Patents

Literature

54results about How to "Relieve mechanical stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Assemblies having stacked semiconductor chips and methods of making same

InactiveUS7071547B2Relieve mechanical stressIncreased yieldSemiconductor/solid-state device detailsSolid-state devicesMicroelectronicsEngineering

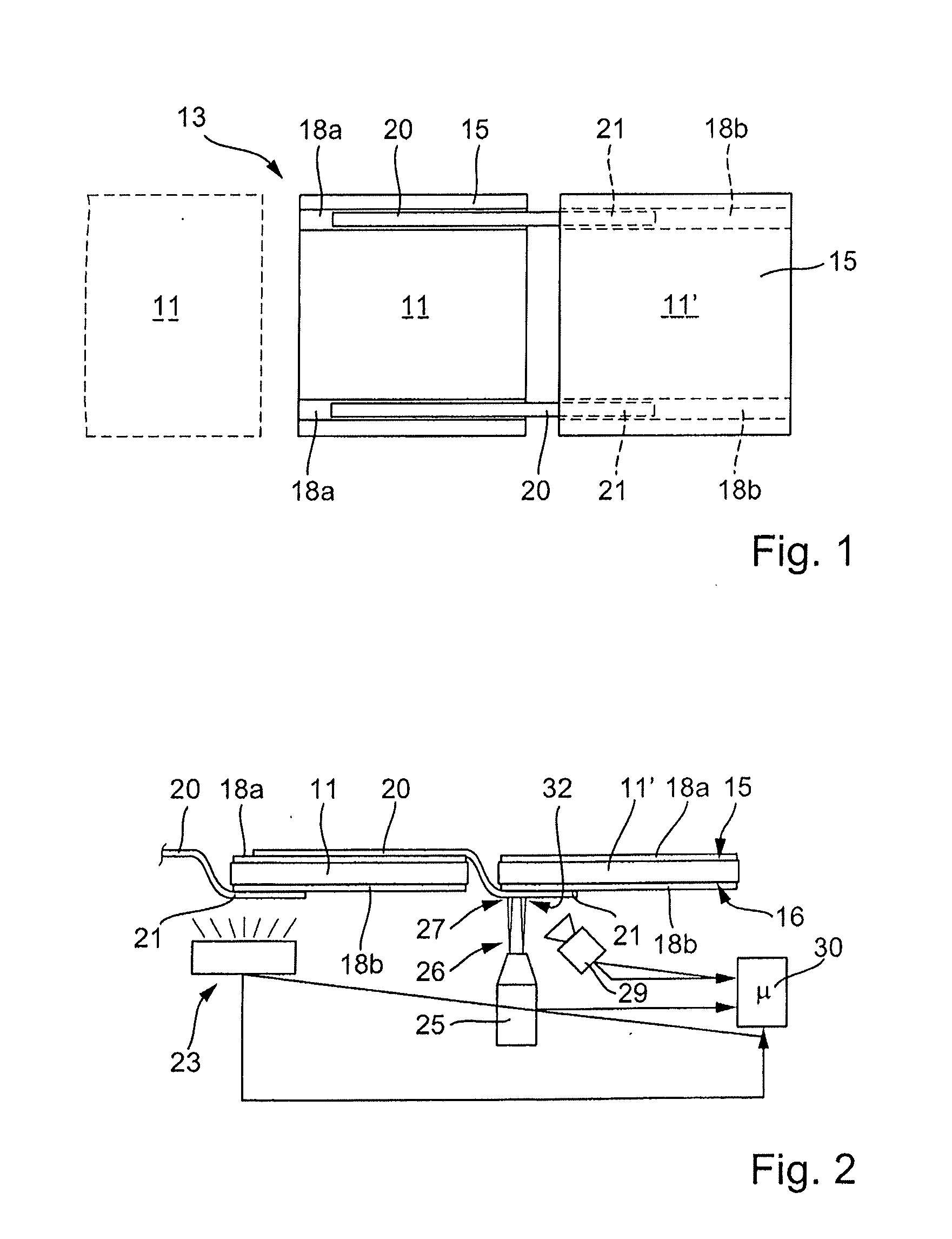

A stacked microelectronic assembly comprises a continuous sheet including a core panel and a plurality of side panels, each having a folded portion that connects the side panel to an edge of the core panel. At least two of the panels are at least partially horizontally aligned with one another in a stack. During manufacture of a stacked microelectronic assembly, failed microelectronic elements are identified and associated side panels thereof are simply cut-off. This results in the production of a usable stacked microelectronic assembly albeit of reduced capacity, or reduced functionality.

Owner:TESSERA INC

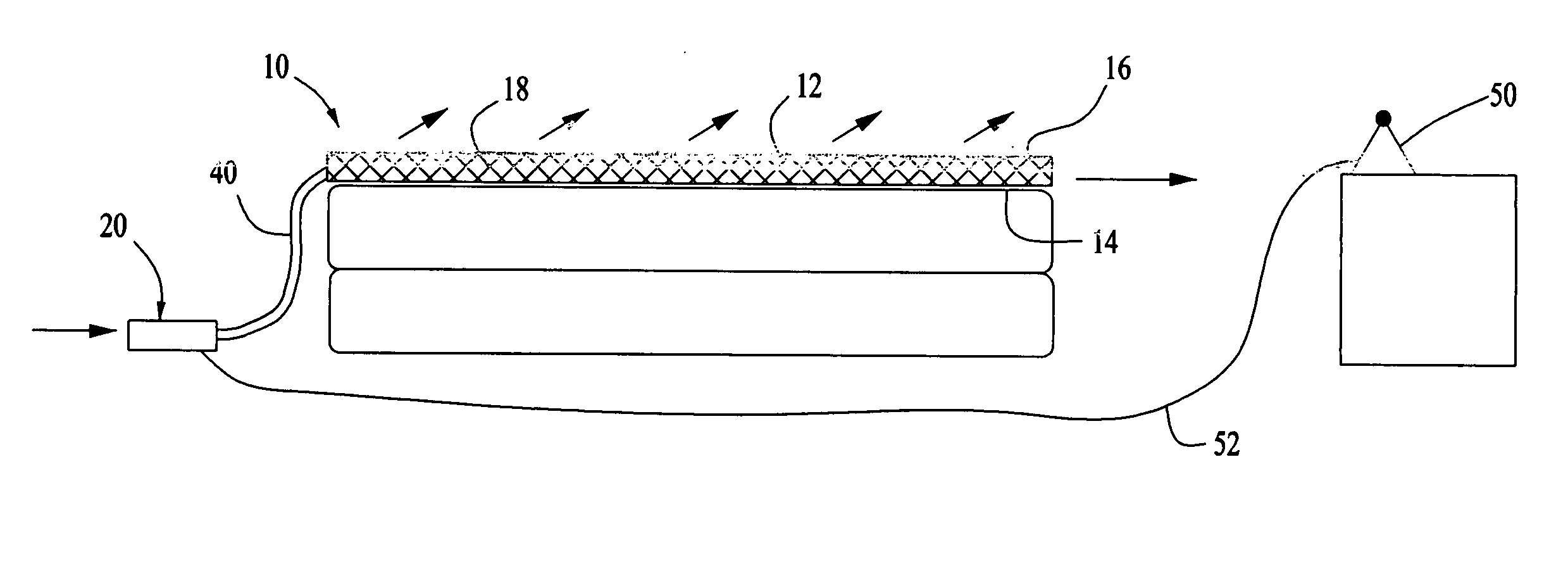

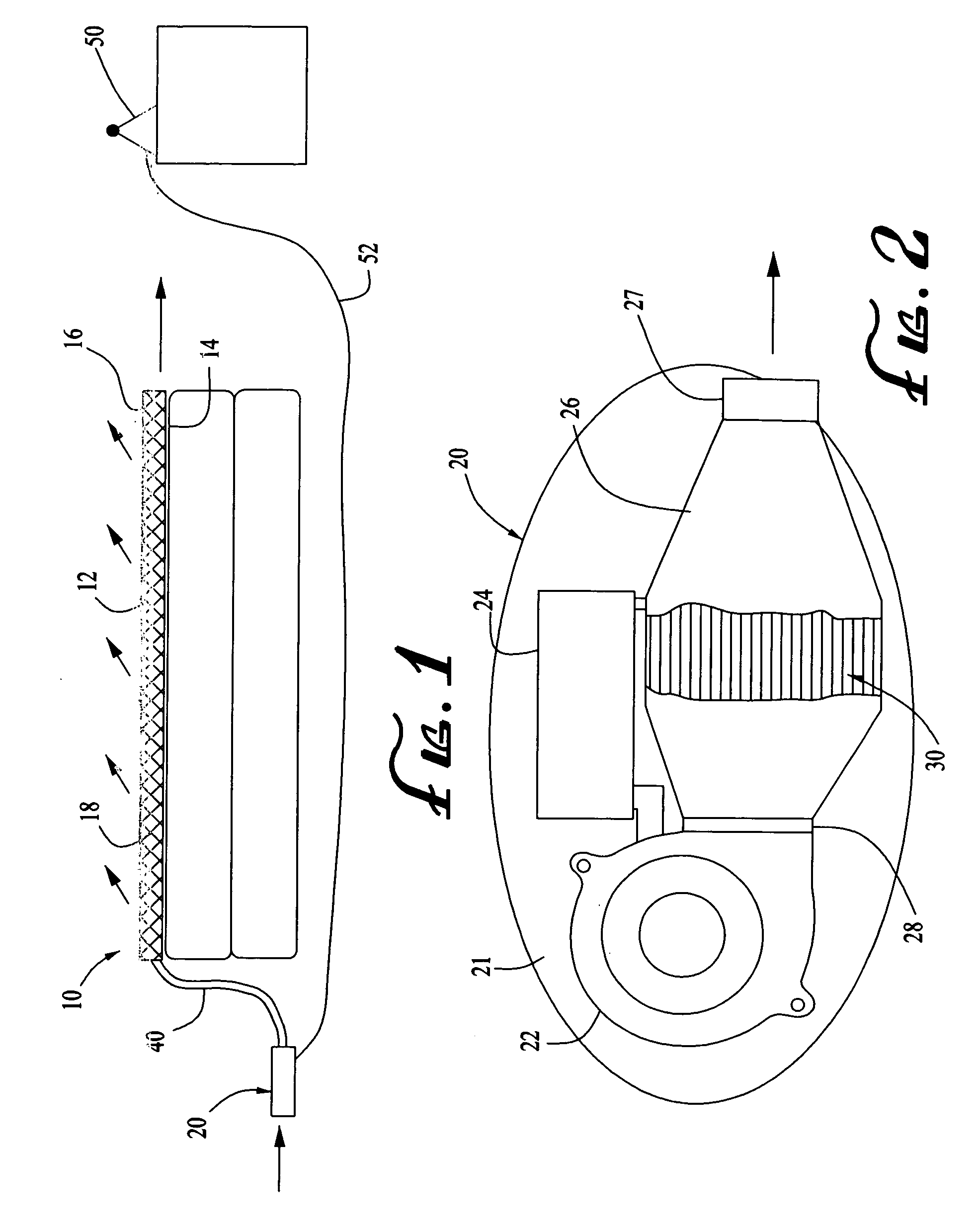

Convective cushion with positive coefficient of resistance heating mode

InactiveUS20070086757A1Eliminate useUse minimizedVehicle seatsStuffed mattressesElectrical resistance and conductanceRemote control

A cushion that is heated convectively using a positive temperature coefficient of resistance type resistive heating element that is provided with heat exchanging surfaces, includes a mattress pad, seat or the like with a bottom surface secured around its perimeter to an air permeable top surface, forming a plenum and containing tubular spacer material or other air flow structure therein. The plenum is connected to a power unit housing a blower, a heating module and a controller unit. The heating module includes a PTC type heating element in conduction with a base plate and a number of heat exchanger fins. Preferably the heating element is sandwiched between a pair of the base plates and the heat exchanger fins, and there is a seal between the base plates to minimize air flow from the blower from passing there between. A remote control for the user's convenience may be provided, and a foldable antenna attachable to the convective unit facilitates wireless communication between the remote control and controller unit. The user resting atop the cushion is able to control the blower and heating module to deliver air of a desired temperature and quantity to the cushion and through the top surface. The invention advantageously replaces the current carrying, conductive wires and insulation found inside prior art heated mattresses, enhancing safety and performance while at the same time offering a cooled or ventilated capability.

Owner:FEHER STEVE

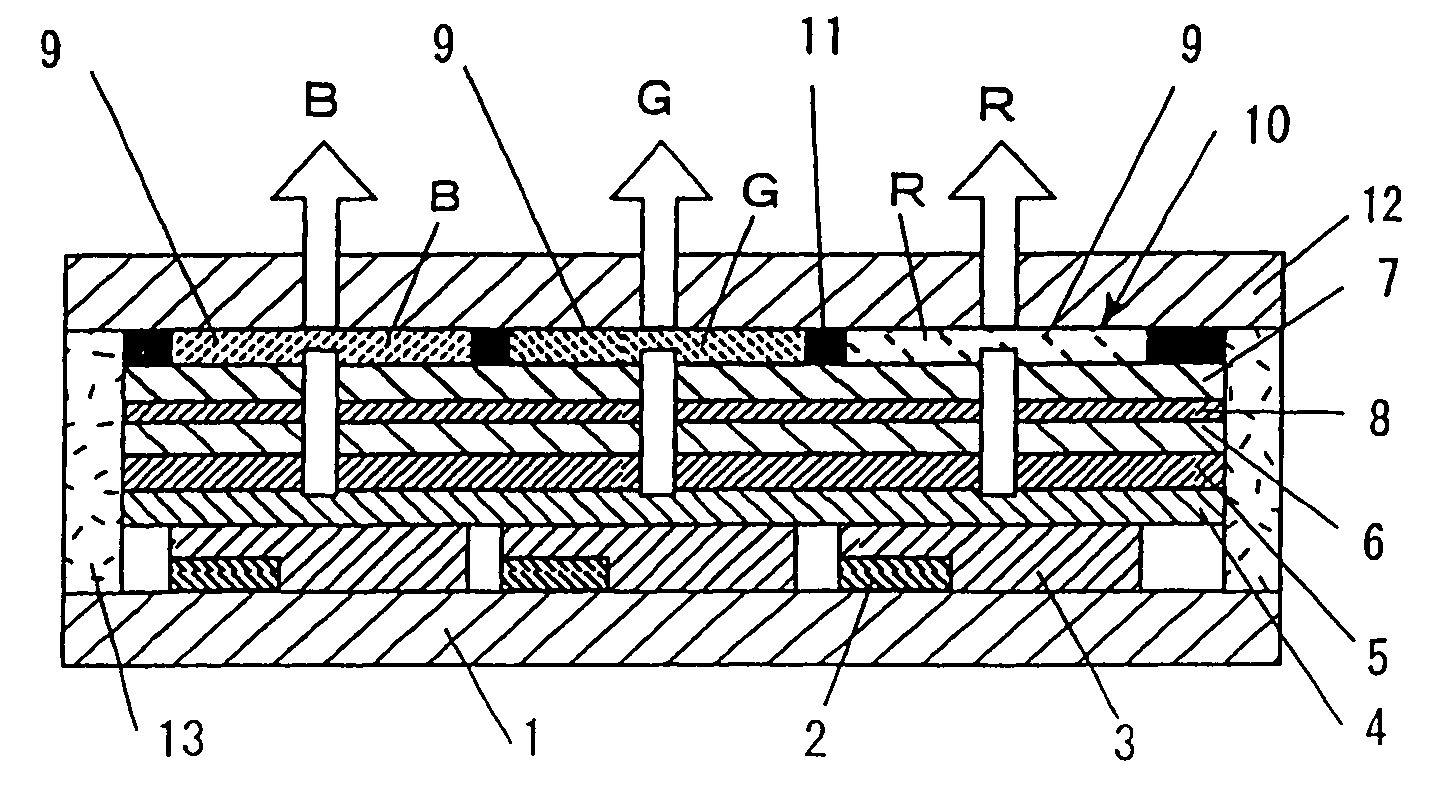

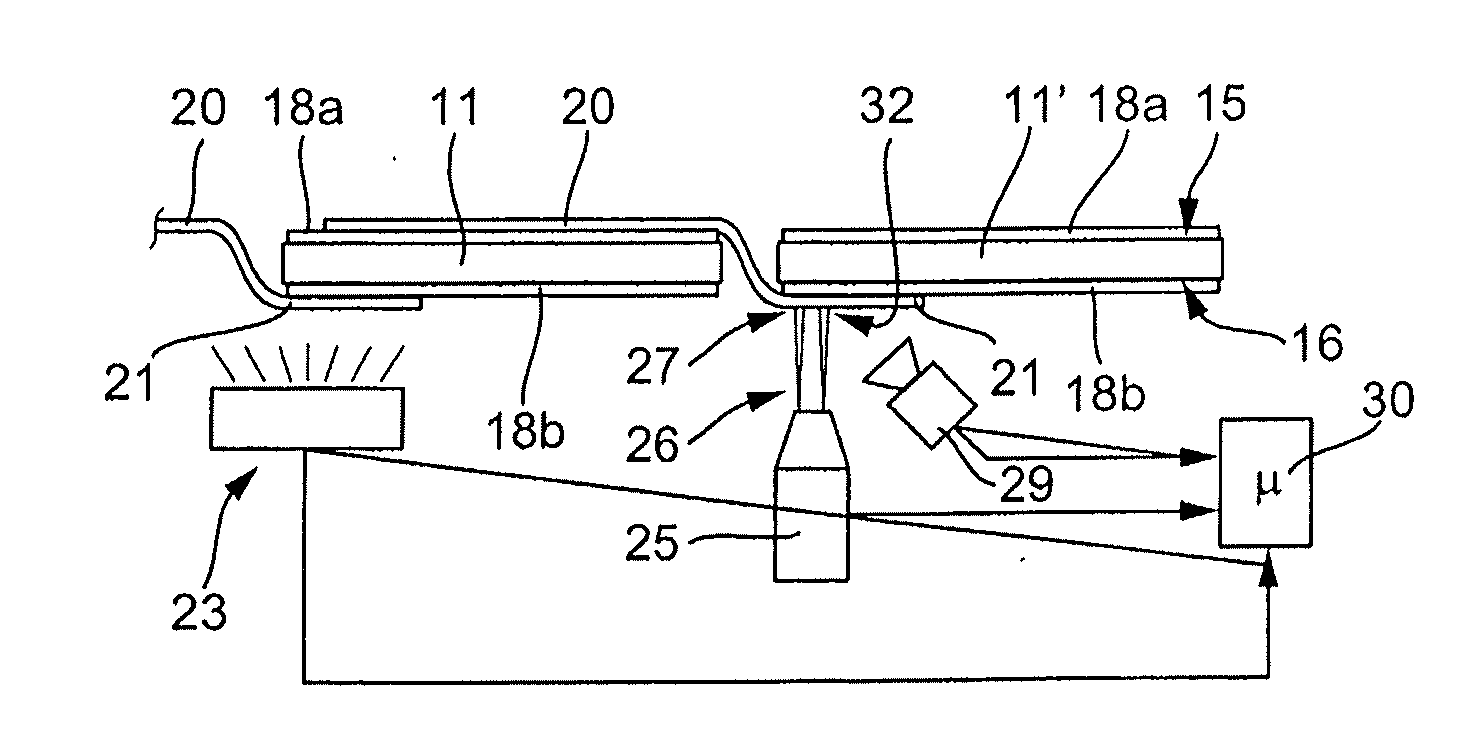

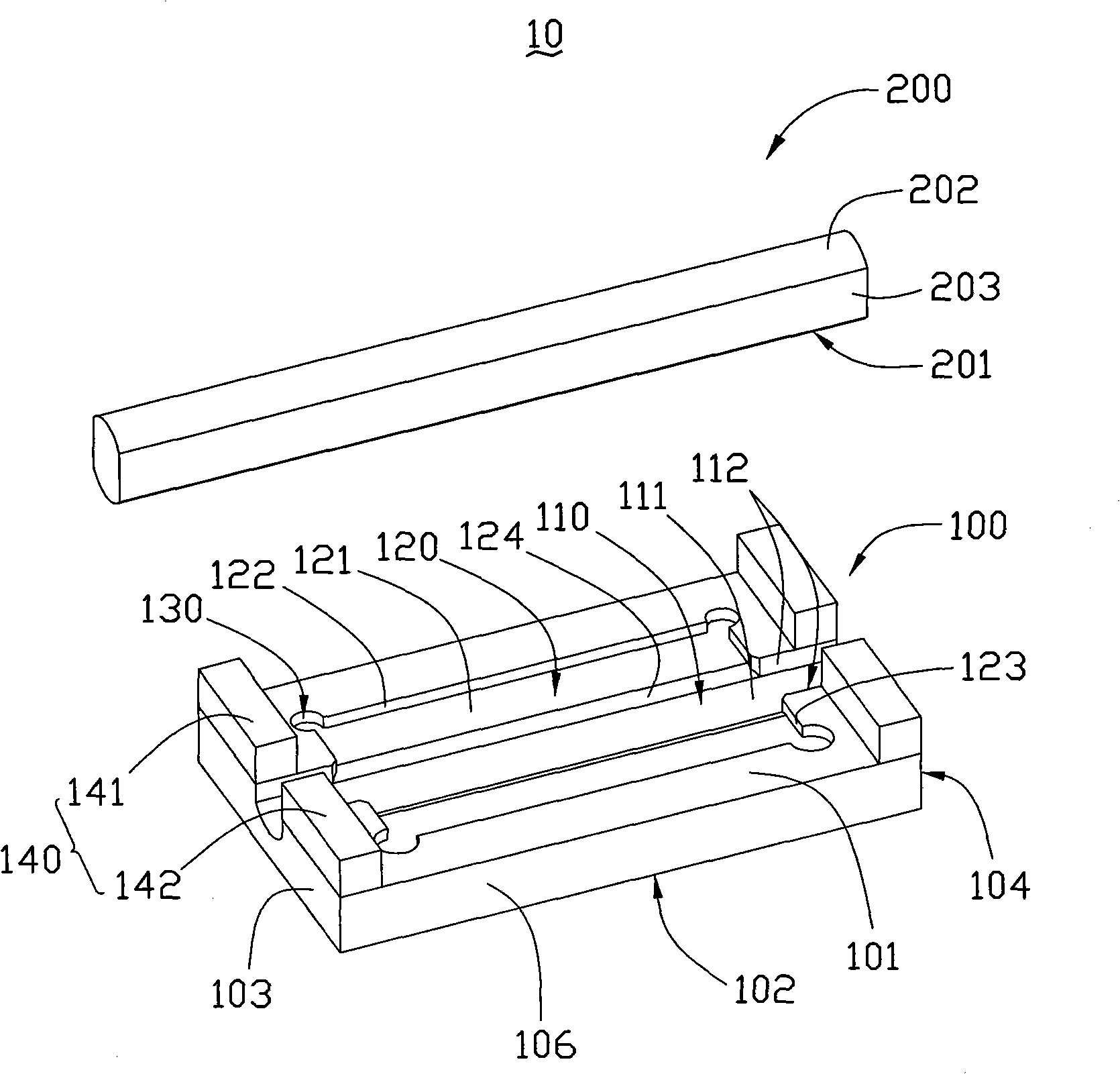

Organic el display

InactiveUS20060113617A1Low Young 's modulusRelieve mechanical stressStatic indicating devicesElectroluminescent light sourcesEngineeringOrganic electroluminescence

A top emission structure color organic EL (electroluminescent) display in which there are bonded together a substrate, having thin film transistors formed thereon, and a transparent substrate, having color-converting filters formed thereon, with an overcoat layer for adjusting the gap between the two substrates and also for relieving stress formed between the substrates without providing a space between the overcoat layers and an electroluminescent device, whereby the organic electroluminescent display has high reliability, without voids that would have an adverse effect on the display performance, and the occurrence of thermal and mechanical stress being suppressed.

