Cells and Batteries

A battery cell and sealing section technology, applied in the field of electrochemical devices, can solve the problems of low packaging strength, limited application of lithium-ion batteries, and low lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

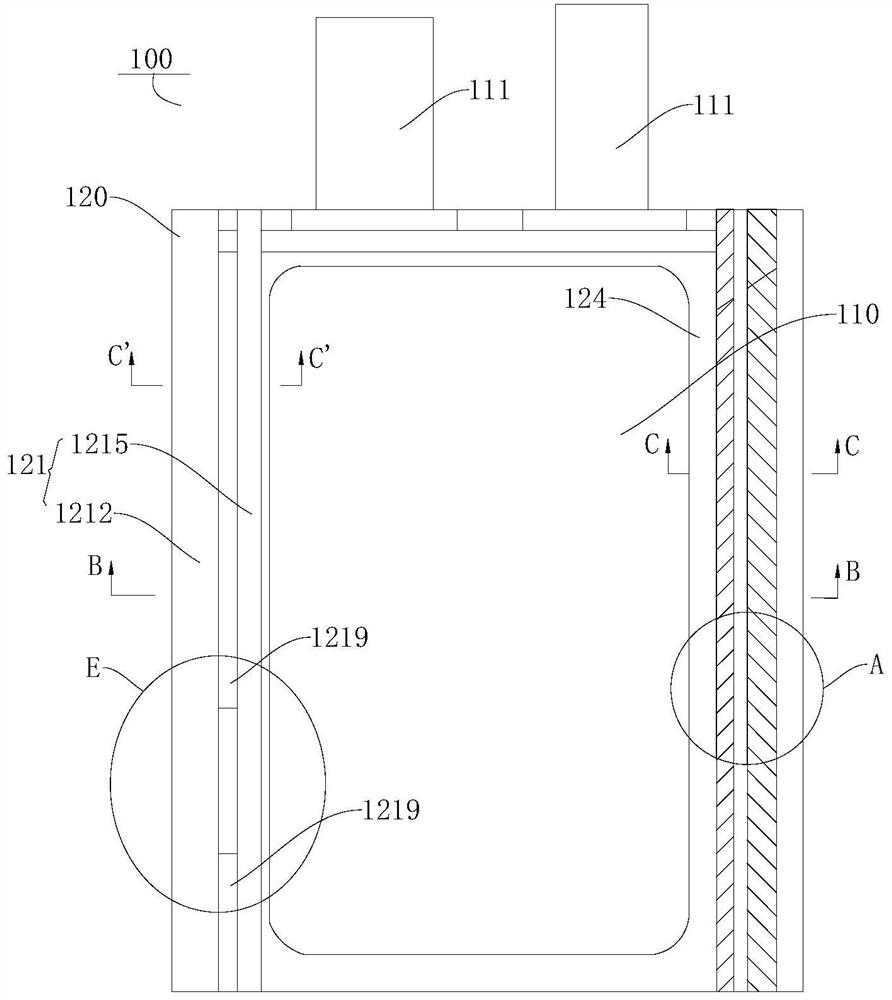

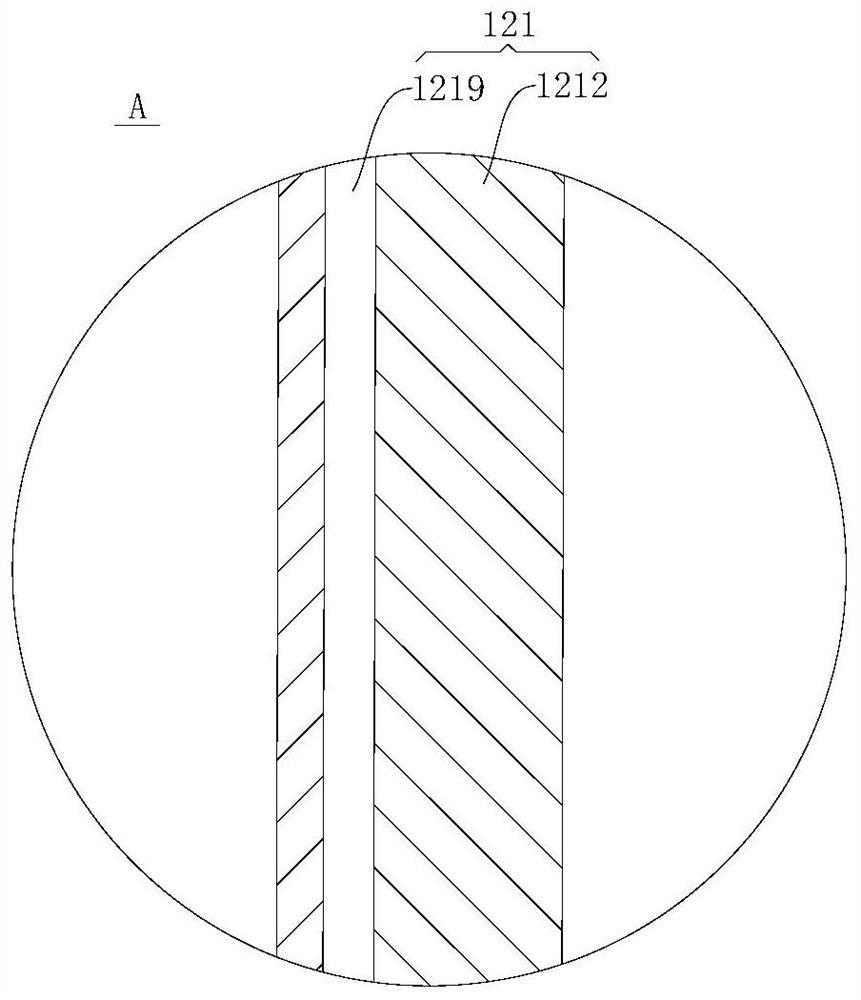

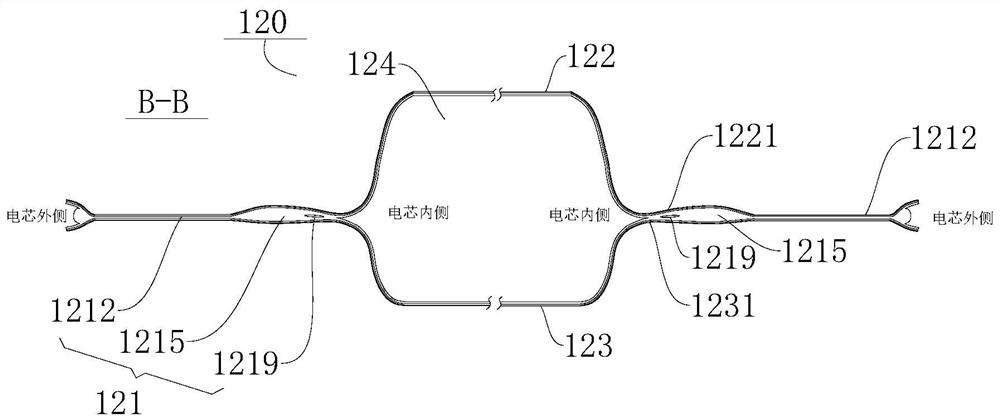

[0077] In this embodiment, the packaging bag 120 is an aluminum-plastic film, and the packaging bag 120 is used to accommodate the electric core 100, and the side sealing part 121 in the packaging bag 120 is pressed as figure 1 After the section line C-C or C-C shown is cut, it is obtained as Figure 6 The sectional view shown. Wherein, the length L1 of the first sealing section 1212 is 5 mm, the length L2 of the second sealing section 1215 is 3 mm, the maximum length L3 of the cavity 1219 is 0.35 mm, and the length L4 of the third sealing section 1216 is 2 mm. The thickness T1 of the first sealing section 1212 is 0.25 mm, the maximum thickness T2 of the second sealing section 1215 is 0.50 mm, the maximum thickness T3 of the cavity 1219 is 0.25 mm, and the minimum thickness T4 of the third sealing section 1216 is 0.30 mm.

[0078] The longitudinal sectional area M of the cavity 1219 is 0.028mm 2 , the sum N of the longitudinal sectional areas of the second sealing section 12...

Embodiment 2

[0081] The packaging bag 120 is an aluminum-plastic film, and the packaging bag 120 is used to accommodate the electric core 100, and the side packaging part 121 in the packaging bag 120 is pressed as follows figure 1 After the section line C-C or C-C shown is cut, it is obtained as Figure 4 The sectional view shown. In