Oil pumping technique based on middle venting gas-prevention oil well pump

An oil-pumping and oil-pumping technology, which is applied to the components, pumps, and pump components of the pumping device for elastic fluids, can solve the problem of shortening the pump inspection period, reducing the fullness of the pump cavity, and the opening lag of the oil pump valve ball. and other problems to achieve the effect of reducing well workover costs, reducing environmental pollution and improving oil intake conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

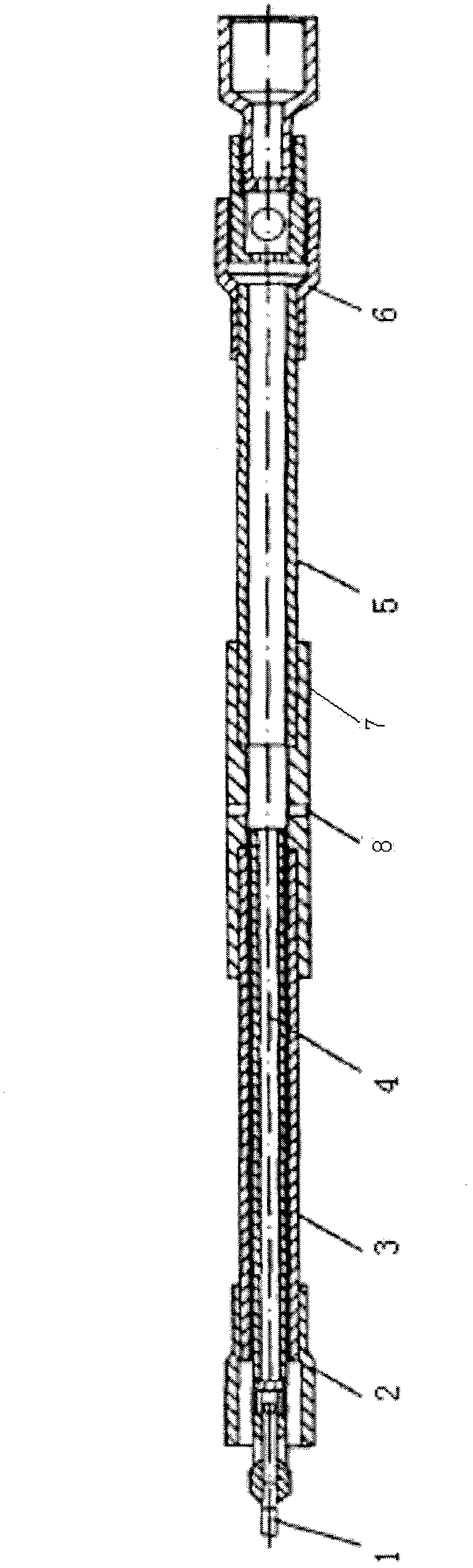

[0028] The oil pumping process based on the middle exhaust gas anti-air pump involved in the present invention comprises the following steps:

[0029] (a) First, turn on the power device, which drives the plunger connecting rod 1, and then drives the plunger 4 to move upward;

[0030] (b) The pressure in the 5 chambers of the lower pump barrel is reduced, the fixed valve is opened, and the upstream and downstream moving valves are closed;

[0031] (c) When the lower end of the plunger 4 goes up and exceeds the vent hole 8 in the middle of the upper pump barrel 3, the oil in the casing enters the pump barrel from the vent hole 8 under the action of submerged pressure. The space that is not filled in the pump barrel is replenished; on the other hand, the gas in the pump space under the exhaust groove of the pump barrel is discharged, so as to realize the exhaust function of the pump;

[0032] (d) The power unit drives the plunger connecting rod 1, and then drives the plunger 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com