Drilling method for preventing water accumulation in goaf

A goaf and drilling technology, applied in drilling equipment and methods, drilling equipment, earth-moving drilling and mining, etc., can solve problems such as treating the symptoms but not the root cause, damaging the inner wall of the rock formation, and blocking the well due to the collapse of the rock formation, so as to improve productivity and yield. efficiency, reducing workover costs, and stabilizing well structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

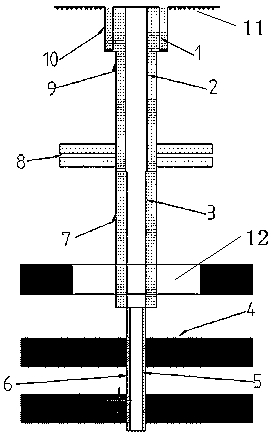

[0019] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0020] A drilling method for preventing water accumulation in a goaf, the specific steps are as follows:

[0021] (1) Before designing the wellbore structure of the ground goaf, draw the aquifer joint well profile according to the surrounding hydrogeological conditions, and estimate the aquifer position of the local surface goaf well according to the aquifer joint well profile;

[0022] (2) drilling construction;

[0023] A 425mm drill bit is drilled to 10m below the bedrock weathering zone to form a drill hole, and a 377mm surface casing is lowered for cementing, and the cement is returned to the ground;

[0024] The second drilling 311mm drill bit is drilled to 10m below the lowest layer of aquifer in the upper part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com