle and the like, and is suitable for high-throughput blade phenotypic analysis.

Owner:DONGHUA UNIV

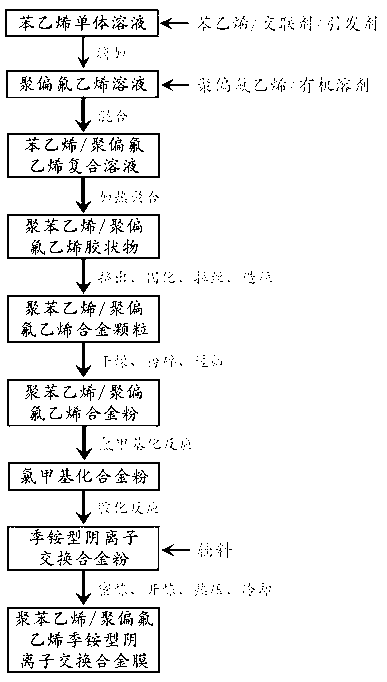

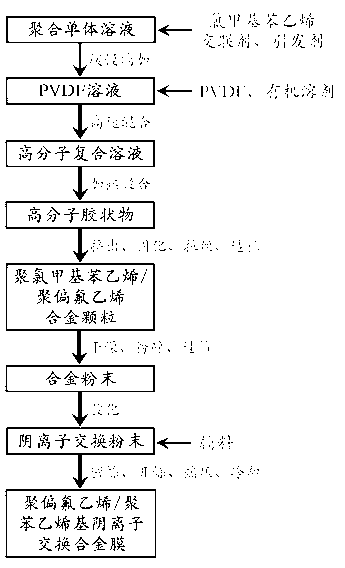

Polystyrene/polyvinylidene fluoride quaternary ammonium type anion exchange alloy film preparation method

InactiveCN103223305AEliminate structural defectsLow film resistanceSemi-permeable membranesPolyvinylidene fluoridePolystyrene

The invention discloses a polystyrene / polyvinylidene fluoride quaternary ammonium type anion exchange alloy film preparation method, which comprises the following steps: dissolving polyvinylidene fluoride firstly, uniformly mixing the polyvinylidene fluoride and a polymerized monomer solution containing styrene, a cross-linking agent and an initiator, and then heating for copolymerization, extruding, solidifying, granulating, drying, crushing and other steps for obtaining polystyrene / polyvinylidene fluoride alloy powder; obtaining a quaternary ammonium type anion exchange alloy powder by applying chloromethylation reaction and amination reaction to alloy powder finally using a hot pressing moulding method, adding auxiliary material, banburying, milling, pulling sheet, hot pressing, cooling and obtaining polystyrene / polyvinylidene fluoride quaternary ammonium type anion exchange alloy membrane. The quaternary ammonium type anion exchange alloy membrane prepared by the invention has the advantages of high-molecular interpenetrating network structure, which completely eliminates the structure defect that the anion exchange resin powder and the high-molecular binder in the traditional interphase anion exchange membrane are not compatible with low resistor.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

