Patents

Literature

64results about How to "Reduce workover costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

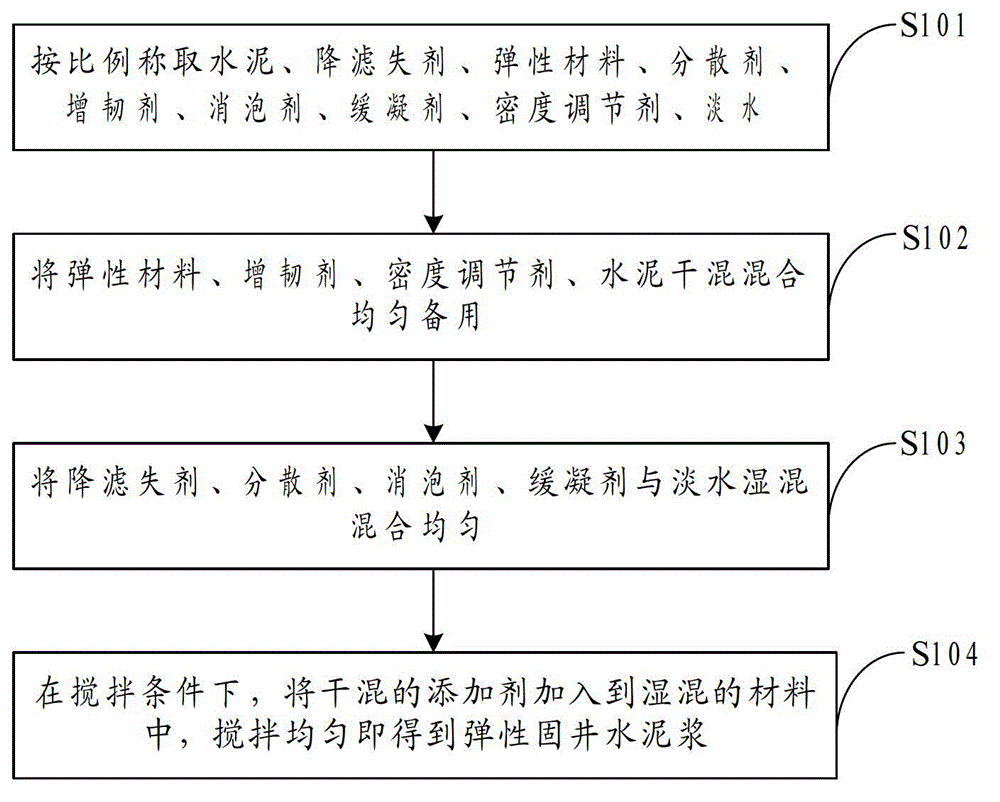

Elastic well cementation cement paste and preparation method thereof

InactiveCN103146368AIncrease elasticityImprove impact resistanceDrilling compositionFresh waterYoung's modulus

The invention discloses an elastic well cementation cement paste and a preparation method thereof. The elastic well cementation cement paste comprises the following components in percentage by weight based on 100% of the cement weight: 1-2% of a fluid loss agent, 4-12% of an elastic material, 0.5-1.5% of a dispersing agent, 0.5-2% of a toughening agent, 0.4-1% of a defoaming agent, 0.5-2% of a retarder, 0-50% of a density regulator and 33-50% of fresh water. The method for preparing the elastic well cementation cement paste comprises the following steps of: firstly, uniformly mixing the elastic material, the toughening agent, the density regulator and cement in a dry manner for later use; then uniformly mixing the fluid loss agent, the dispersing agent, the defoaming agent, the retarder and the fresh water in a wet manner; and finally, under a stirring condition, adding an additive obtained after dry mixing into a material obtained after wet mixing, and uniformly stirring to obtain the elastic well cementation cement paste. The elastic well cementation cement paste increases the elasticity of cement stone and reduces the Young modulus, and a cement ring has high impact resistance and toughness, so that the damages of downhole operation to the cement ring are reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

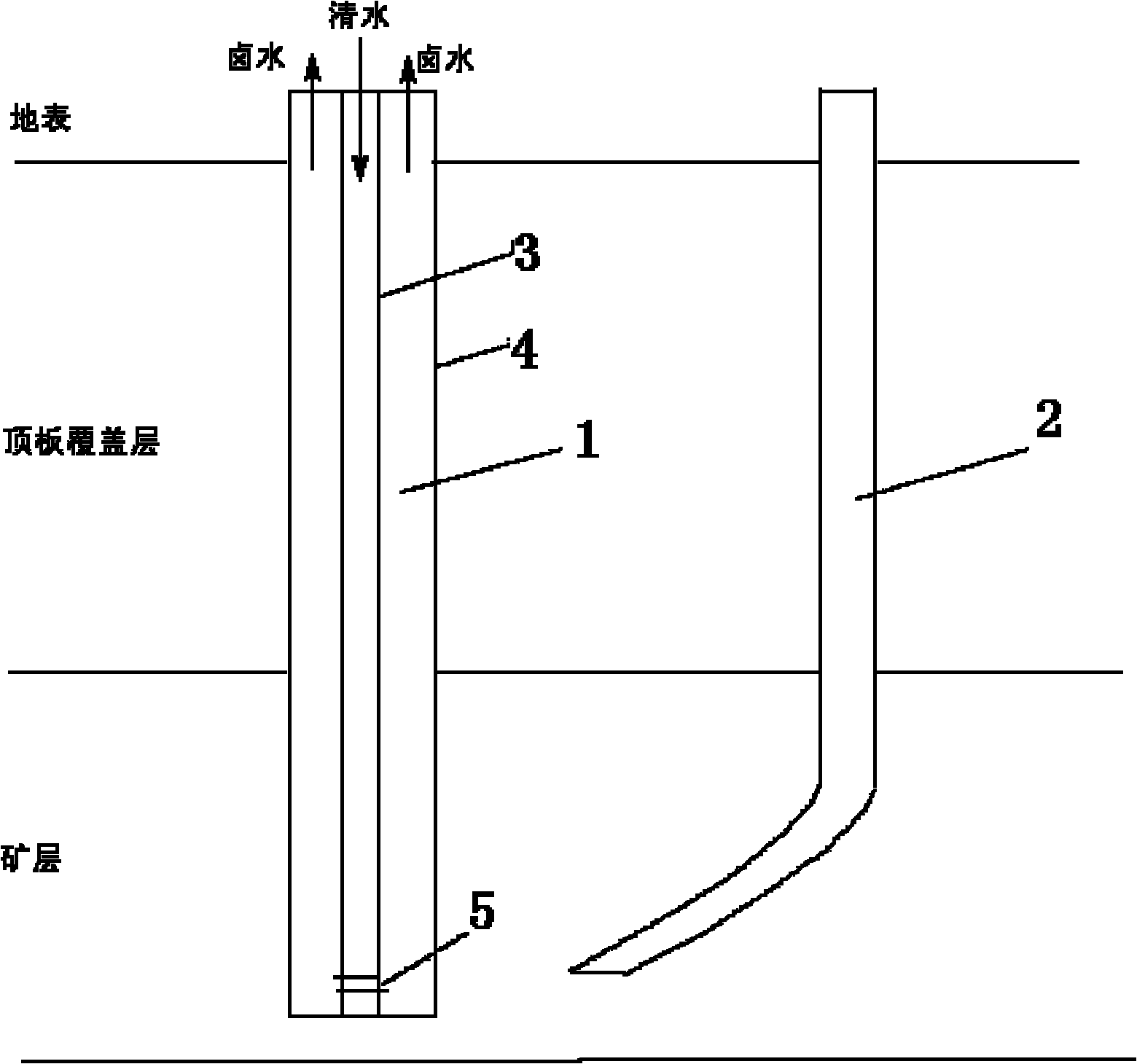

Salt mine double-well solution mining method

InactiveCN102108853AAccurately control the concentration of halogenAvoid cloggingFluid removalPotential accidentHigh pressure

The invention relates to a salt mine double-well solution mining method, in particular a salt mine double-well solution mining method. In the method, injection holes are formed on two sides of the bottom of an under central pipe in a vertical well; in a double well production process, part of clean water is separated and injected into the central pipe in the vertical well when the clean water is injected into a horizontal well, so that the clean water flows into a casting from the injection holes of the central pipe in the vertical well to dilute oversaturated brine in the casting in the vertical well; and the injection water flow in the central pipe of the vertical shaft is displayed and monitored by an electromagnetic flowmeter, so the concentration of the brine discharged from the vertical well can be controlled accurately. The method has the advantages that: 1, the concentration of the brine discharged from the vertical well in a double-well solution mining process can be accurately controlled; 2, the concentration of the brine discharged is prevented from being overhigh in a production process so as not to arouse crystallization and block the underground casting or a ground brine return pipe, and thus, the safe, continuous and high-efficiency production capacity of the salt wells is improved; and 3, as a large amount of high-pressure clean water is injected into the central pipe in the vertical well to wash the underground casting in the vertical well and the ground brine return pipe, the crystallization or scaling on the pipe wall can be prevented, potential accidents are eliminated, and well repair times and cost can be reduced greatly.

Owner:荆州沙隆达控股有限公司

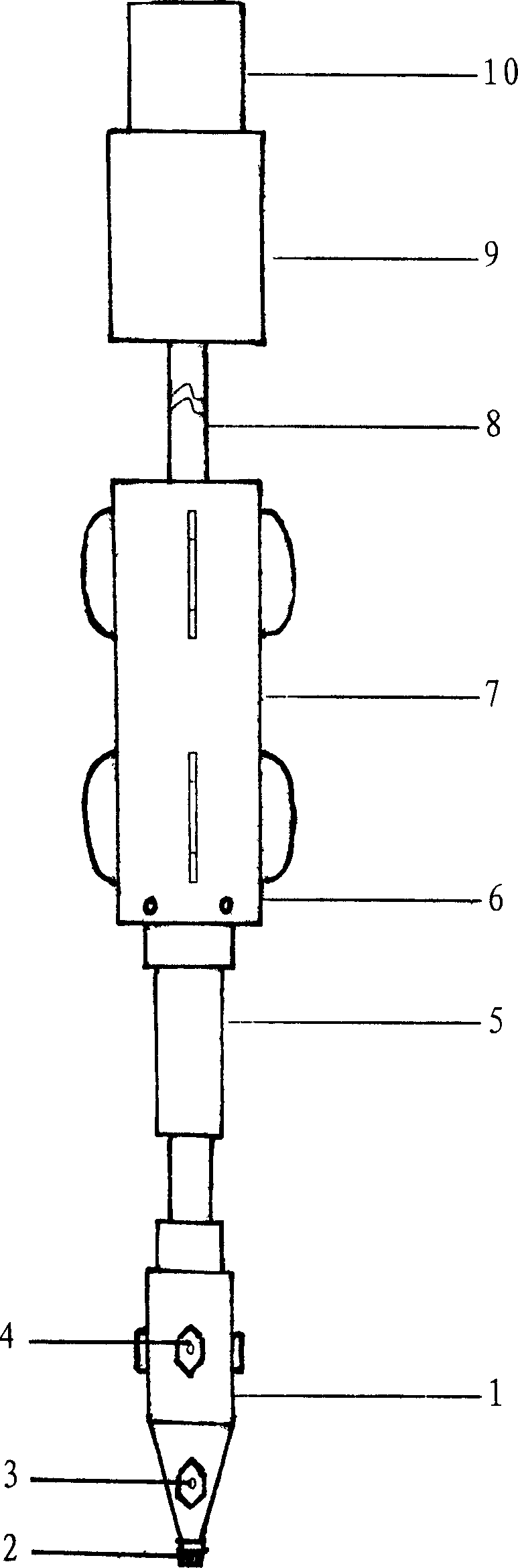

Inner pipe water pressure pulse flushing device

InactiveCN1975097ASolve the problem of unblocking after blockingExtended service lifeFluid removalFlushingPipe waterJet flow

The present invention relates to a casing hydraulic pulse flushing device. It is composed of jet flow head, sand-cleaning nozzle, couple nozzle, cleaning nozzle, damper, guider, pin bolt, flushing pipe and filter. Said invention also provides their connection mode and working principle of said flushing device.

Owner:中国石化股份胜利油田分公司孤岛采油厂

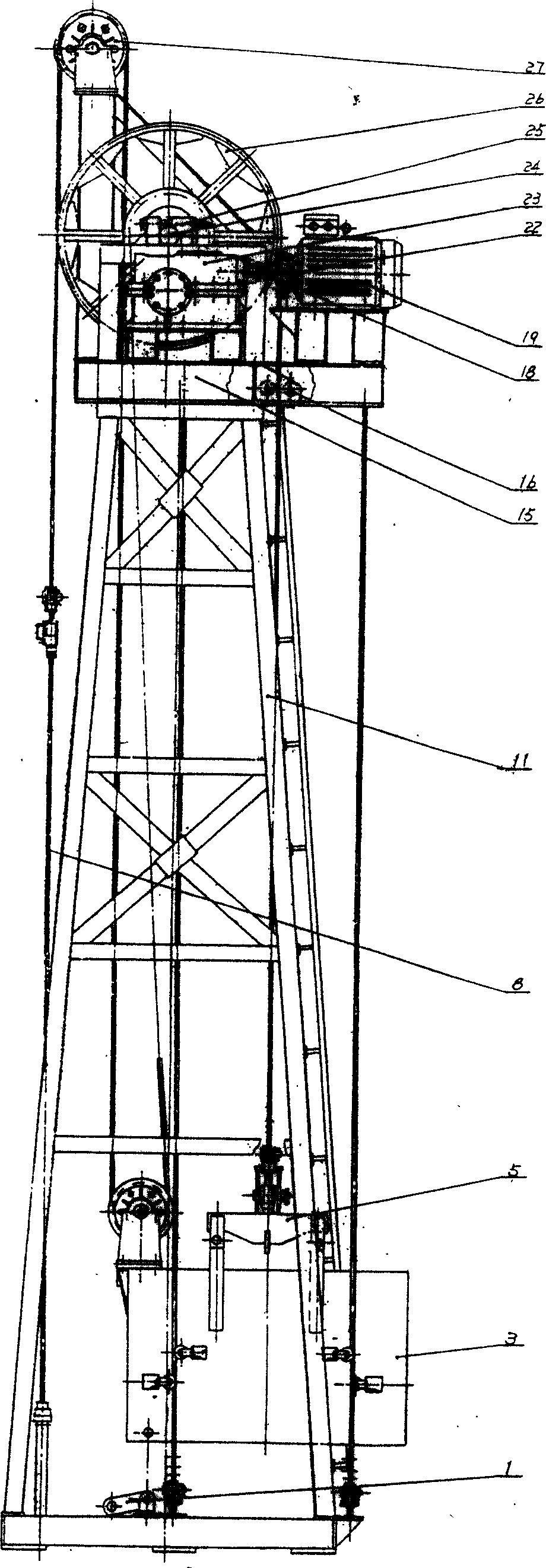

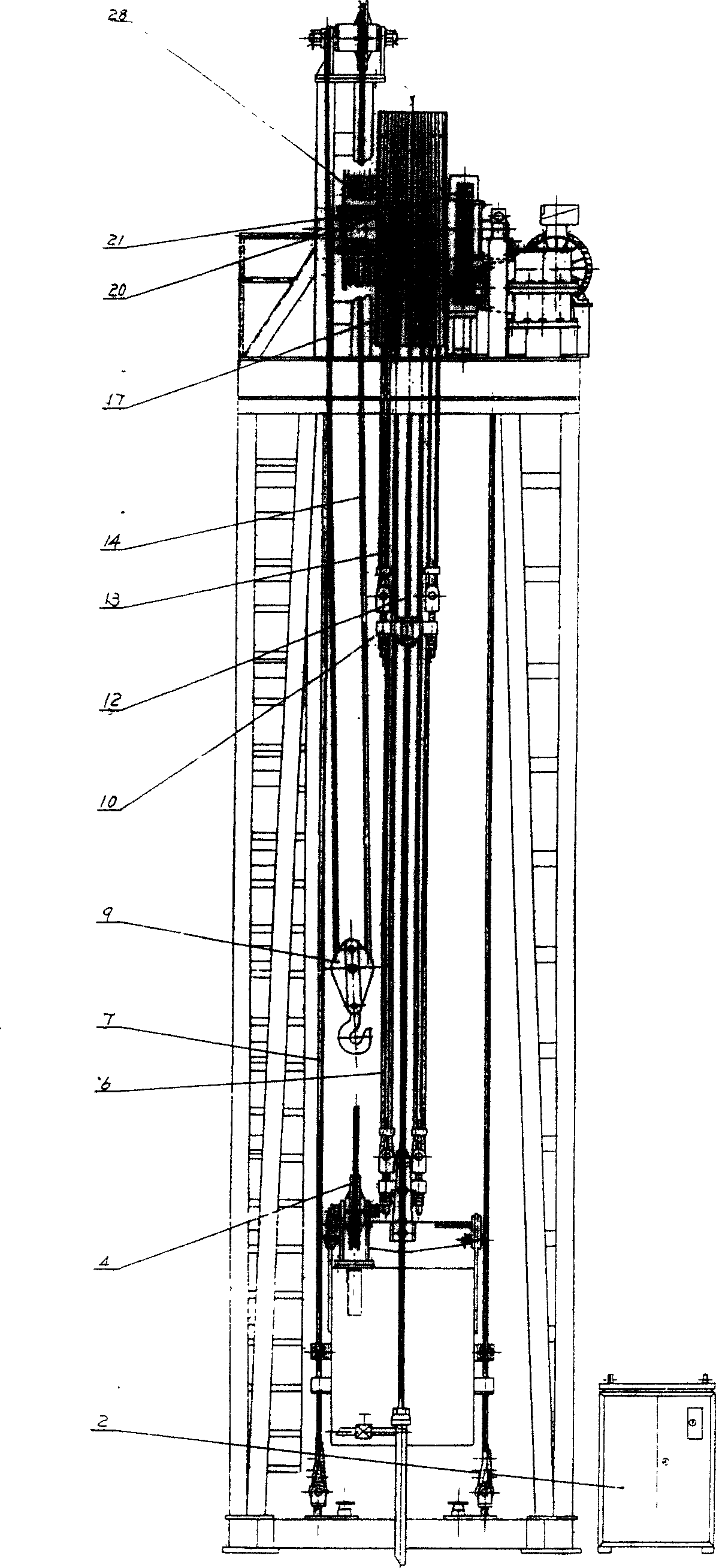

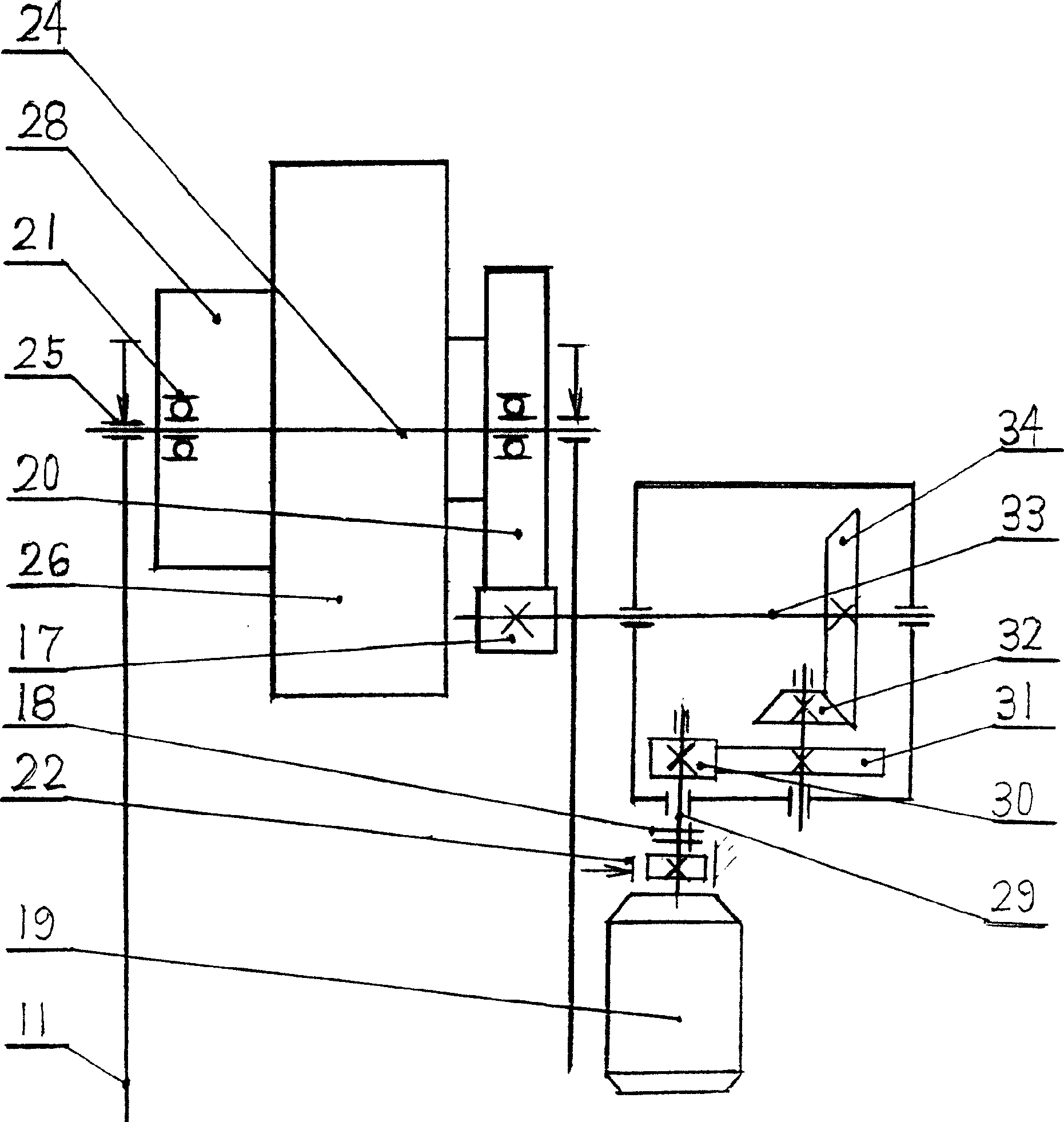

Oil-pumping workover rig

InactiveCN1710248APrevents overloading and falling of the counterweightPrevent overloading and the impact of the counterweight fallingFluid removalGear wheelElectric control

The invention discloses a oil extracting well mending machine relating to oil plant mechanic which includes main frame, electric control unit, weight, rope hanger, oil extracting rod, motor , small gear, large gear, head pulley, lifting motor, reduction gear box, guiding wheel and rope hanger is set on top of the balance weight, stand platform is set on top of main frame, guiding wheel, gripper, head pulley clamp, protecting rope passes through gripper fixing on the head pulley on one end and linking to rope hanger on the other end, oil extracting rope links with hanger at one end and on the pulley at the other end, the balance rope links with rope hanger at one end and with the head pulley at the other end symmetric to the oil extracting rope. The lifting rope is fixed on the lifting wheel at one end and the other end with upper guiding wheel stand passing through lower guiding wheel and upper guiding wheel and moving pulley, a weight balancer is set at the bottom of the main frame. The invention is of large oil extracting force and high efficiency which lowers the mending cost by 95 percent, and save energy by 30 to 50 percent; and the work is stable, reliable, durable and all the technique parameter easily adjustable.

