Patents

Literature

173results about How to "Low Young's modulus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

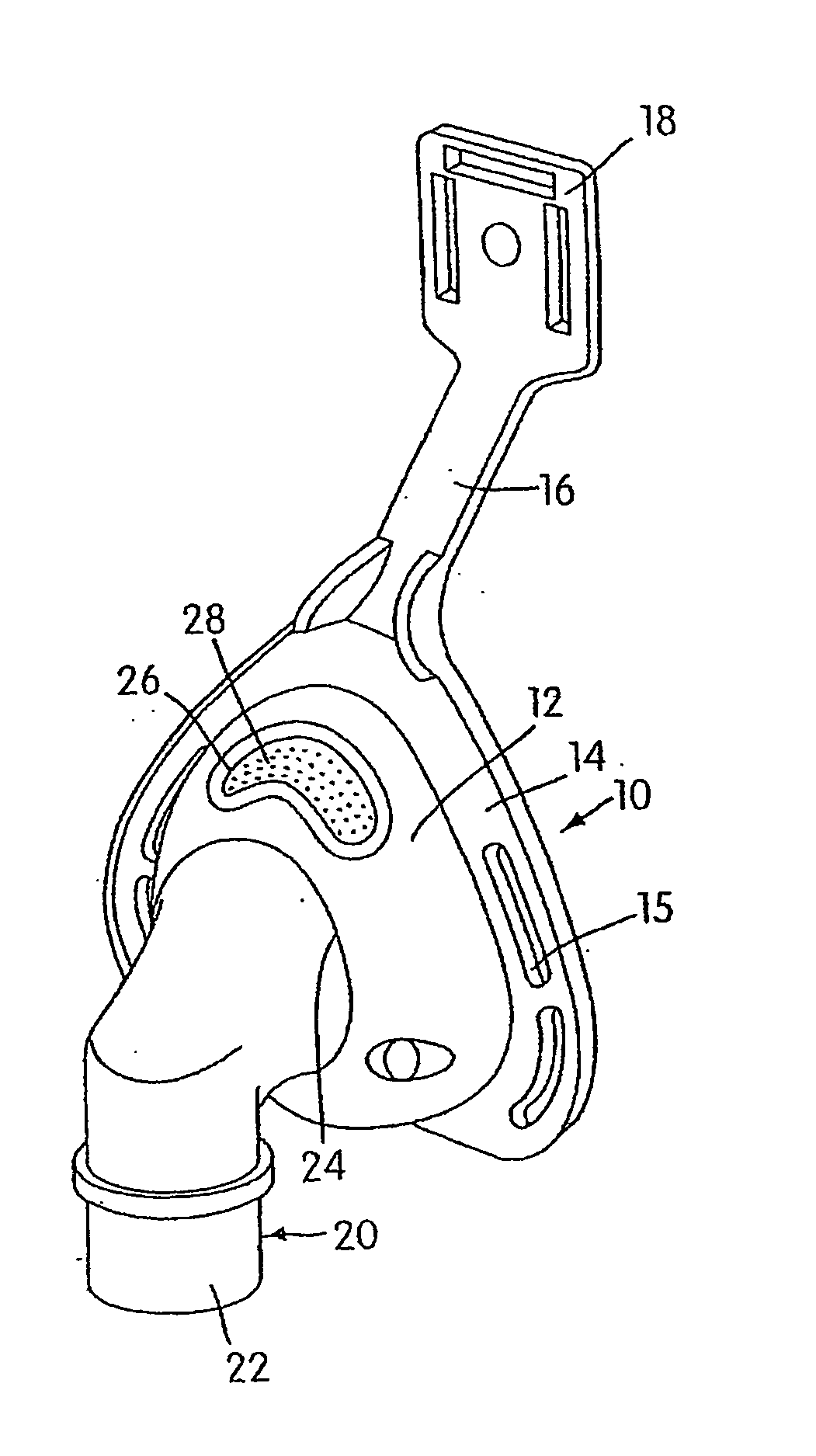

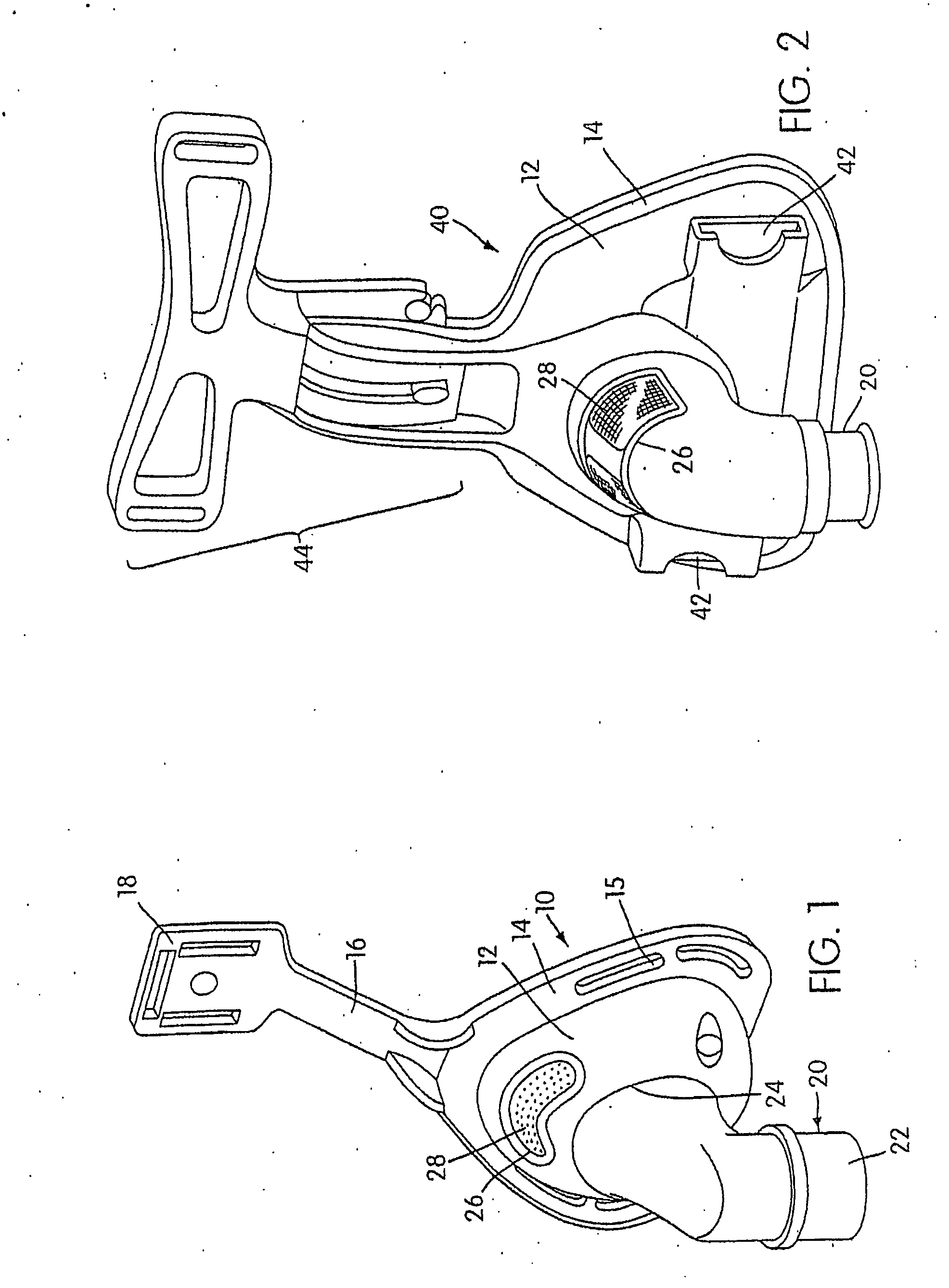

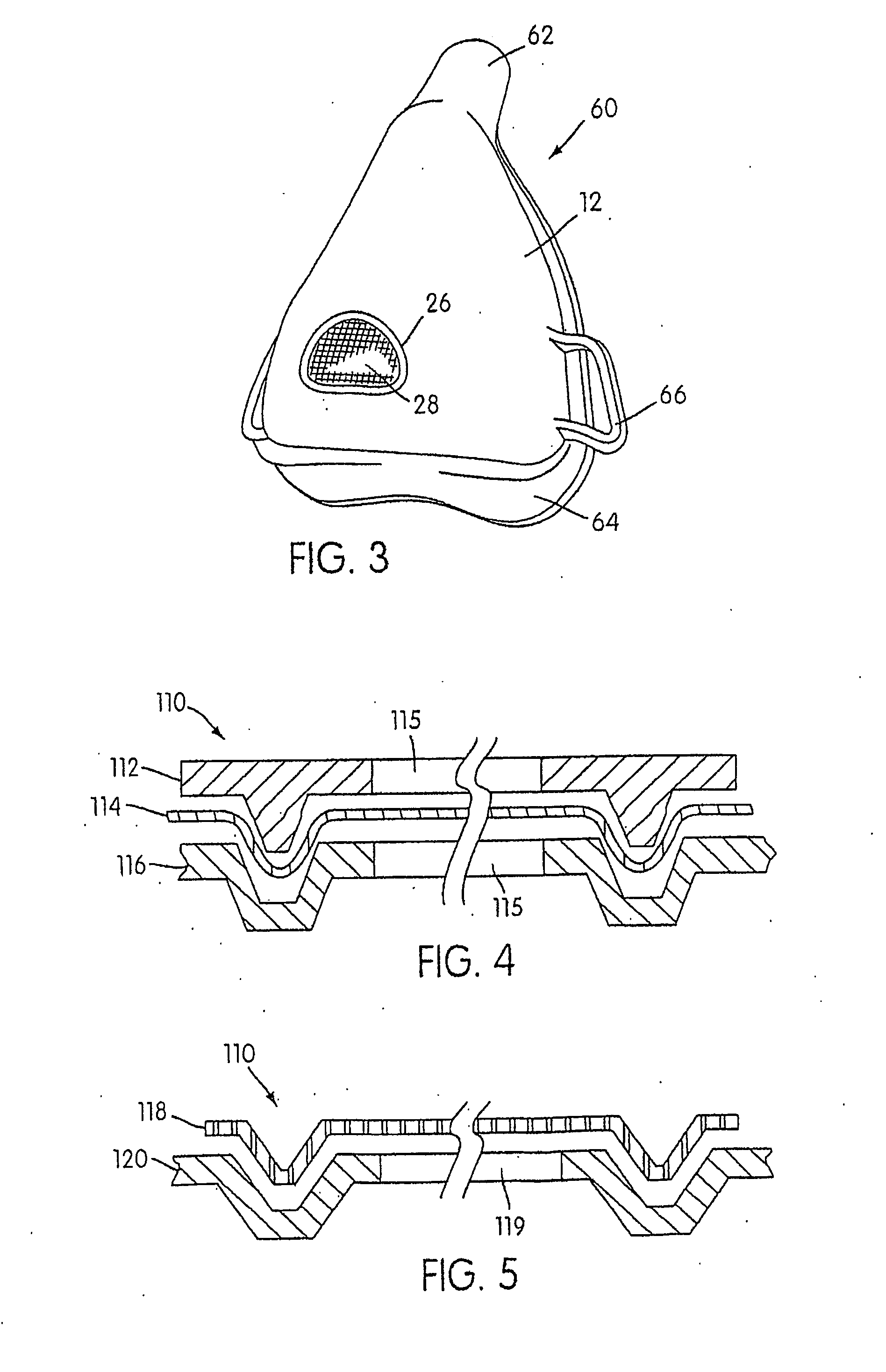

Respiratory mask having gas washout vent and gas washout vent assembly for respiratory mask

InactiveUS20100154798A1Negative Poisson 's RatioLow young 's modulusRespiratory masksBreathing masksPolypropyleneRespiratory mask

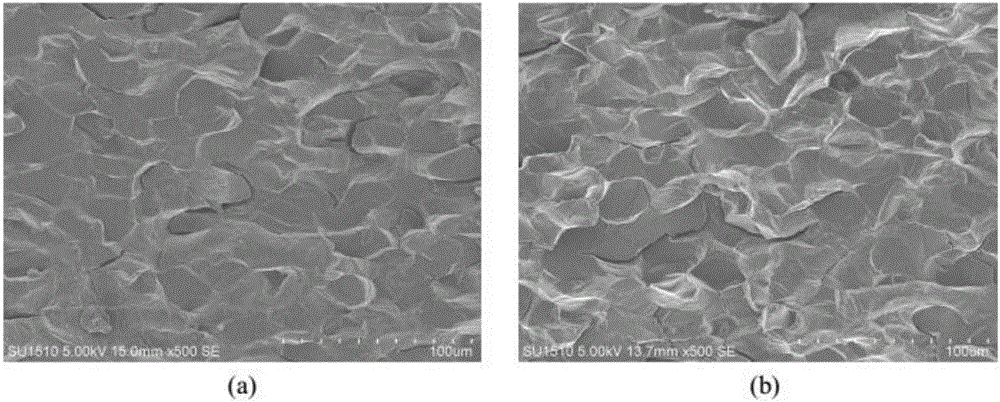

A vent assembly for use with a respiratory mask of the type used in CPAP treatment. In one embodiment, the vent is made of a thin air permeable membrane (28). The membrane can be made of a hydrophobic material such as expanded polytetrafluoroethylene (PTFE). An expanded PTFE membrane is mounted on a polypropylene scrim. The pores of the ePTFE membrane have a reference pore size of 10 to 15 microns. Alternatively, the vent assembly includes a stainless steel vent having holes with diameters less than about 0.2 mm. In another embodiment, the membrane has a superficial cross-sectional area of approximately 500 mm2. In further embodiments, a vent of a mesh material, e.g., an auxetic vent (200) or a PTFE mesh, may be used as an air permeable membrane, either alone or in combination with a traditional vent structure.

Owner:RESMED LTD

Preparation method of flexible silica aerogel

The invention discloses a preparation method of a flexible silica aerogel, relating to a silica aerogel. The invention provides the preparation method of the flexible silica aerogel, which takes methyl alkoxy-series silane as a silicon source precursor. The preparation method comprises the steps of mixing methyl trimethoxysilane or methyl trimethoxysilane, an anhydrous ethanol solution and water, further adding hydrochloric acid, regulating the pH value of the solution to 2-2.5, then adding ammonia water to obtain a sol, standing, then preparing a wet gel, further aging the wet gel, and then drying to prepare the flexible silica aerogel. The prepared flexible silica aerogel has the advantages of low density and high porosity, and simultaneously overcomes the shortcomings of poor integrity and great brittleness. According to the preparation method, the complicated steps of complex solvent exchange and gel modification are not required, so that the operation is simple and easy, the process is controllable, the cost is low, the period is short, and the continuous production can be realized.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

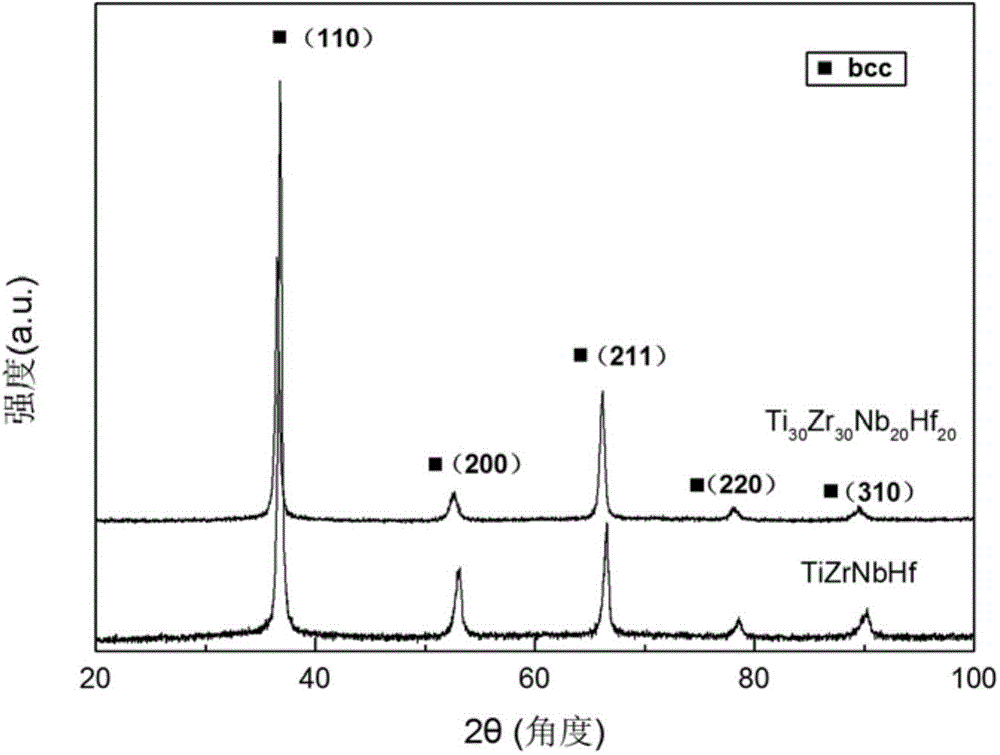

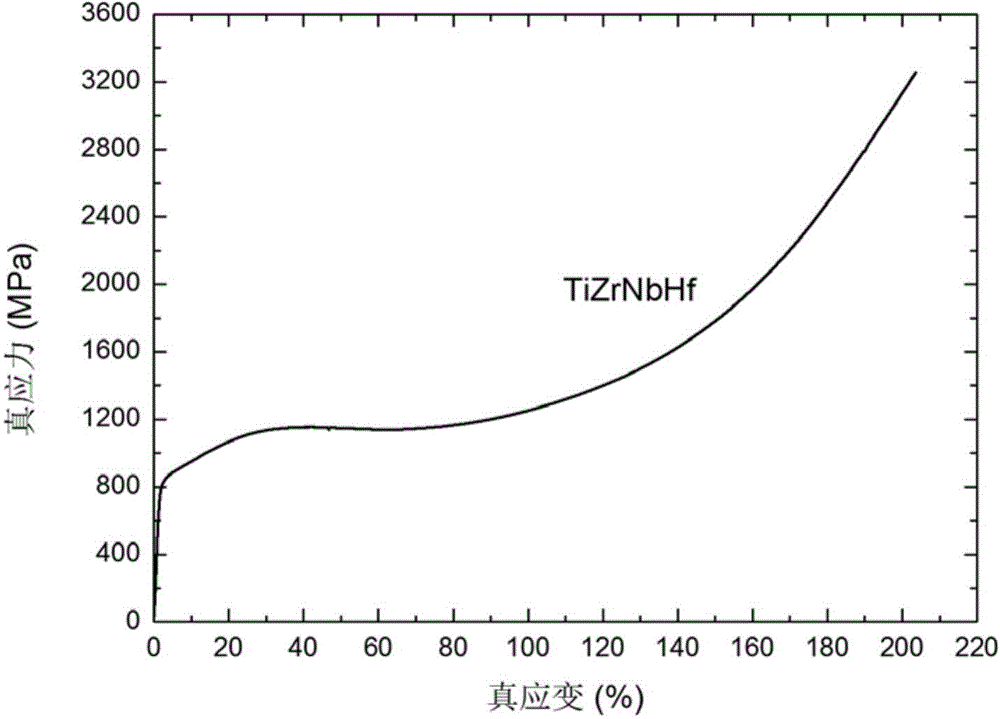

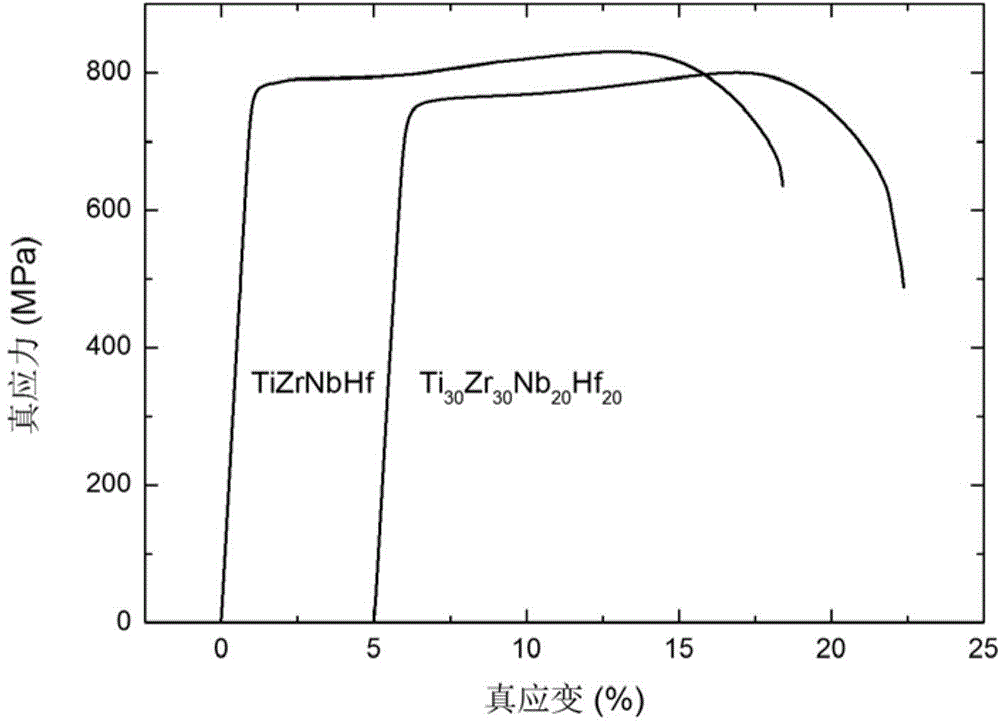

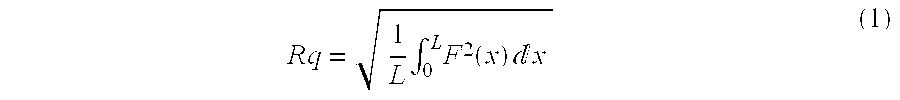

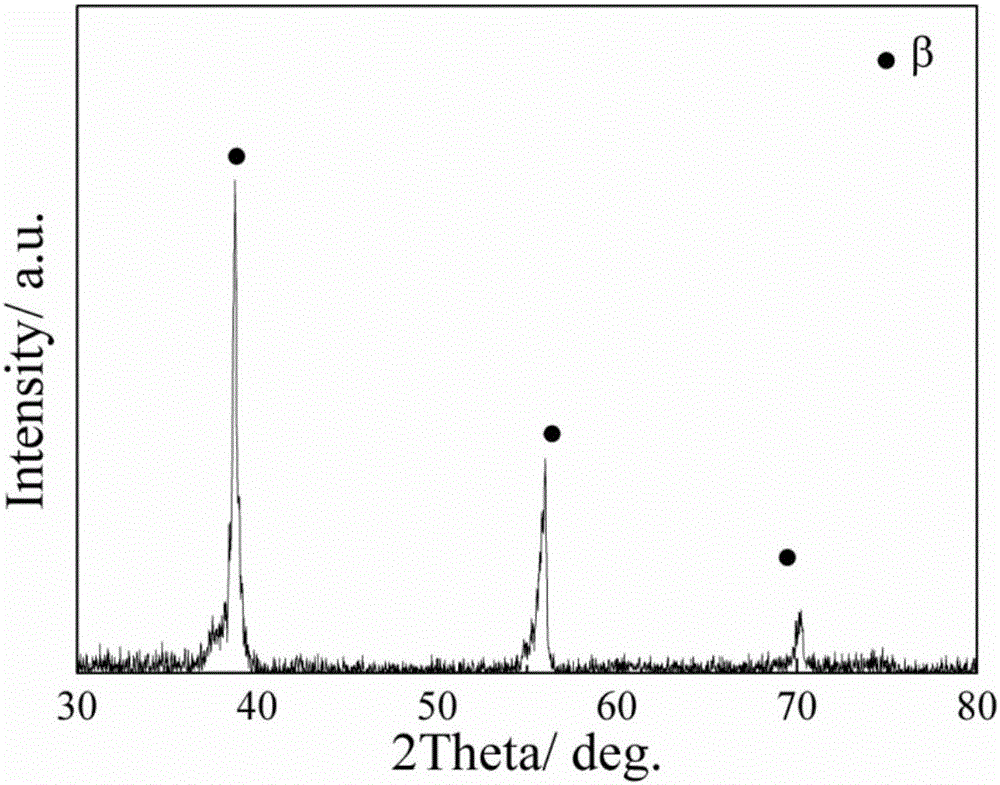

High-strength low-elasticity modulus TiZrNbHf high-entropy alloy and preparation method thereof

ActiveCN103602874ALow Young's modulusExcellent structural stabilityHigh entropy alloysYoung's modulus

The invention relates to a high-strength low-elasticity modulus TiZrNbHf high-entropy alloy and a preparation method thereof; the component of the high-entropy alloy is TiaZrbNbcHfd, wherein a is not less than 20 and not more than 35, b is not less than 20 and not more than 35, c is not less than 20 and not more than 35, and d is not less than 20 and not more than 35. The preparation method of the alloy comprises the following steps: descaling metallurgy raw materials (Ti, Zr, Nb and Hf metals), precisely weighing and proportioning according to a mole ratio for smelting alloy; smelting the alloy by using a non-consumable vacuum arc furnace or a cold crucible suspension furnace, smelting the alloy in a water-cooling copper crucible, suction casting or pouring the alloy in a copper mold through vacuum suction casting or metal mold equipment so as to obtain high-entropy alloy rod or platy material. The high-entropy alloy has high strength, low Young modulus, and excellent structure property stability at a high temperature, the alloy element is non-toxic to human body or low in toxicity; and therefore, the high-entropy has good application prospect on biomedical and high-temperature components.

