Method and device for quickly separating optical crystals by using laser light

An optical crystal and laser technology, applied in laser welding equipment, manufacturing tools, welding/welding/cutting items, etc., can solve the problems of expensive equipment, severely restricted separation speed, complex mechanism, etc., to eliminate vibration and mechanical stress, maintain Physical properties, the effect of eliminating pollution damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

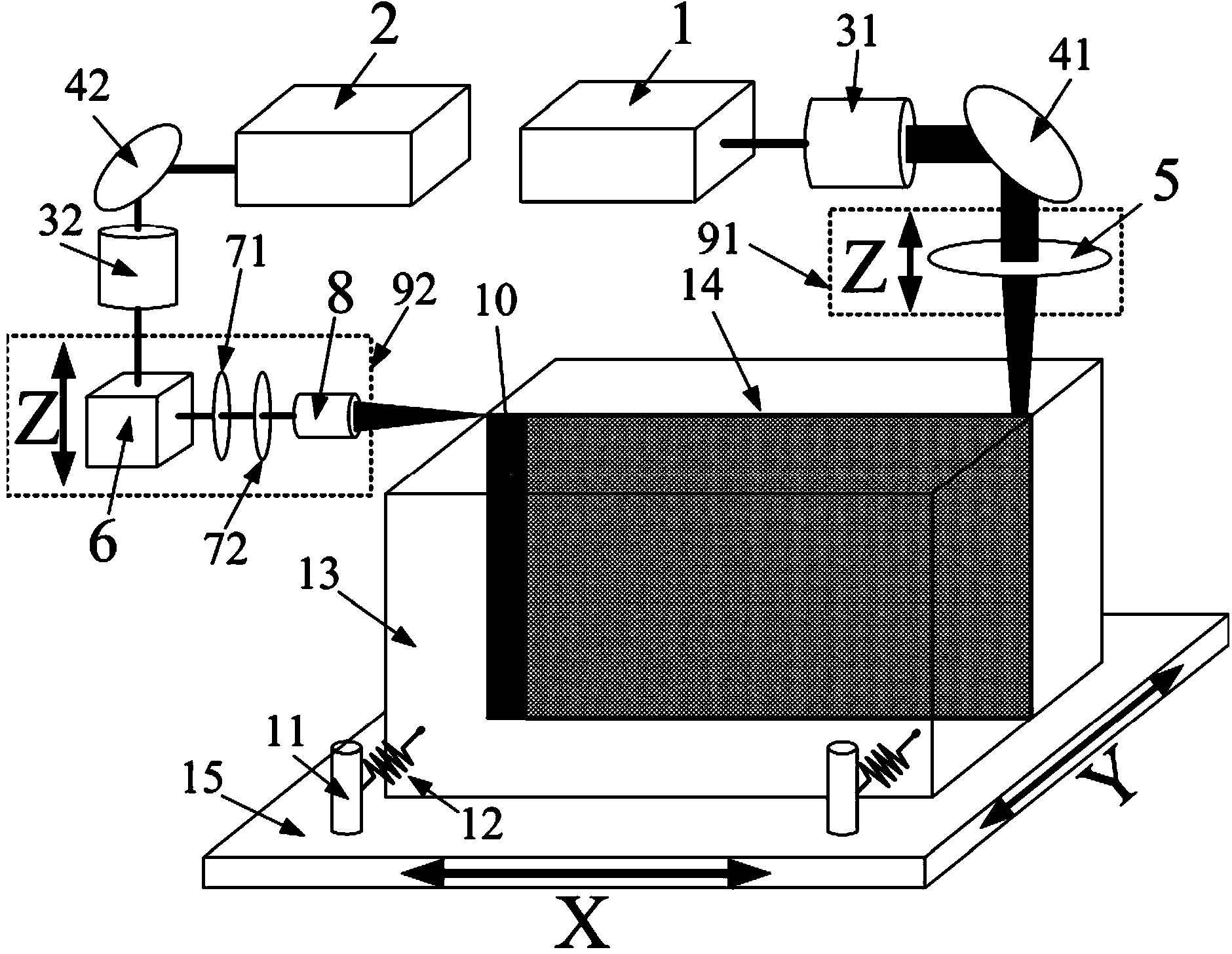

example 1

[0059] The present invention adopts a femtosecond laser with a pulse width of 518 fs, a wavelength of 1030 nm, and a maximum single pulse energy of 200 μJ as an ultrafast laser. The YLP-50 model CW fiber laser of German IPG Company is used as an ordinary high-power laser, and its maximum output average power is 50W. The focused spot diameter of the ultrafast laser is less than 5 μm, and the spot diameter of the high-power ordinary laser is about 50 μm. The separation optical crystal is KDP crystal, the pattern length is 100 mm, and the thickness is 12 mm. Experimental method: adopt the first laser rapid separation optical crystal method, adjust the single pulse energy of the ultrafast laser to 200μJ, the scanning speed of the ultrafast laser to 50mm / s, the output power of the ordinary high-power laser to 30W, and the scanning speed to 400μm / s , the moving speed is 2mm / s. Experimental results: The optical crystal is separated along the separation track, the separation side wal...