Owner:金成群

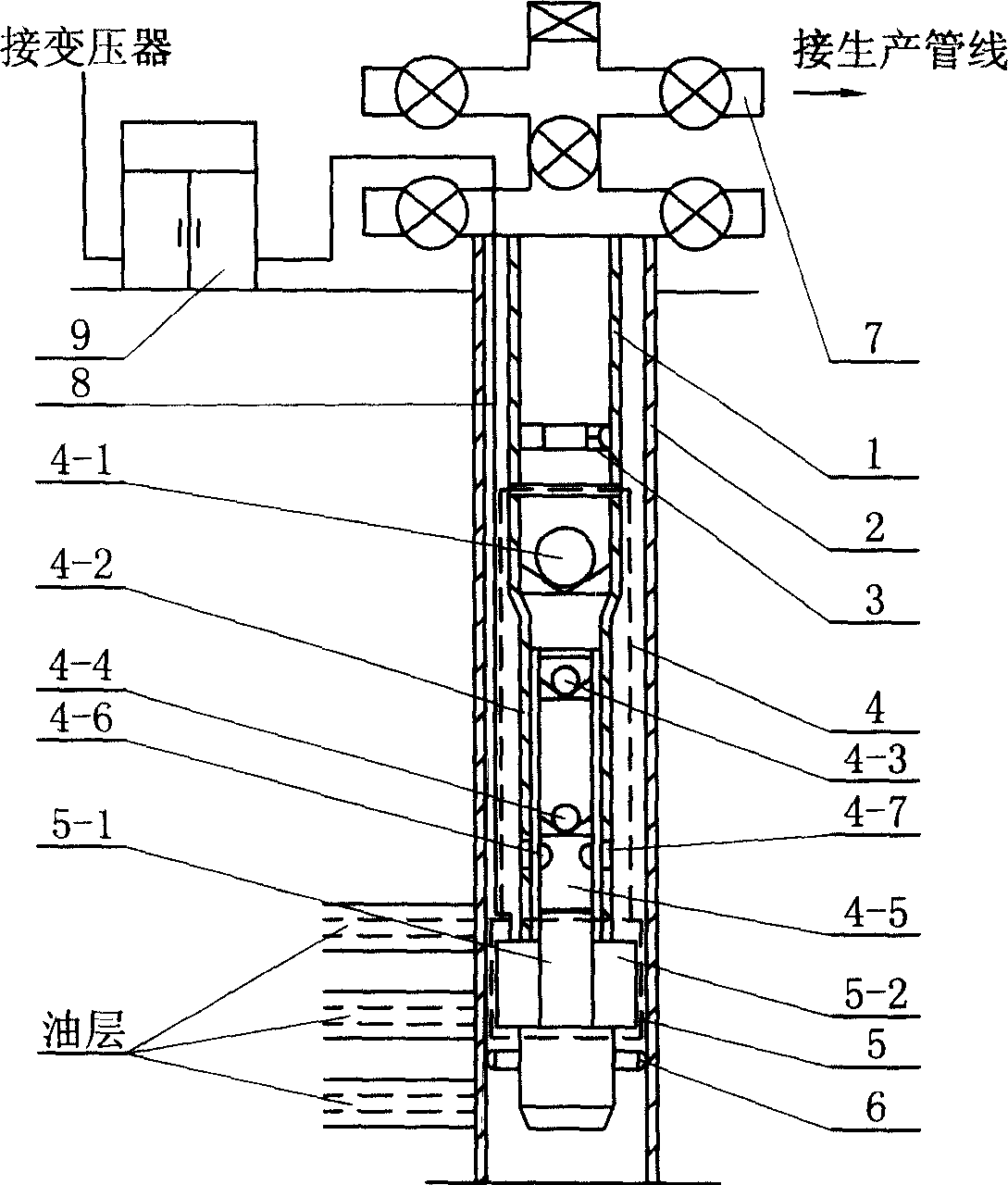

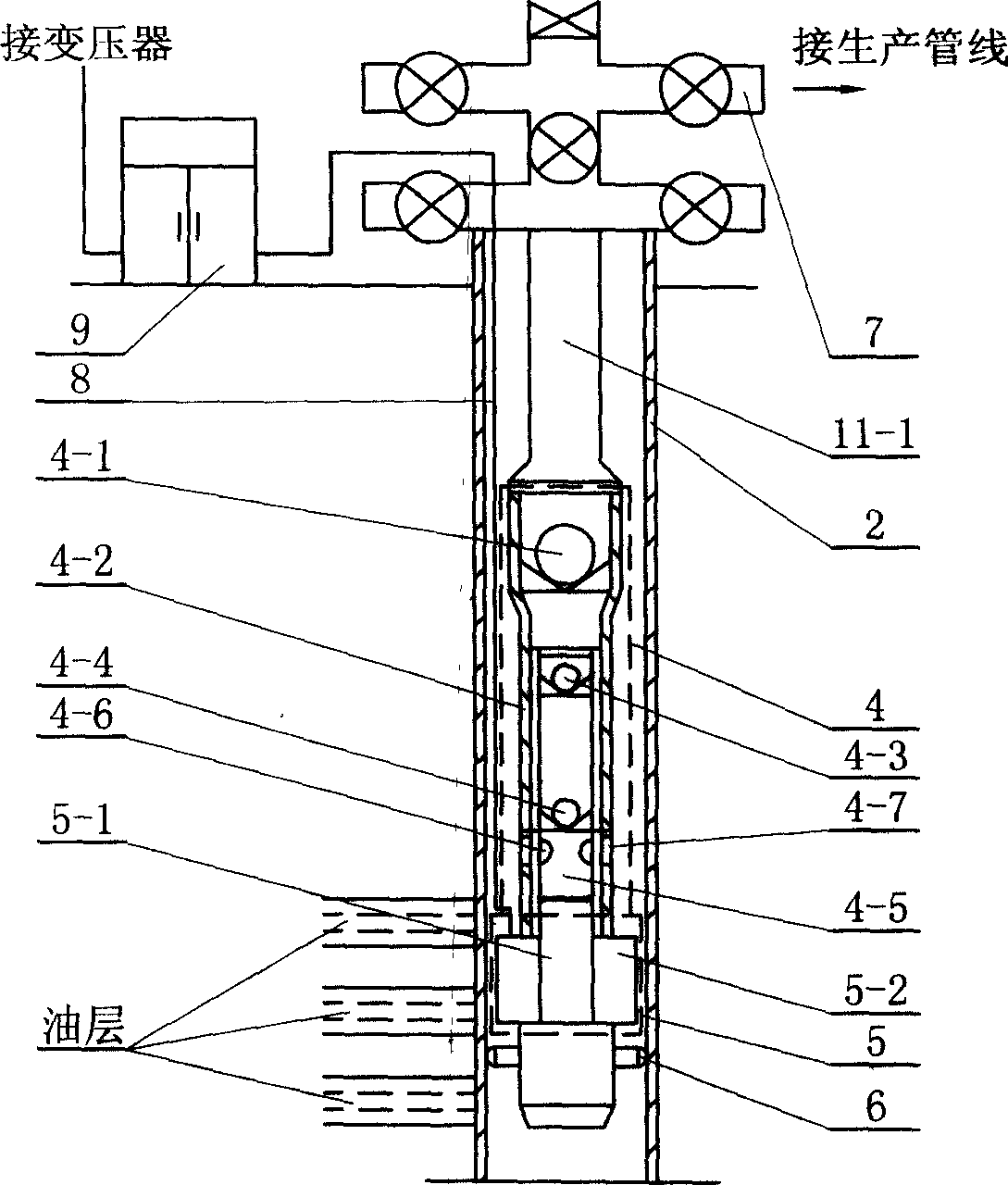

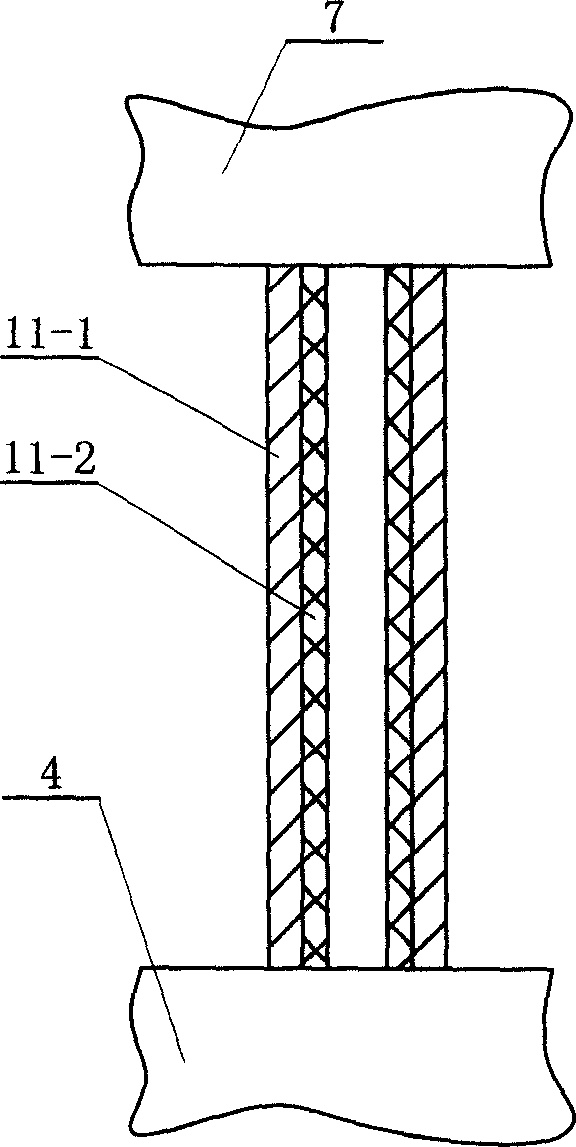

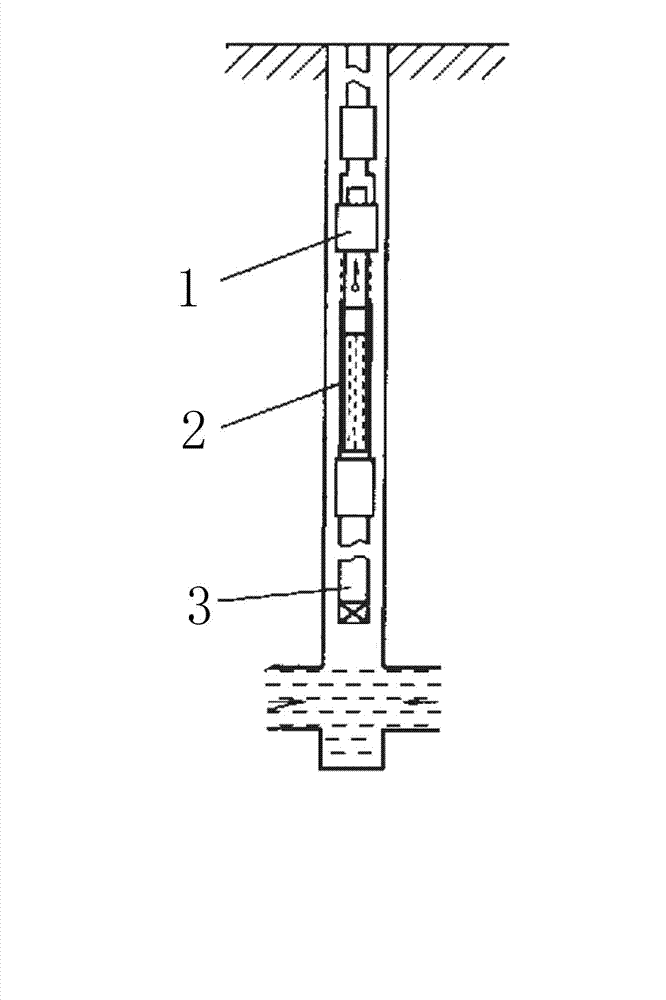

Small displacement high lift reciprocating submersible electric pump

The invention relates to a low cubic capacity high lift reciprocation oil hidden electric pump. The outlet end of the plunger type oil pump connects to the bottom of the oil pipe, and the bottom of the plunger type oil pump fixed to the top of the motor. The bottom of the stator of the motor is fixed on the top of centralizer or oil pipe anchor in sleeve. One end of wire is connected to the connection terminal of the motor, and the other end is connected to variable frequency speed control device. It has the advantage of decreasing the operation of the broken and abrasion of the pumping bar, decreasing the cost to maintain the oil well, and is easy to manage.

Owner:DAQING OILFIELD CO LTD

Fully functional anti-spouting oil drain device

ActiveCN101975042ABlowout preventionSimple and fast operationWell/borehole valve arrangementsSealing/packingEnergy conservationOil well

The invention relates to a fully functional anti-spouting oil drain device which is characterized in that a one-way oil drain valve is adopted and is arranged in a hole on the wall of a body; a plurality of body flow channel holes are arranged on the body in the radial direction; an axial long hole and a plurality of sliding sleeve flow channel holes corresponding to the body flow channel holes are arranged on a sliding sleeve; the sliding sleeve is arranged in the inner cavity of the body and is in clearance fit with the inner cavity; a compression spring is arranged between a guiding body and the sliding sleeve, and the upper end and the lower end of the compression spring are respectively connected with the guiding body and the sliding sleeve; and a hole plate is positioned in the inner cavity of the sliding sleeve. The oil drain device of the invention realizes the purpose of effectively preventing the well fluid from being spouted when a pump and a tubular column are conveyed into an oil well, the well is repaired, the pump is inspected and the tubular column is lifted. The invention has the advantages of safety, reliability, simple and convenient operation and the like, saves the energy sources, reduces the pollution, improves the working efficiency and lowers the well repair cost.

