Oil tube centralizer

A technology of centralizer and oil pipe, applied in drilling pipe, casing, drilling equipment and other directions, can solve the problems of increasing workover costs of oil and water wells, workload of large workover operations, and difficulty in removing jams, etc., and achieves significant economic benefits, The effect of reducing the cost of well workover and the difficulty of unblocking work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

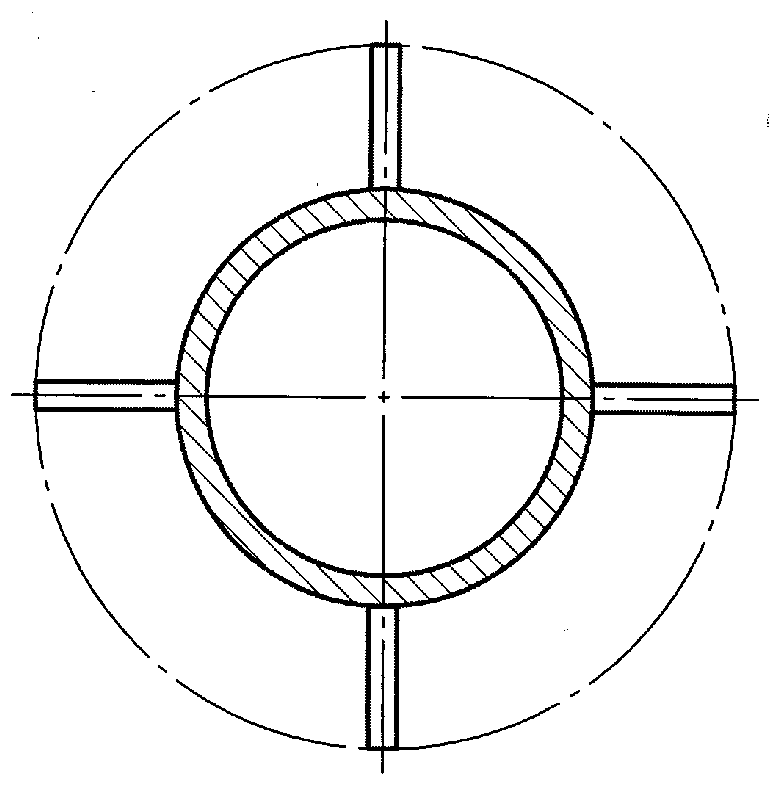

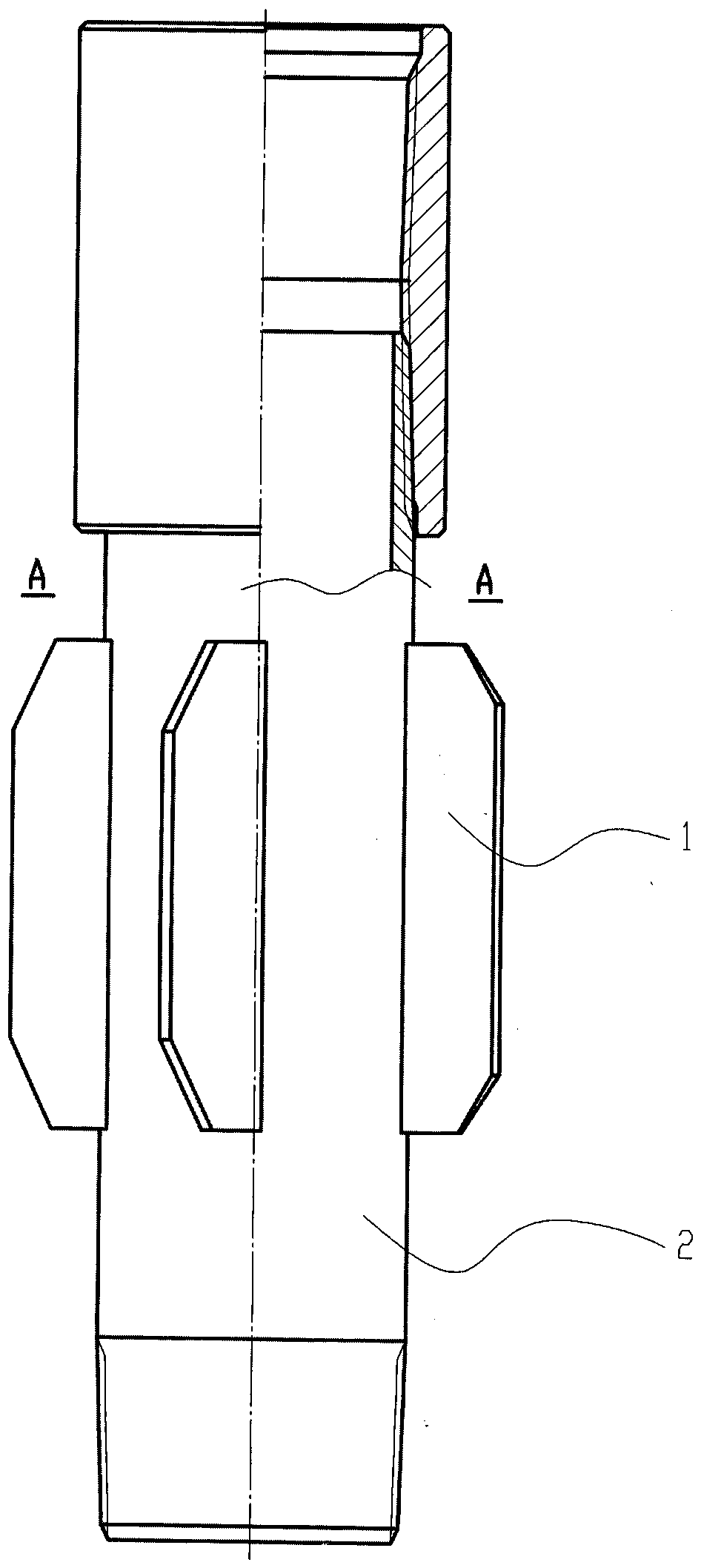

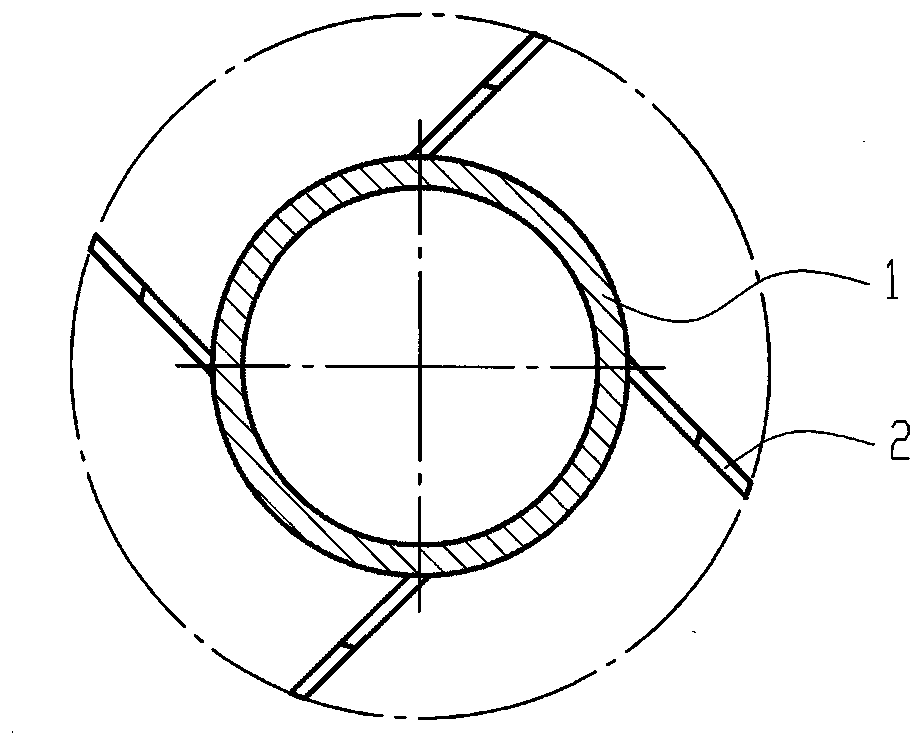

[0009] Attached below figure 2 , 3 Embodiments of the present invention are further described:

[0010] Depend on figure 2 , 3 It can be seen that the embodiment of the present invention includes a centralizing sheet 1 and an inner pipe 2, and the centralizing sheet 1 is installed on the inner pipe 2 (welded), the quantity of the centralizing sheet 1 is 3-8 pieces, and the two ends of the centralizing sheet 1 have chamfers, The axis of the centralizing sheet 1 and the inner tube 2 is at an angle of 20-70︒ (cannot form a plane), and the outer edges of several centralizing sheets 1 are on the same cylinder (points on the outer edges of several centralizing sheets 1 can be connected form a circle), the axis of the cylinder is coaxial with the axis of the inner tube 2.

[0011] The quantity of righting piece 1 is generally 4, and the included angle of the axis of righting piece 1 and inner pipe 2 is generally 45︒. The thickness of the centralizing sheet 1 is generally 3-8 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com