Owner:SHARP KK

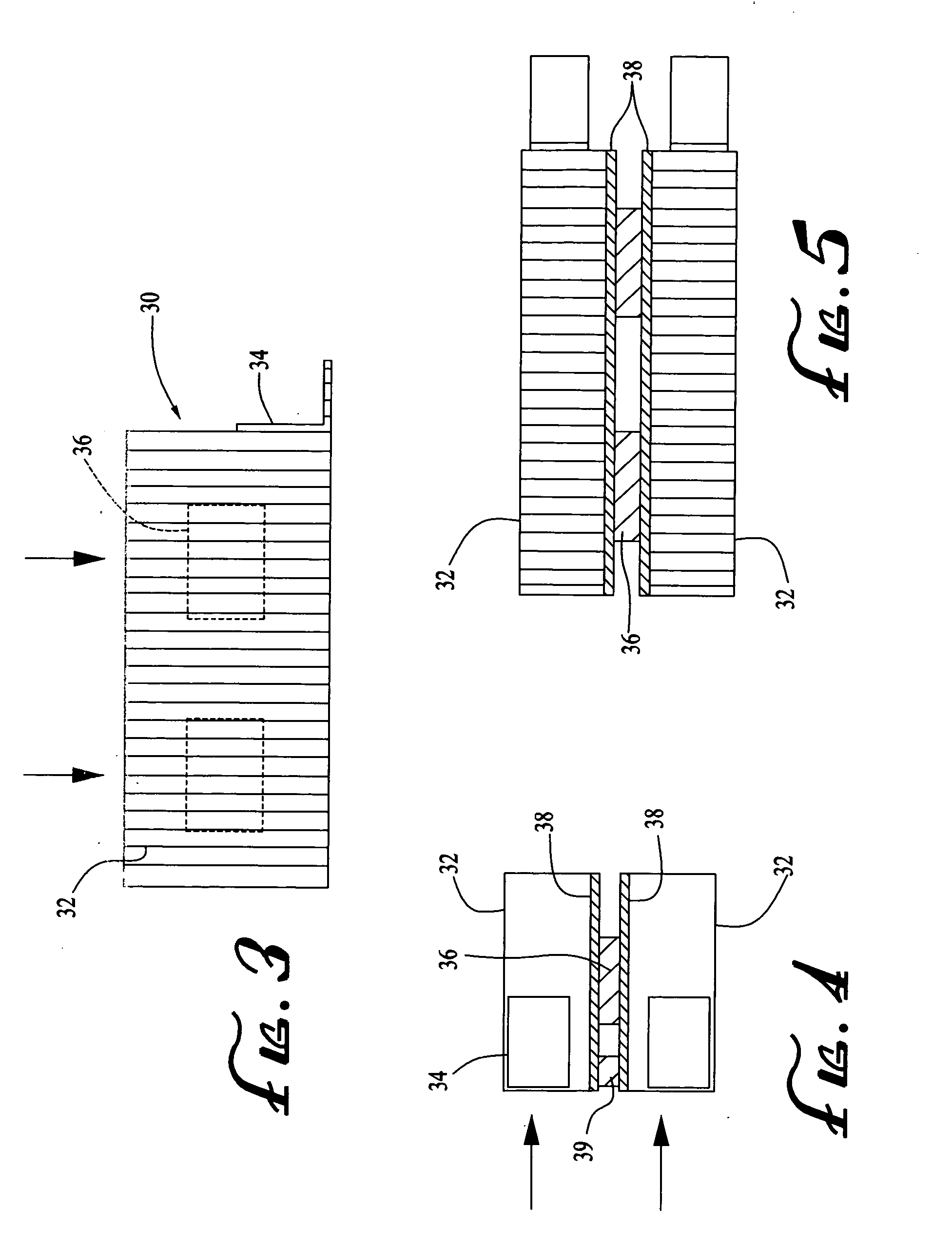

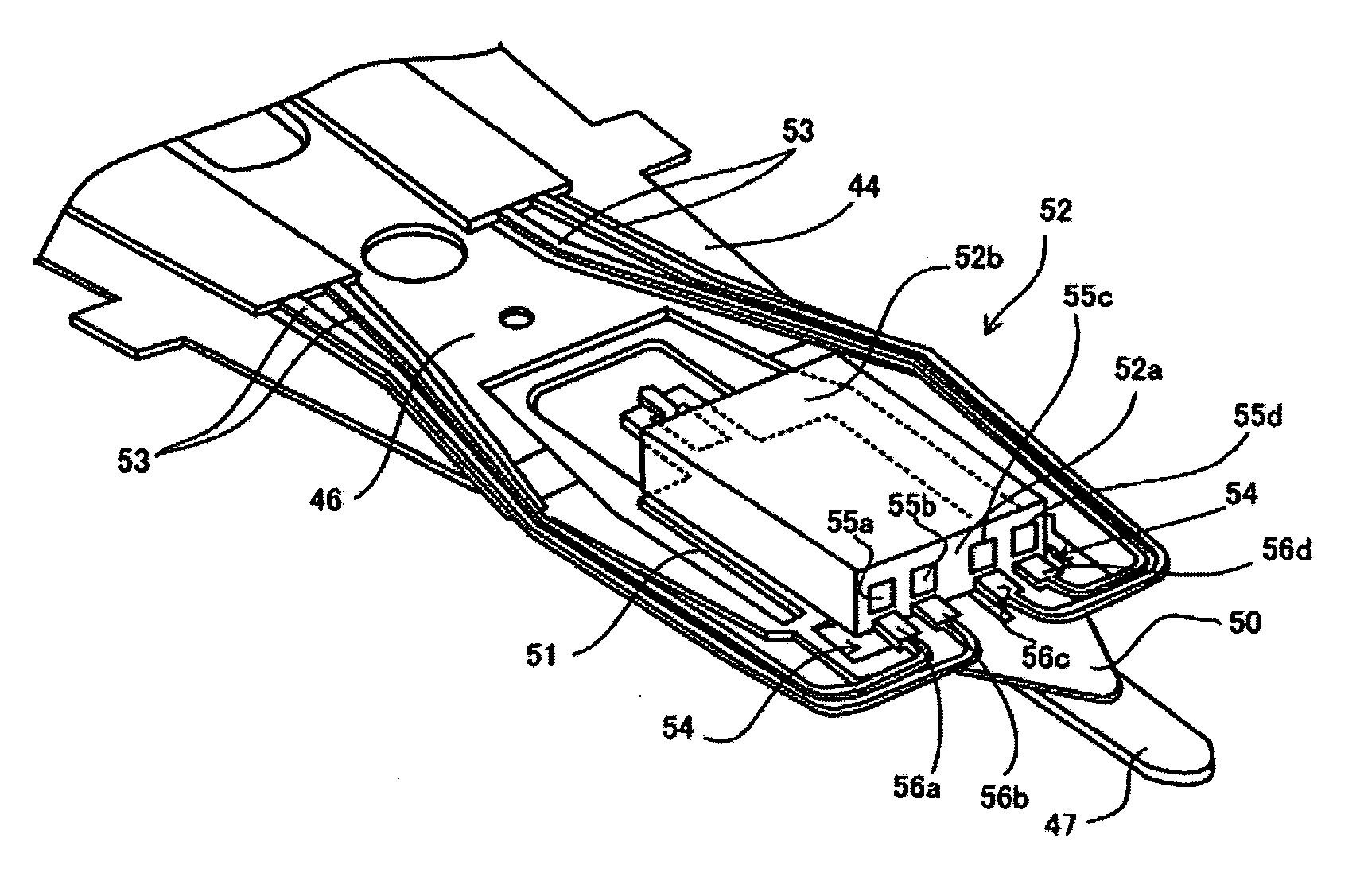

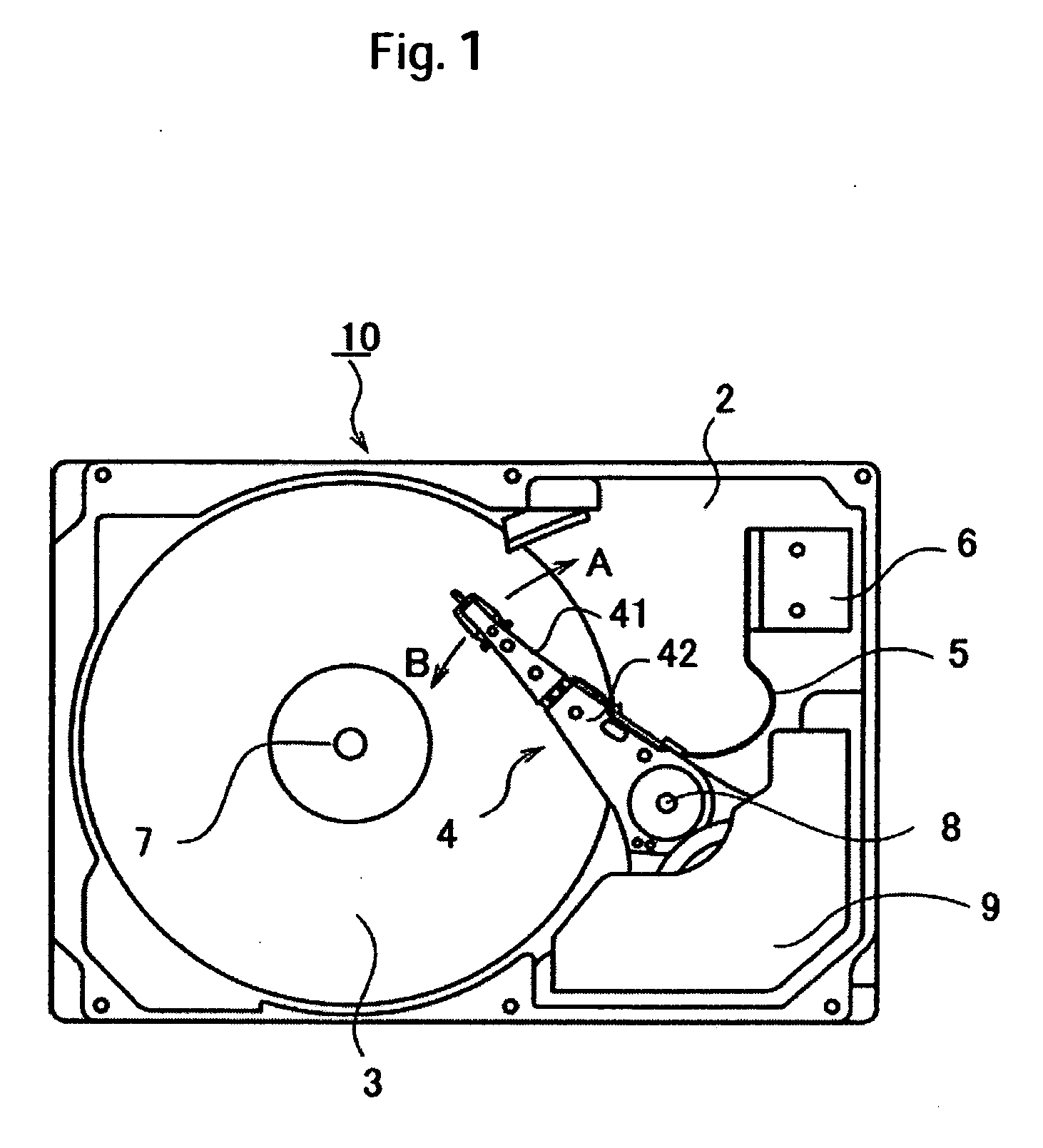

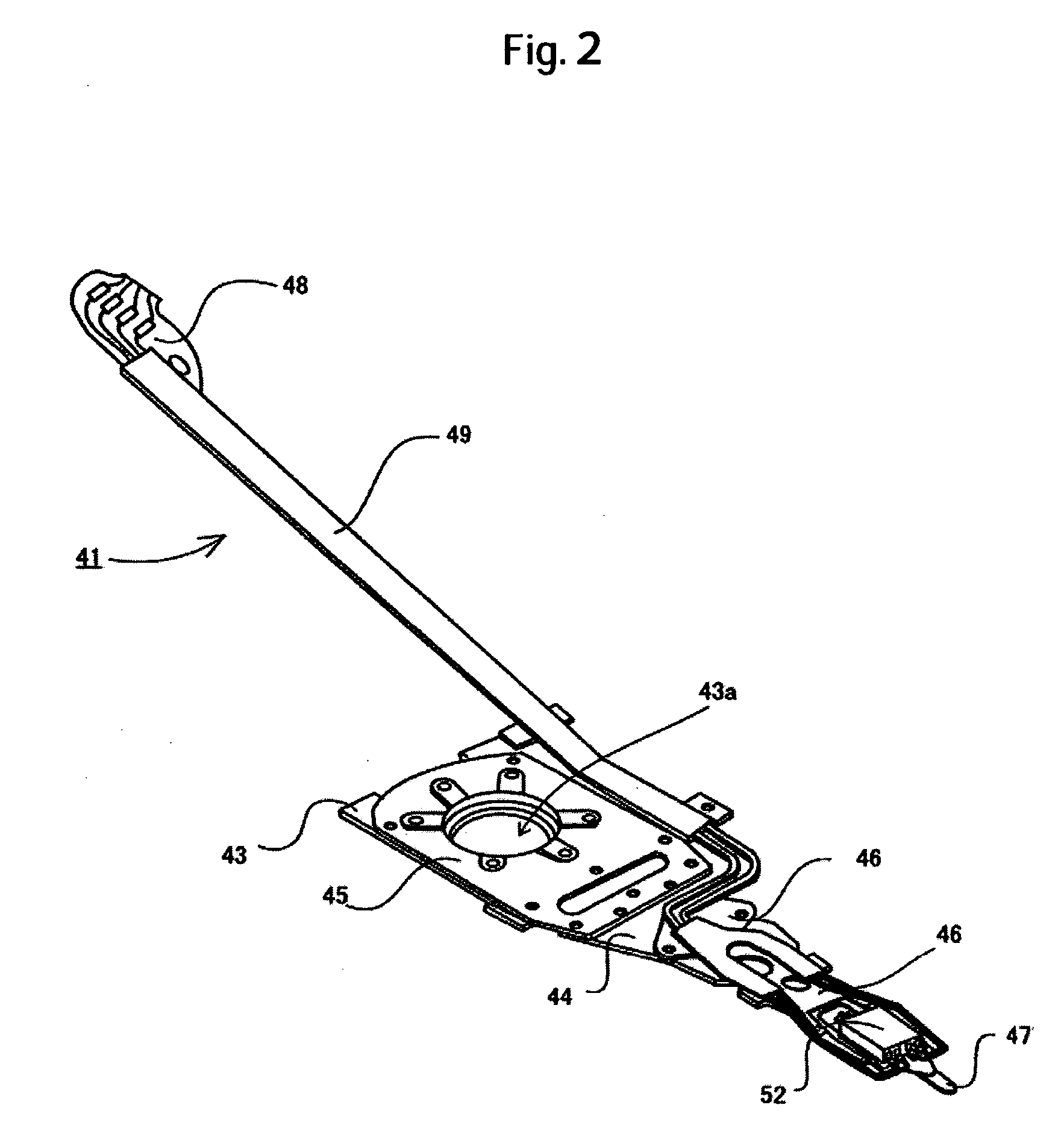

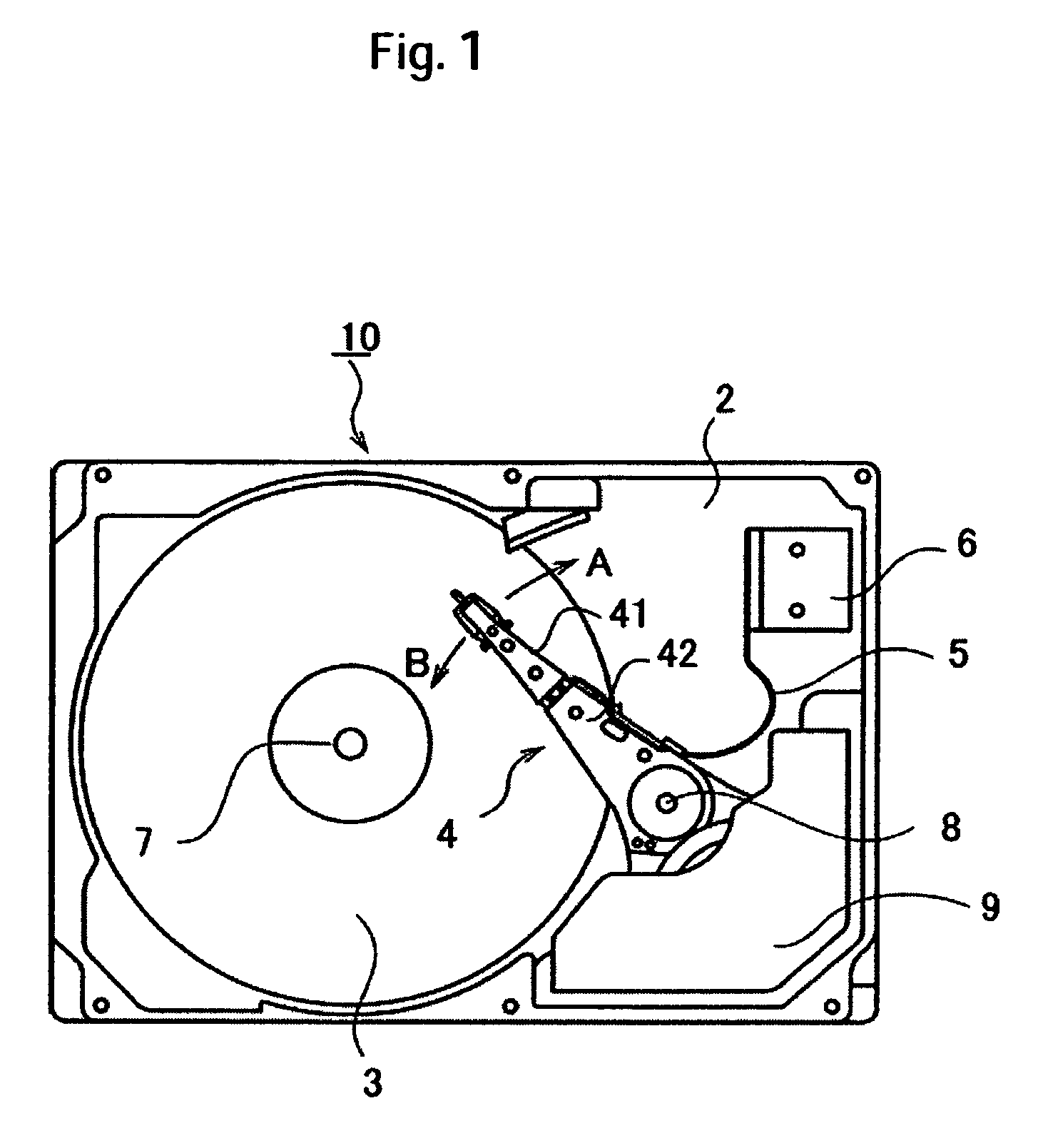

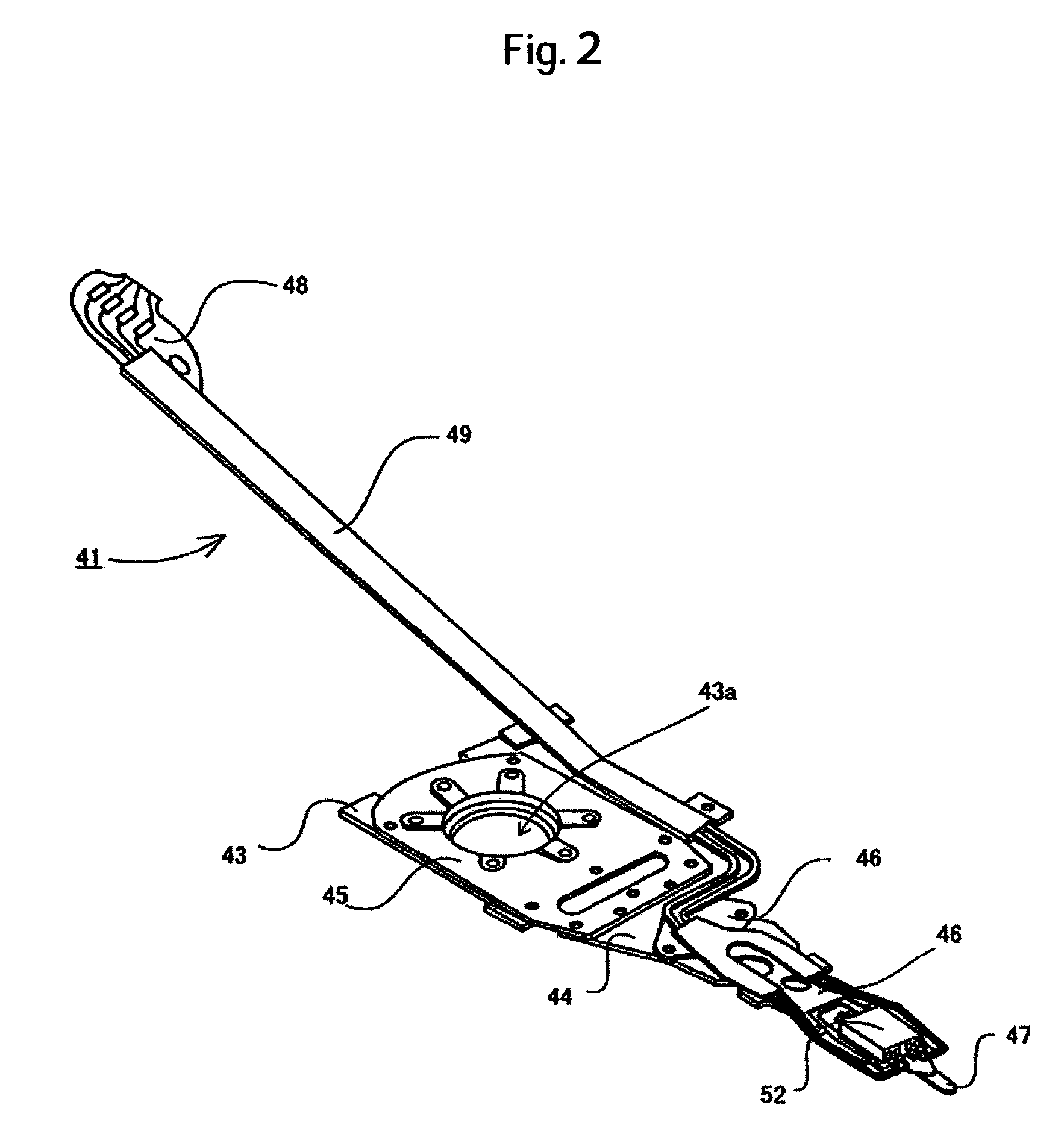

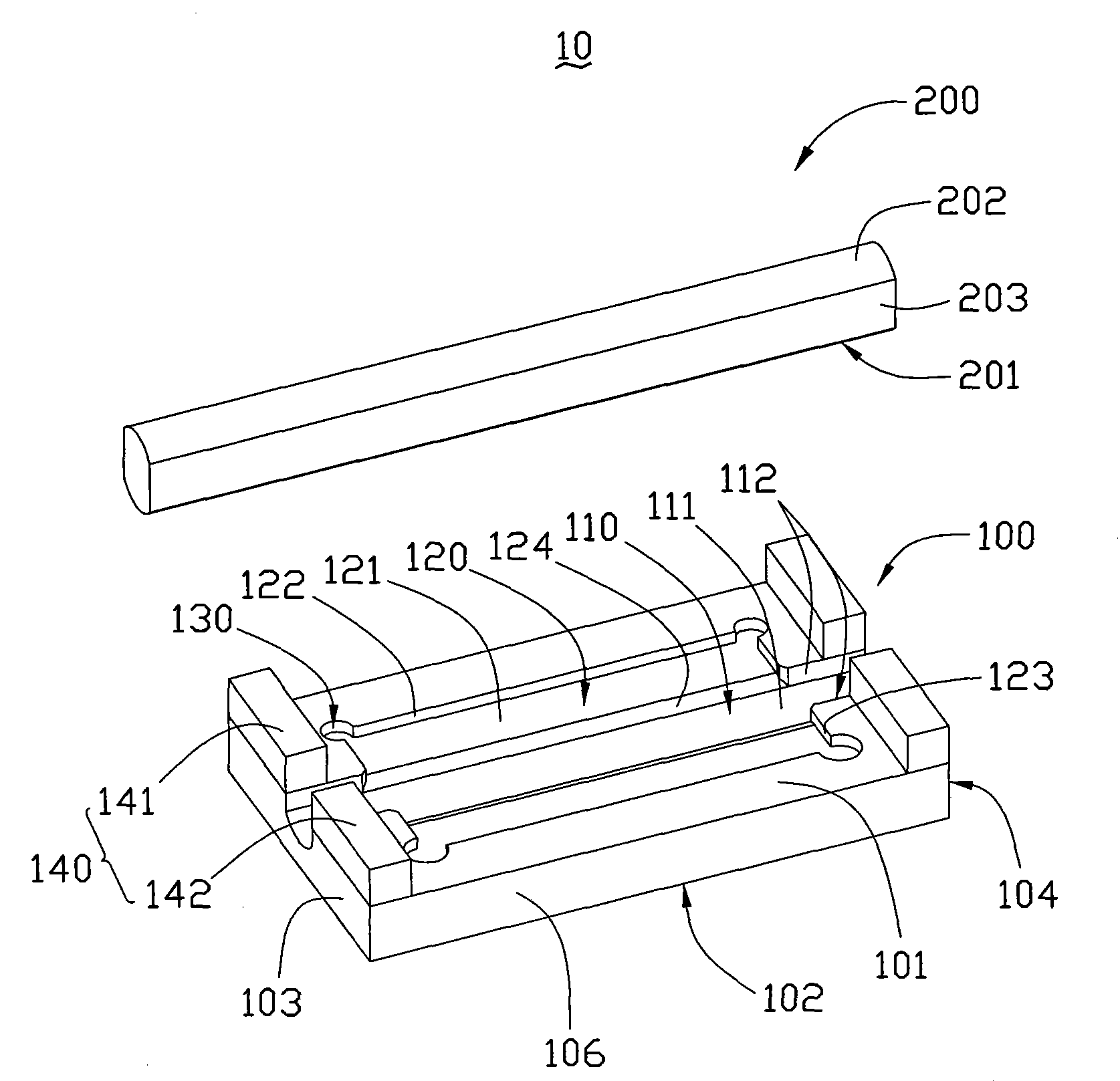

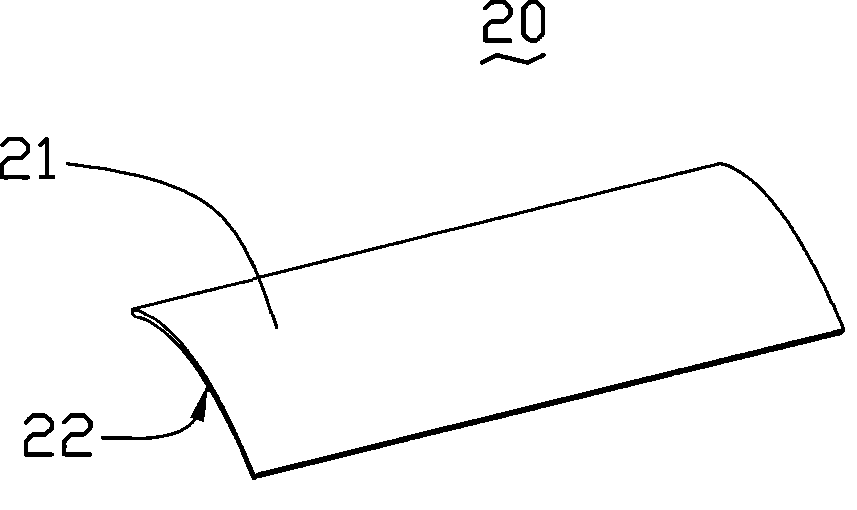

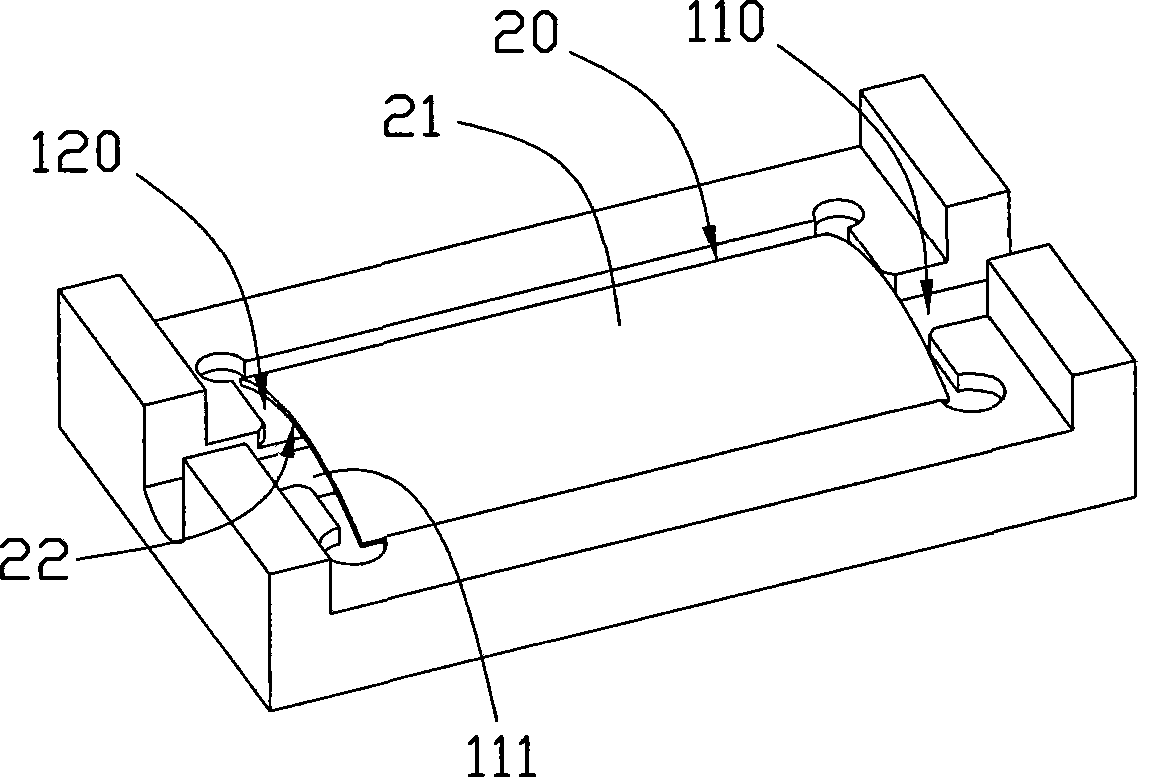

Manufacturing method of head gimbal assembly with solder fillet and head gimbal assembly

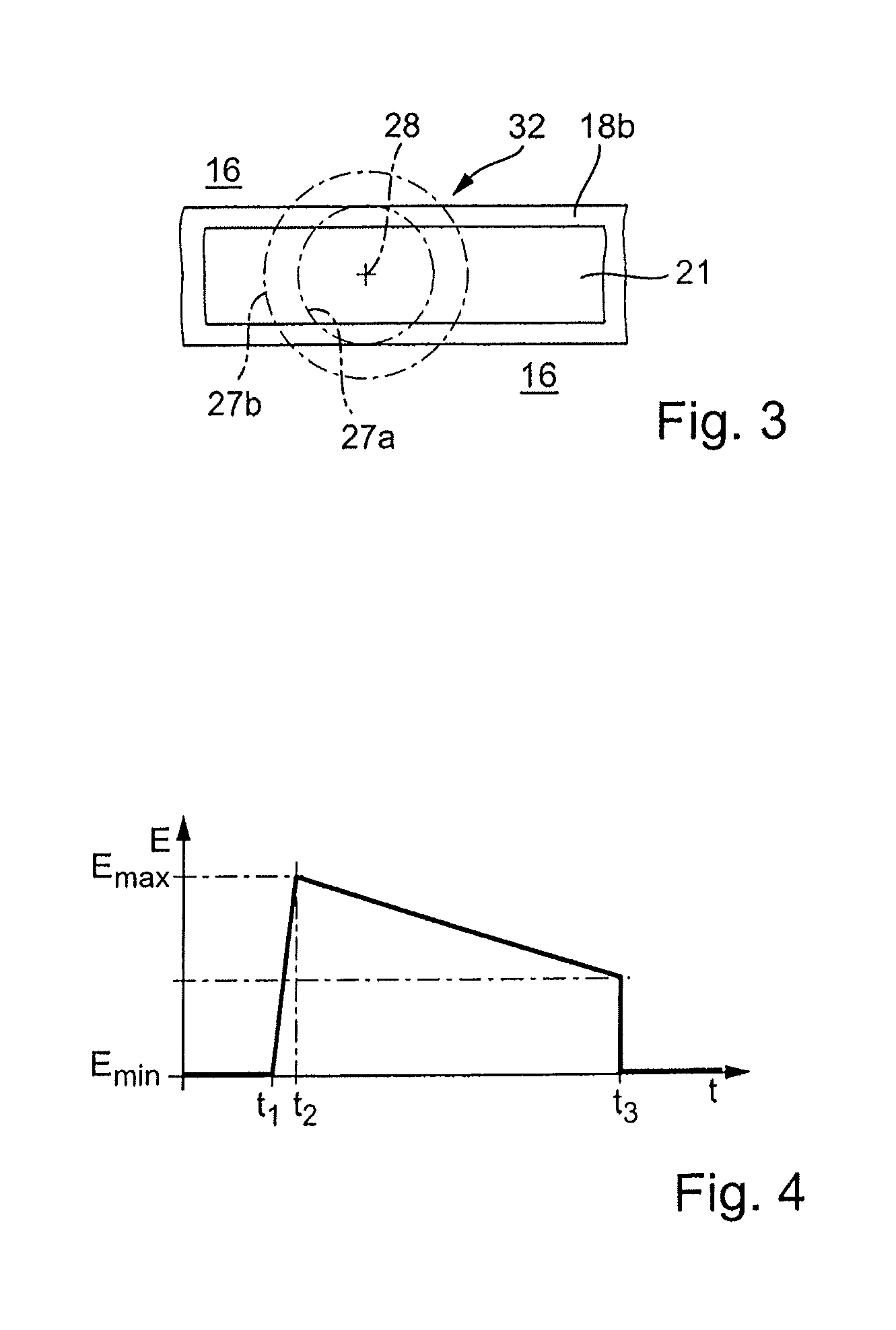

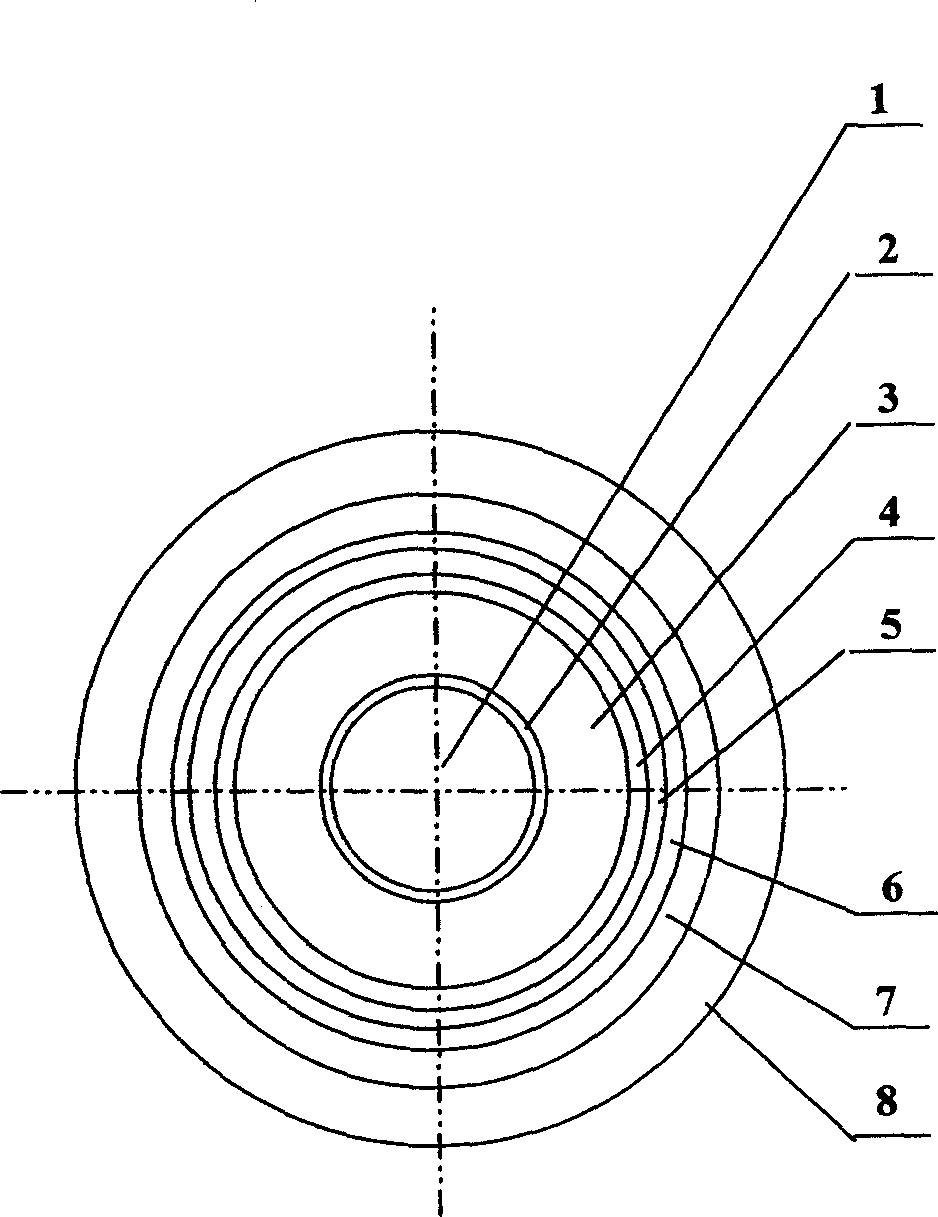

InactiveUS20060193084A1Easy solder connectionIncrease productionElectrical connection between head and armFinal product manufactureMagnetic disksGimbal

Embodiments of the invention relate to making reconnection when a soldered connection fails in a head / slider used in a magnetic disk drive. In one embodiment, a solder mass deposited on a slider pad of a head / slider is separated from a lead pad and a solder ball connection is yet to be made between the slider pad and the lead pad. A shaping tip is heated to a temperature near a melting point of a solder. The shaping tip is moved in parallel with a surface of the slider pad toward the side of the lead pad to soften the solder mass. The solder mass is thereafter irradiated with a laser beam so as to form a solder fillet, thereby making a soldered connection between the lead pad and the slider pad.

