Semisolid injection molding machine with multi-station injection

An injection molding machine and semi-solid technology, applied in the field of semi-solid injection molding machines, can solve problems such as insufficient injection pressure, small injection volume, slow melting process, etc., to reduce injection pressure, improve local strength, and reduce injection speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

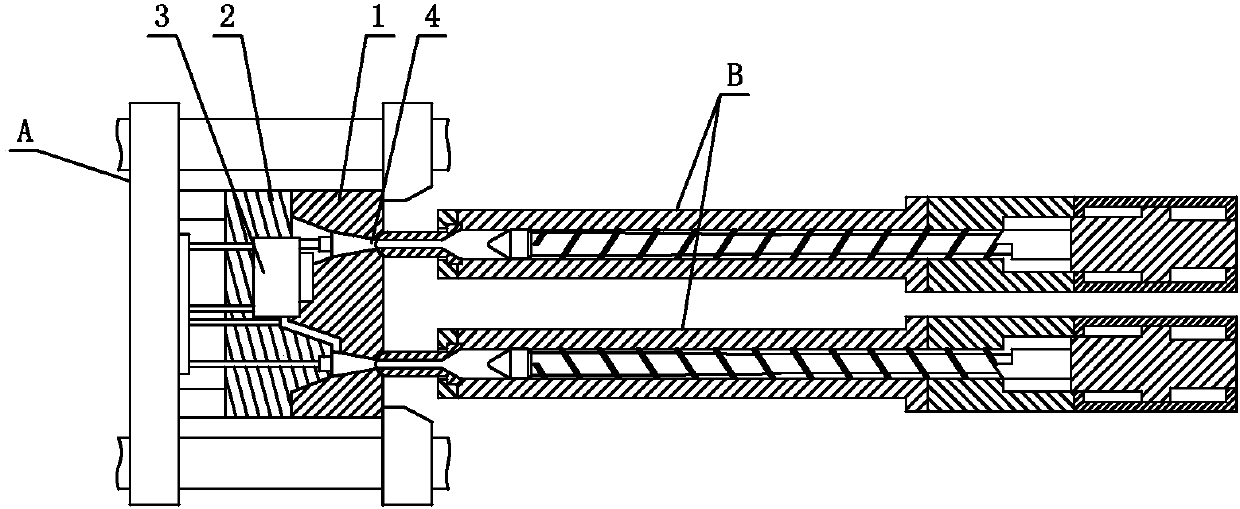

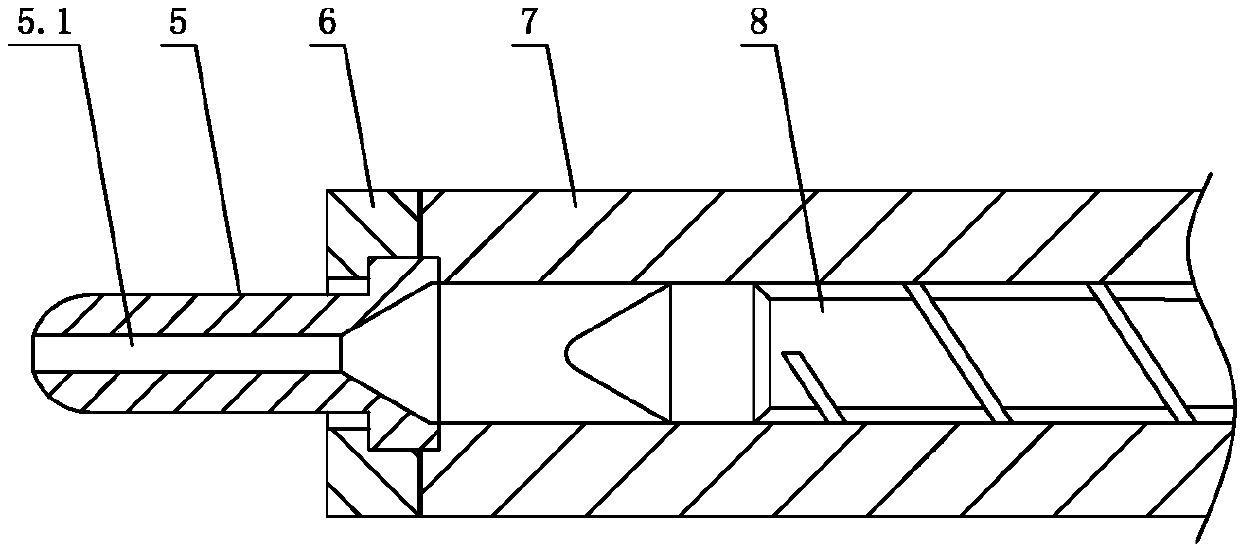

[0024] see figure 1 and figure 2 , the multi-station injection semi-solid injection molding machine is a double-station injection semi-solid magnesium alloy injection molding machine, which includes an injection mold A, a semi-solid injection mechanism B and a coordinated control system. The injection mold A is provided with interconnected Injection cavity 3 and injection gate 4; two sets of semi-solid injection mechanism B are arranged side by side, and two injection gates 4 are set corresponding to semi-solid injection mechanism B, and the two injection gates 4 are respectively connected to the injection cavity through different injection channels 3. Two injection gates 4 are respectively arranged on one end surface of the injection mold A, and the semi-solid injection mechanism B communicates with the corresponding injection gates 4 . This structure injects semi-solid magnesium alloy by setting two sets of semi-solid injection mechanism B, which can effectively increase t...