example 2

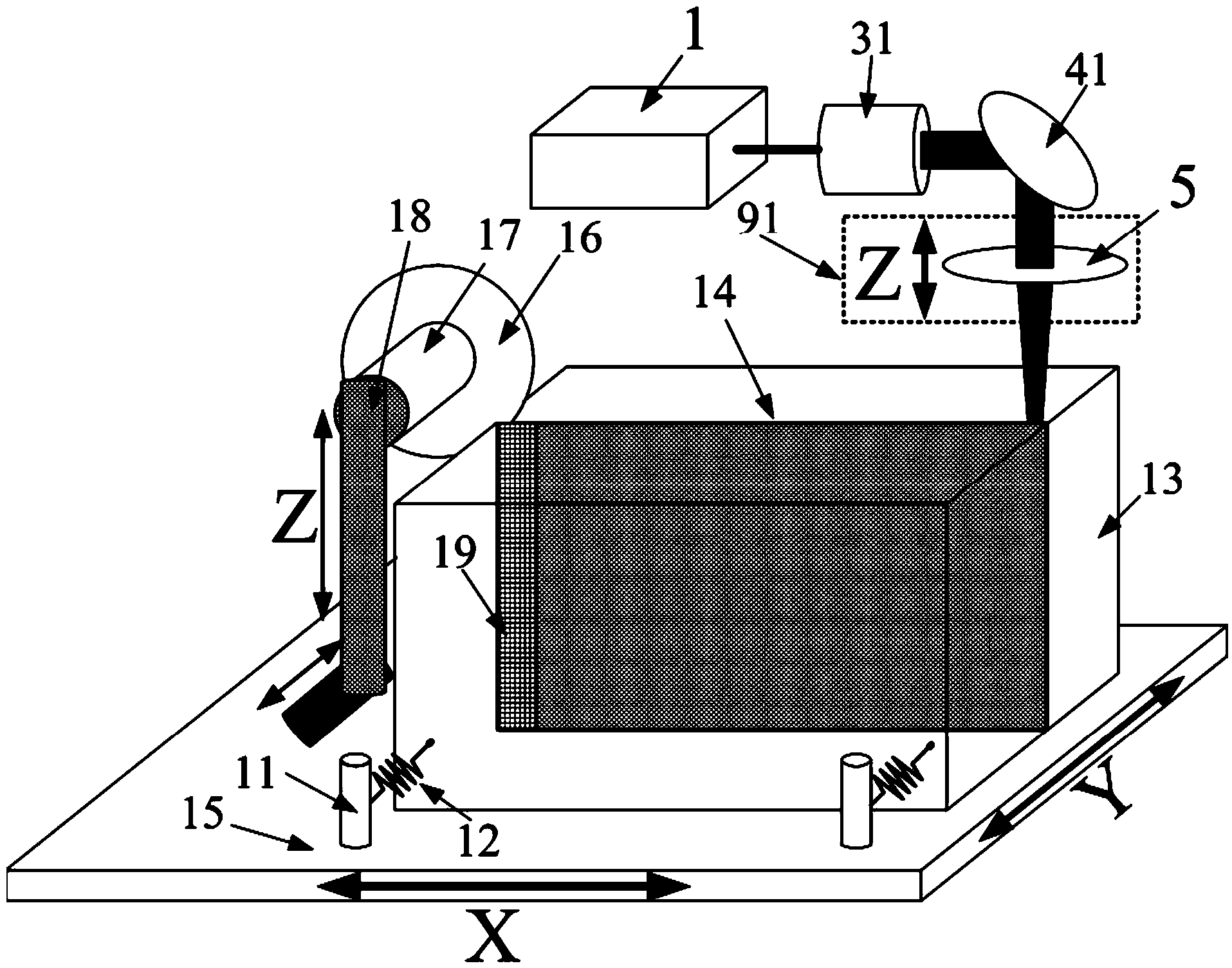

[0061]The present invention adopts a servo motor with a maximum rotational speed of 4000 rpm, the moving speed of the motor along the Z-axis guide rail is 1 mm / s, and the moving feed distance of the motor along the X-axis is 10 μm. The diameter of the micro-diamond grinding wheel is 20 mm, and the thickness of the outermost ring of the grinding wheel is 100 μm. The YLR-50 series pulsed fiber laser from German IPG company is used as a common high-power laser, the output wavelength is 1070nm, the highest average output power is 50W, and the maximum single pulse energy is 1mJ. The focus spot size of ordinary high-power laser is 30μm, the separation optical crystal is KDP crystal, the sample length is 200mm, and the thickness is 11.8mm. Test method: adopt the second method of laser rapid separation of optical crystals. Adjust the rotation speed of the servo motor to 2500 rpm, the output power of the fiber laser to 10 W, the pulse energy to 1 mJ, the scanning speed to 200 μm / s, an...

example 3

[0063] The present invention adopts a servo motor with a maximum rotational speed of 1000 rpm, the moving speed of the motor along the Z-axis guide rail is 100 μm / s, and the moving feed distance of the motor along the X-axis is 30 μm. The diameter of the micro-diamond grinding wheel is 10 cm, and the thickness of the outermost ring of the grinding wheel is 100 μm. A domestic 50W green laser is used as a common high-power laser. The focus spot size of ordinary high-power laser is 20μm, the separation optical crystal is KDP crystal, the sample length is 400mm, and the thickness is 30mm. Test method: adopt the second method of laser rapid separation of optical crystals. Adjust the rotation speed of the servo motor to 500 rpm, the output power of the laser to 40 W, the pulse energy to 1 mJ, the scanning speed to 400 μm / s, and the moving speed to 4 mm / s. Experimental results: The optical crystal is separated along the separation track, the separation side wall is smooth and flat,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com