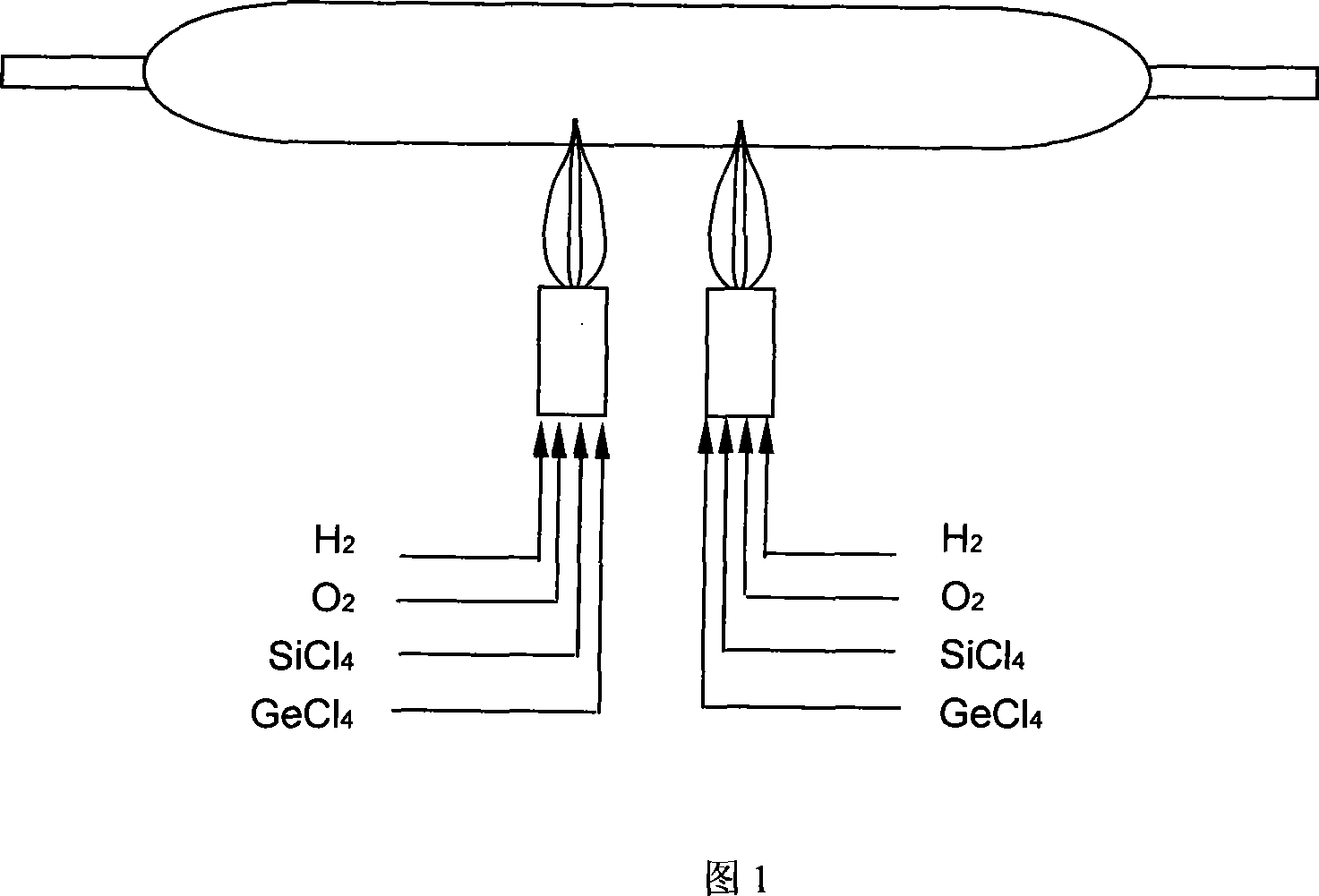

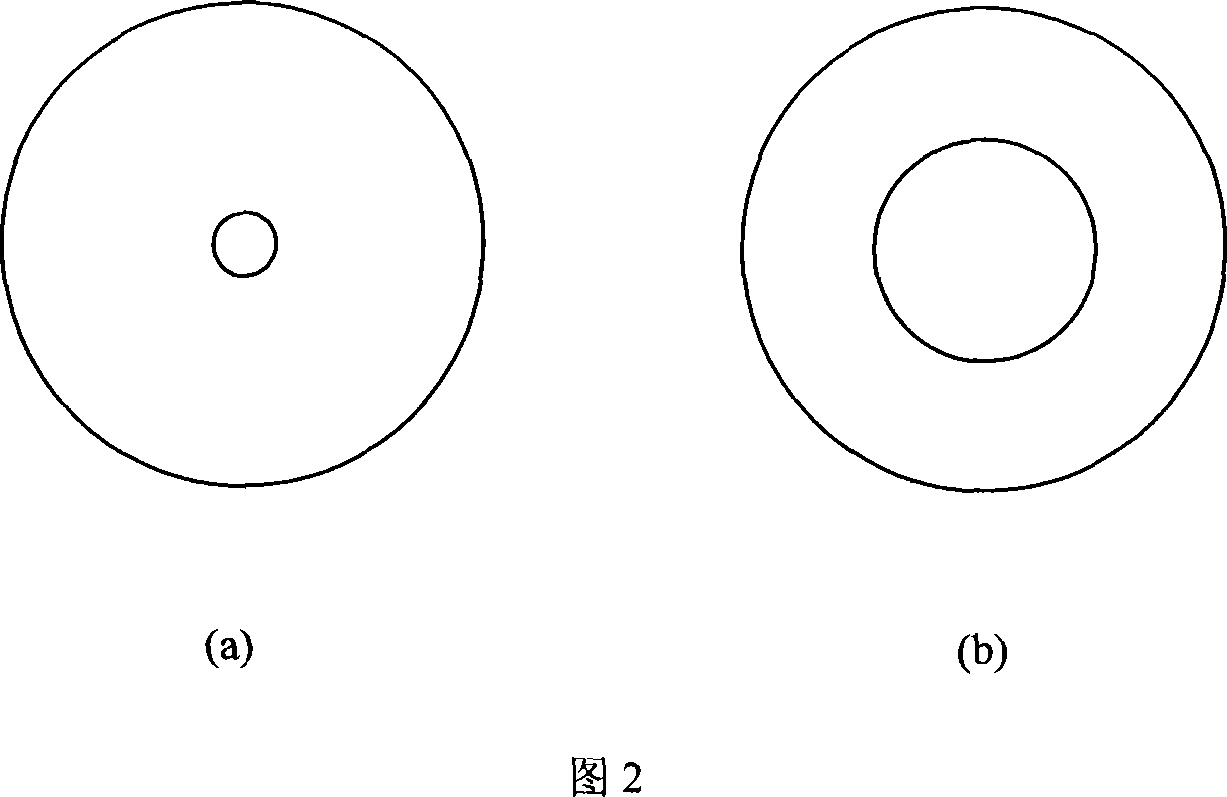

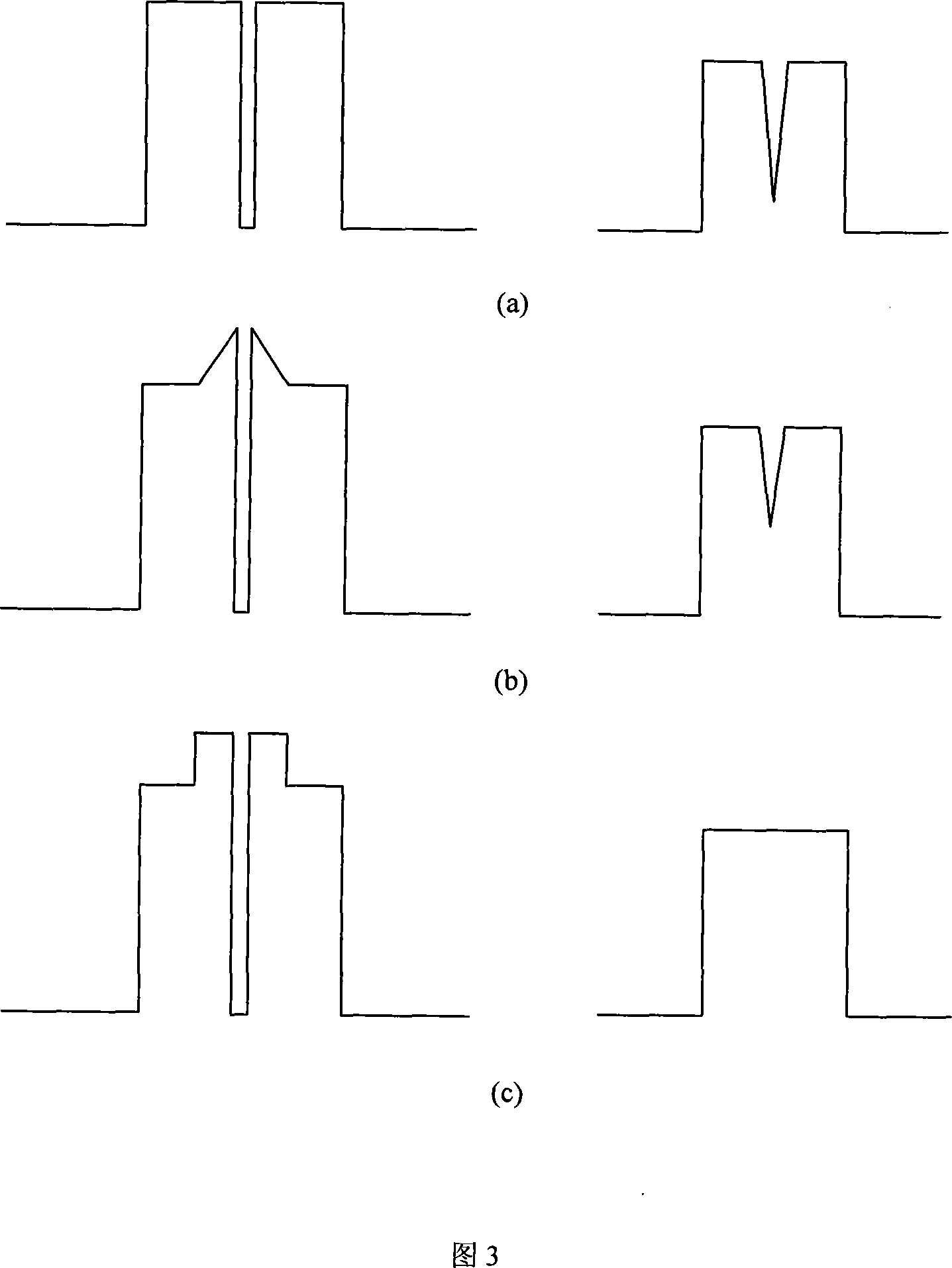

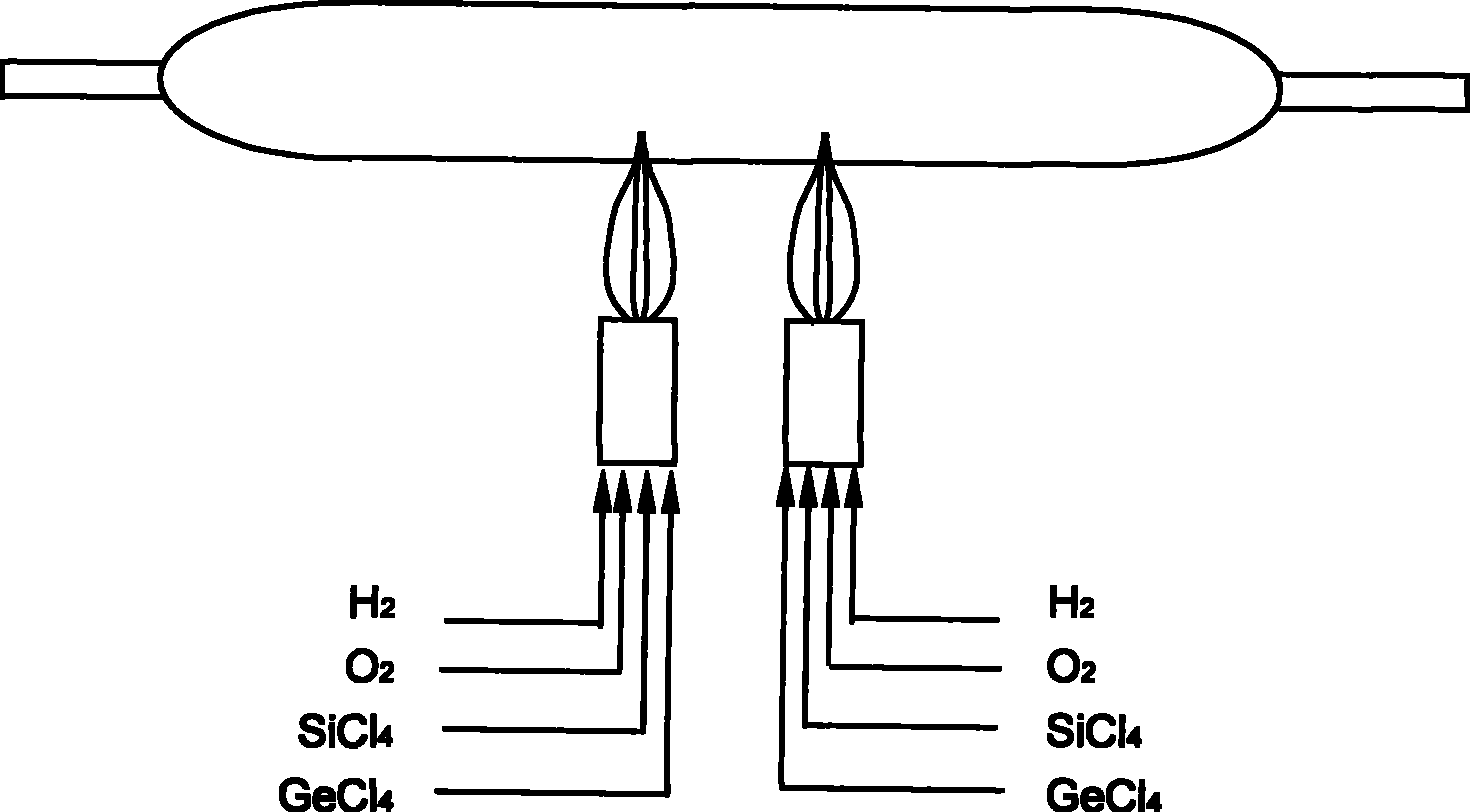

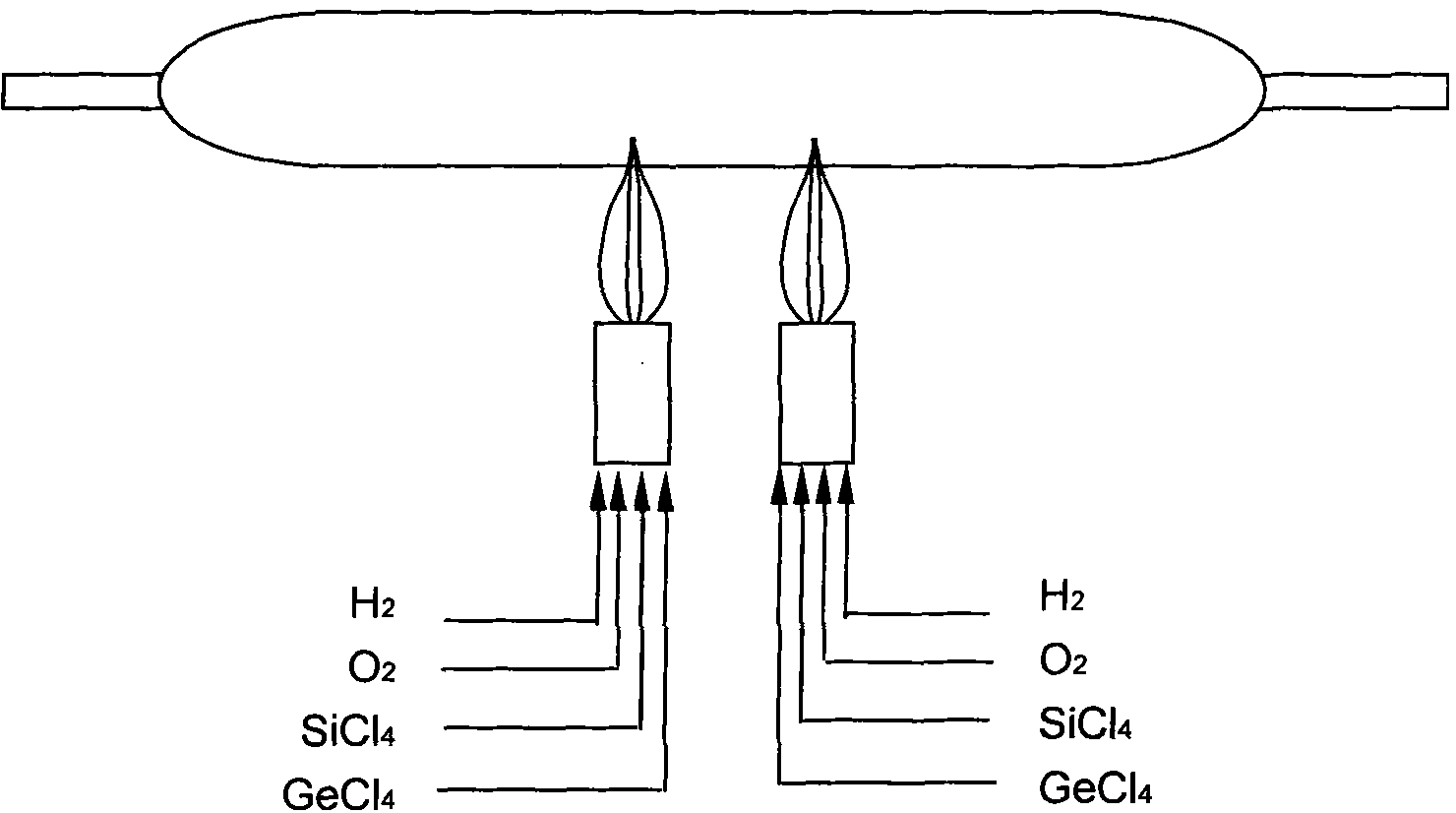

Process of preparing fiber preformrod

ActiveCN101066834AEliminate network structure flawsExcellent anti-hydrogen aging propertiesGlass making apparatusGlass productionChemistryBridging oxygen

The process of preparing fiber preformed rod includes deuterium-hydrogen displacement reaction on quartz rod with low hydroxyl radical content and high purity for deuterium atom to occupy the non-bridge oxygen bond in quartz glass so as to reduce the probability of hydroxyl radical to diffuse, plasma flame etching to eliminate surface adsorbed hydroxyl radical of the quartz rod completely, depositing GeO2 and SiO2 onto the surface of the quartz rod, combined loose perform rod with central quartz rod, and dewatering and sintering in a sintering furnace to obtain transparent fiber preformed rod. The present invention is suitable for large- scale production and has low production cost, and the fiber preformed rod may be drawn into mono-mode fiber with low attenuation at 1383 nm wavelength, high hydrogen ageing resistance and very low PMD.

Owner:JIANGSU FASTEN CO LTD

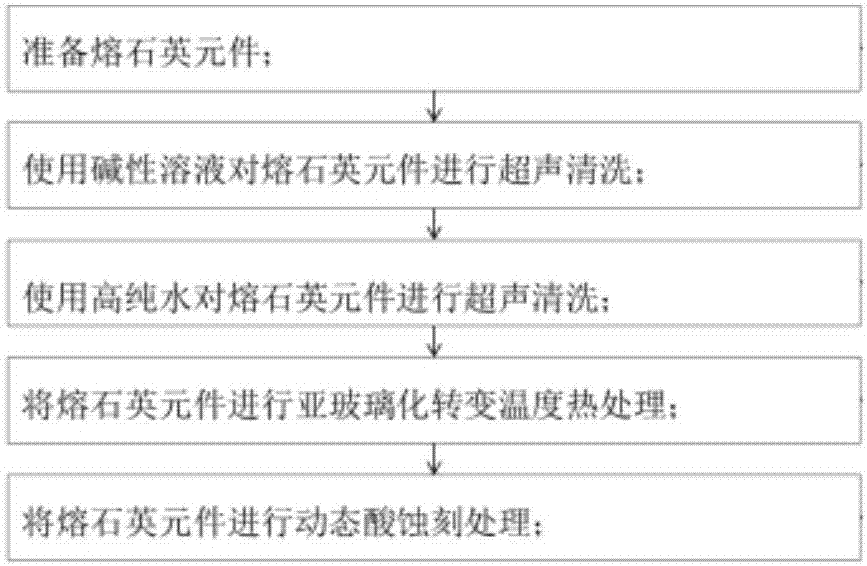

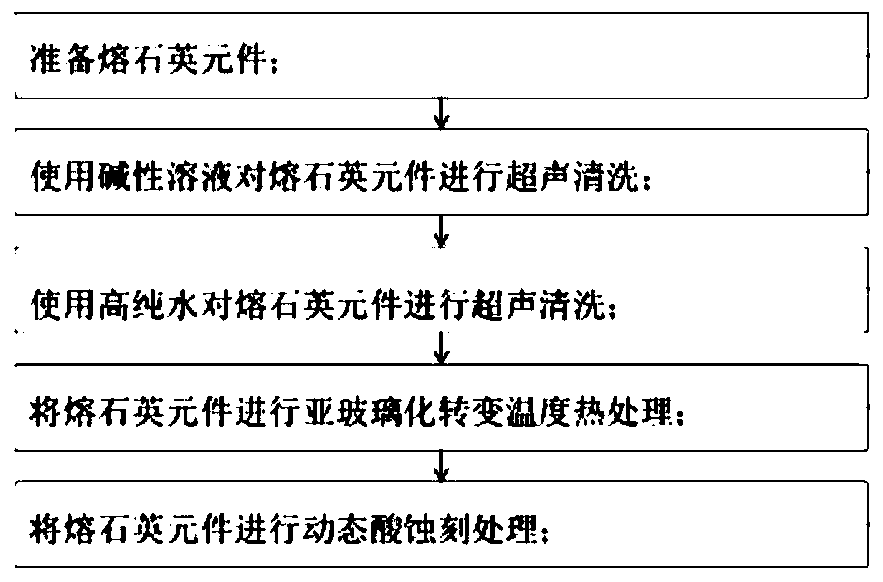

Method for improving uvioresistant laser damage for fused quartz optical element

ActiveCN107021650AImprove surface cleanlinessImproved resistance to UV laser damageVitrificationAcid etching

The invention discloses a method for improving uvioresistant laser damage for fused quartz optical element, comprising: using an alkaline solution to perform ultrasound cleaning on the fused quartz element; using ultrapure water to perform ultrasound cleaning on the fused quartz element cleaned by the alkaline solution, and drying the same; performing secondary vitrification conversion temperature heating treatment on the fused quartz element cleaned by the ultrapure water; and performing dynamic acid etching and drying on the fused quartz element after the heat treatment. The invention achieves the purposes of eliminating the structural defects of the fused quartz and improving uvioresistant laser damage for fused quartz by controlling parameters such as the temperature and the time of the secondary vitrification conversion temperature heating treatment, frequency of the dynamic acid etching sound field, solution concentration, and etching time, so as to meet running requirements of solid laser device with high power.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

Polystyrene /polystyrene anion exchange alloy film preparation method

InactiveCN103223306AEliminate structural defectsLow film resistanceSemi-permeable membranesPolyvinylidene fluorideIon-exchange membranes