Owner:张川民

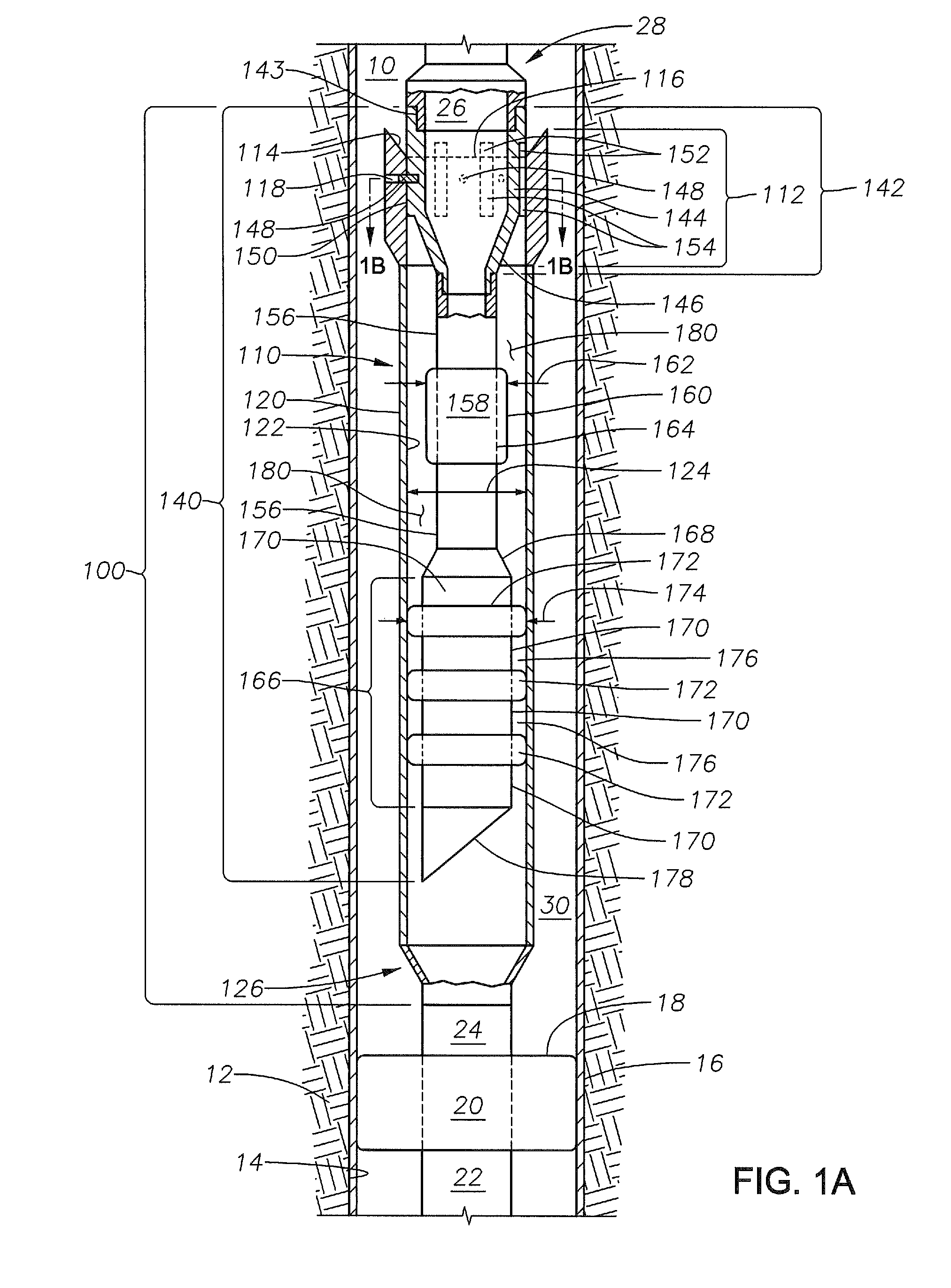

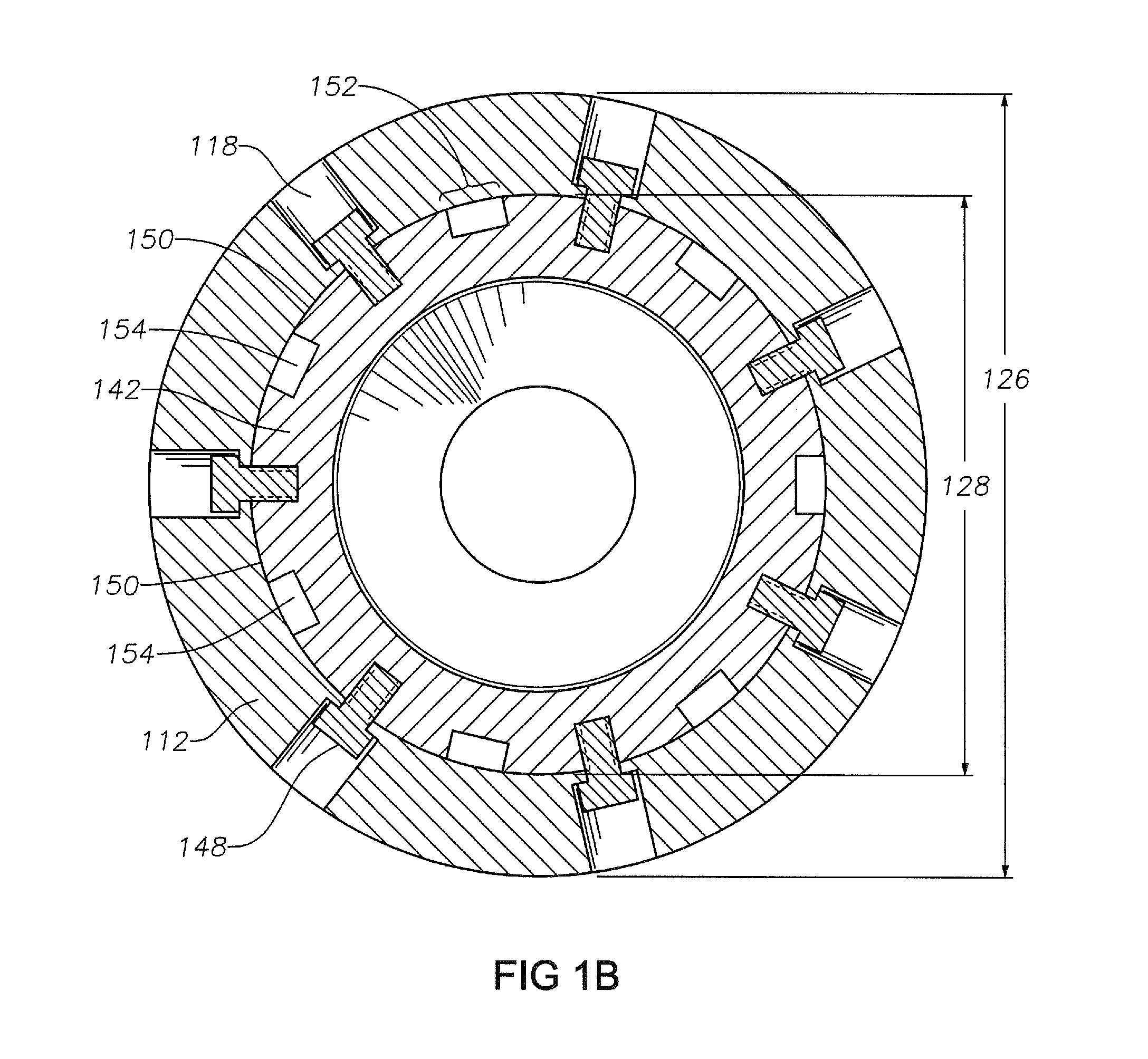

Apparatus and method for preventing tubing casing annulus pressure communication

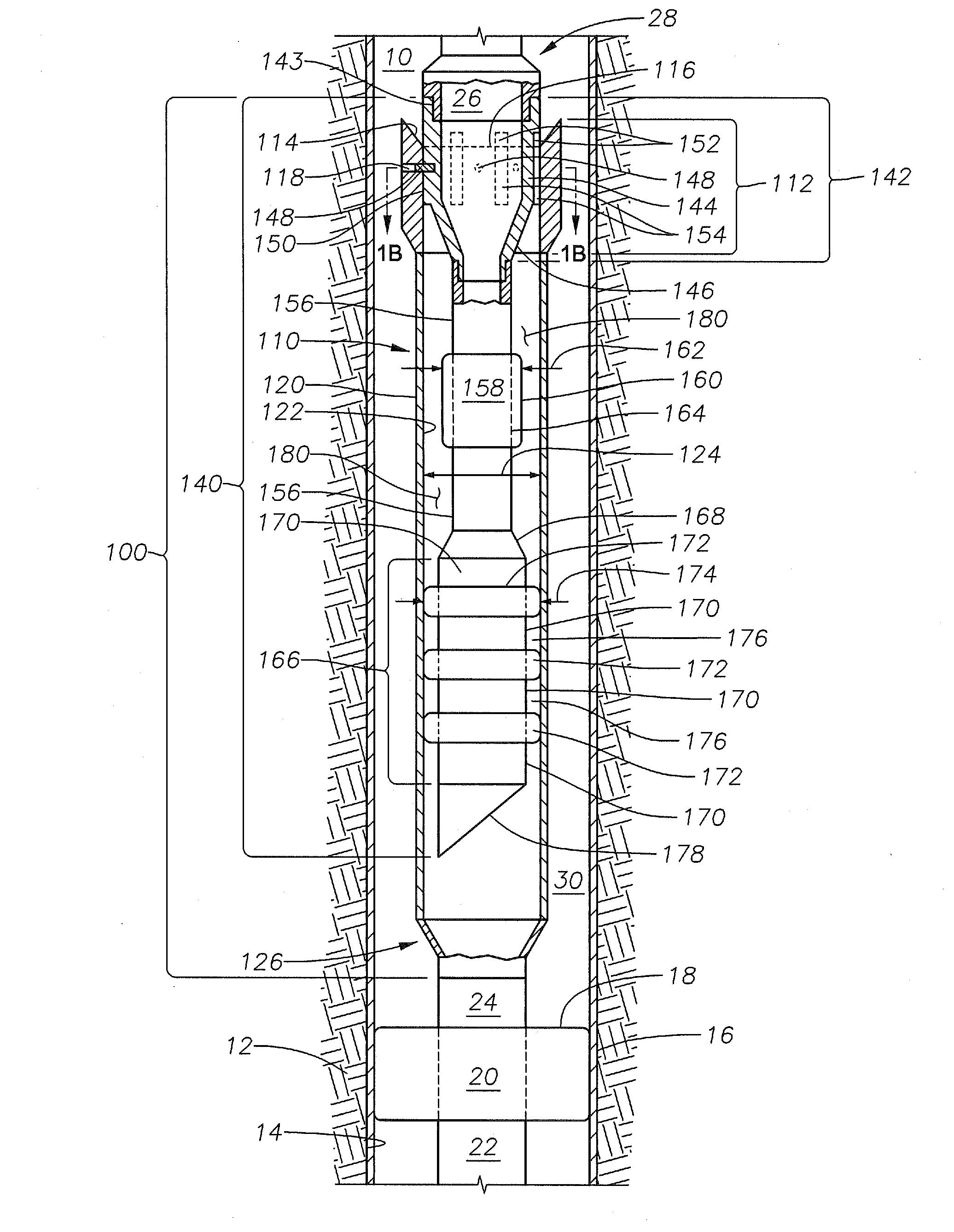

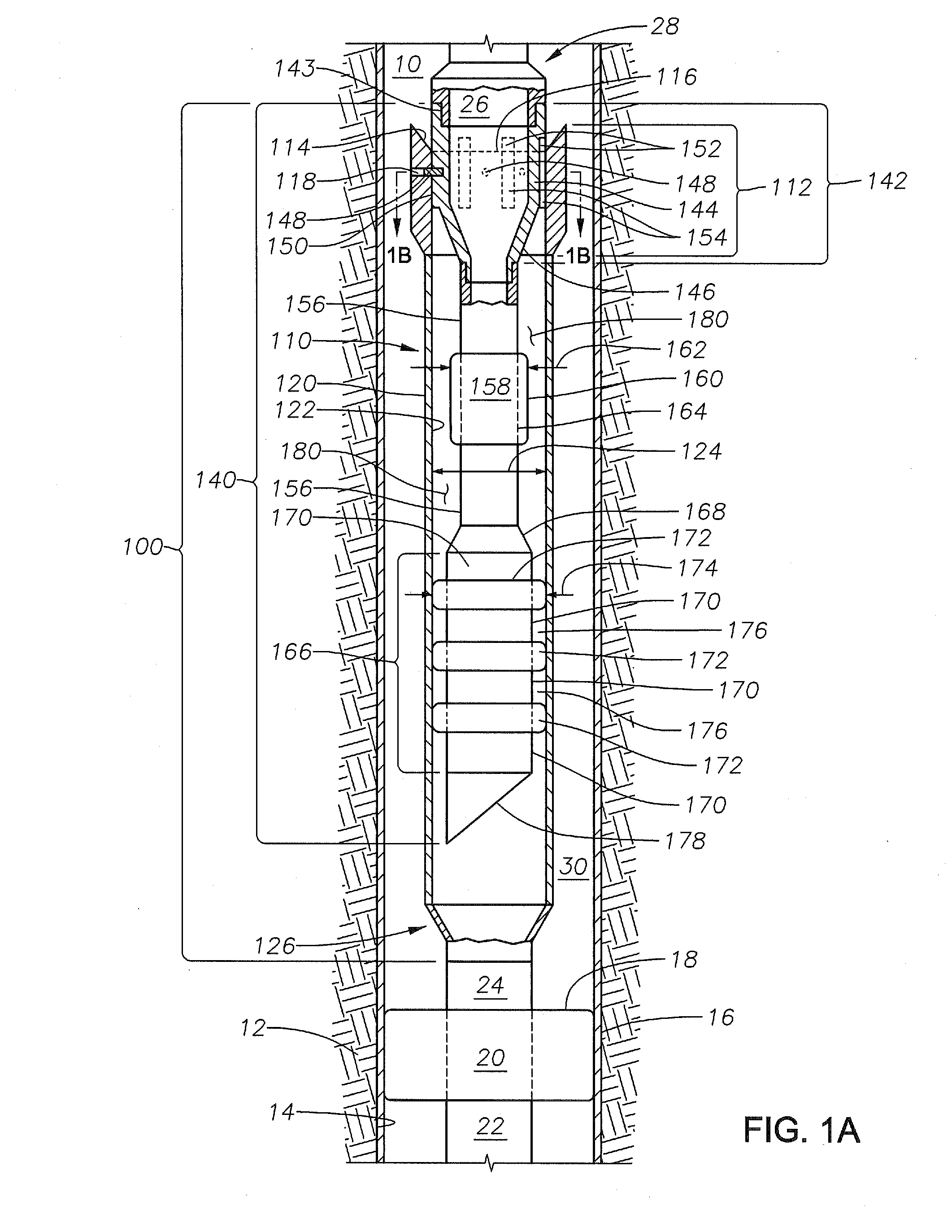

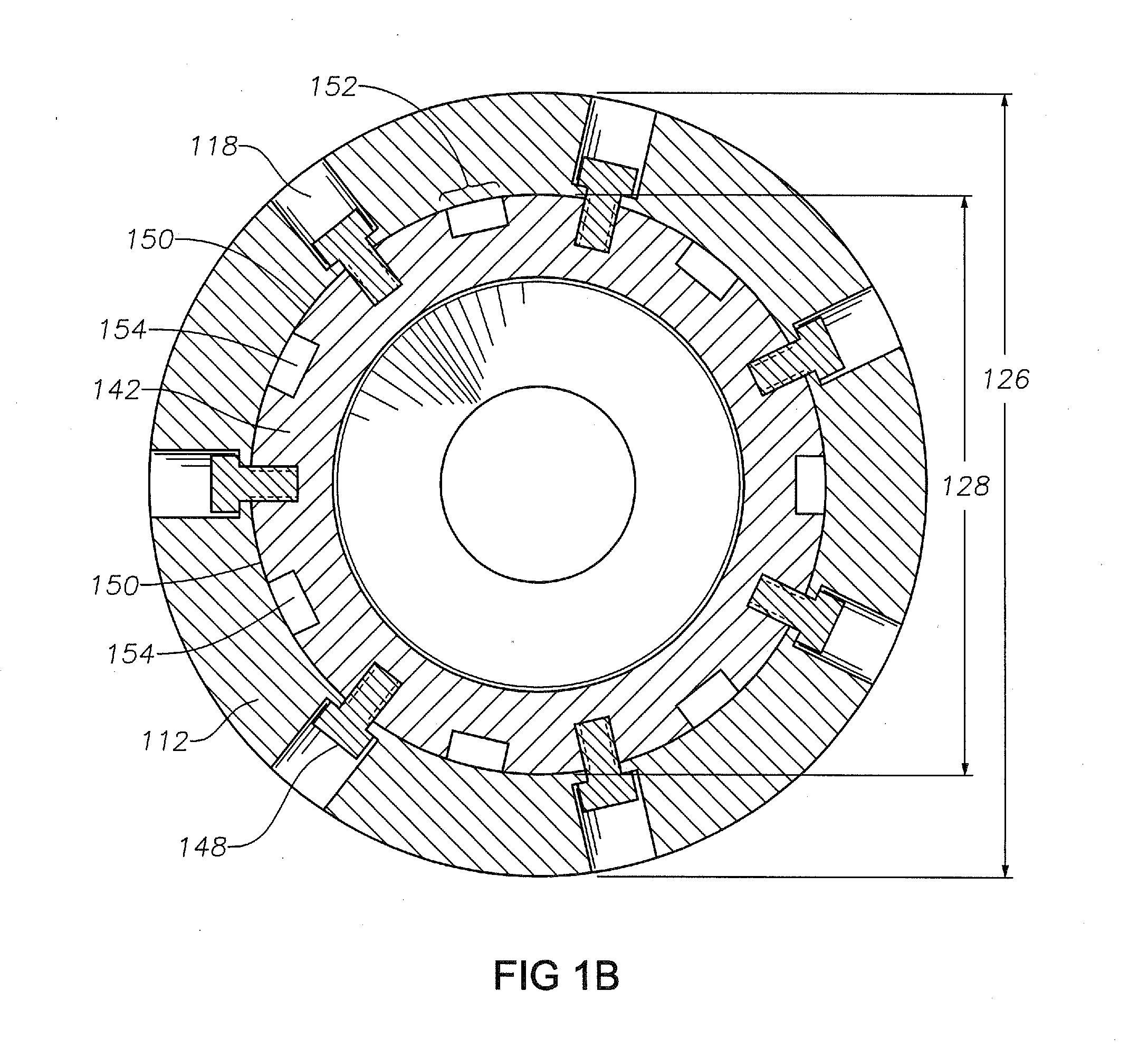

ActiveUS20160010411A1Minimizes fluid exposureReduce workover costsFluid removalSealing/packingEngineeringMechanical engineering

A method of installation of a completion assembly apparatus into a wellbore with a liner hangar packer includes introducing the completion assembly apparatus into the wellbore, where the hybrid sealing assembly couples to the polished bore receiver assembly such that the hybrid sealing assembly is not operable to move laterally within the polished bore receiver assembly, positioning the completion assembly apparatus such that the completion assembly apparatus couples with the liner hangar packer, which establishes fluid communication between the polished bore receiver assembly and a portion of the wellbore downhole from the liner hanger packer, and operating the completion assembly apparatus such that the hybrid sealing assembly decouples from the polished bore receiver assembly such that the hybrid sealing assembly is operable to move laterally within the polished bore receiver assembly. The hybrid sealing assembly includes an unswollen swellable packer operable to swell upon exposure to a swelling material.

Owner:SAUDI ARABIAN OIL CO

Well-repairing process for casing deformed oil and water well

The invention relates to a casing deformation oil-water well repair technics. The sand-washing technology and the anti-sand technics with a gravel-filled string are adopted by the invention. Sand is first washed to a preset position with a specially made sand-washing tool, and then the anti-sand string is put into the well. A certain amount of quartz sand is filled outside the string to complete the well. Thus, a well bore hole is reinforced and an oil flow or water injection passage is formed, so as to reach the purpose of production recovery for an oil well and water injection recovery for a water injection well. The casing deformation oil-water well repair technics provided by the invention avoids the overhaul procedure. The sand prevention work can be directly carried out, the well repair cost is reduced, and the construction period is shortened. Moreover, when the sand is effectively prevented, the intention is provided with a certain channelizing effect for an oil layer, which is favorable for increasing the oil well output or the water injection amount of the water injection well.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

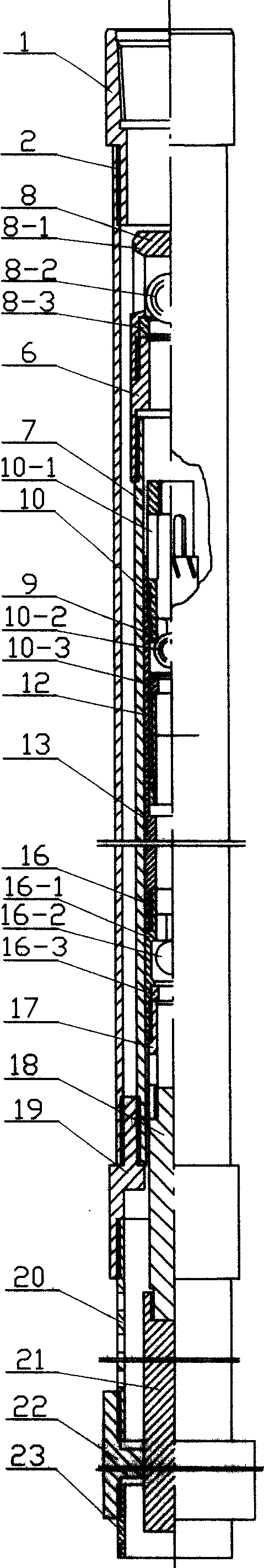

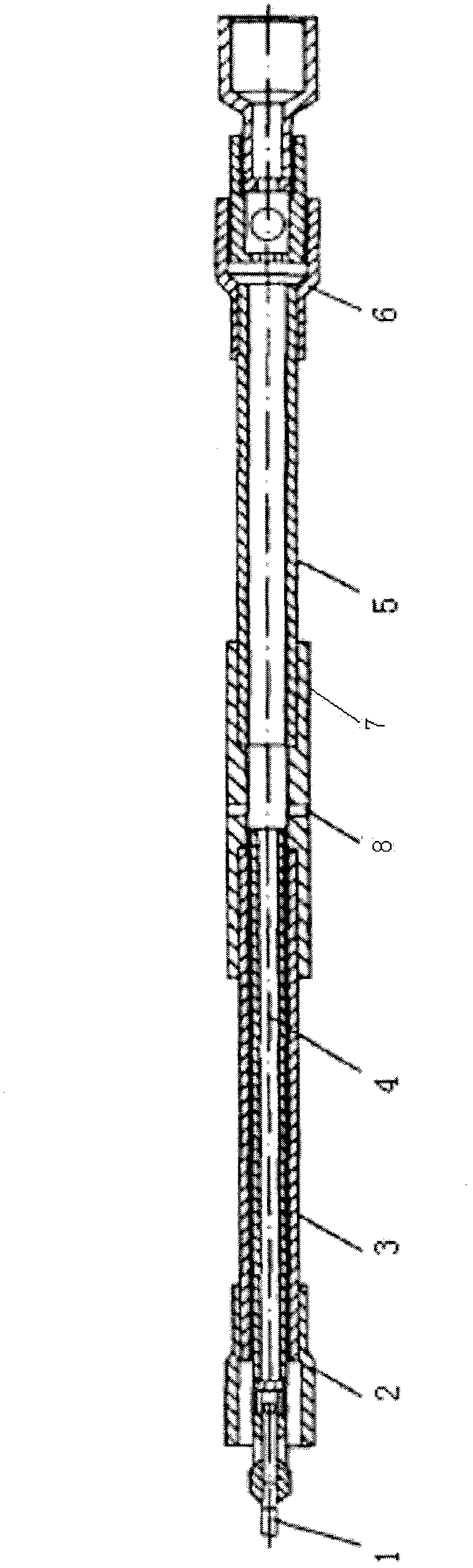

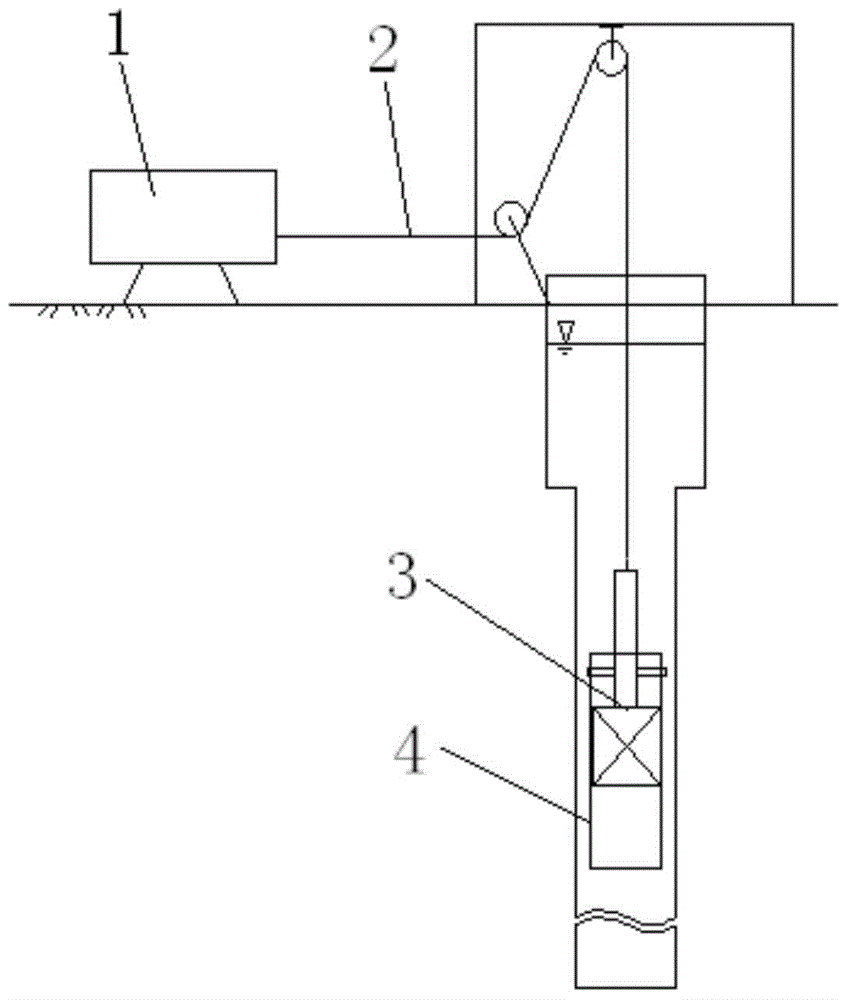

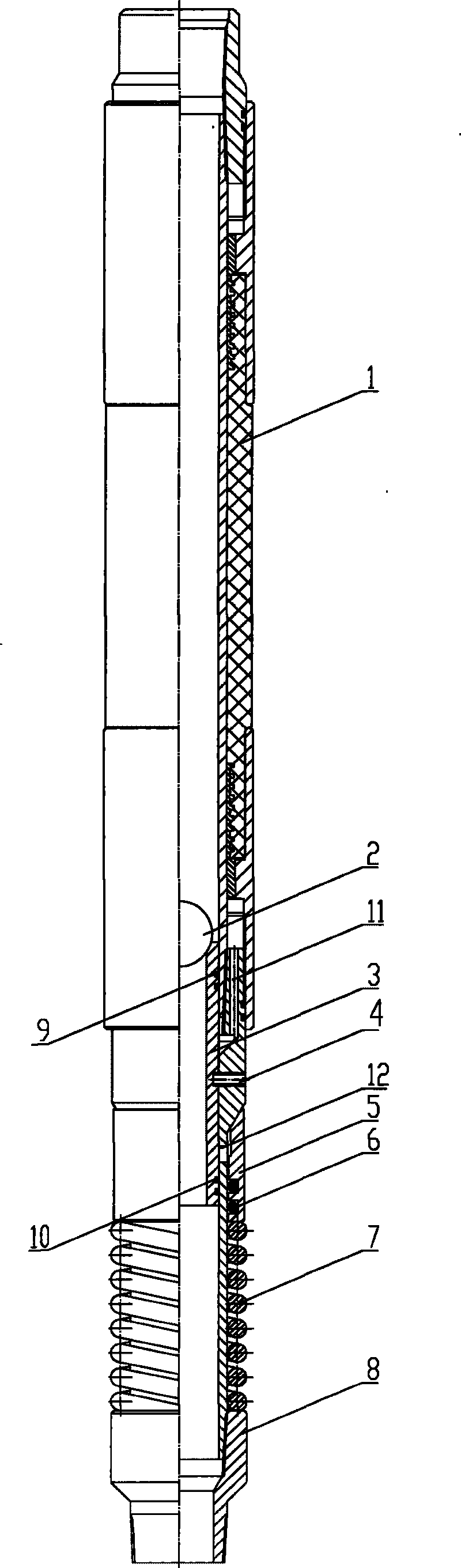

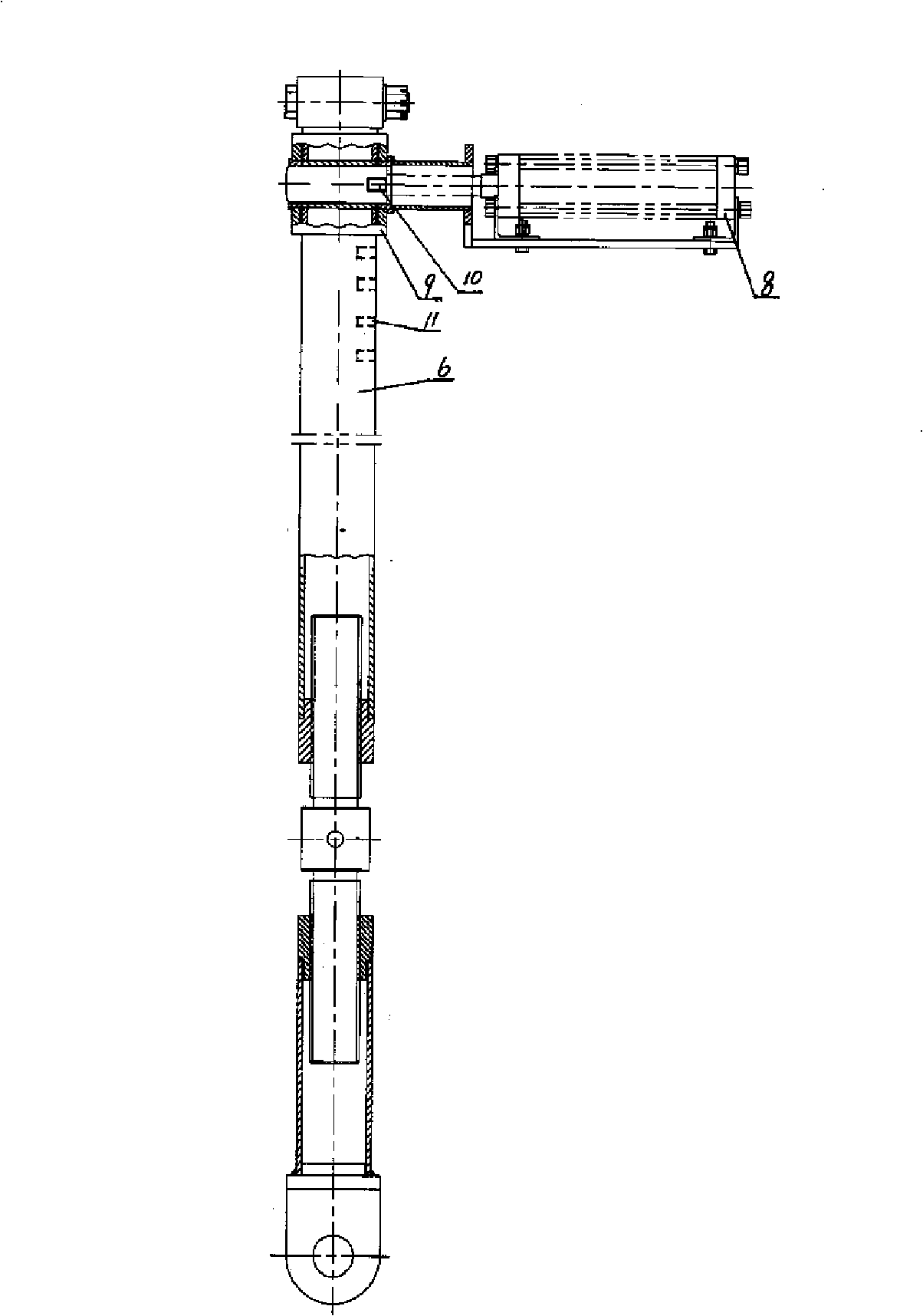

Lifting device for petroleum production vane pump of petroleum well

InactiveCN106703771AReduce labor intensityImprove efficiencyFluid removalRotary piston pumpsSingle platePour point

The invention belongs to the technical field of petroleum production of petroleum wells, and particularly relates to a lifting device for a petroleum production vane pump of a petroleum well. The lifting device comprises a single-plate anchor, a pump straightener, a sand spinner, a vane pump body, a sand settler, a spline transmission barrel assembly, a high temperature gas injection valve, a sucker rod, a petroleum pipe, a wellbore sleeve, a Christmas tree, a driving head and a polish rod, wherein the wellbore sleeve is arranged below the ground surface; the single-plate anchor, the pump straightener, the sand spinner, the vane pump body, the sand settler, the spline transmission barrel assembly, the high temperature gas injection valve and the petroleum pipe which are connected in sequence from bottom to top are arranged in the wellbore sleeve; the sucker rod is inserted into the petroleum pipe, and the lower end of the sucker rod is connected with the high temperature gas injection valve; the Christmas tree is located above the ground surface; the polish rod is inserted into the Christmas tree, and is connected with the upper end of the sucker rod; the polish rod is connected with the driving head and can be driven by the driving head to rotate. The lifting device for the petroleum production vane pump of the petroleum well is applicable to thermal recovery of thin petroleum, thick petroleum and high pour point petroleum and does not have gas locking in a high temperature gas-containing well; for sand-containing well, a sand spinning filter is arranged below the pump, so that the use range is wide.