no. 2 example

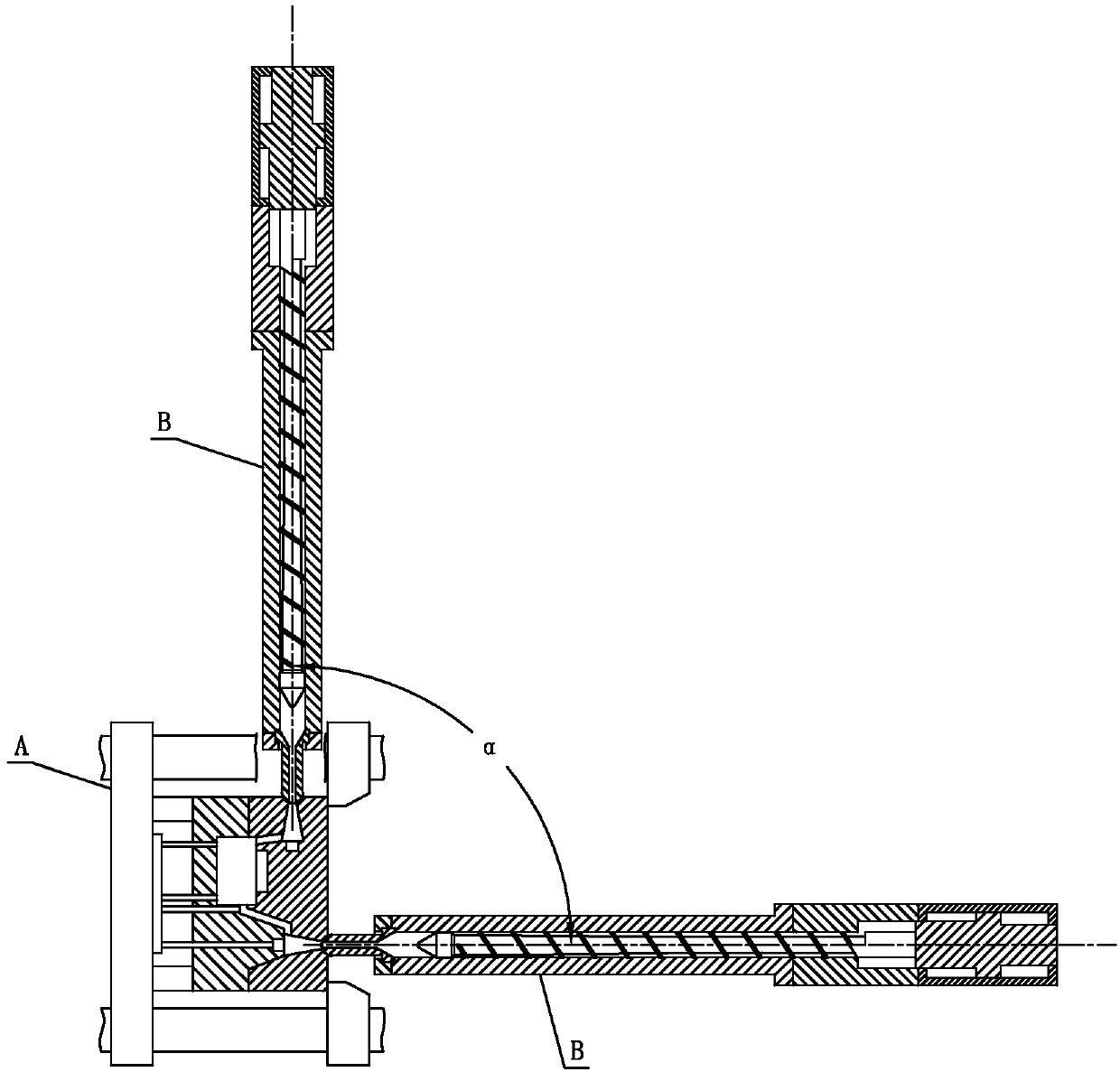

[0032] see image 3 , the semi-solid injection molding machine for multi-station injection is different from the first embodiment in that: there are two sets of semi-solid injection mechanisms B, and there is an angle α between the two sets of semi-solid injection mechanisms B, and α is 90°. The end face and the side of the injection mold A are respectively provided with injection gates 4 communicating with the injection mold cavity 3 , and the two semi-solid injection mechanisms B are respectively communicated with the corresponding injection gates 4 .

[0033] This distribution method of the semi-solid injection mechanism B does not need to modify the fixed plate of the clamping mechanism, but only needs to adjust the relative position of the mold gate, and the realization method is more flexible; the corresponding injection mold A is similar to a two-component injection mold, that is, after the injection Two injection gates 4 are arranged on the mold A, and the two injectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com