The invention discloses a polystyrene / polystyrene anion exchange alloy film preparation method, which comprises the following steps: adding a polymerized monomer solution which is composed of 1-(chloromethyl)-4-ethenylbenzene, a cross-linking agent and an initiator into a polyvinylidene fluoride solution, and then heating for copolymerization, extruding, solidifying, granulating, drying, crushing and other steps for obtaining PCMS / polyvinylidene fluoride alloy powder; reacting the alloy powder and the amination solution, washing, transforming, drying and obtaining the anion exchange powder; finally using a hot pressing moulding method, adding auxiliary material, banburying, milling, pulling sheet, hot pressing and obtaining polyvinylidene fluoride / polystyrene anion exchange alloy membrane. The anion exchange alloy membrane manufactured by the invention has the advantages of high-molecular interpenetrating network structure, whose membrane area resistance is greatly lower than the traditional interphase anion exchange membrane, and the comprehensive properties of the membrane approaches to the homogeneous anion exchange membrane. The invention avoids the usage of carcinogenic reagent chloromethyl ether, and is easy for realization of industrial production.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

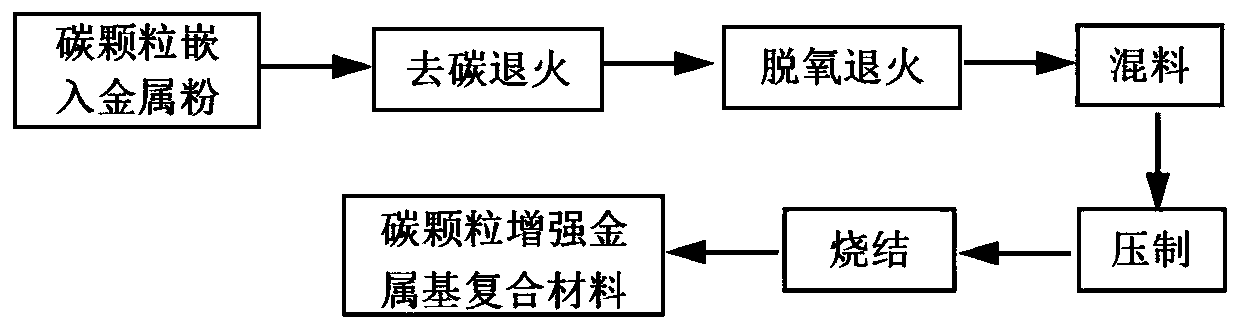

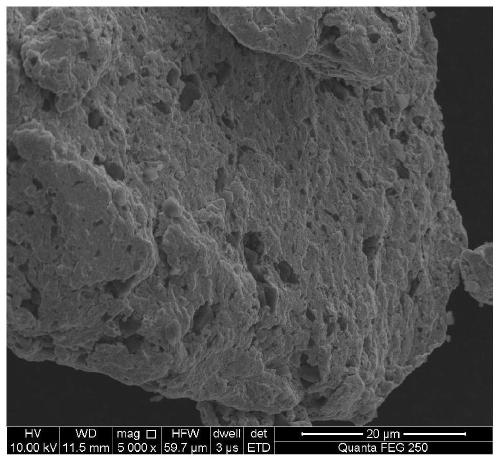

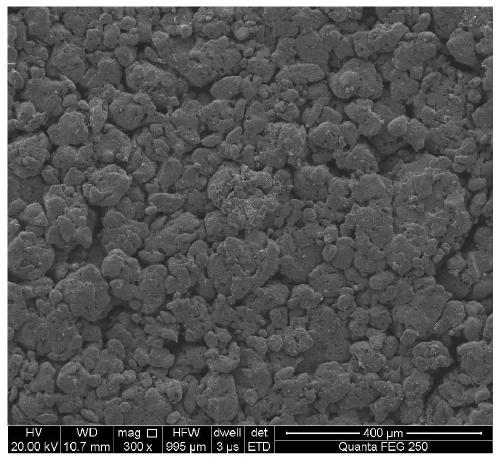

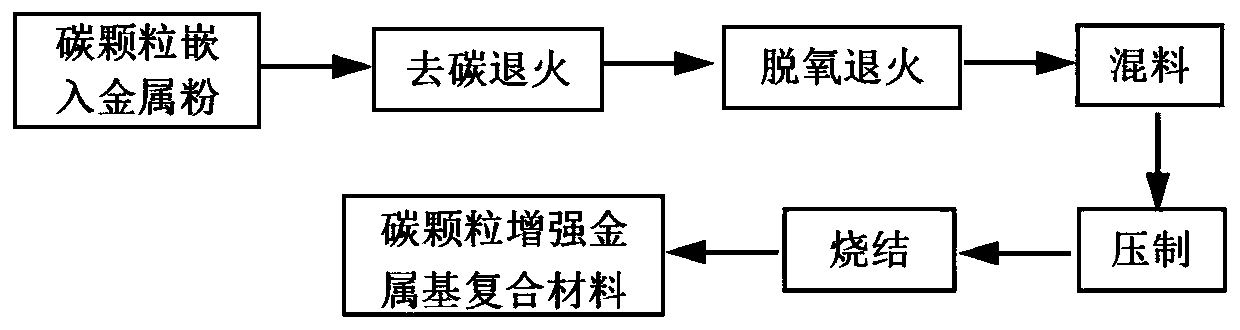

Preparation method of metal-carbon composite

ActiveCN109695007AImprove wear resistanceImproved sinter diffusionMaterials preparationCarbon composites

The invention relates to a preparation method of a metal-carbon composite, and belongs to the technical field of metal material preparation. Carbon particles are embedded in metal powder to conduct pre-oxidation treatment, carbon particles on the surfaces of metal particles are removed, the metal particles are reduced in a reduction atmosphere, and then the metal particles are mixed with other components to be pressed and sintered to obtain the metal-carbon composite. The preparation method successfully solves the problem that surface sintering is not compact during the sintering process of the metal powder with the carbon particles being embedded in. Under the premise that the metal powder is compact in sintering, the mechanical performance and abrasion resistance of the designed and prepared metal composite are greatly improved. The preparation technology is simple and the cost is low.

Owner:CENT SOUTH UNIV

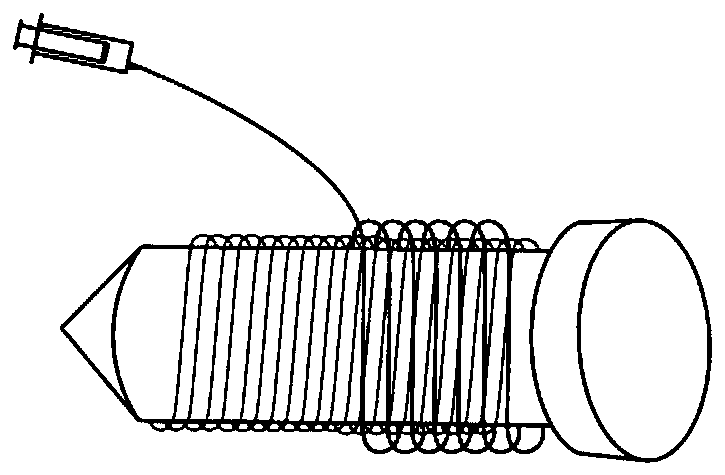

Chitosan bone nail material with spiral orientation structure and preparation method thereof

The invention discloses a chitosan bone nail material with a spiral orientation structure and a preparation method thereof. The method comprises the following steps: preparing a chitosan solution by adopting a mechanical stirring method; performing wet spinning on the chitosan solution by utilizing an injection device with a duct; performing orientation stretching and sequential spiral winding collection on primary fiber by adopting a collecting device at adjustable rotating speed, thereby acquiring a chitosan fiber bar with a compact three-dimensional piling structure; washing the bar till pH=6-8 and then placing into a SBF (Simulated Body Fluid) for mineralizing; and cleaning and drying, thereby acquiring the chitosan bone nail. A medical chitosan bone nail prepared according to the invention has a height orientation structure and a self-threading function; the step of externally threading is avoided; the structure defects and the raw material waste brought by the process of externally threading are eliminated; the bone induction regeneration capacity of the bone nail is greatly promoted in the mineralizing process; the bone nail is expected to be applied to the field of bone regeneration and repairing.

Owner:ZHEJIANG UNIV

Preparation method for polystyrene/polyvinylidene fluoride cation exchange membrane

ActiveCN102814125BEliminate structural defectsLow membrane resistanceSemi-permeable membranesCross-linkPolystyrene

The invention discloses a preparation method for a polystyrene / polyvinylidene fluoride cation exchange membrane. According to the method, polyvinylidene fluoride is used as a matrix material for the membrane. The method comprises the following steps: dissolving polyvinylidene fluoride and then fully mixing dissolved polyvinylidene fluoride with styrene and a cross-linking agent so as to obtain a homogeneous polymer solution; carrying out heat-initiated crosslinking copolymerization so as to obtain gelatinoid with an interpenetrating network structure; subjecting the gelatinoid to polymer physical processing so as to obtain polystyrene / polyvinylidene composite powder; then preparing cation exchange powder by using a sulfonation method for a storng-acid cation exchange resin as reference; and finally preparing the cation exchange membrane by using a hot pressing molding method for a heterogeneous cation exchange membrane. The polystyrene / polyvinylidene fluoride cation exchange composite high polymer membrane prepared in the invention has the interpenetrating network structure, so the structural defect of incompatibility between cation exchange resin powder and a high polymer binder in conventional heterogeneous cation exchange membranes is eradicated, membrane resistance is substantially reduced, and comprehensive properties of the polystyrene / polyvinylidene fluoride cation exchange membrane in the invention are closer to comprehensive properties of cation exchange membranes.

Owner:辽宁易辰膜科技有限公司

3D printing diamond/metal matrix composite material and preparation method and application thereof

ActiveCN113770381AEffective bezel settingFine grainAdditive manufacturing apparatusVacuum evaporation coating3d printMetal matrix composite

The invention discloses a 3D printing diamond / metal-based composite material and a preparation method and application thereof. The 3D printing diamond / metal-based composite material comprises core-shell structure doped diamond, a metal-based material and an additive, and the core-shell structure doped diamond comprises a core, a transition layer, a shell, a coating, a porous layer and a modification layer. The preparation method of the material comprises the following steps: uniformly mixing diamond, a metal matrix and the additive, and then carrying out 3D printing according to a three-dimensional CAD slicing model to finally obtain the composite material designed by the model. According to the 3D printing diamond / metal matrix composite material, the obtained metal matrix and the diamond surface are mainly subjected to metallurgical bonding, and the bonding strength of the diamond / metal matrix can be improved, so that the use performance of the composite material and a diamond tool is improved, the core-shell structure doped diamond is good in ablation resistance, and the problem of diamond thermal damage in the 3D printing forming process can be effectively avoided and reduced.

Owner:CENT SOUTH UNIV

FRP-SMA steel bridge deck pavement structure

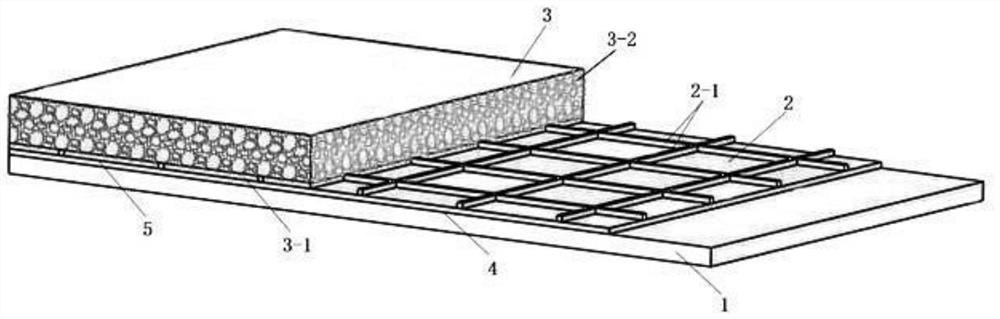

PendingCN113186816ALow costImprove economic levelBridge structural detailsArchitectural engineeringBridge deck

The invention discloses an FRP-SMA steel bridge deck pavement structure. The structure is composed of an FRP pavement protection layer and an SMA pavement wearing layer which are laid from bottom to top. The top face, facing the SMA pavement wearing layer, of the FRP pavement protection layer is provided with convex-edge matts-shaped shear keys; and the thickness of the SMA pavement wearing layer embedded into the matts of the FRP pavement protection layer is a thermosetting SMA thin layer, and the rest thickness is a thermoplastic SMA thin layer. According to the present invention, the convex-edge matts-shaped shear keys of the FRP pavement protection layer can restrain the SMA mixture to drive the interface bonding resin to slide during the SMA pavement wearing layer construction so as to ensure the interface connection quality, and can provide the synergistic effect with the thermosetting SMA thin layer of the SMA pavement wearing layer so as to enhance interface shear connection in the transverse bridge direction and the longitudinal bridge direction after the SMA wearing layer molding, so that the structure form is more reasonable, structural stress is safer, design and construction quality is more controllable, engineering cost is more economical, the two technical problems which are difficult to solve in the asphalt concrete steel bridge deck pavement structure can be solved, and the technical and economic levels of flexible steel bridge deck pavement are remarkably improved.

