Push rod type indicating device and rubber plug falling indication cementing head

An indicating device and push rod technology, which is used in wellbore/well components, earthwork drilling, sealing/packing, etc., can solve the problem that the rubber plug cannot leave the cement head normally, cannot touch the bottom of the well, and leave a lot of ash. It can reduce the cost of cementing and workover, improve the quality of cementing, and improve the success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

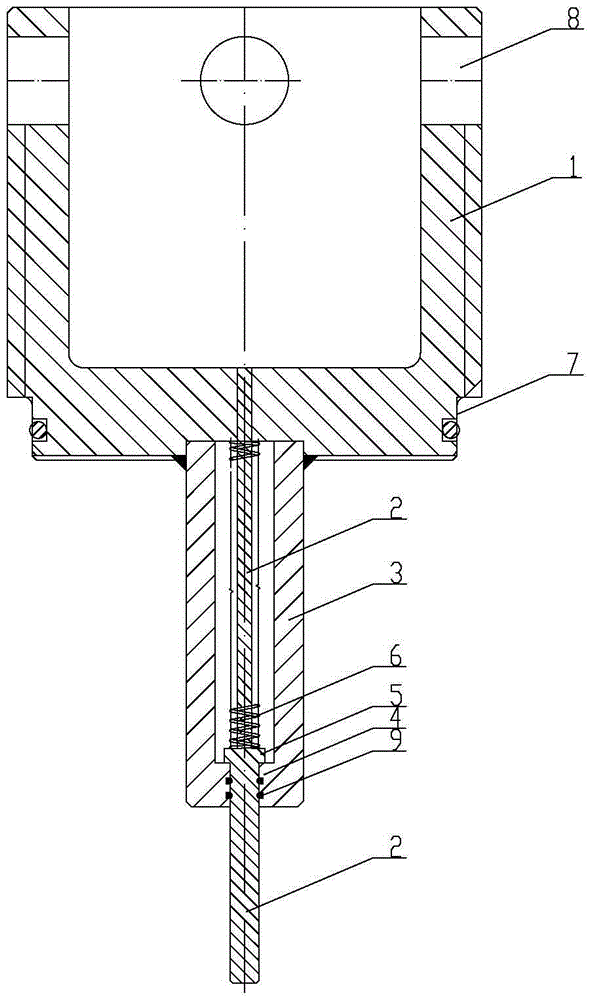

[0023] Example 1, as attached figure 1 , 2 3, the push rod type indicating device includes a gland 1, a push rod 2 and a sleeve body 3 with an opening facing upward; a sleeve body 3 is fixedly connected to the lower end of the gland 1, and the bottom of the gland 1 is provided with The connecting hole of the sleeve body 3 is integrally fixed with a retaining ring 4 on the inner side of the lower end of the sleeve body 3, and a ring block 5 is integrally fixed on the lower outer side of the push rod 2, and the ring block 5 of the push rod 2 is seated on the sleeve body On the retaining ring 4 of 3, the lower part of the push rod 2 is located outside the sleeve body 3, the upper end of the push rod 2 is located in the mounting hole of the gland 1, and the push rod 2 above the ring block 5 in the sleeve body 3 is installed with Compression spring 6. In this way, under normal circumstances, the compression spring 6 is in a natural state, the lower end of the compression spring 6 c...