Owner:UNIV OF SCI & TECH BEIJING

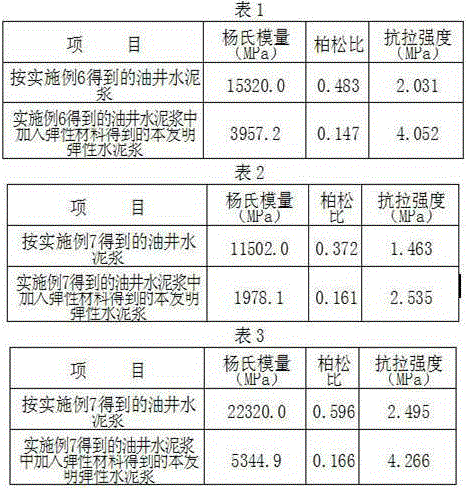

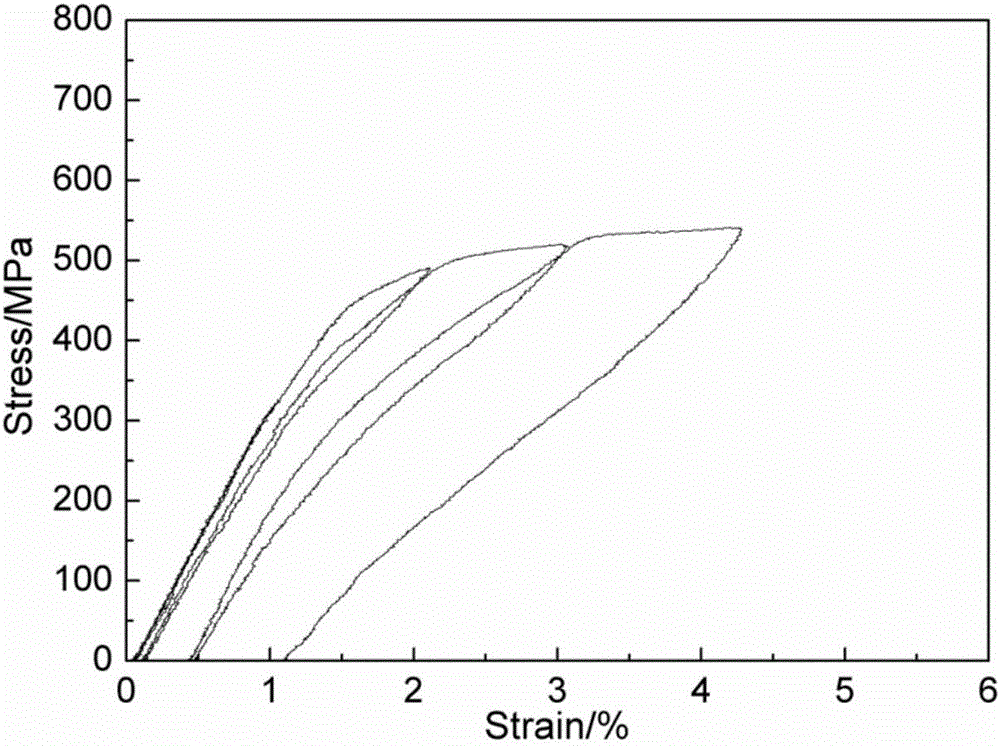

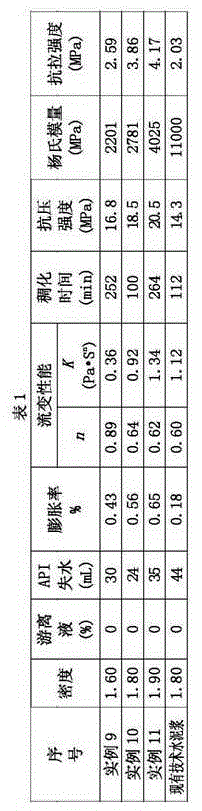

Elastic cement paste and preparation method thereof

InactiveCN105254226ALow Young's modulusHigh tensile strengthDrilling compositionWell cementingYoung's modulus

The invention relates to the technical field of oil well cement paste, in particular to elastic cement paste and a preparation method thereof. The elastic cement paste is prepared from oil well cement paste and elastic materials, wherein the mass of the elastic materials is 3-40% that of cement in the oil well cement paste. Compared with corresponding oil well cement paste, the Young modulus of the obtained elastic cement paste is greatly lowered, and the strength of extension of the obtained elastic cement paste is greatly improved. By adopting the elastic cement paste for carrying out well cementing operation, the problem that microcracks are produced inside set cement and / or micro annular clearances are produced on a cement-formation interface in the trial production processes such as oil gas well follow-up perforation and multi-stage large fracturing due to the inherent brittleness of the set cement is effectively solved. It is shown that the elastic materials can significantly improve the capacity of resisting of set cement for resisting external force deformation, the Young modulus of the set cement is lowered, the strength of extension of the set cement is improved, annulus breakthrough flow is reduced, and the requirement for perforation and multi-stage large-scale fracturing production can be met.

Owner:CNPC XIBU DRILLING ENG

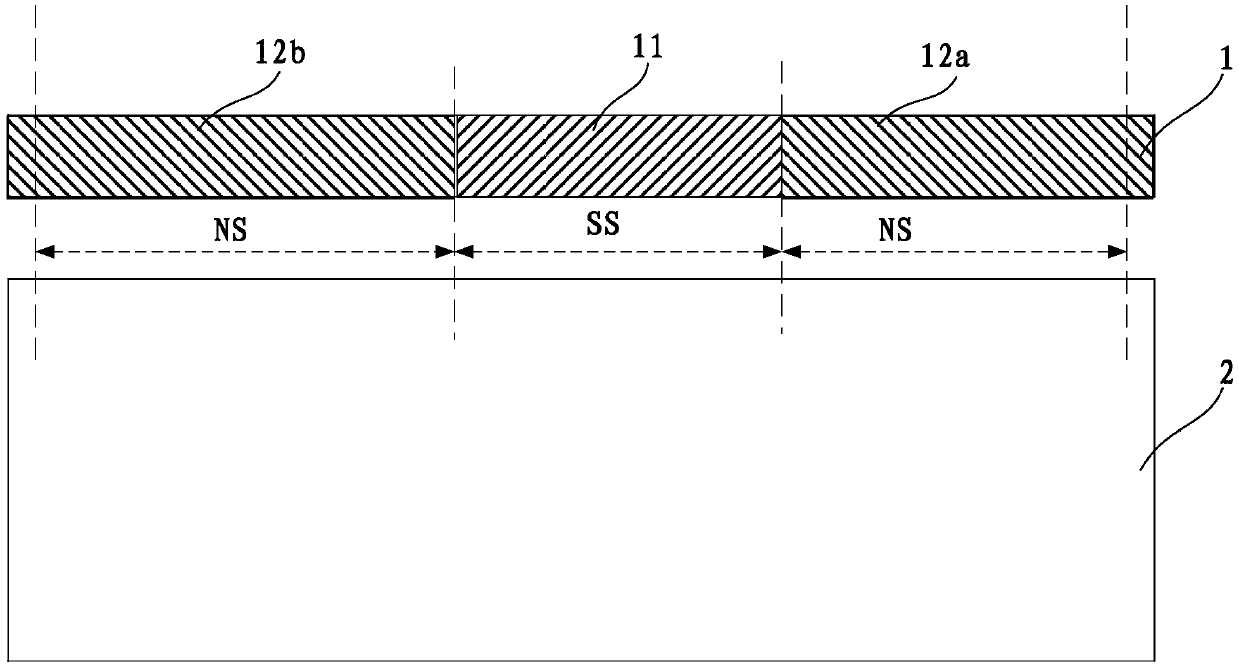

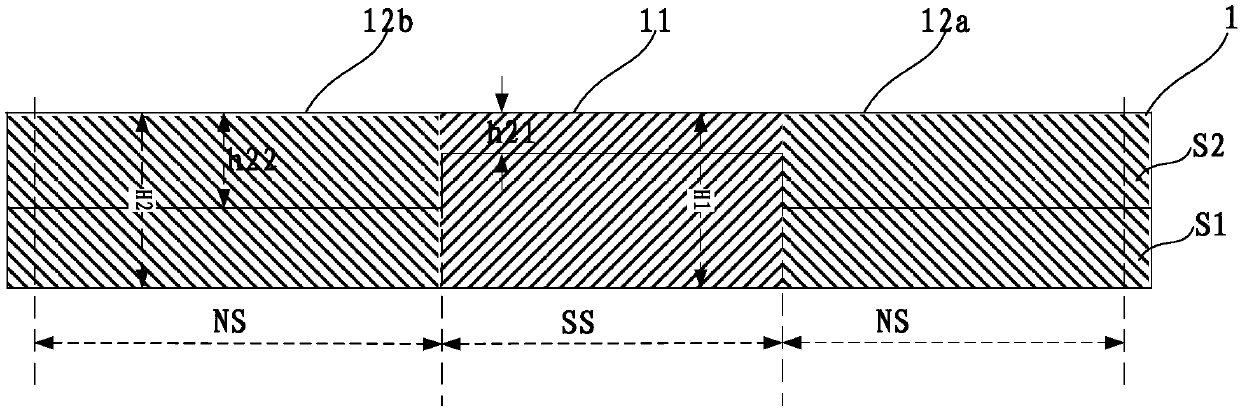

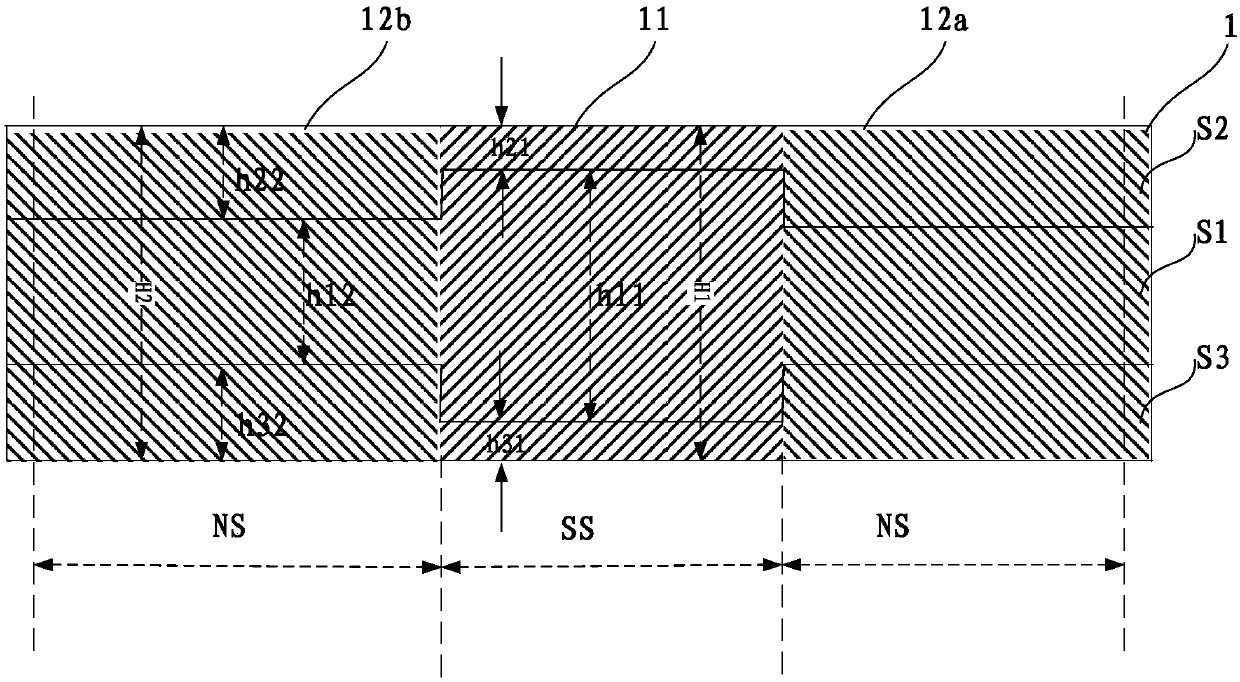

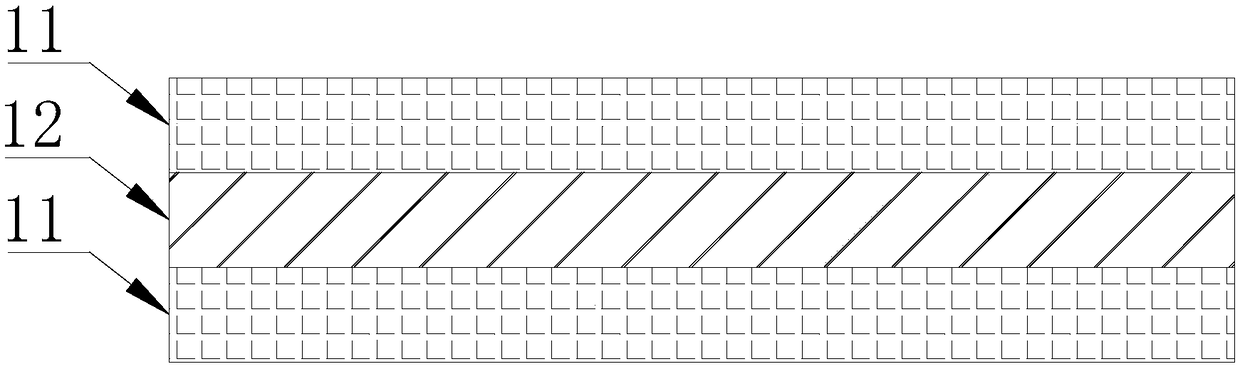

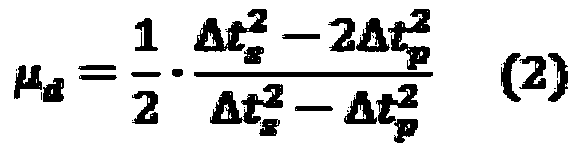

Protective cover plate and flexible display device

ActiveCN109671363ASolve technical problems that are difficult to pass the stress testLow Young's modulusIdentification meansYoung's modulusEngineering

The invention provides a protective cover plate and a flexible display device. The protective cover plate comprises a bending part and a non-bending part, wherein the bending part is located in a bending region, and the non-bending part is located in a non-bending region, and the Young modulus of the bending part is smaller than that of the non-bending part. In this way, since the bending part ofthe protective cover plate has the low Young modulus, the bending part can pass a bending test, meanwhile, the non-bending part has the high Young modulus and therefore can pass a pressure test, and the technical problem is solved that a non-bending part of an existing protective cover plate passes a pressure test with difficulty.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

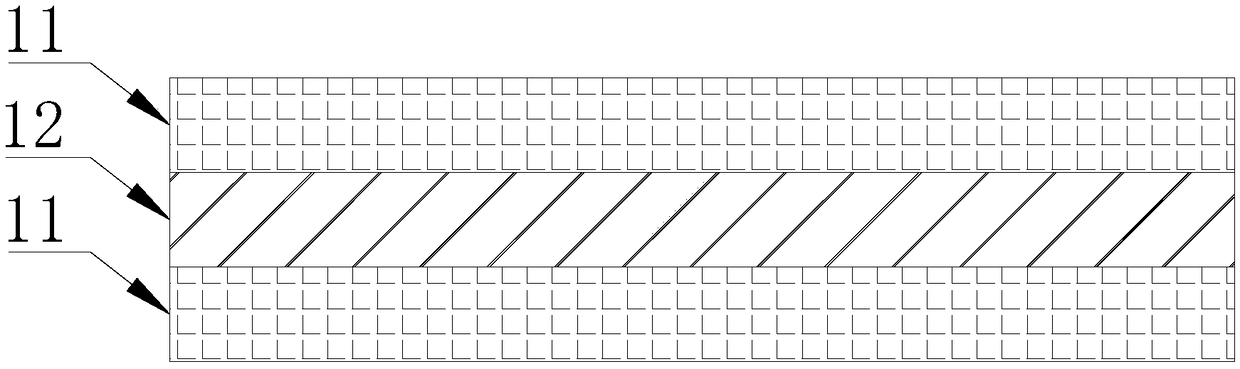

Loudspeaker diaphragm and loudspeaker

ActiveCN108551642AIncrease stiffnessIncrease dampingPolymeric diaphragmsLoudspeakersPolyesterElastomer

The invention discloses a loudspeaker diaphragm and a loudspeaker. The diaphragm includes two surface layers that are compounded together and at least one intermediate layer located between the two surface layers, wherein at least one of the surface layers is a thermoplastic polyester elastomer film layer, at least one of the intermediate layers is an adhesive layer, a thermoplastic polyester elastomer is a copolymer composed of a polyester hard segment A and a polyether or aliphatic polyester soft segment B, the thickness of the thermoplastic polyester elastomer film layer is 5-70 microns, and the thickness of the adhesive layer is 1-40 microns.

Owner:GOERTEK INC

Loudspeaker diaphragm and loudspeaker

ActiveCN108966088AIncrease stiffnessIncrease dampingPolymeric diaphragmsPolyureas/polyurethane adhesivesPolyesterLoudspeaker

The invention discloses a loudspeaker diaphragm and a loudspeaker. The loudspeaker diaphragm comprises two surface layers compounded together and at least one intermediate layer located between the two surface layers. At least one surface layer is a thermoplastic polyester elastomer film layer; and the at least one intermediate layer is an adhesive layer. The Young's modulus of the thermoplastic polyester elastomer film layer is 1-1000MPa; the loss factor thereof is larger than or equal to 0.015; and the elastic recovery rate thereof is greater than or equal to 80% after 10% of strain.

