Inner pipe water pressure pulse flushing device

A flushing device and pulse technology, applied in the direction of flushing wellbore, production fluid, wellbore/well components, etc., can solve problems such as affecting crude oil production, sand control pipe blockage, etc., to improve service life, save well workover costs, and improve production. time rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further disclose the technical solution of the present invention, the following is a detailed description with embodiments in conjunction with the accompanying drawings of the specification:

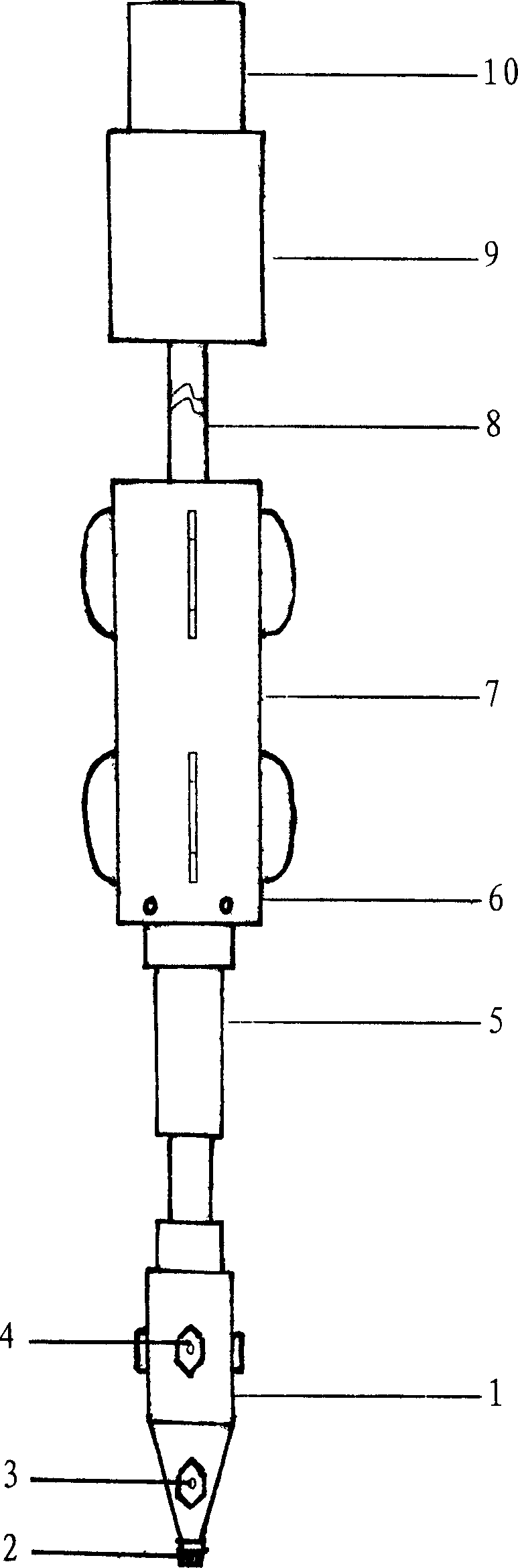

[0015] The invention consists of a jet head 1, a sand flushing nozzle 2, a couple nozzle 3, a cleaning nozzle 4, a damper 5, a guide 6, a pin 7, a flushing pipe 8 and a filter 9. It is characterized in that the screen of the filter 9 and The punching pipe 8 is threadedly connected, the punching pipe 8 is threadedly connected to the reducer joint of the damper through the center of the guide 6, the rotor of the damper 5 is connected to the damper body through a bearing, the damper rotor is threaded to the jet head 1, and the sand flushing nozzle 2 is installed on the axial top end of the jet head 1, the force couple nozzle 3 is installed laterally on the cone surface of the jet head at a certain phase angle, and the cleaning nozzle 4 is installed radially on the cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com