Polystyrene/polyvinylidene fluoride quaternary ammonium type anion exchange alloy film preparation method

A polyvinylidene fluoride and polystyrene technology, applied in the field of functional polymer film preparation, can solve problems such as difficulty in ensuring product performance stability, high requirements for process control and equipment, and difficulty in precise control of the reaction process. Effect of quality control, film resistance reduction, elimination of structural defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

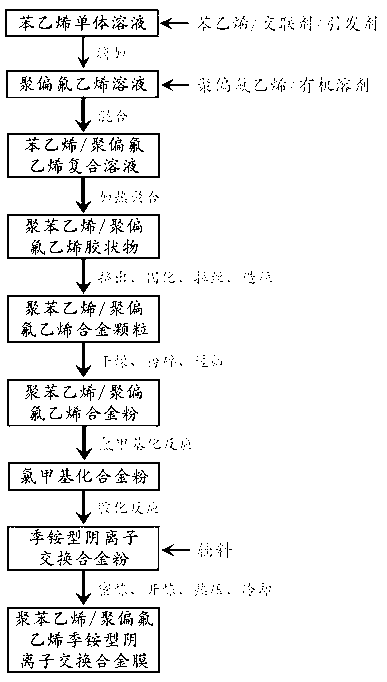

[0014] Such as figure 1 Shown, the preparation method of polystyrene / polyvinylidene fluoride quaternary ammonium type anion exchange alloy membrane of the present invention, comprises the following steps:

[0015] 1. First, slowly add the monomer solution composed of styrene, crosslinking agent and initiator in a mass ratio of 100:2~10:1~10 into the polyvinylidene fluoride solution, and the monomer solution and polyvinylidene fluoride The mass ratio of the vinyl fluoride solution is 5~40:100, and it is fully mixed to obtain a uniform styrene / polyvinylidene fluoride composite solution.

[0016] The adopted monomer solution is uniformly mixed with styrene, cross-linking agent and initiator. The cross-linking agent used in the step (1) is divinylbenzene, and the usage amount is 2% to 10% of the mass of styrene; if the ratio is too small, the water content and swelling of the membrane will be too large, and if the ratio is too large Then it is difficult to implement subsequent t...

Embodiment 1

[0027] 1) Add 50 kg of polyvinylidene fluoride powder (brand DF-1, Shanghai Sanaifu Co., Ltd.) into a 500-liter glass-lined reactor, pour in 200 liters of dimethylacetamide, heat to 90°C, and stir for 2 Hours, a completely dissolved polyvinylidene fluoride solution was formed. In a 50-liter glass reactor, add 36 kg of styrene, 4 kg of divinylbenzene (63.2% purity, provided by Shangyu Puer Resin Co., Ltd.) and 2.4 kg of benzoyl peroxide, and stir for 1 hour at room temperature to obtain Styrene polymerized monomer solution. Slowly add the styrene monomer solution into the rapidly stirring polyvinylidene fluoride solution through the head tank, and finish the addition within 30 minutes, and then continue to stir for 30 minutes to obtain a uniform styrene / polyvinylidene fluoride composite solution .

[0028] 2) Subsequently, release the composite solution from the 500-liter glass-lined reactor, put it into a covered stainless steel polymerization container (volume 400 liters), ...

Embodiment 2

[0034] With 46 kilograms of styrene, 4 kilograms of divinylbenzene (content is 80.5%) and 3 kilograms of azobisisobutyronitrile, prepare styrene monomer solution, replace the styrene monomer solution in embodiment 1, all the other materials The ratio and operation method remain unchanged. According to the same method as in Example 1, the polystyrene / polyvinylidene fluoride quaternary ammonium anion exchange alloy membrane was prepared.

[0035] According to the measurement method described in the national standard (HY / T 034.2-1994), the performance parameters of the prepared anion exchange alloy membrane are as follows: the average thickness of the membrane is 0.32 mm, the water content is 50.7%, and the exchange capacity is 2.21 mmol / g Dry film, the surface resistance of the film is 3.7 Ω. cm 2 , the ion selective transmittance is 96.2%, and the membrane burst strength is 0.43 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

| Burst strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com