Embodiment 2

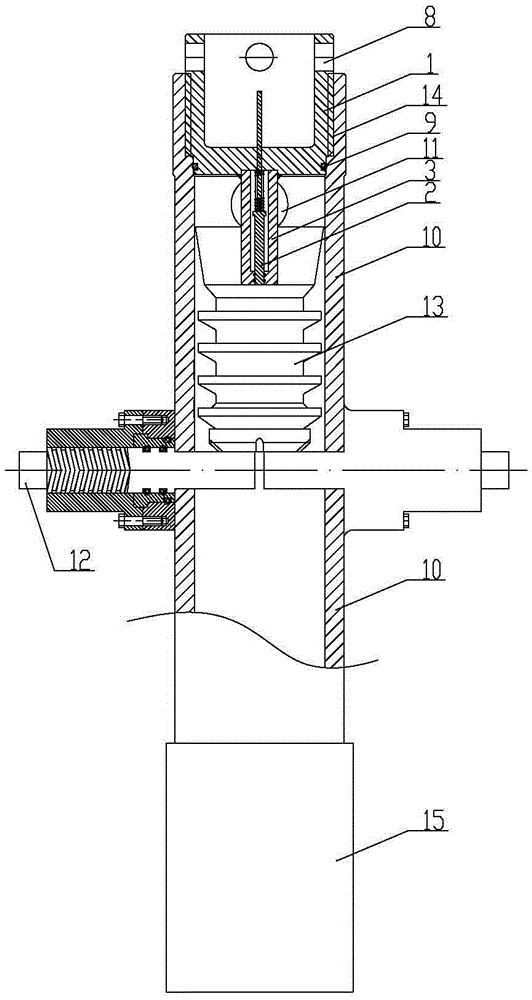

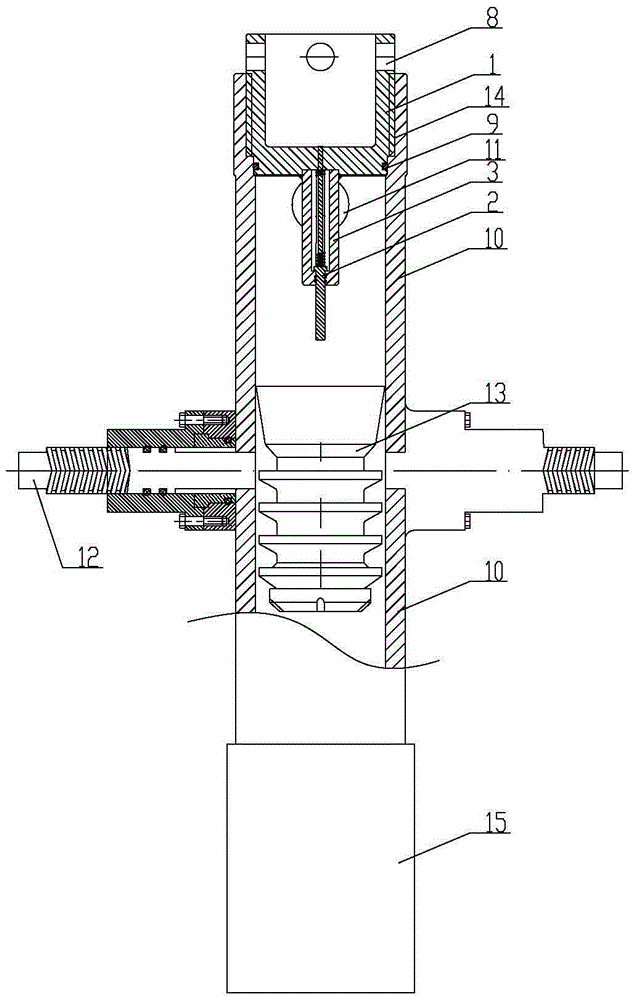

[0029] Example 2, as attached figure 2 As shown, the rubber plug using a push rod type indicating device to downwardly indicate the cement head includes a push rod type indicating device and a cement head body 10; the lower outer side of the gland 1 and the upper end inner side of the cement head body 10 are fixedly installed together. The upper part of the cement head body 10 is provided with a slurry replacement hole 11 communicating with the cavity of the cement head body 10, a stop pin 12 is fixedly installed in the middle of the cement head body 10, and a rubber plug 13 is arranged in the cavity of the cement head body 10 , The rubber plug 13 is seated on the stop pin 12 and is located between the mixing hole 11 and the stop pin 12, and the lower end of the push rod 2 is pressed against the rubber plug 13. The cement head body 10, the stop pin 12 and the rubber plug 13 are all the prior art; through the push rod type indicating device, the cement head body 10, the stop pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com