Owner:张锡祥

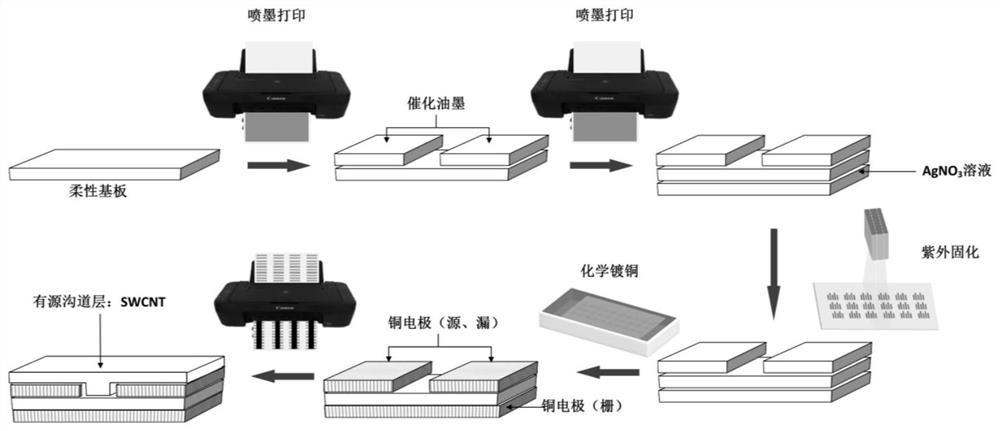

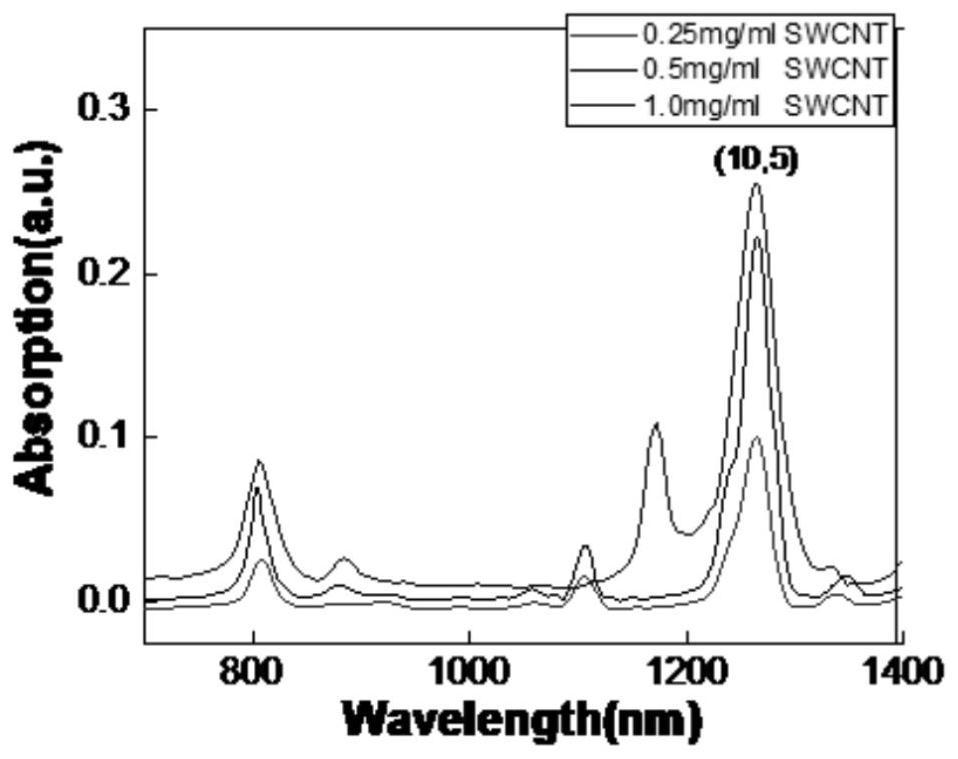

Full-printed semiconductor carbon nanotube field effect transistor and preparation method thereof

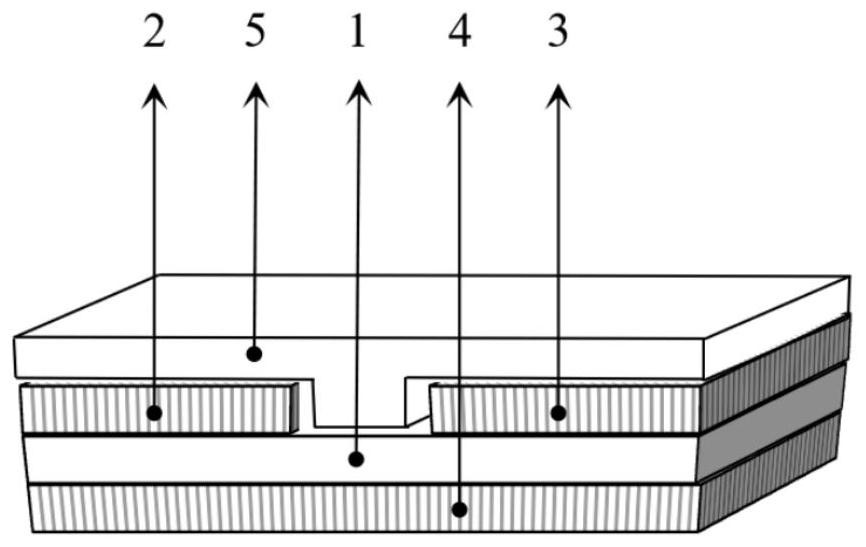

PendingCN113193114ASimple preparation processPromote crystallizationMaterial nanotechnologySolid-state devicesGate dielectricDevice material

The invention belongs to the technical field of semiconductor devices, and particularly relates to a full-printed semiconductor carbon nanotube field effect transistor and a preparation method thereof. The transistor comprises a bottom gate electrode (4), an insulated gate dielectric layer (1), a source electrode (2), a drain electrode (3) and a source semiconductor channel layer (5) from bottom to top. The preparation method comprises the following steps: firstly, preparing a high-purity dispersion liquid which is suitable for an ink-jet printing process and is enriched with semiconductor carbon nanotubes; a source electrode (2) and a drain electrode (3) are prepared on the front surface of the flexible substrate, and a large-area back gate electrode (4) is prepared on the back surface of the flexible substrate; and finally, a layer of single-walled carbon nanotube ink is printed on the source electrode and the drain electrode through an ink-jet printing process to serve as an active semiconductor channel layer (5) so as to complete the full-printing preparation of the flexible semiconductor single-walled carbon nanotube field effect transistor. Based on the technical means of high-selectivity purification of the carbon nanotubes, full-printing preparation of the field effect transistor and the like, the manufacturing method of the carbon nanotube field effect transistor, which is simple, efficient and easy for large-scale preparation, is provided, and the obtained flexible transistor device has the characteristics of excellent electrical properties and bending and stretching resistance.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