Owner:WESTERN DIGITAL TECH INC

Method for Soldering Contact Wires to Solar Cells

InactiveUS20110163085A1Reduce stepsReduce stressCooking-vessel materialsSolid-state devicesSolderingEngineering

In a method for soldering contact wires to a side of a solar cell for producing the electrical contact-making, the solar cells have at least one metallic strip-shaped region. A contact wire is soldered onto the latter for the electrical connection of the solar cell, wherein the soldering duration or the duration of the energy input externally onto the soldering region is very short and is less than 800 ms.

Owner:SCHMID TECH SYST

Manufacturing method of 35 KW environmental protection type A kind fire proof power cable for underground railway circuit

InactiveCN1556529AReduce erosionPrevents water and electrical trees from formingPlastic/resin/waxes insulatorsPower cables with screens/conductive layersCross-linked polyethyleneOxide

The invention relates to a method of making a 35Kv environmental-protection Class-A fireproof power cable for subway main lines, selecting a tightly-compressed and intertwisted circular conductor, coating the external surface of the conductor with a semiconductor material and a cross-linked polytene material in turn, adopting an oxide cross-linking or electronic irradiation technique to graft flame-retardant molecules and carbon-forming units onto the cross-linked polytene material, then coating with a copper band, then winding many layers of high flame-retardant gelatinized glass cloth bands on the copper band, using a copper band for butt welding in the axial direction of an insulated line core on the glass cloth winding layer and rolling into a ripple metallic tube, making a thermal-protecting coating on the ripple metallic tube and finally extruding a low-smoke, halogen-free, flame-retardant and environmental-protection polyolefin material outer jacket on the heat insulating layer. Its flame retardancy can meet the requirement of 1A-level flame-retardant test, and they have low burning losses, high photo-permeability and small toxicity. It has the properties of moisture proofing and preventing bio-disoperation like termite resistance, mouse preventing property, etc.

Owner:BAOSHENG SCI & TECH INNOVATION

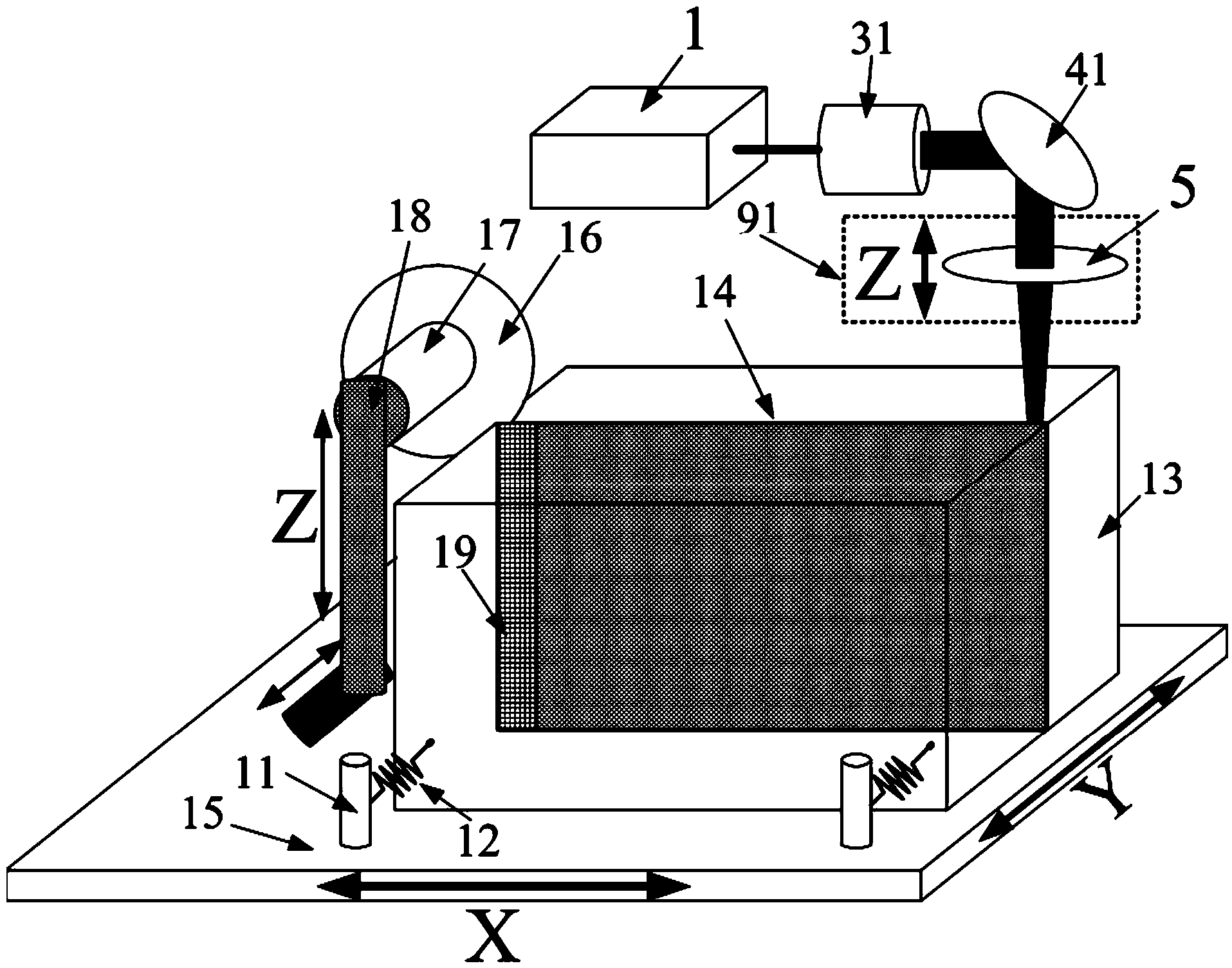

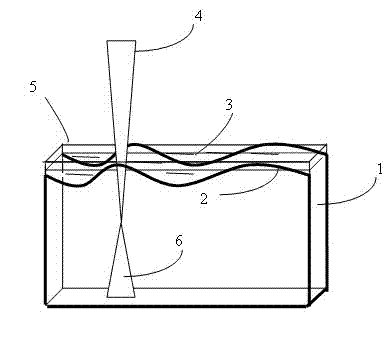

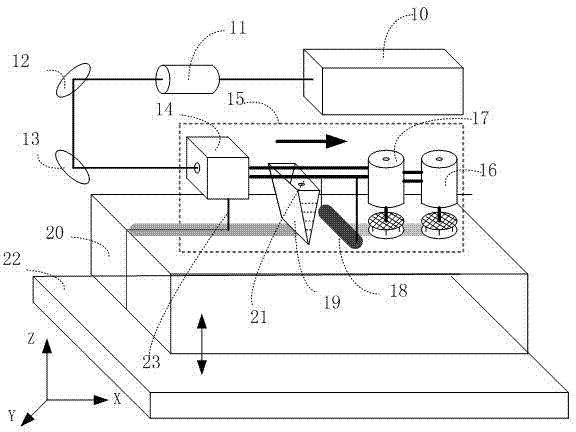

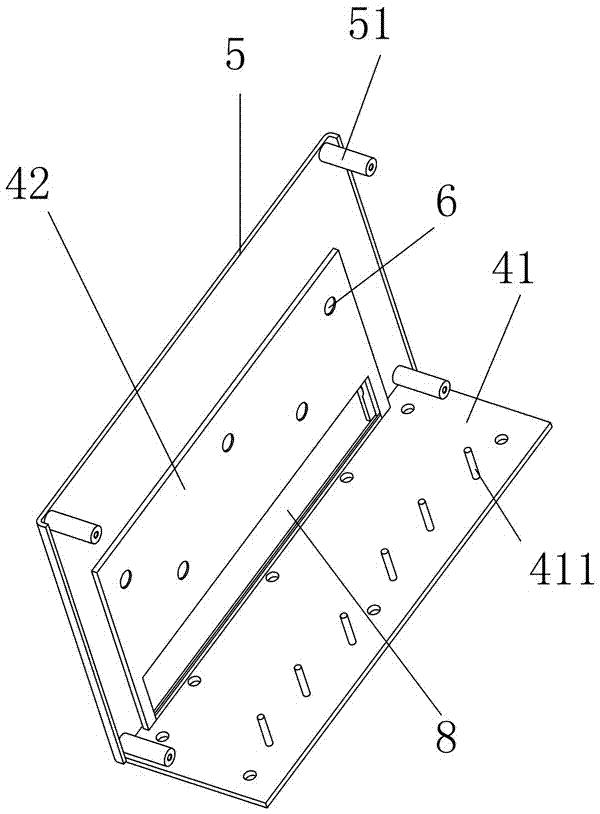

Method and device for quickly separating optical crystals by using laser light

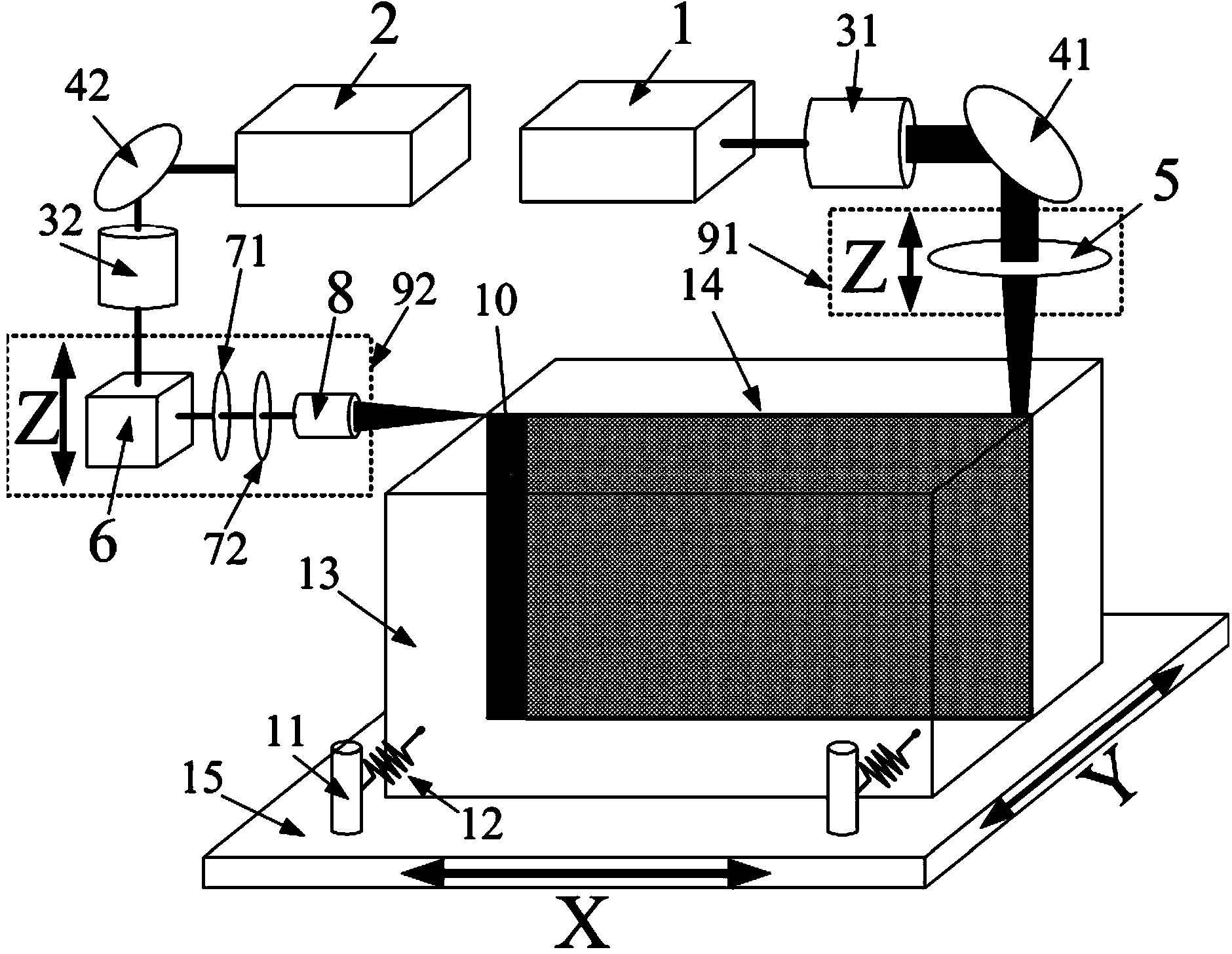

ActiveCN103831527ARelieve mechanical stressPrecise Separation SizeWelding/soldering/cutting articlesLaser beam welding apparatusLaser lightThermal expansion

The invention discloses a method for quickly separating optical crystals by using layer light. The method comprises the following steps of setting the separating direction of the optical crystals by using ultrafast laser light or a miniature diamond grinding wheel; forming a precast microcrack with the direction along a to-be-separated path at a separation starting end; performing scanning heating on the preformed microcrack by using focusing laser light to form a laser-induced microcrack; quickly moving the focusing laser light along the to-be-separated path until the laser moving speed is the same with the crack expansion speed; enabling the focusing laser light to always follow the foremost end of the microcrack; performing thermal expansion effect on materials on two sides of the microcrack; generating forward squeezing force and lateral pulling stress on the tip of the microcrack; and pulling materials of the crystals so as to realize high-quality separation of the crystals. A device comprises a microcrack preforming mechanism, a single-focus-point laser machining system and a two-dimensional worktable. By using the method and the device, the separation speed, the separation accuracy, the machining safety and the machining quality of the optical crystals can be improved, non-loss separation of the optical crystals is realized, and a quasi-polishing-level finishing separation surface is formed.

Owner:武汉飞能达激光技术有限公司

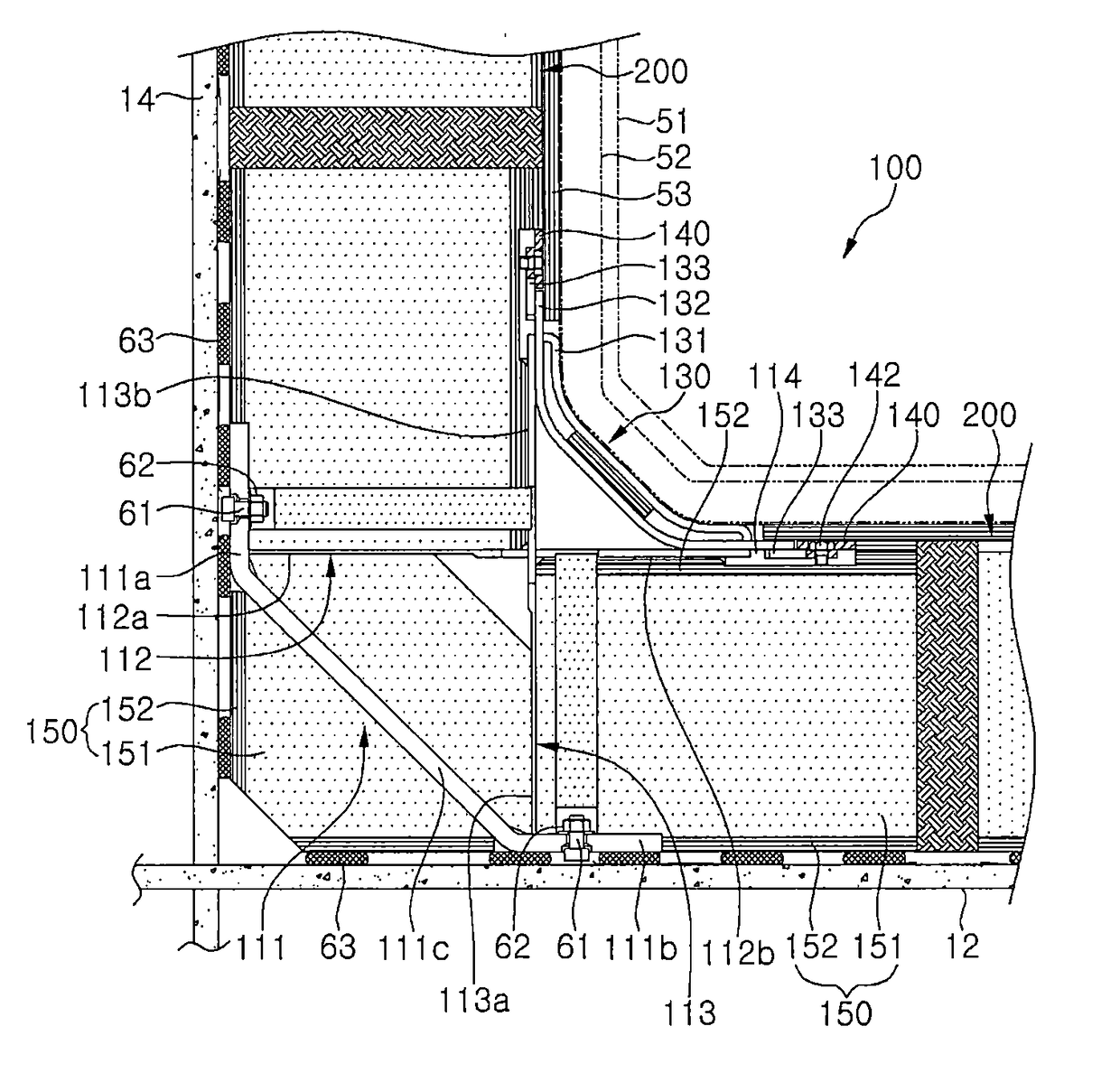

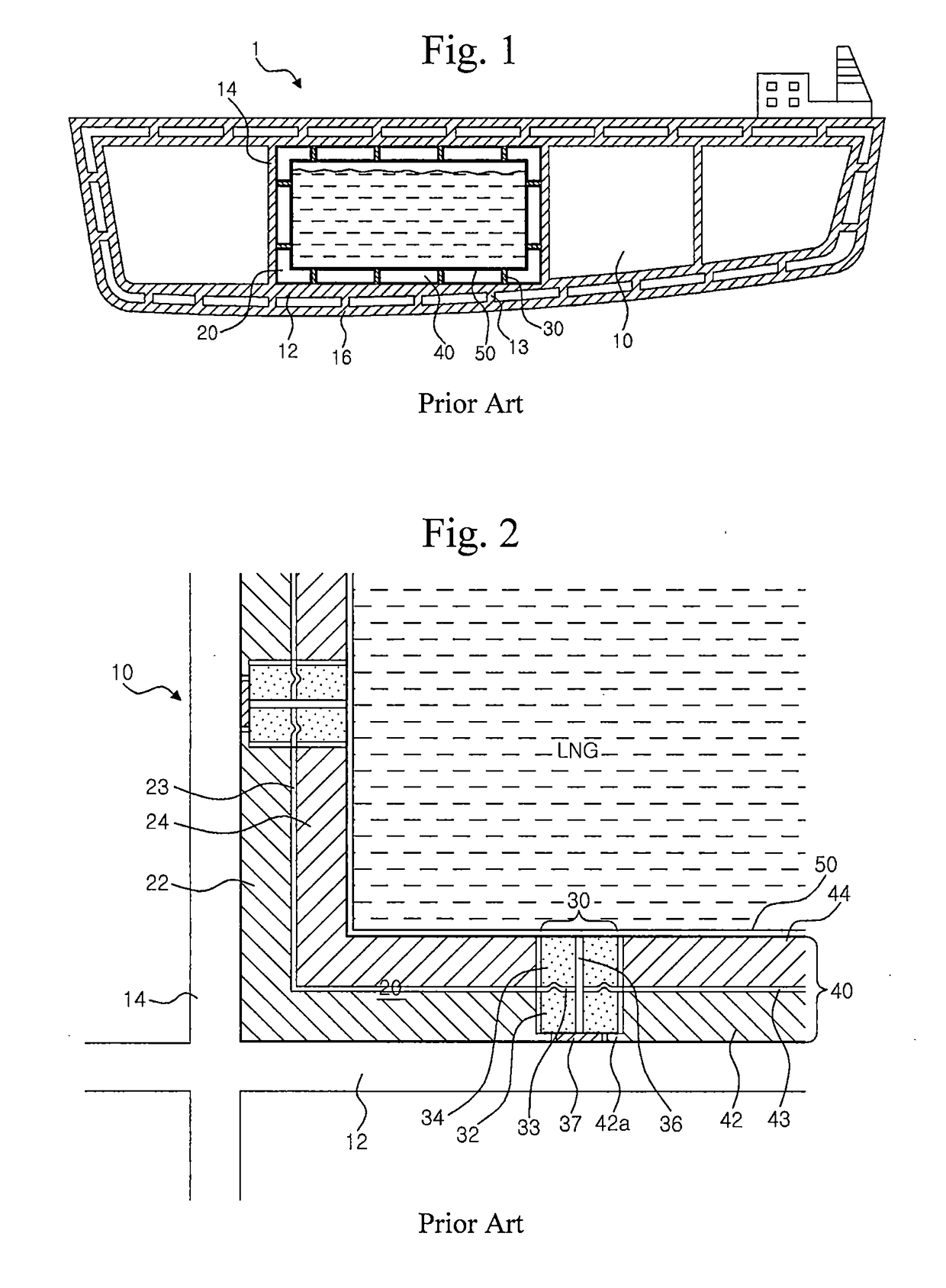

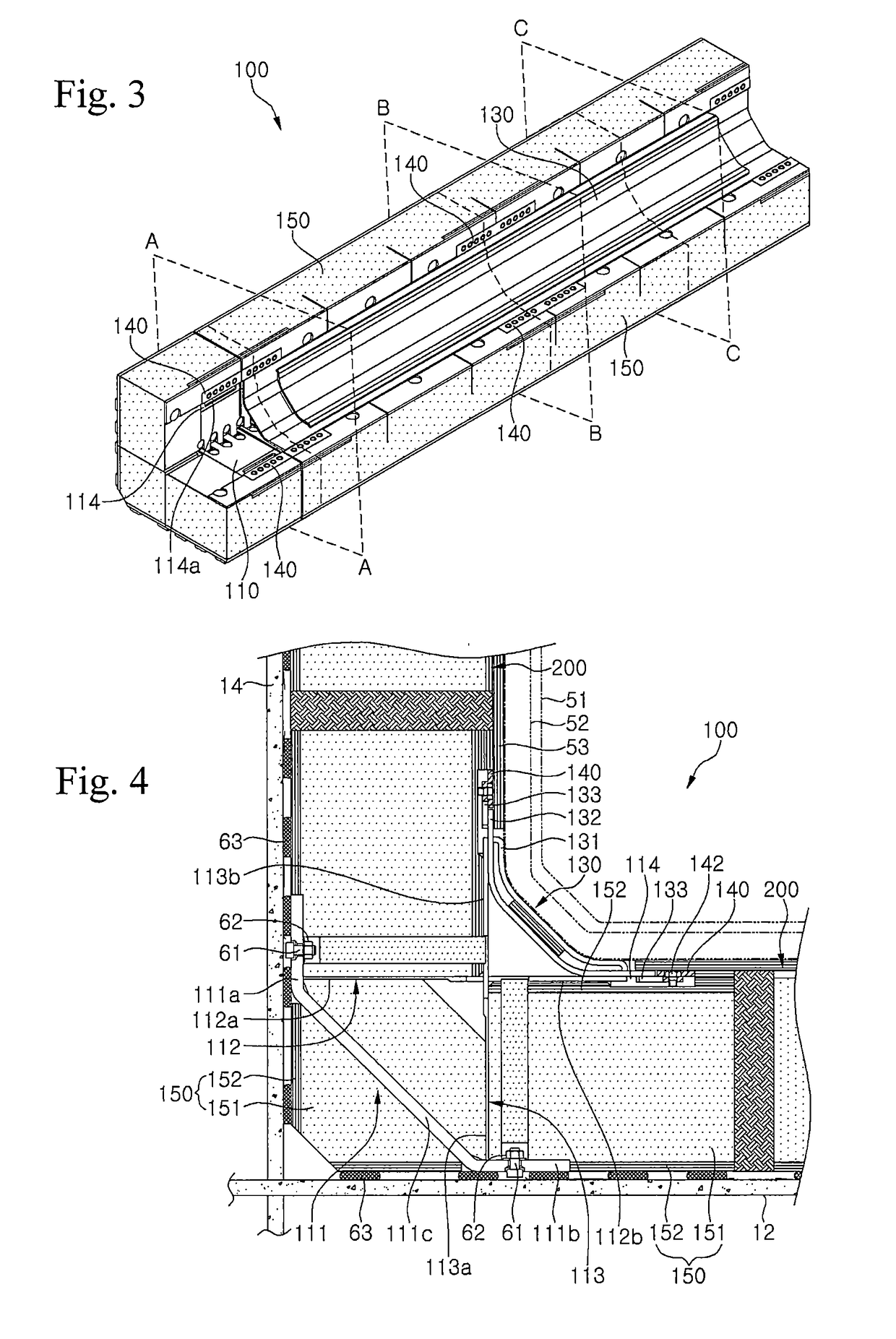

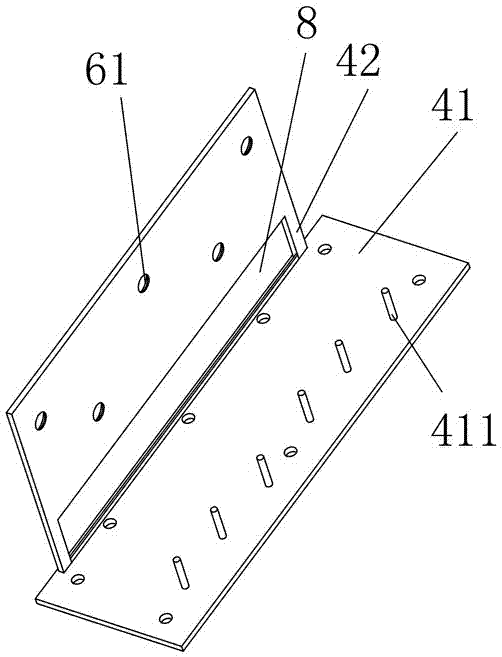

Corner structure of LNG storage tank

ActiveUS20170227164A1Simple processImprove workabilityVessel geometry/arrangement/sizeVessel wallsEngineeringMechanical engineering

A corner structure comprises: a fixed member fixed to a corner of a storage tank; a movable member supported on the fixed member so as to be linearly movable; a stop member attached to the fixed member to prevent the movable member from being detached from the fixed member; and a heat insulating member disposed between a sealing wall and a hull. The fixed member comprises a guide portion provided with a guide recessed portion, the movable member comprises a guide protruding portion inserted into the guide recessed portion, and the width and the length of the guide protruding portion are smaller than the width and the length of the guide recessed portion, so that the movable member can be supported on the fixed member to be movable in the longitudinal direction and in the direction perpendicular to the longitudinal direction.