Owner:GOERTEK INC

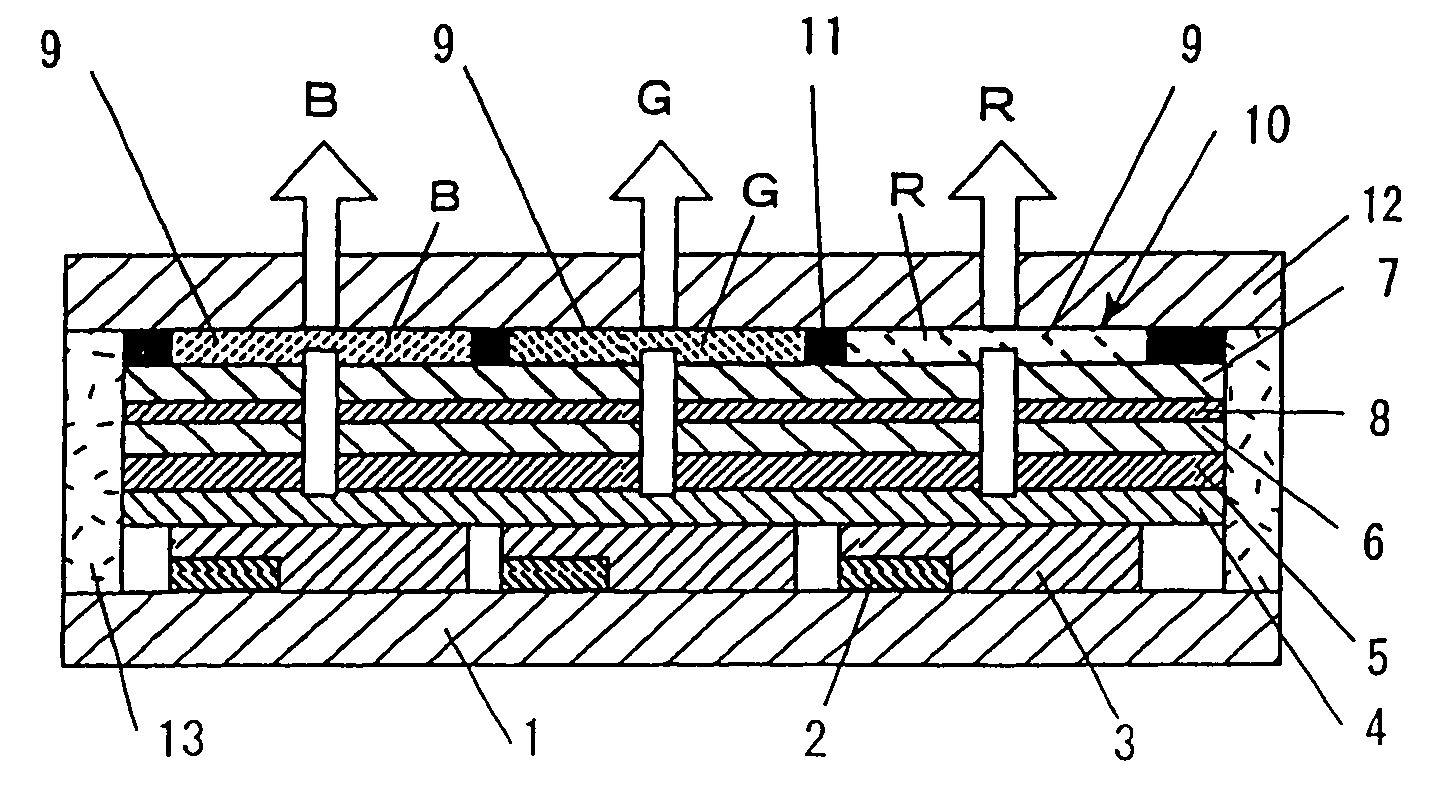

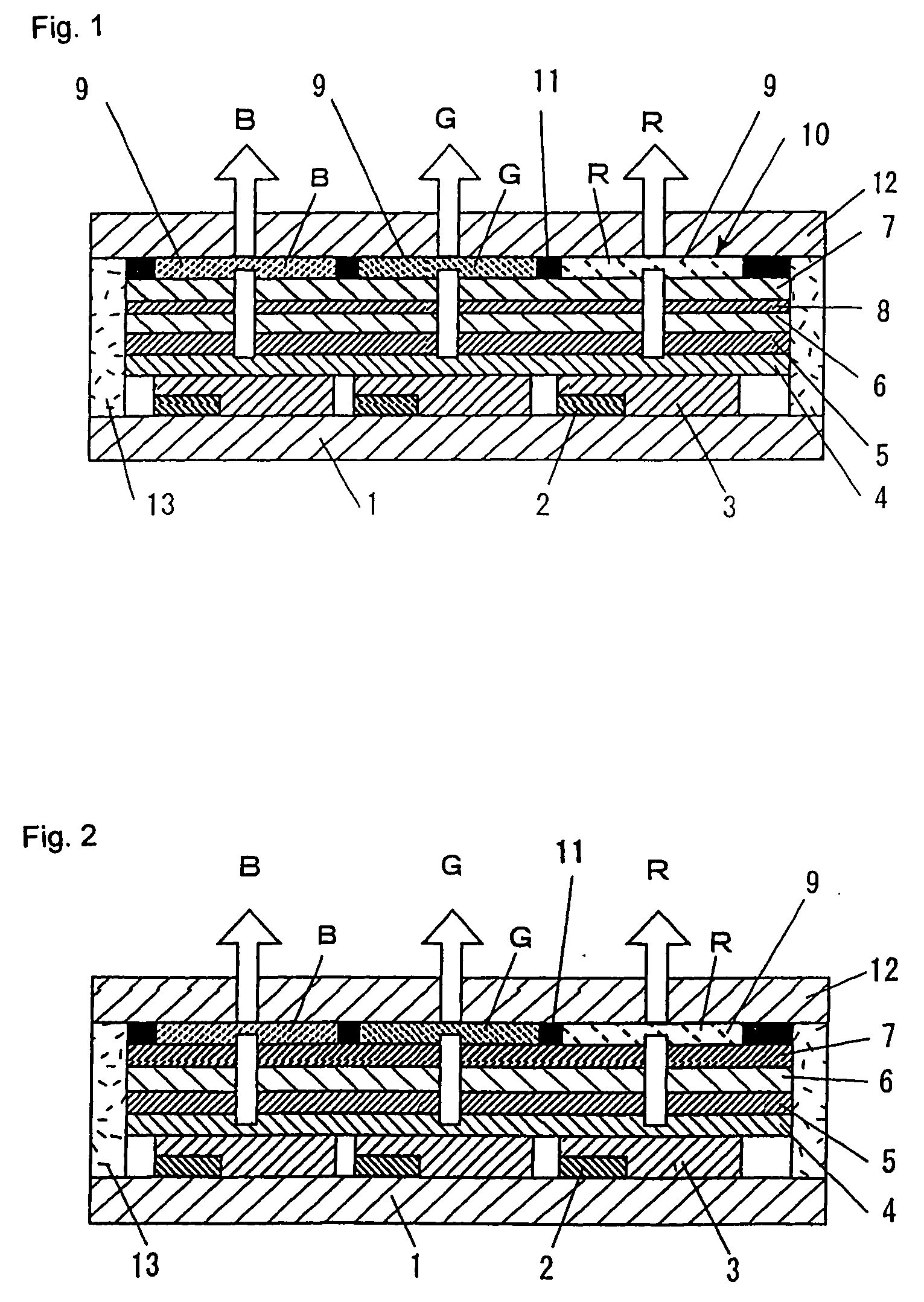

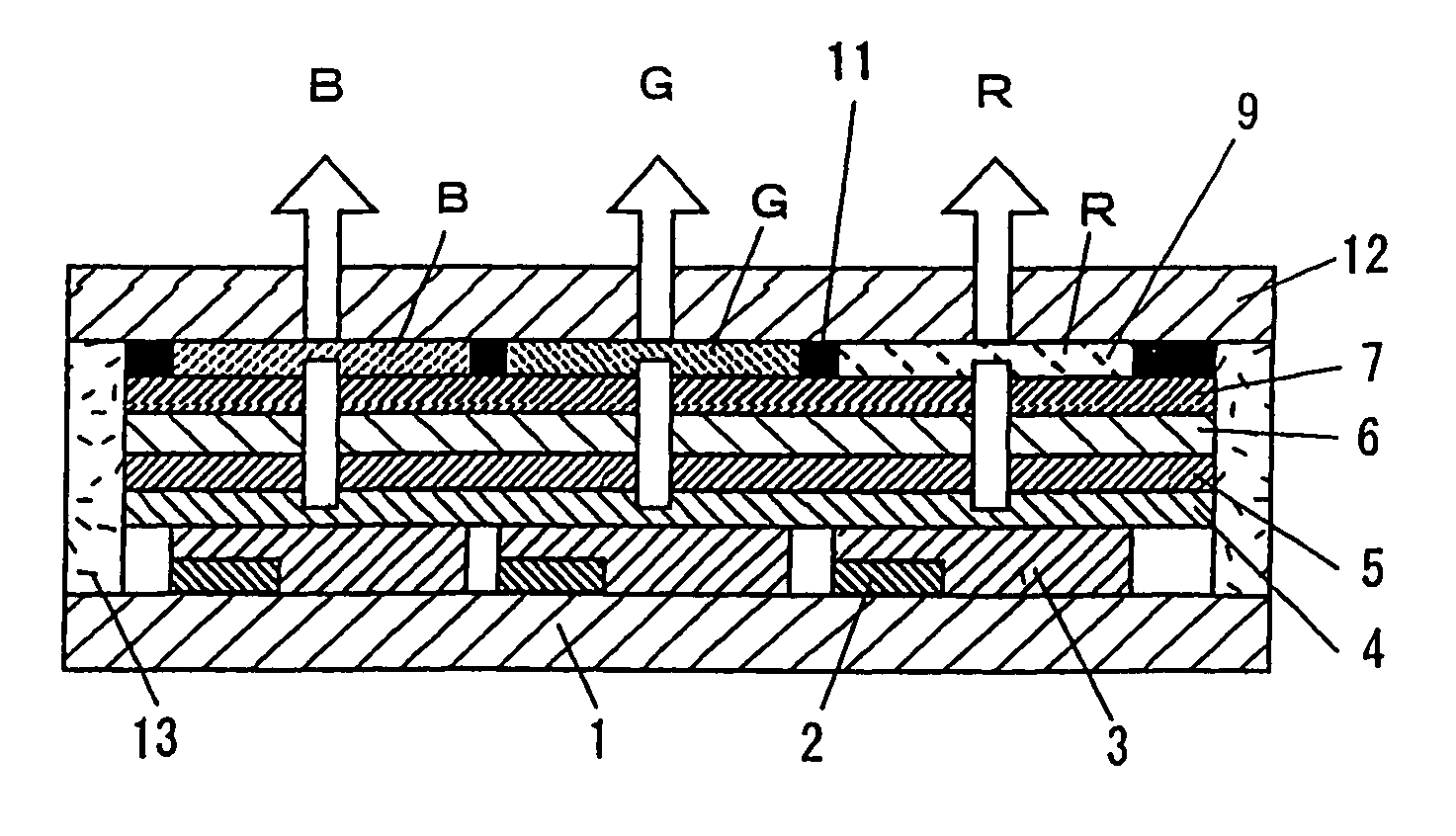

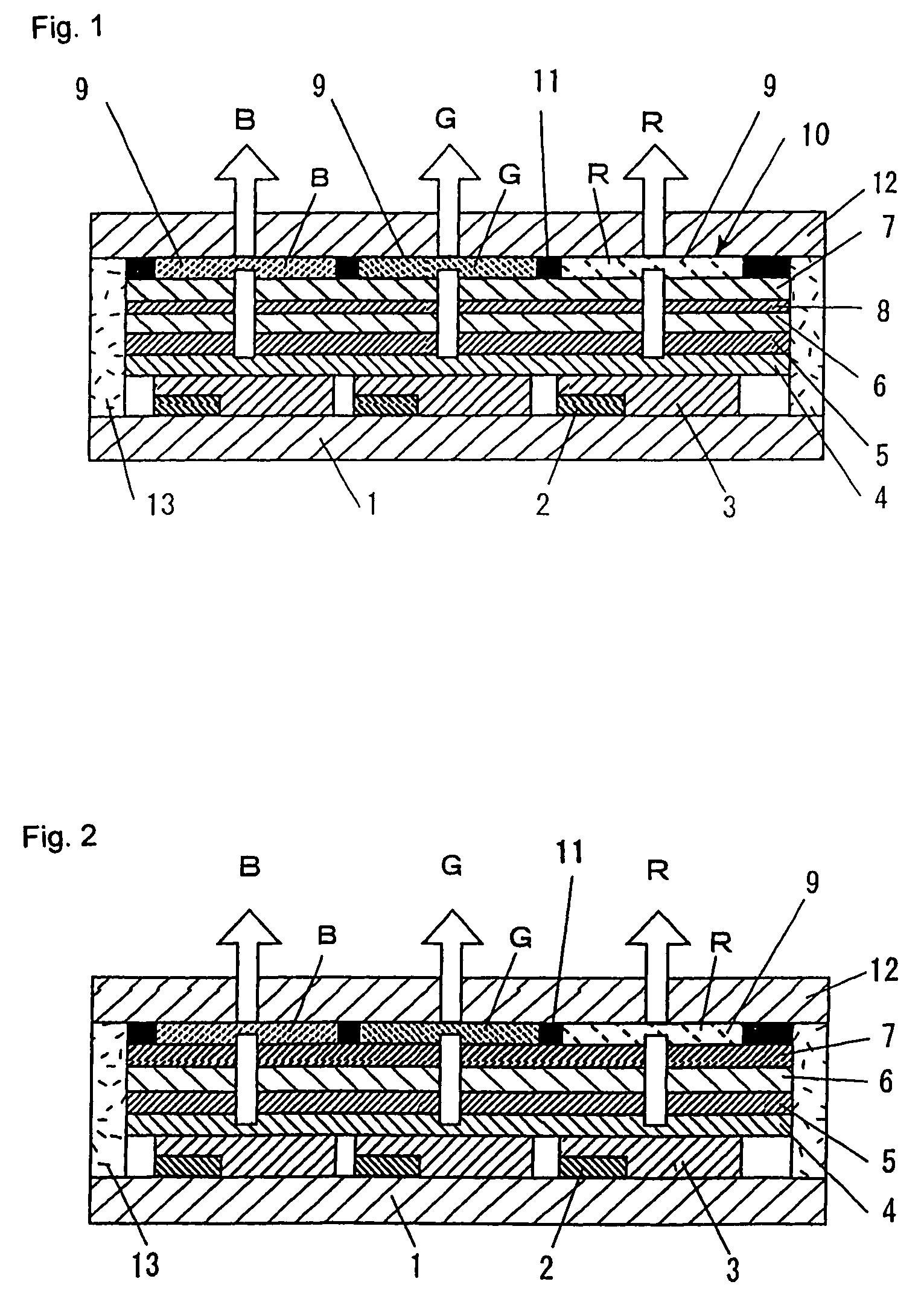

Organic el display

InactiveUS20060113617A1Low Young 's modulusRelieve mechanical stressStatic indicating devicesElectroluminescent light sourcesEngineeringOrganic electroluminescence

A top emission structure color organic EL (electroluminescent) display in which there are bonded together a substrate, having thin film transistors formed thereon, and a transparent substrate, having color-converting filters formed thereon, with an overcoat layer for adjusting the gap between the two substrates and also for relieving stress formed between the substrates without providing a space between the overcoat layers and an electroluminescent device, whereby the organic electroluminescent display has high reliability, without voids that would have an adverse effect on the display performance, and the occurrence of thermal and mechanical stress being suppressed.

Owner:SHARP KK

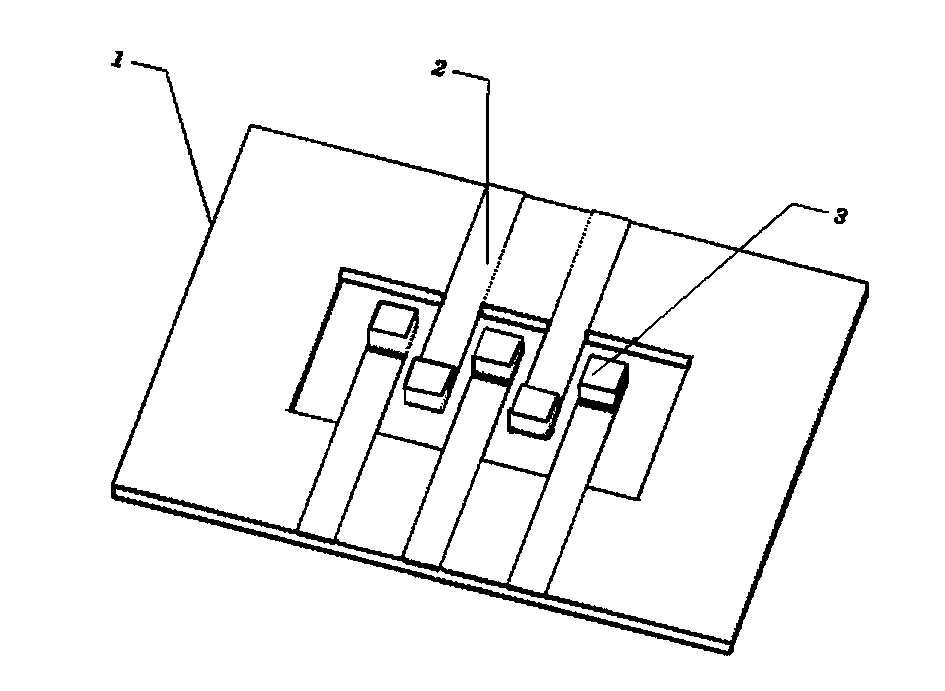

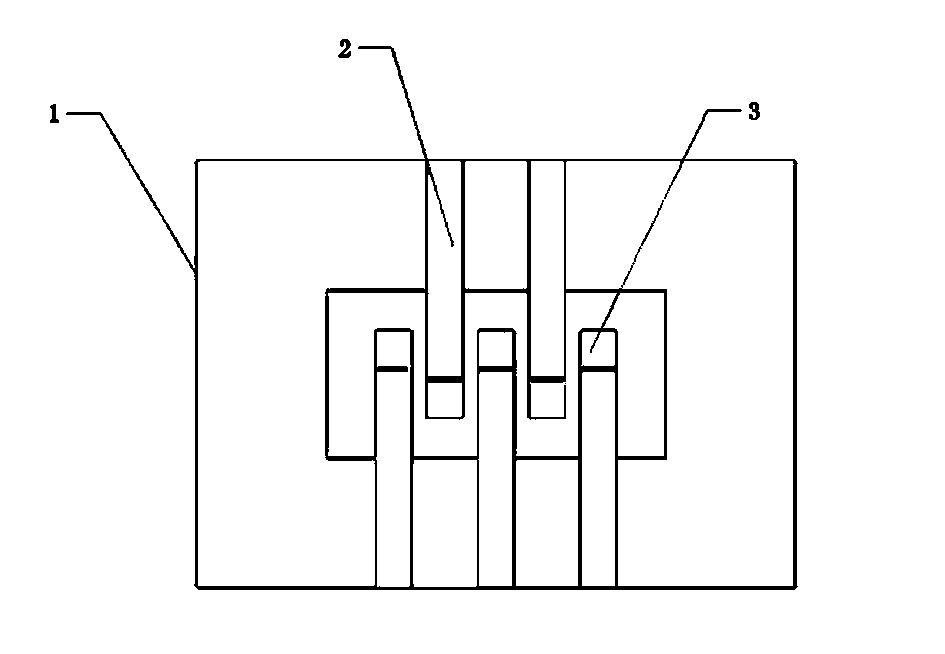

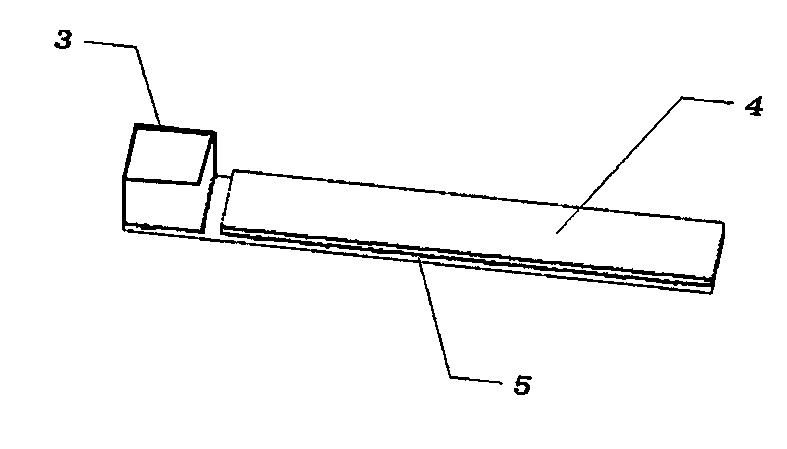

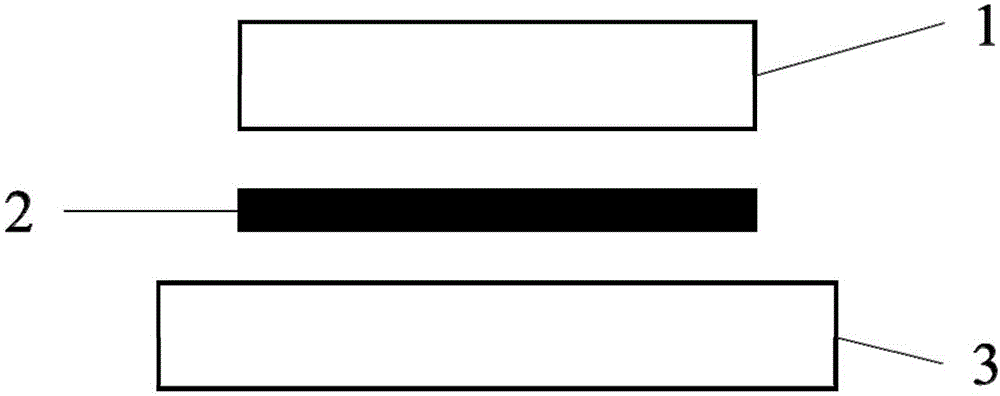

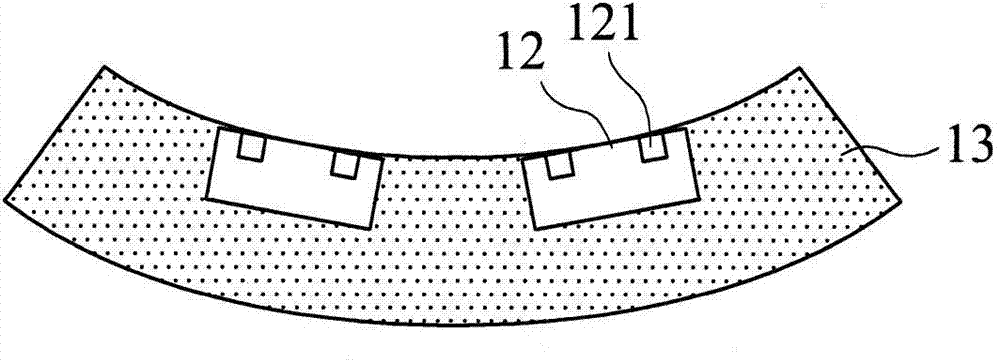

Vibration pick-up structure on basis of flexible main beam for vibration energy harvester

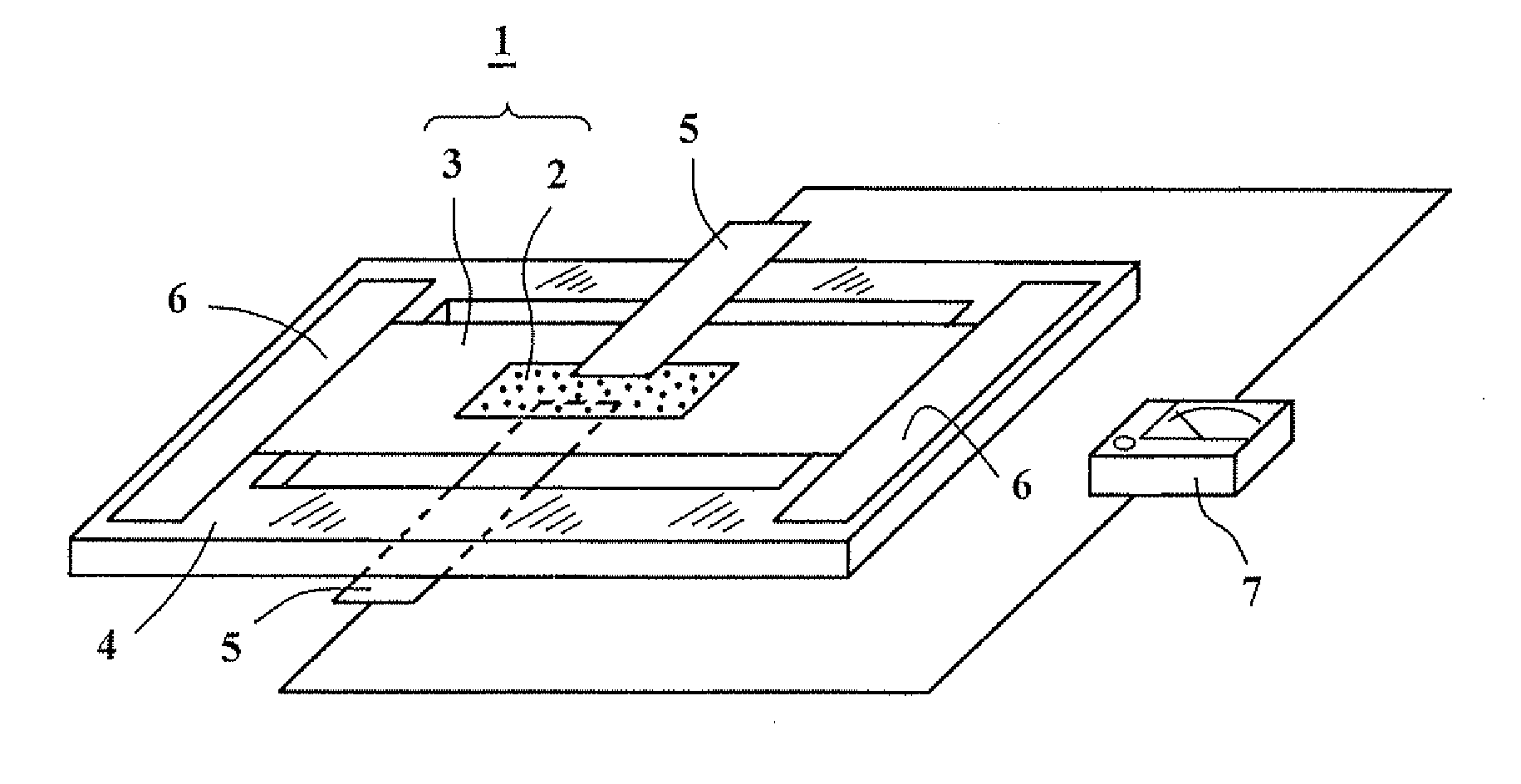

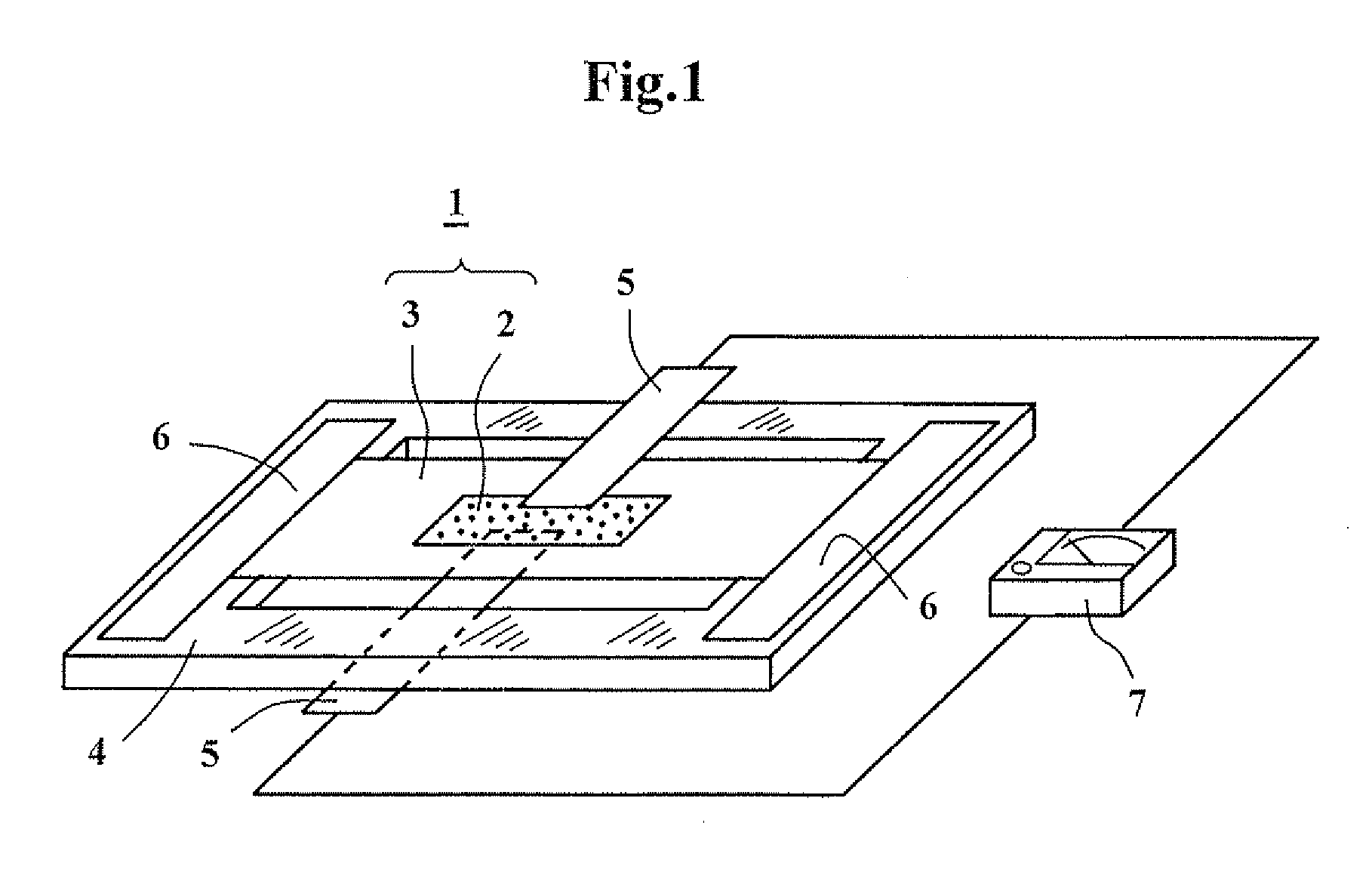

ActiveCN103633879ALow Young's modulusIncrease structural flexibilityPiezoelectric/electrostriction/magnetostriction machinesFrequency bandBroadband

The invention discloses a vibration pick-up structure on the basis of a flexible main beam for a vibration energy harvester. The vibration pick-up structure comprises the flexible main beam, a plurality of piezoelectric cantilever beams and mass blocks. The flexible main beam is of a rectangular frame structure, and a rectangular hole is formed in the middle of the flexible main beam; one end of each cantilever beam is fixedly adhered on the upper surface of the flexible main beam, the other end of each piezoelectric cantilever bream is suspended above the rectangular hole, and each mass block is adhered at the suspended end of the corresponding piezoelectric cantilever beam; the multiple piezoelectric cantilever beams are respectively arranged on two sides of the rectangular holes to form forking fingers and are parallel and equidistant to short sides of the rectangular hole. By the aid of the forking finger type multi-cantilever-beam vibration pick-up structure on the basis of the flexible main beam in the design, high-order vibration pick-up frequencies and of a system can be greatly reduced, low-order vibration pick-up frequencies of the system can be reduced, and accordingly a vibration energy harvesting frequency band of the system can be effectively broadened. Compared with the traditional vibration pick-up structure of a vibration energy harvester, the vibration pick-up structure has the advantages that broadband vibration energy can be harvested in ultra-low frequency ranges of frequencies lower than 100Hz, output voltage can be increased, and accordingly the energy harvesting efficiency can be improved.