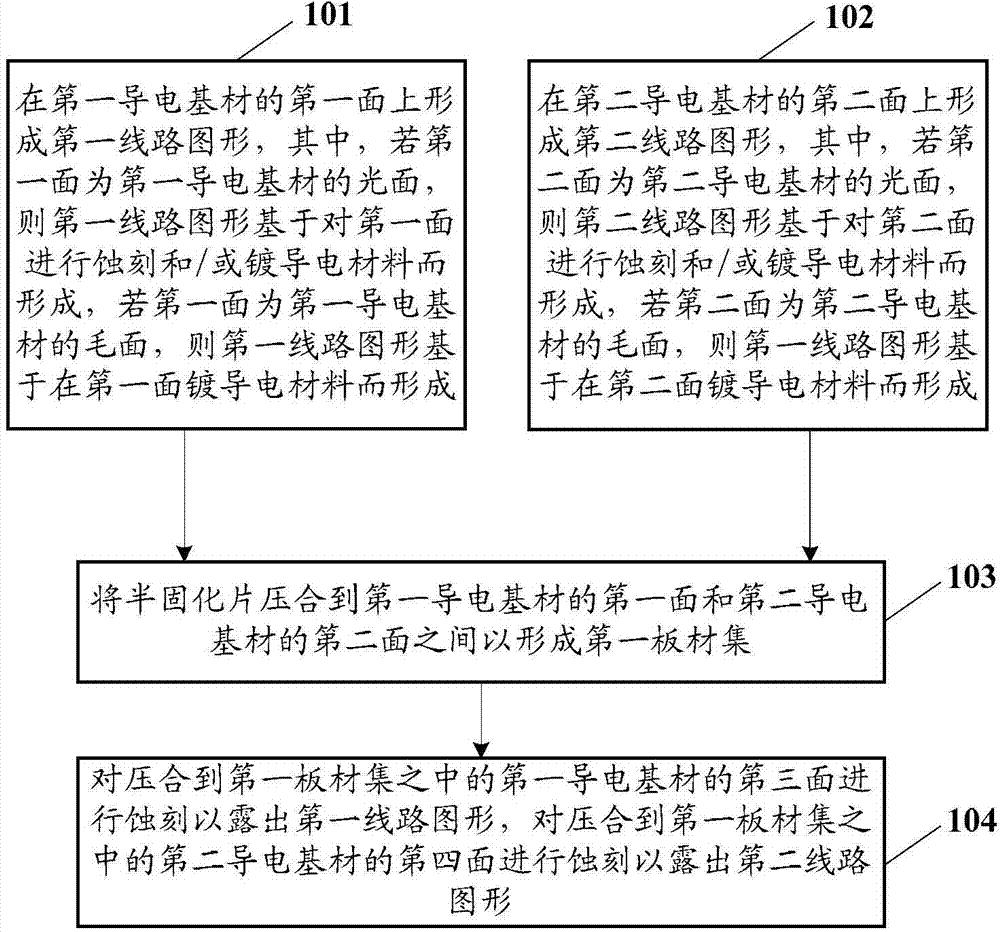

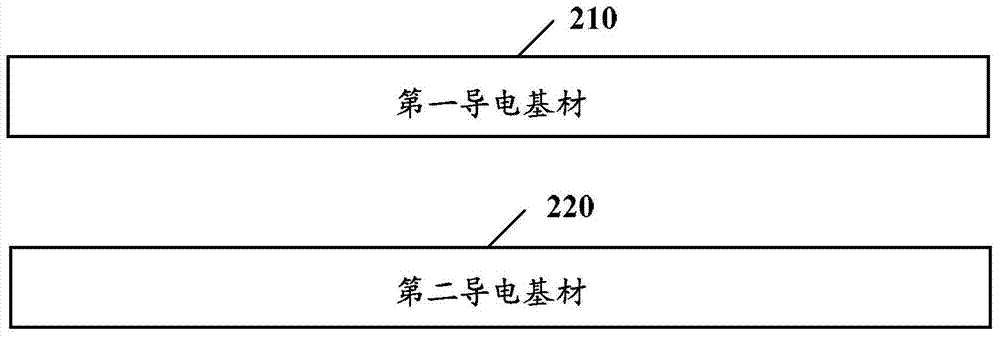

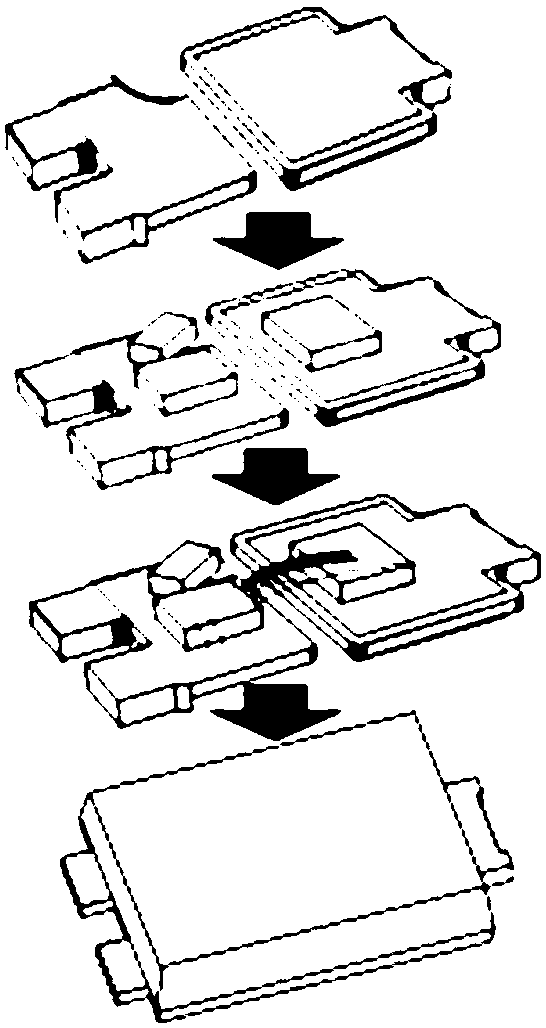

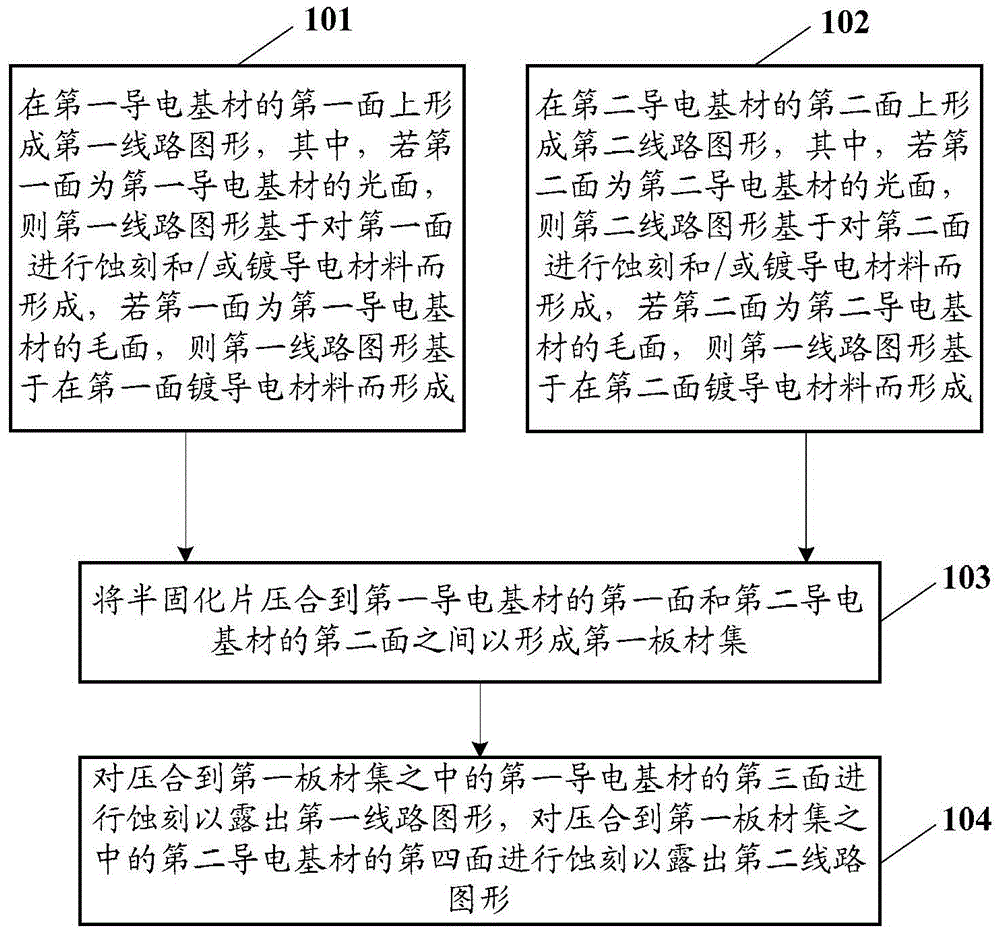

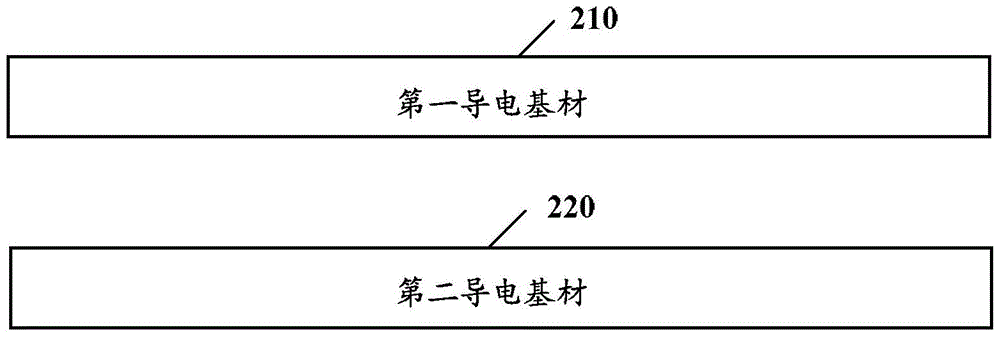

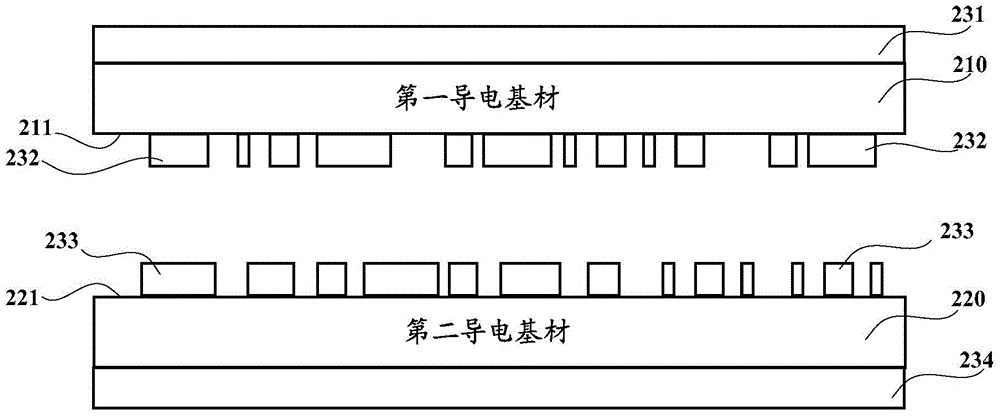

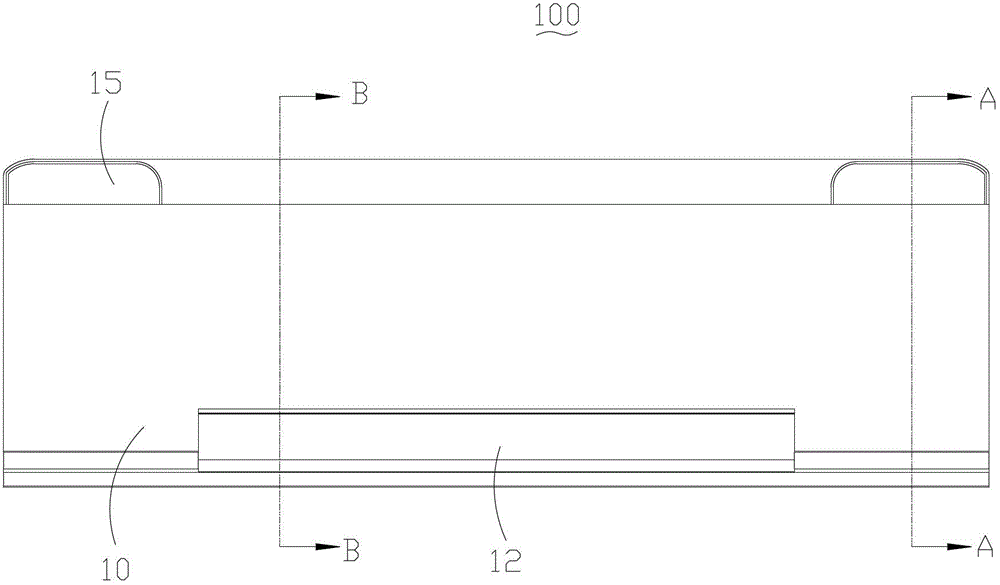

Circuit board processing method and device

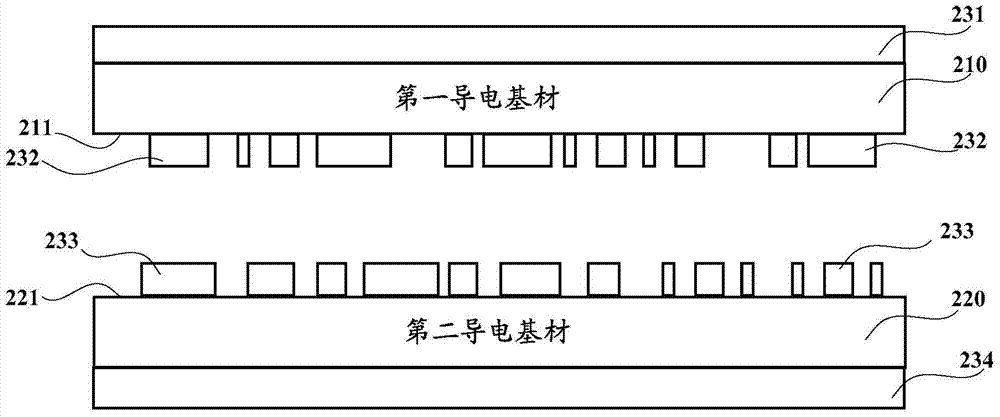

ActiveCN104735929AImprove flatnessGuaranteed withstand voltageMultilayer circuit manufactureEngineeringConductive materials

The embodiment of the invention discloses a circuit board processing method and device. The circuit board processing method comprises the steps that a first line pattern is formed on a first face of a first conductive substrate, and if the first face is a rough face of the first conductive substrate, the first line pattern is formed based on the mode that the first face is plated with a conductive material; a second line pattern is formed on a second face of a second conducive substrate, and if the second face is a rough face of the second conductive substrate, the second line pattern is formed based on the mode that the second face is plated with the conductive material; a prepreg is arranged between the first face of the first conductive substrate and the second face of the second conductive substrate through press fit, so that a first board material set is formed; a third face of the first conductive substrate in the first board material set is etched so that the first line pattern can be exposed, and a fourth face of the second conductive substrate in the first board set is etched so that the second line pattern can be formed. According to the scheme, on the premise that the thickness of the prepreg in the PCB is controlled to the greatest extent, the voltage resistance of the PCB is improved.