Owner:KC LNG TECH CO LTD

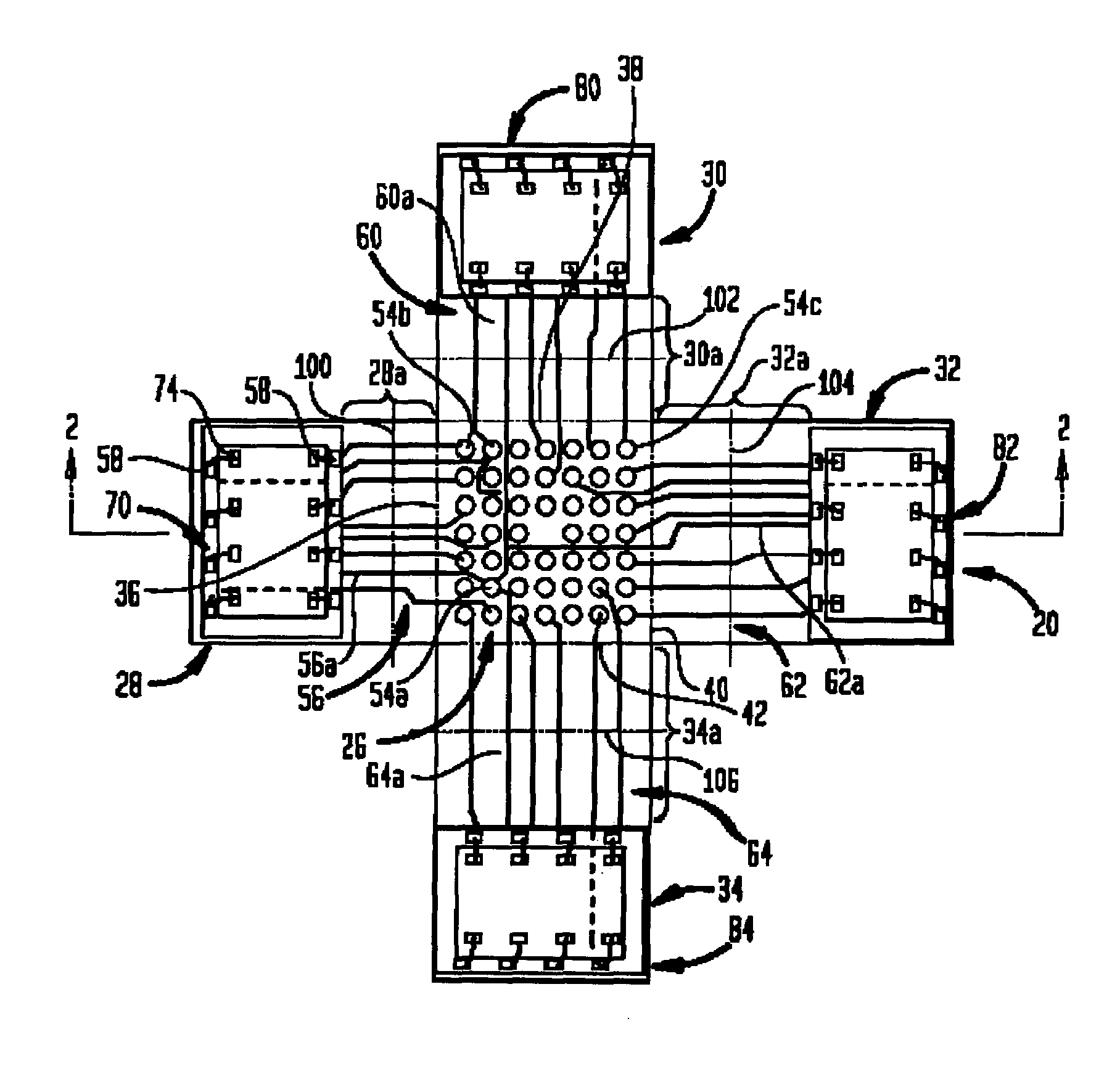

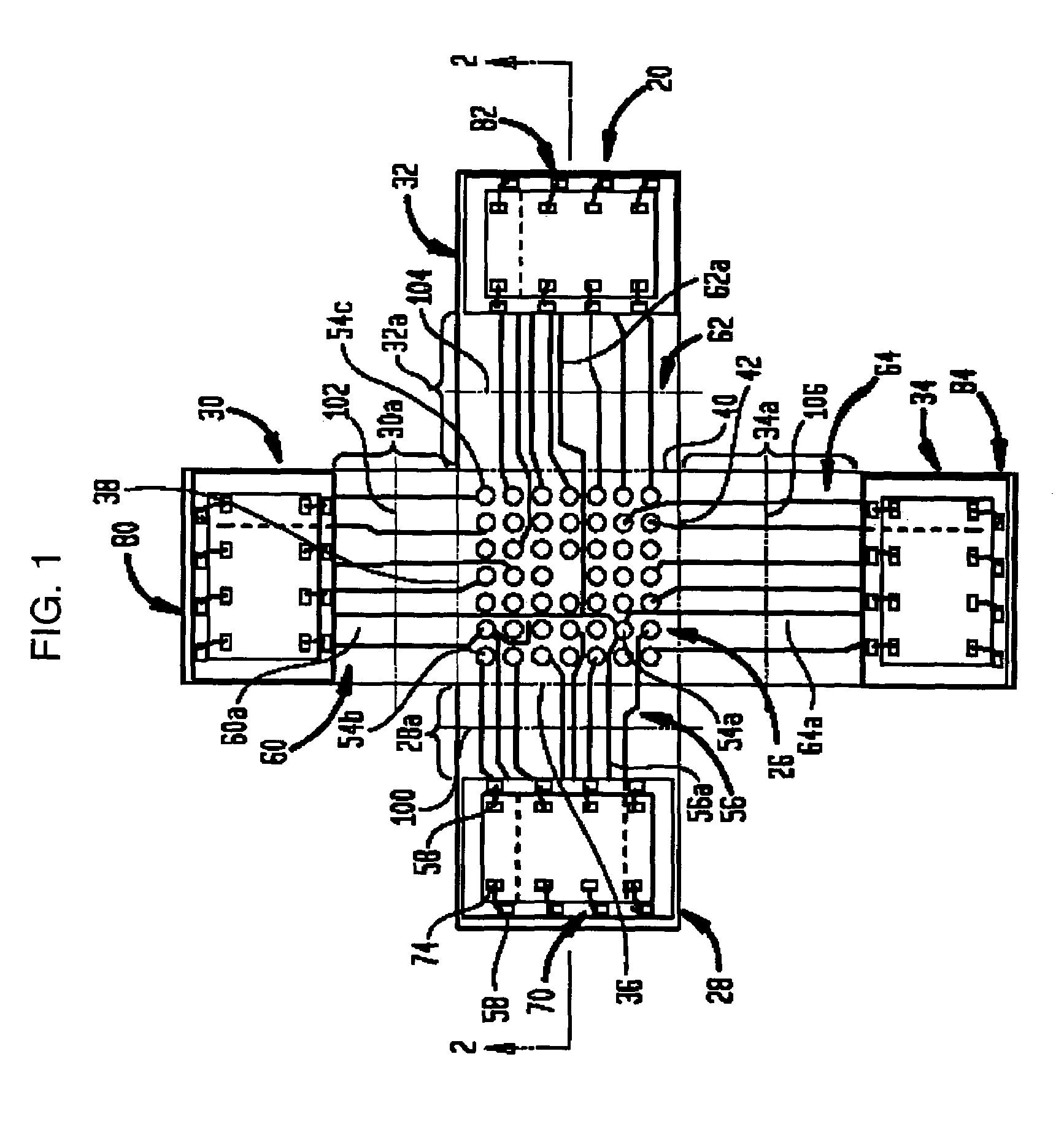

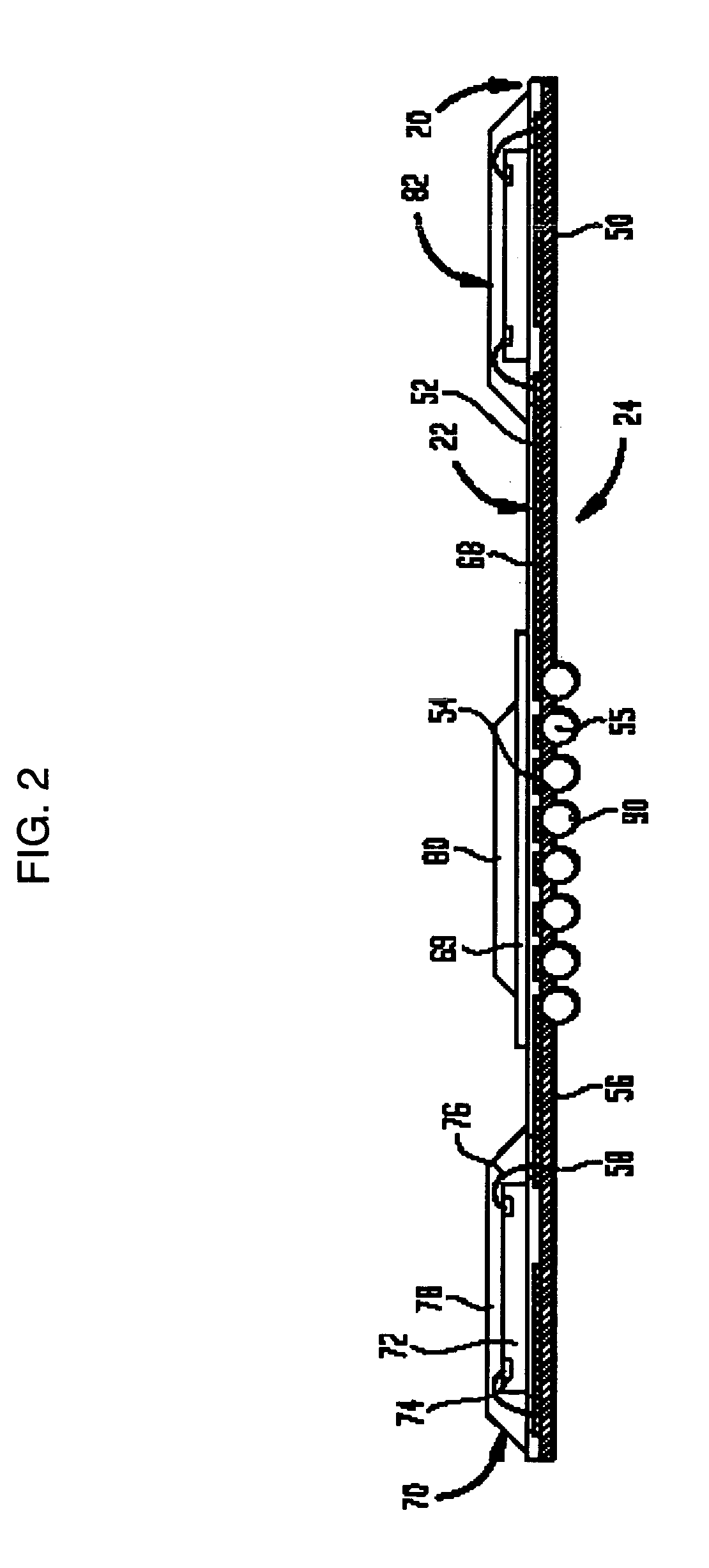

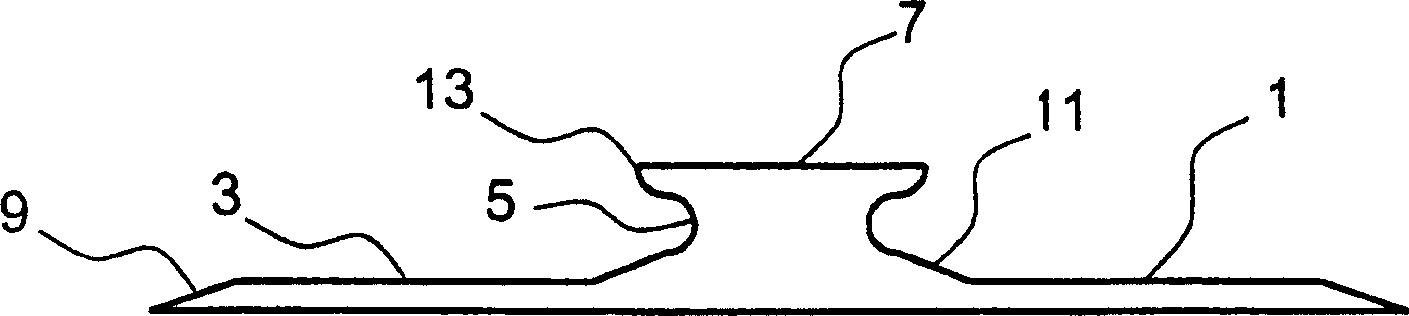

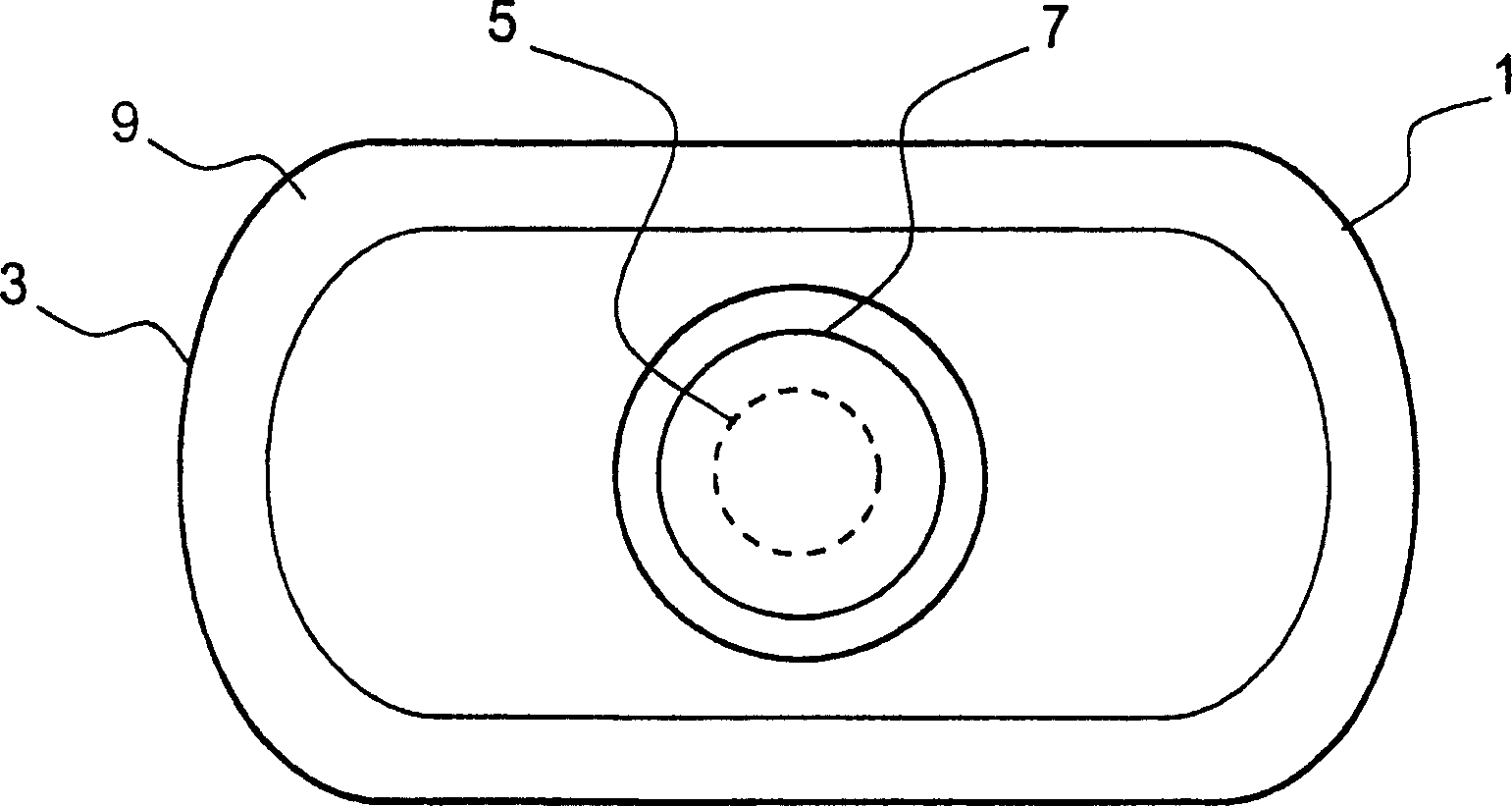

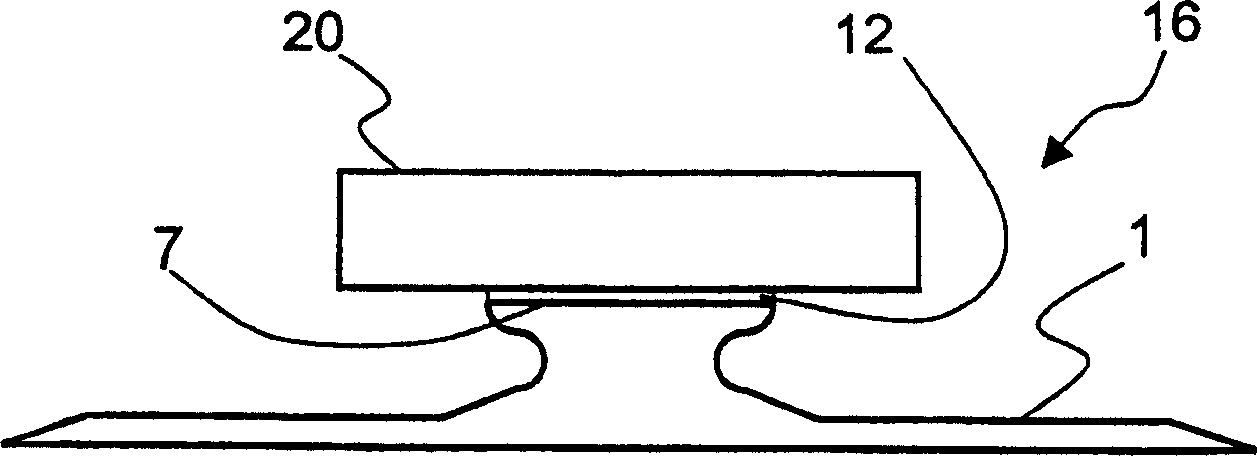

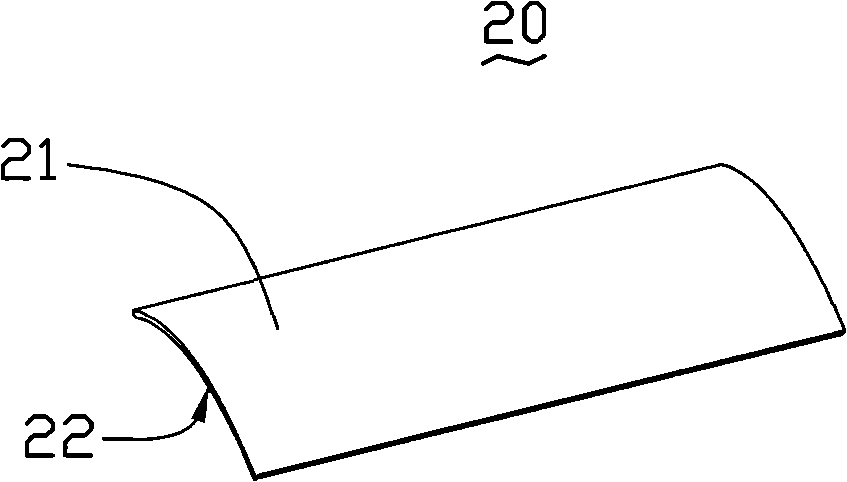

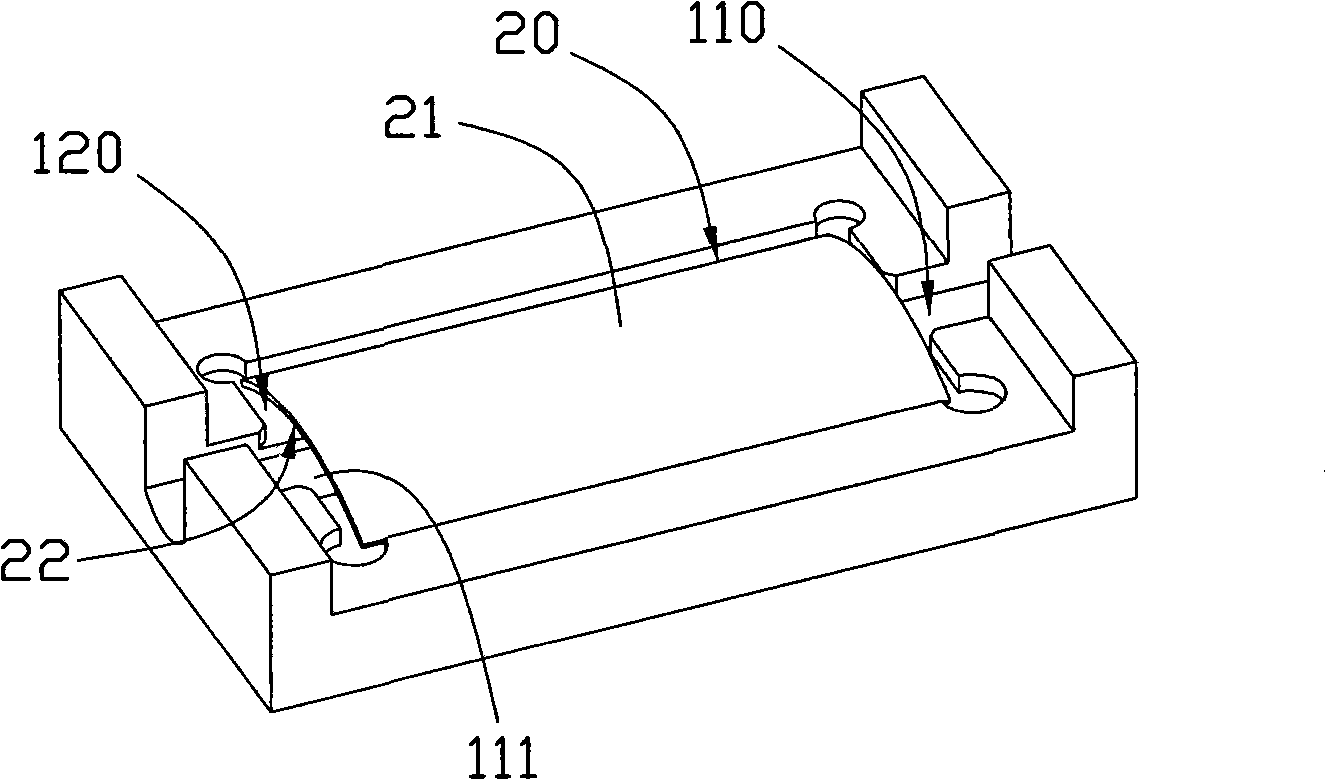

Post patch for mounting devices inside tires

InactiveCN1636773AVersatilityRelieve mechanical stressElectric signal transmission systemsTyre measurementsEngineeringElectronic component

A system, method and device for integrally installing electrical components, electronic components and devices in a pneumatic tire, including a specially structured mounting connection plate for mounting at least one electronic device supported by a substrate. The mounting web is preferably adapted to be positioned on the inner liner of a pneumatic tire and is configured to isolate any mounted electronic devices from tire related phenomena including mechanical stress, vibration, heat and other The reaction produced by the rotational motion of the tire. An embodiment of a mounting board includes a circular or rectangular platform for supporting various electronic components, and circular, rectangular or cross-shaped posts for connecting the base of the mounting board to the platform supporting the electronic device. Selected electronic devices may be encapsulated by an encapsulating material to facilitate operative connection of the electronic device to the tire web.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

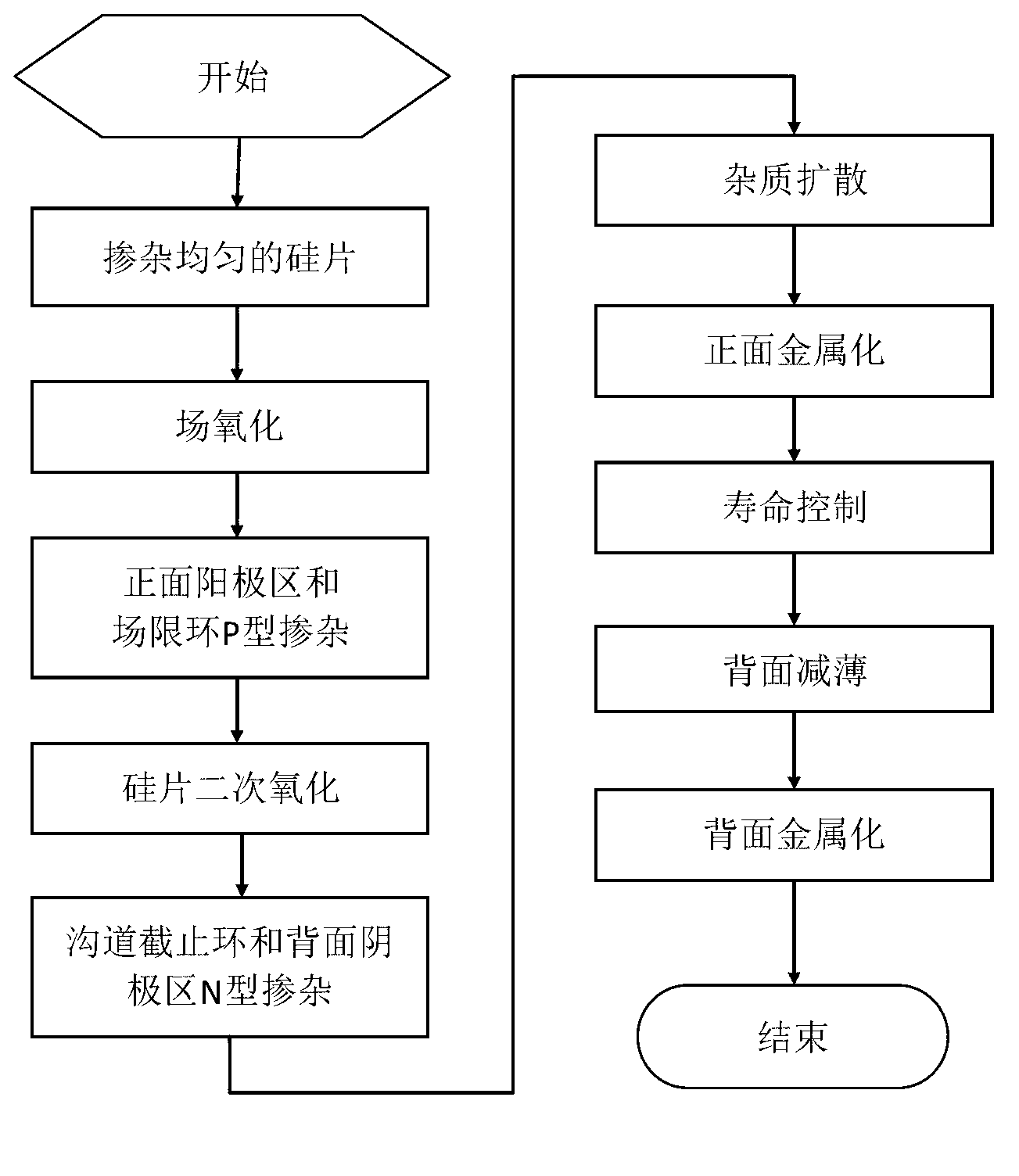

Manufacturing method of high-voltage quick-recovery diode

ActiveCN102842501ALow costReduce processing stepsSemiconductor/solid-state device manufacturingDiffusion methodsImpurity doping

The invention provides a manufacturing method of a high-voltage quick-recovery diode, and the method comprises following steps of simultaneously implementing P-type impurity doping of an anode area and a terminal field limiting ring on the front surface of an N-type monocrystalline silicon sheet which is uniformly doped through field oxidation and ion injection; adopting a diffusion method to simultaneously implement the N-type impurity doping of a silicon sheet front surface groove interception ring and a silicon-sheet back surface cathode area after the anode area and the terminal field limiting ring area are protected by an oxidation film; implementing the heat diffusion propulsion simultaneously for the P-type impurities and N-type impurities in a high-temperature diffusion furnace; and implementing the back surface metallization after completing the front surface metallization, electron radiation minority carrier lifetime control and removal of a back surface damaged layer. According to the method, the machining steps are simple, and a deep N-type doped layer on the back surface of the silicon sheet is favorable for improving the reverse recovery characteristic of the diode and improving the blocking voltage.

Owner:CHINA ELECTRIC POWER RES INST +1

Head gimbal assembly method with solder fillet formed by laser irradiating a shaped solder mass

InactiveUS7486480B2Increase productionLower component costsElectrical connection between head and armFinal product manufactureSolder ballEngineering

Embodiments of the invention relate to making reconnection when a soldered connection fails in a head / slider used in a magnetic disk drive. In one embodiment, a solder mass deposited on a slider pad of a head / slider is separated from a lead pad and a solder ball connection is yet to be made between the slider pad and the lead pad. A shaping tip is heated to a temperature near a melting point of a solder. The shaping tip is moved in parallel with a surface of the slider pad toward the side of the lead pad to soften the solder mass. The solder mass is thereafter irradiated with a laser beam so as to form a solder fillet, thereby making a soldered connection between the lead pad and the slider pad.

