Light-emitting diode and manufacturing method thereof

A technology for light-emitting diodes and a manufacturing method, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of low luminous efficiency of light-emitting diodes, and achieve the effects of improving internal quantum efficiency and improving luminous efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

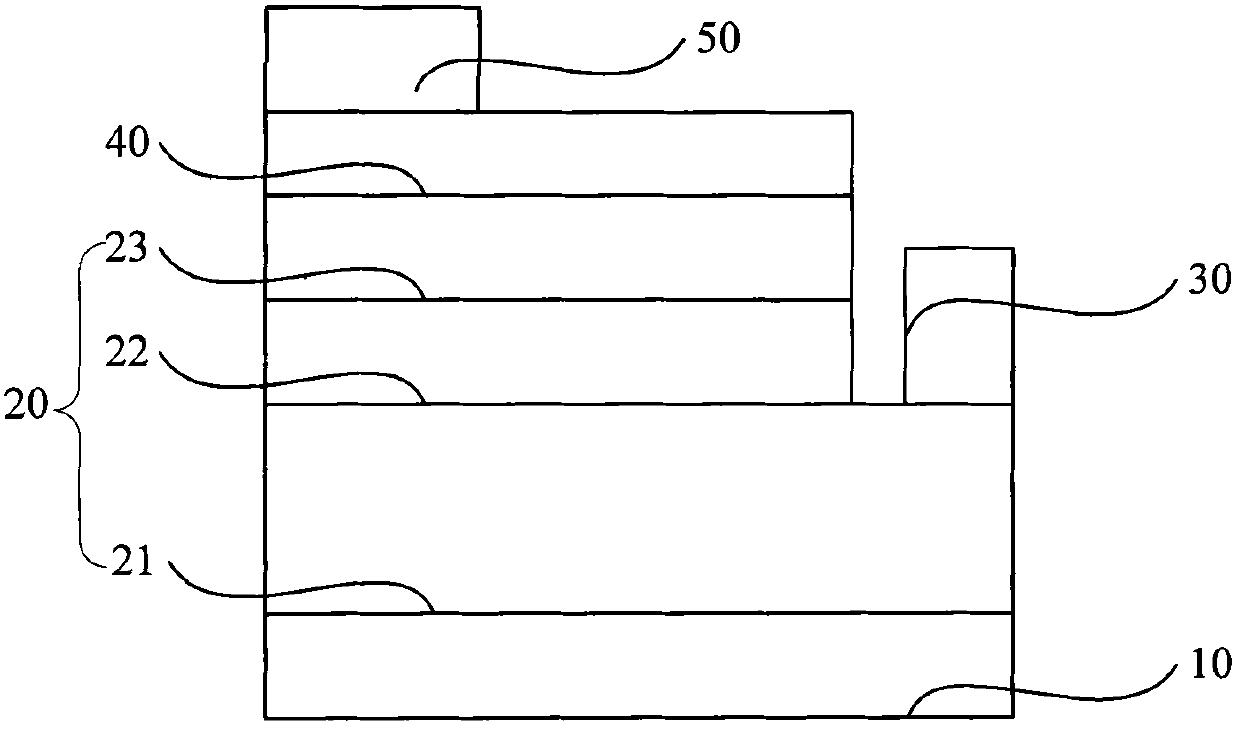

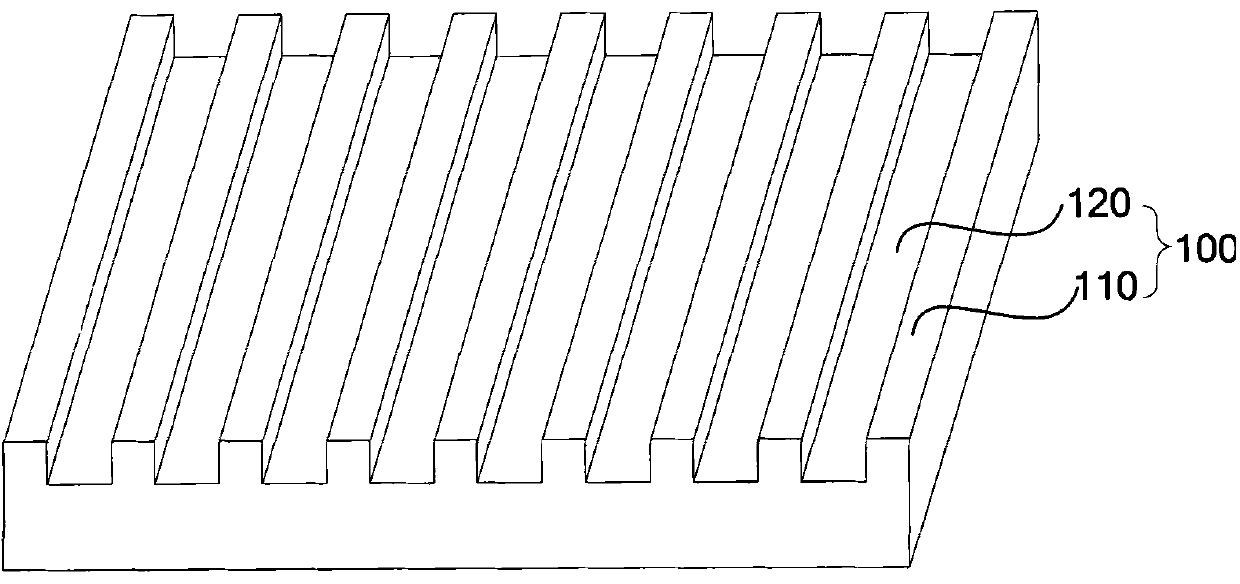

[0052] The light-emitting diode of Embodiment 1 provided by the present invention includes a substrate, a semiconductor layer, and a transparent conductive layer in sequence, and also includes a first electrode and a second electrode that can be electrically connected to the outside to provide electric energy to the light-emitting diode. The layer is electrically connected, and the second electrode is electrically connected to the transparent conductive layer; wherein, the upper surface of the substrate has several grooves and some protrusions; The semiconductor layer is located directly above the groove, the protruding semiconductor layer is located directly above the protrusion; the transparent conductive layer is located above the semiconductor layer, and is used to supply current to the semiconductor layer of the groove. The substrate is a patterned substrate. The semiconductor layer longitudinally includes a first semiconductor layer connected to the substrate, a light em...

Embodiment 2

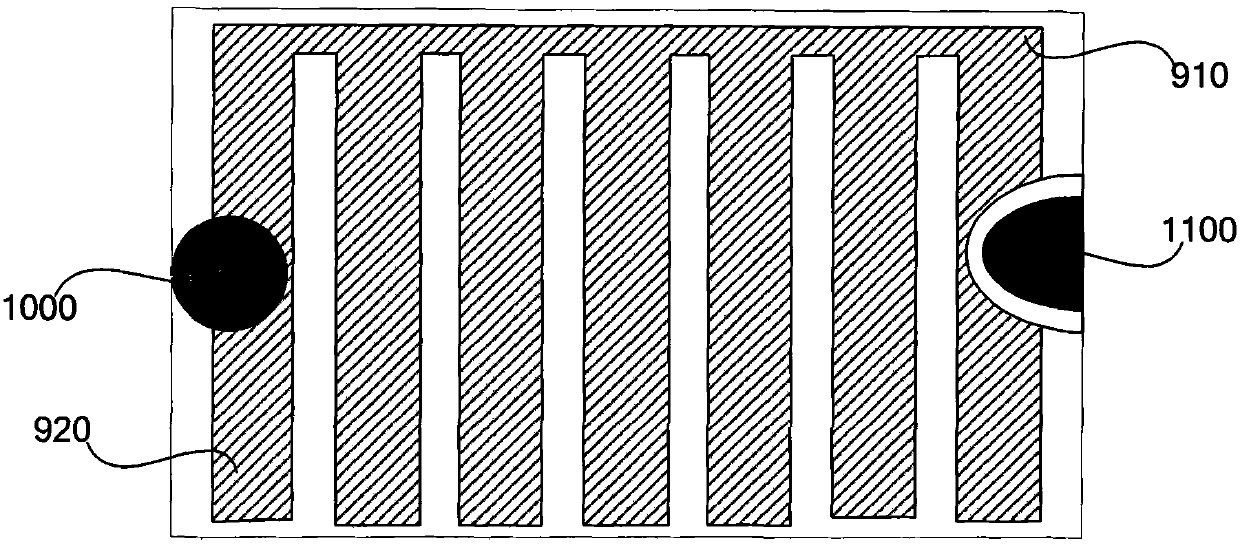

[0074] Please refer to Figure 5 The light-emitting diode according to the second embodiment of the present invention includes the patterned substrate 2100 described above, and above the patterned substrate 2100 are a nucleation layer 2200, a buffer layer 2300, an N-type