Owner:SHENNAN CIRCUITS

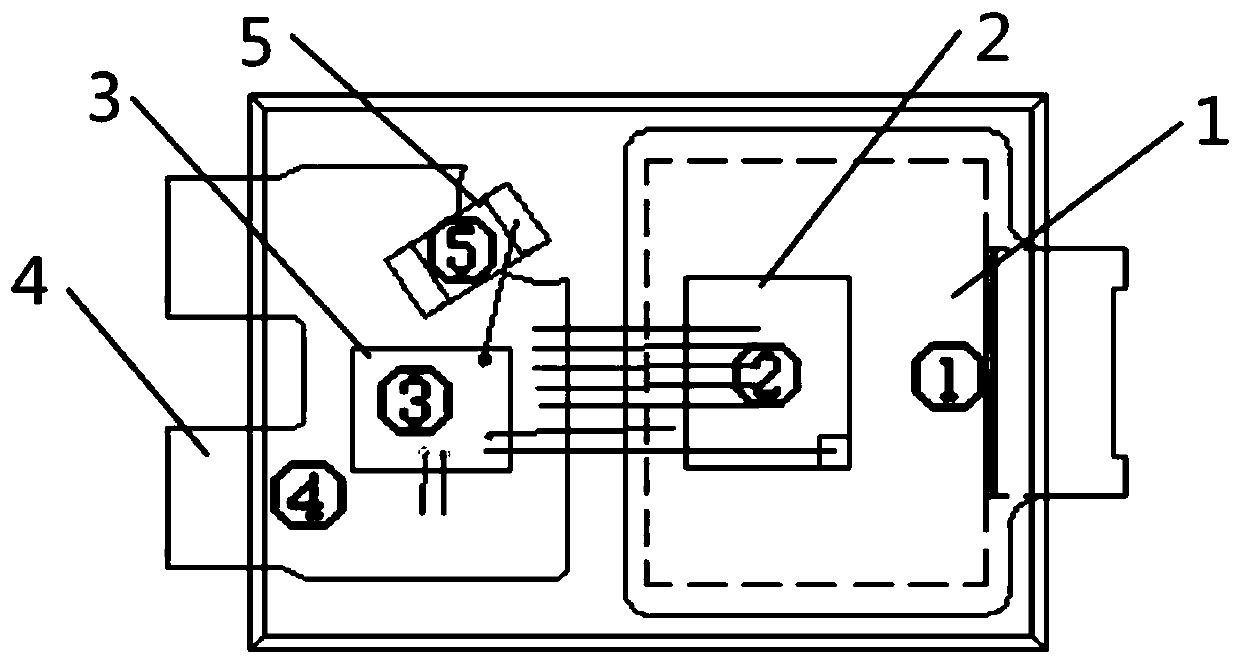

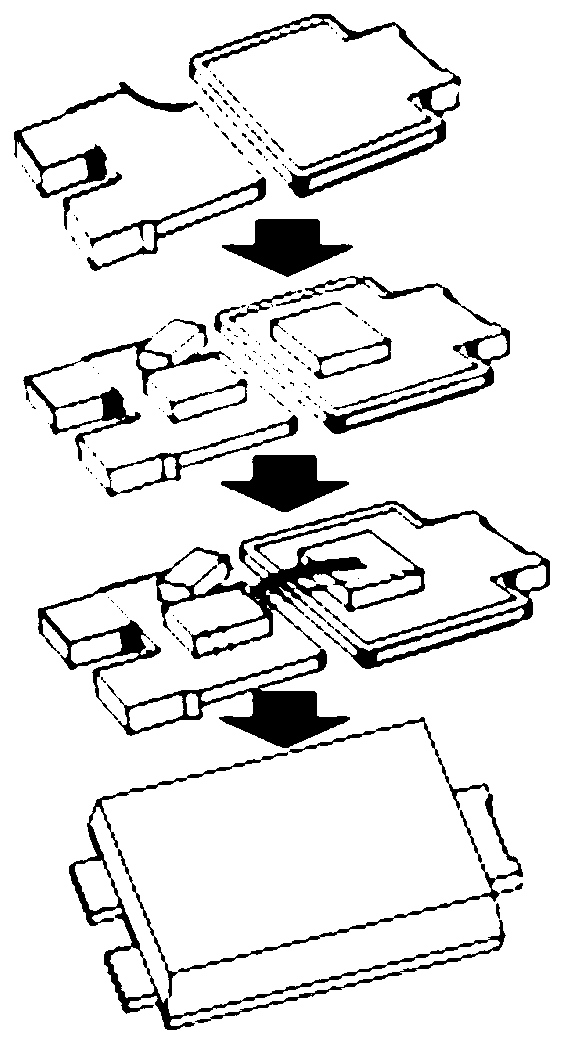

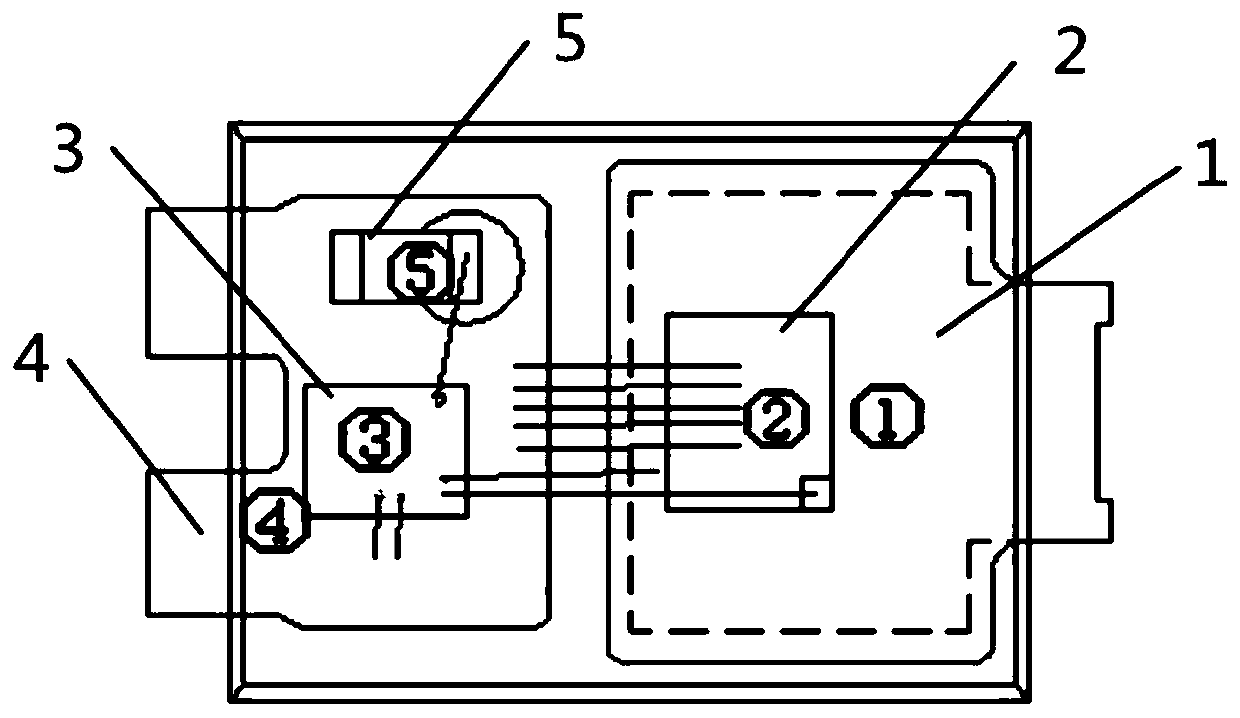

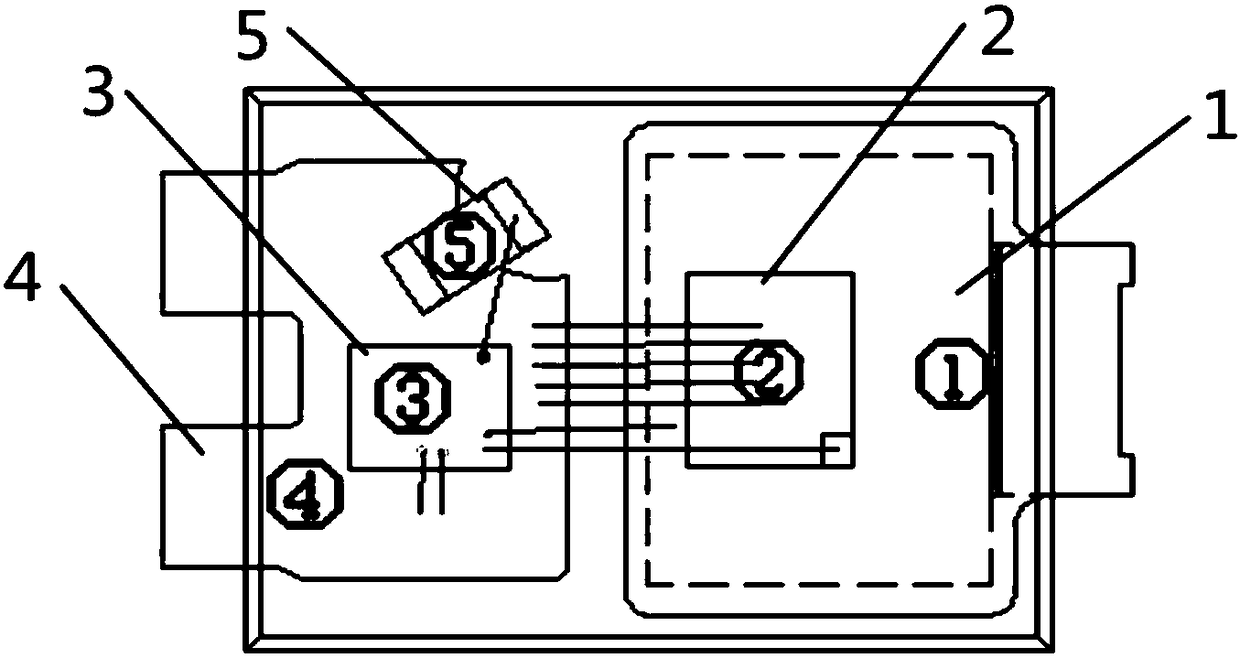

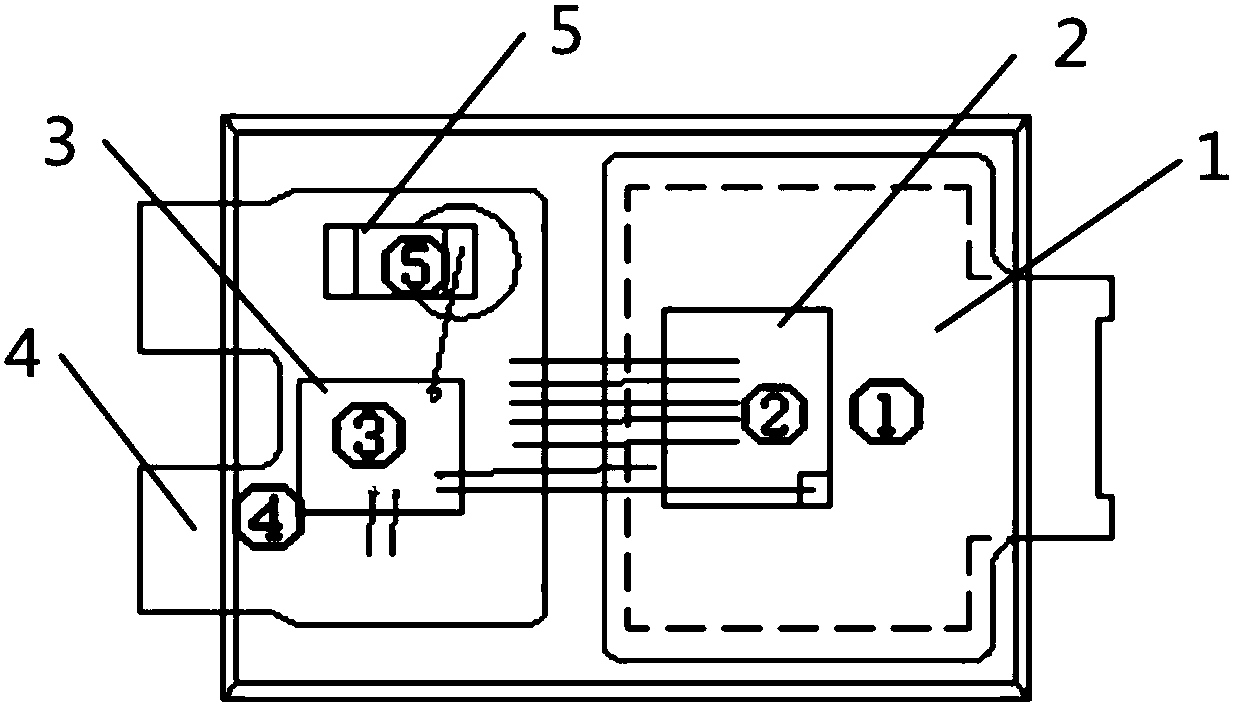

Two-chip synchronous rectifier diode

ActiveCN108281415BSmall sizeSimplify the installation processSemiconductor/solid-state device detailsSolid-state devicesCapacitanceMOSFET

The invention discloses a two-piece synchronous rectification diode, which comprises a first frame, a MOSFET chip, a control IC chip, a second frame, and a built-in capacitor. The second frame has two external pins, and the control IC chip is fixed on the second On the frame, the external terminal of the built-in capacitor is connected to the second frame; the first frame is provided with an external pin, and the MOSFET chip is fixed on the first frame; between the MOSFET chip and the control IC chip, between the control IC chip and the built-in Connections between internal terminals of the capacitor, between the MOSFET chip and the second frame, and between the control IC chip and the first frame are connected by bonding wires. The two-piece synchronous rectification diode optimizes the structure, integrates the available area of the PAD, and eliminates structural defects that may cause defects.