Owner:WESTERN DIGITAL TECH INC

Circuit board leveling apparatus and method for leveling circuit board

InactiveCN101360395AEliminate internal stressReduce warpagePrinted circuit manufactureElectrical and Electronics engineering

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

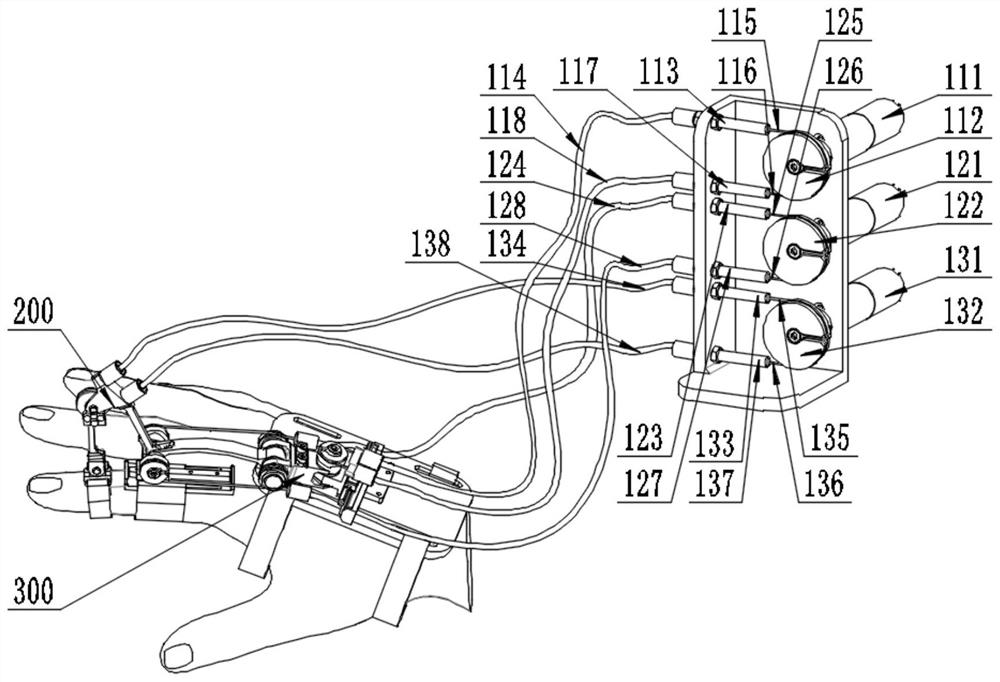

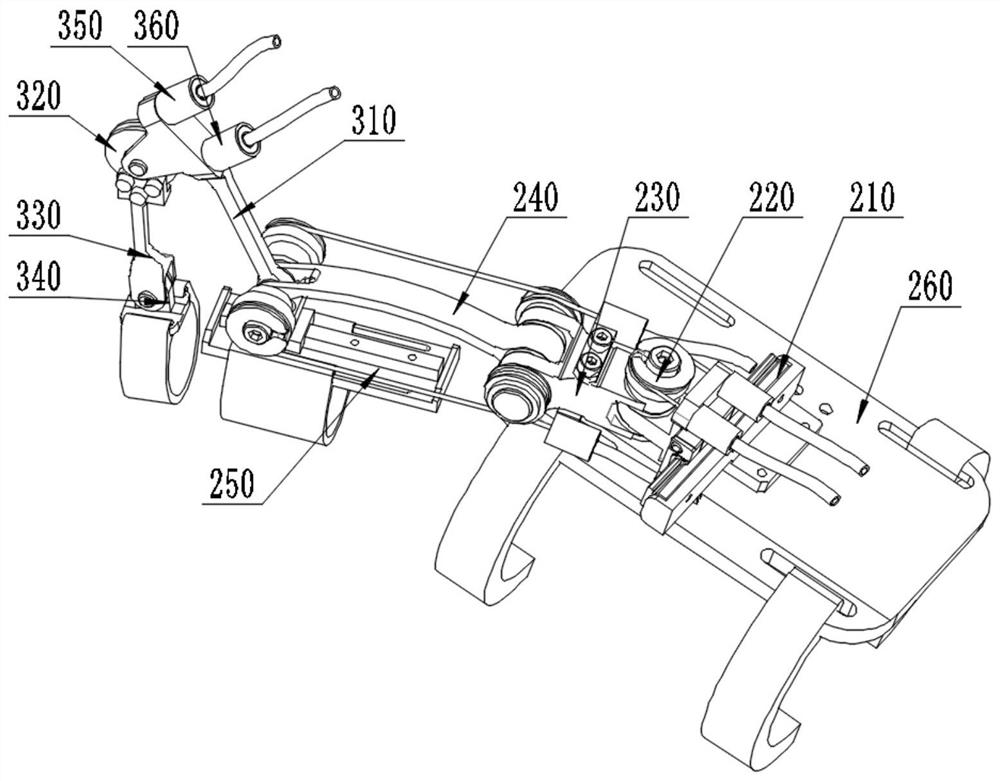

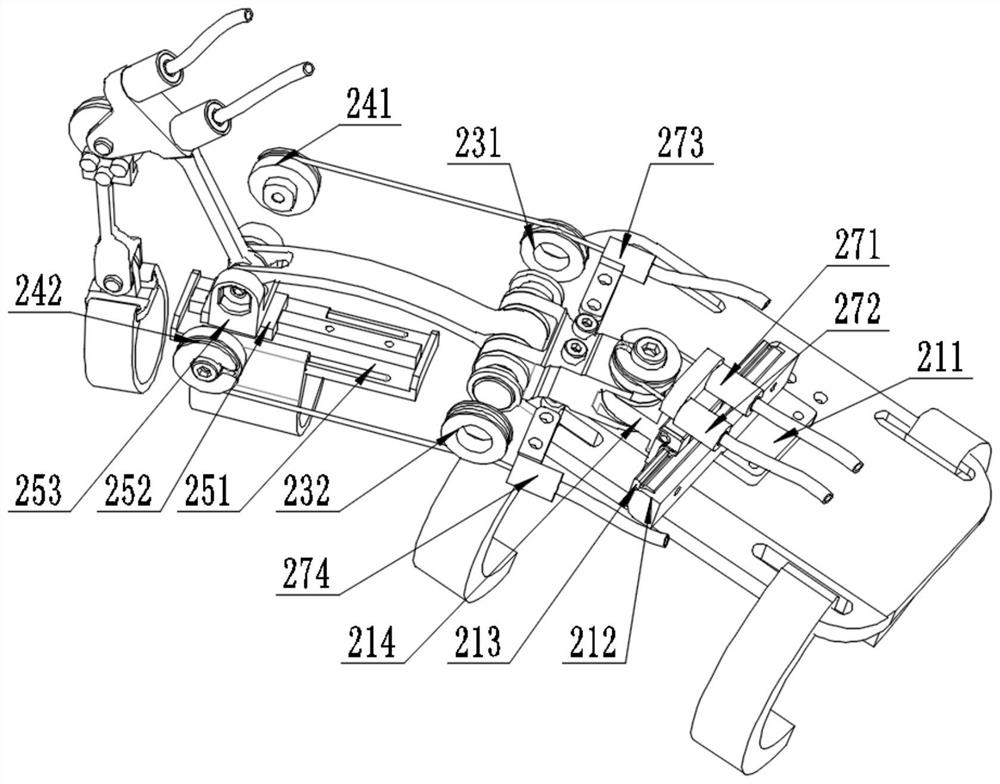

Finger rehabilitation exoskeleton robot with adduction, abduction, flexion and stretching functions

ActiveCN112641598AImplement Adaptive AlignmentRelieve mechanical stressChiropractic devicesStretch exerciseExoskeleton robot

The invention belongs to the field of biomechanical engineering, aims to solve the problem that an existing finger rehabilitation robot assisting metacarpophalangeal joints in adduction, abduction, flexion and stretching movement cannot achieve self-adaptive alignment of man-machine joints, and particularly relates to a finger rehabilitation exoskeleton robot with adduction, abduction, flexion and stretching functions. The finger rehabilitation exoskeleton robot comprises three driving assemblies, a metacarpophalangeal joint transmission assembly and a near-end joint transmission assembly, wherein inner and outer driving rope wheels in the metacarpophalangeal joint transmission assembly can control the adduction and abduction movement of the human hand under the driving of the first driving assembly; a first fixed rope wheel and a second fixed rope wheel in the metacarpophalangeal joint transmission assembly can control the flexion and stretching movement of the near-end phalanx under the driving of the second driving assembly; and the near-end joint transmission assembly can control the flexion and stretching movement of the middle phalanx under the driving of the third driving assembly. According to the invention, the self-adaptive alignment of the man-machine joints of the rehabilitation robot capable of doing the adduction, abduction, flexion and stretching movement can be realized, and meanwhile, the joint mechanical stress generated between a man and a machine can be effectively eliminated.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI +1

Flip-chip assembly and manufacture method thereof

InactiveCN101567349ARelieve mechanical stressIncrease production capacitySemiconductor/solid-state device detailsSolid-state devicesFlip chip interconnectSemiconductor chip

The invention discloses a flip-chip assembly and manufacture method thereof. Various aspects can be implemented for providing flip-chip interconnect structures for connecting or mounting semiconductor chips to supporting substrates, such as cards, circuit boards, carriers, lead frames, and the like. In general, one aspect can be a method of providing a flip-chip interconnect structure that includes providing a semiconductor work piece that includes one or more bond pads. The method also includes depositing a first non-reflowable layer that has a first melting temperature higher than a predetermined first reflow temperature. The method further includes depositing a reflowable stress relief layer that reflows at the predetermined first reflow temperature. The method additionally includes depositing a second non-reflowable layer that has a second melting temperature higher than the predetermined first reflow temperature such that the deposited reflowable stress relief layer is between the first and the second non-reflowable layers.

Owner:CHENGDU MONOLITHIC POWER SYST

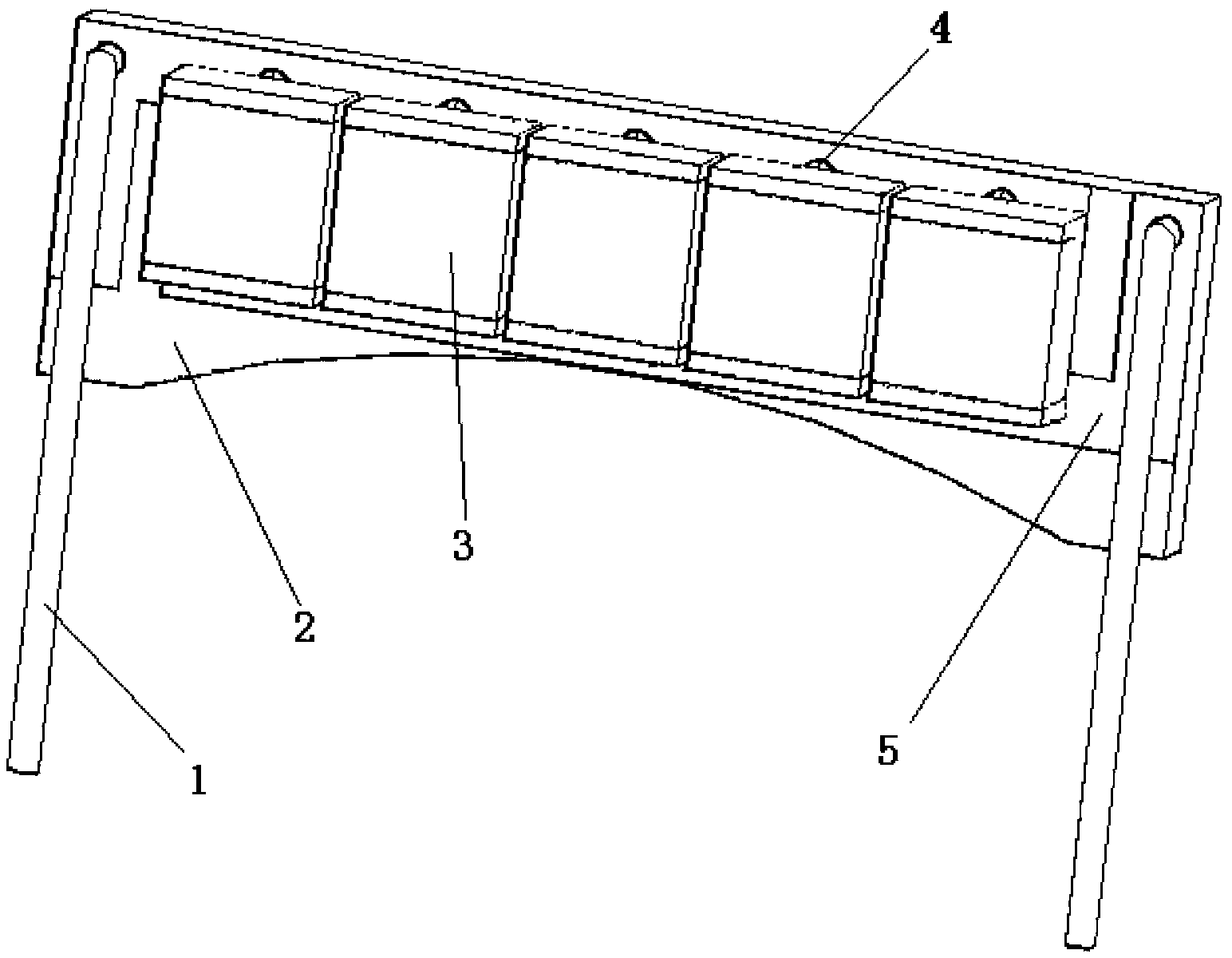

High capacity multilayer ceramic dielectric capacitor composed of chips and provided with leads

InactiveCN104299786AAvoid enteringReduce volumeMultiple fixed capacitorsFixed capacitor housing/encapsulationDielectricCopper foil

The invention provides a high capacity multilayer ceramic dielectric capacitor composed of multiple chips and provided with leads. The high capacity multilayer ceramic dielectric capacitor relates to the electronic circuit technology field, and comprises leads, a substrate, ceramic dielectric capacitor chips, a metalized through hole and two copper foils. The metalized through hole is disposed in the substrate, and the copper foils are disposed on the substrate. The ceramic dielectric capacitor chip comprises a plurality of chips, and the two copper foils are parallelly disposed on the substrate in a coated manner. The ceramic dielectric capacitor chips are vertically disposed on the substrate at equal interval. The capacitor chips disposed on two sides of the substrate are connected together through the metalized through hole. A segment of each of the leads is bent vertically to be hooked with the metalized through hole of the substrate, and the lower part of each of the leads below the bent segment is directly disposed on the corresponding copper foil in a welded manner. The ceramic dielectric capacitor chips, the leads and the substrate are sleeved with the housing, the heat conductive silica gel can be poured in the housing in a sealed manner, and at last a housing cover can be used to seal the potting materials. The high capacity multilayer ceramic dielectric capacitor provided by the invention has advantages of strong anti-mechanical stress performance and strong thermal stress performance.

Owner:BEIJING YUANLIU HONGYUAN ELECTRONICS TECH

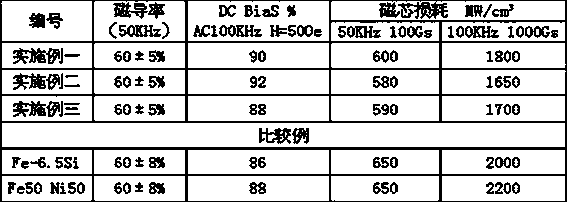

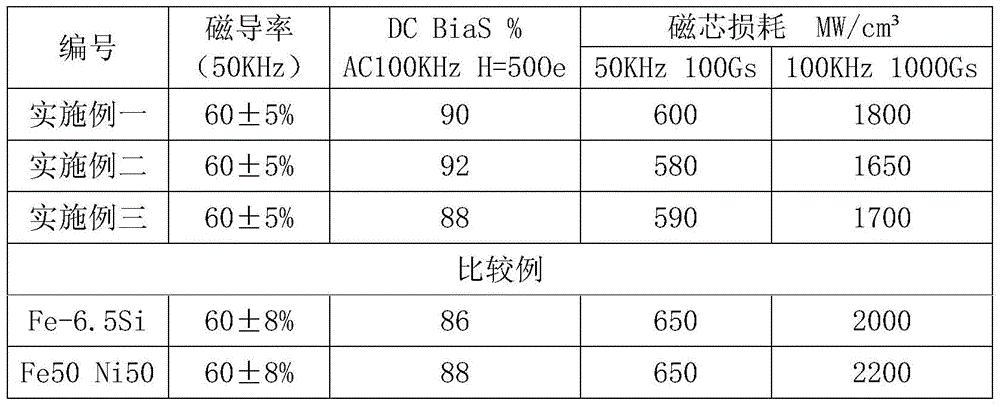

Manufacturing method for soft-magnetic Fe-Si-Al-Ni alloy powder

InactiveCN103551565AImprove crushing ball milling performanceGood workmanshipInorganic material magnetismSilicon alloyMaterials science

A manufacturing method for soft-magnetic Fe-Si-Al-Ni alloy powder comprises smelting alloy formed by 4.0% to 5.0% of Si, 3.0% to 4.0% of Al, 1.0% to 2.5% of Ni, 0.1% to 0.4% of Ti, 0.1% to 0.4% of Mn, 0.1% to 0.5% of P, 0.02% or less of C, and the balance Fe through an induction heating vacuum rapid solidification furnace, performing rapid solidification on the alloy to manufacture sheet materials, and subjecting the sheet materials to mechanical crushing, thermal processing of crushed materials, ball milling of the materials into fine powder, annealing treatment and screening and particle size distribution. The method has the advantages that the smelting alloy material is pure, the alloy saturation induction density Bs is more than 18000 gausses, and the adding of Ni can guarantee that the alloy magnetostriction coefficient is zero; excellent soft magnetic properties are provided during magnetic powder core manufacturing, and the AC / DC superposition performance is good particularly when the magnetic conductivity of pressed products is mu e60, for example, when AC is 100 KHz, DCH is equal to 50 Oe, mu 50 >=88% mu O, and the magnetic core loss is lower than that of the high-flux Fe50 Ni50 magnetic powder core, so that the soft-magnetic Fe-Si-Al-Ni alloy powder can replace Fe50 Ni50 and Fe-Si alloy magnetic powder cores to be used in electronic and electric industries.

Owner:武汉欣达磁性材料有限公司

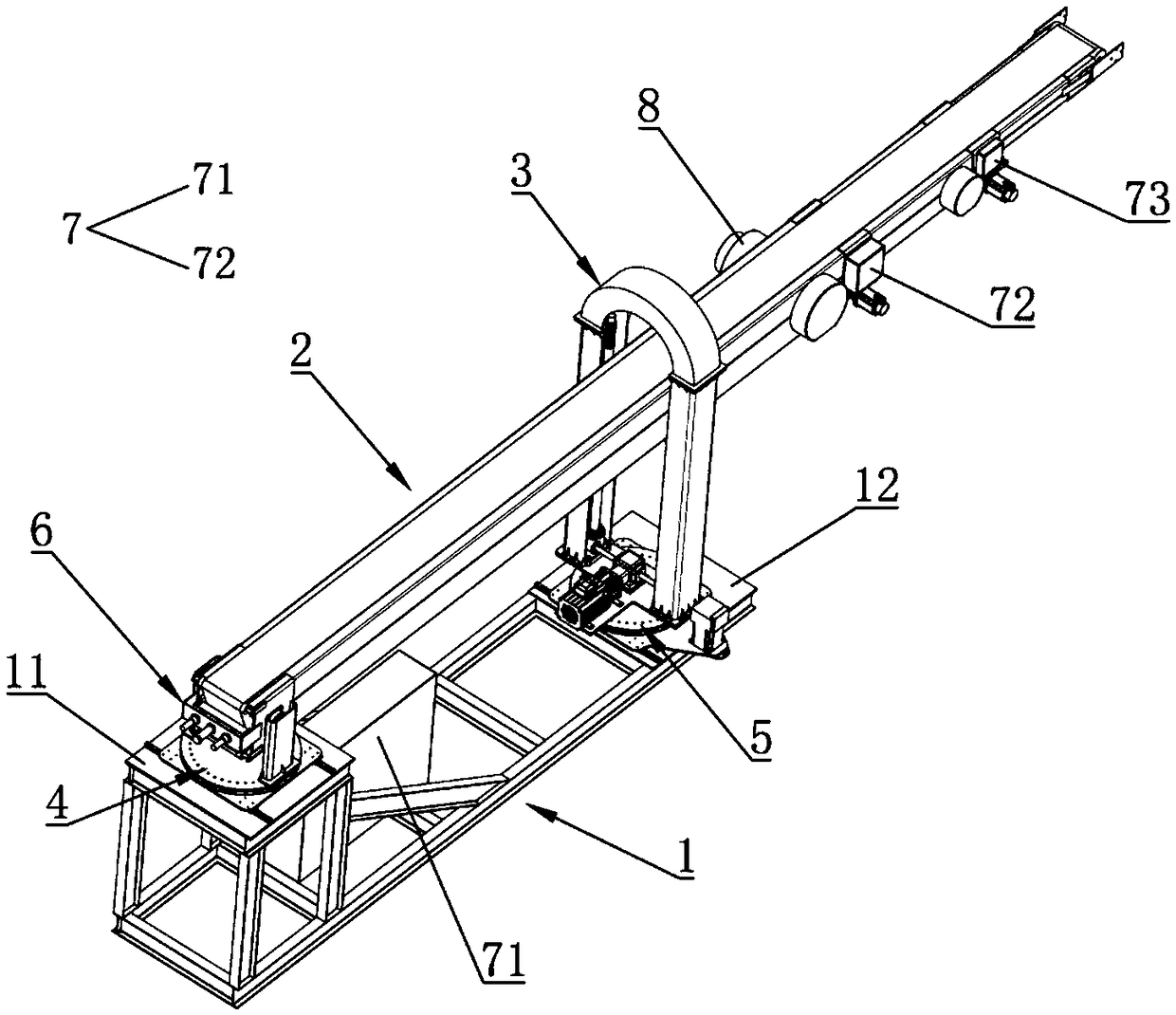

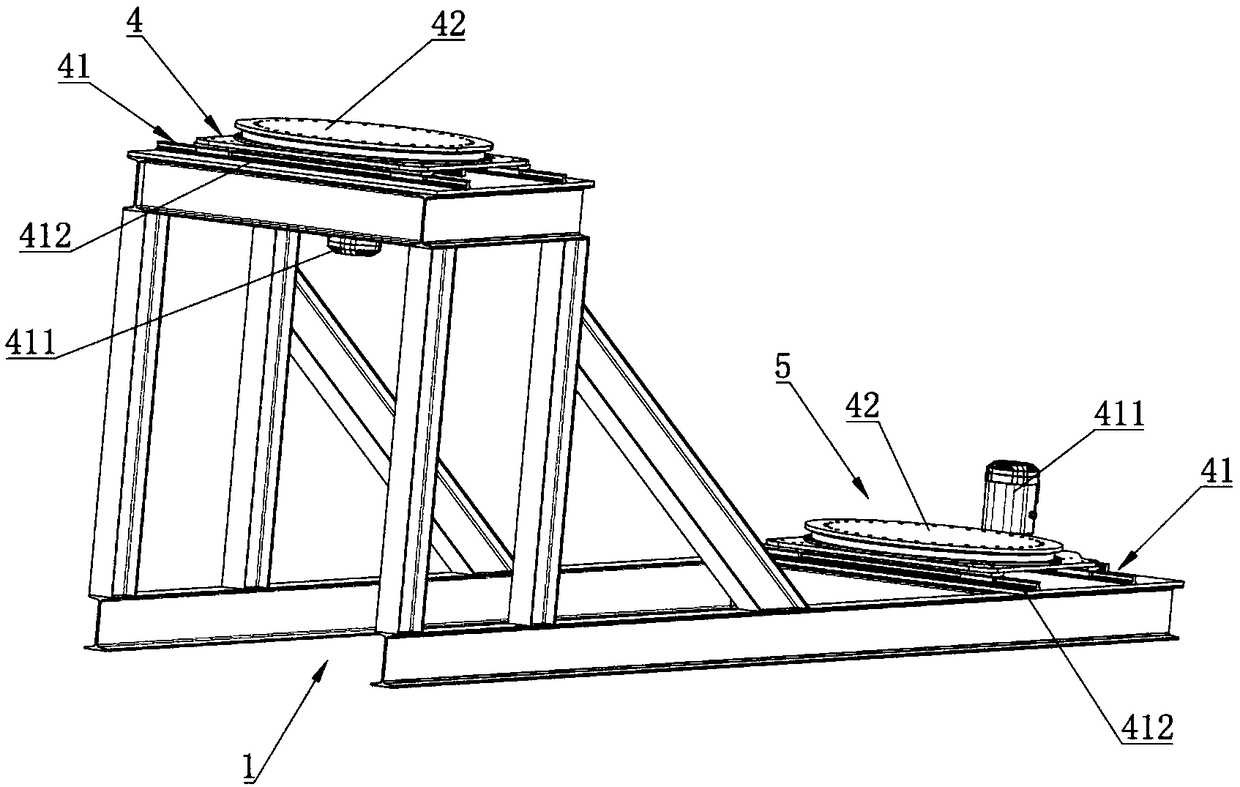

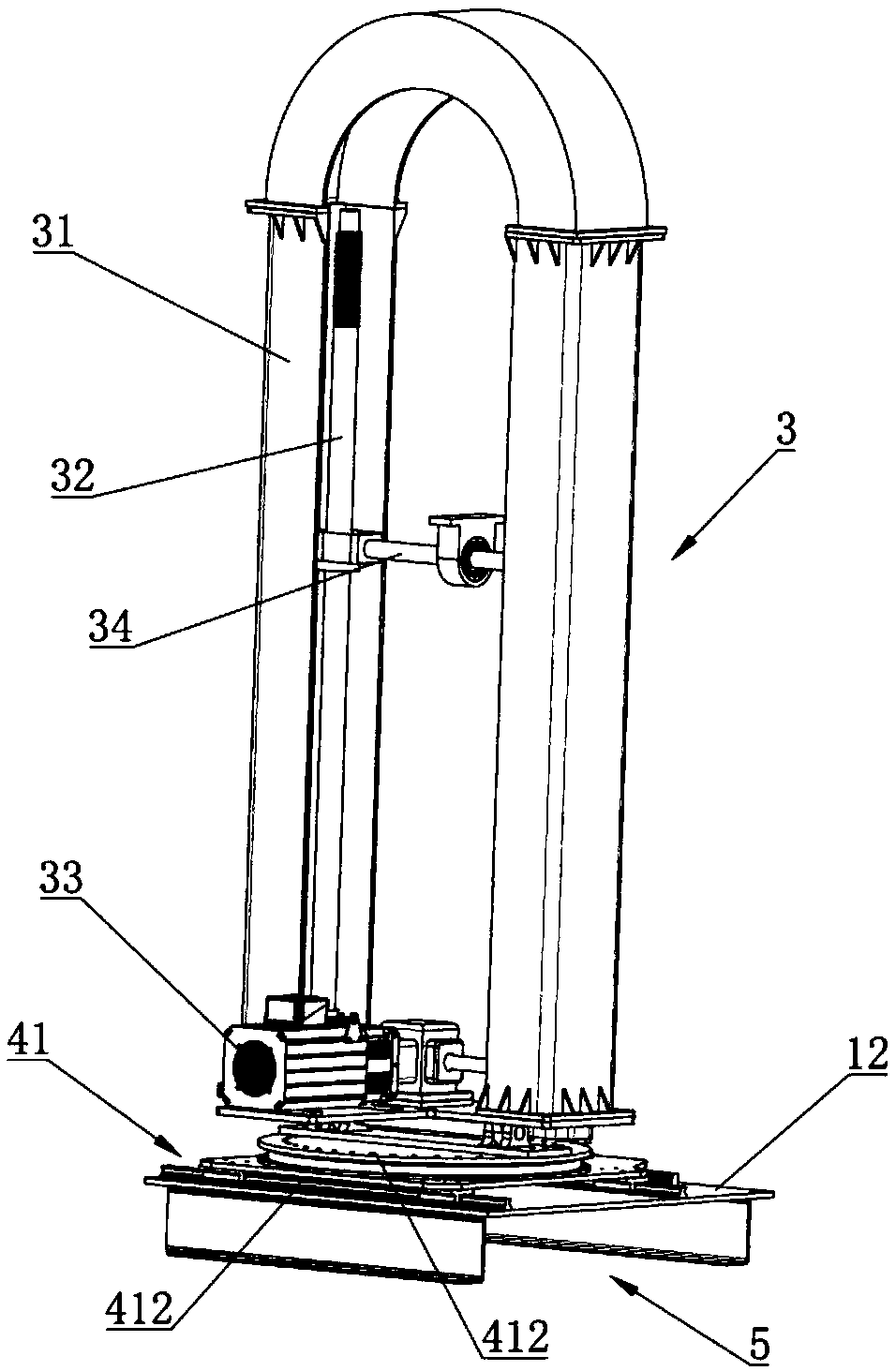

Cargo stacking robot

ActiveCN109230578ARealize free adjustmentEasy to stackStacking articlesDe-stacking articlesEngineeringRobot

The invention relates to the technical field of cargo stacking and in particular to a cargo stacking robot comprising a base, a mechanical arm device and a support device, wherein the base comprises afirst platform and a second platform; the first platform is equipped with a first translational rotating device; a second translational rotation device is mounted on the second platform; one end of the mechanical arm device is rotatably connected to the first translational rotation device; one end of the support device is rotatably connected with the second translational rotation device; the mechanical arm device is connected with the support device and comprises a basic arm and a telescopic arm; the basic arm is provided with a telescopic cavity; the telescopic arm sleeves the telescopic cavity of the basic arm to stretch and retract; the first end of the basic arm is rotatably connected with the first translational rotating device; and the position of the basic arm adjacent to the second end is rotatably connected to the support device. The cargo stacking robot improves cargo stacking stability, reduces cargo stacking cost, is flexible to use, and facilitates cargo stacking from different heights and directions.

