Elastic well cementation cement paste and preparation method thereof

A technology of cementing slurry and elasticity, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., and can solve problems such as high brittleness, low elasticity of cement slurry, and channeling of oil and gas layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

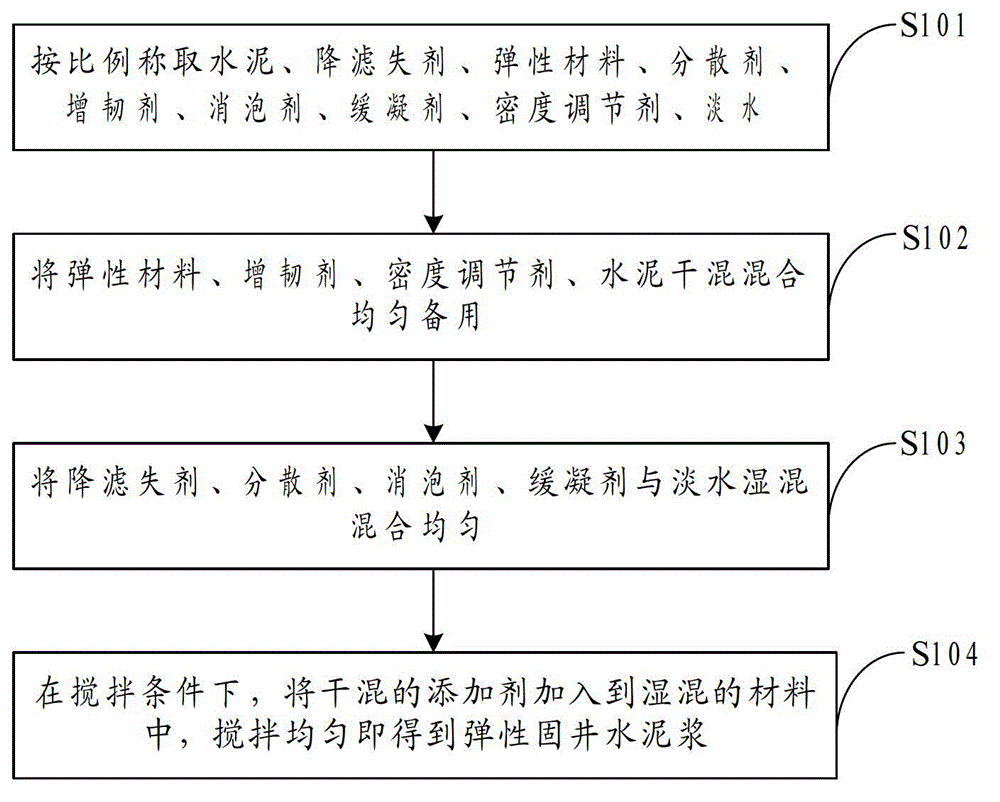

[0017] The preparation method comprises the following steps:

[0018] Step S101, weighing cement, fluid loss reducer, elastic material, dispersant, toughening agent, defoamer, retarder, density regulator, fresh water in proportion;

[0019] Step S102, dry mixing the elastic material, the toughening agent, the density regulator, and the cement for later use;

[0020] Step S103, wet mixing the fluid loss control agent, dispersant, defoamer, retarder and fresh water;

[0021] Step S104, under stirring conditions, add the dry-mixed additive obtained in step S102 to the wet-mixed material obtained in step S103, and stir evenly to obtain elastic cementing cement slurry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com