this embodiment, the length L1 of the first sealing section 1212 is 3 mm, the length L2 of the second sealing section 1215 is 1 mm, the maximum length L3 of the cavity 1219 is 0.018 mm, and the length L4 of the third sealing section 1216 is 0.3 mm . The thickness T1 of the first sealing section 1212 is 0.18mm, the maximum thickness T2 of the second sealing section 1215 is 0.33mm, the thickness of the cavity 1219 is very small, and the minimum thickness T4 of the third sealing section 1216 is 0.22mm.

[0082] The longitudinal sectional area M of the cavity 1219 is 0.007mm 2 , the sum N of the longitudinal sectional areas of the second sealing section 1215 an...

Embodiment 3

[0085]Different from Embodiment 2, in this embodiment, the length L1 of the first sealing section 1212 is 4.5mm, the length L2 of the second sealing section 1215 is 3.3mm, and the maximum length L3 of the cavity 1219 is 1.4mm. The length L4 of the triple seal section 1216 is 0.22mm. The thickness T1 of the first sealing section 1212 is 0.15 mm, the maximum thickness T2 of the second sealing section 1215 is 0.39 mm, the maximum thickness T3 of the cavity 1219 is 0.29 mm, and the minimum thickness T4 of the third sealing section 1216 is 0.31 mm.

[0086] The longitudinal sectional area M of the cavity 1219 is 0.119mm 2 , the sum N of the longitudinal sectional areas of the second sealing section 1215 and the third sealing section 1216 is 0.431mm 2 , the longitudinal section area K of the first sealing section 1212 is 0.045mm 2 , M:N=0.28, N:K=9.6.

[0087] One side sealing portion 121 of the packaging bag 120 obtained in embodiment 3 is cut open and cut into a sample strip wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com