Owner:TAIYUAN UNIV OF TECH

Elastic well cementation cement paste and preparation method thereof

InactiveCN103146368AIncrease elasticityImprove impact resistanceDrilling compositionFresh waterYoung's modulus

The invention discloses an elastic well cementation cement paste and a preparation method thereof. The elastic well cementation cement paste comprises the following components in percentage by weight based on 100% of the cement weight: 1-2% of a fluid loss agent, 4-12% of an elastic material, 0.5-1.5% of a dispersing agent, 0.5-2% of a toughening agent, 0.4-1% of a defoaming agent, 0.5-2% of a retarder, 0-50% of a density regulator and 33-50% of fresh water. The method for preparing the elastic well cementation cement paste comprises the following steps of: firstly, uniformly mixing the elastic material, the toughening agent, the density regulator and cement in a dry manner for later use; then uniformly mixing the fluid loss agent, the dispersing agent, the defoaming agent, the retarder and the fresh water in a wet manner; and finally, under a stirring condition, adding an additive obtained after dry mixing into a material obtained after wet mixing, and uniformly stirring to obtain the elastic well cementation cement paste. The elastic well cementation cement paste increases the elasticity of cement stone and reduces the Young modulus, and a cement ring has high impact resistance and toughness, so that the damages of downhole operation to the cement ring are reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

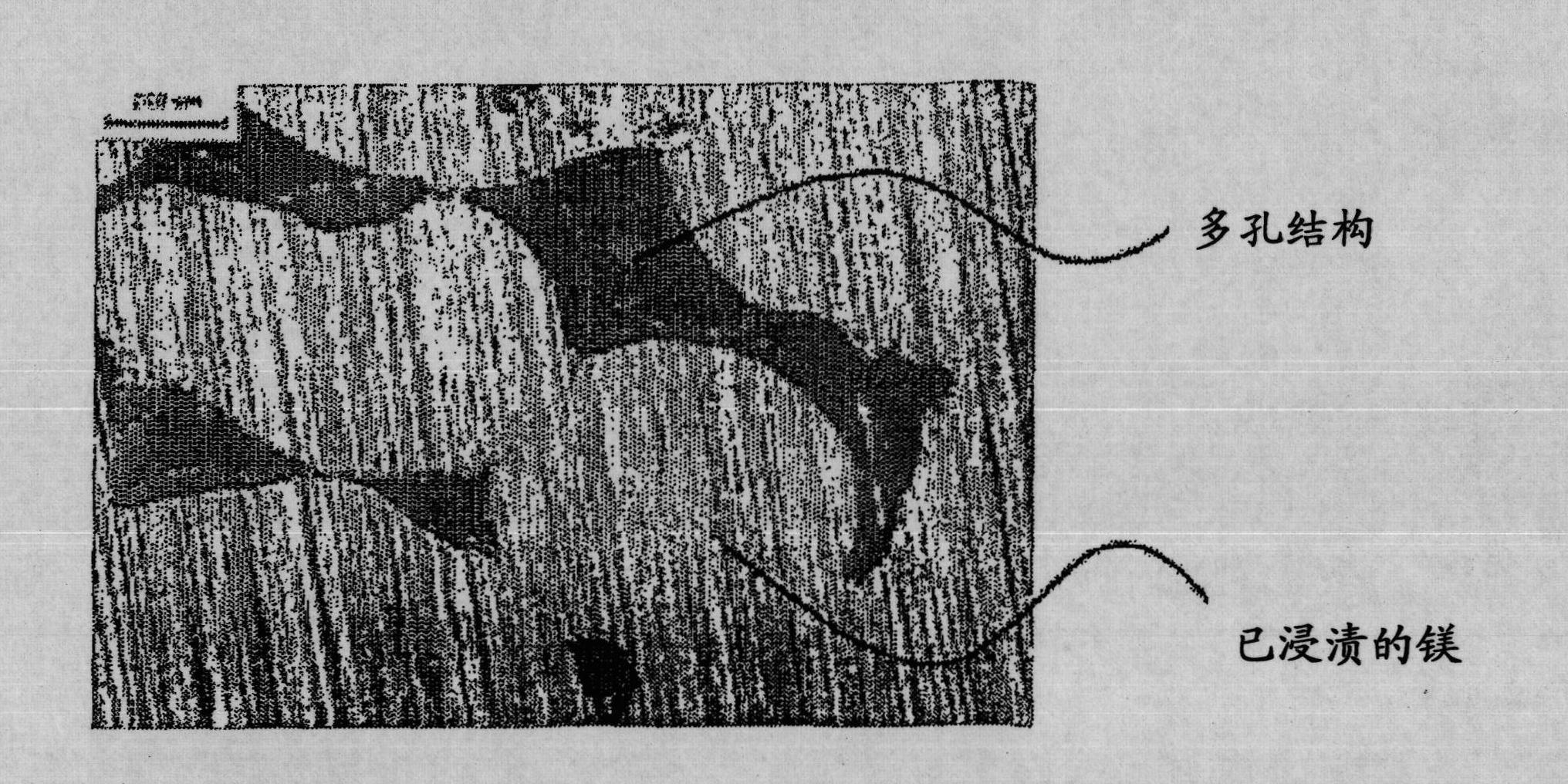

Composite implant having porous structure filled with biodegradable alloy and method of magnesium-based manufacturing the same

InactiveCN102014798AIncrease spawn ratePromote generationDental implantsBone implantAlloyMechanical property

The present invention provides a composite implant comprising pores of a porous structure filled with a biodegradable magnesium-based alloy. Further, the present invention provides a composite implant which filles pores of the porous structure prepared by a metal, a ceramic or a polymer with a biodegradable magnesium-based alloy. Mechanical properties of the composite implant of the present invention are improved because a magnesium-based alloy filled in its pores increases the strength of a porous structure comprised of a metal, a ceramic or a polymer. Futher, it can be expected that the magnesium-based alloy filled in the porous structure is decomposed in a living body, thus increasing bone formation rate. Accordingly bone tissue can be rapidly formed because the composite implant of the present invention has high strength and excellent interfacial force between the composite implant and bone tissue, compared to conventional porous materials.

Owner:U & I INC

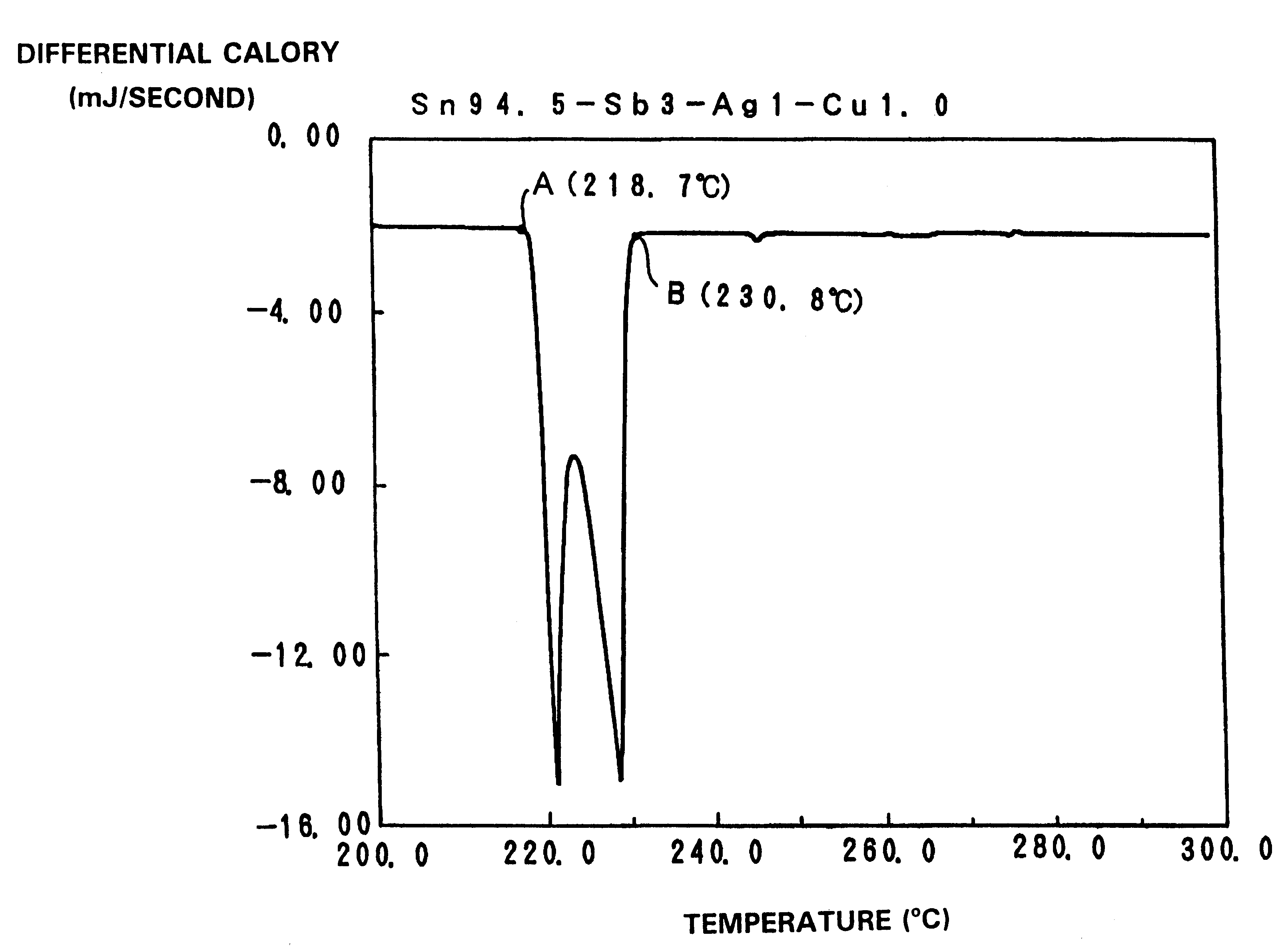

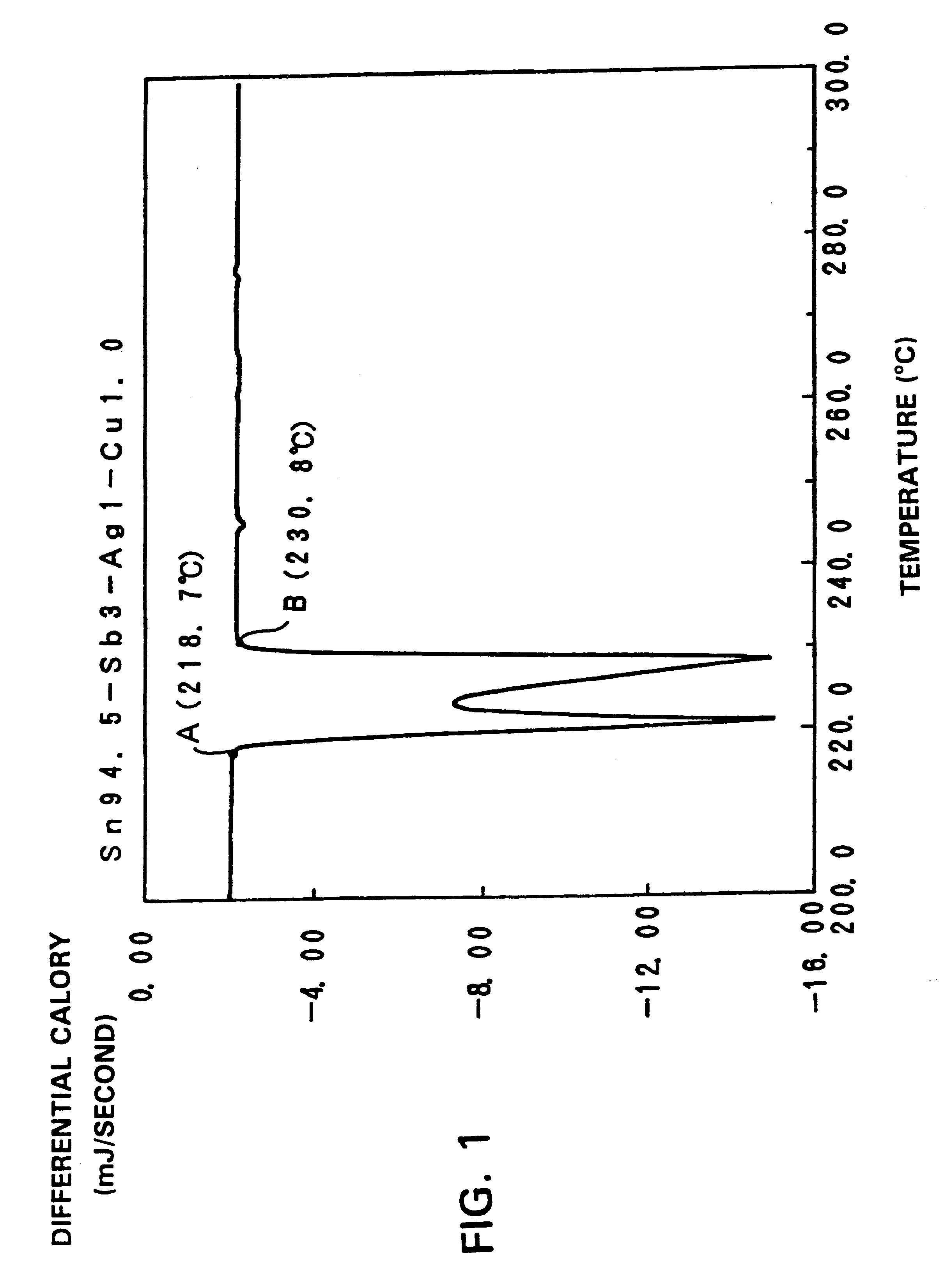

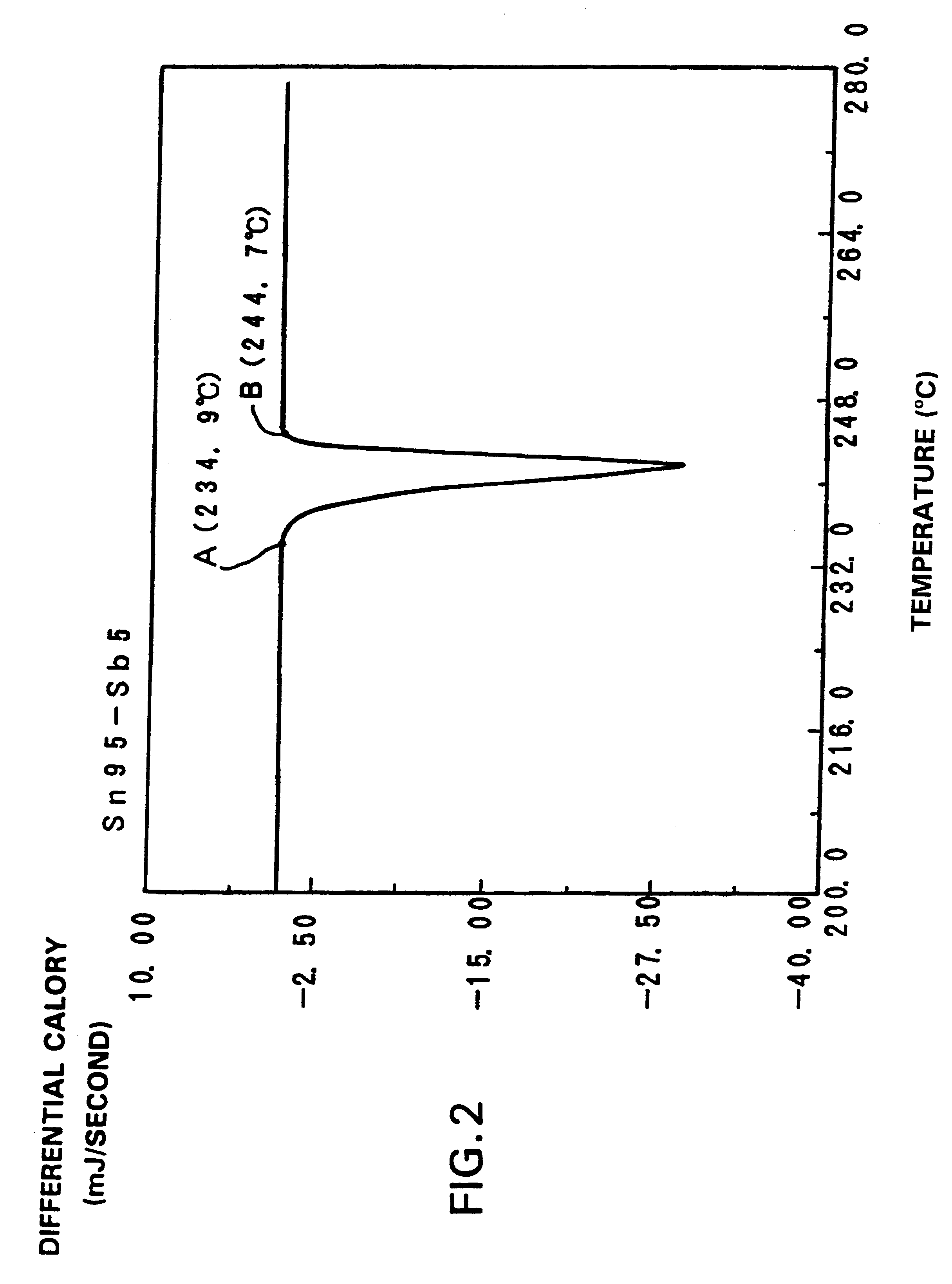

Solder alloy

InactiveUS6229248B1Low Young 's modulusSufficient tensile characteristicPrinted circuit assemblingPiezoelectric/electrostriction/magnetostriction machinesYoung's modulusElectronic component

The invention provides a solder alloy of Sn, Sb, Ag and Cu, wherein the Sb is about 1.0-3.0 wt %; the Ag is about 1.0 wt % or more and about 2.0 wt % or less; the Cu is about 1.0 wt % or less; and the remainder is Sn. The solder alloy has a comparatively low Young's modulus and sufficient tensile characteristics. Therefore, it resists peeling from the bonded electrode, etc., even though a heat stress is added. Also, a solder which has an excellent solderbility to metal phases such as Cu and Ni can be provided. Therefore, a solder alloy excellent in thermal shock resistance can be provided. The solder alloy may be used for soldering the inside of an electronic component.

Owner:MURATA MFG CO LTD

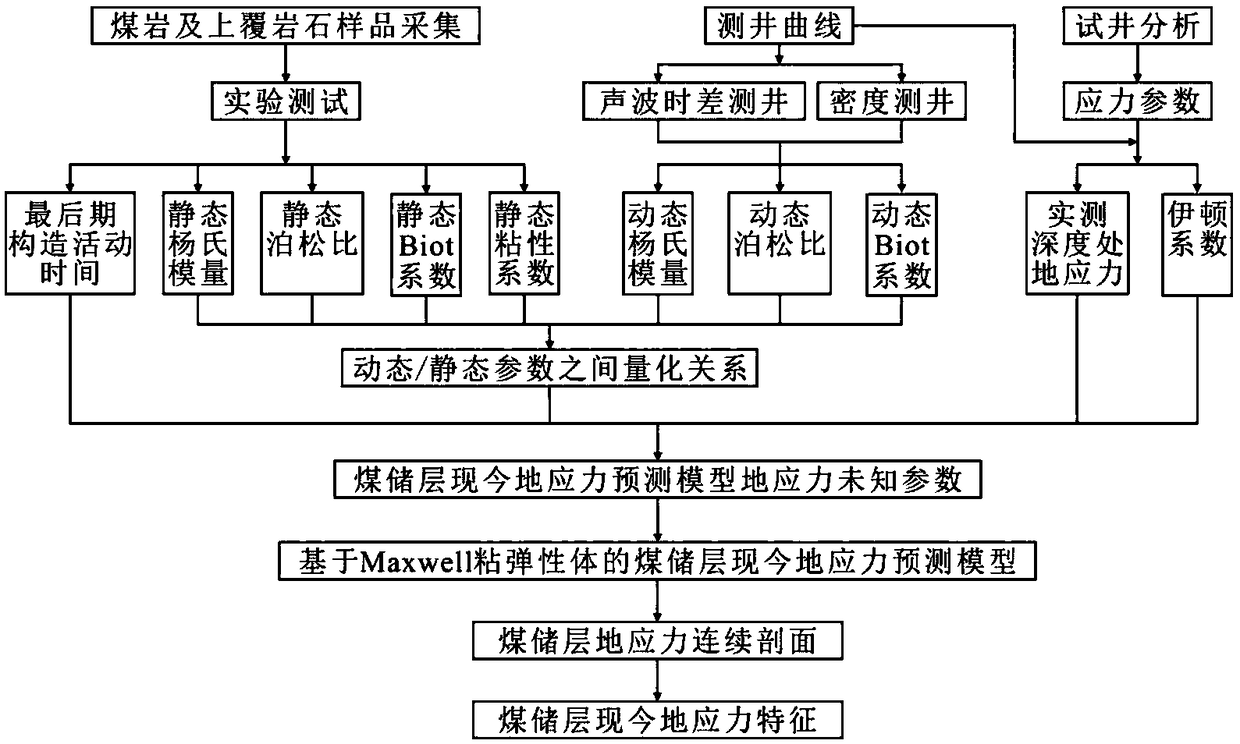

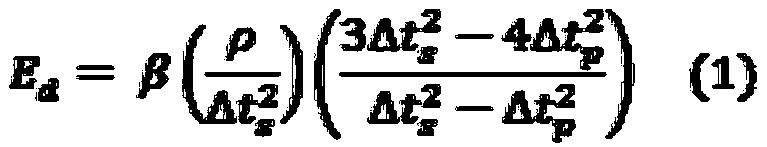

Coal reservoir present geostress prediction method

ActiveCN109113742ALow Young's modulusLow high Poisson's ratioMining devicesData processing applicationsYoung's modulusUltimate tensile strength

The invention relates to a coal reservoir present geostress prediction method, which is characterized in that on the coal rock parameter experiment test and logging curve calculation basis, the quantitative relationship between the static parameter and the dynamic parameter is built; the rock mechanical characteristics of low Young modulus, high poisson ratio, low intensity, easy damage and the like of the coal rock are considered; unknown parameters in the present geostress module based on a Maxwell cola reservoir are obtained through inversion; the coal reservoir geostress profile based on the logging curve is built; the goal of predicting the coal reservoir present geostress is achieved. The targeted performance is high; the coal reservoir present geostress can be accurately predicted;the foundation is laid for the effective exploration and development of coal bed gas; the risk and the cost are reduced; the method can be widely applied to the technical field of coal bed gas exploration and development.

