Well-repairing process for casing deformed oil and water well

A process method and oil-water well technology, applied in wellbore/well components, earthwork drilling, production fluid, etc., can solve the problems of complex construction process, application influence, long construction period, etc., to shorten the construction period, increase the injection rate, The effect of saving workover cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

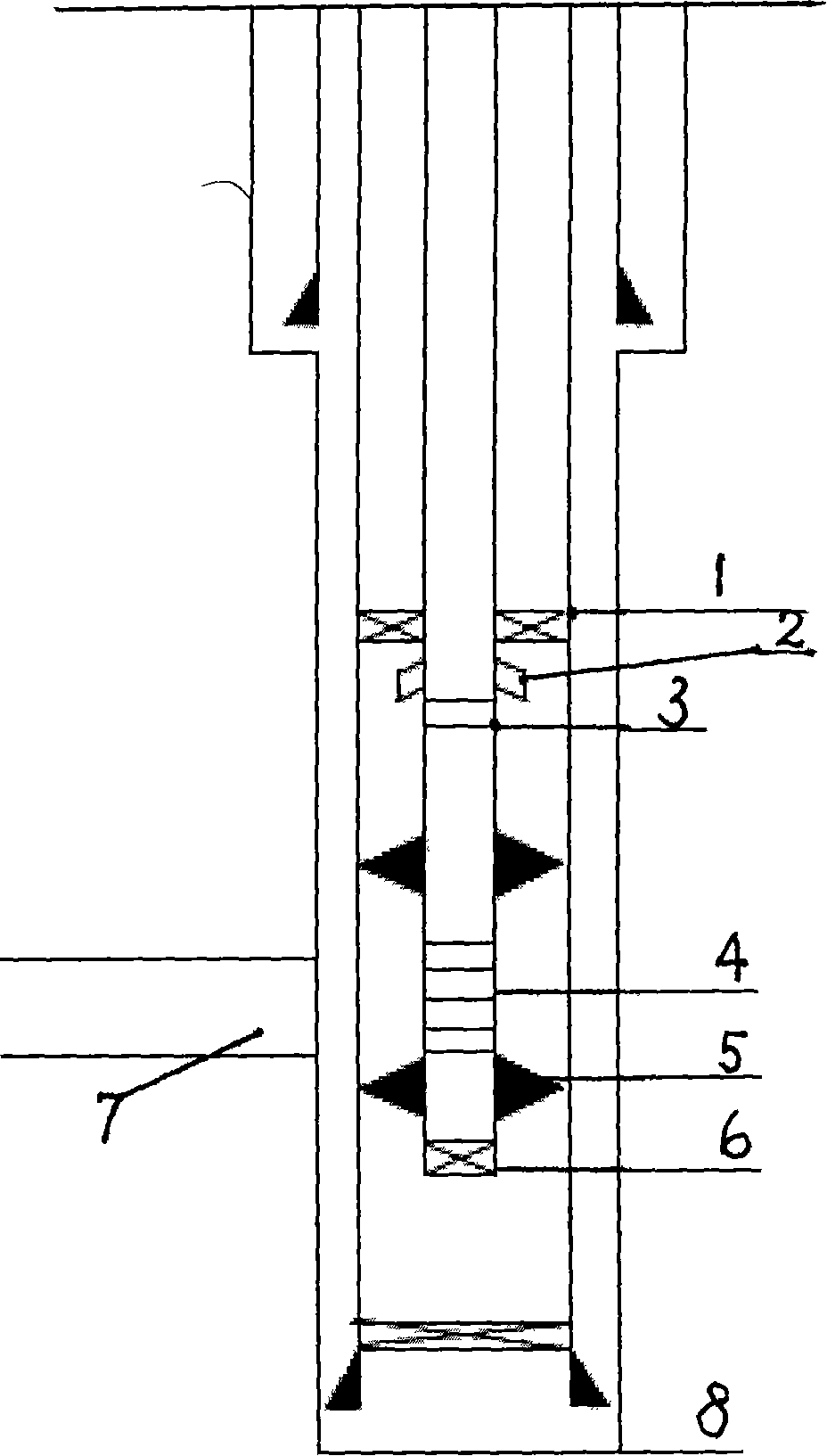

[0024] Describe below in conjunction with accompanying drawing.

[0025] As shown in the figure: the gravel packing sand control string used in the present invention is composed of thickened oil pipe 1, filling device 2, signal nipple 3, high pressure packing sand control screen 4, centralizer 5, and plug 6 from top to bottom. The well condition tubing string can be one of the following three assembly structures from bottom to top:

[0026] Top filling: plug + tubing pup without coupling + sand control screen without coupling + tubing pup without coupling + safety joint without coupling + signal screen + tubing pup without coupling + top filling device + tubing

[0027] Bottom filling: plug + tubing pup without coupling + bottom filling device + sand control screen without coupling + tubing pup without coupling + safety joint without coupling + signal screen + tubing pup without coupling + packing device + tubing

[0028] No filling: plug + tubing pup without coupling + sand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com