Owner:GUAGNZHOU SYL AUTOMATIC CONTROL TECH CO LTD

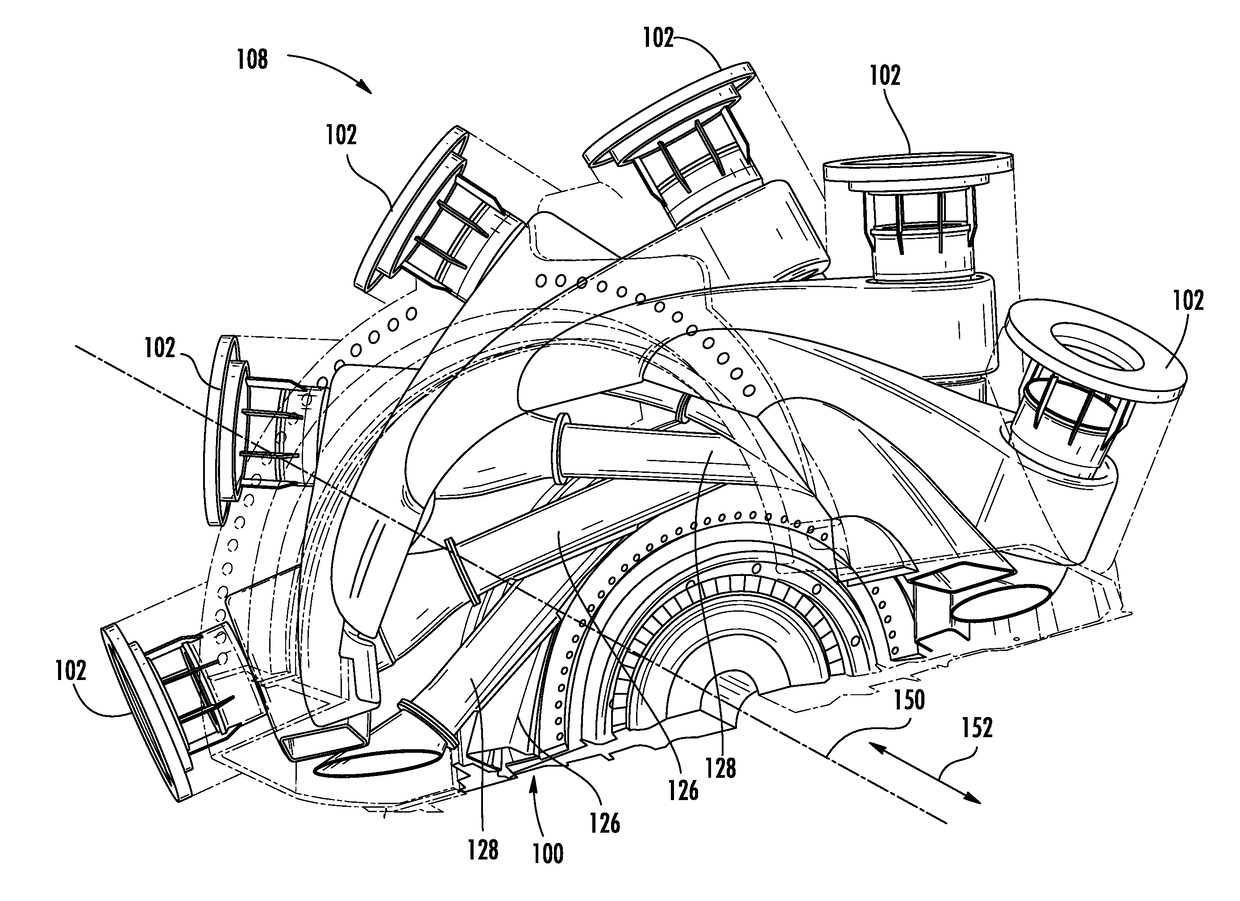

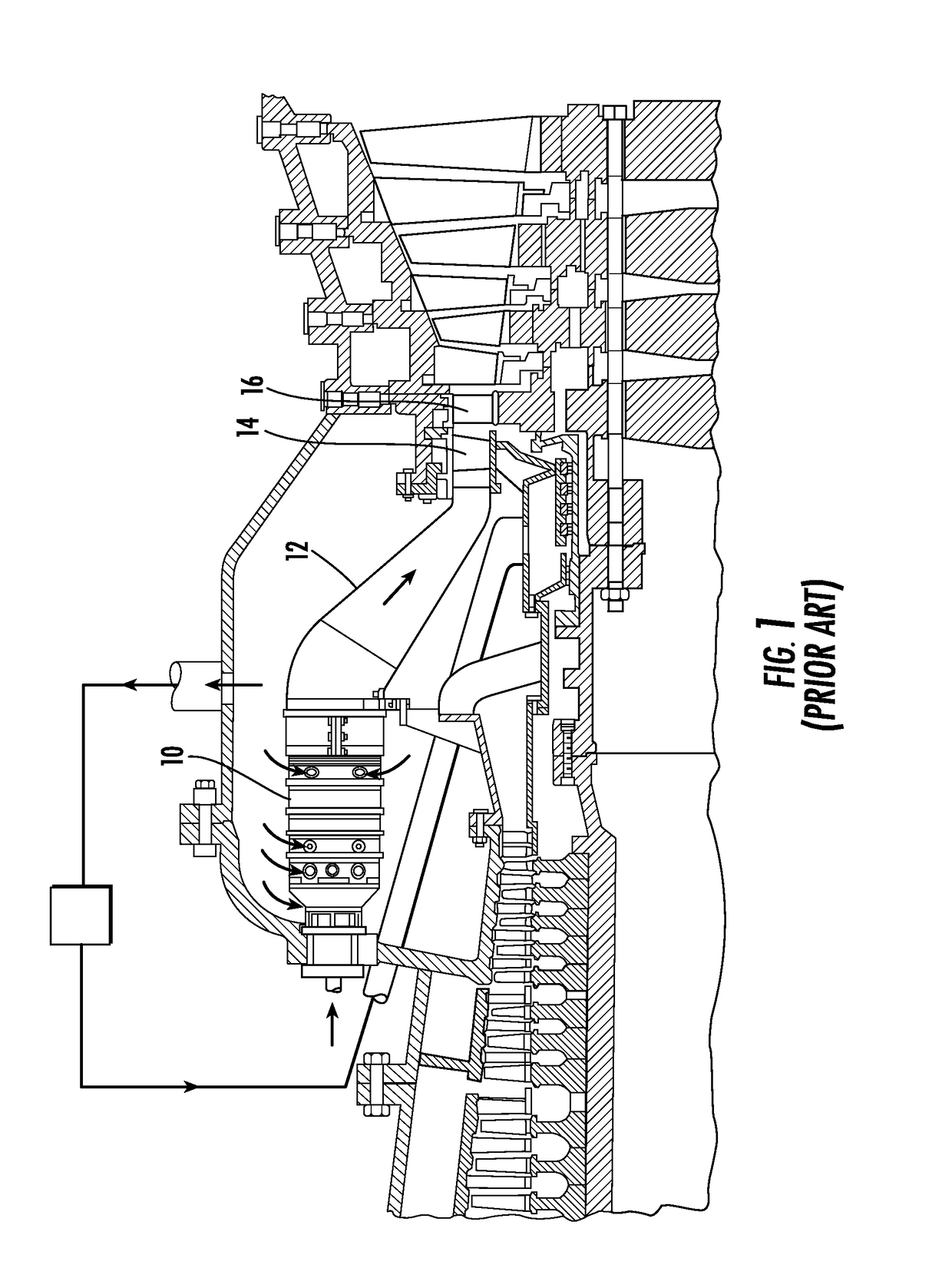

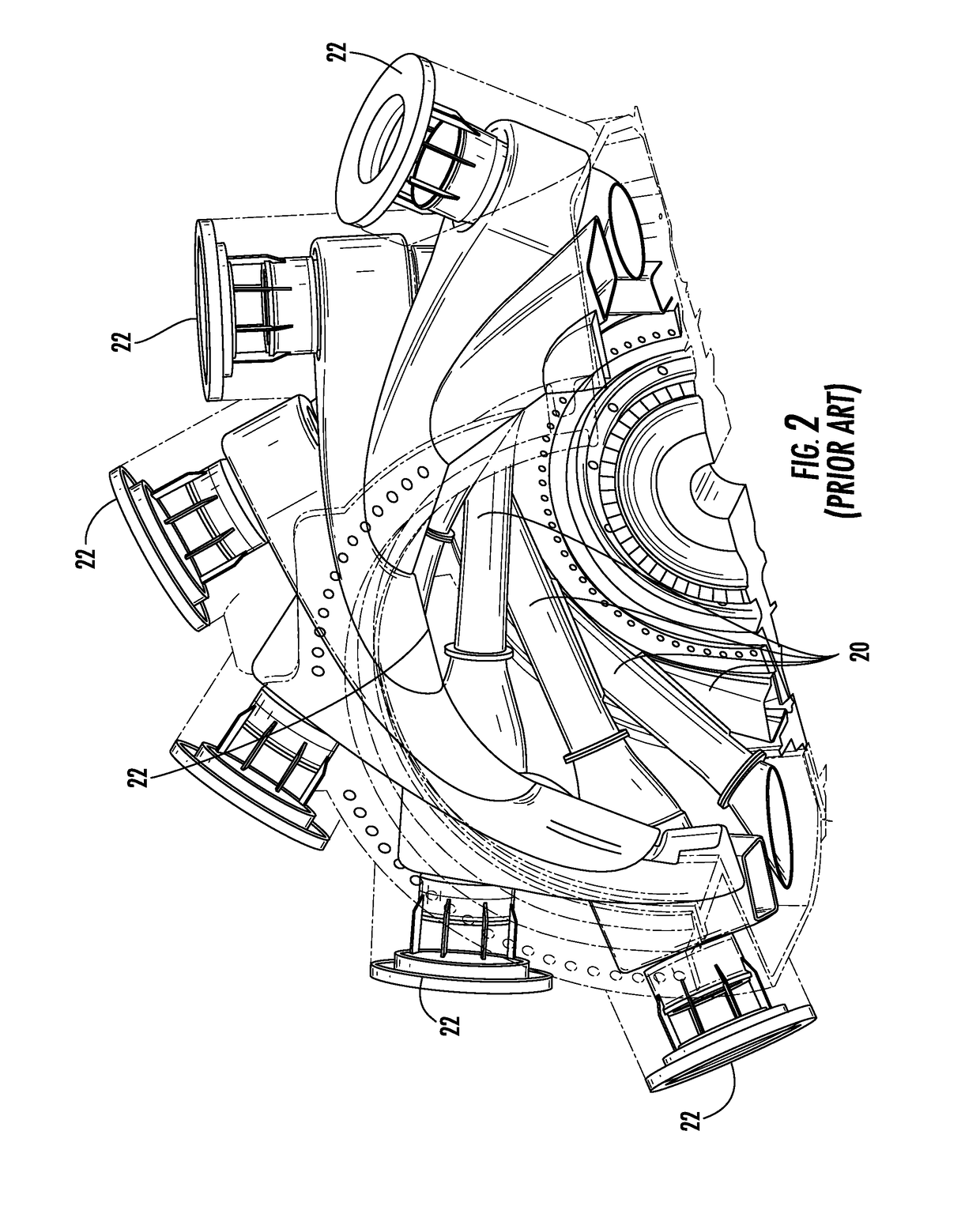

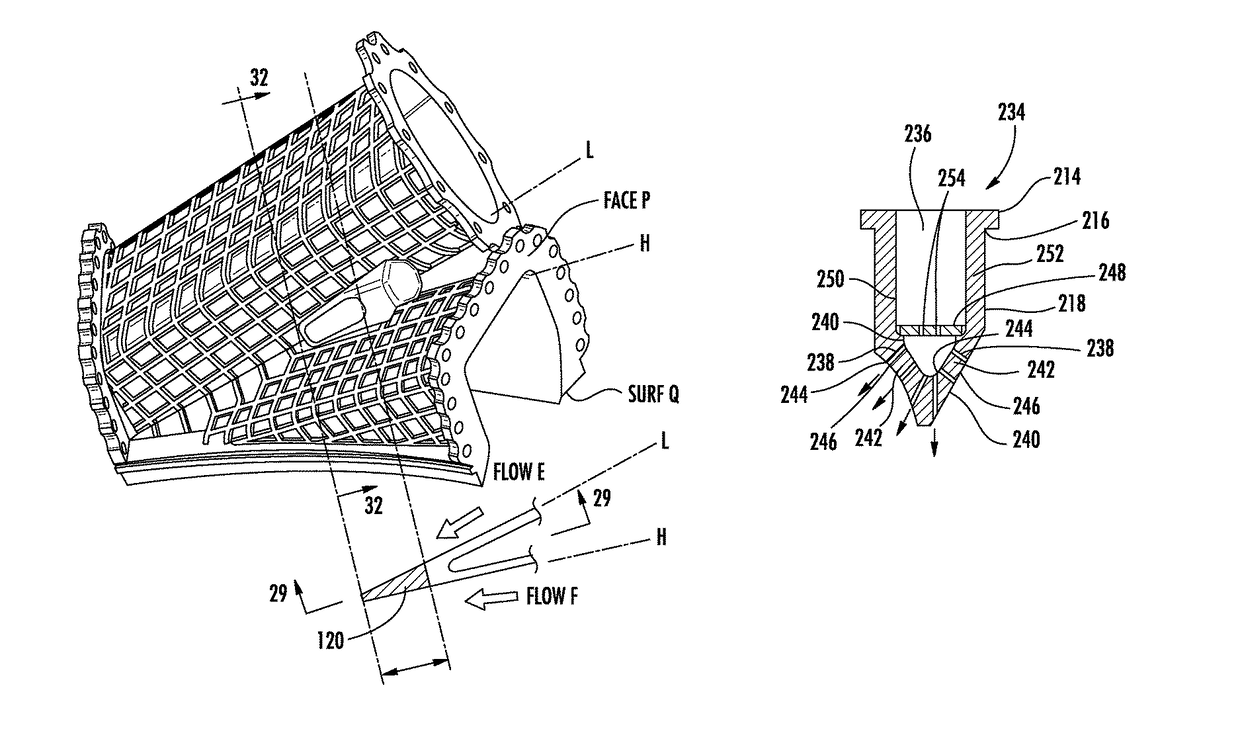

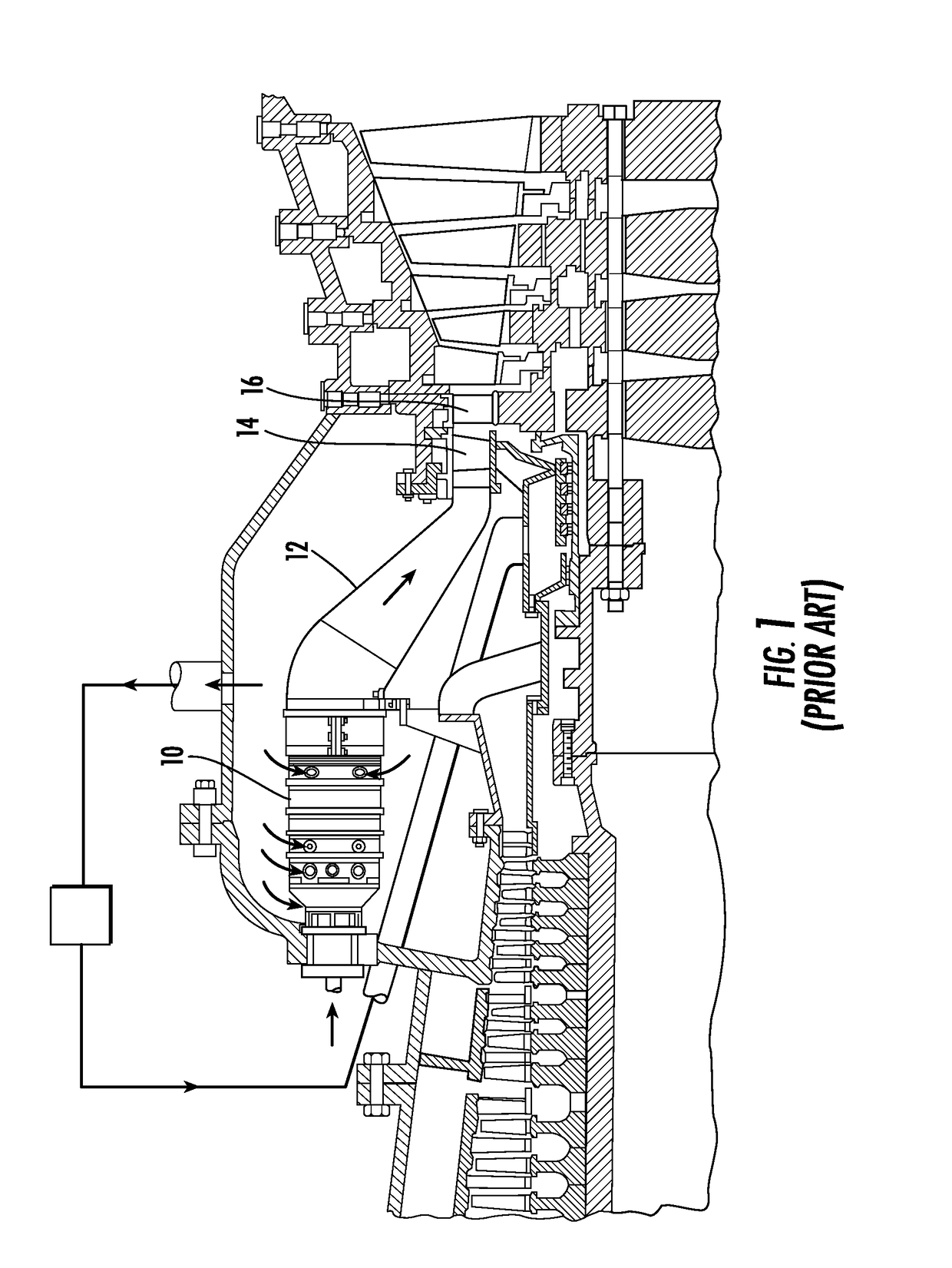

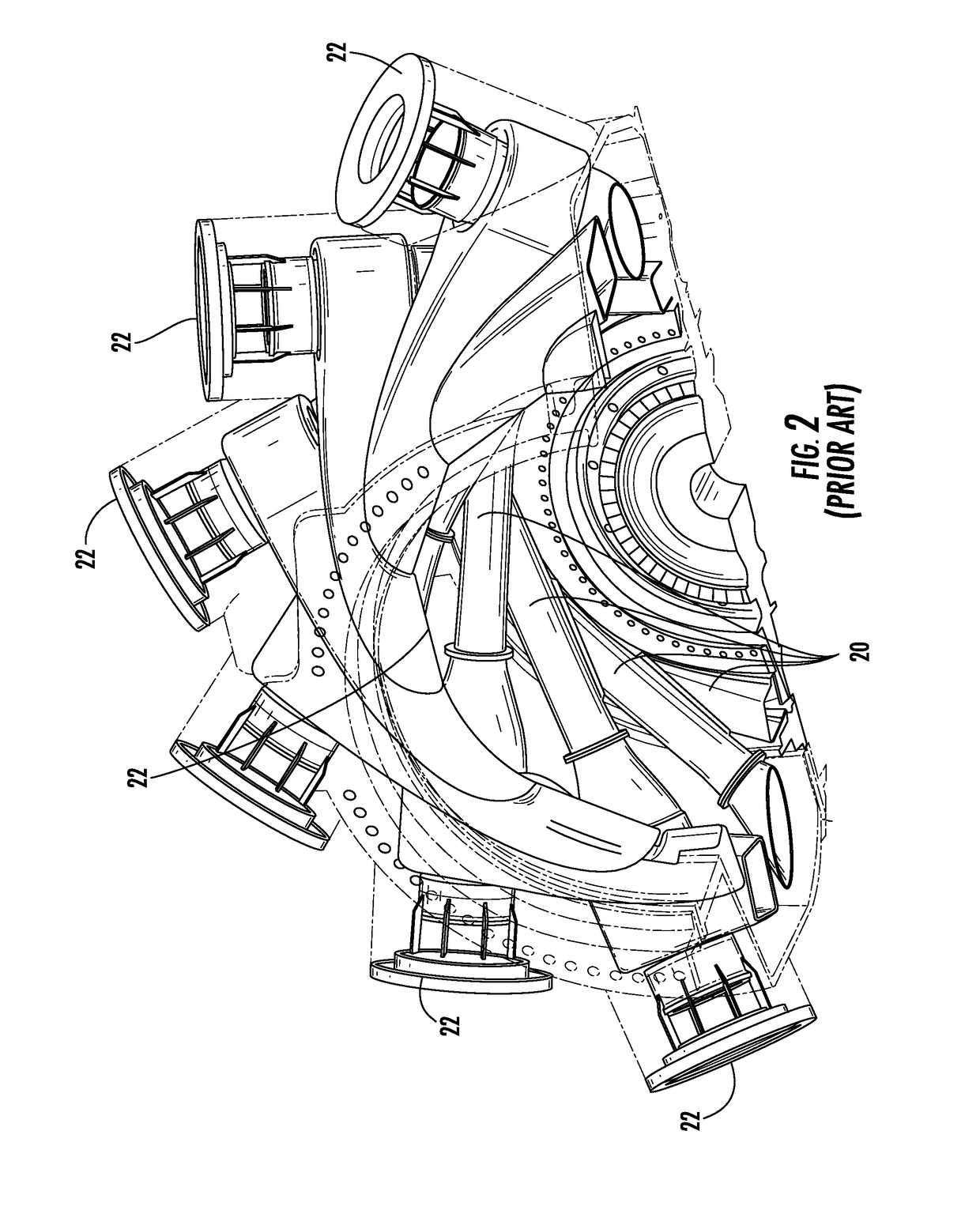

Converging flow joint insert system at an intersection between adjacent transitions extending between a combustor and a turbine assembly in a gas turbine engine

InactiveUS20170114652A1Eliminates stress formationProlong lifeContinuous combustion chamberEngine manufactureCombustorEngineering

A transition duct system for routing a gas flow from a combustor to the first stage of a turbine section in a combustion turbine engine, wherein the transition duct system includes one or more converging flow joint inserts forming a trailing edge at an intersection between adjacent transition ducts is disclosed. The transition duct system may include a transition duct having an internal passage extending between an inlet to an outlet and may expel gases into the first stage turbine with a tangential component. The converging flow joint insert may be contained within a converging flow joint insert receiver and disconnected from the transition duct bodies by which the converging flow joint insert is positioned. Being disconnected eliminates stress formation within the converging flow joint insert, thereby enhancing the life of the insert. The converging flow joint insert may be removable such that the insert can be replaced once worn beyond design limits.

