Device and method for cleaning, activating or pre-treating workpieces by blasting carbon dioxide snow

A dry ice frost and pretreatment technology, applied in chemical instruments and methods, explosion generating devices, manufacturing tools, etc., can solve the problems of high investment and operating costs, damage to the surface of the substrate, etc., and achieve improved cleaning effects, less logic costs, and improved The effect of cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

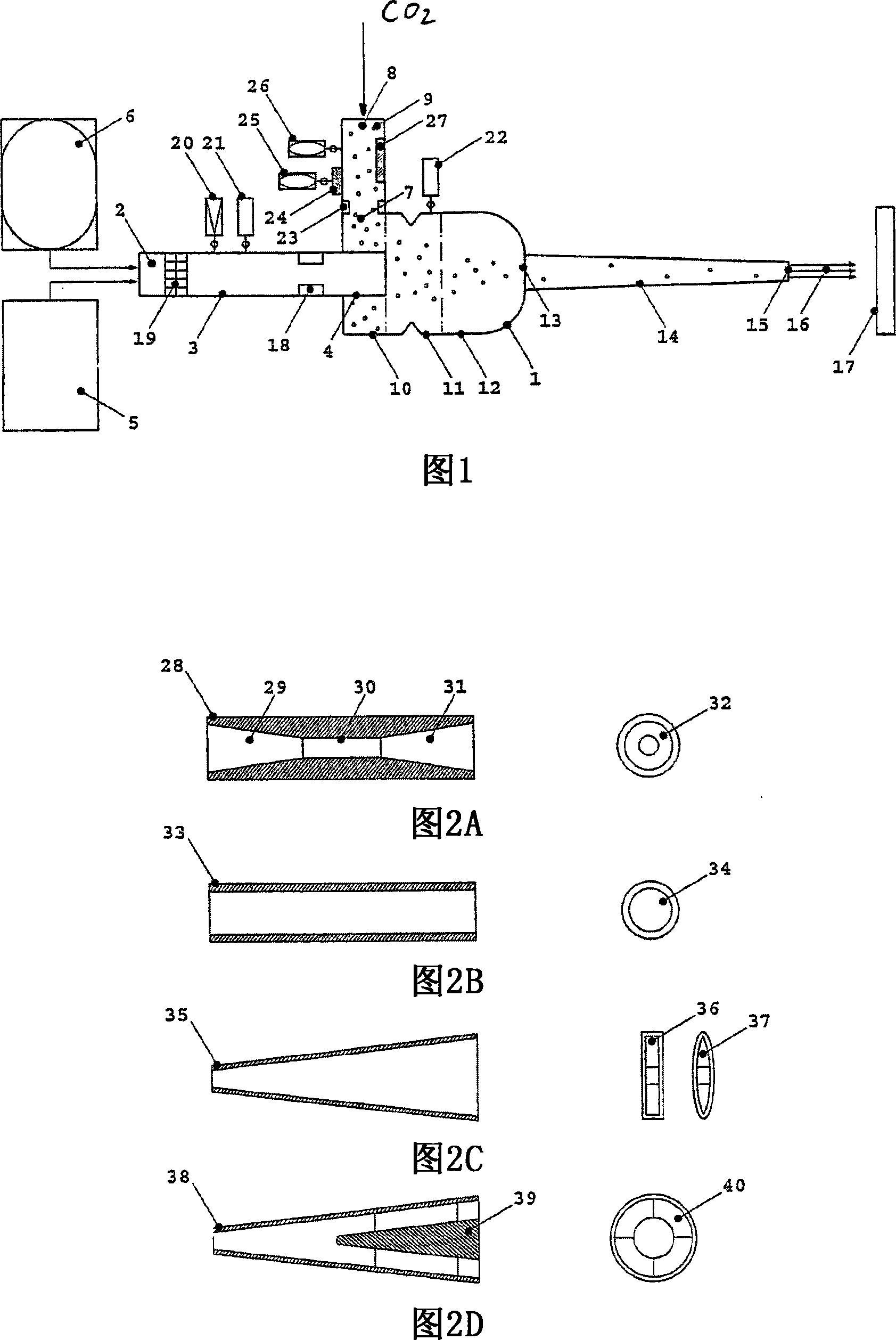

[0048] In order to increase the vortex mixing in the third area 12 of the mixing chamber 1 and even improve the injection efficiency, a mechanical installation fitting 18 is provided on the inner circumference of the gas delivery pipe 3 and / or the pipe 4 extending into the mixing chamber 1, which makes the gas flow 2 is in a helical rotation / vortex state, and even stabilizes the airflow.

Embodiment approach 3

[0050] In order to increase the temperature of the gas flow 2 and thus the spraying efficiency and to reduce liquid condensation on the workpiece surface 17 , a heating device 19 is integrated with a temperature sensor in the gas delivery line 3 upstream of the pipe 4 extending into the mixing chamber 1 .

[0051] Implementation mode 4 / 5:

[0052] In order to increase the spraying efficiency and / or to achieve certain properties of the surface after cleaning, pretreatment and / or actuation, the propellant metering system 20 is metered in the gas delivery pipe 3 before the pipe 4 which projects into the mixing chamber 1 The fixed propellant particles and / or water droplets metered by the liquid metering system 21 and / or the corrosion inhibitor are preferably phosphates.

Embodiment approach 6

[0054] In order to increase blasting efficiency and / or to achieve certain properties of the surface after cleaning, pre-treatment and / or actuation, water droplets and / or corrosion inhibitor, preferably phosphate and / or immobilized blasting agent particles, are directly passed through delivery system 22 Introduction into the mixing chamber, preferably into the first region 10 or the second region 11 of the mixing chamber 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com