Owner:CHINA UNIV OF MINING & TECH

Interconnection brazing material and interconnection forming method thereof

ActiveCN106271177ASolve the problem of long time consumption of phase methodLow Young's modulusWelding/cutting media/materialsMetal working apparatusAmount of substanceThird phase

The invention provides an interconnection brazing material and an interconnection forming method thereof. The heating technological temperature of a product applied by the interconnection brazing material is T, the interconnection brazing material contains a component A with the melting point larger than T, a component B with the melting point smaller than T and a third-phase component C with the melting point larger than T; the third-phase component C accounts 0-30% the total mass of the component A, the component B and the third-phase component C. A compound AxBy is formed through a reaction between the component A and the component B at the heating technological temperature; the ratio of amounts of substances of the component A to the component B is larger than x / y, the third-phase component C does not react with the component A or the component B, the hardness of the third-phase component C is smaller than those of the component A, the component B and the compound AxBy. According to the technical scheme, a high-melting-point welding joint is obtained, and the Young modulus and the thermal expansion coefficient of a joint can be adjusted by adjusting the proportion of the components inside the brazing material.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Curable Organopolysiloxane Composition For Transducers And Applications Of Such Curable Silicone Composition For Transducers

ActiveUS20150344671A1Increase energy densityImprove featuresPiezoelectric/electrostriction/magnetostriction machinesSkin careTransducerSilicone

The present invention provides a curable organopolysiloxane composition capable of producing a cured article that can be used as a transducer and provided with excellent mechanical characteristics and / or electrical characteristics. The present invention also relates to a novel curable organopolysiloxane composition for transducer use comprising a curable organopolysiloxane composition and a compound having a highly dielectric functional group.

Owner:DOW TORAY CO LTD +1

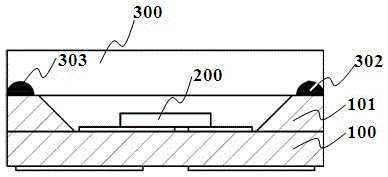

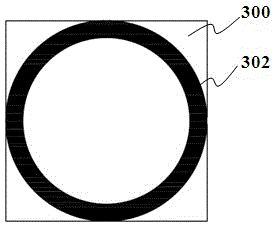

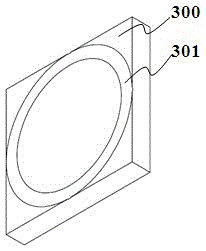

Ultraviolet light emitting diode packaging structure and manufacturing method therefor

ActiveCN106025037AExtended service lifeImprove reliabilitySolid-state devicesSemiconductor devicesAdhesive glueEngineering

The invention discloses an ultraviolet light emitting diode packaging structure and a manufacturing method therefor. The ultraviolet light emitting diode packaging structure comprises a bracket, an LED chip and a packaging cover body, wherein a circuit is formed on the bracket; the LED chip is fixed on the bracket and electrically connected with the circuit on the bracket; the packaging structure is characterized in that a groove structure is arranged on the periphery of the lower surface of the packaging cover body; the groove structure is filled with an organic adhesive glue; and the packaging cover body is arranged above the LED chip and connected with the bracket through the organic adhesive glue.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

Organic el display

InactiveUS7119409B2Low Young 's modulusMechanical and thermal stressStatic indicating devicesElectroluminescent light sourcesEngineeringTransistor

In the case of a top emission structure color organic EL display in which are bonded together a substrate having thin film transistors formed thereon and a transparent substrate having color-converting filters formed thereon, an overcoat layer for adjusting the gap between the substrates and an overcoat layer for relieving stress are formed between the substrates without providing a space between the overcoat layers and the EL device, whereby there can be provided an organic EL display having high reliability, with the occurrence of voids that would have an adverse effect on the display performance being prevented, and the occurrence of thermal and mechanical stress being suppressed.

Owner:SHARP KK

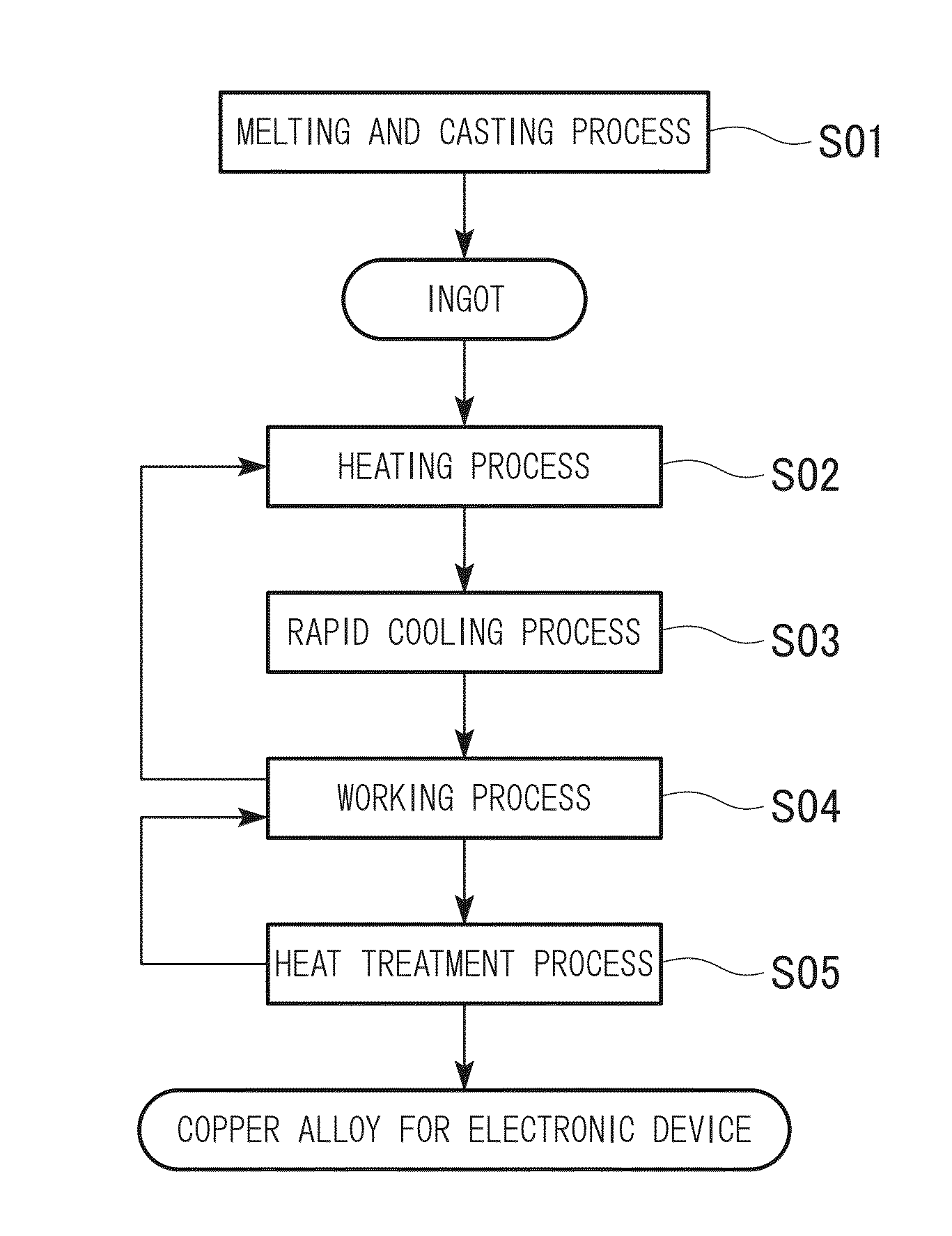

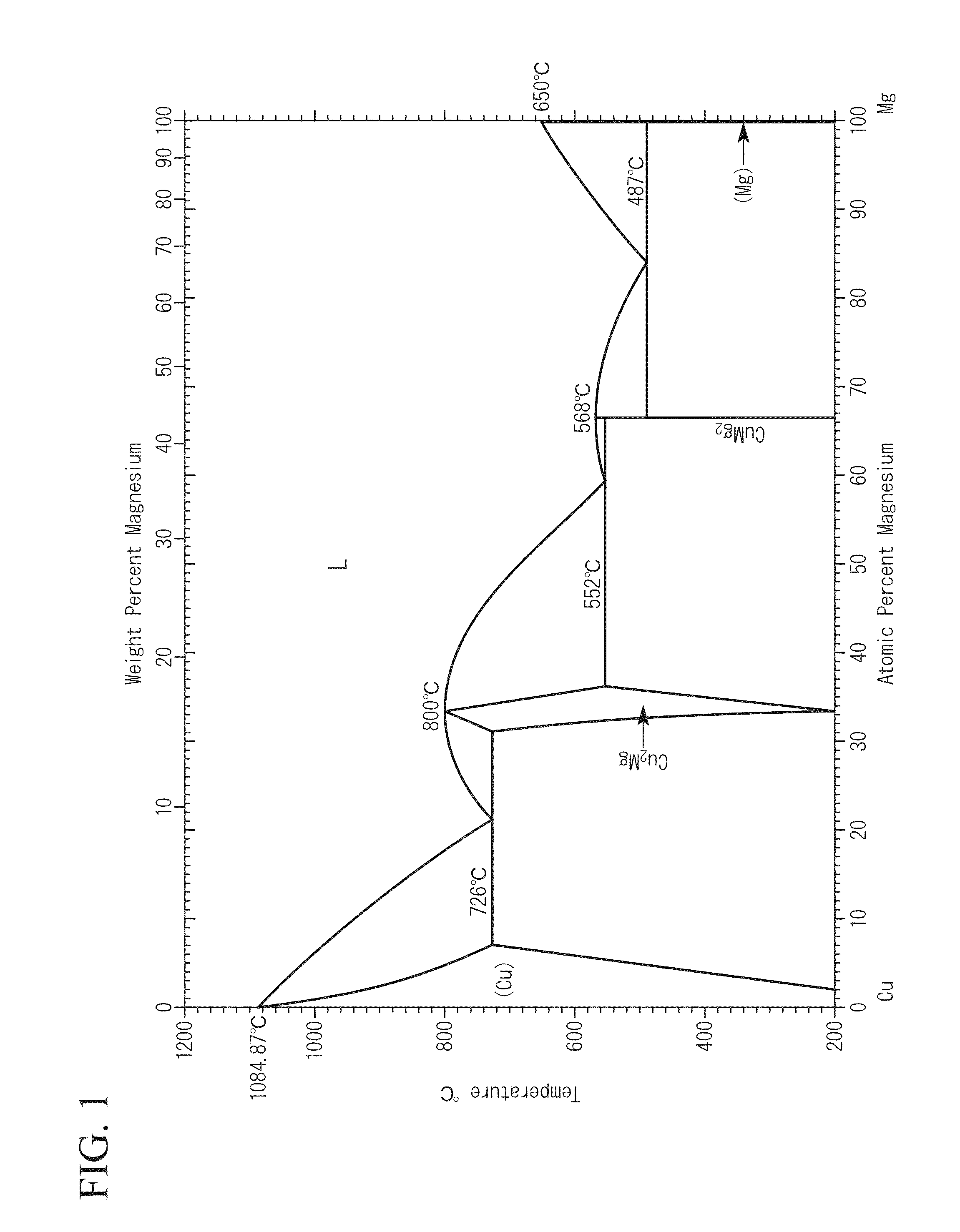

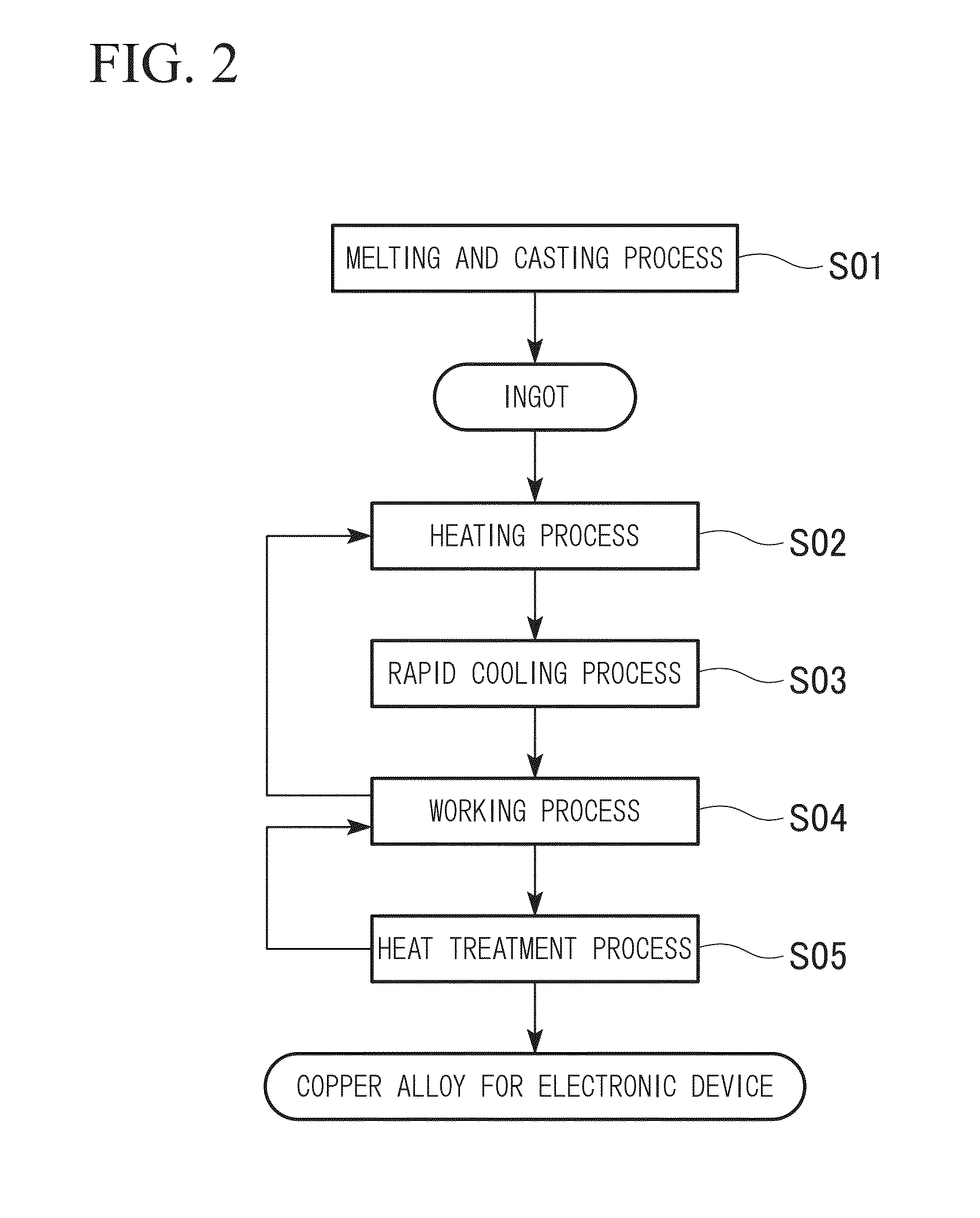

Copper alloy for electronic device, method for producing copper alloy for electronic device, and copper alloy rolled material for electronic device

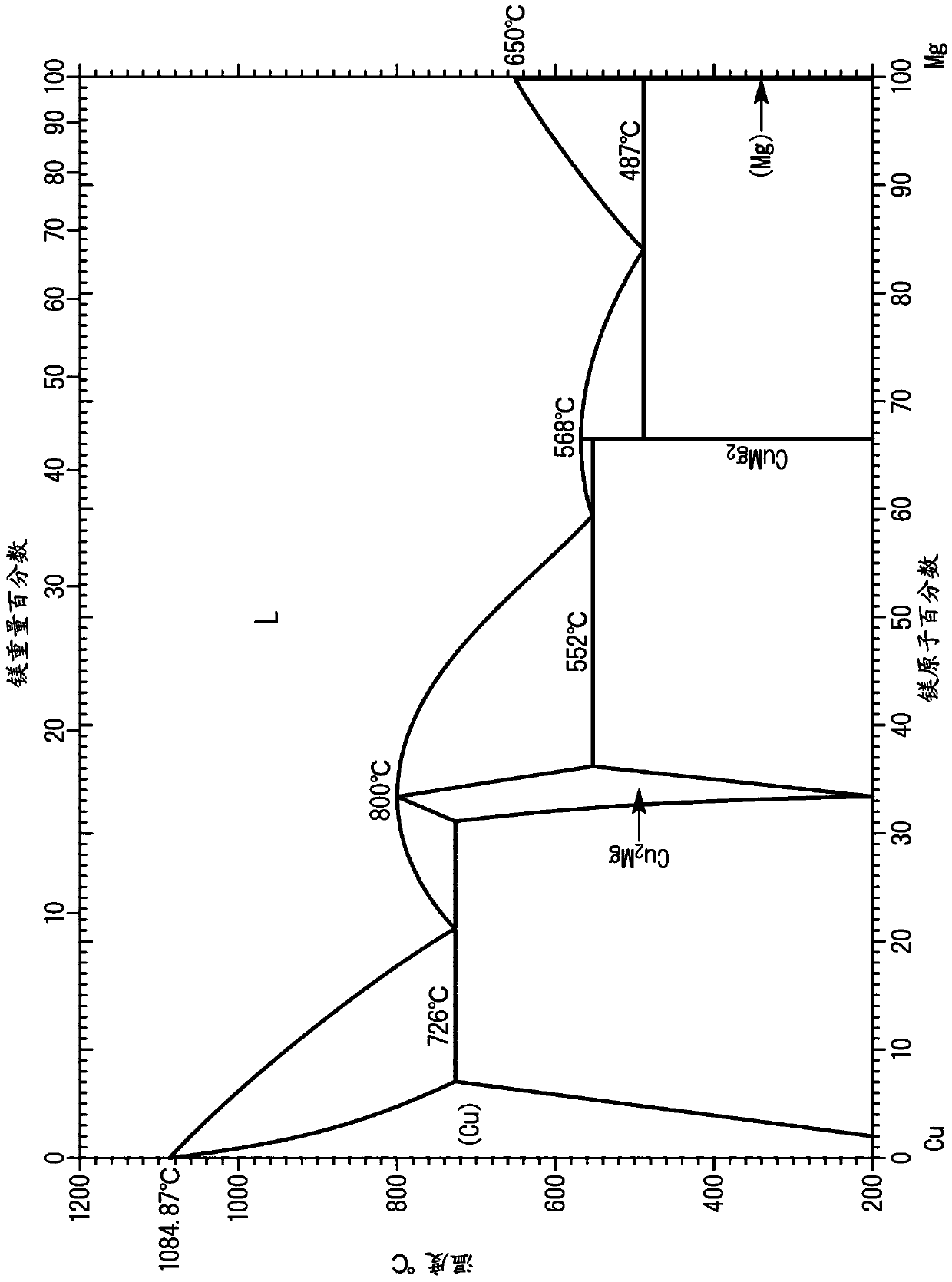

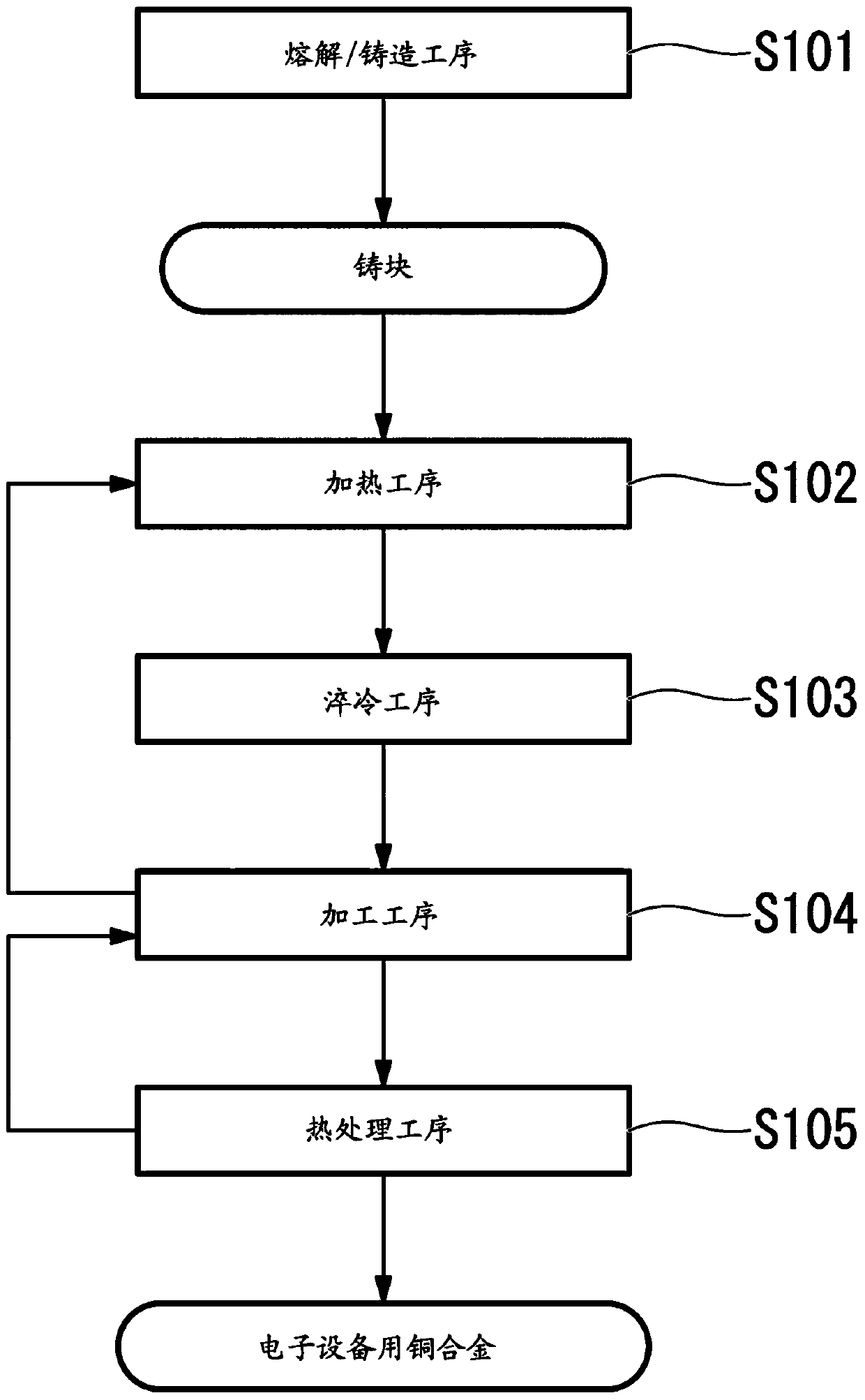

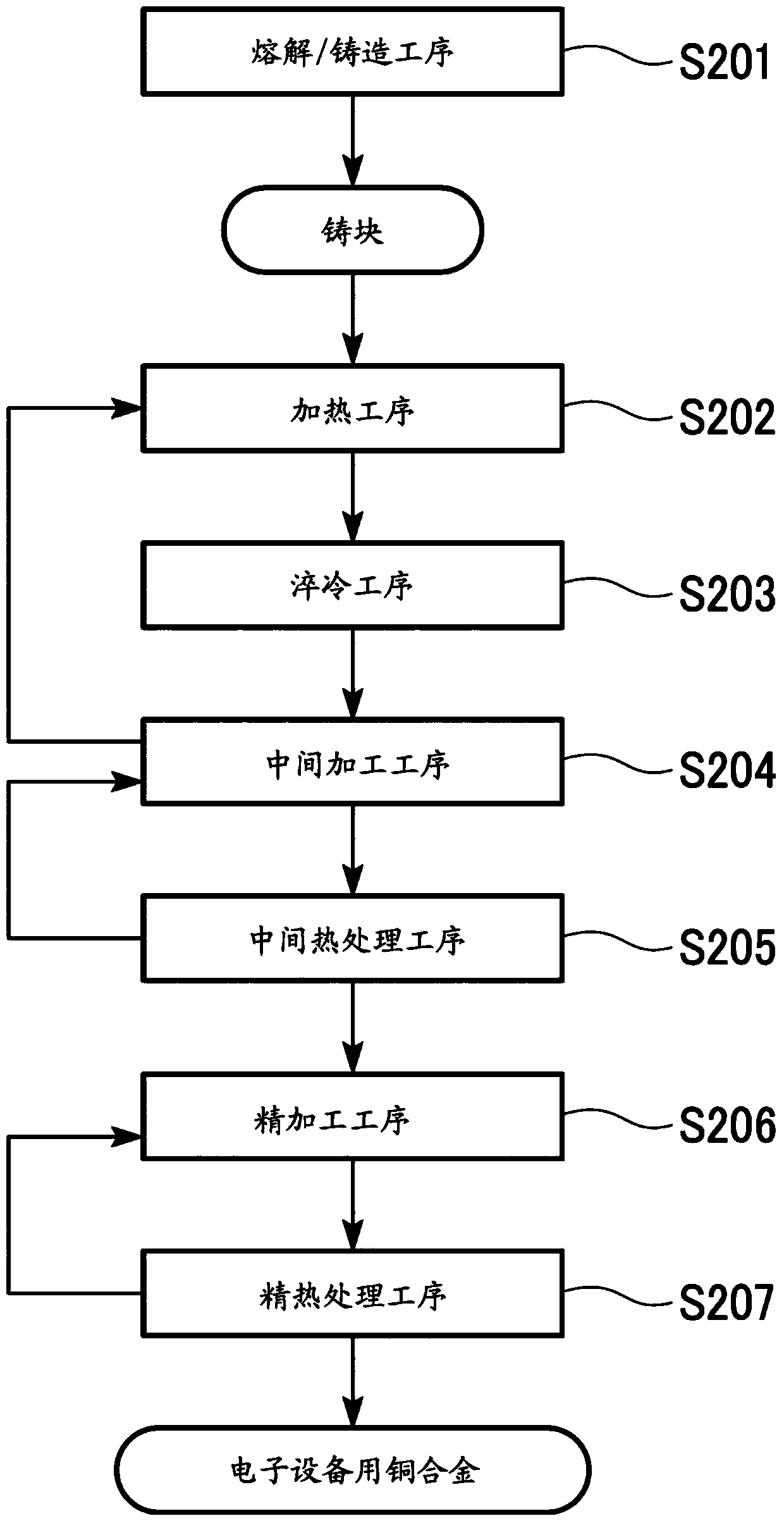

ActiveUS20130048162A1Low young 's modulusHigh proof stressConductive materialMetal/alloy conductorsTernary alloyBinary alloy

One aspect of this copper alloy for an electronic device is composed of a binary alloy of Cu and Mg which includes Mg at a content of 3.3 to 6.9 atomic %, with a remainder being Cu and inevitable impurities, and a conductivity σ (% IACS) is within the following range when the content of Mg is given as A atomic %,σ≦{1.7241 / (−0.0347×A2+0.6569×A+1.7)}×100.Another aspect of this copper alloy for an electronic device is composed of a ternary alloy of Cu, Mg, and Zn which includes Mg at a content of 3.3 to 6.9 atomic % and Zn at a content of 0.1 to 10 atomic %, with a remainder being Cu and inevitable impurities, and a conductivity σ (% IACS) is within the following range when the content of Mg is given as A atomic % and the content of Zn is given as B atomic %,σ≦{1.7241 / (X+Y+1.7)}×100X=−0.0347×A2+0.6569×A Y=−0.0041×B2+0.2503×B.