Owner:SIEMENS ENERGY INC

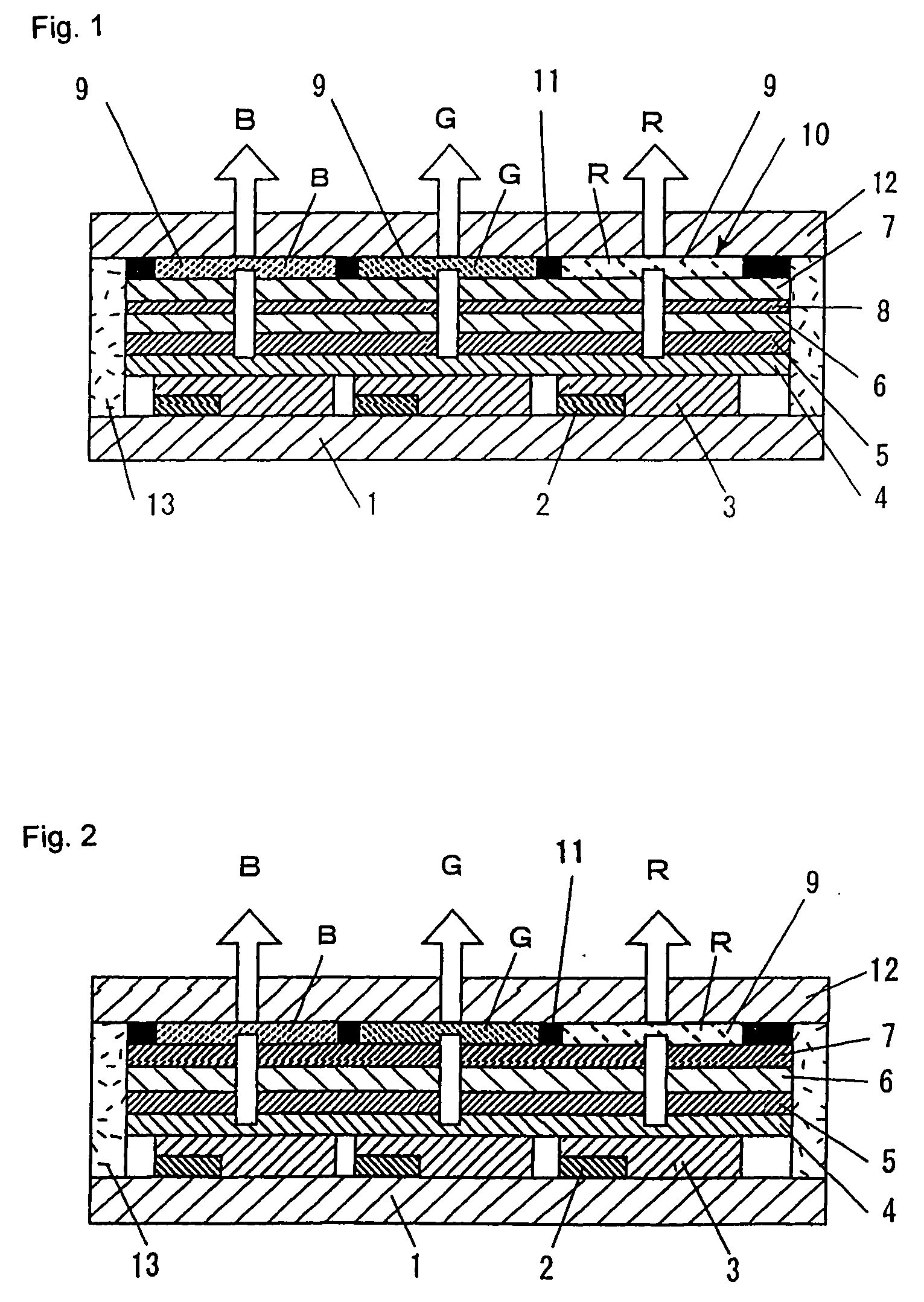

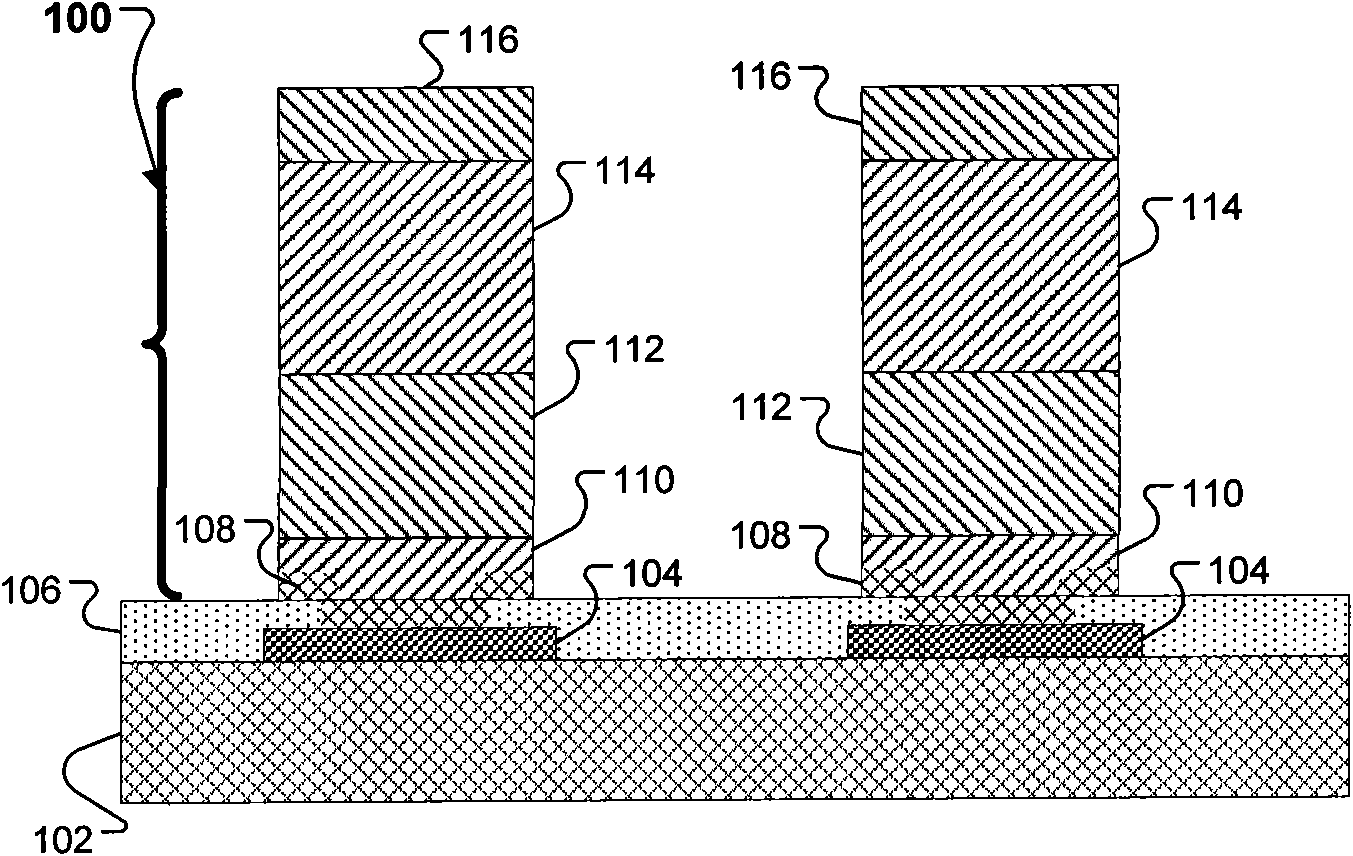

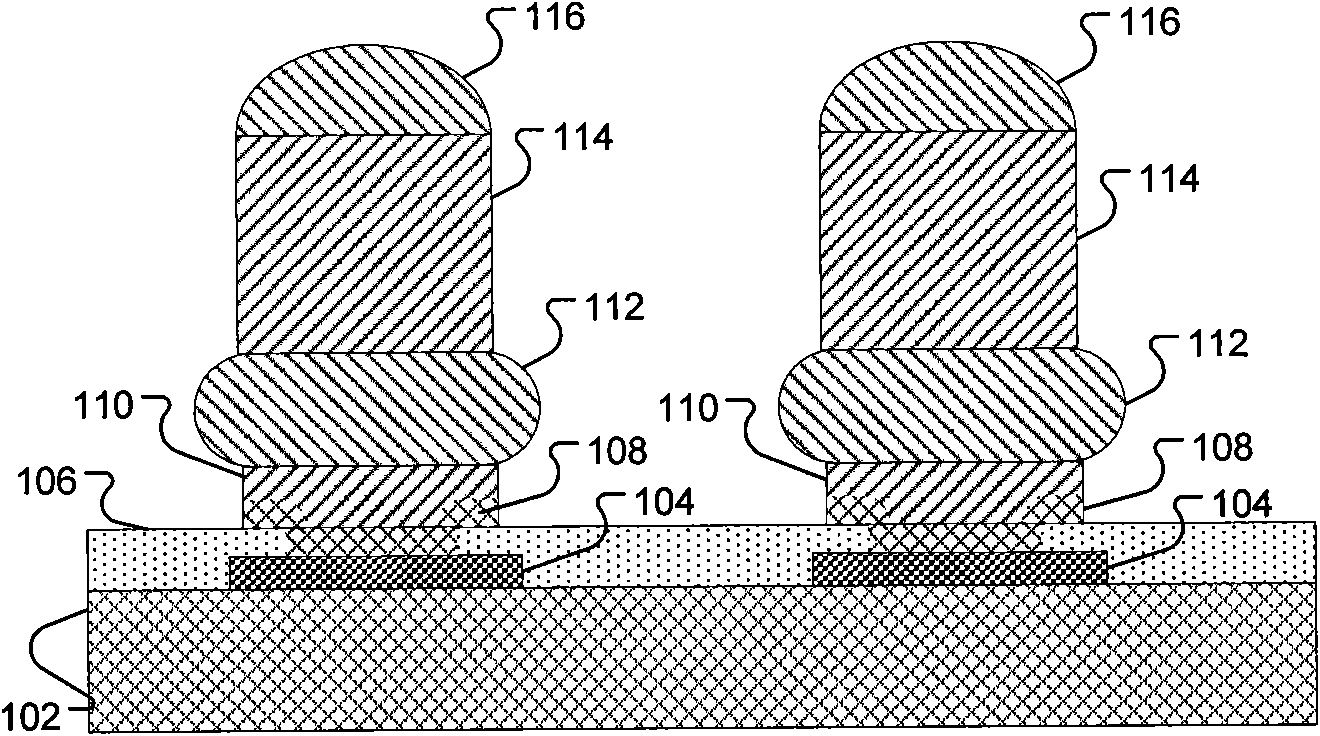

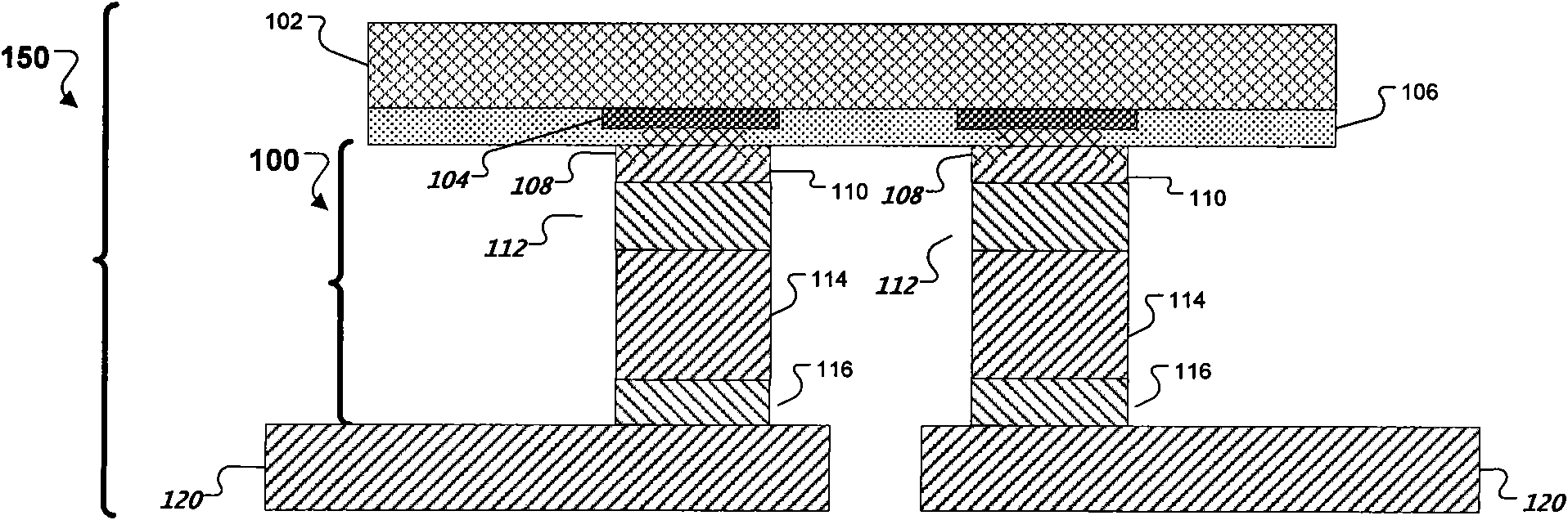

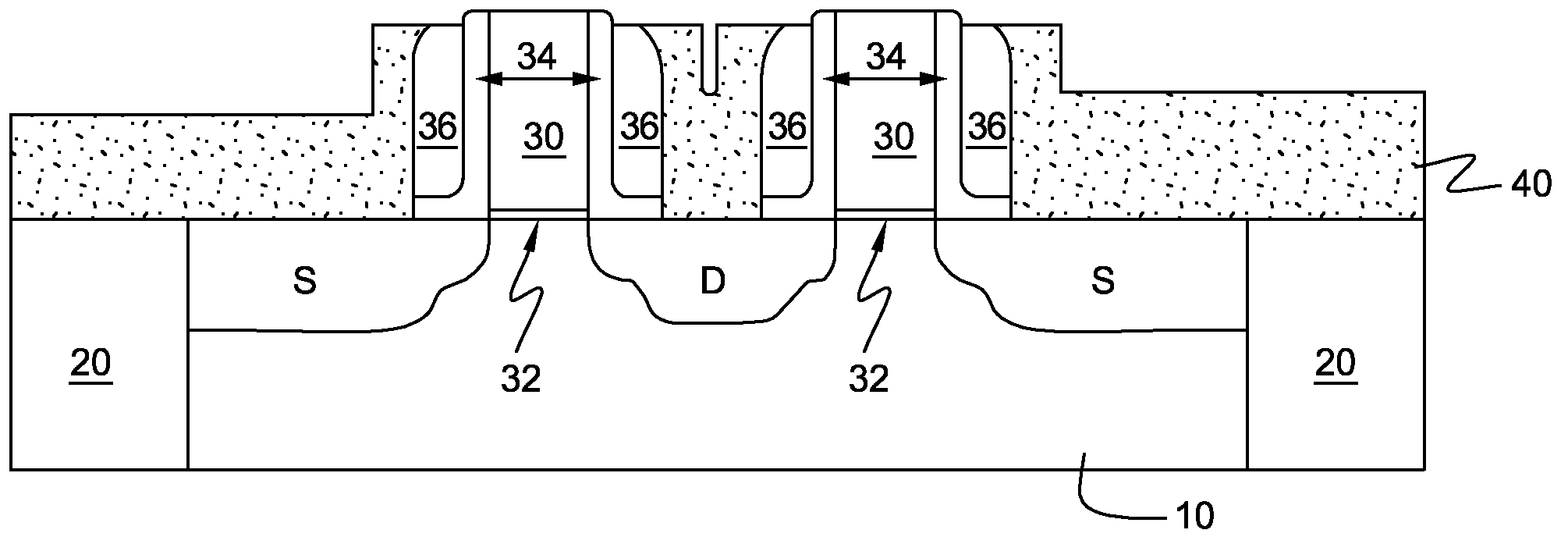

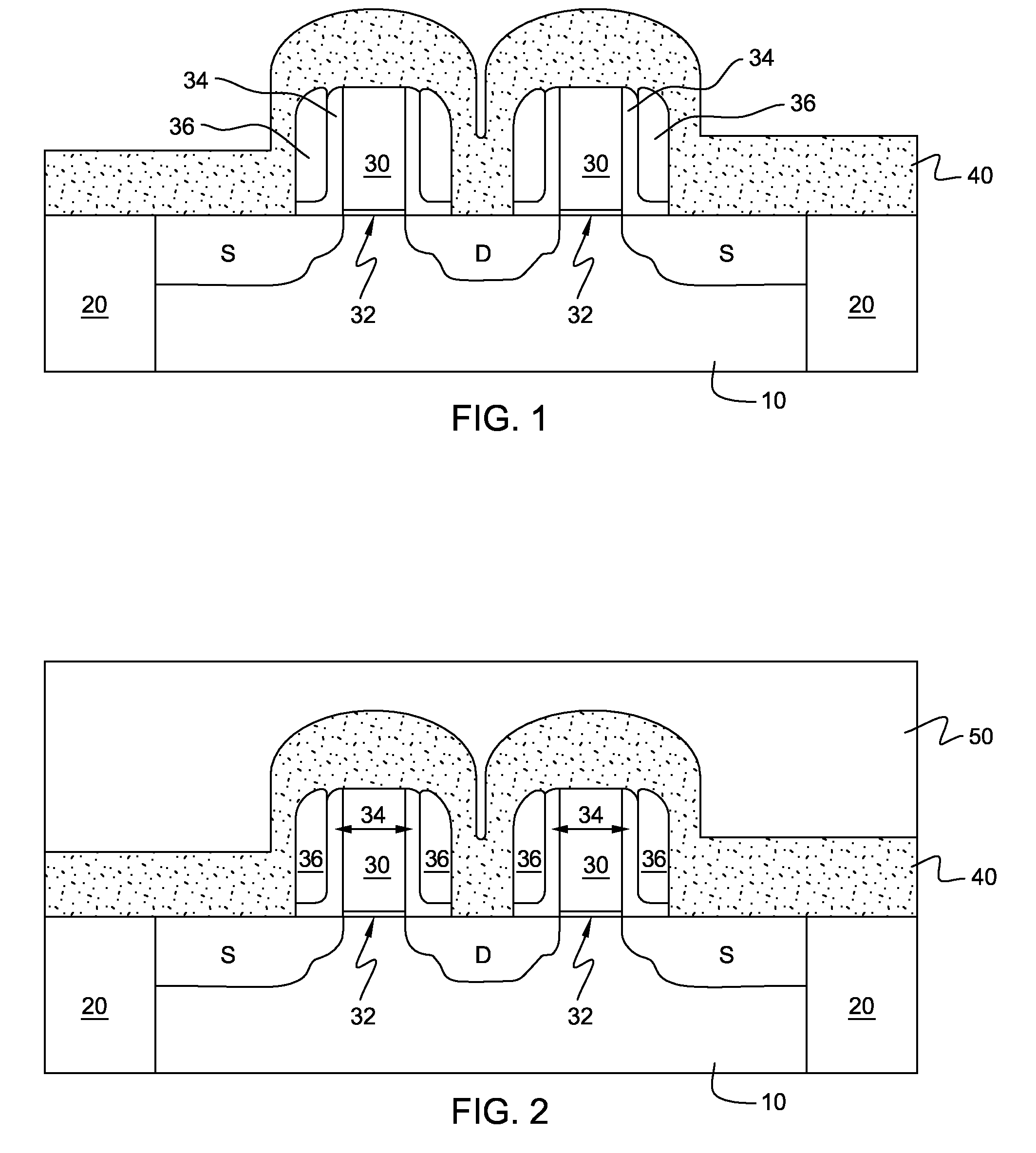

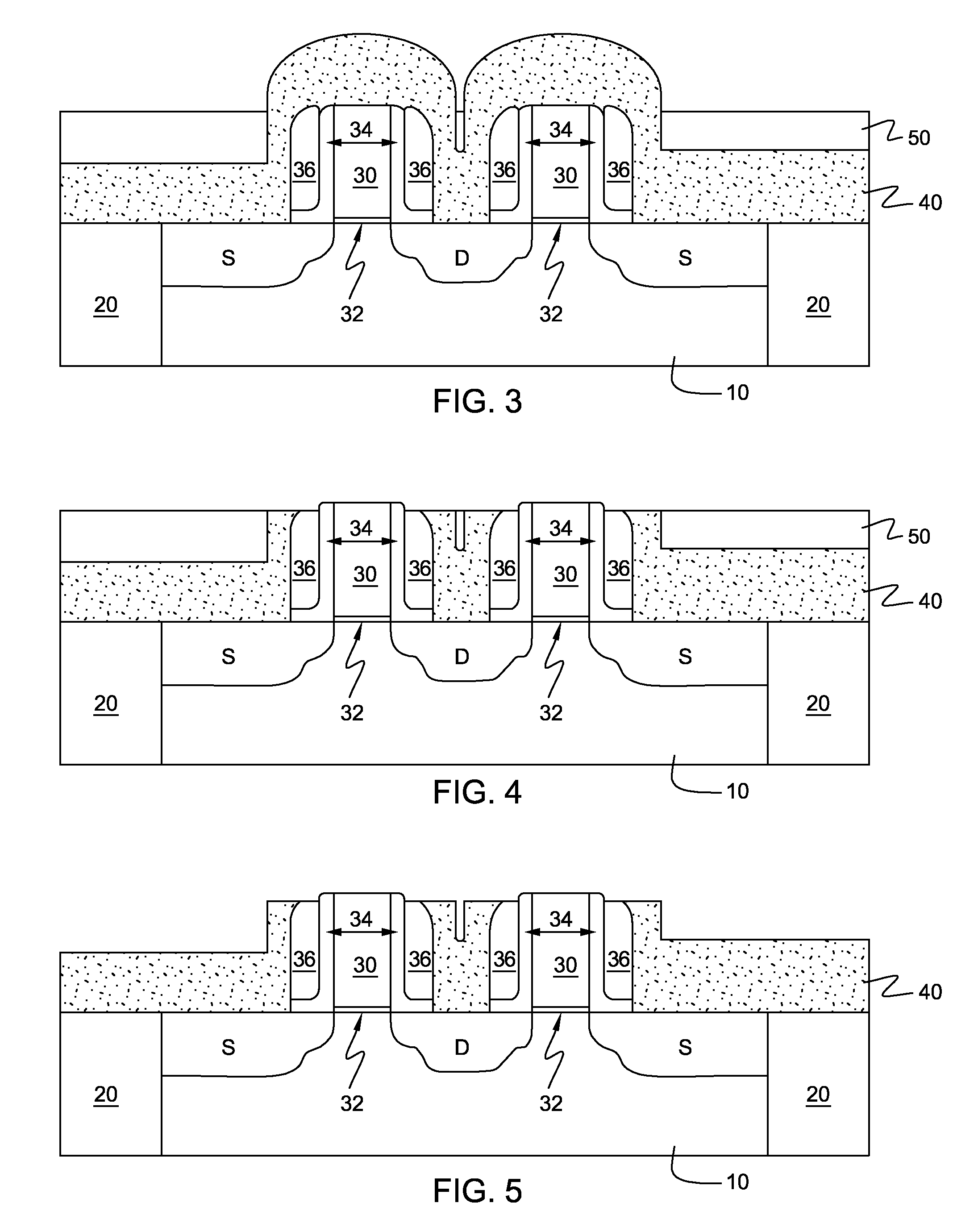

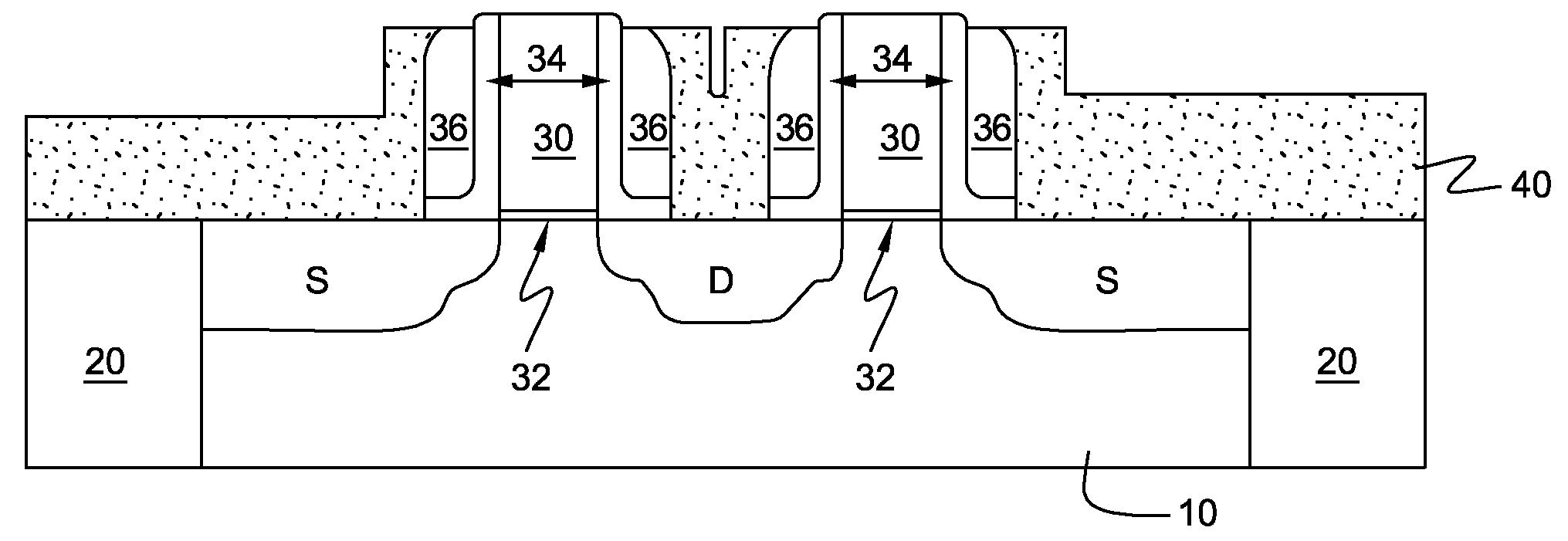

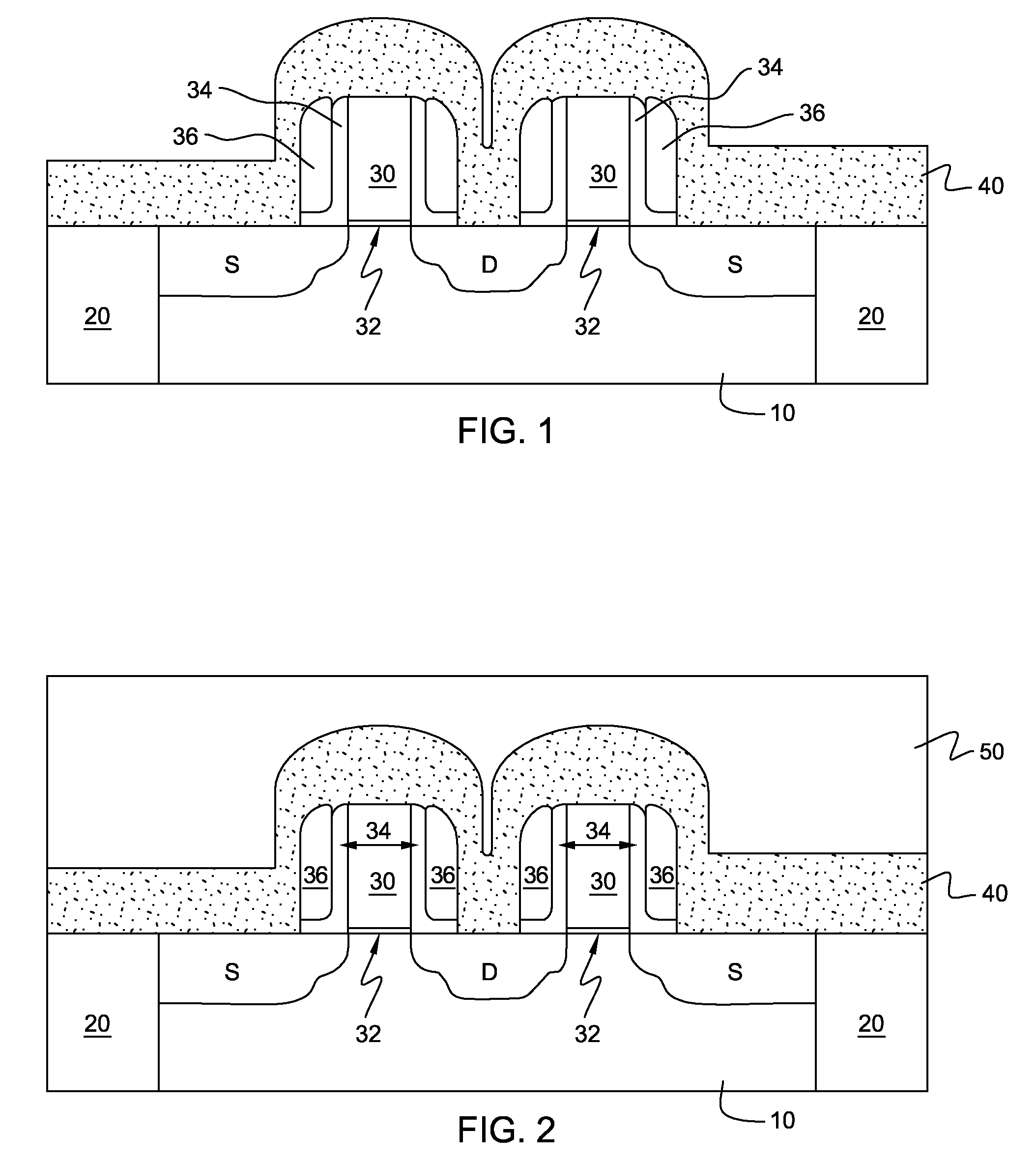

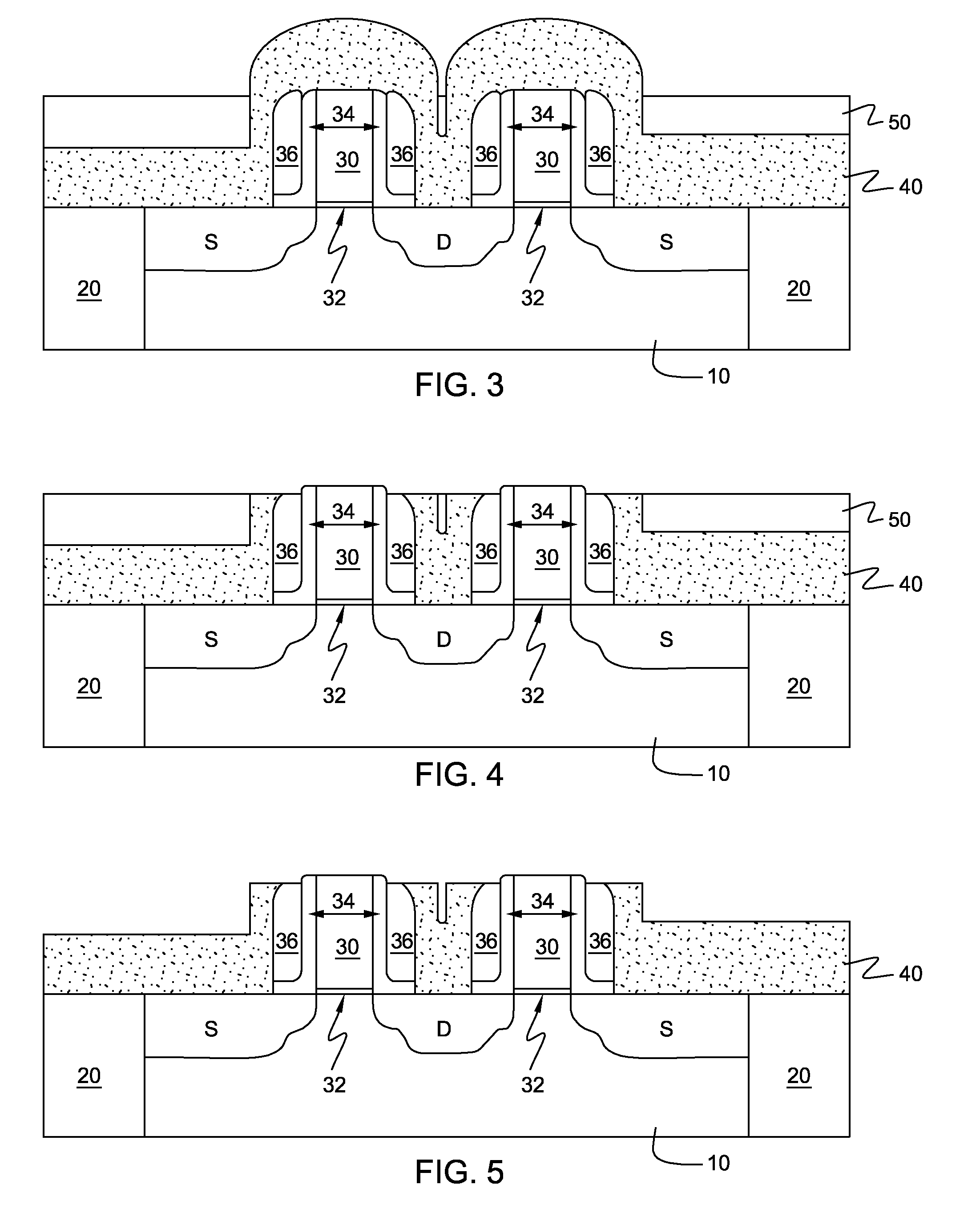

Method and structure for reducing induced mechanical stresses

InactiveUS7572689B2Avoiding degradation of FET performanceReduce processTransistorSolid-state devicesSemiconductorBiomedical engineering

Methods and structures for relieving stresses in stressed semiconductor liners. A stress liner that enhances performance of either an NFET or a PFET is deposited over a semiconductor to cover the NFET and PFET. A disposable layer is deposited to entirely cover the stress liner, NFET and PFET. This disposable layer is selectively recessed to expose only the single stress liner over a gate of the NFET or PFET that is not enhanced by such stress liner, and then this exposed liner is removed to expose a top of such gate. Remaining portions of the disposable layer are removed, thereby enhancing performance of either the NFET or PFET, while avoiding degradation of the NFET or PFET not enhanced by the stress liner. The single stress liner is a tensile stress liner for enhancing performance of the NFET, or it is a compressive stress liner for enhancing performance of the PFET.

Owner:TAIWAN SEMICON MFG CO LTD

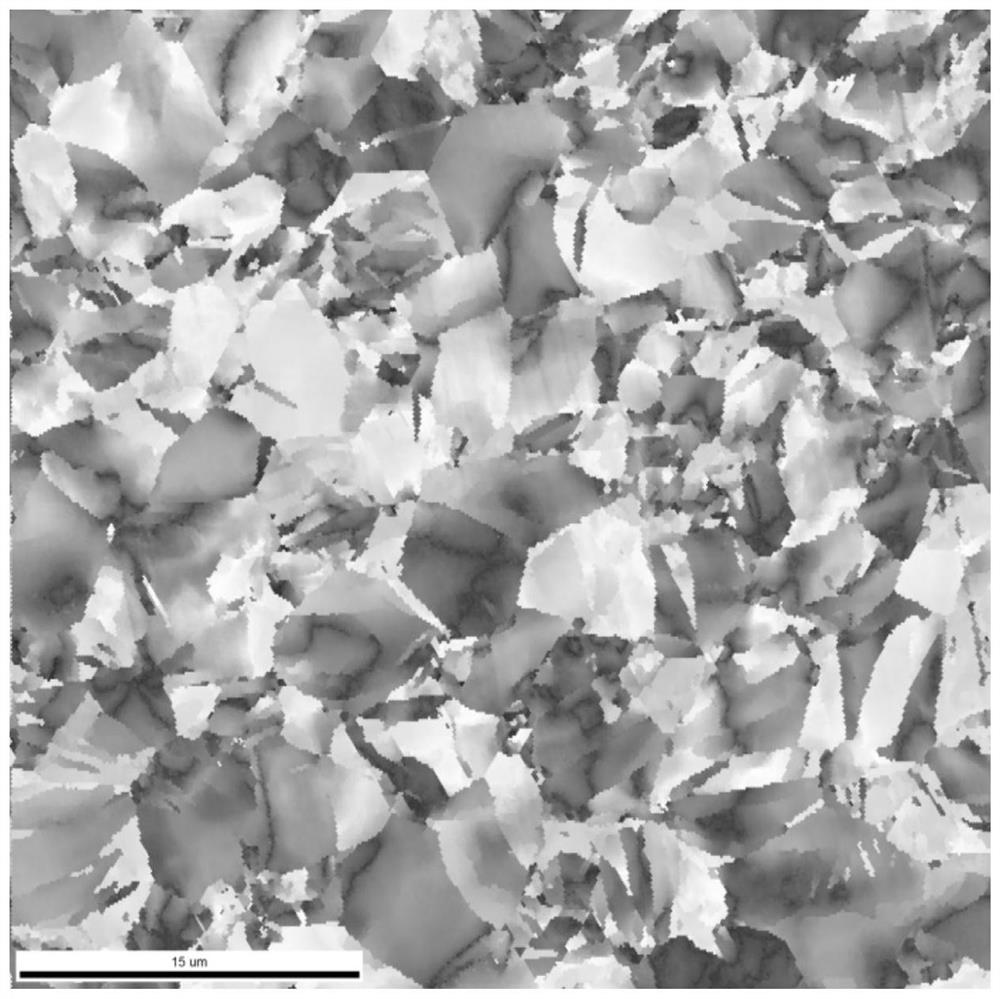

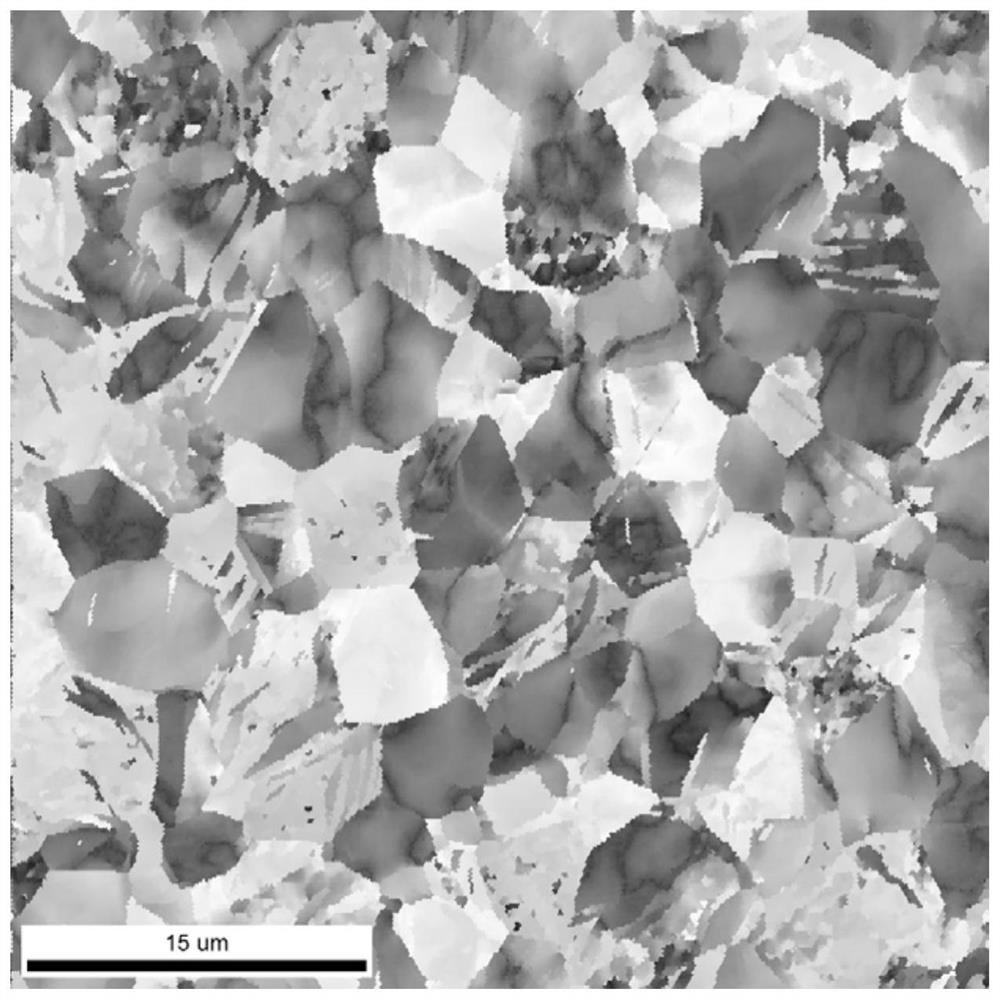

Method for preparing high-purity ruthenium target EBSD samples

PendingCN111855337AQuality improvementRelieve mechanical stressPreparing sample for investigationCold airTest sample

The invention relates to a method for preparing high-purity ruthenium target EBSD samples, and belongs to the technical field of EBSD sample preparation. The method comprises the following steps of: cutting a high-purity ruthenium target line into to-be-tested samples, carrying out mechanical grinding and polishing on the to-be-tested samples, cleaning the to-be-tested samples, polishing the to-be-tested samples with a silicon dioxide suspension for 20-30 minutes at a gradually reduced polishing speed, and polishing the samples with clear water for 20-30 seconds at last; and cleaning the surfaces of the samples by using a neutral detergent, washing the surfaces of the samples under a faucet until the surfaces of the samples are fully cleaned, and finally drying the samples by cold air of ablower. The method is easy and convenient in operation, the surface mechanical stress of the high-purity ruthenium target can be removed, meanwhile, pollution and structure change are not brought tothe surface of the samples, and the real high-quality test sample is obtained.