Owner:山东芯诺电子科技股份有限公司

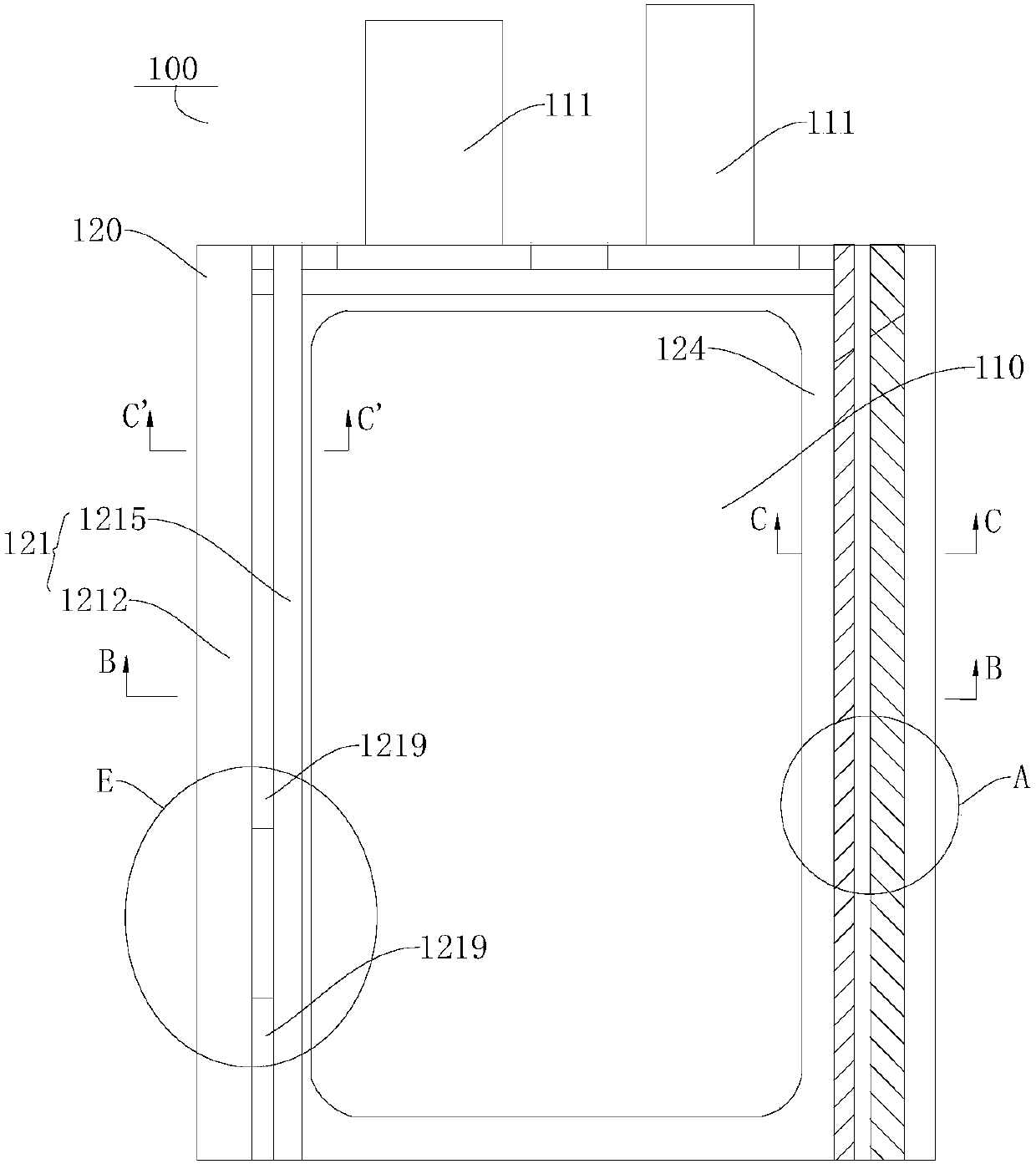

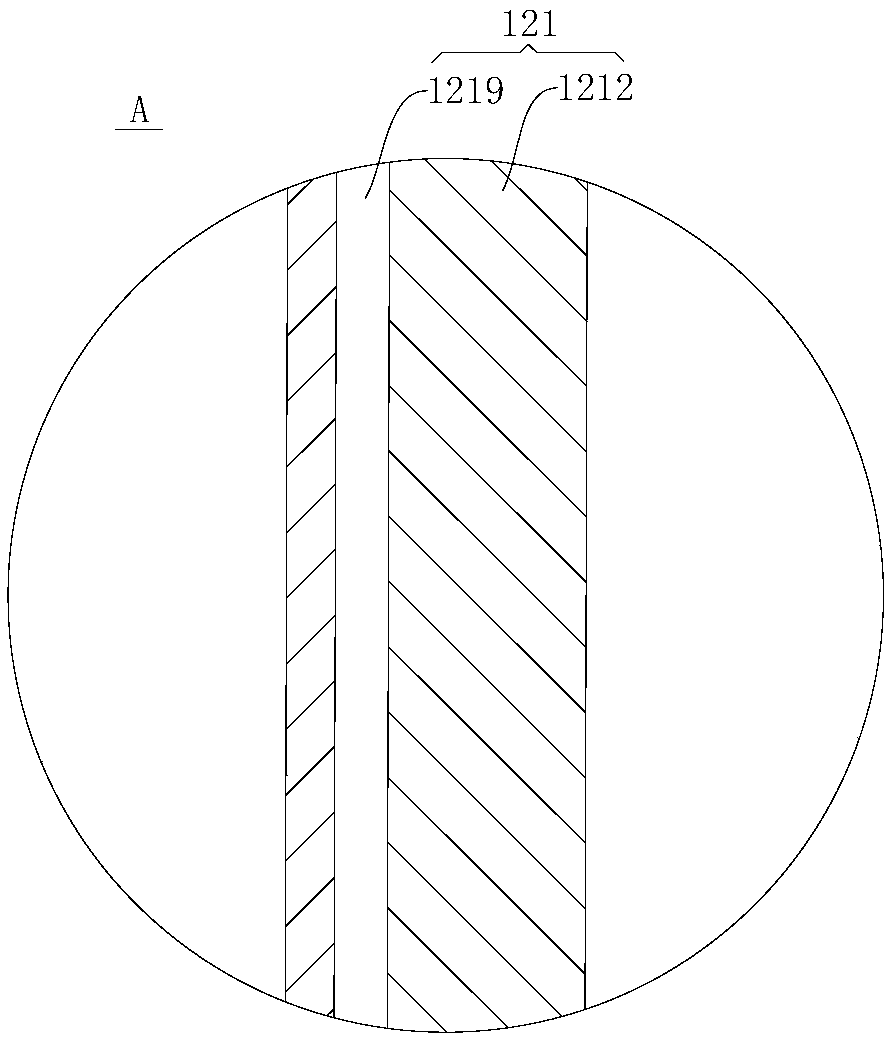

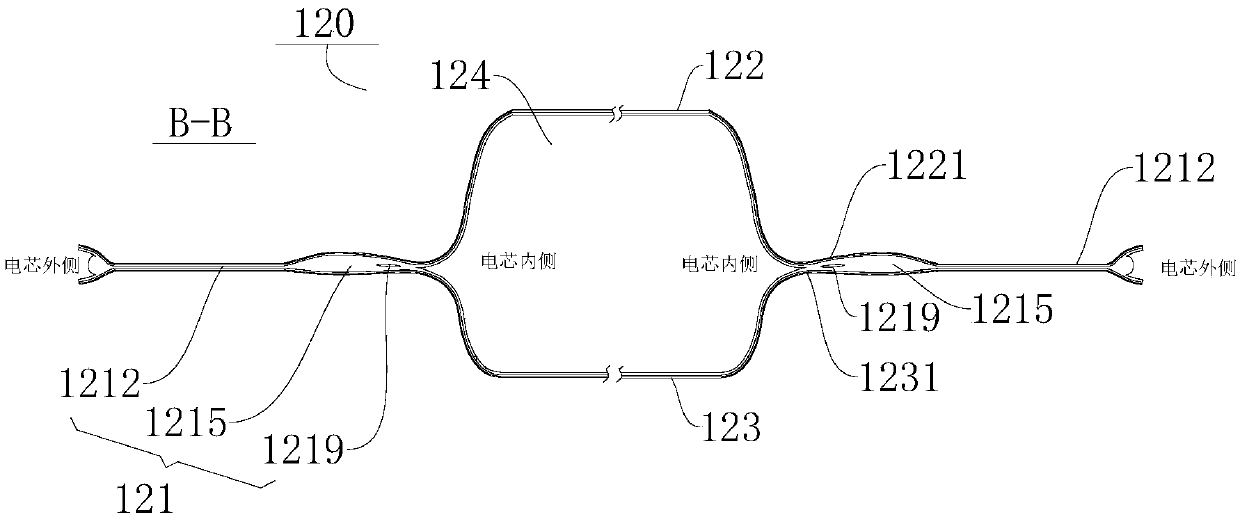

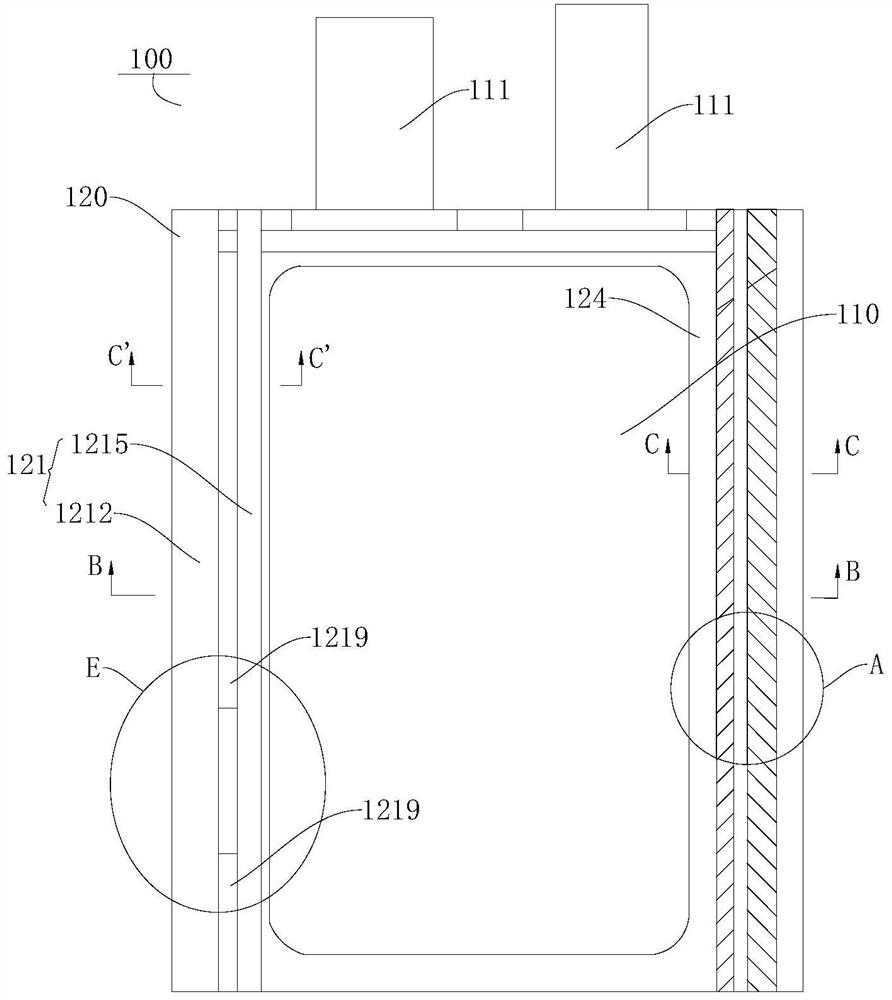

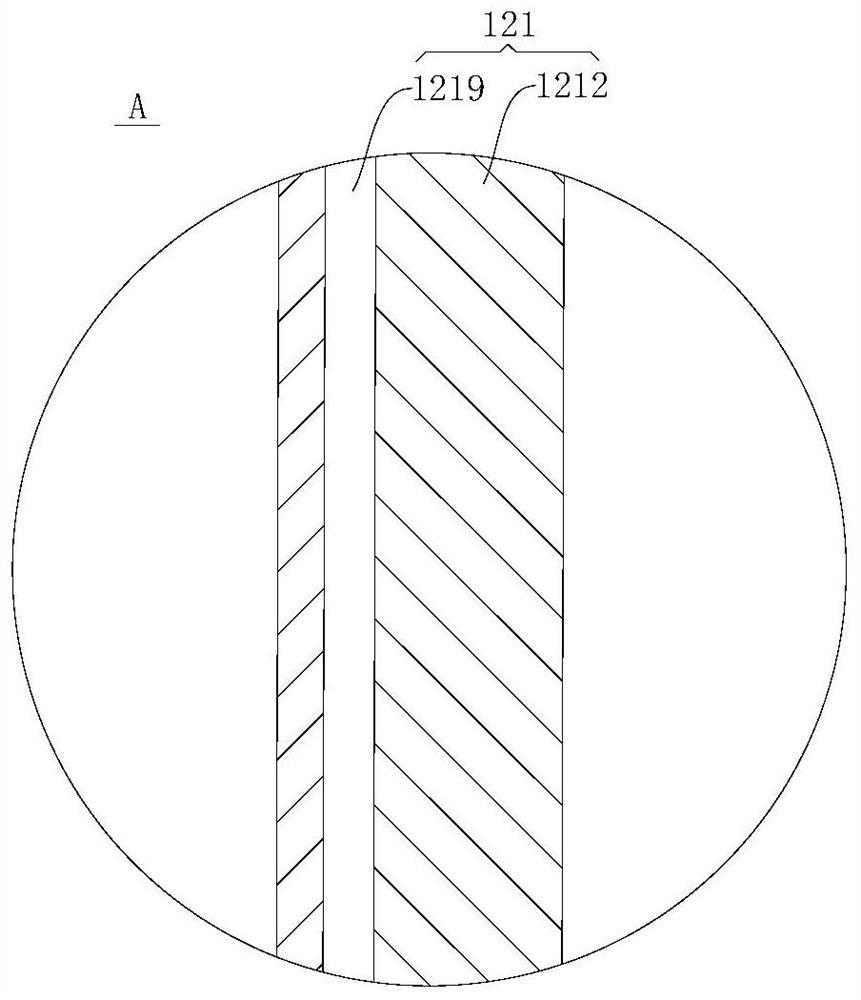

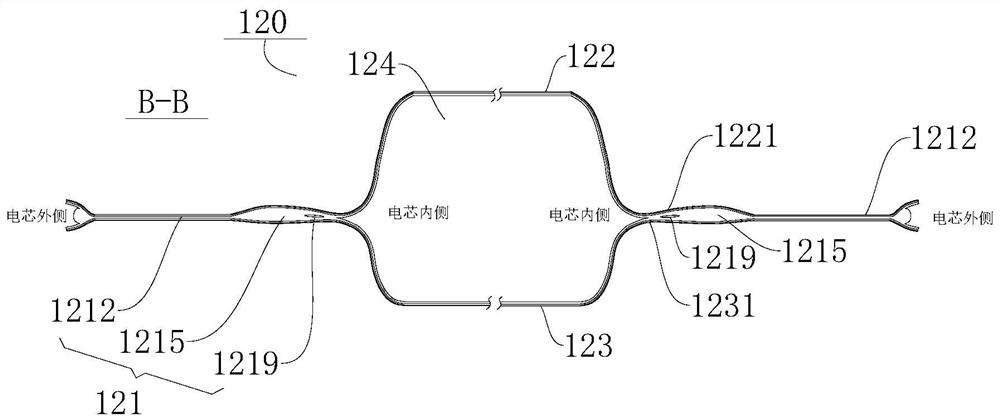

Battery cell and battery

ActiveCN111341945AImprove securityImprove package strengthWound/folded electrode electrodesSmall-sized flat cells/batteriesEngineeringMechanical engineering

The invention discloses a battery cell and a battery. The battery cell comprises a battery cell body and a packaging bag for accommodating the battery cell body; the packaging bag comprises a packaging part, and the packaging part comprises a sealing area; and a cavity is formed in the sealing area. According to the battery cell, the cavity is formed in the sealing area, so thermal stress caused by temperature gradient can be eliminated, the mechanical stress of the right angle of the sealing head on the packaging bag is eliminated, and the mechanical stress of the battery cell body is eliminated. Therefore, the morphology of the glue overflowing area of the packaging part can be improved, the structural defects of the glue overflowing area are overcome, the packaging strength of the packaging part of the battery cell is greatly improved, and the reliability and safety of the battery cell are improved.

