Semiconductor ultraviolet source device

An ultraviolet light source and semiconductor technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of low LED luminous efficiency, achieve the effect of improving luminous efficiency, eliminating tilt effect, and improving internal quantum efficiency IQE

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

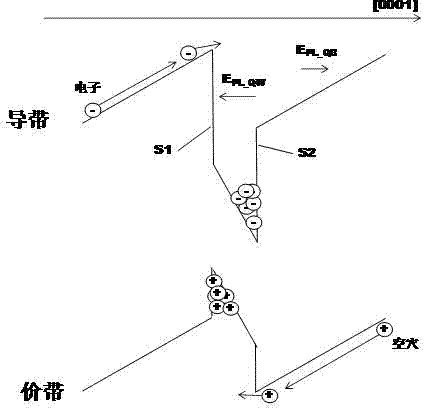

[0032] Embodiment 1, in order to facilitate processing, the epitaxial material of the semiconductor ultraviolet light source device in this embodiment is group III nitride of wurtzite structure, and the main epitaxial growth plane of the epitaxial structure of the device is the (0001) plane.

[0033] The ultraviolet LED of this embodiment is formed on the substrate 10 (see Figure 4), the substrate 10 may be a suitable substrate material such as silicon (eg Si), sapphire (eg c-plane sapphire or c-plane patterned sapphire), AlN, GaN or AlGaN. An epitaxial substrate 20 is formed on the substrate 10, preferably an epitaxial AlN epitaxial layer, or an AlGaN epitaxial layer with a high Al composition. The thickness of the epitaxial substrate 20 is preferably 100 nm to 3 μm. Above the epitaxial substrate is an electron supplying layer 40 N-type AlGaN with a thickness of at least 2 μm in order to have good electrical conductivity and material quality. In order to improve the materi...

Embodiment 2

[0037] The difference between the second embodiment and the first embodiment is that the Al composition of the electron supply layer 40 in this embodiment is higher than the Al composition of the quantum barrier 552 or the average Al composition of the quantum barrier, such as the N-type electron supply layer. The aluminum composition of 40 is 1.1 to 1.2 times that of the quantum barrier. In this way, it is convenient to apply in-plane biaxial compressive stress to the quantum barrier, causing the piezoelectric polarization electric field to partially offset the self-polarization electric field, and facilitating the transport of electrons and holes to the quantum well.

Embodiment 3

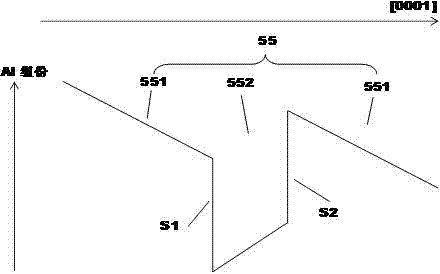

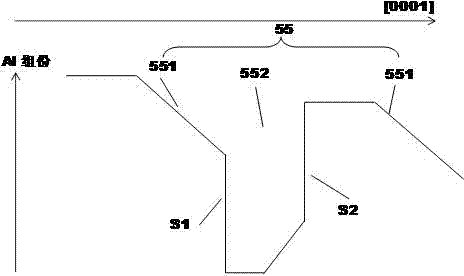

[0038] Embodiment 3: The AlINGaN ultraviolet LED epitaxially formed along the c direction in this embodiment has a light-emitting region composed of AlInGaN / AlInGaN multiple quantum wells, wherein the Al composition of the quantum barrier is x Al-QB refer to Figure 2-2 , the component gradient along the c direction satisfies:

[0039] when hour, , that is: in the first half of the barrier, the aluminum composition gradient of the quantum barrier along the epitaxial growth direction is zero;

[0040] when hour, , in the second half of the barrier, the aluminum composition gradient of the quantum barrier along the epitaxial growth direction ranges from -0.1% / nm to -2% / nm;

[0041] And the Al composition of the quantum well, x Al-QW , the component gradient along the c direction satisfies:

[0042] when hour, , that is: in the first half of the well, the aluminum composition gradient of the quantum well along the epitaxial growth direction is zero;

[0043] when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com