Blue LED epitaxial structure with suppression polarization effect barrier layer

A polarization effect and epitaxial structure technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as limited effects, achieve the effects of suppressing overflow, improving crystal quality, and suppressing polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

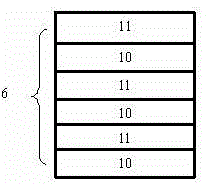

[0060] The barrier layer 6 for suppressing the polarization effect is grown for 3 cycles in nitrogen, hydrogen or a hydrogen-nitrogen mixed environment.

[0061] ①Grow Al first x Ga 1-x The N layer 10 was grown at a temperature of 700° C., the growth pressure was 300 mbar, and the thickness was 50 nm; the SiN layer 11 was regrown at a growth temperature of 700° C., the growth pressure was 300 mbar, and the thickness was 50 nm.

[0062] ② Second, grow Al x Ga 1-x The N layer 10 is grown at a temperature of 700° C., the growth pressure is 300 mbar, and the thickness is 75 nm; the SiN layer 11 is regrown at a growth temperature of 700° C., the growth pressure is 300 mbar, and the thickness is 40 nm.

[0063] ③Secondary growth of Al x Ga 1-x The N layer 10 is grown at a temperature of 700° C., the growth pressure is 300 mbar, and the thickness is 100 nm; the SiN layer 11 is regrown at a growth temperature of 700° C., the growth pressure is 300 mbar, and the thickness is 30 nm...

Embodiment 2

[0065] The barrier layer 6 for suppressing the polarization effect is grown for 3 cycles in nitrogen, hydrogen or a hydrogen-nitrogen mixed environment.

[0066] ①Grow Al first x Ga 1-x The N layer 10 is grown at a temperature of 800° C., the growth pressure is 300 mbar, and the thickness is 50 nm; the SiN layer 11 is regrown at a growth temperature of 800° C., the growth pressure is 300 mbar, and the thickness is 50 nm.

[0067] ② Second, grow Al x Ga 1-x The N layer 10 is grown at a temperature of 800° C., the growth pressure is 300 mbar, and the thickness is 75 nm; the SiN layer 11 is regrown at a growth temperature of 800° C., the growth pressure is 300 mbar, and the thickness is 40 nm.

[0068] ③Secondary growth of Al x Ga 1-x The N layer 10 is grown at a temperature of 800° C., the growth pressure is 300 mbar, and the thickness is 100 nm; the SiN layer 11 is regrown at a growth temperature of 800° C., the growth pressure is 300 mbar, and the thickness is 30 nm.

Embodiment 3

[0070] The barrier layer 6 for suppressing the polarization effect is grown for 3 cycles in nitrogen, hydrogen or a hydrogen-nitrogen mixed environment.

[0071] ①Grow Al first x Ga 1-x The N layer 10 is grown at a temperature of 900° C., the growth pressure is 300 mbar, and the thickness is 50 nm; the SiN layer 11 is regrown at a growth temperature of 900° C., the growth pressure is 300 mbar, and the thickness is 50 nm.

[0072] ② Second, grow Al x Ga 1-x The N layer 10 was grown at a temperature of 900° C., the growth pressure was 300 mbar, and the thickness was 75 nm; the SiN layer 11 was regrown at a growth temperature of 900° C., the growth pressure was 300 mbar, and the thickness was 40 nm.

[0073] ③Secondary growth of Al x Ga 1-x The N layer 10 is grown at a temperature of 900° C., the growth pressure is 300 mbar, and the thickness is 100 nm; the SiN layer 11 is regrown at a growth temperature of 900° C., the growth pressure is 300 mbar, and the thickness is 30 nm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com