Owner:丹东纳泰石油机械有限公司

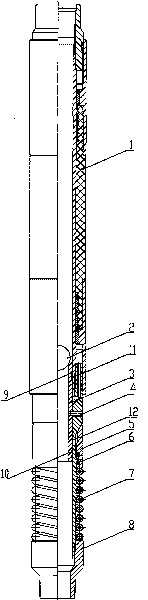

Well dynamic direct-driven plunger oil-well pump

InactiveCN1673534AHigh energy consumptionRealize start-stop and reversing protectionFlexible member pumpsFluid removalStatorOil well

The well power driven plunger type oil pumping pump is one lifting device for oil extracting machine in oil field. The well power driven plunger type oil pumping pump has outer tube, pump tube inside the outer tube and connected to pump tube union, fixed valve assembly, plunger and sand scraping cup inside the pump tube, upper plunger valve assembly, lower plunger valve assembly with oil intake union, link rod, motor and sieve tube. The oil pumping pump has high efficiency and low cost.

Owner:DAQING OILFIELD CO LTD

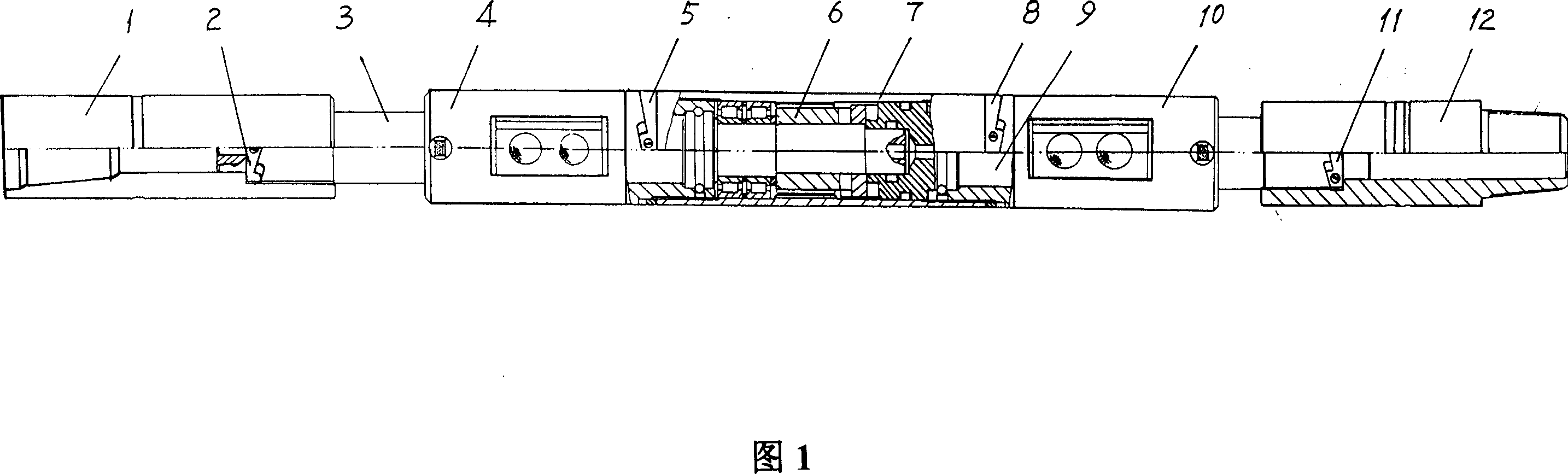

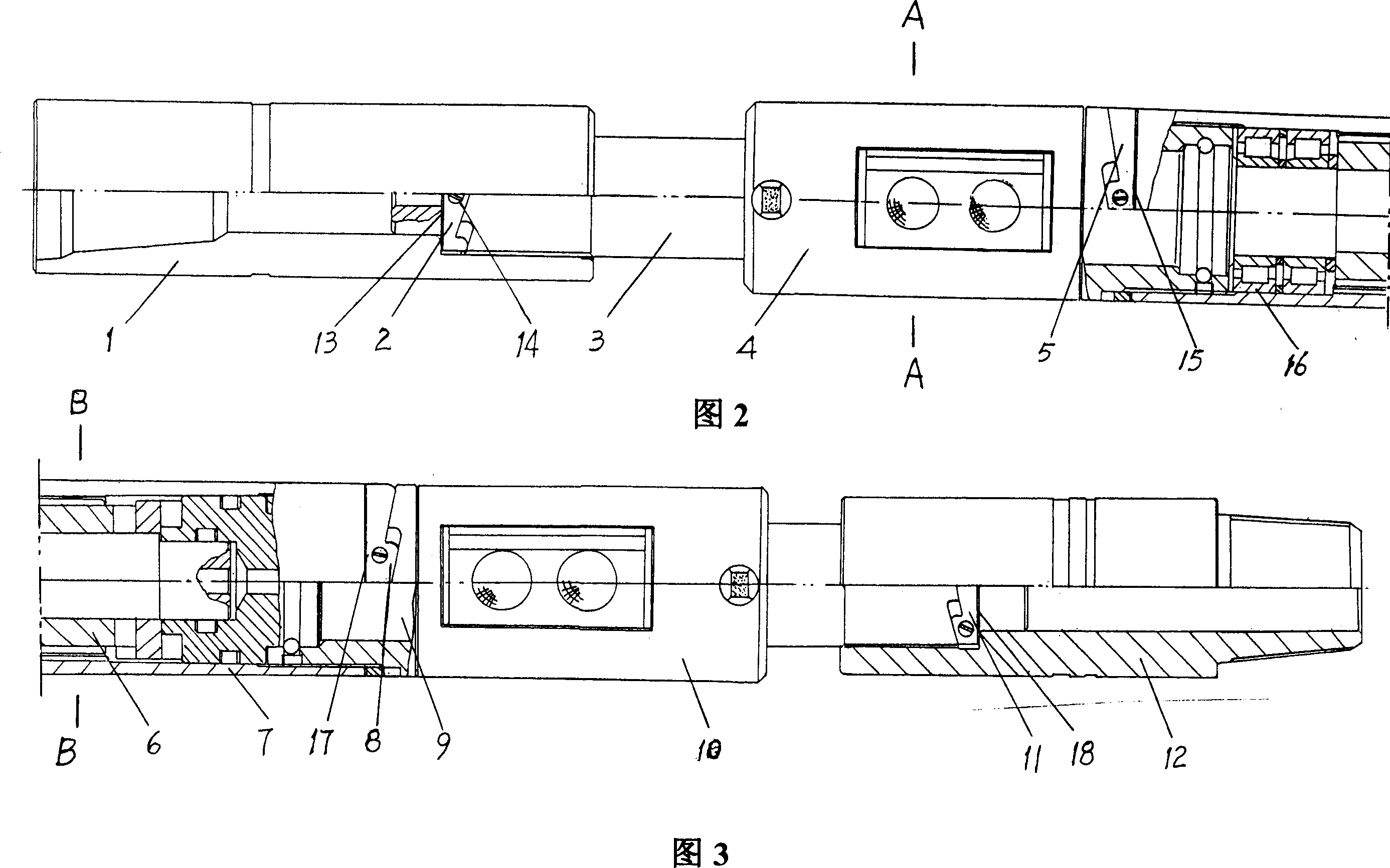

Reverse buckling equipment

InactiveCN1920240AReversing, unlocking and salvage is normalIncrease success rateConstructionsBorehole/well accessoriesSurface toothEngineering

The invention relates to a reversed clamper, which comprises: upper connector, eccentric axle, upper and lower anchor devices, inner gear, and rotation gear, bearing element, output axle and lower connector, wherein between the lower part of upper connector and the upper end of eccentric axle, between the upper and lower ends of inner gear, between upper and lower anchor devices, and between the lower end of output axle and the upper part of lower connector, there are torque rings whose circumferences contacted with the eccentric axle, upper and lower anchor devices and output axle have slope sliding channels; said slope sliding channels are reversed to the slope sliding channels of said elements; and their circumferences contacted with the lower part of upper connector, upper and lower ends of inner gear, and the upper part of lower connector have mesh end surface teeth. The invention can replace reversed clamp rod, to increase the torque after speed reduction, to reduce the cost and improve the efficiency.

Owner:周德育

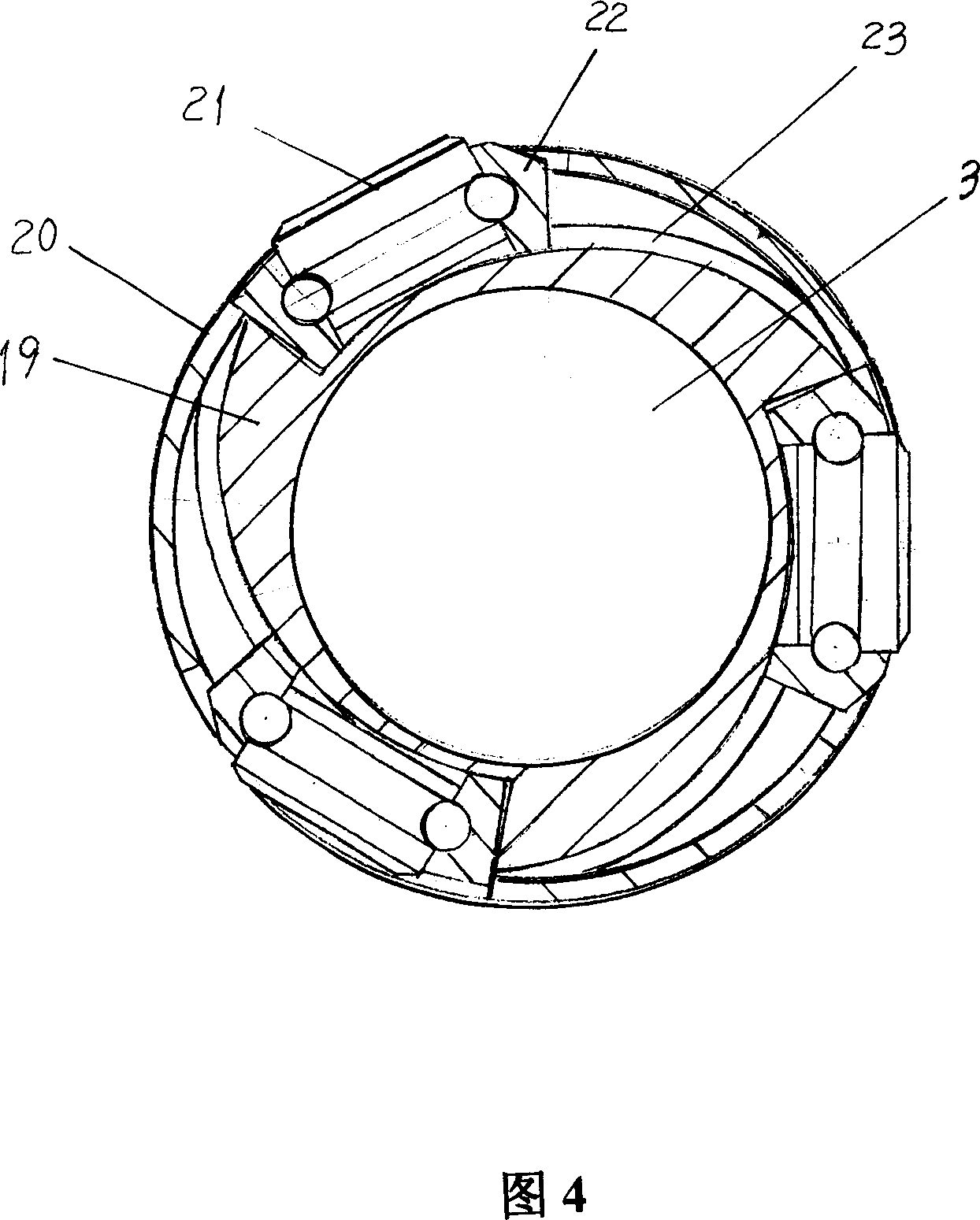

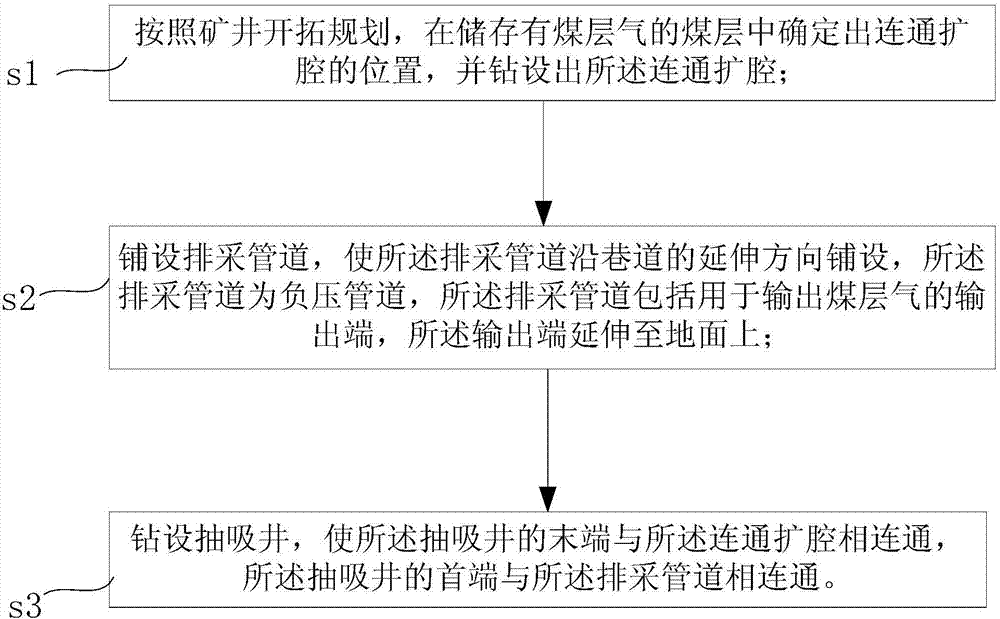

Coalbed methane extraction system and construction method

InactiveCN107152261AReduce manufacturing costReduce energy consumptionFluid removalWell drillingEnergy consumption

The invention discloses a coalbed methane extraction system and a construction method. The coalbed methane extraction system comprises a communicating expansion cavity, a discharge and mining pipeline and a pumping well, wherein the communicating expansion cavity is used for collecting coalbed methane from a coalbed and is arranged in the coalbed; the discharge and mining pipeline is paved along the extending direction of a roadway, is a negative pressure pipeline and comprises an output end used for outputting the coalbed methane, the output end extends to the ground surface, the tail end of the pumping well is communicated with the communicating expansion cavity, and the head end of the pumping well is communicated with the discharge and mining pipeline. The invention further provides the construction method of the coalbed methane extraction system to construct the coalbed methane extraction system. According to the provided coalbed methane extraction system and the construction method, the energy consumption is reduced, the extraction cost of the coalbed methane is lowered, the cost for ground construction is lowered, and the operation cost for a drilling well is lowered.

Owner:CHINA SHENHUA ENERGY CO LTD +2

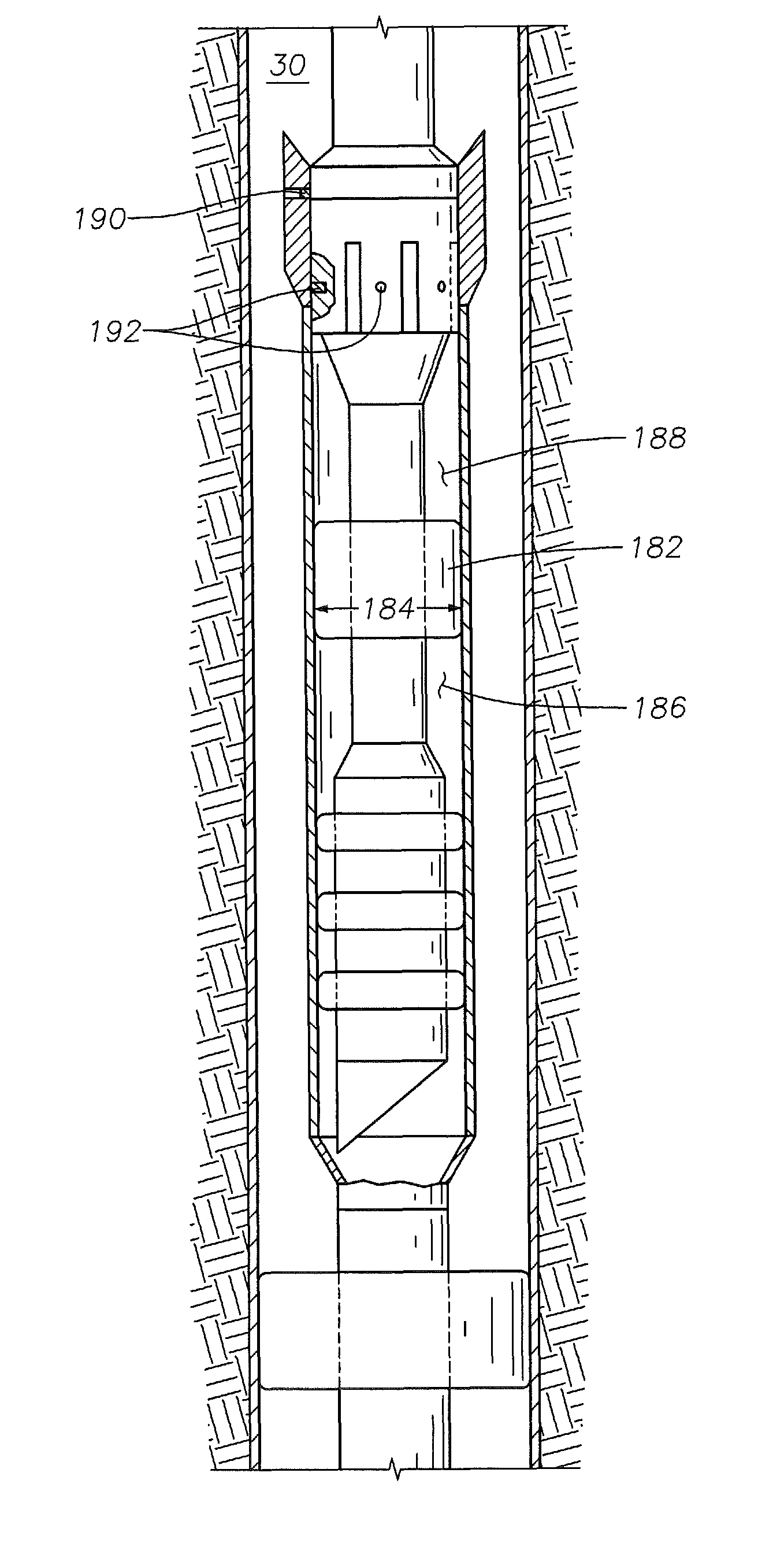

Apparatus and method for preventing tubing casing annulus pressure communication

ActiveUS9500057B2Reduce decreaseImprove sealingFluid removalSealing/packingEngineeringMechanical engineering

A method of installation of a completion assembly apparatus into a wellbore with a liner hangar packer includes introducing the completion assembly apparatus into the wellbore, where the hybrid sealing assembly couples to the polished bore receiver assembly such that the hybrid sealing assembly is not operable to move laterally within the polished bore receiver assembly, positioning the completion assembly apparatus such that the completion assembly apparatus couples with the liner hangar packer, which establishes fluid communication between the polished bore receiver assembly and a portion of the wellbore downhole from the liner hanger packer, and operating the completion assembly apparatus such that the hybrid sealing assembly decouples from the polished bore receiver assembly such that the hybrid sealing assembly is operable to move laterally within the polished bore receiver assembly. The hybrid sealing assembly includes an unswollen swellable packer operable to swell upon exposure to a swelling material.

