A kind of preparation method and application of phase change river sand with high refractory performance

A technology of refractory performance and river sand is applied in the field of preparation of phase change river sand with high refractory performance, which can solve the problems of unrealizable economic conditions, high cost and insignificant effect, and achieves elimination of structural defects, improvement of refractory performance, and improvement of internal structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A method for preparing phase-change river sand with high refractory performance. The river sand is calcined at a constant temperature to change from α phase to β phase, and then quenched with water (such as directly pouring the river sand calcined at constant temperature into enough tap water) , to shape the phase transition.

[0023] As an improvement, the preparation method of the phase-change river sand with high refractory performance comprises the following steps:

[0024] 1) Calcining the natural river sand at constant temperature for T minutes (10min≤T≤60min) at S degree Celsius (573℃≤S≤870℃) to make the river sand fully phase change;

[0025] 2) The river sand calcined at a constant temperature is quenched in water to shape the phase change, that is, the phase change river sand is obtained.

[0026] As an improvement, the main component of the river sand is α-quartz (SiO 2 ).

[0027] In addition, the invention also provides a phase-change river sand prepared...

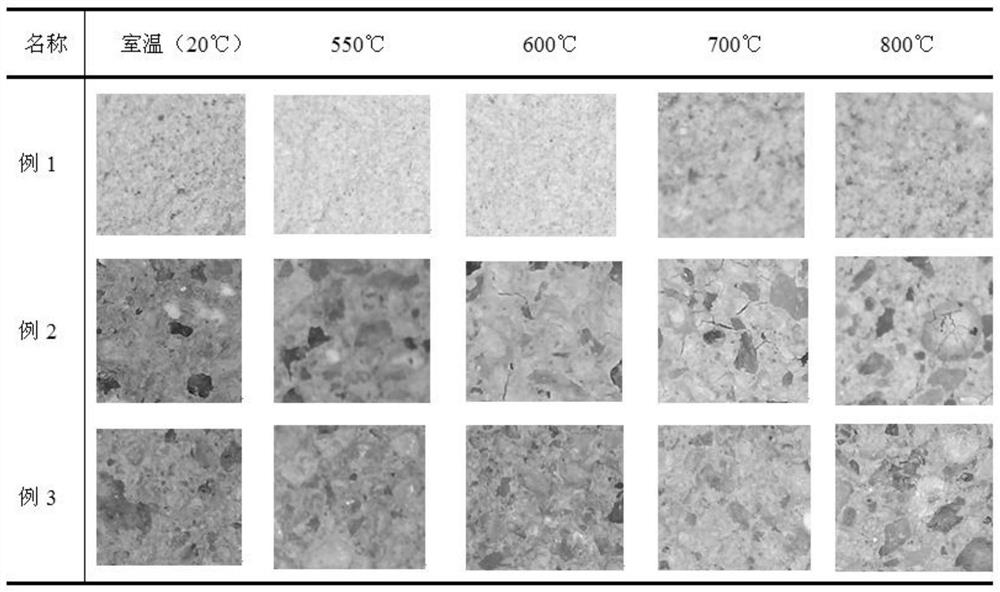

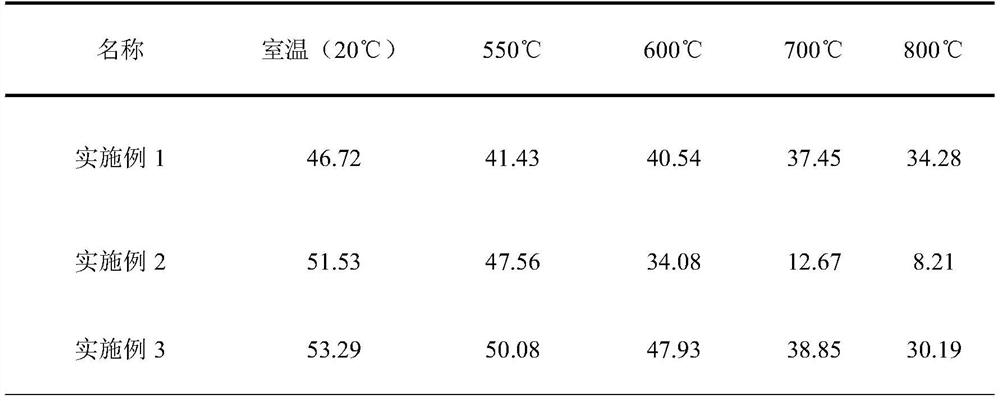

Embodiment 1

[0031] Prepare cement paste specimens with a water-cement ratio of 0.5 with P.I 42.5 cement.

[0032] 1) The size of the prepared test piece is 40mm*40mm*160mm;

[0033] 2) After 28 days of standard curing, the test pieces are subjected to high temperature resistance tests at 550°C, 600°C, 700°C, and 800°C;

[0034] 3) The test equipment is a wire heating type high temperature furnace;

[0035] 4) The heating rate is 50°C / min;

[0036] 5) Constant temperature at 550°C, 600°C, 700°C, and 800°C for 30 minutes respectively;

[0037] 6) The test piece after constant temperature is cooled to room temperature with the furnace, and then the compressive strength test is carried out.

Embodiment 2

[0039] P.I 42.5 cement and water-washed river sand are used to prepare mortar specimens with a lime-sand ratio of 1:3 and a water-cement ratio of 0.5.

[0040] Other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com