Owner:MITSUBISHI MATERIALS CORP

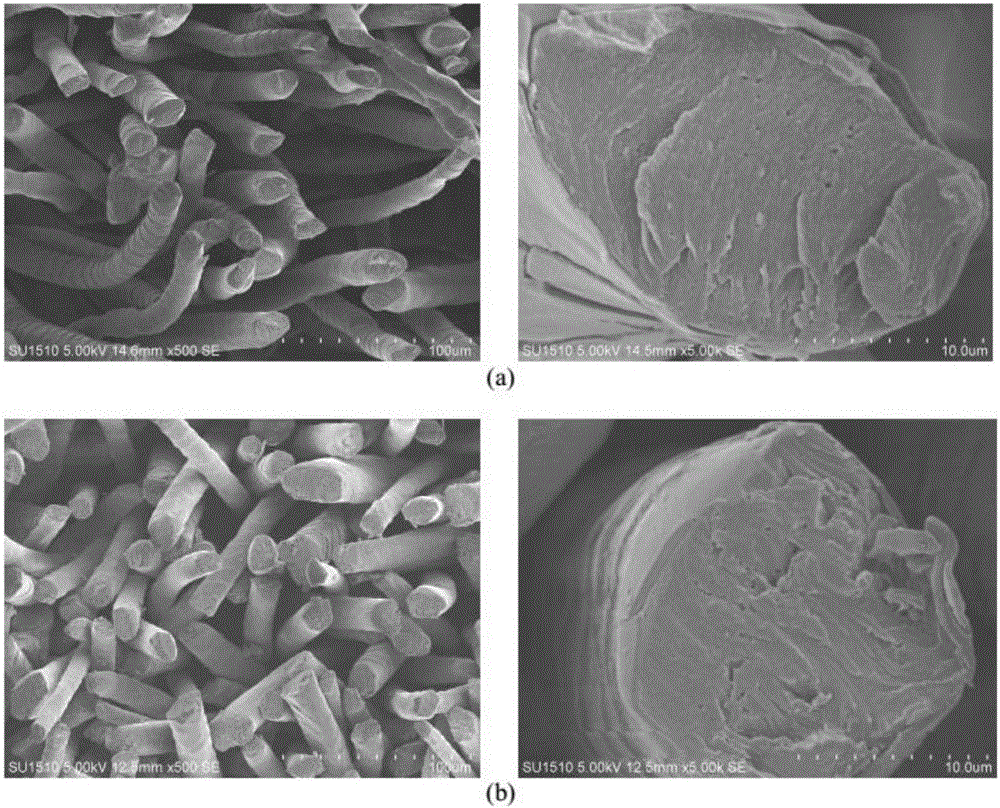

Method for preparing titanium based spherical powder with reduced particle size through gas atomization

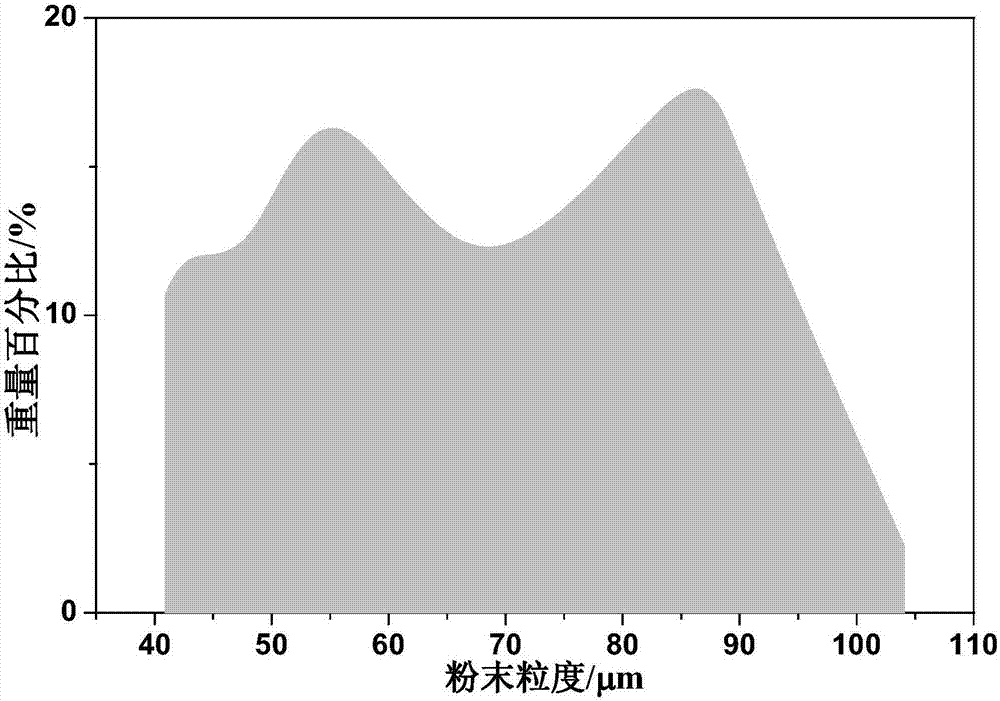

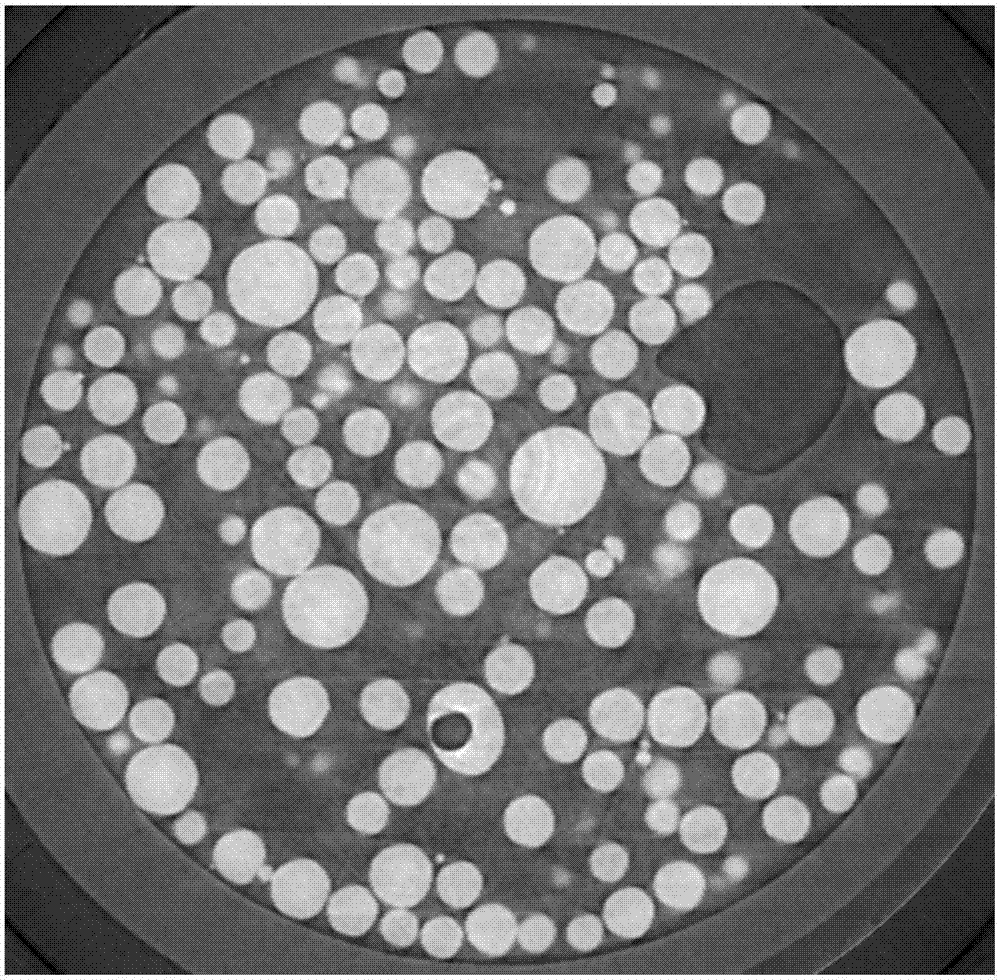

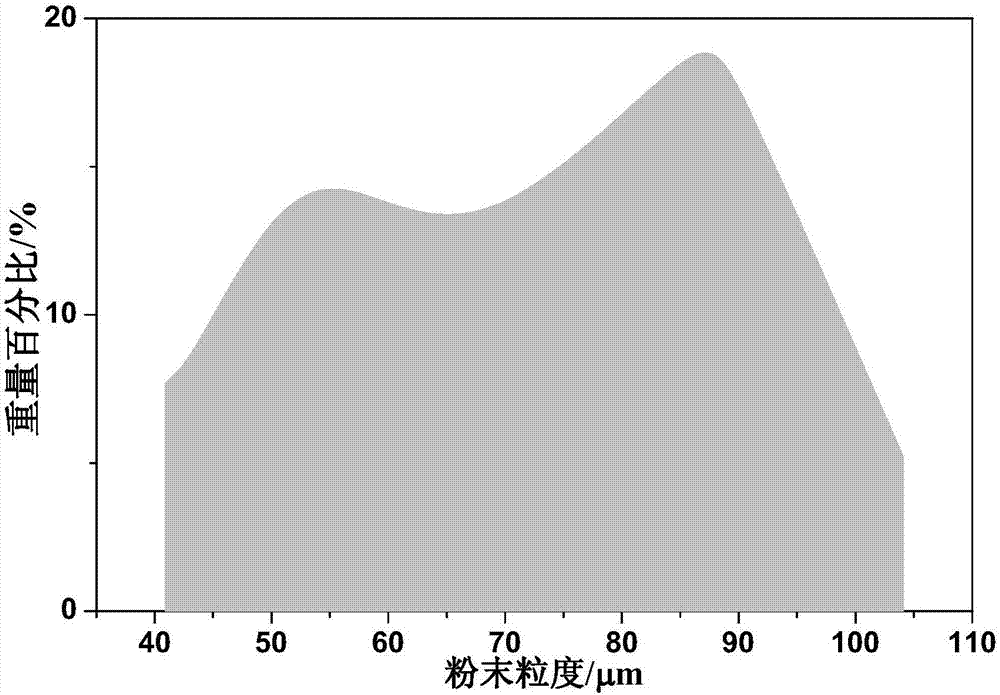

ActiveCN107498059AGood physical propertiesLarge particle sizeTransportation and packagingMetal-working apparatusCrucibleGlobular shaped

The invention discloses a method for preparing titanium based spherical powder with reduced particle size through gas atomization. The method comprises steps as follows: step one, a titanium based raw material and a tin material are placed in a smelting crucible, and the smelting crucible is put in a smelting chamber of a vacuum induction melting gas atomization equipment for vacuum induction melting; step two, after the titanium based raw material and the tin material are melted through vacuum induction melting, argon is introduced for protection, a graphite diversion pipe located at the bottom of the smelting crucible is heated, a melted liquid produced after melting of the titanium based raw material and the tin material freely falls into an atomization chamber through the graphite diversion pipe and subjected to vacuum induction melting gas atomization treatment, atomized powder is obtained, and titanium based spherical powder is obtained from a collecting tank. According to the method, tin is introduced into the titanium raw material or a titanium alloy raw material for reducing viscosity of the melted liquid obtained after smelting, so that the raw materials are easy to break during gas atomization, the particle size of the prepared powder becomes small, wherein the yield of the powder with the particle size smaller than 45 mu m in the titanium based spherical powder is not lower than 28%, pores in the powder are reduced, and the amount of hollow powder is reduced.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Semi-conductor packaging member and manufacturing method therefor

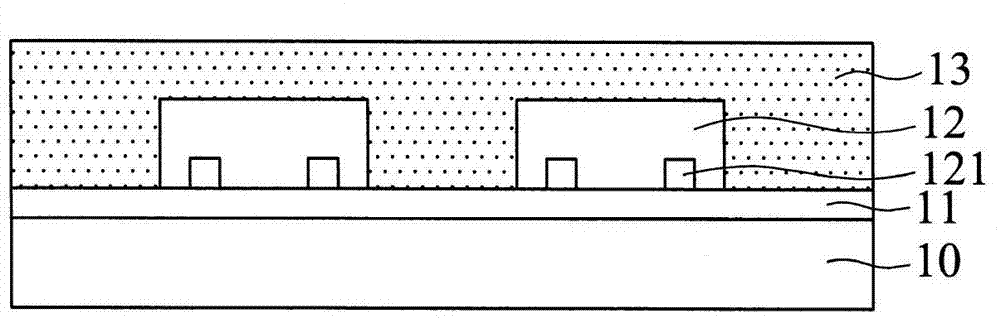

ActiveCN104517911ASmall coefficient of thermal expansionLow Young's modulusSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

A semi-conductor packaging member and a manufacturing method therefor are disclosed. The manufacturing method comprises the following steps: a first bearing member and a plurality of semi-conductor assemblies are provided, the semi-conductor assemblies have acting surfaces and a plurality of welding pads formed on the acting surfaces, the semi-conductor assemblies are arranged on the first bearing member through the acting surfaces, packaging rubber bodies are formed on the first bearing member to respectively wrap the semi-conductor assemblies, gaps are arranged among the packaging rubber bodies, and a buffer layer is formed on the first bearing member to wrap the packaging rubber bodies and fill the gaps; the first bearing member is removed and therefore the acting surfaces, the welding pads, the packaging rubber bodies and the buffering layer of the semi-conductor assemblies can be exposed. Thus the semi-conductor packaging member and the manufacturing method therefor can prevent the packaging rubber bodies from being warped, and the yield rate of the semi-conductor packaging member can be improved.

Owner:SILICONWARE PRECISION IND CO LTD

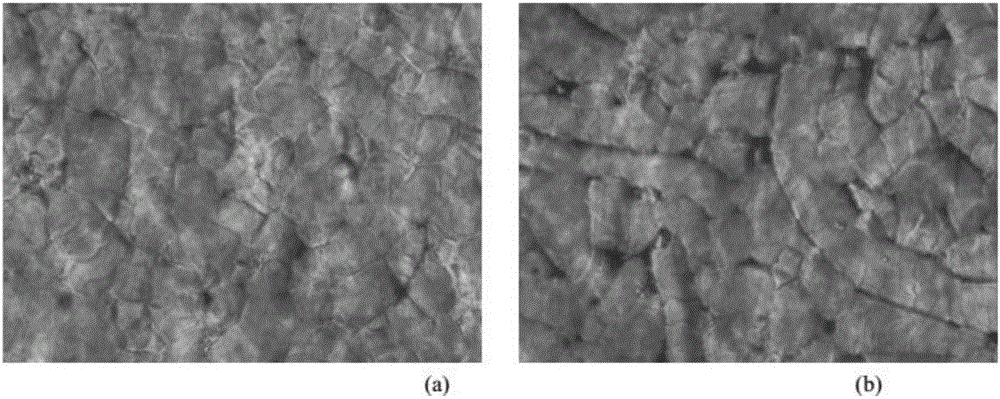

High-flexibility waste-wool-base biological plastic and preparation method thereof

The invention discloses a high-flexibility waste-wool-base biological plastic and a preparation method thereof, belonging to the technical field of biological plastics. Quick freeze-drying is adopted to maximally keep the gaps in the wool fibers so as to provide a favorable environment for the fusion of the wool powder and plasticizer in the next step, so that more ethanediol can enter the inside of the wool fibers, thereby enhancing the disulfide bond rupture rate of the wool keratin. The liquid nitrogen freeze-drying treatment effectively enhances the flexibility of the wool-base biological plastic, so that the wool-base biological plastic has higher extensibility and smaller Young's modulus. The wool-base biological plastic is degradable, has favorable heat insulation, sound insulation and electric insulation properties, and is applicable to buildings, interior decoration and other fields with higher requirements for electric insulation, heat insulation and sound insulation. Meanwhile, the keratin biological plastic has favorable biocompatibility, is biodegradable, and has the biomedical potential.

Owner:红蚂蚁装饰股份有限公司

Chemical resistant highly-transparent polyester film and method for preparing same

The invention discloses a chemical resistant and high transparent polyester alloy film and the preparation method. The polyester alloy film is prepared through polyethylene terephthalate (PET) and polyethylene terephthalate (PTT) by a twin-screw extruder with a slenderness ratio of 40 to 100; wherein the content of PPT is 30 percent to 80 percent, and the rest is PET. The peak temperature of the cold crystallization of the prepared film is ranged from 80 DEG C to 125 DEG C; the vitrification conversion temperature is 59 DEG C to 70 DEG C. The preparation method is characterized in that the dried PTT and PET slices are melted and extruded together through the extruder, so that an unoriented polyester alloy film is prepared. The invention has the advantages that: the prepared film has lower modulus of the Young, high transparency and excellent organic solvent blushing resistance; the film can keep a high transparency while soaking in various typical organic solvent; the total haze value is less than 2.5 percent, wherein the inner haze is less than 1.0 percent, and the haze value does not increase along with time.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Well cementing cement slurry and preparation method thereof

InactiveCN107628781AImprove the micro interfaceImprove deformation abilityDrilling compositionCement slurryFlexural strength

The invention discloses a well cementing cement slurry and a preparation method thereof, wherein the well cementing cement slurry comprises the following components in parts by weight: 100 parts of cement, 1-4 parts of an elastic toughness material, 1-4 parts of an expanding agent, 5-10 parts of a latex, 10-100 parts of a density regulator, 1-2 parts of an early strength agent, 2-8 parts of a filtration-reducing agent, 1-2 parts of a drag reducer, 1-10 parts of a retarder, and 20-80 parts of water. The prepared well cementing cement slurry not only has low elastic modulus, but also has high impact resistance and flexural strength as well as compressive strength.

