Manufacturing method of 35 KW environmental protection type A kind fire proof power cable for underground railway circuit

A power cable and manufacturing method technology, applied in the field of cable production and manufacturing, can solve the problems of accident rescue work, loss of people's life and property, environmental temperature rise, cable burning, etc. Erosion mitigation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

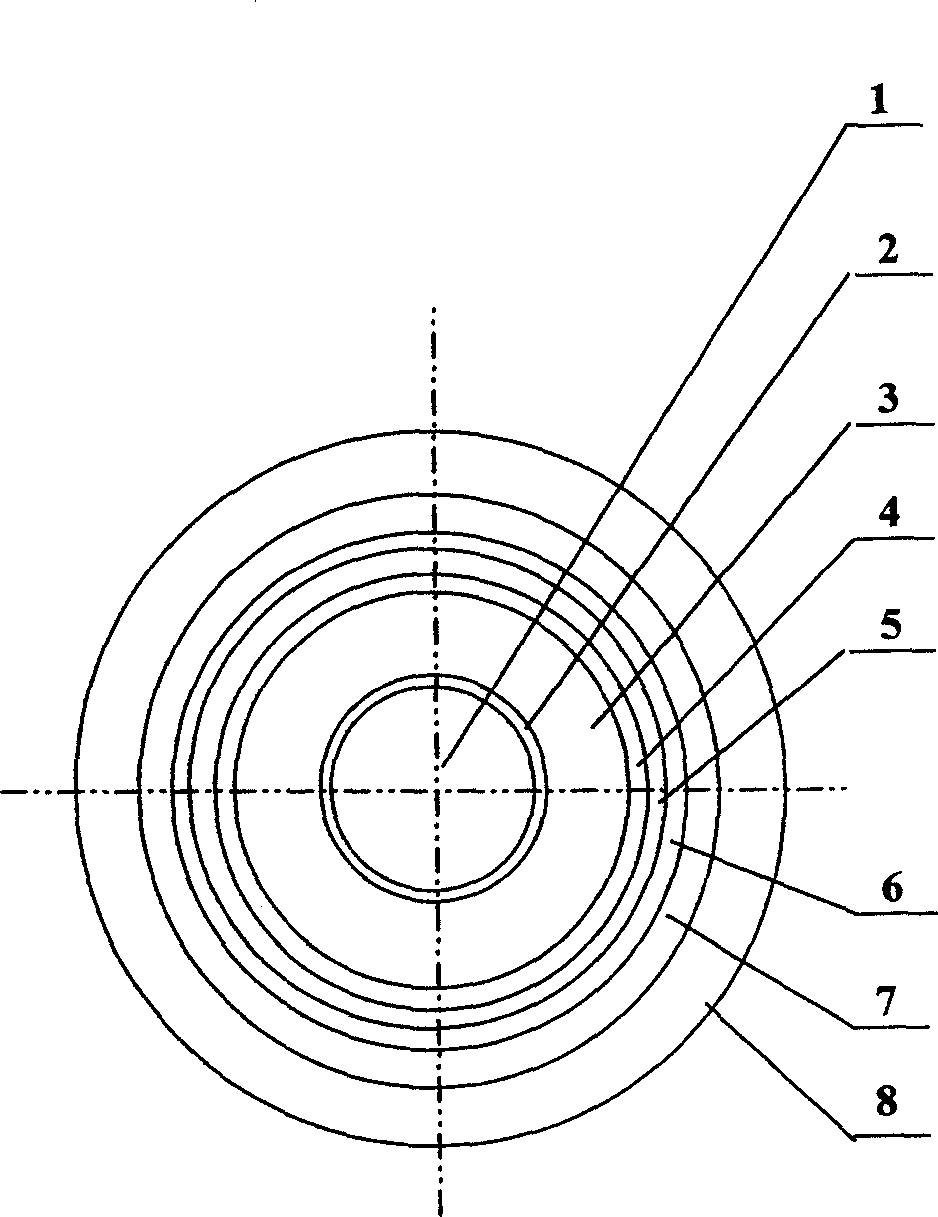

[0021] Adopt the second kind of tight-pressed stranded circular conductor specified in GB / T3956, the tightness of the conductor can reach more than 90%, the roundness can reach more than 98%, and the surface of the conductor is smooth, free of burrs and scratches. First wrap the conductor shielding layer 2 of semi-conductive material on the outer surface of the conductor 1, then extrude the insulating layer 3 of high-purity cross-linked polyethylene material, and use oxide cross-linking or electron beam irradiation technology on the outer surface of the insulating layer 3, Molecules and carbon-forming units with flame-retardant functions are grafted onto the insulating layer of cross-linked polyethylene material to achieve a non-metallic semi-conductive insulating shielding layer 4 with char-forming properties on the surface, and coated on the non-metallic semi-conductive insulating shielding layer 4 Copper strip metal shielding layer 5, and then on the metal shielding layer 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com