Owner:NINGDE AMPEREX TECH

Method for Improving the Resistance of Ultraviolet Laser Damage to Fused Silica Optical Elements

ActiveCN107021650BEliminate structural defectsDoes not change surface topographyVitrificationAcid etching

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

A kind of preparation method of metal-carbon composite material

The invention relates to a preparation method of a metal-carbon composite, and belongs to the technical field of metal material preparation. Carbon particles are embedded in metal powder to conduct pre-oxidation treatment, carbon particles on the surfaces of metal particles are removed, the metal particles are reduced in a reduction atmosphere, and then the metal particles are mixed with other components to be pressed and sintered to obtain the metal-carbon composite. The preparation method successfully solves the problem that surface sintering is not compact during the sintering process of the metal powder with the carbon particles being embedded in. Under the premise that the metal powder is compact in sintering, the mechanical performance and abrasion resistance of the designed and prepared metal composite are greatly improved. The preparation technology is simple and the cost is low.

Owner:CENT SOUTH UNIV

A 3D printing diamond/metal matrix composite material and its preparation method and application

ActiveCN113770381BEffective bezel settingFine grainAdditive manufacturing apparatusVacuum evaporation coatingMetal matrix compositeDiamond tool

The invention discloses a 3D printing diamond / metal matrix composite material and a preparation method and application thereof. The 3D printing diamond / metal matrix composite material comprises a core-shell structure doped diamond, a metal-based material and additives. Structure doped diamond includes core, transition layer, outer shell, coating, porous layer and modification layer. The material preparation method is to mix diamond, metal matrix and additives evenly and then perform 3D printing according to the three-dimensional CAD slice model, and finally obtain the composite material designed by the model; the metal matrix obtained by 3D printing the diamond / metal matrix composite material of the present invention Metallurgical bonding with the diamond surface can improve the bonding strength of diamond / metal matrix, thereby improving the performance of composite materials and diamond tools, and the core-shell structure doped diamond has good ablation resistance, which can effectively avoid and reduce 3D printing. Diamond thermal damage during forming.

Owner:CENT SOUTH UNIV

Two-piece synchronous rectification diode

ActiveCN108281415ASmall sizeSimplify the installation processSemiconductor/solid-state device detailsSolid-state devicesCapacitanceMOSFET

The invention discloses a two-piece synchronous rectification diode. The two-piece synchronous rectification diode comprises a first framework, a metal-oxide-semiconductor field-effect transistor (MOSFET) chip, a control IC chip, a second framework and a built-in capacitor, wherein the second framework is provided with two external pins, the control IC chip is fixed on the second framework, the second framework is connected with an external wiring end of the built-in capacitor, the first framework is provided with an external pin, the MOSFET chip is fixed on the first framework, and the MOSFETchip and the control IC chip, the control chip and an internal wiring end of the built-in capacitor, the MOSFET chip and the second framework and the control chip and the first framework are connected by bonding wires. By the two-piece synchronous rectification diode, the structure is optimized, the available area of a PAD is integrated, and unfavorable structure defect easy to cause is removed.

Owner:山东芯诺电子科技股份有限公司

Process of preparing fiber preformrod

ActiveCN101066834BReduce or even eliminate hydroxyl contentElimination of hydroxyl contentGlass making apparatusGlass productionUltrasound attenuationHydrogen

Owner:JIANGSU FASTEN CO LTD

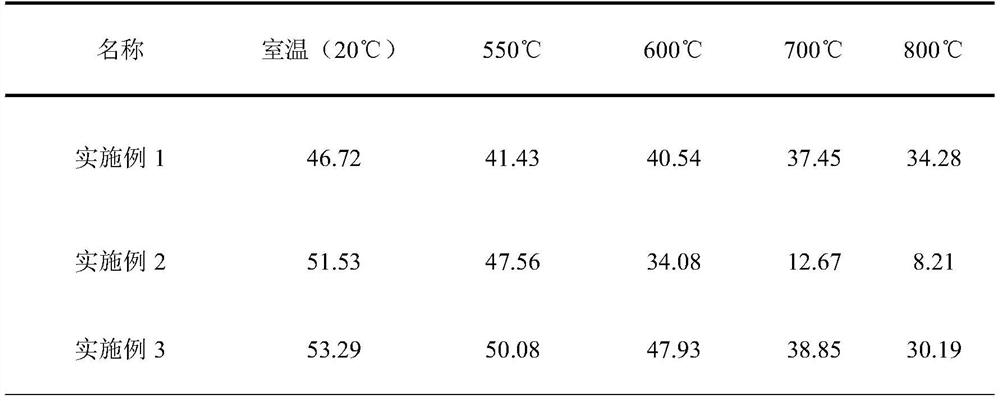

Method for improving mechanical performance and thermal shock resistance of compact heavy refractory product

InactiveCN101723693BImprove mechanical propertiesImprove toughnessFireproof paintsPorosityPhosphorous acid

The invention relates to a method for improving the mechanical performance and the thermal shock resistance of a compact heavy refractory product, which is characterized by comprising the following steps of: immerging the produced compact heavy refractory product into a phosphate solution which is formed by adding phosphorous acid with the concentration not less than 85wt% into active magnesium oxide and / or active aluminum oxide with the phosphorous acid weight of 3-5wt% for reaction, wherein the previous and subsequent weighing change is larger than 5-8 percent; taking out the mixture, drying and carrying out medium temperature processing at the temperature of 600-800 DEG C, thereby not only improving the mechanical performance of the refractory product, for example, the density is improved by 3-6 percent, the intensity is improved by about 20-40 percent, the high temperature folding strength at the temperature of 1,100 DEG C is respectively improved to 28 (porzite-silicon carbide) from the original about 23 and improved to 25 (porzite) from the original about 18, and the porosity is also reduced; but also improving the toughness of the compact heavy refractory product, for example, the porosity is reduced, the thermal shock resistance is improved, the times of water cooling at the temperature of 1,100 DEG C are respectively increased to 70 times (porzite-silicon carbide) from the original about 50 times and increased to 14 times (porzite) from the original 3 times, and wearing resistance tests are decreased to 5.4 percent from the original 6.3 percent (a weighing method), so that the service life of a dry coke quenching furnace can be prolonged by 1-2 times.

Owner:宜兴市恒祥耐火材料有限公司

Circuit board processing method and equipment

ActiveCN104735929BImprove flatnessGuaranteed withstand voltageMultilayer circuit manufactureConductive materialsVoltage

The embodiment of the invention discloses a circuit board processing method and device. The circuit board processing method comprises the steps that a first line pattern is formed on a first face of a first conductive substrate, and if the first face is a rough face of the first conductive substrate, the first line pattern is formed based on the mode that the first face is plated with a conductive material; a second line pattern is formed on a second face of a second conducive substrate, and if the second face is a rough face of the second conductive substrate, the second line pattern is formed based on the mode that the second face is plated with the conductive material; a prepreg is arranged between the first face of the first conductive substrate and the second face of the second conductive substrate through press fit, so that a first board material set is formed; a third face of the first conductive substrate in the first board material set is etched so that the first line pattern can be exposed, and a fourth face of the second conductive substrate in the first board set is etched so that the second line pattern can be formed. According to the scheme, on the premise that the thickness of the prepreg in the PCB is controlled to the greatest extent, the voltage resistance of the PCB is improved.

Owner:SHENNAN CIRCUITS

wall mounted air conditioner

ActiveCN104110726BEliminate structural defectsImprove satisfactionDucting arrangementsCondensate preventionCold airEngineering

The invention provides a wall-mounted air conditioner which comprises a shell, an air inlet, a first air outlet, a heat exchanger and a cross-flow fan. The air inlet is formed in the shell, the first air outlet is formed in the lower portion of the shell, the heat exchanger is arranged in the shell, and the cross-flow fan is mounted in the shell and used for enabling air flow entering from the air inlet to be discharged from the first air outlet; the wall-mounted air conditioner further comprises a second air outlet, a centrifugal fan and a driving mechanism, the second air outlet is arranged in the upper portion of the shell, the centrifugal fan is mounted in the shell and used for enabling the air flow entering from the air inlet to be discharged from the second air outlet, and the driving mechanism is used for driving the cross-flow fan and the centrifugal fan to rotate. The second air outlet is additionally arranged in the topmost of an existing wall-mounted air conditioner, so that structural defect that the air conditioner blows air obliquely and downwardly is eliminated, and cold air of the air conditioner can be completely prevented from being blown to people; in addition, good outlet airflow organizing and regulating capacities are achieved under different conditions of cooling, heating and the like, free regulation can be achieved according to preferences of users, comfortableness of indoor environment can be improved, and user's satisfaction can be improved.

Owner:GD MIDEA AIR CONDITIONING EQUIP CO LTD

A kind of chitosan bone nail material with helical orientation structure and preparation method thereof

The invention discloses a chitosan bone nail material with a spiral orientation structure and a preparation method thereof. The method comprises the following steps: preparing a chitosan solution by adopting a mechanical stirring method; performing wet spinning on the chitosan solution by utilizing an injection device with a duct; performing orientation stretching and sequential spiral winding collection on primary fiber by adopting a collecting device at adjustable rotating speed, thereby acquiring a chitosan fiber bar with a compact three-dimensional piling structure; washing the bar till pH=6-8 and then placing into a SBF (Simulated Body Fluid) for mineralizing; and cleaning and drying, thereby acquiring the chitosan bone nail. A medical chitosan bone nail prepared according to the invention has a height orientation structure and a self-threading function; the step of externally threading is avoided; the structure defects and the raw material waste brought by the process of externally threading are eliminated; the bone induction regeneration capacity of the bone nail is greatly promoted in the mineralizing process; the bone nail is expected to be applied to the field of bone regeneration and repairing.

Owner:ZHEJIANG UNIV

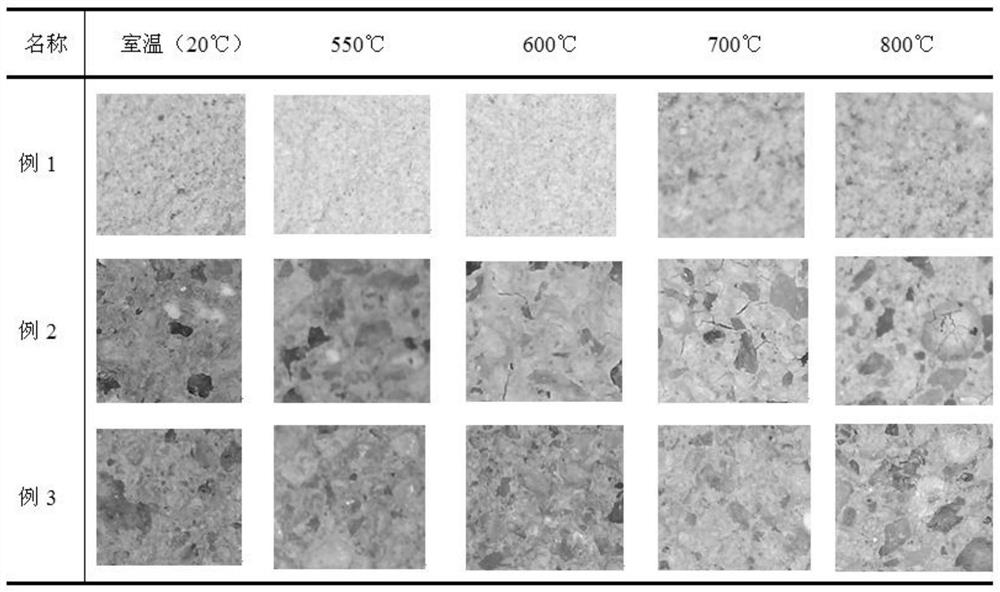

A kind of preparation method and application of phase change river sand with high refractory performance

The invention discloses a method for preparing phase-change river sand with high refractory performance. The river sand is calcined at a constant temperature to change from alpha phase to beta phase, and then quenched with water to make the phase change finalized. The invention pre-phase-transforms and shapes the river sand through high-temperature calcination and water quenching, so as to eliminate the volume effect of the river sand at high temperature; the invention also provides the application of the phase-change river sand in the preparation of high refractory performance concrete. This method effectively solves the concrete cracking problem caused by the instantaneous volume expansion of river sand when the river sand experiences high temperature, thereby improving the fire resistance of ordinary concrete, and at the same time, the mechanical strength is also greatly improved.

Owner:SUQIAN LIYIN IND

Cells and Batteries

ActiveCN111341945BImprove securityImprove package strengthWound/folded electrode electrodesSmall-sized flat cells/batteriesEngineeringMechanical engineering

The application discloses a battery cell and a battery. The battery cell includes a battery cell body and a packaging bag for containing the battery cell body. The packaging bag includes a packaging part, and the packaging part includes a sealing area, and a cavity is provided in the sealing area. According to the electric core of the present application, by providing a cavity inside the sealing area, the thermal stress caused by the temperature gradient can be eliminated, the mechanical stress caused by the right angle of the head to the packaging bag can be eliminated, and the mechanical stress caused by the main body of the electric core can be eliminated, thereby It can improve the morphology of the overflowing glue area of the packaging part, improve the structural defects of the overflowing glue area, thereby greatly improving the packaging strength of the packaging part of the battery cell, and improving the reliability and safety of the battery core.

Owner:NINGDE AMPEREX TECH

Rope drum and method for the production thereof

PendingCN111788021AAvoid warpingSmall sizeScrew-threads articlesWinding mechanismsStructural engineeringWinch

The present invention relates to rope drums for winding and unwinding ropes, having a drum shell, to which end disks are fastened at the end faces, and to rope winches having such rope drums. The invention also relates to a method for producing such a rope drum. According to the invention, the drum shell is seamlessly rolled from an annular workpiece blank by means of a rope groove profile embossed in a non-cutting manner.

Owner:LIEBHERR COMPONENTS BIBERACH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com