Owner:四川弘晟石油工程技术服务有限公司

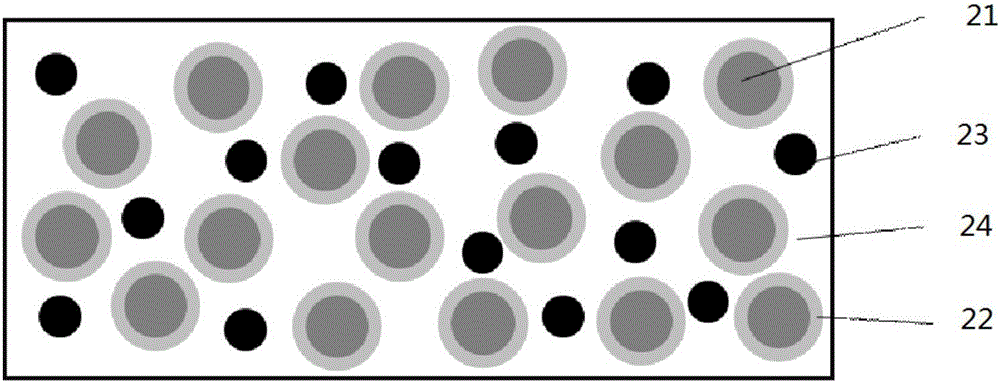

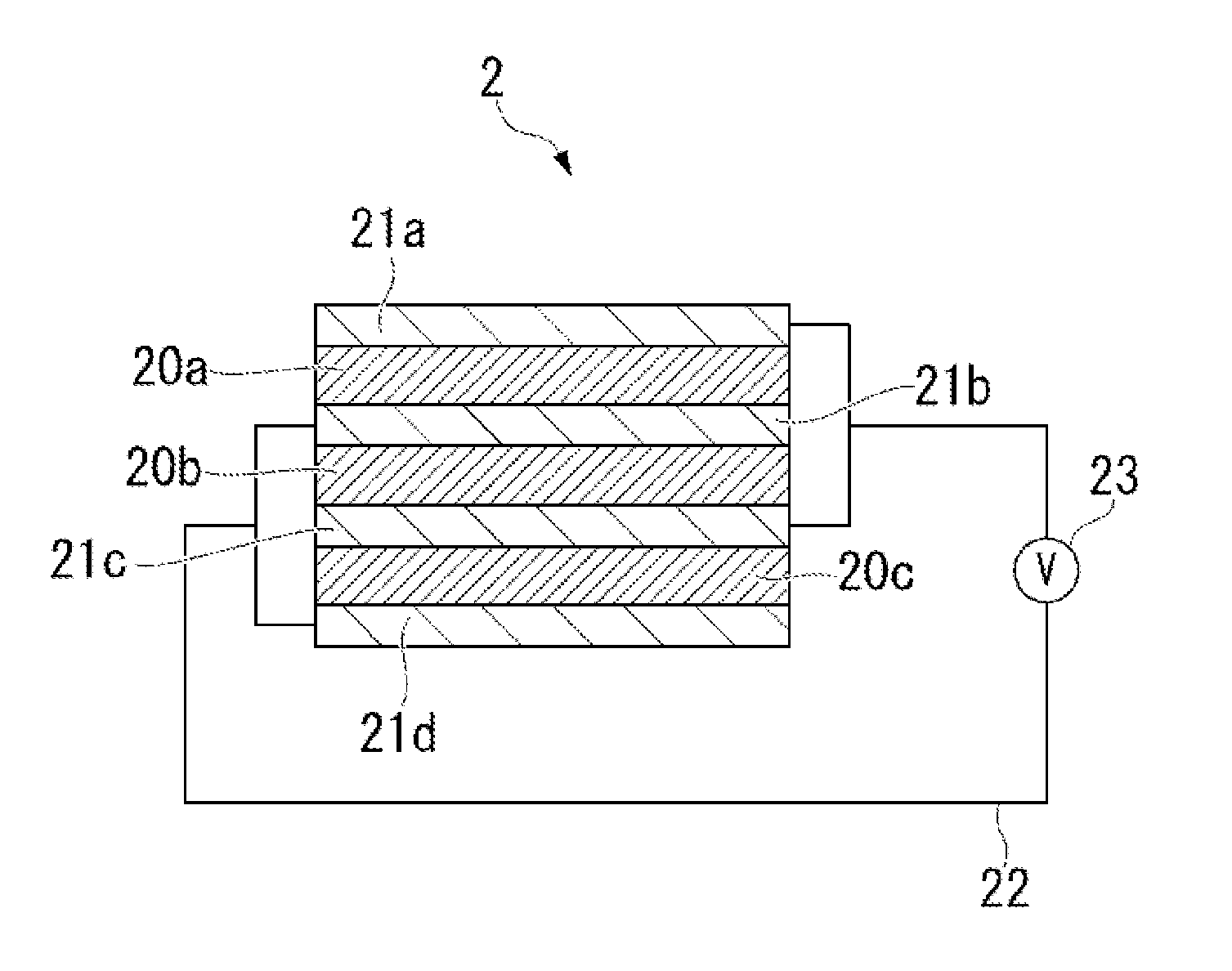

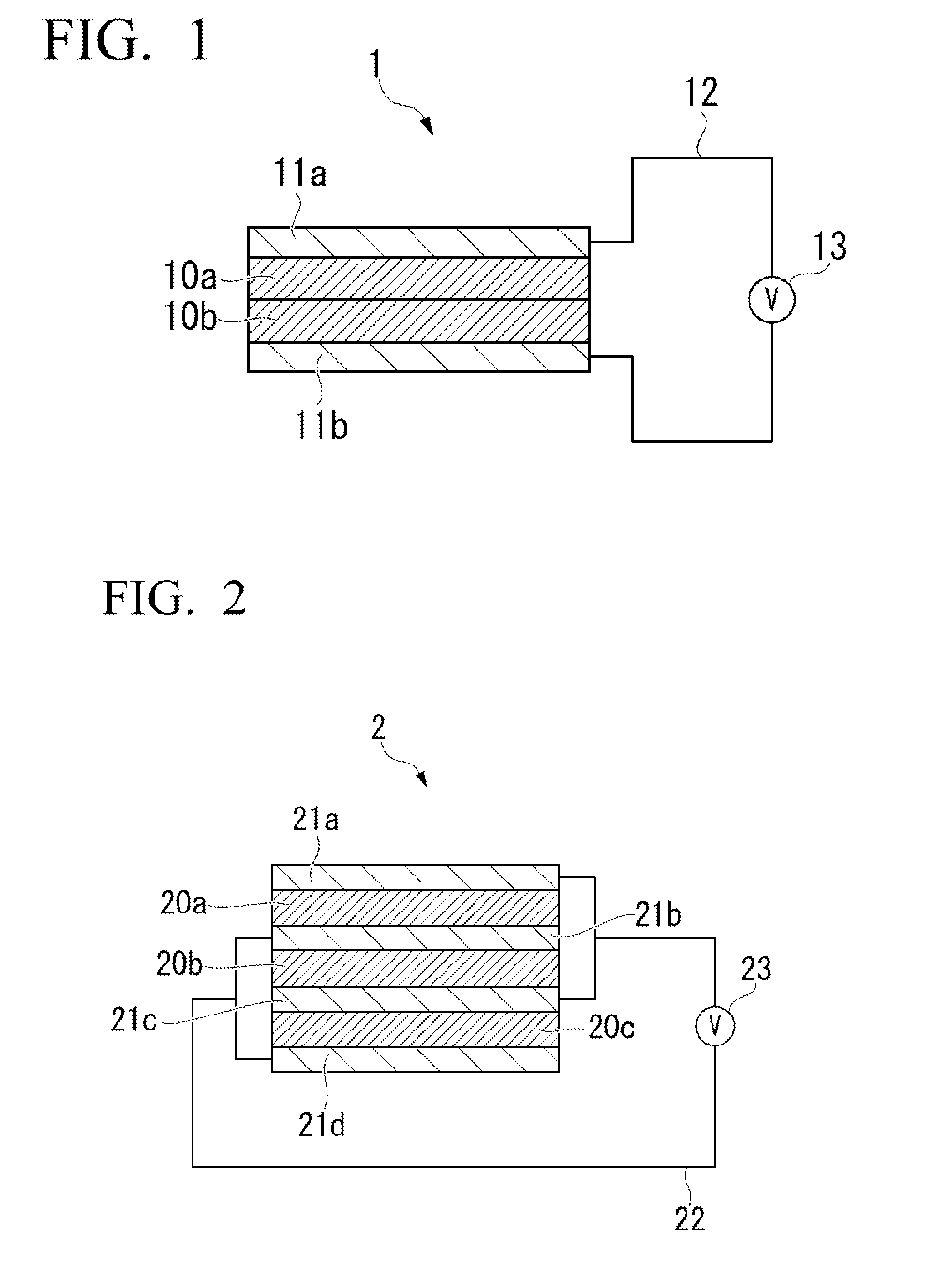

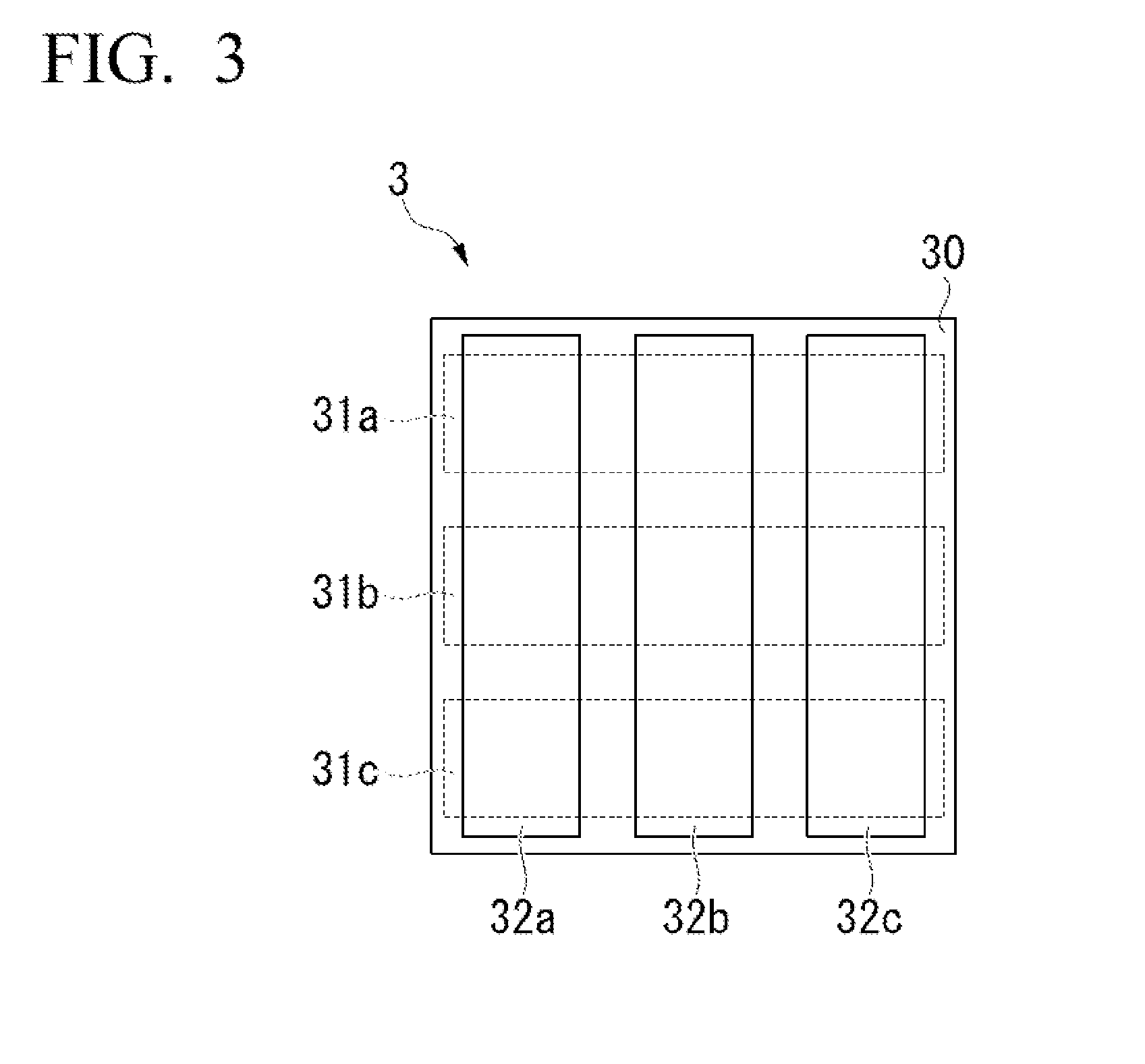

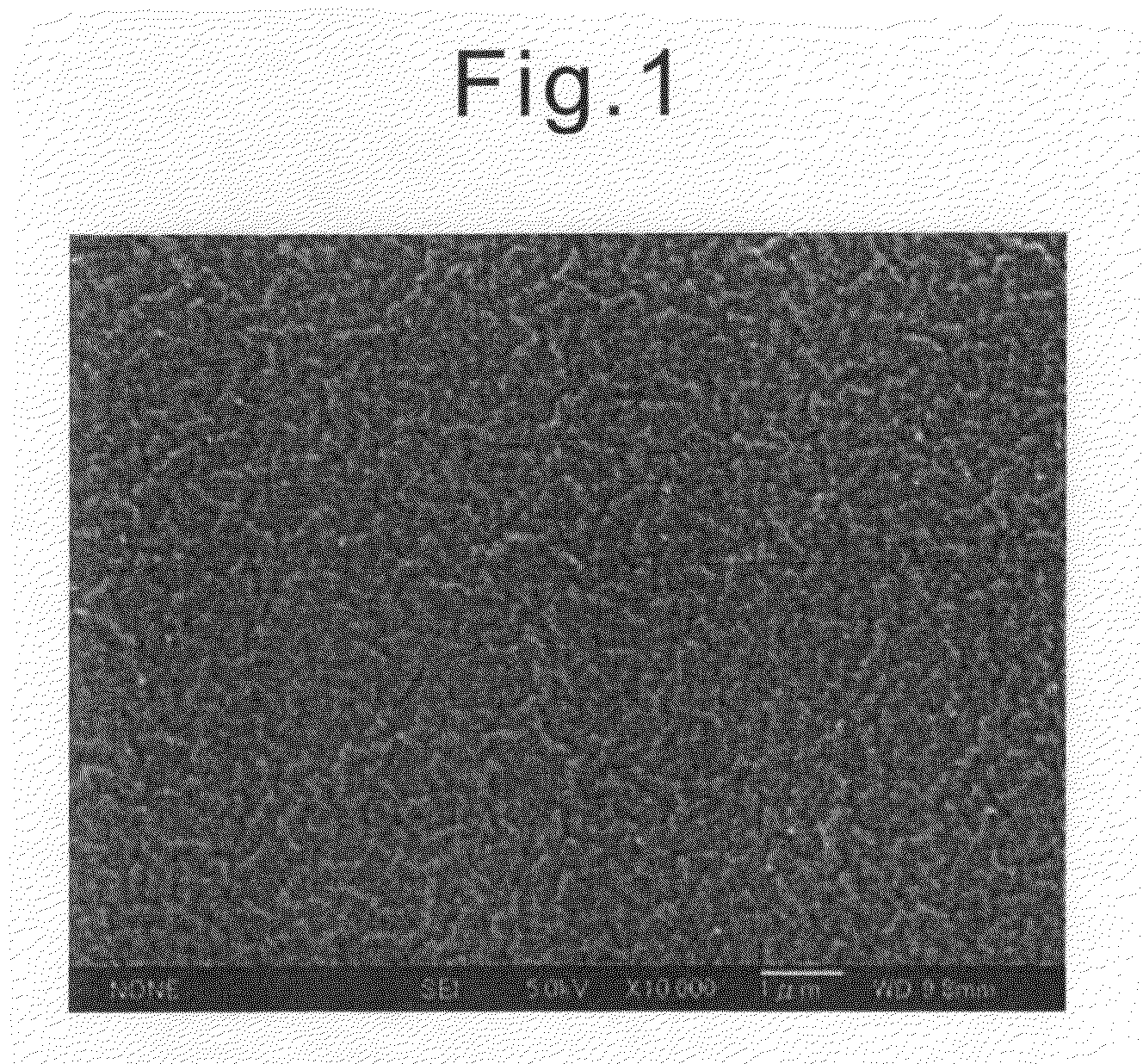

Dielectric material for polymeric actuator, and polymeric actuator using the same

InactiveUS20110018400A1High dielectric constantGuaranteed uptimePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device material selectionElectric fieldHigh dielectric permittivity

It is intended to provide a dielectric material for polymeric actuator, which has a high dielectric constant, low Young's modulus and excellent operation performance, which can be simply formed, and which has high production efficiency. It is also intended to provide a polymeric actuator which comprises the dielectric material and has excellent operation performance.The dielectric material for a polymeric actuator comprised of a moveable part of the polymeric actuator driven by an electric field comprising;a block copolymer (A) having a microphase-separated structure including a polymer block (B1) and a polymer block (B2) both of which are immiscible with each other,wherein a main compositional unit in both of the polymer block (B1) and the polymer block (B2) is a (meth)acrylic ester unit, the polymer block (B1) has an alpha-dispersion temperature of 70° C. or more, and the polymer block (B2) has an alpha-dispersion temperature of 25° C. or less. The polymeric actuator comprises the dielectric material provided between electrodes.

Owner:KURARAY CO LTD +1

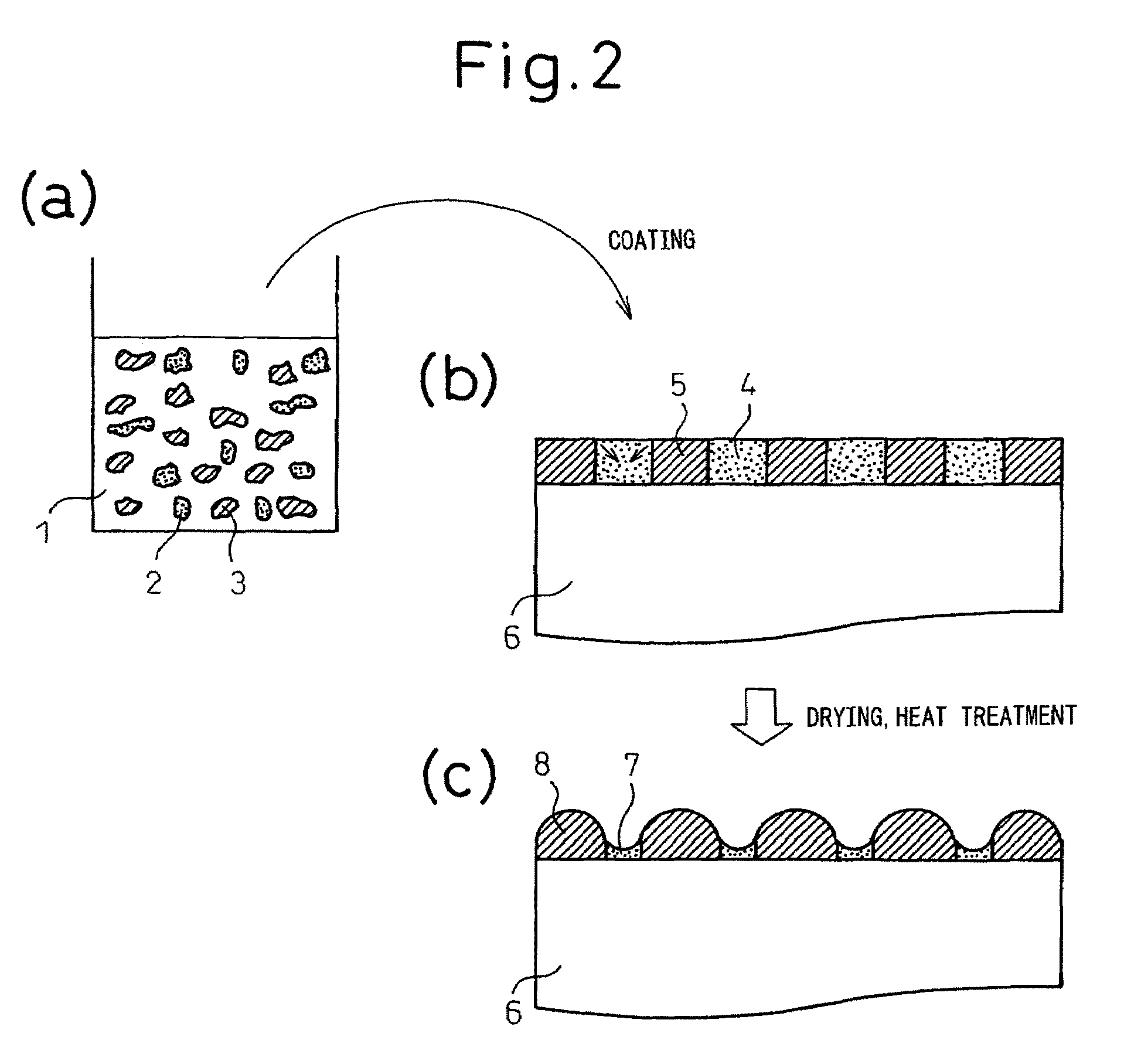

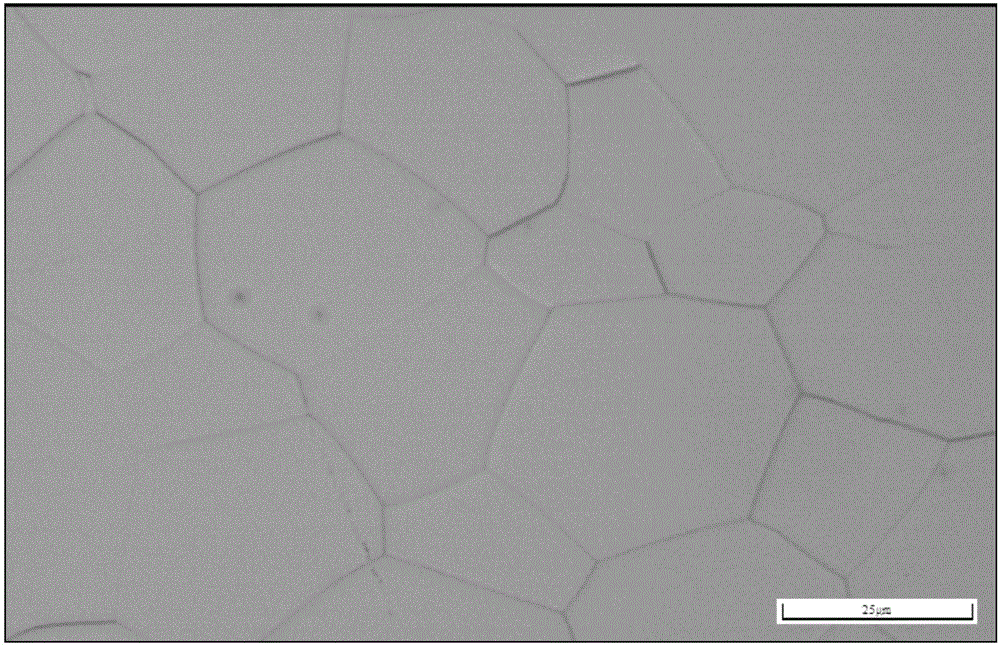

Coating solution for forming flat-surface insulating film, flat-surface insulating film-coated substrate, and production method of a flat-surface insulating film-coated substrate

InactiveUS7951458B2Low Young 's modulusHigh surface flatnessGroup 4/14 element organic compoundsPlastic/resin/waxes insulatorsSolubilityOrganic solvent

A coating solution for forming a flat-surface insulating film, which is a coating solution obtained by dissolving a poly(diorgano)siloxane A having a mass average molecular weight of 900 to 10,000 and a metal alkoxide B in an organic solvent C and further adding water, wherein the molar ratio A / B of the poly(diorgano)siloxane A to 1 mol of the metal alkoxide B is from 0.05 to 1.5, the organic solvent C has a hydroxyl group, the solubility of water in 100 g of the organic solvent C is from 3 to 20 g, and the molar ratio C / A of the organic solvent C to 1 mol of the poly(diorgano)siloxane A is from 0.05 to 100. This coating solution for forming a flat-surface insulating film ensures that an organic modified silicate composed of a poly(diorgano)siloxane and a metal alkoxide can be formed as a thick film having 1 μm or more and can be an organic modified silicate insulating film causing no irregularities due to phase separation and having a low Young's modulus and flexibility high enough to follow the deformation of a substrate board, as well as high film surface flatness allowing for mounting of microcomponents of an electronic device or the like.

Owner:NIPPON STEEL CHEMICAL CO LTD

Low-modulus medical titanium alloy and preparation method thereof

The invention discloses low-modulus medical titanium alloy comprising Nb with the molar concentration of 10-25%, Cr with the molar concentration of 1-8%, Sn with the molar concentration of 0-2% and the balance Ti. The invention further provides a preparation method of the low-modulus medical titanium alloy. The method includes the steps that under the argon protection atmosphere condition, a cast ingot is subjected to homogenizing annealing; solution treatment is conducted under the vacuum condition, and then the cast ingot is placed in water for quenching; cold machining forming is conducted at room temperature; a sample obtained after cold machining forming is re-crystallized and annealed under the vacuum condition, wherein re-crystallization and annealing temperature is 700-900 DEG C, time lasts for 0.5-2 h and a cooling mode is water quenching or ice water quenching; the low-modulus medical titanium alloy is obtained. The titanium alloy has good cold machining performance, and is high in strength, low in Young modulus, good in corrosion resistance and biocompatibility and suitable for the medical fields like bone implantation.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Elastic anti-channeling cement slurry and preparation method thereof

InactiveCN105238376AImprove performanceReduce water lossDrilling compositionWell cementingYoung's modulus

The invention relates to the technical field of cement slurry for well cementation, and discloses an elastic anti-channeling cement slurry and a preparation method thereof. The elastic anti-channeling cement slurry is composed of the following raw materials: cement, elastic materials, coarse silicon sand, silicon powder, fine silicon sand, an expanding agent, additives, and water. The provided elastic anti-channeling cement slurry has the advantages of stable property, low water loss, and strong anti-gas-channeling and anti-water-invasion performances, is capable of effectively inhibiting the high pressure oil gas layer and active water layer so as to prevent gas and water channeling in reservoir, and solves the technical problem that the well cementation is very difficult in the reservoir where the water and gas channeling is severe. At the same time, the obtained elastic anti-channeling cement slurry also has the advantages of low Young modulus, high tensile strength, large cementing strength, and slightly expanded volume, is capable of improving the quality of cementing on the cement-formation interface, meets the requirements of multiple large-scale fracturing exploitations, and obtains high output of oil and gas flow in the reservoir, where oil, gas, and water are active.