Owner:SAUDI ARABIAN OIL CO

Drilling method for preventing water accumulation in goaf

InactiveCN111021959AReduce well collapseReduce Well Flooding AccidentsSealing/packingDrilling machines and methodsMining engineeringWell drilling

The invention belongs to the technical field of coalbed methane, and particularly relates to a drilling method for preventing water accumulation in a goaf. The drilling method for preventing water accumulation in the goaf aims to solve the problem mainly existing in a current well bore structure that a large amount of formation water gushing out of aquifers in an open hole area enters the goaf, and thus wall rock in a well is leached. The drilling method comprises the following specific steps that (1) joint well profiles of the aquifers are drawn through the surrounding hydrogeological condition, and positions of the aquifers of a ground mined-off well are estimated; and (2) drilling construction is conducted, specifically, a first-spud drill bit of 425 mm drills to the depth of 10 m belowa weathering belt of bedrock, a surface casing of 377 mm is driven in for well cementation, and cement is returned to the ground; a second-spud drill bit of 311 mm drills to the depth of 10 m below the last aquifer on the upper part of the goaf, then an intermediate casing of 273 mm is driven in for well cementation, and cement is returned to the ground; and a third-spud drill bit of 241.5 mm drills to a bottom plate of the goaf of a coal seam by 10 m for finishing a hole, or to a position of complete slurry (wind) leakage for finishing a hole, and barefoot well completion is conducted. The drilling method for preventing water accumulation in the goaf greatly reduces accidents of well collapse, well plugging and well flooding, thereby reducing the workover cost caused by the accidents.

Owner:山西蓝焰煤层气集团有限责任公司

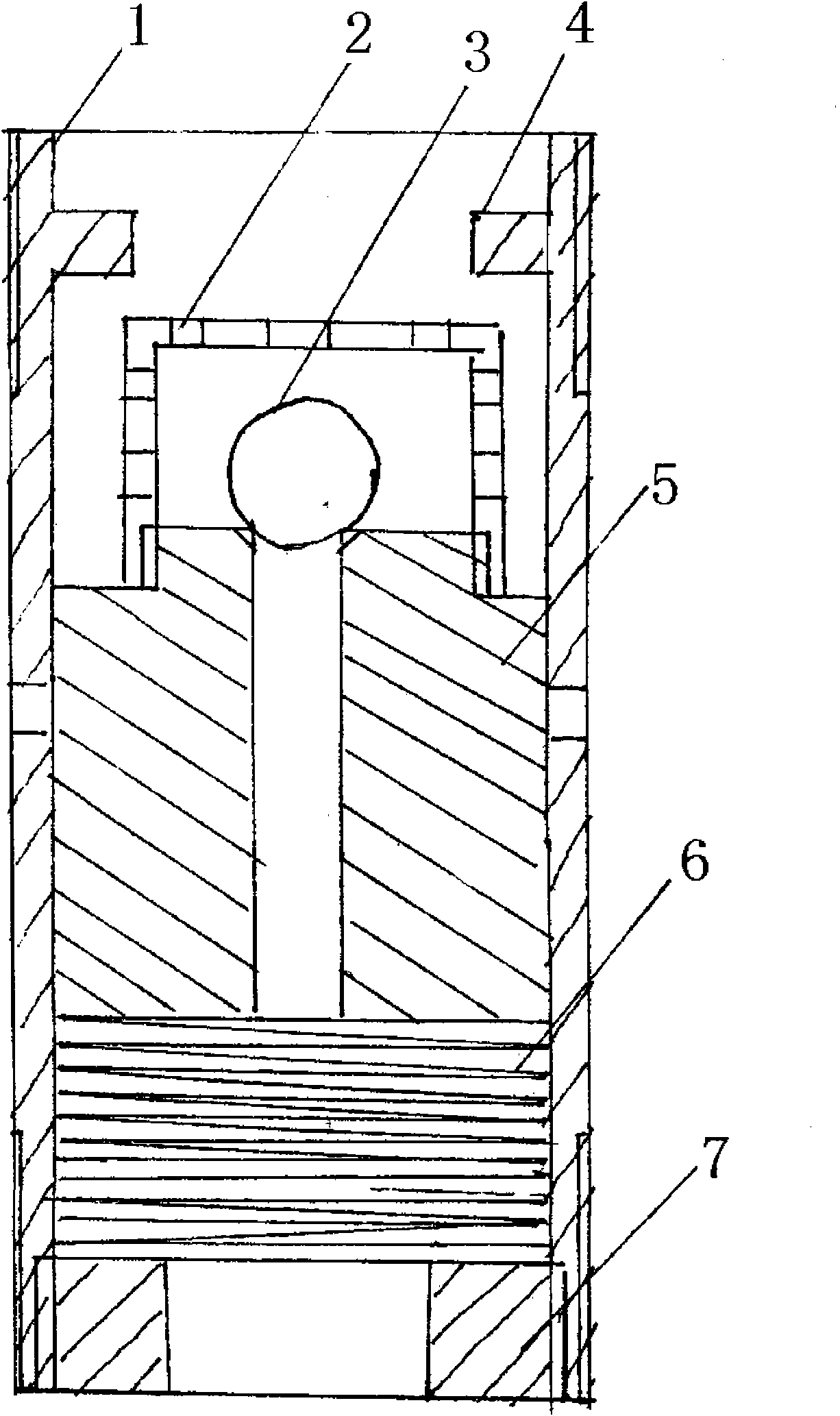

Oil pumping technique based on middle venting gas-prevention oil well pump

InactiveCN103133303AReduce workover costsReduce pollutionPositive displacement pump componentsFlexible member pumpsOil wellPlunger

The invention discloses an oil pumping technique based on a middle venting gas-prevention oil well pump. The technique includes: (a) a power device is started to drive a plunger to move upward; (b) a fixed valve is opened and an upper traveling valve and a lower traveling valve are closed; (c) oil in a sleeve enters a pump cylinder from a venting hole under the action of the sinking pressure; and (d) the power device drives the plunger to move downward, the venting hole of the pump cylinder is sealed by the surface of the plunger, the traveling valves are opened, and oil in the lower portion of the pump cylinder is discharged to an oil pipe through an inner hole of the plunger. The technique improves the oil inlet conditions, and promotes fullness of a cavity of the pump cylinder below a venting groove of the pump cylinder. Therefore, compared with a conventional pump, the pump can effectively promote the pump efficiency. The oil pipe and the sleeve are communicated mutually through the venting groove in the middle of the pump cylinder. A second-time venting groove is formed in the pump cylinder, the effect that an oil drain device is not installed in the well can be achieved, and oil well maintenance cost and environmental pollution are reduced. Due to the fact that the venting grooves are formed in the pump cylinder, a pressure test can not be carried out on the whole pipe column after well completion.

Owner:潘美林

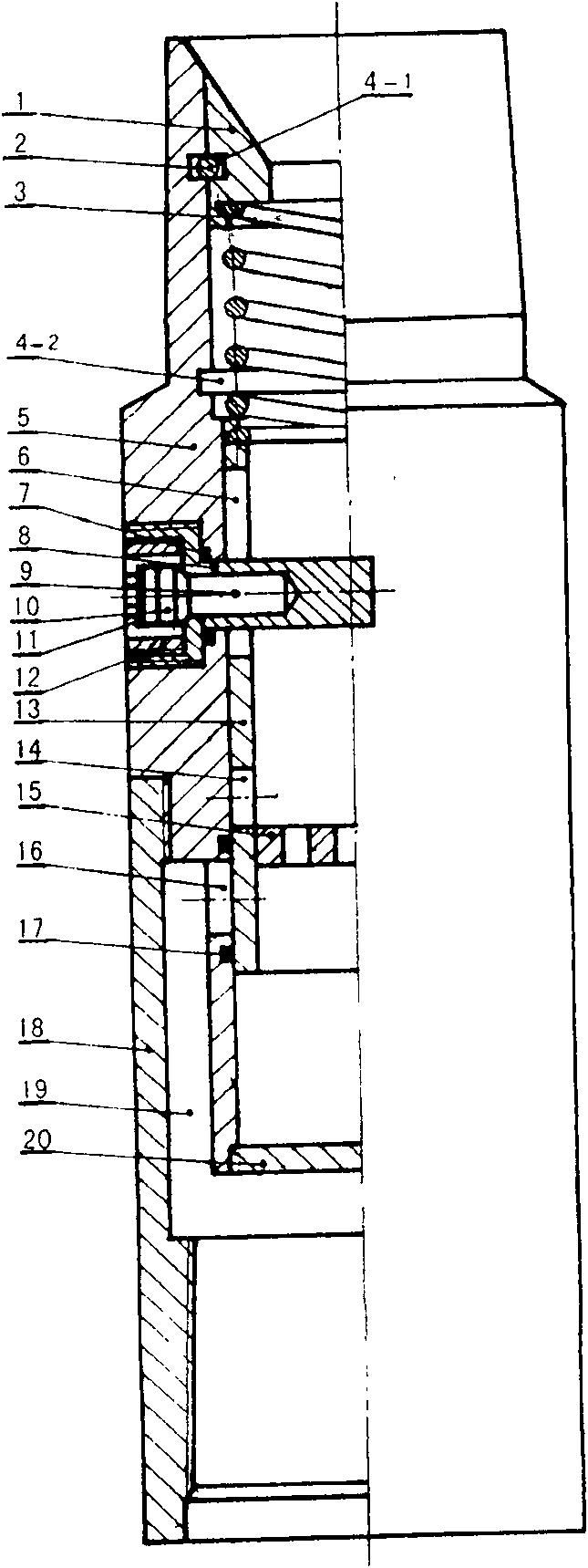

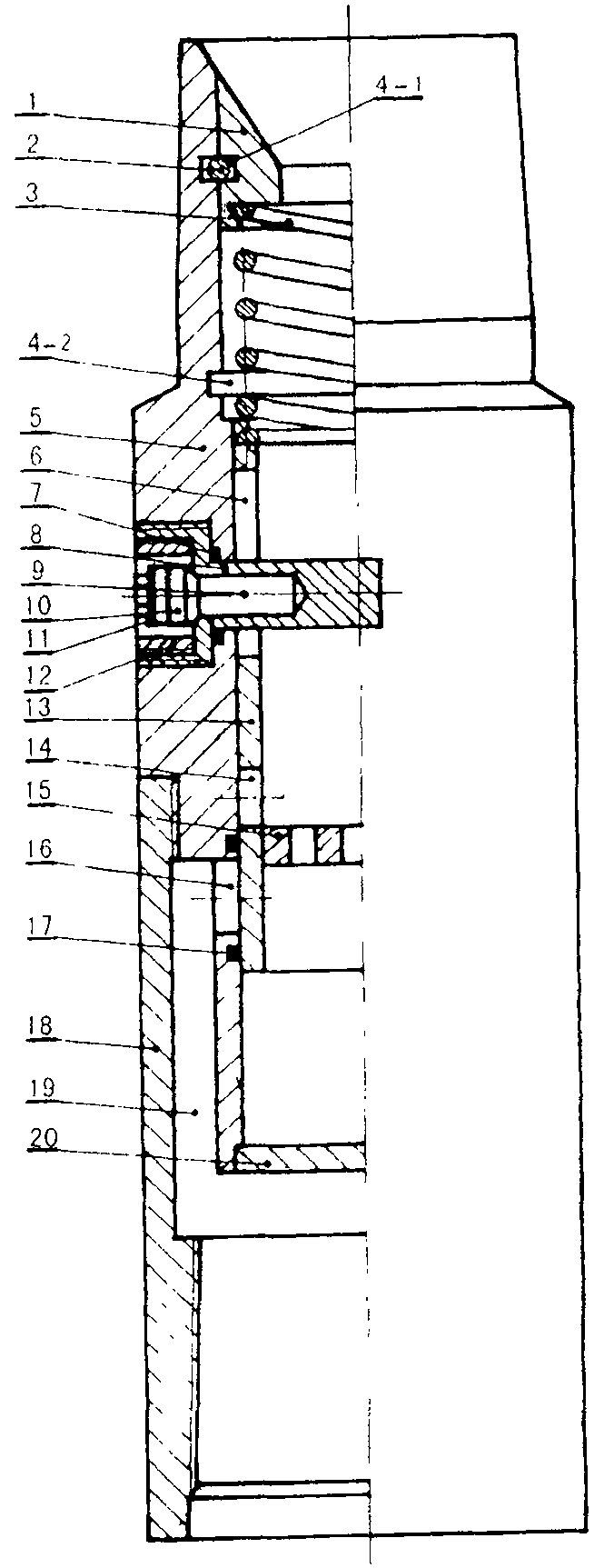

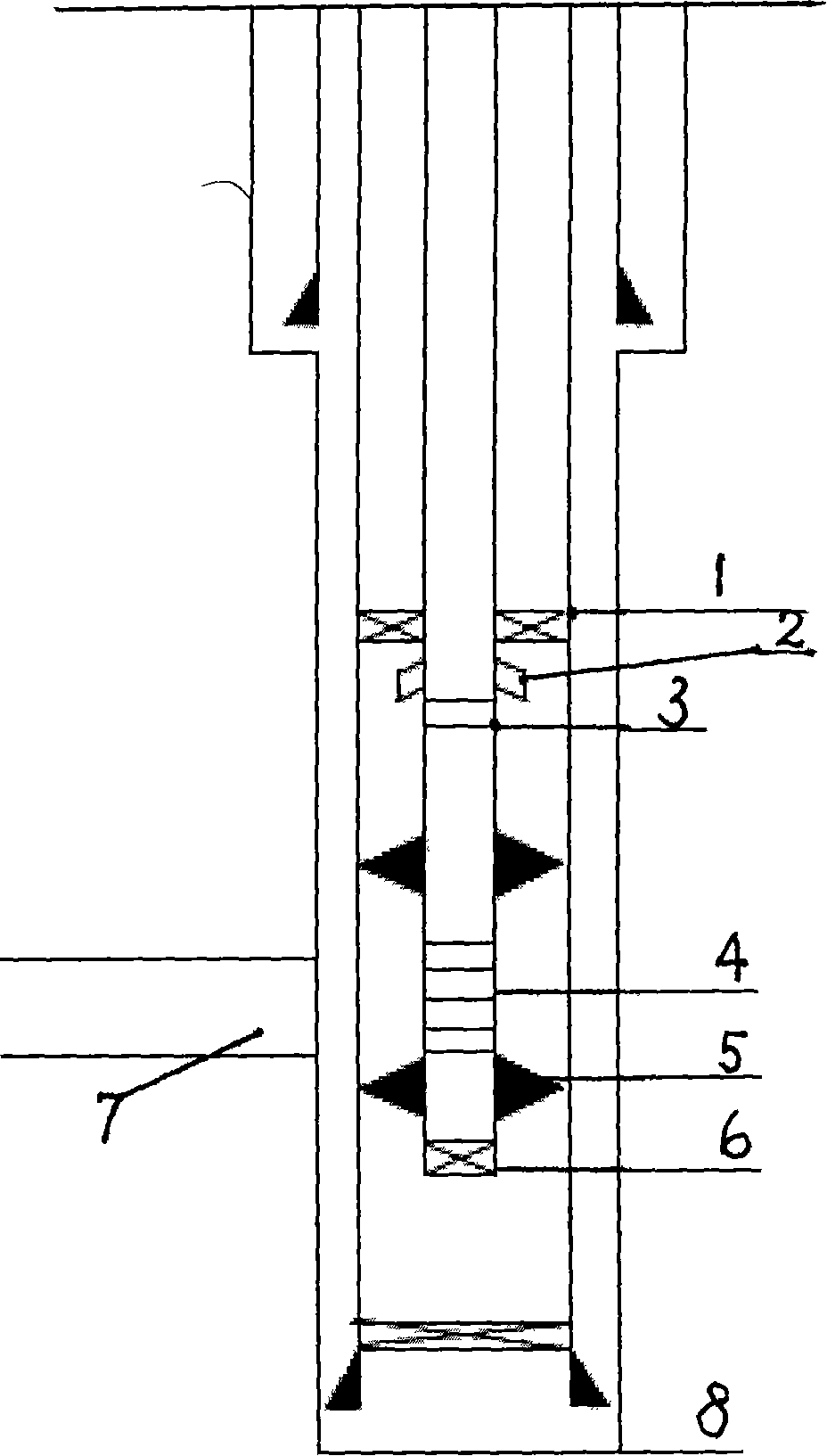

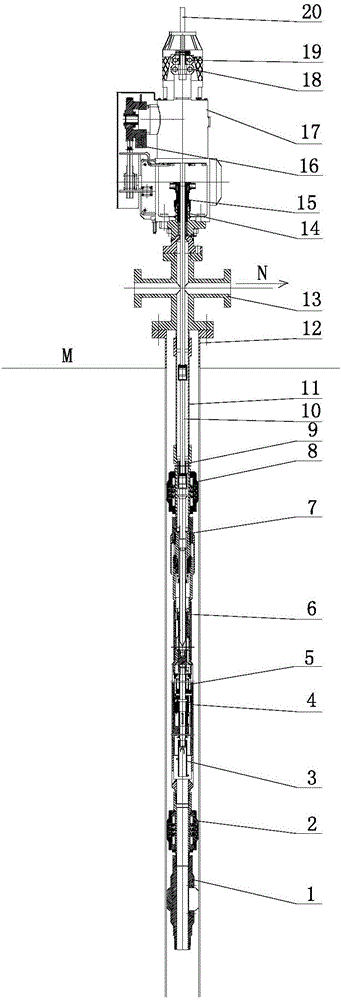

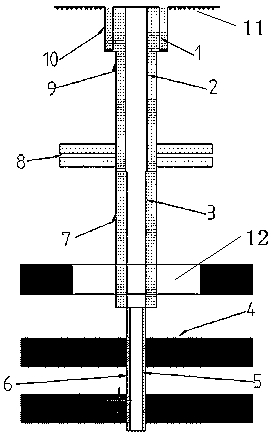

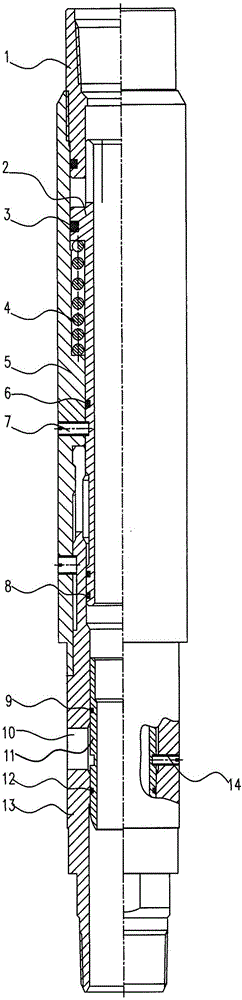

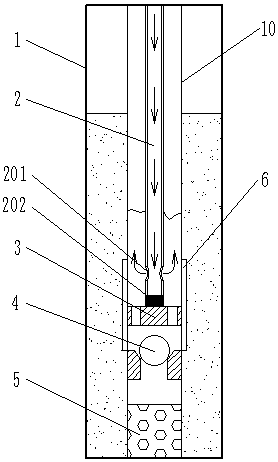

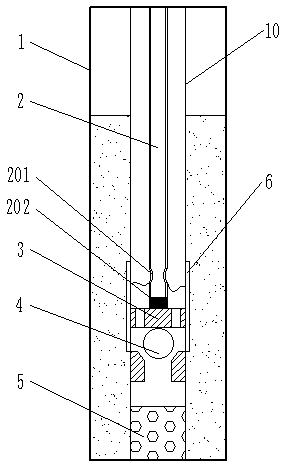

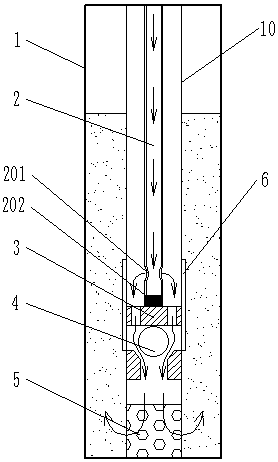

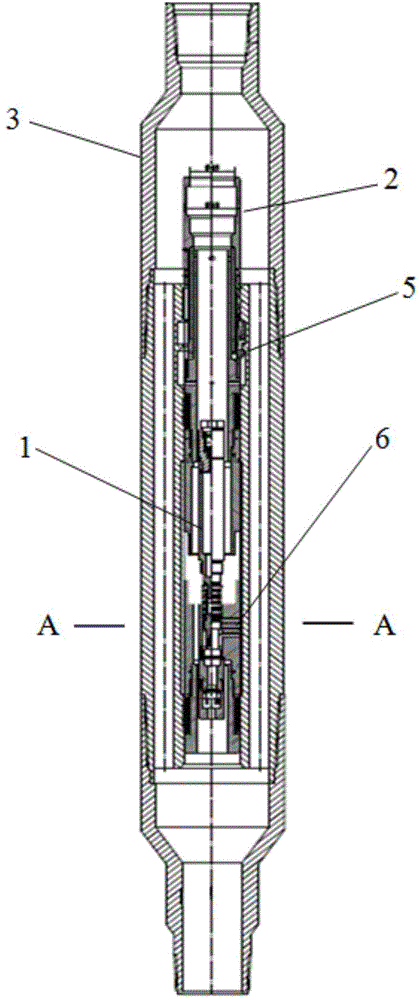

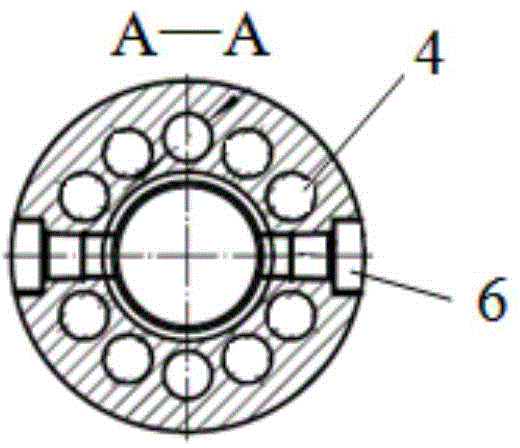

Fully-enclosed device of upper part of injecting layer for downhole operation of high-pressure water injection well

InactiveCN102094595AAutomatically realize air-tight sealingStop upFluid removalWell/borehole valve arrangementsHigh pressure waterWorking set

The invention belongs to the field of fully-enclosed equipment of an upper part of an injecting layer for downhole operation of an oil field, and particularly relates to a fully-enclosed device of the upper part of the injecting layer for downhole operation of a high-pressure water injection well. The fully-enclosed device comprises a release (1) connected with an oil pipe screw thread, an automatic sealing mechanism (2) connected with the inner wall of an oil pipe in a matching way, automatic sealing and anchoring mechanisms (3 and 4) for an oil casing annular space and a tail water injecting mechanism; the automatic sealing and anchoring mechanisms (3 and 4) for the oil casing annular space are sealed through rotating a pipe column and applying a work setting force to a wellhead to seal the oil casing annular space; the automatic sealing mechanism (2) adopts a one-way valve structure to ensure that high-pressure water in an oil layer is prevented from channeling from the oil pipe; and a packer of the tail water injecting mechanism is used for sealing so as to ensure injection allocation in a layered way. By virtue of the invention, water injection is stopped when downhole operation is required due to a damaged drivepipe or other emergencies during high-pressure water injecting, full sealing of the oil pipe and oil casing annular space can be automatically realized, thereby the high-pressure water is prevented from channeling, and a repair task on the water injection well can be rapidly completed by minor repair.

