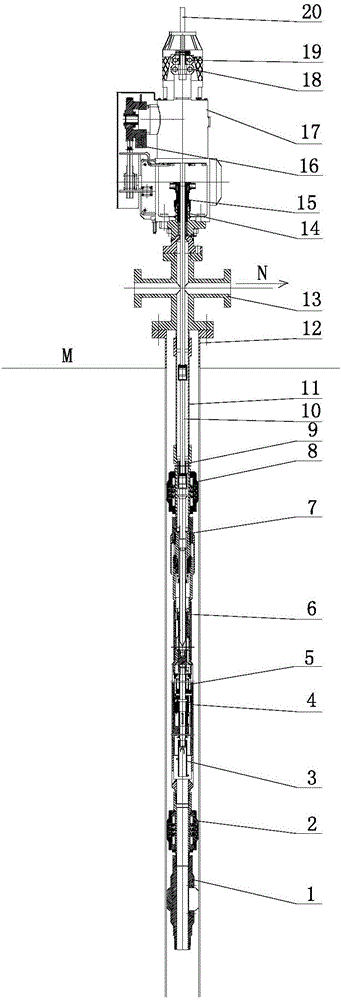

Lifting device for petroleum production vane pump of petroleum well

A lifting device and vane pump technology, which is applied in the direction of wellbore/well valve devices, pumps, pump components, etc., can solve the problems that the huff and puff thermal recovery process cannot be applied, it is not suitable for large-scale promotion, and it cannot lift heavy oil. , to achieve the effect of wide operating temperature range, wide application range and saving workover costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

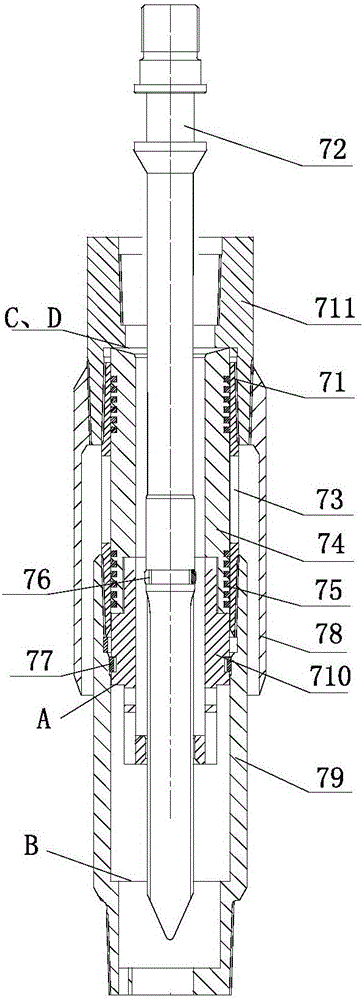

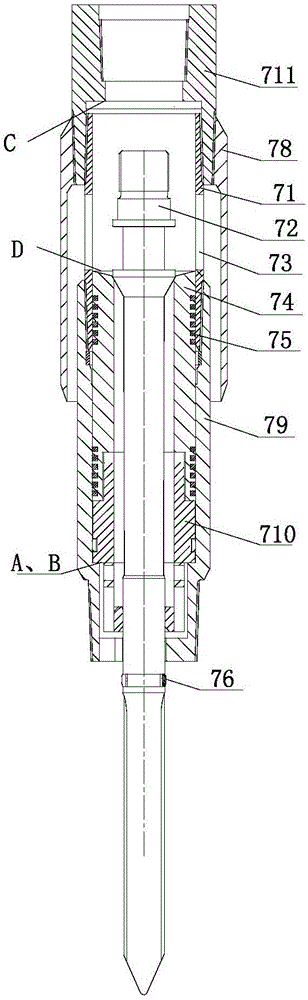

[0063] like Figure 4-7 As shown, the vane pump 4 is a single-acting vane pump, and the single-acting vane pump includes a main shaft 41, a pump body 43, a rotor 413, a stator 414 and blades 420, wherein the main shaft 41 is rotatably installed in the pump body 43, and the stator 414 Fixedly connected with the inner wall of the pump body 43, the rotor 413 is sleeved on the main shaft 41 and forms an annular gap with the stator 414. The two sides of the annular gap are the low-pressure oil suction area E and the high-pressure oil discharge area F respectively. The rotor 413 is provided with a plurality of vane slots 428 symmetrically along the circumferential direction, and a vane 420 is respectively inserted in each vane slot 428, and an oil guiding and tightening structure communicating with the ring gap is provided between the two symmetrically arranged vane slots 428. The oil guiding and tightening structure makes the two symmetrically arranged vanes 420 abut against the in...

Embodiment 2

[0076] like Figure 8-11 As shown, the vane pump 4 is a double-acting vane pump, including a main shaft 41, a pump body 43, an upper cam 422, a rotor 413, a stator 414, a lower cam 427 and a vane 420, wherein the main shaft 41 passes through the upper bearing part and the lower bearing part Installed in the pump body 43, the stator 414 is fixedly connected to the inner wall of the pump body 43, the rotor 413 is sleeved on the main shaft 41, and forms an annular gap with the stator 414, and there are low-pressure oil suction areas on both sides of a diameter of the annular gap F and the high-pressure oil discharge area E, the outer circumference of the rotor 413 is provided with a plurality of blade grooves 428, and a blade 420 is inserted in each blade groove 428. Port 424 communicates. The upper cam 422 and the lower cam 427 are sleeved on the main shaft 41 and are fixedly connected with the upper bearing part and the lower bearing part respectively; each blade 420 is pushed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com