semiconductor layer (first semiconductor layer) 2400, The light emitting layer 2500 , the second semiconductor barrier layer 2600 on the light emitting layer 2500 , the magnesium doped P type semiconductor layer 2700 , the heavily doped P type semiconductor layer 2800 with a rough structure 2810 , and the transparent conductive layer 2900 . The patterned substrate 2100 has grooves 2120 and protrusions 2110 . The light emitting diode of the embodiment of the present invention further includes an N-type electrode 21100 and a P-type electrode 21000 . There are two differences between the present embodiment and the first embodiment. One is that the structure of the transparent conductive layer of the light-emitti...

Embodiment 3

[0077] Please refer to Figure 6, the light-emitting diode of the third embodiment of the present invention is a light-emitting diode with a vertical structure, including: an N-type semiconductor layer (first semiconductor layer) 3400, a light-emitting layer 3500, a second semiconductor barrier layer 3600 located on the light-emitting layer 3500, magnesium A doped P-type semiconductor layer 3700 , a heavily doped P-type semiconductor layer 3800 with a rough structure 3810 , an insulating strip 31200 just covering the rough structure 2810 , and a bright conductive layer 3900 . The light emitting diode of the embodiment of the present invention further includes an N-type electrode 31100 and a P-type electrode 31000 . The N-type electrode 31100 is electrically connected to the N-type semiconductor layer 3400 and located below it, and the P-type electrode 31000 is electrically connected to the transparent conductive layer 2900 and located above it. The light emitting diode of thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com