Owner:CNPC GREATWALL DRILLING ENG

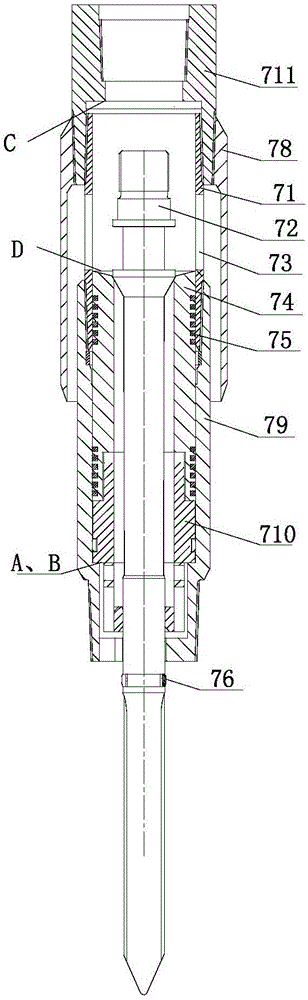

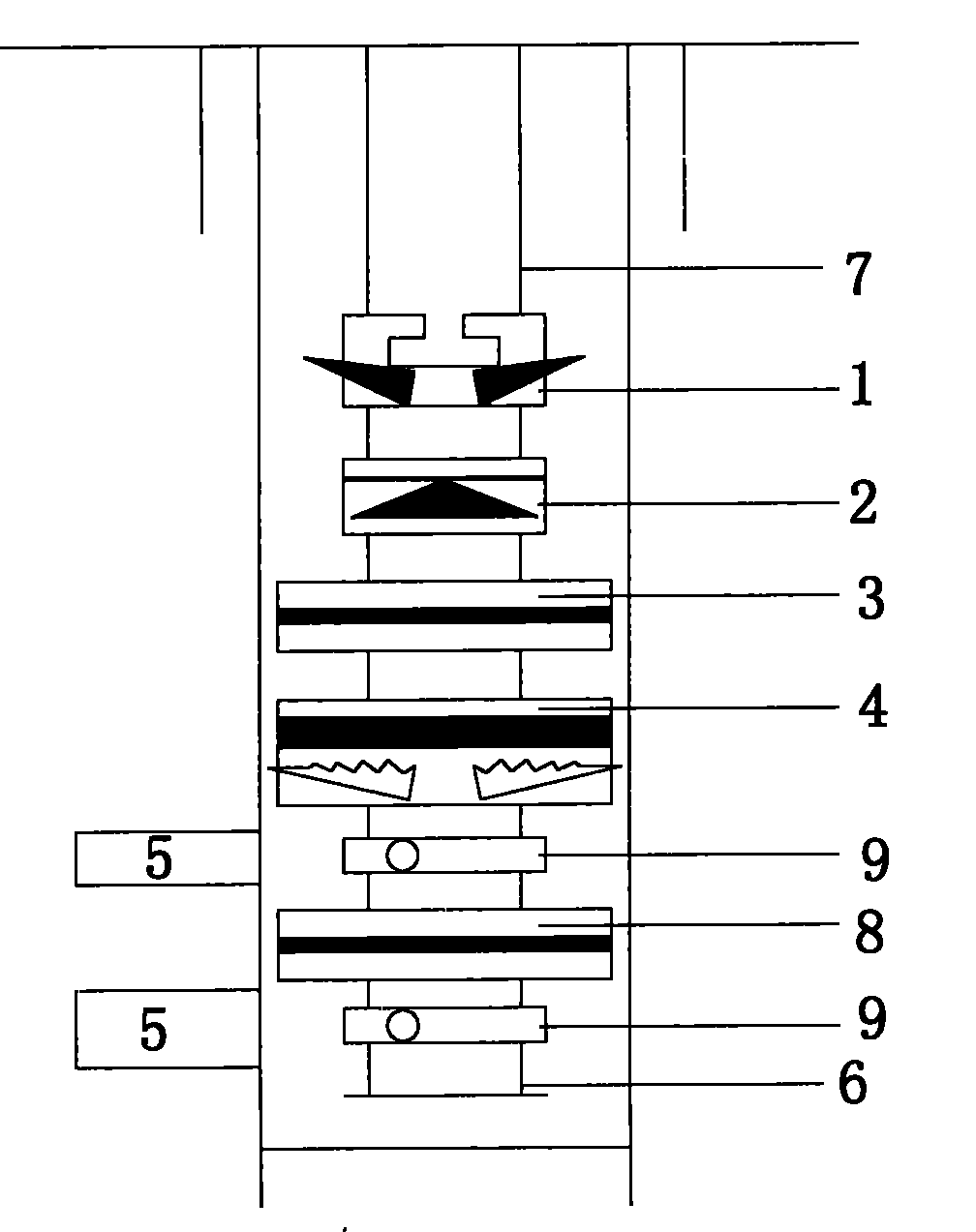

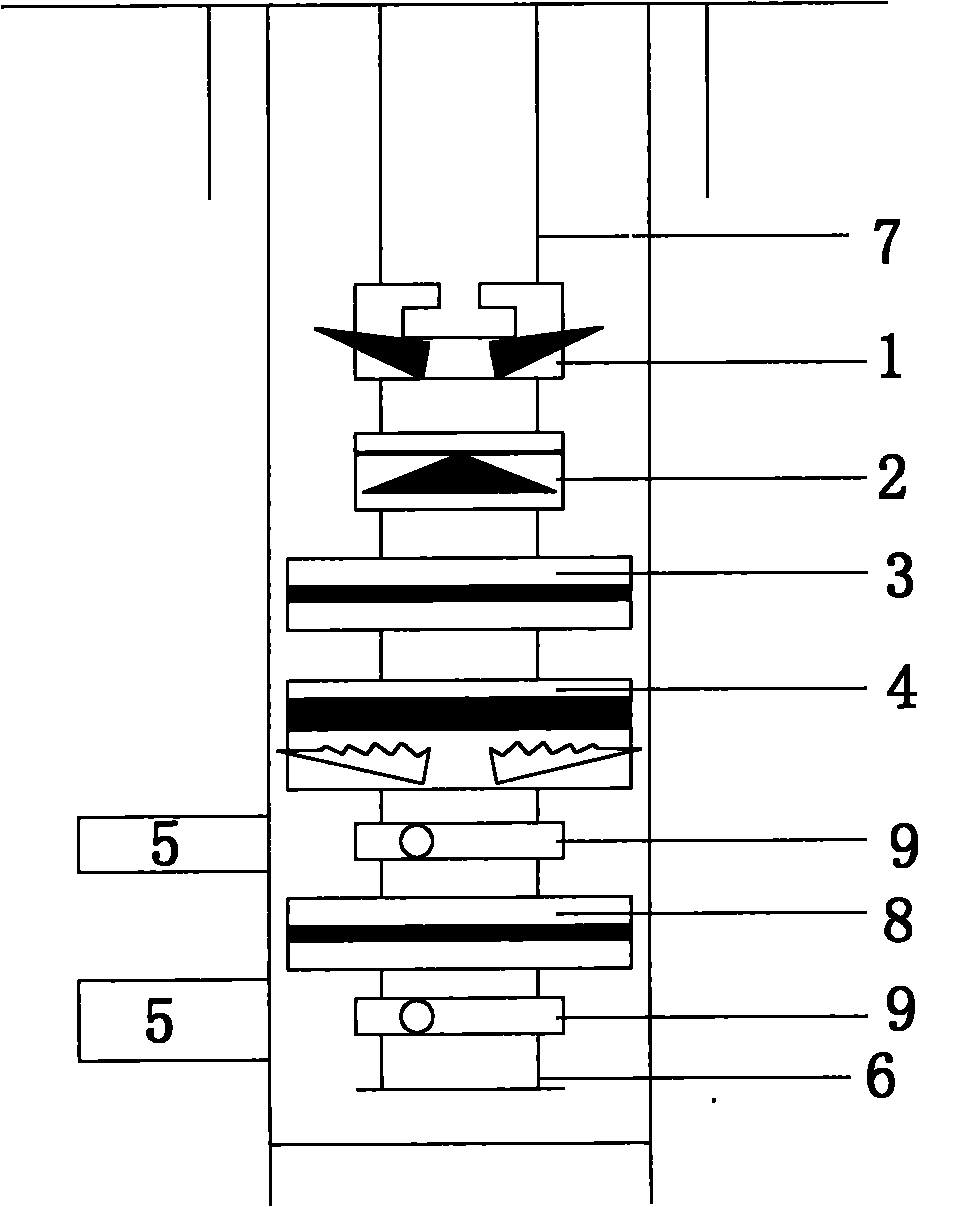

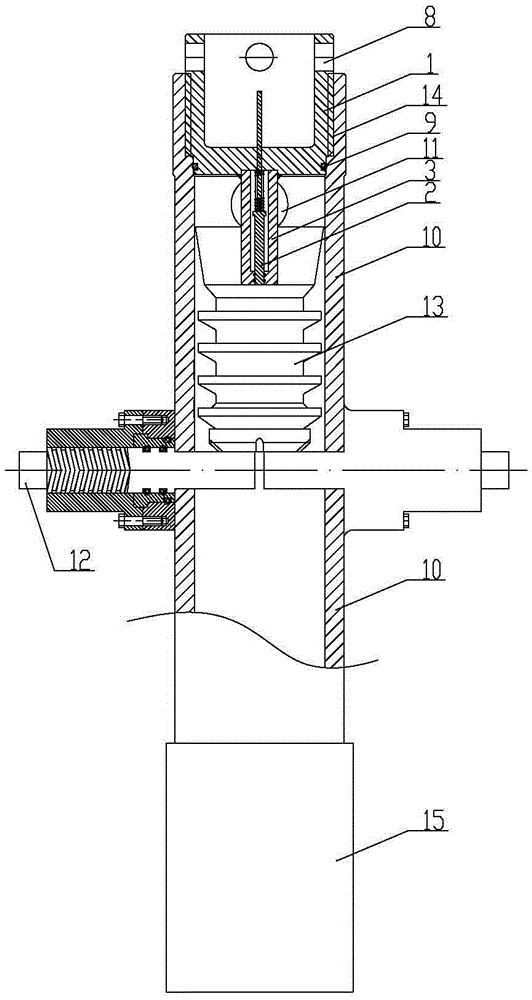

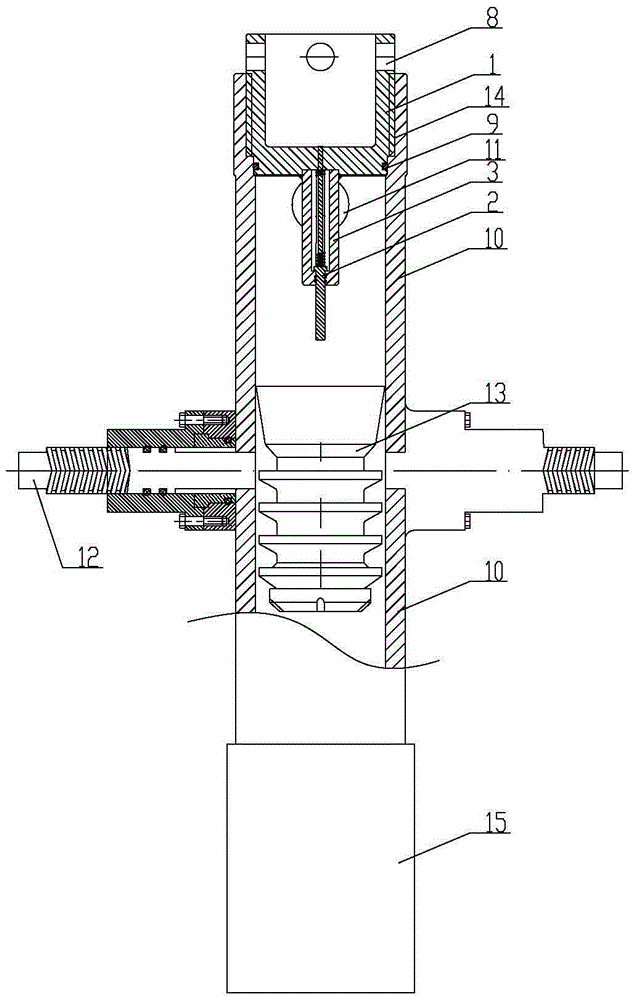

Safety trip device for fracturing string

ActiveCN105545222AReduce homework workloadEasy constructionDrilling rodsFluid removalEngineeringShear pin

The invention relates to a safety trip device for a fracturing string. The upper portion of an inner suspending pipe is milled into strip bodies, the strip bodies are suspended on a suspending circular bead in an outer suspending pipe, an upper seal ring, a middle seal ring and a lower seal ring are installed on a lock sleeve, the lock sleeve is sleeved with a spring, the lock sleeve is installed into the outer suspending pipe, and the outer wall of the lock sleeve stops that milled strip bodies on the upper portion of the inner suspending pipe; the lower portion of an upper connector is connected with the upper portion of the outer suspending pipe, a kerf is formed in the upper portion of the lock sleeve, a part of the kerf is installed into the upper connector, and the outer suspending pipe is connected through a lock pin; the upper seal ring is located above the spring, the middle seal ring is located between the spring and the lock pin, the lower portion of the lock sleeve is inserted into the inner suspending pipe, the gap between the lock sleeve and the inner suspending pipe is sealed by the lower seal ring, and the lower seal ring is located below the milled strip bodies on the upper portion of the inner suspending pipe; a communicating groove is formed in the inner suspending pipe, a sliding sleeve upper seal ring and a sliding sleeve lower seal ring are installed on a sliding sleeve, and the sliding sleeve covers the communicating groove in the inner suspending pipe and is fixed by a sliding sleeve shear pin.

Owner:东营市兆鑫工贸有限责任公司

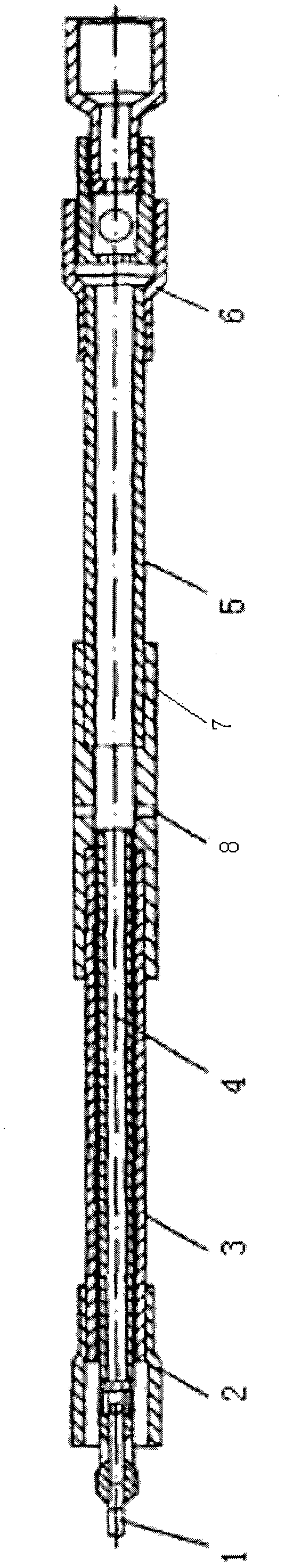

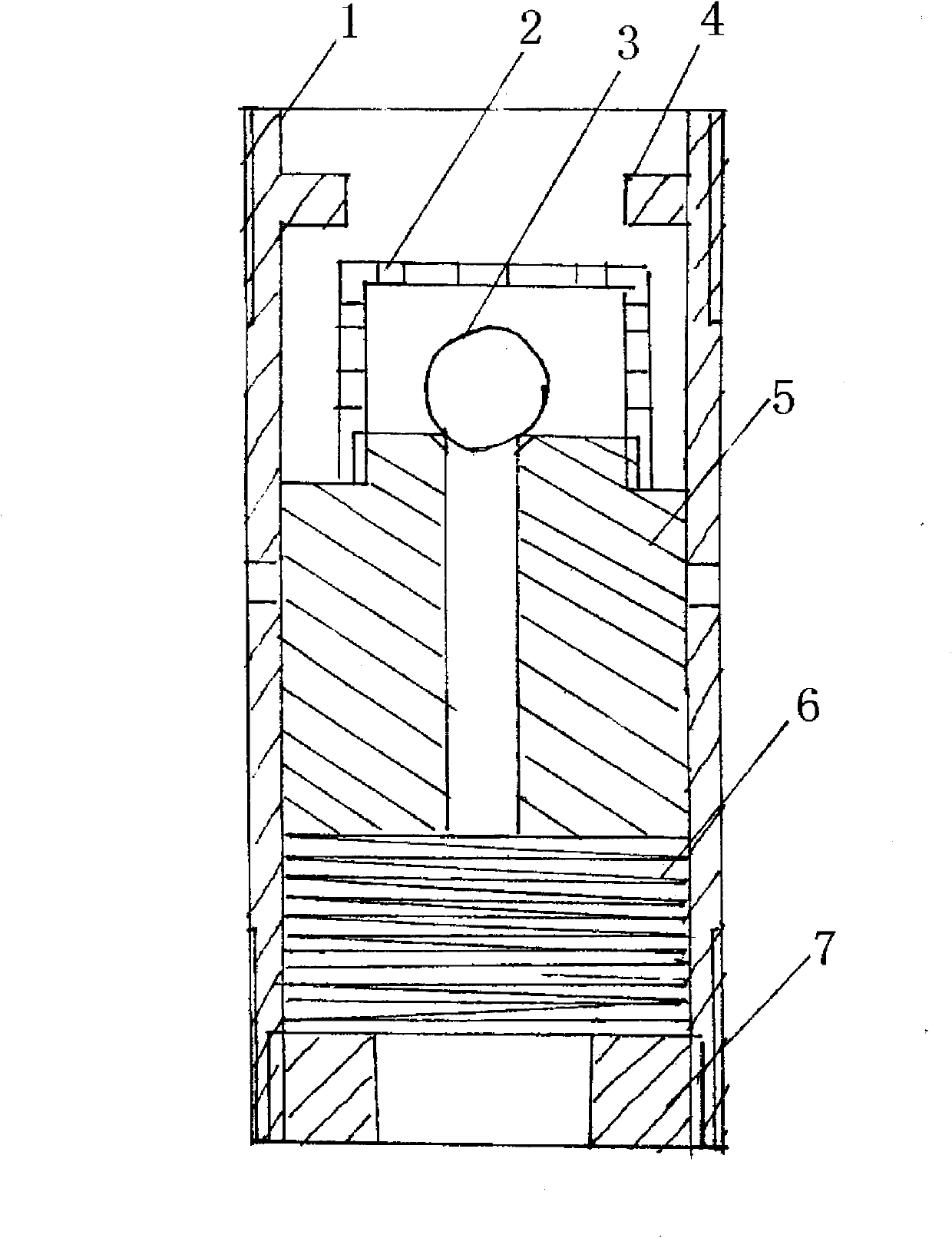

Middle exhausting gas prevention oil-well pump and oil pumping technology thereof

InactiveCN103133335AImprove fullnessReduce pollutionPositive displacement pump componentsFlexible member pumpsEngineeringOil well

The invention discloses a middle exhausting gas prevention oil-well pump which is mainly composed of an upper pump cylinder, a lower pump cylinder, a plunger and a plunger connecting bar, wherein the upper pump cylinder and the lower pump cylinder are communicated, the plunger is arranged inside the upper pump cylinder, and the plunger connecting bar is connected with the plunger. The upper pump cylinder and the lower pump cylinder are connected in series through a connecting cylinder. At least one exhausting hole is formed at the side wall of the connecting cylinder. The invention further discloses an oil pumping technology based on the middle exhausting gas prevention oil-well pump. The plunger of the middle exhausting gas prevention oil-well pump is long, and due to an exhausting groove in the middle of each pump cylinder, oil inlet conditions are improved, fullness of a chamber of each pump cylinder at the lower portion of the exhausting groove of each pump cylinder is improved. Therefore, compared with a conventional pump, the middle exhausting gas prevention oil-well pump can effectively improve pump efficiency, an oil pipe and a sleeve are mutually communicated through the exhausting grooves in the middle of the pump cylinders, so that only the plunger is lifted out of the pump cylinders, steam huff and puff on a heavy oil well can be conducted without moving a tubing string. A secondary exhausting groove is formed in each pump cylinder, so that a drip needs not to be installed under a pit, and well repairing cost and environment pollution are reduced. Due to the fact that the exhausting grooves are formed on the pump cylinders, a pressure test cannot be conducted on the whole tubing string after well completion.