Owner:GUOBIAO BEIJING TESTING & CERTIFICATION CO LTD

Laser separation machining method and device for optical crystal

ActiveCN102728958ARelieve mechanical stressPrecise Separation SizeLaser beam welding apparatusLaser processingCoating system

The invention discloses a laser separation machining method and a laser separation machining device for optical crystal. The method comprises the following steps of: simply roughly rubbing and polishing the convex-concave surface of the optical crystal along a laser separation machining locus, and cleaning a hydrolysis atomization layer and impurities on the surface to form a transparent locus of which the width is greater than the diameter of a laser incident light spot; uniformly coating a saturated solution of the same optical crystal material on the surface of the wiped optical crystal to fill the convex-concave part of the surface of the optical crystal; and performing scanning separation machining by adopting laser along the locus of the saturated solution of the optical crystal. The device comprises a laser machining system and a solution coating system; and a laser focusing device, a solution coating device, a wiping device, a polishing device and a polishing device are sequentially arranged on a linear moving mechanism along the X-axis direction. By the method and the device, a non-fragmented optical crystal sheet with high separation precision, abrupt separation machining port, smooth cut separation surface and high separation quality can be obtained, and negative effects caused by over high laser temperature can be effectively inhibited.

Owner:武汉飞能达激光技术有限公司

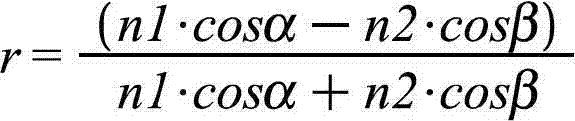

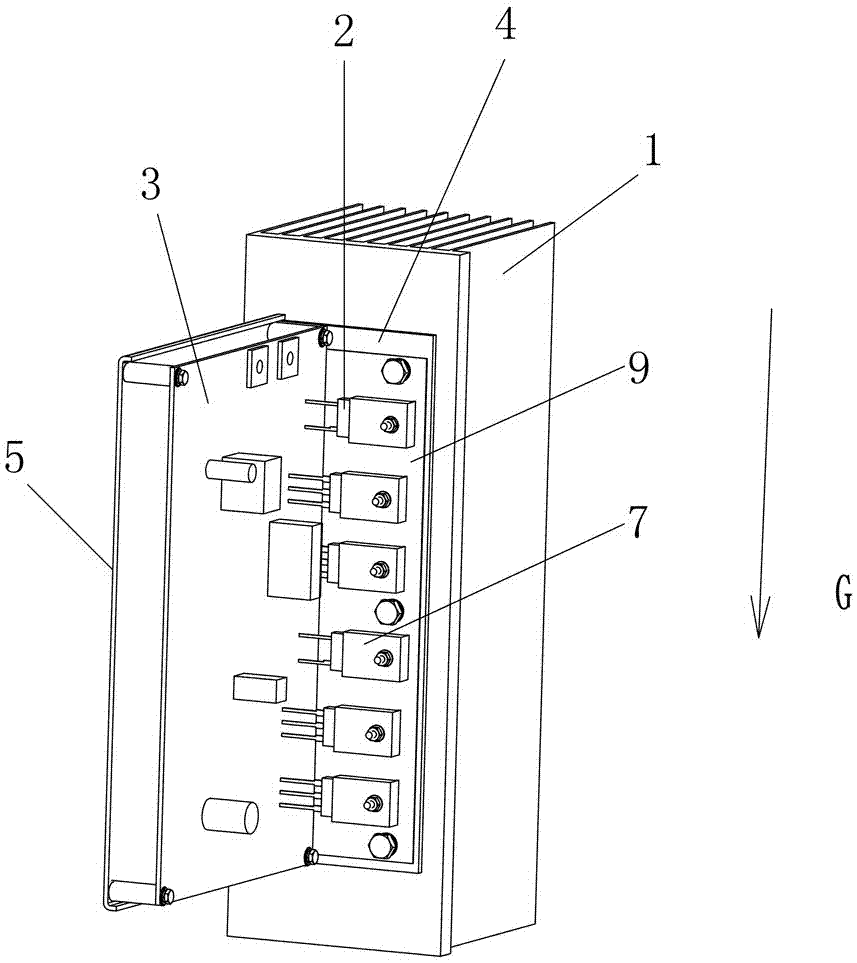

Power assembly and assembling method thereof

ActiveCN107197607AGuaranteed installation reliabilityEasy power expansionStackable modulesCooling/ventilation/heating modificationsComputer engineeringHeat spreader

The invention discloses a power assembly comprising a radiator, a power device, a PCB, a heat dissipation base plate and a support side plate, wherein the heat dissipation base plate is installed on the surface of the radiator, the support side plate is connected with the heat dissipation base plate, the power device is installed on the heat dissipation base plate via a fastener, the PCB is installed on the support side pate via the fastener and arranged to be vertical to the heat dissipation base plate, pins of the power device are arranged to facing the PCB and welded with the PCB. The power assembly has the advantages of being simple in process, high in efficiency and capable of avoiding generation of mechanical stress when in assembling. The assembling method comprises the steps of connecting the support side plate with the heat dissipation base plate; installing the PCB on the support side plate and pre-fastening, and installing the power device on the heat dissipation base plate and pre-fastening; welding the power device with the PCB; screwing a pre-fastened bolt in place, and removing dust and excess materials, thus completing installation of the power device. The method has the advantages of being simple in process, high in efficiency, and capable of eliminating the mechanical stress caused by reassembly after welding.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

Method and structure for reducing induced mechanical stresses

InactiveUS20090121295A1Improve performanceAvoid performance degradationTransistorSolid-state devicesBiomedical engineeringSemiconductor

Methods and structures for relieving stresses in stressed semiconductor liners. A stress liner that enhances performance of either an NFET or a PFET is deposited over a semiconductor to cover the NFET and PFET. A disposable layer is deposited to entirely cover the stress liner, NFET and PFET. This disposable layer is selectively recessed to expose only the single stress liner over a gate of the NFET or PFET that is not enhanced by such stress liner, and then this exposed liner is removed to expose a top of such gate. Remaining portions of the disposable layer are removed, thereby enhancing performance of either the NFET or PFET, while avoiding degradation of the NFET or PFET not enhanced by the stress liner. The single stress liner is a tensile stress liner for enhancing performance of the NFET, or it is a compressive stress liner for enhancing performance of the PFET.

Owner:TAIWAN SEMICON MFG CO LTD

Circuit board leveling apparatus and method for leveling circuit board

InactiveCN101360395BEliminate internal stressReduce warpagePrinted circuit manufactureEngineeringElectrical and Electronics engineering

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

Manufacturing method of soft magnetic silicon-aluminum-nickel alloy powder

InactiveCN103551565BImprove crushing ball milling performanceGood workmanshipInorganic material magnetismVolumetric Mass DensityParticle-size distribution

A manufacturing method for soft-magnetic Fe-Si-Al-Ni alloy powder comprises smelting alloy formed by 4.0% to 5.0% of Si, 3.0% to 4.0% of Al, 1.0% to 2.5% of Ni, 0.1% to 0.4% of Ti, 0.1% to 0.4% of Mn, 0.1% to 0.5% of P, 0.02% or less of C, and the balance Fe through an induction heating vacuum rapid solidification furnace, performing rapid solidification on the alloy to manufacture sheet materials, and subjecting the sheet materials to mechanical crushing, thermal processing of crushed materials, ball milling of the materials into fine powder, annealing treatment and screening and particle size distribution. The method has the advantages that the smelting alloy material is pure, the alloy saturation induction density Bs is more than 18000 gausses, and the adding of Ni can guarantee that the alloy magnetostriction coefficient is zero; excellent soft magnetic properties are provided during magnetic powder core manufacturing, and the AC / DC superposition performance is good particularly when the magnetic conductivity of pressed products is mu e60, for example, when AC is 100 KHz, DCH is equal to 50 Oe, mu 50 >=88% mu O, and the magnetic core loss is lower than that of the high-flux Fe50 Ni50 magnetic powder core, so that the soft-magnetic Fe-Si-Al-Ni alloy powder can replace Fe50 Ni50 and Fe-Si alloy magnetic powder cores to be used in electronic and electric industries.

Owner:武汉欣达磁性材料有限公司

Converging flow joint insert system at an intersection between adjacent transitions extending between a combustor and a turbine assembly in a gas turbine engine

InactiveUS9803487B2Eliminates stress formationProlong lifeContinuous combustion chamberEngine manufactureCombustorEngineering

A transition duct system for routing a gas flow in a combustion turbine engine is provided. The transition duct system includes one or more converging flow joint inserts forming a trailing edge at an intersection between adjacent transition ducts. The converging flow joint insert may be contained within a converging flow joint insert receiver and may be disconnected from the transition duct bodies by which the converging flow joint insert is positioned. Being disconnected eliminates stress formation within the converging flow joint insert, thereby enhancing the life of the insert. The converging flow joint insert may be removable such that the insert can be replaced once worn beyond design limits.

Owner:SIEMENS ENERGY INC

Anti-wear bucket tooth for excavator and production process thereof

InactiveCN109385499ARaise the ratioReasonable formulaSoil-shifting machines/dredgersFurnace typesWear resistantHardness

The invention provides an anti-wear bucket tooth for an excavator and a production process thereof, and relates to the technical field of bucket tooth production. The anti-wear bucket tooth comprisesthe following components in percentage by mass: 1.0-2.0 wt % of C, 12.0-20.0 wt % of Cr, 1.0-2.0 wt % of Ni, 0.5-1.5 wt % of Mn, 0.8-1.2 wt % of Si, 0.3-0.4 wt % of Ti, 0.2-1.0 wt % of Zr, 0.1-0.2 wt% of Re, 0.05-0.1 wt % of B, 0.2-0.3 wt % of Y, 0.1-0.3 wt % of W, 0.05-0.1 wt % of Nb, 0.06-0.10 wt % of P, 0.02-0.06 wt % of S, 2.0-3.0 wt % of a coupling agent, 1.6-2.0 wt % of a defoaming agent, 2.2-2.6 wt % of a flexibilizer and the balance of Fe and impurities. According to the invention, a plurality of wear-resistant components are adopted as bucket tooth fillers, and are reasonably proportioned, so that the components cooperate with each other, and the mechanical property of the bucket tooth is remarkably improved, and meanwhile, the prepared bucket tooth prepared through additive addition, heat treatment and the like is high in toughness, high in hardness, high in tensile strength, high in wear resistance and corrosion resistance, and is convenient to use and excellent in performance.

Owner:安徽中建材开源新材料科技有限公司

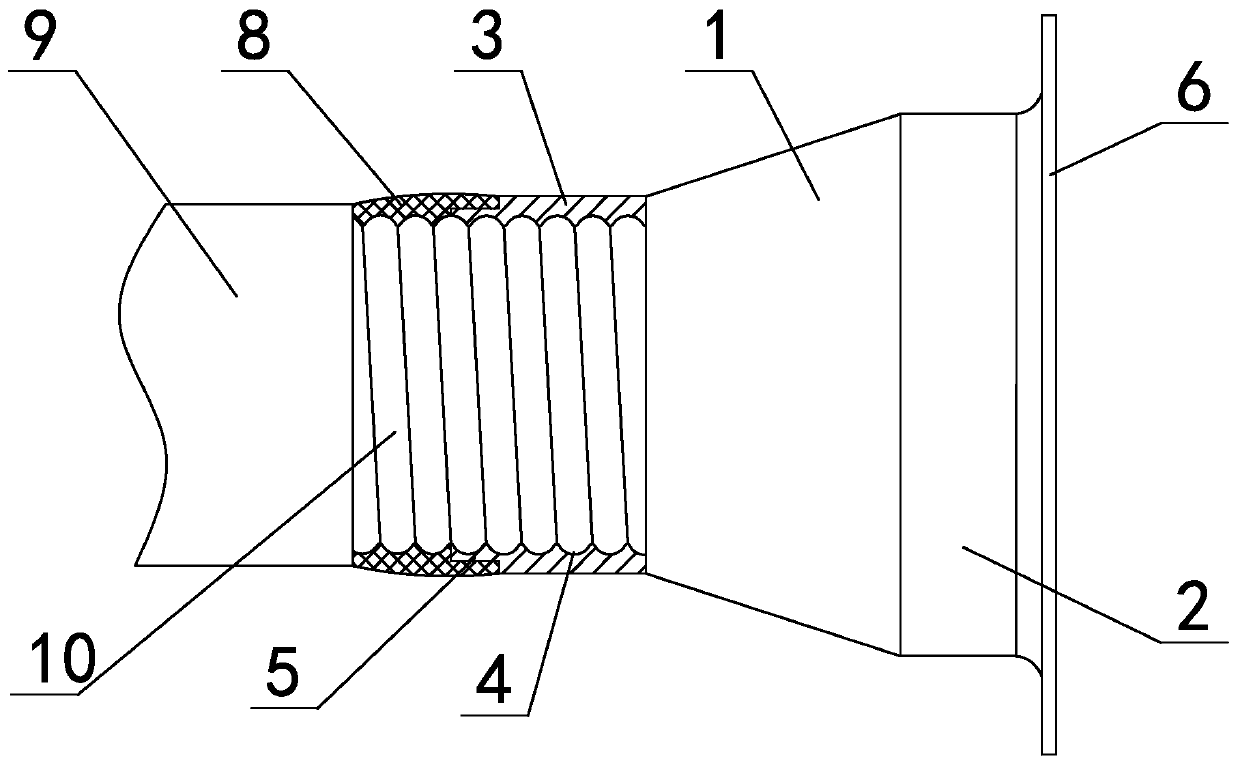

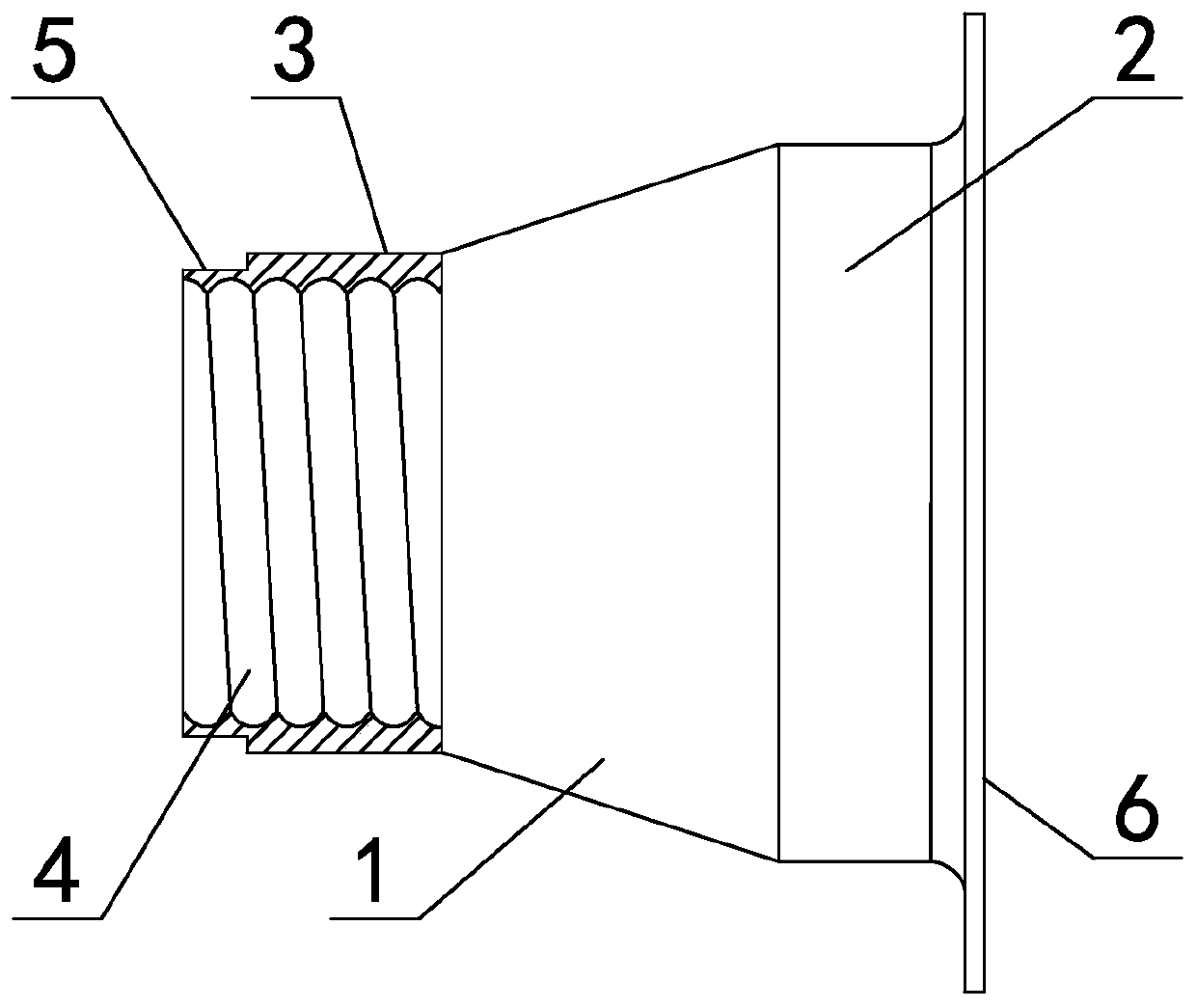

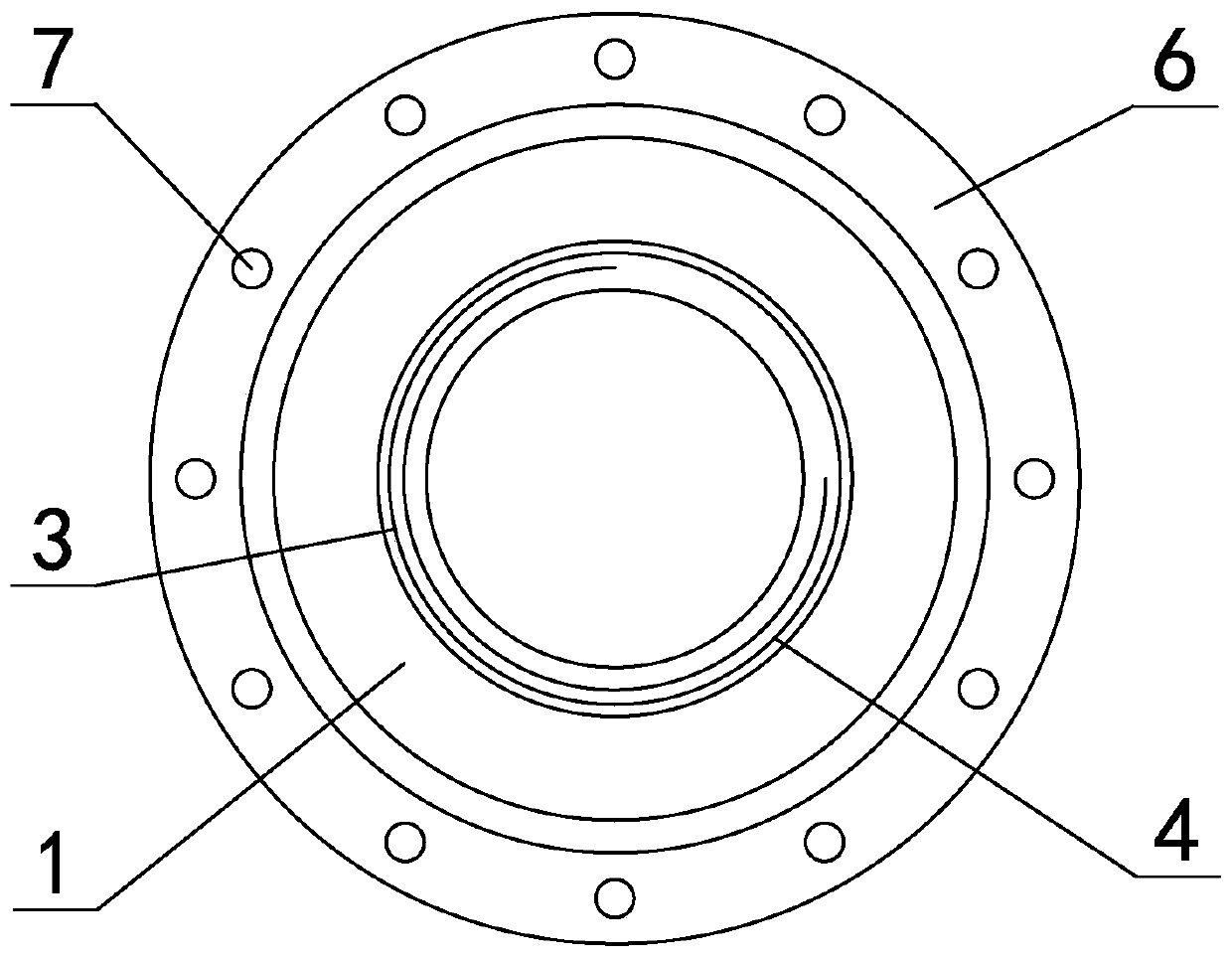

Cable terminal tail pipe and connecting process thereof

ActiveCN111293664AImprove waterproof sealing performanceHigh hardnessCable terminationsApparatus for joining/termination cablesConical tubeStructural engineering

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD JIAXING POWER SUPPLY CO

Novel flexible silica gel and preparation method thereof

The invention discloses novel flexible silica gel and a preparation method thereof, and belongs to the technical field of flexible silica gel. The preparation method of the novel flexible silica gel uses the following components: deionized water, a silica gel material, carbon black, a vulcanizing agent, a bridging agent, an antistatic agent and hydroxymethyl cellulose, and further uses the following components: an anti-aging agent, a tackifying agent and a filler. According to the method provided by the invention, the hydroxymethyl cellulose and the deionized water are put into a reaction kettle, stirring and heating are performed, then the silica gel material, the bridging agent, the anti-aging agent, the tackifying agent and the filler are put, so that the flexible silica gel has a better anti-aging effect and does not cause breakage or slitting after being used for a long period of time, the problem that the service life is reduced because flexible silica gel has a larger permanentdeformation rate after being subjected to stretching action can be avoided, and the flexible silica gel can eliminate most of mechanical stress and has shock absorption protection effects, has stablephysical and chemical properties and low production costs, and is suitable for promotion and applications.

Owner:姚国辉

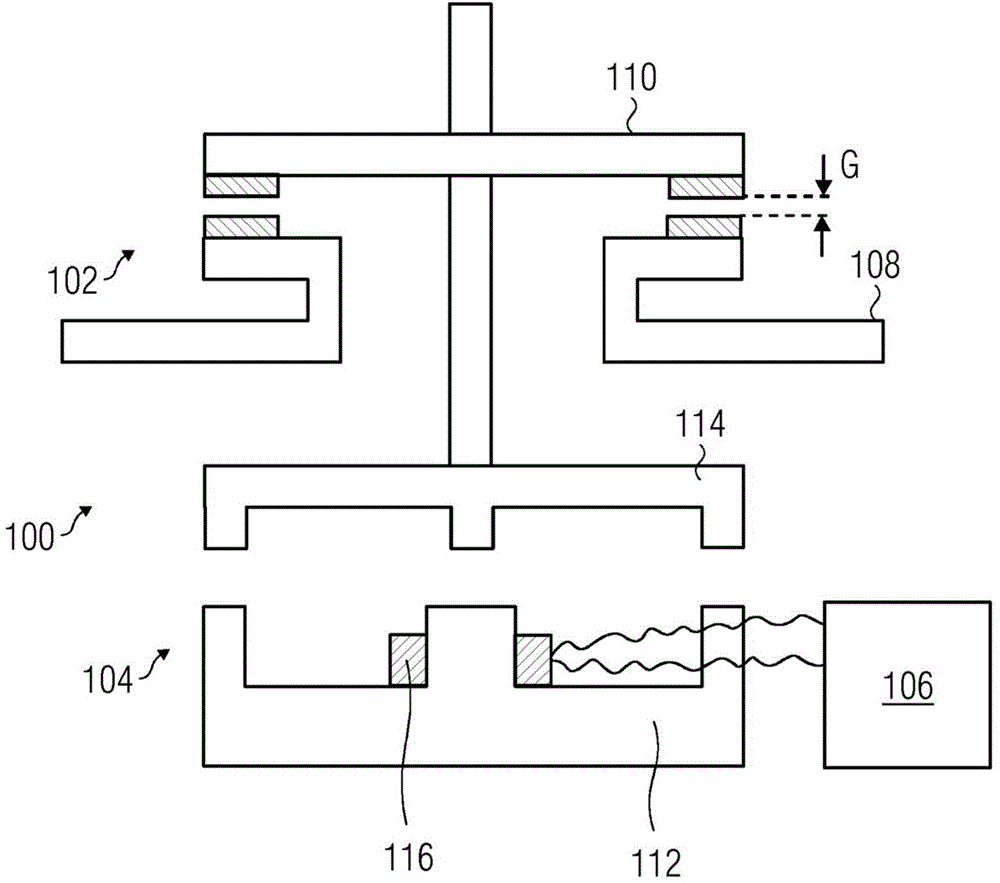

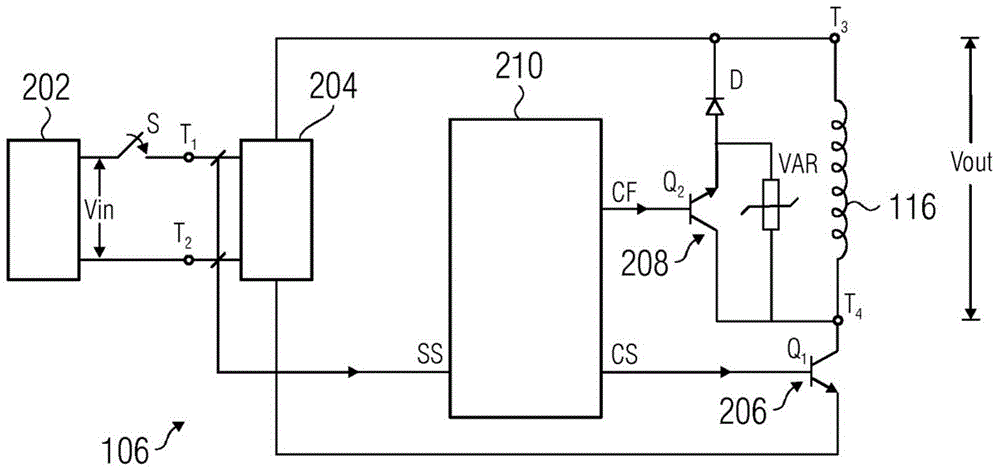

Regulated power supply assembly for use in electrical switch

InactiveCN104620347AMove away quicklyAchieving "soft openingEmergency protective arrangements for limiting excess voltage/currentRelaysPower flowExcitation current

Regulated power supply assembly for use in electrical switch A regulated power supply assembly (106) suitable for use in an electrical switch (100) is disclosed. The regulated power supply assembly regulates an excitation current provided to an electromagnetic assembly (104) within the electrical switch. The regulated power supply assembly includes switching means (206), free-wheeling means (208), and controlling means (210). The switching means regulates an excitation current provided to an electromagnetic assembly. The free-wheeling means provide a freewheeling current flow path for the excitation current. The controlling means are configured for regulating the switching means and the free-wheeling means such as to regulate the excitation current during transition from the closed position to the open position.

Owner:SIEMENS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com