Owner:CNPC XIBU DRILLING ENG

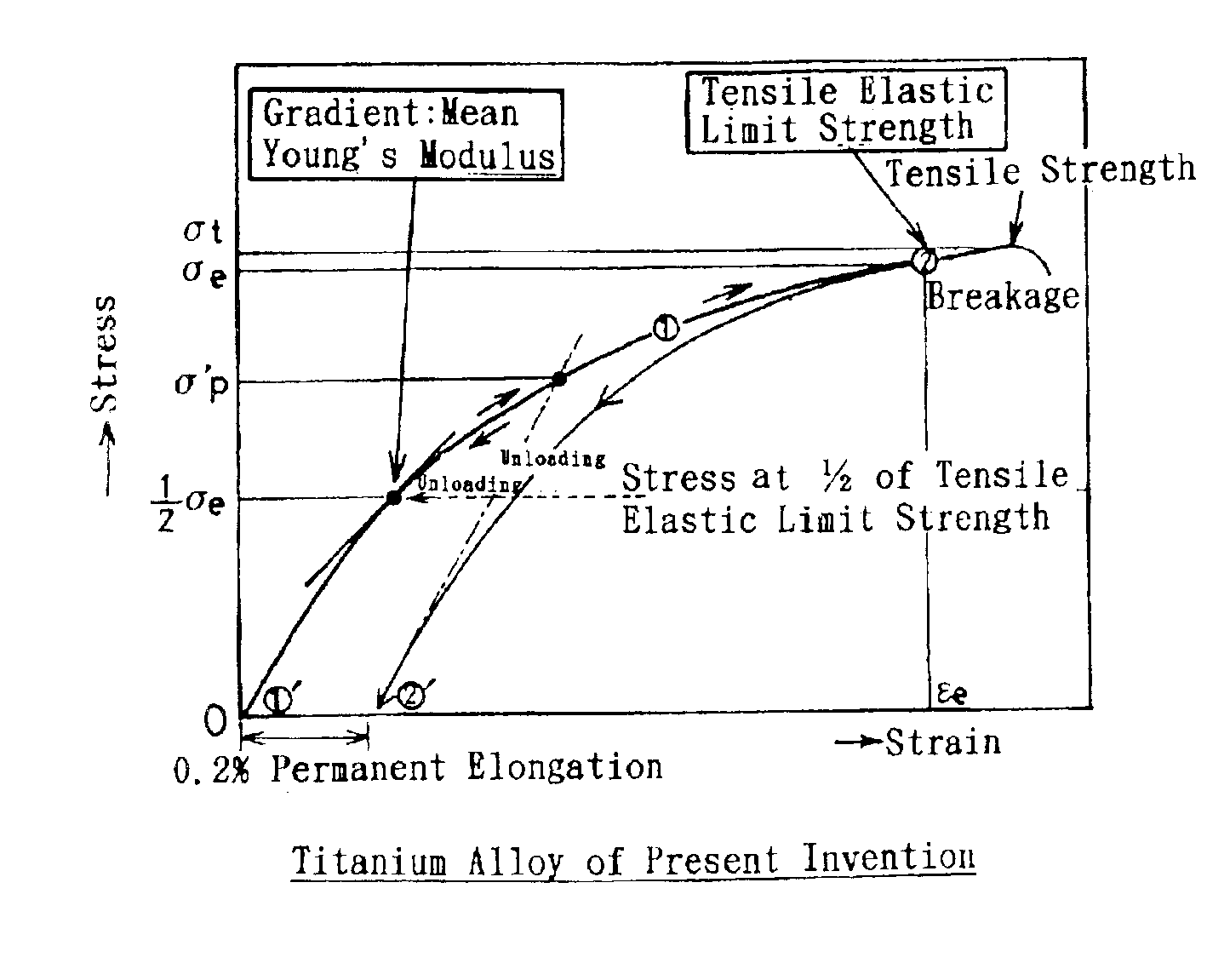

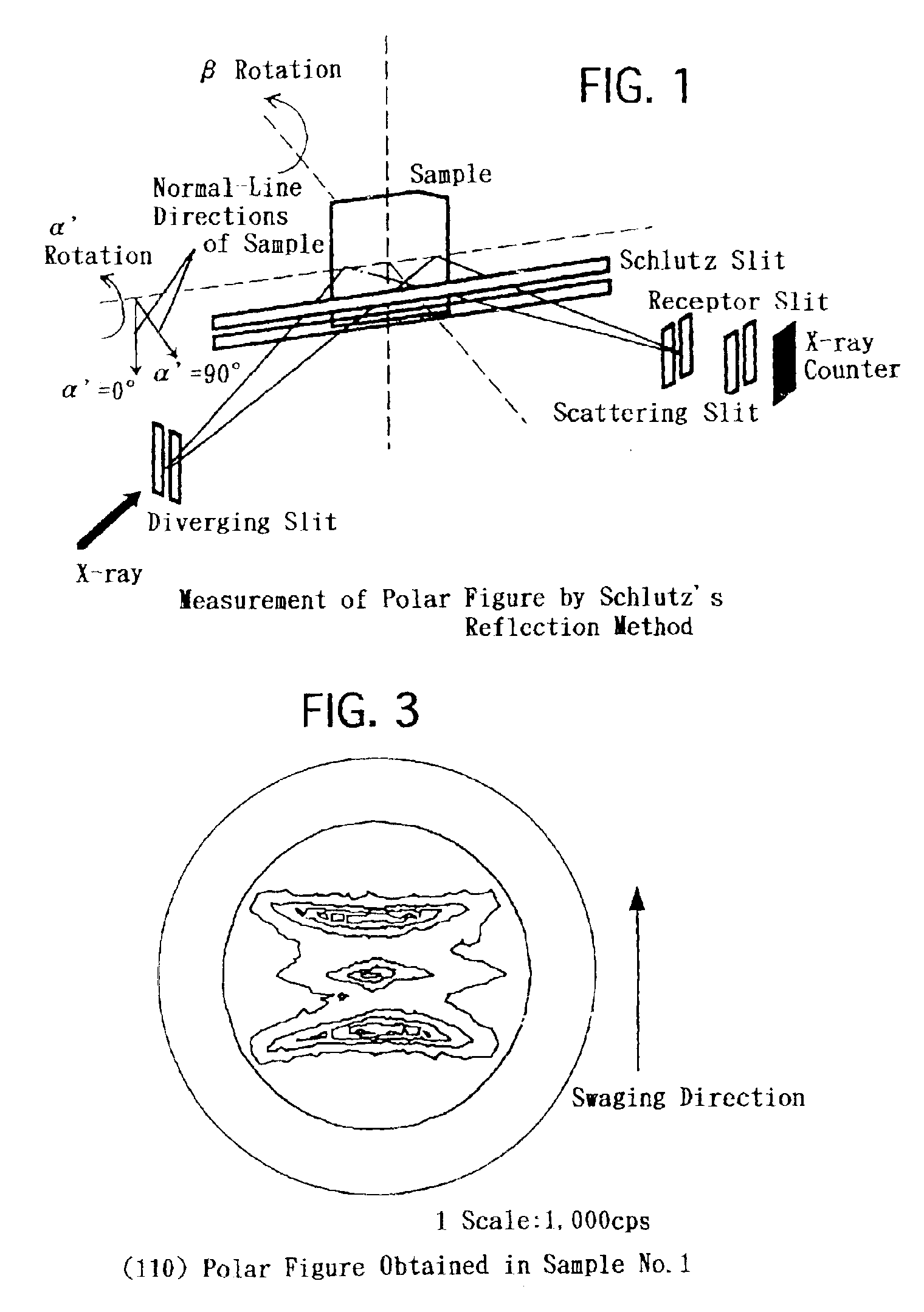

Titanium alloy member

A titanium alloy member is characterized in that it comprise 40% by weight or more titanium (Ti), a IVa group element and / or a Va group element other than the titanium, wherein a summed amount including the IVa group element and / or the Va group element as well as the titanium is 90% by weight or more, and one or more members made in an amount of from 0.2 to 2.0% by weight and selected from an interstitial element group consisting of oxygen, nitrogen and carbon, and that its basic structure is a body-centered tetragonal crystal or a body-centered cubic crystal in which a ratio (c / a) of a distance between atoms on the c-axis with respect to a distance between atoms on the a-axis falls in a range of from 0.9 to 1.1. This titanium alloy member has such working properties that conventional titanium alloys do not have, is flexible, exhibits a high strength, and can be utilized in a variety of products.

Owner:KK TOYOTA CHUO KENKYUSHO

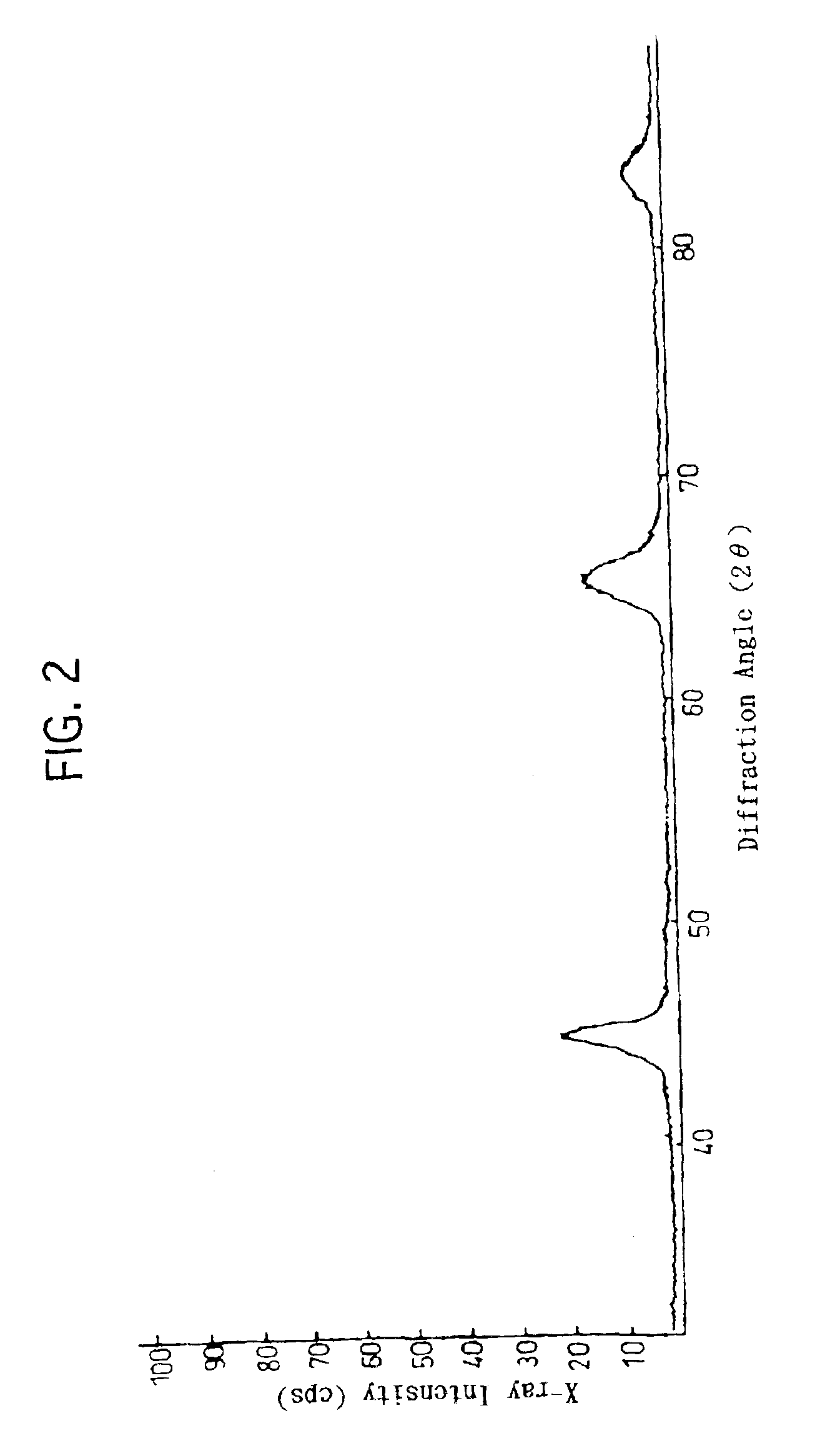

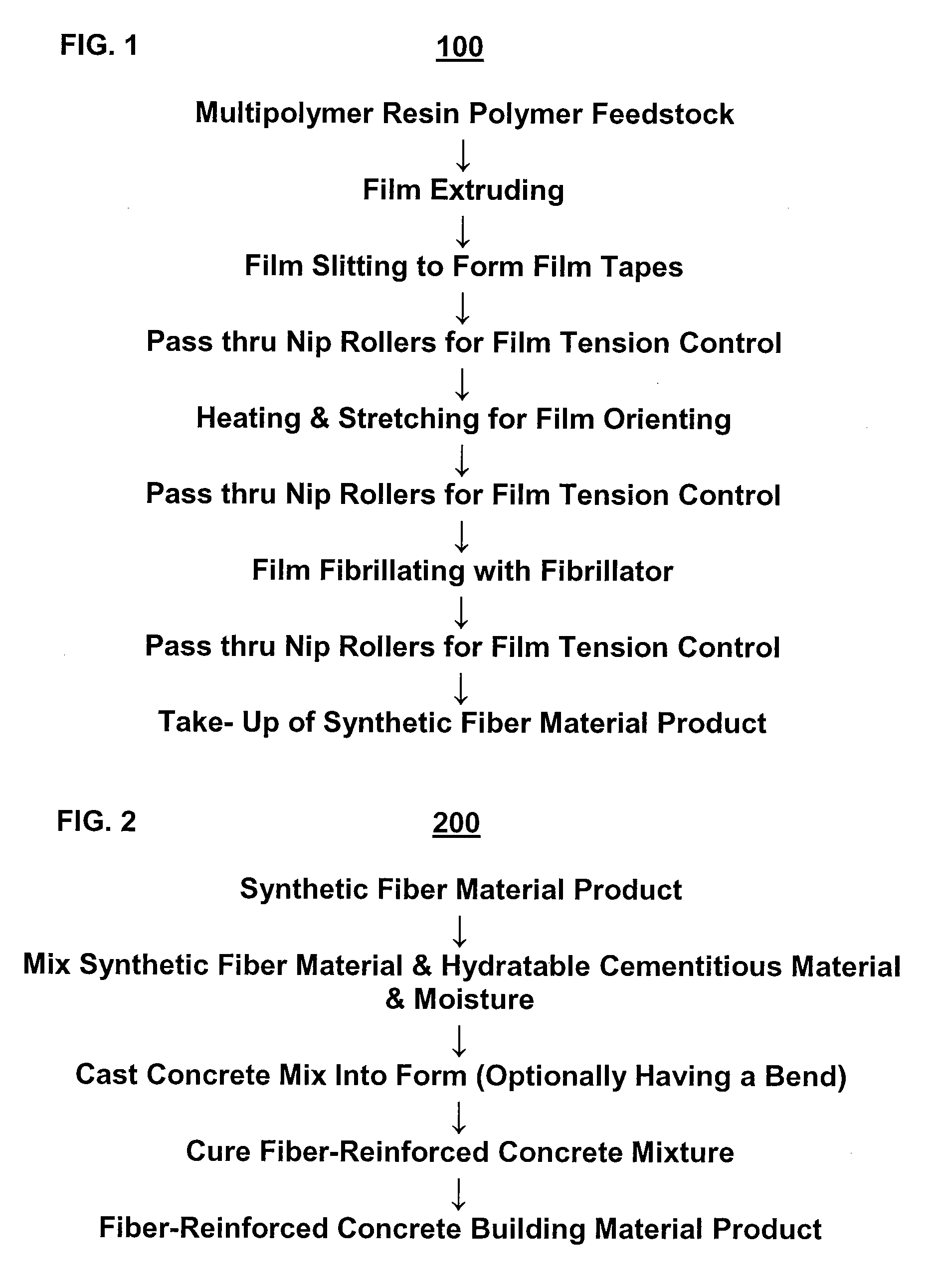

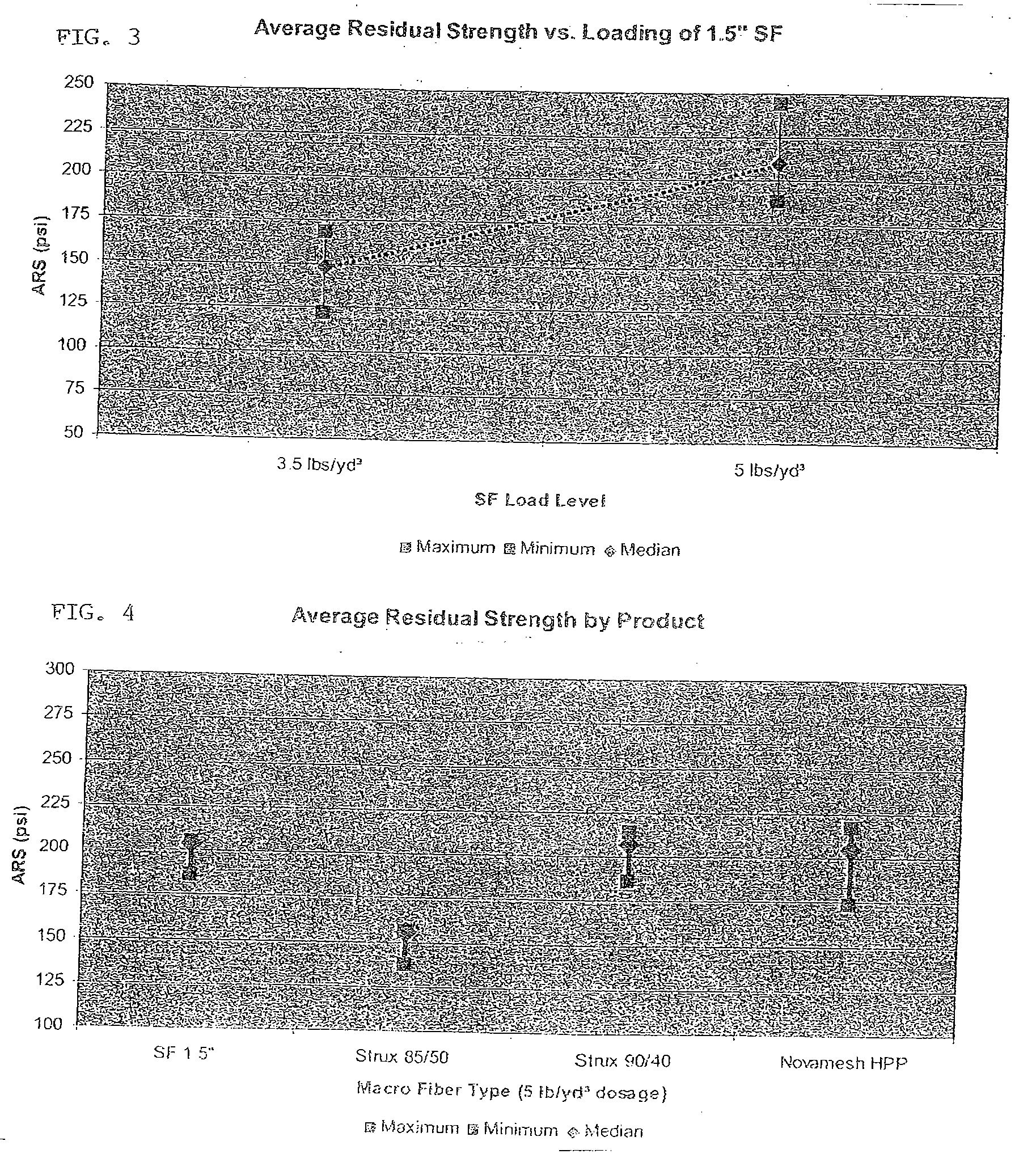

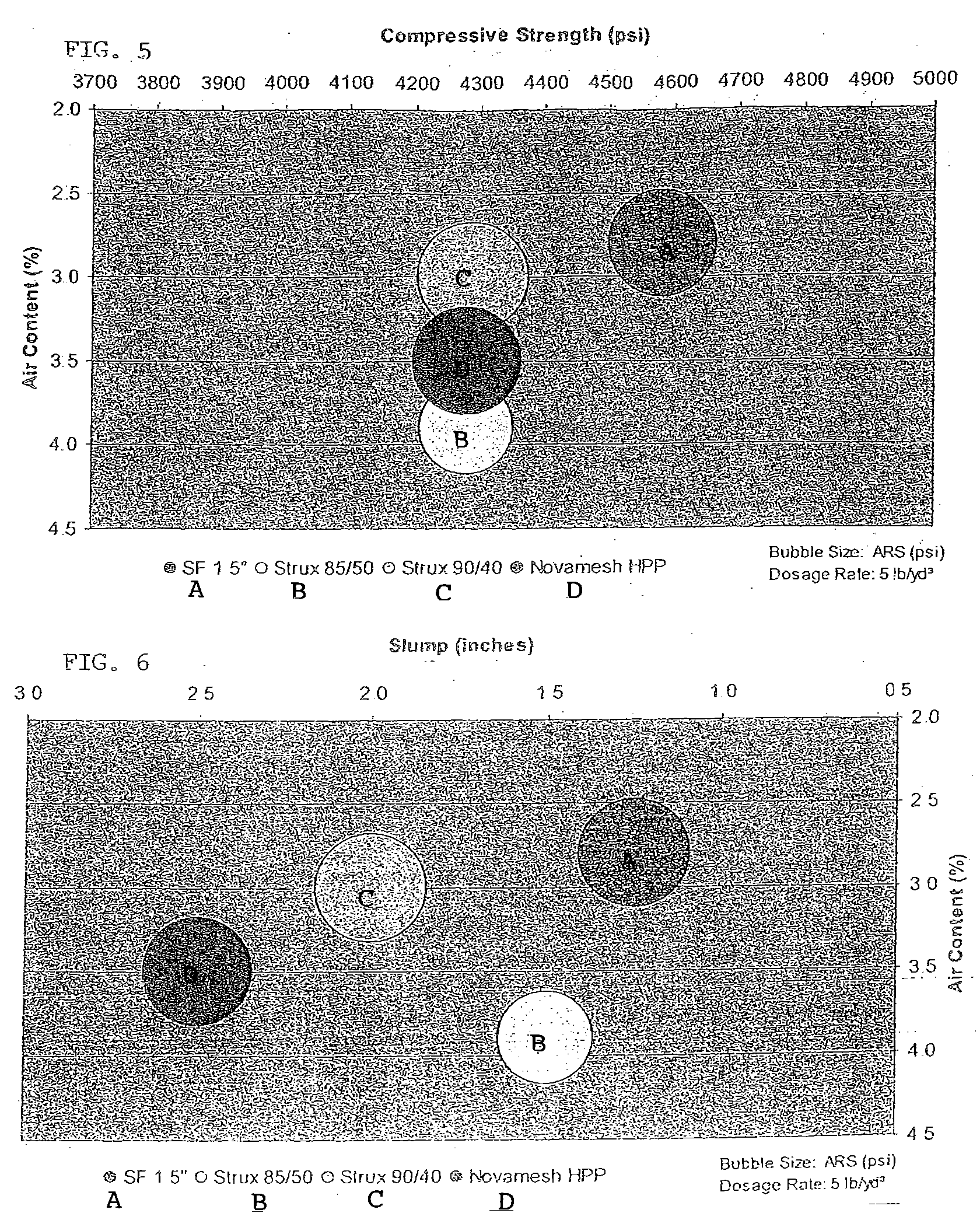

Profiled Structural Concrete Fiber Material And Building Products Including Same, And Methods

InactiveUS20060276088A1Good finishabilityHigh strengthLayered productsFilament/thread formingBuilding productYoung's modulus

A synthetic fiber material made with multipolymer blends which have been fibrillated in oriented film form is provided that is useful as a secondary reinforcement material, which has a low Young's modulus for a more uniform distribution throughout a cementitious mixture incorporating the fiber material, and imparts good finishability, strength, and improved plastic shrinkage crack control, in addition to providing improved conformability within cementitious forms, especially within forms comprising bends equal to or greater than about 45 degrees. Improved cementitious compositions and fiber-reinforced concrete building products incorporating the synthetic fiber materials are also provided, as well as methods for making the synthetic fiber materials.

Owner:FABPRO ORIENTED POLYMERS L L C

Copper alloy for electronic devices, method for producing copper alloy for electronic devices, copper alloy plastic working material for electronic devices, and component for electronic devices

ActiveCN103502487ALow Young's modulusExcellent stress relaxation resistanceConductive materialMetal/alloy conductorsElectric devicesElectric equipment

One embodiment of this copper alloy contains Mg in an amount within the range from 3.3% by atom (inclusive) to 6.9% by atom (exclusive) and Cr and / or Zr respectively in an amount within the range from 0.001% by atom (inclusive) to 0.15% by atom (inclusive), with the balance made up of Cu and unavoidable impurities. When the Mg concentration is represented by A% by atom, the electrical conductivity s (% IACS) satisfies the following formula (1). s = {1.7241 / (-0.0347 × A2 + 0.6569 × A + 1.7)} × 100 (1) One embodiment of this method for producing a copper alloy comprises: a step wherein a copper material having the composition of the above-described copper alloy is heated to a temperature within the range from 300°C to 900°C (inclusive); a step wherein the heated copper material is quenched to 200°C or less at a cooling rate of 200°C / min or more; and a step wherein the quenched copper material is worked.

Owner:MITSUBISHI MATERIALS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com