Owner:潘美林

Cable transmission drillable type water source well leaking stoppage method

InactiveCN104790895ARealize pluggingExtended service lifeSurveyConstructionsCable transmissionWater source

The invention relates to the technical field of water well repairing, in particular to a cable transmission drillable type water source well leaking stoppage method. The cable transmission drillable type water source well leaking stoppage method comprises the steps that according to the situations of sand gushing and effluent salt water of a problem water well, a logging truck is used in cooperation with a downhole television to find the position of a leakage point of the problem water well, the damage situation of the leakage point is determined, and meanwhile the hole diameter of the problem water well is measured. The cable transmission drillable type water source well leaking stoppage method improves the transmission speed, can achieve leaking stoppage of water wells with the depth being smaller than 200 meters, can achieve repeated operation on the water wells, achieves the purpose of repeated leaking stoppage repairing operations on the same water well, improves the well repairing success rate, prolongs the service life of the water well, relives the labor intensity of well repairing, and reduces the well repairing cost.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

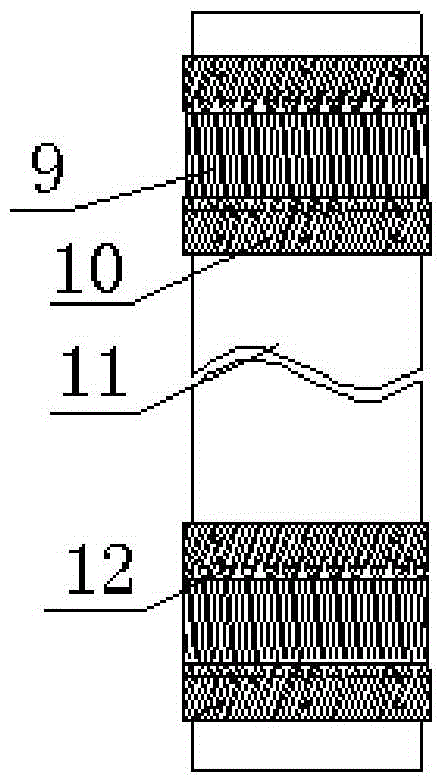

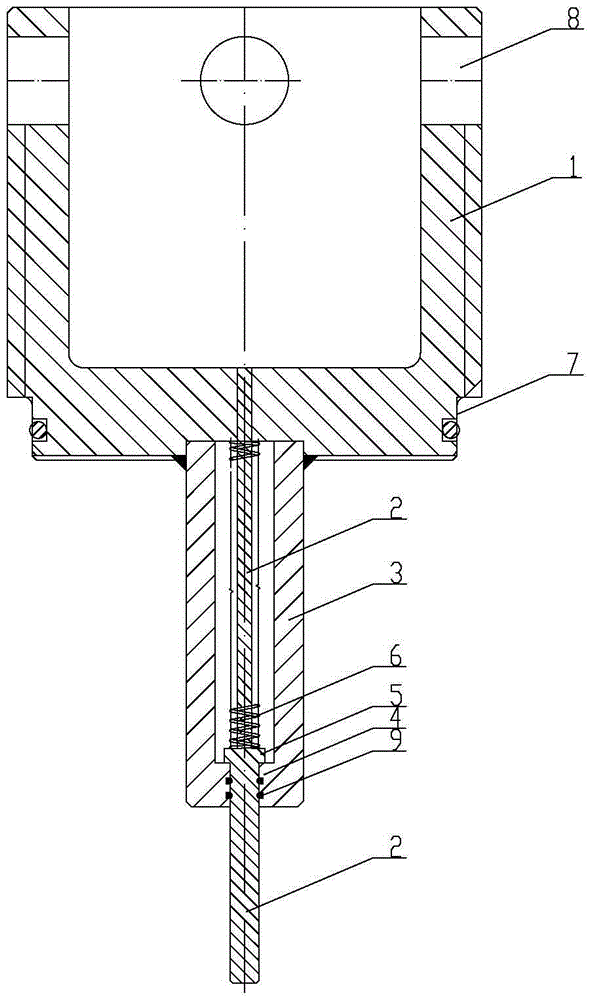

Push rod type indicating device and rubber plug falling indication cementing head

ActiveCN105350941ACompact and reasonable structureEasy to operateSealing/packingWell cementingEngineering

The invention relates to the technical field of cementing tools, and provides a push rod type indicating device and a rubber plug falling indication cementing head. The push rod type indicating device comprises a gland with an upward opening, a push rod and a sleeve; the lower end of the gland is fixedly connected with the sleeve, the bottom of the gland is provided with an installation hole communicated with a cavity of the sleeve, the inner side of the lower end of the sleeve is integrally fixed with a baffle ring, and the outer side of the lower portion of the push rod is integrally fixed with an annular clamping block. According to the push rod type indicating device and the rubber plug downward indication cementing head, the structure is reasonable and compact, through matched usage of the push rod type indicating device, a cementing head body, a stop pin and a rubber plug, the purpose of judging whether the rubber plug falls or not by observing stretching out and retracting of the push rod when rubber plug pressing is performed in well cementing operation is achieved, and the serious problems that pressure bumping cannot be performed and a large number of cement plugs are reserved in the downhole due to the fact that the rubber pug cannot fall are prevented from occurring; the advantages of being safe and reliable is achieved, operation is facilitated, the well cementing construction success rate is increased, the well cementing quality is improved, and meanwhile the well cementing and repairing cost is greatly reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Well repair method for treating coalbed methane well sand burial

ActiveCN110984880AShorten workover timeReduce workover costsDrilling rodsConstructionsGas liftProcess engineering

The invention discloses a coalbed methane development production use, and particularly relates to a well repair technology in a coalbed methane well production process. Under the condition that a welldoes not need to be majorly repaired, the problem that a coalbed methane well oil tube column is buried by sand can be solved. A gas lift manner is firstly used for draining water remaining in an oilpipe to the ground, hydraulic column pressure borne by a fixed valve ball is unloaded, through magnetic force, a fixed valve is opened, through gas, circulation to space of sand and pulverized coal sediment space is achieved, a mixture of sand, pulverized coal and water is roiled, and the constraint of solid sediment on the oil pipe column is reduced. The method has the advantages that the characteristic that fluid flows to drive solid particles is used for relieving the constraint of the solid sediment on the oil pipe column, and the tedious heavy repair can be avoided; and the method is used for greatly saving the well repair cost, and meanwhile, the damage to the coalbed methane well capacity due to long-time shutdown can be avoided.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

Up-running-proof pipe string sealing check device

ActiveCN101761332AShorten workover timeReduce workover costsSurveySealing/packingEngineeringConical surface

The invention relates to an up-running-proof pipe string sealing check device, a communicating hole is further arranged on a lower joint of an expansion type packer, a sealing sleeve is sheathed on the lower joint of the expansion type packer, the sealing sleeve covers the communicating hole, an outer sealing ring is arranged between the lower joint of the expansion type packer and the sealing ring, a conical port at the upper end of the sealing sleeve is in matching and contact with the outer conical surface of the lower joint of the expansion type packer, a connecting head is mounted at thelower part of the lower joint of the expansion type packer, a constant pressure spring is arranged between the sealing sleeve and the connecting head, a sliding sleeve is mounted in the lower joint of the expansion type packer, the sealing ring is mounted on the outer wall at the upper part of the sliding sleeve, a lower sealing ring is mounted on the outer wall at the lower part of the sliding sleeve, the upper sealing ring is positioned above a pressure transfer hole, the lower sealing ring is positioned below the communicating hole, the sliding sleeve is fixed on the lower joint of the expansion type packer through a pin, and a valve ball is positioned on an upper port of the sliding sleeve. The device can use an up-running-proof back-off pipe string for carrying out the string pressure testing sealing check, thereby reducing the next pressure testing sealing check pipe string, saving the workover cost, reducing the workover time and having significant economic benefits.

Owner:南通山口精工机电有限公司

Device for displacing oil underground, preventing reflow and automatically relieving pressure

InactiveCN101769140APrevent reversalAvoid pollutionWell/borehole valve arrangementsSealing/packingCoil springPetroleum engineering

The invention discloses a device for displacing oil underground, preventing reflow and automatically relieving pressure, which mainly comprises a body, a sealing ball cover, a sealing ball, a sliding block, a spring, limiting blocks and a spring seat, wherein the body is set into a cylinder shape; the circumferences of the upper part and the lower part of the body are provided with male threads; the inner circumference of the upper part is provided with a plurality of limiting blocks; the inner circumference of the lower part is provided with female threads; the center the upper end part of which is provided with the sealing ball cover is provided with a center hole in the middle of the body; the cylindrical sliding blocks of the sealing ball is arranged at the upper part of the center hole; a spiral spring is arranged at the middle lower part of the center hole; the spring seat which is in threaded connection with the body is arranged at the lower part of the center hole; the middle of the body is provided with a plurality of oil draining holes; the sliding blocks and the body are in movable sealing fit; male threads at the lower end of the body are connected with threads of an outlet pipe of an underground lifting pump; and male threads at the upper end of the body are connected with an oil pipe column. The invention has the advantages of simple structure, reliable sealing, no soft sealing member, long service life, no need of replacement, reduction of times for pulling the oil pipe and well repairing cost economization.

Owner:XI'AN PETROLEUM UNIVERSITY +1

Sand preventing device

The invention relates to a sand preventing device and particularly relates to a sand preventing device for oil wells. The sand preventing device comprises a hollow cylindrical body, a connector is arranged on the upper portion of the body, and a bag pipe column is fixedly arranged on the lower portion of the body. The sand preventing device is characterized in that a plurality of filtering holes are arranged on the body. According to the sand preventing device, the body and the bag pipe column are arranged on the lower portion of an oil well pump, the length of the oil well pump is not relatively prolonged, time for dirt and sands to burry oil layers is delayed, the phenomenon that pump valves and pistons are snapped by sands is avoided, the dirt in shafts can be stored, abrasion of the sands on a pump valve seat and a pump bushing is lessened, pump efficiency is improved, the pump inspection period is prolonged, times of workover treatment are reduced, crude output is increased, and well workover expenses are reduced.

Owner:SHAANXI ZHONGMING ENERGY INVESTMENT

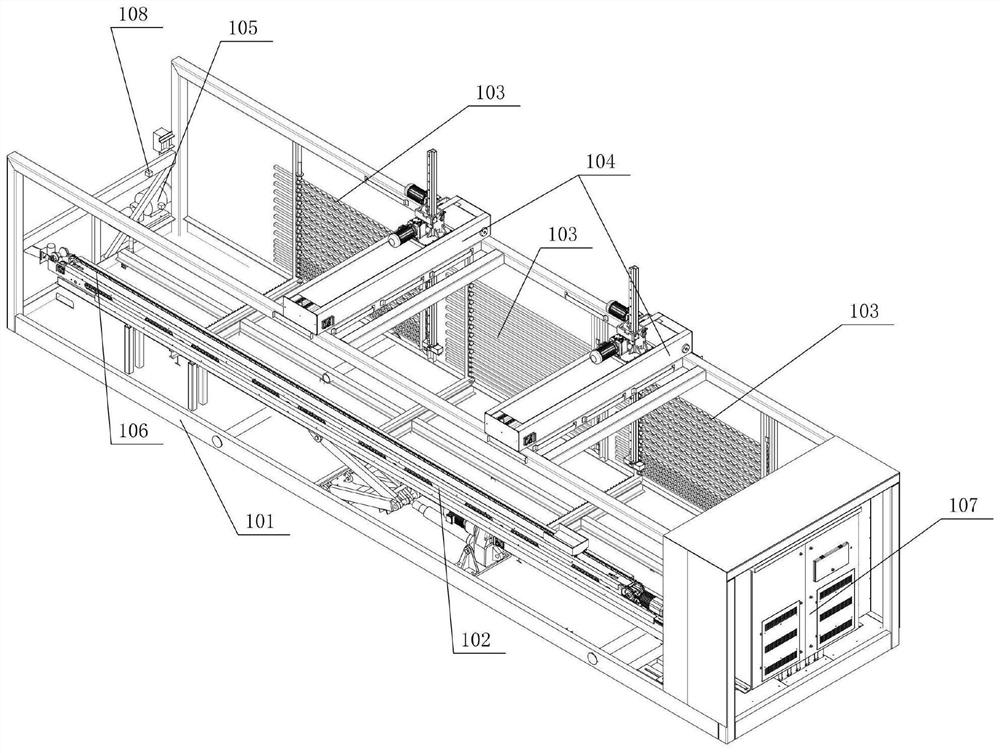

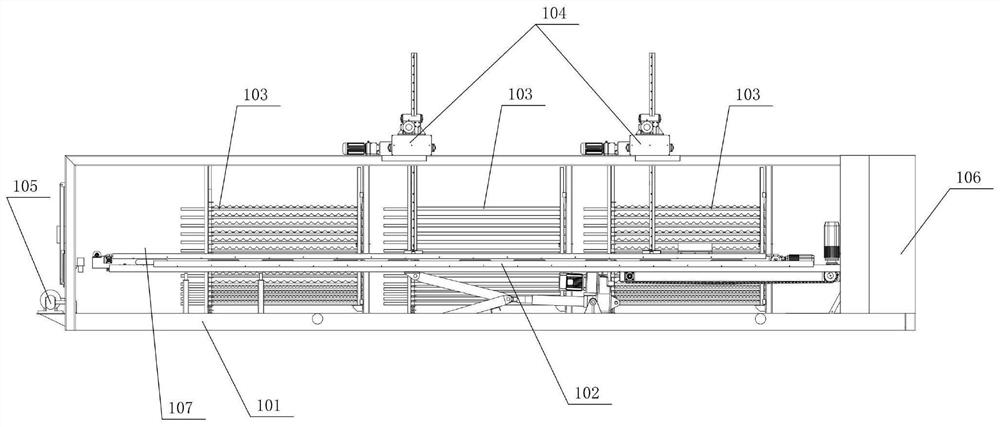

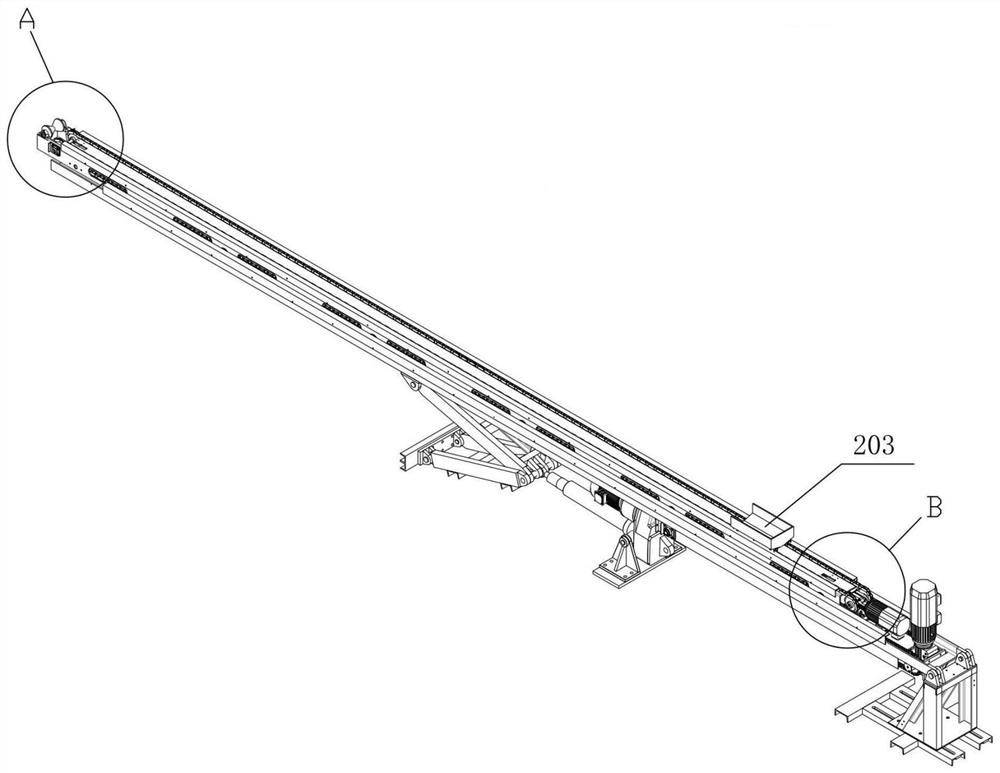

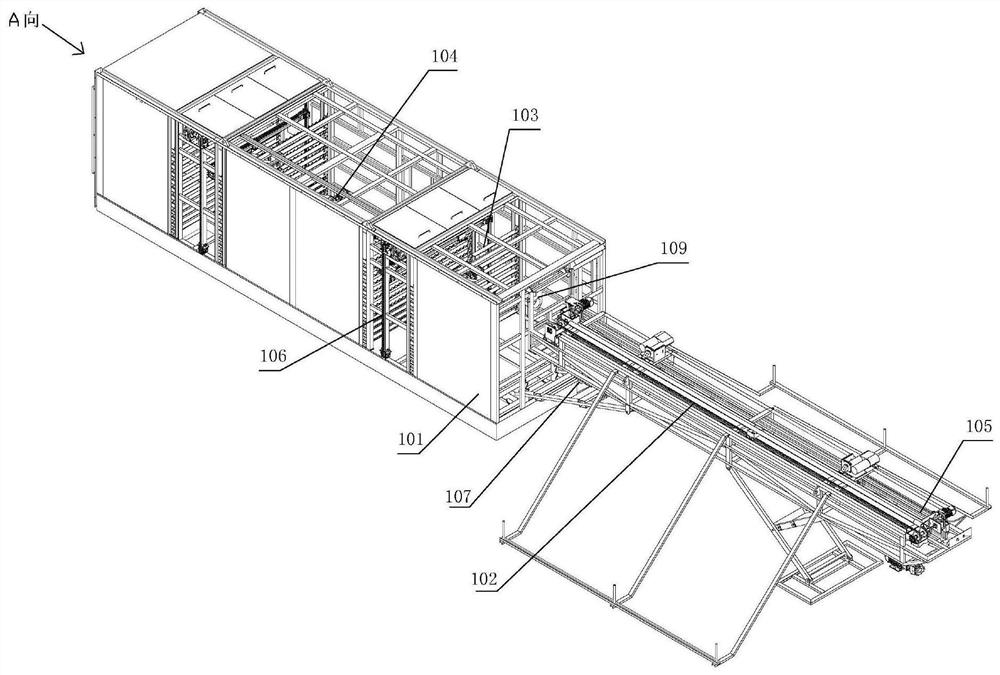

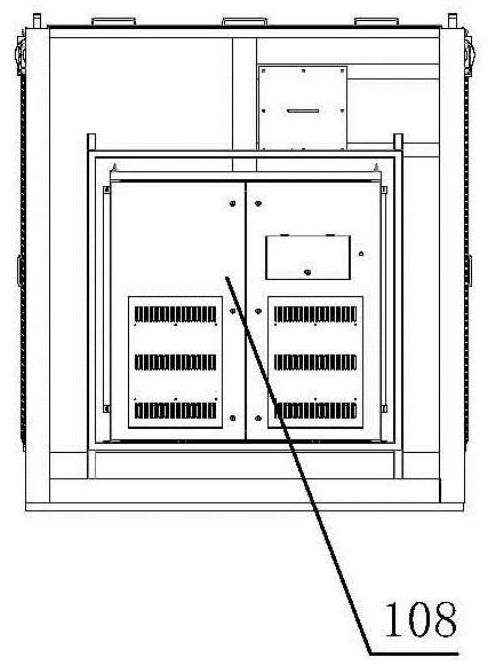

Environment-friendly pipe rod storage and measurement system for well drilling/workover operation

PendingCN113356772ARealize integrated productionReduce labor intensityDrilling rodsMeasurement devicesTransport systemWell drilling

The invention relates to an environment-friendly pipe rod storage and measurement system for well drilling / workover operation. The environment-friendly pipe rod storage and measurement system comprises a main body pipe box, a pipe rod conveying system, a pipe rod moving and transporting system, a rotary layered placing system and a pipe rod length measuring system. The pipe rod conveying system and the rotary layered placing system are arranged in the main body pipe box, the pipe rod moving and transporting system is arranged on the upper portion of the main body pipe box, and the pipe rod length measuring system is embedded in the pipe rod conveying system. According to the environment-friendly pipe rod storage and measurement system, automatic discharging and sorting of sucker rods and sucker pipes in the workover process are achieved, the labor intensity is reduced, the operation efficiency is improved, the workover cost is reduced, and the natural environment is protected; and the advantages that the length of pipe rods is automatically measured, and the precision and the efficiency are high are achieved.

Owner:西安宝德智能科技有限公司

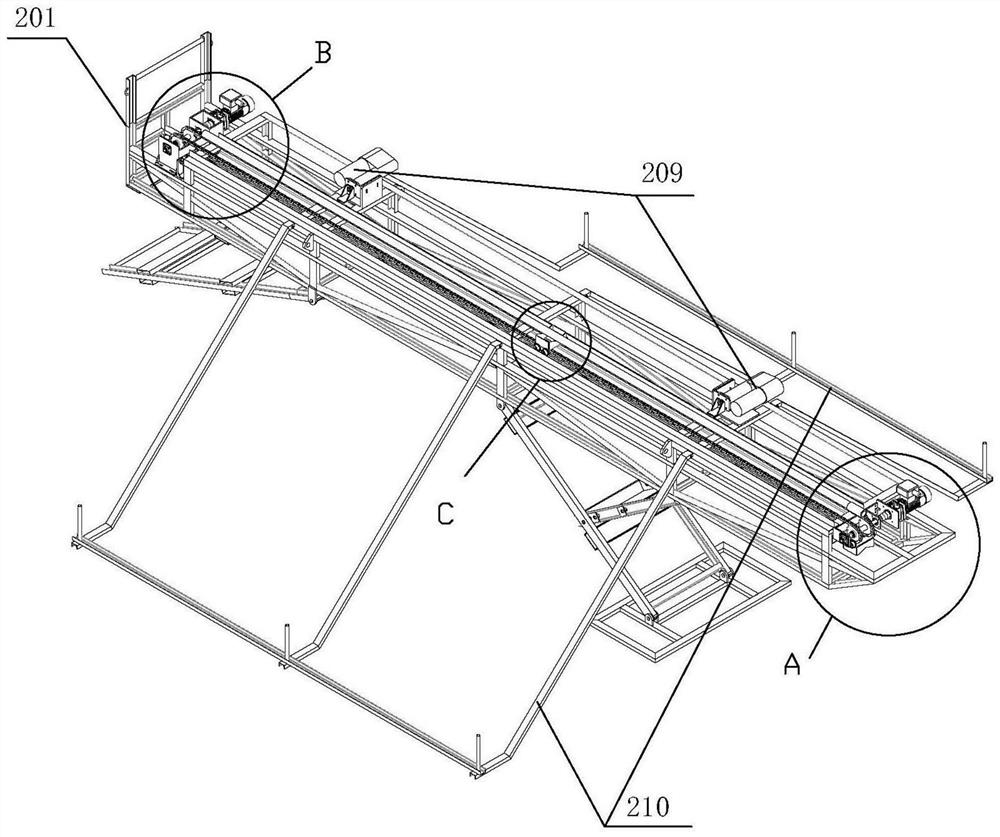

Oil pumping pipe rod storage, cleaning and maintenance system for drilling/workover treatment

PendingCN112360365AReduce labor intensityReduce workover costsDrilling rodsHollow article cleaningEngineeringStructural engineering

The invention relates to an oil pumping pipe rod storage, cleaning and maintenance system for drilling / workover treatment. The system comprises a main pipe box, a pipe rod conveying system, a layeredbracket structure, a pipe rod bearing system, an automatic cleaning system and a pipe rod placing system. The rear end of the pipe rod conveying system is hung at the front end of the main pipe box, the pipe rod bearing system is arranged in the main pipe box and corresponds to the pipe rod conveying system in position, the pipe rod placing system and the layered bracket structure are both arranged in the main pipe box, and the automatic cleaning system is arranged outside the main pipe box and corresponds to the layered bracket structure in position. The operation efficiency can be improved,the well repairing cost is reduced, and the natural environment is protected.

