Rope drum and method for the production thereof

A technology of drums and ropes, applied in hoisting devices, metal rolling, and threaded products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

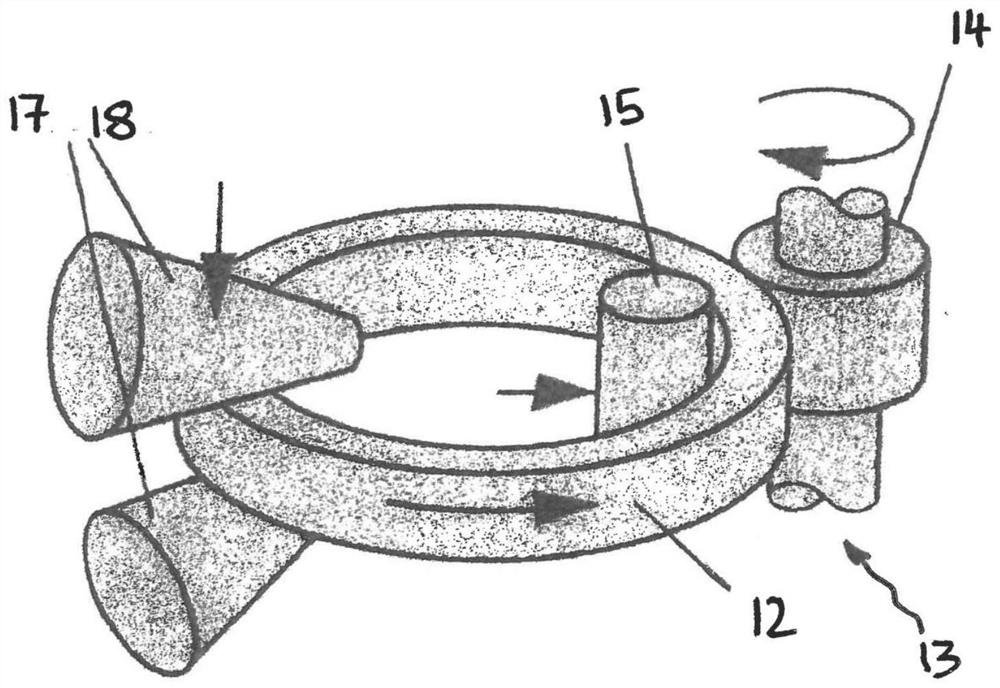

Embodiment Construction

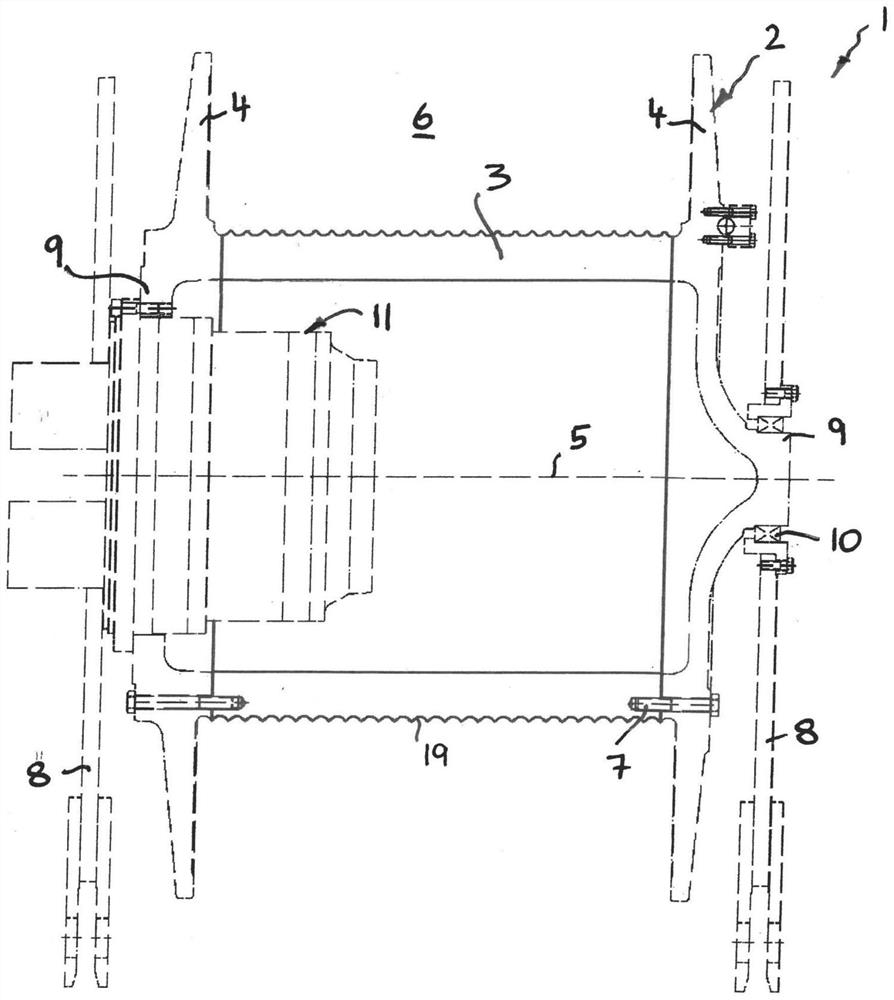

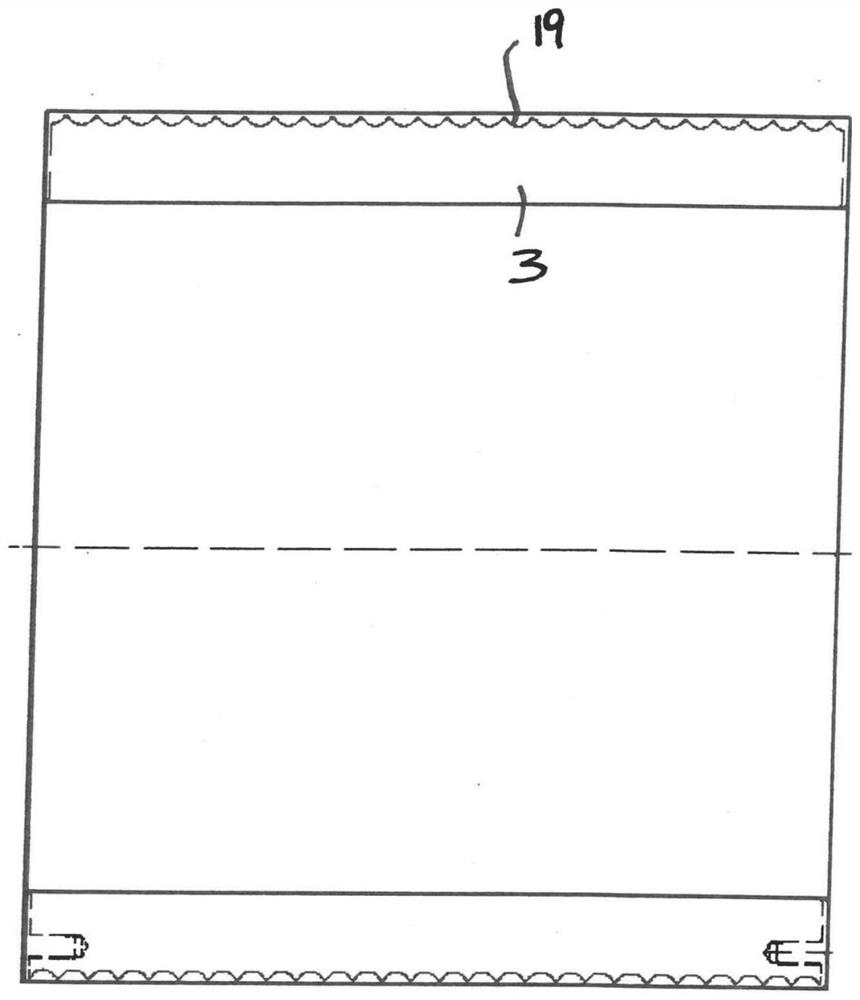

[0032] Such as figure 1 As shown, the rope winch 1 comprises a rope drum 2 having an at least approximately cylindrical drum housing 3 and two end plates 4 which are arranged transversely to the longitudinal axis 5 of the drum housing 3 Extends, adjoins the reel housing 3 at the end face and protrudes radially on the reel housing 3 to laterally limit the winding space 6 on the outer circumference of the reel housing 3 .

[0033] The end plate 4 is fastened particularly firmly on the drum housing 3 at the end face, wherein the end plate 4 can advantageously be formed separately from the drum housing 3 and the end plate 4 can be formed in a form-fitting or force-fitting manner. It is fixed on the reel housing 3 in a manner, for example, by stud bolts 7 , and the stud bolts 7 can screw the end plate 4 fixedly to the end surface of the reel housing 3 .

[0034] In this case, the rope drum 2 can be rotatably supported on the winch frame 8 , wherein the end plate 4 advantageously h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com