Owner:西安宝德智能科技有限公司

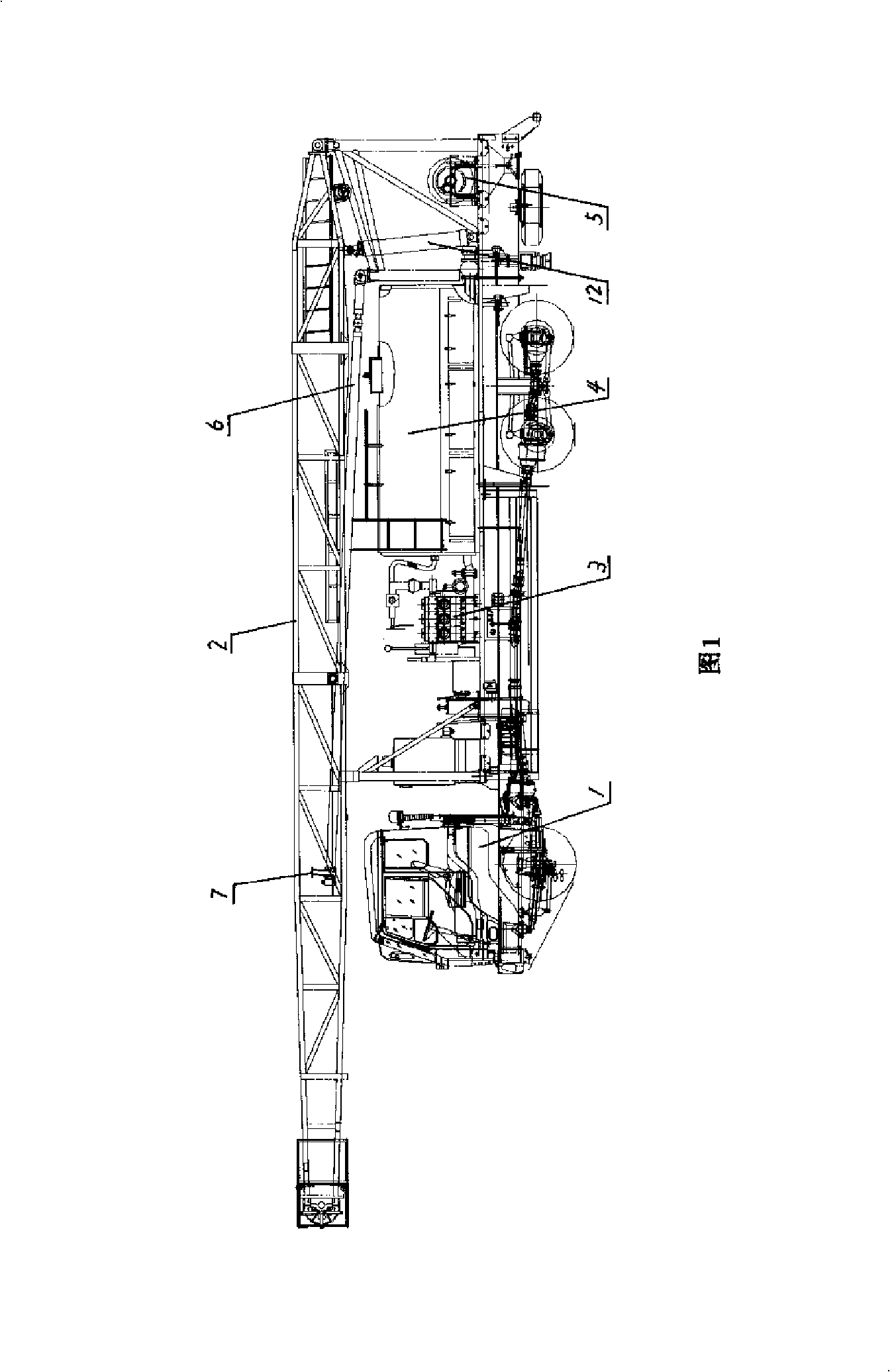

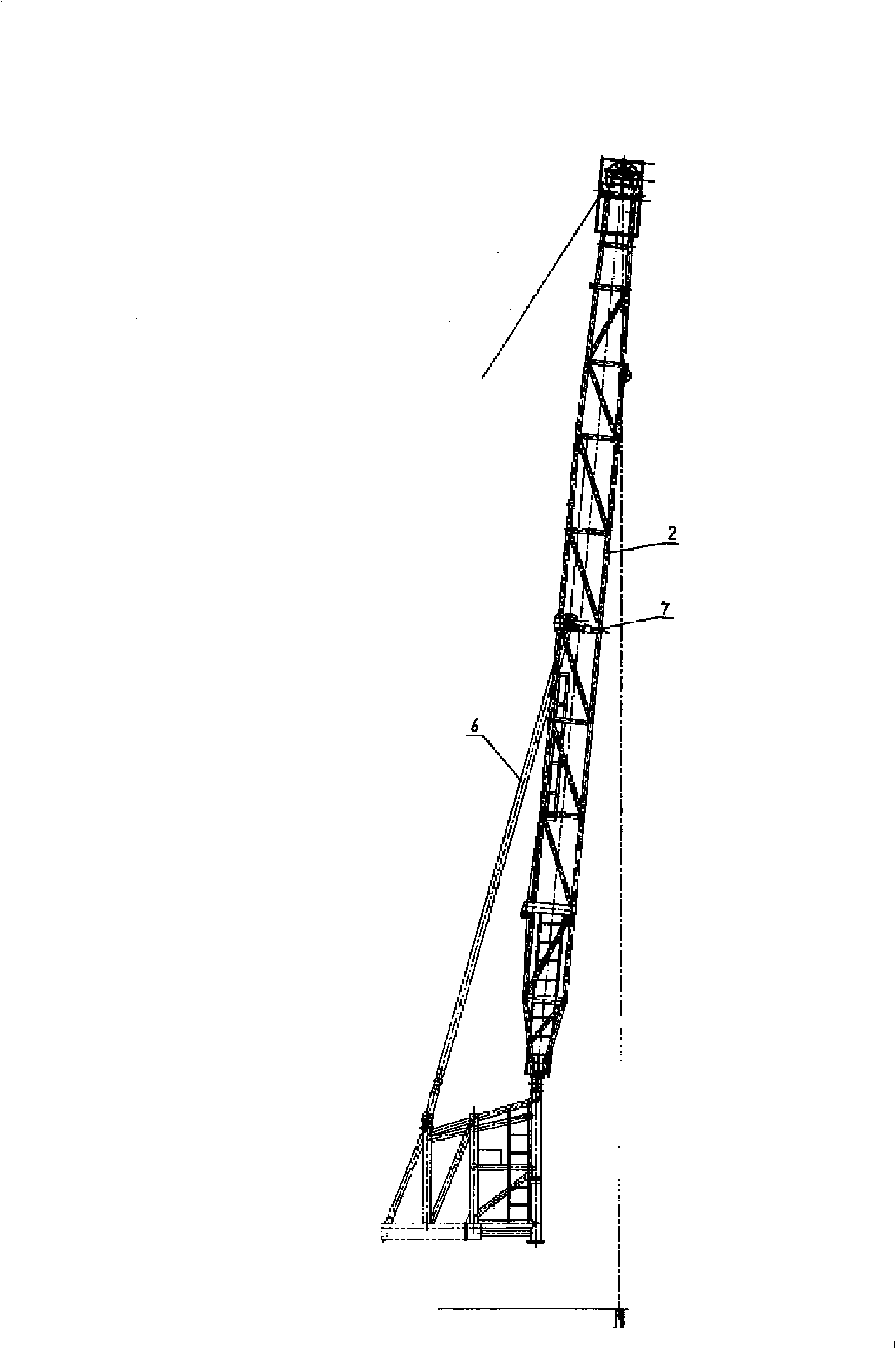

Combined sand-washing well repairing machine

ActiveCN101408094AImprove efficiencyReduce workover costsFlushingDrilling machines and methodsProcess engineeringWinch

The invention relates to a vehicle-mounted petroleum workover rig, in particular to a combined sand removal workover rig, which is particularly applicable to sand removal operation of a screw pump viscous oil well and simultaneously is applicable to the sand removal operation of common oil wells and workover operation of rated hook load with 15 tons. The workover rig comprises a vehicle-mounted chassis and a vehicle-mounted derrick. The vehicle-mounted chassis is provided with a sand removal pump, a solution tank and a winch; and the sand removal pump is connected with the solution tank, thus realizing multiple functions with one machine and continuous operation. The equipment is used for sand removal operation of the screw pump viscous oil well, can replace a traditional crane, a well-flushing vehicle and a pumper, realizes multiple functions with one machine, improves the efficiency, reduces the equipment and reduces the workover cost. The equipment is provided with a hoisting system, thus not only being capable of carrying out broken down operation of sand removal but also being capable of carrying out minor overhaul operation of rated load with 15 tons. The derrick adopts a self-rendering structure of a long and diagonal draw bar so as to lead the equipment not only to be capable of carrying out operation on a vertical well but also to be capable of carrying out operation on a deviated well with the angle of more than 45 degrees. The equipment has flexible operation and is energy-saving and oil-saving.

Owner:TONGHUA PETROCHEM MACHINERY MFG

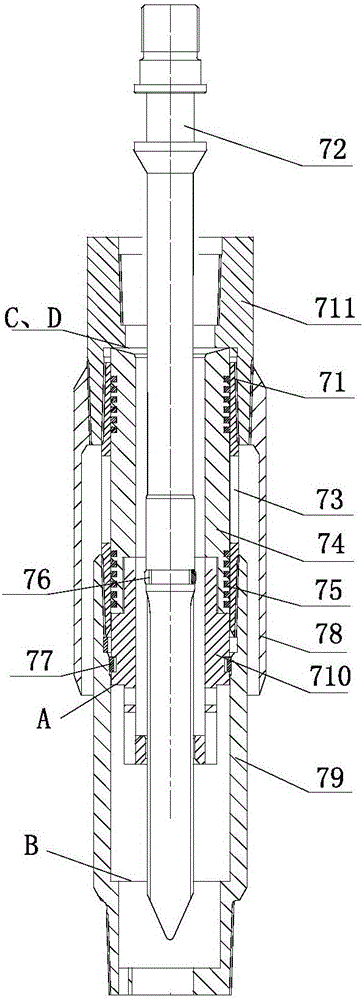

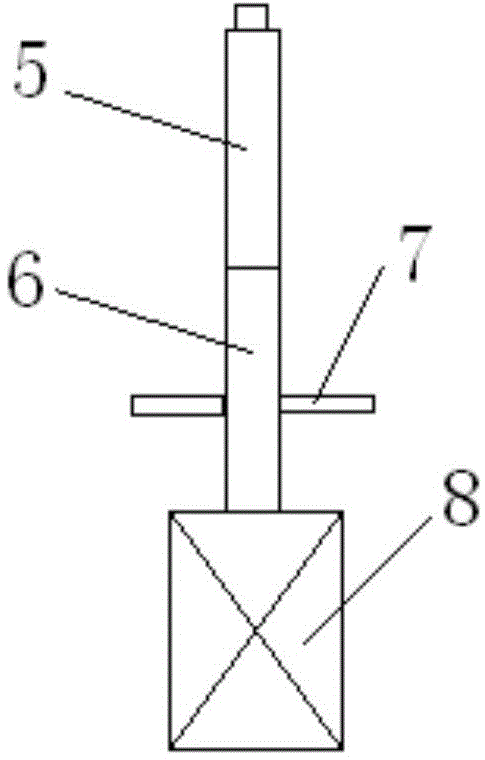

CYT-1 concentric dropping-fishing type gas lifting tool and use method thereof

The invention provides a concentric dropping-fishing type gas lifting tool and a use method thereof, and belongs to the technical field of petroleum and natural gas water discharge gas extraction. The concentric dropping-fishing type gas lifting tool comprises a dropping-fishing type gas lifting valve, a valve bag and a concentric gas lifting work tube, wherein the dropping-fishing type gas lifting valve is built in the valve bag, the valve bag is locked with the concentric gas lifting work tube through an X-shaped lock core, the gas lifting work tube and gas and water flowing passages (10 through holes with the diameter being 19mm) arranged in the work tube adopt the concentric structural design, and the outer side of a tube body of the work tube is symmetrically provided with two one-way valves. The concentric dropping-fishing type gas lifting tool and the use method have the advantages that the work tube and the gas and water flowing passages arranged in the work tube adopt the concentric structural design, the dropping-fishing operation of the gas lifting valve is simple and reliable, the dropping-fishing success rate is effectively improved, in addition, the pulling-resistant intensity of the work tube is high, and scales cannot be easily accumulated.

Owner:PETROCHINA CO LTD

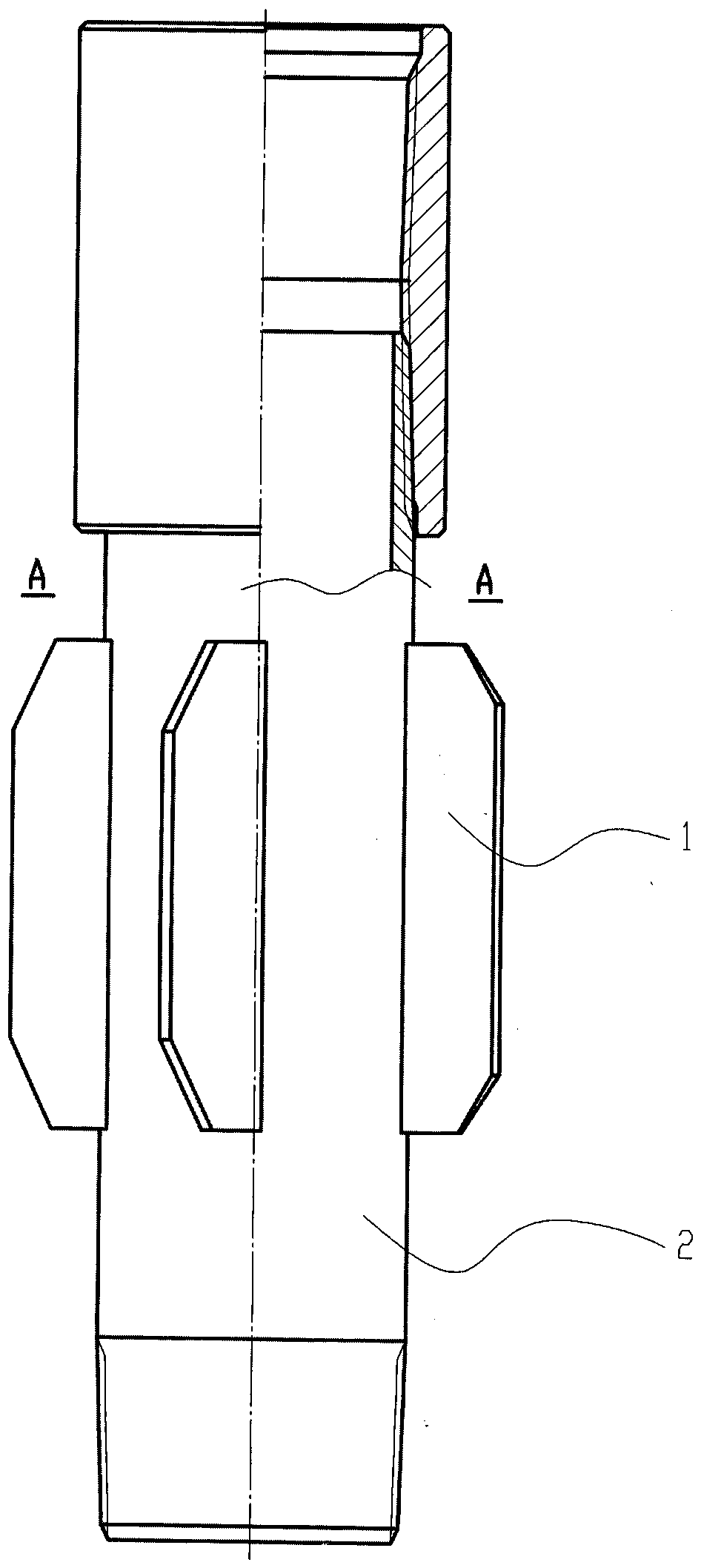

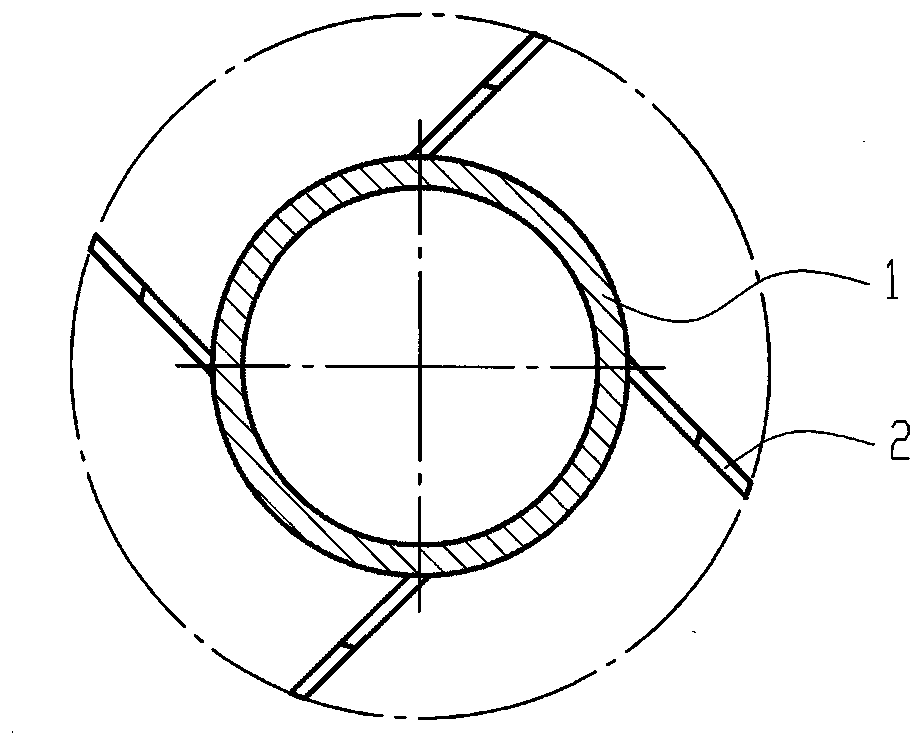

Oil tube centralizer

ActiveCN108331537AReduce the difficulty of unblocking workReduce workover costsDrilling rodsDrilling casingsEngineeringOil water

The invention provides an oil tube centralizer. The two ends of each centralizing piece are provided with chamfers, the included angle between each centralizing piece and the axis of an inner tube is20-70 degrees, and the outer edges of the multiple centralizing pieces are on the same cylinder shape; the axis of the cylinder shape and the axis of the inner tube are coaxial, the minimum positionsof the chamfers of the centralizing pieces can be smaller than the inner diameter of a washover cylinder, after the conical positions at the upper ends of the centralizing pieces are sleeved with thewashover cylinder, the weight of a washover tubular column presses on the centralizing pieces with the included angle between the centralizing pieces and the axis of the inner tube being 20-70 degrees, and the weight of the washover tubular column makes the centralizing pieces to generate bending force towards the interior of the washover cylinder, so that the centralizing pieces are deformed andinwards stored in the washover cylinder; through washover, falling objects such as sand which jams the tubular column can be washed over, the tubular column provided with the oil tube centralizer canbe smoothly subjected to jam releasing, the difficulty of jam releasing work can be reduced, the workover cost of an oil-water well is reduced, and the remarkable economic benefits are achieved.

Owner:山东博诺利石油装备有限公司

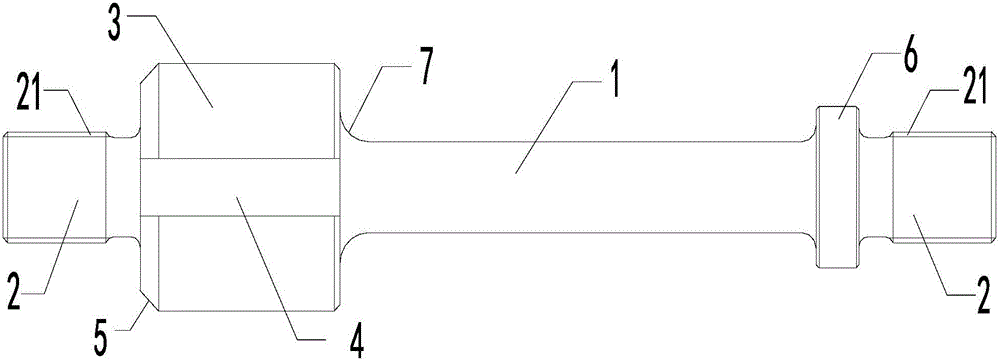

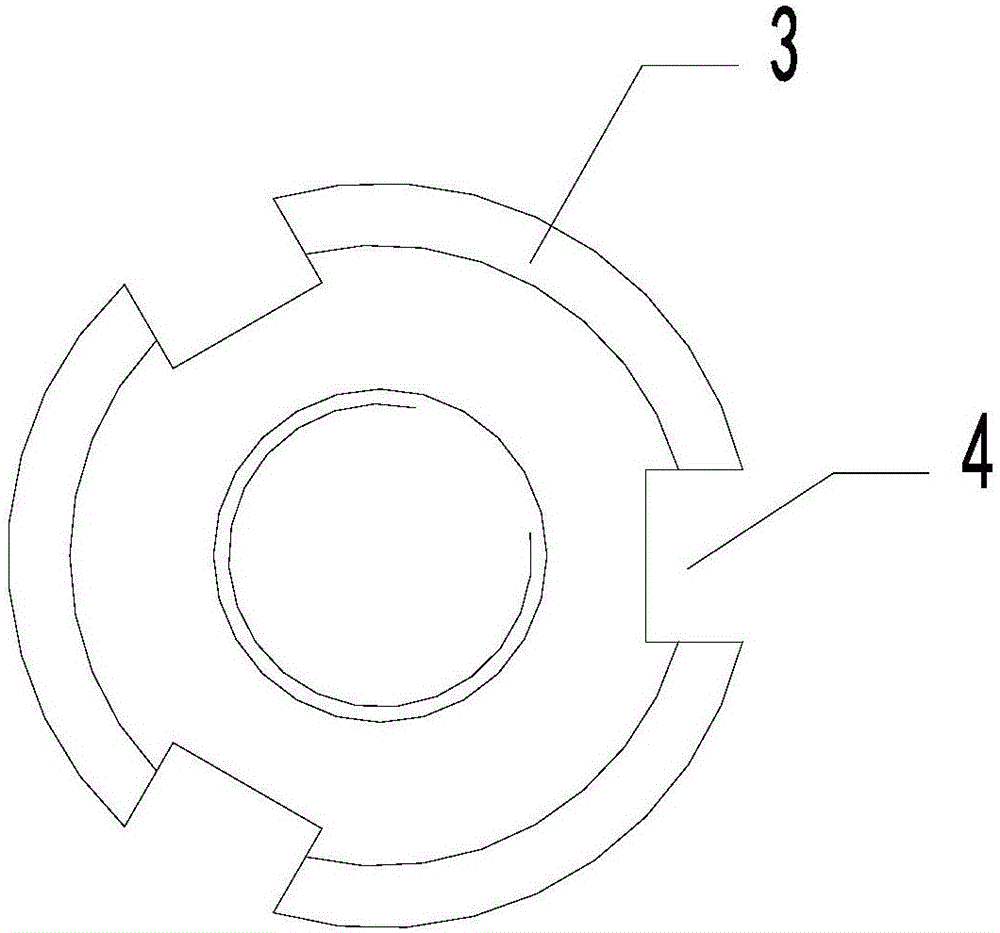

Suspension device of sucker rod

InactiveCN106089125AReduce workover costsReduce production efficiencyDrilling rodsDrilling casingsOil productionEngineering

The invention discloses a suspension device of a sucker rod. The suspension device of the sucker rod comprises a cylindrical suspension body. Connection parts are connected to the two sides of the suspension body, and the surface of each connection part is provided with an outer thread. The connection parts are used for being connected with the sucker rod. The suspension body is provided with at least one groove which penetrates through the suspension body in the axial direction. When the suspension body is placed in an oil tube suspension unit, the grooves can form a channel for air injection. By means of the suspension device of the sucker rod, the air injection process can be completed without lifting a rod string, so that the increased well repairing cost caused by ascending and descending the sucker rod is reduced, and the oil production efficiency is prevented from being reduced.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com