Patents

Literature

111results about How to "Improve local strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

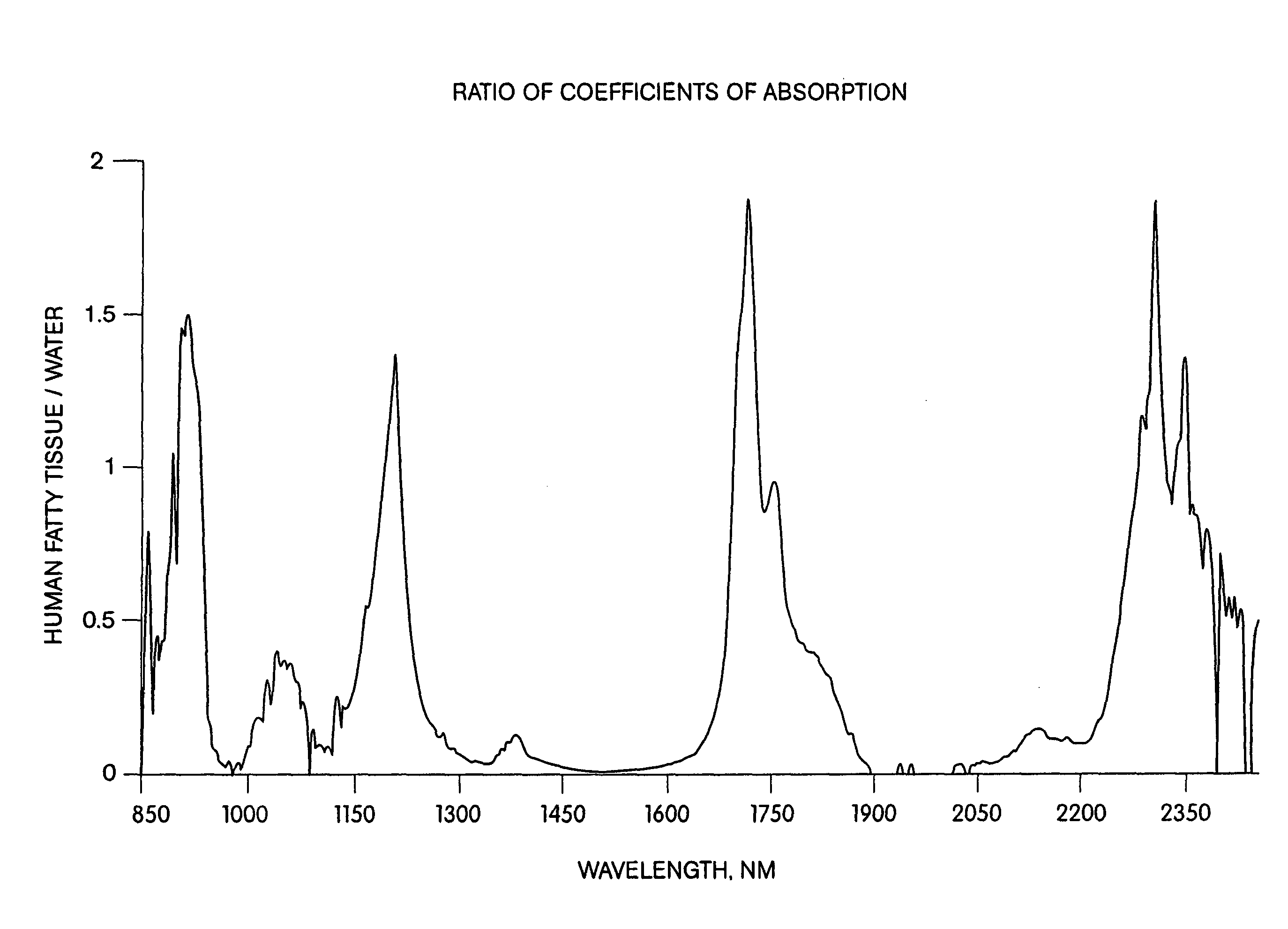

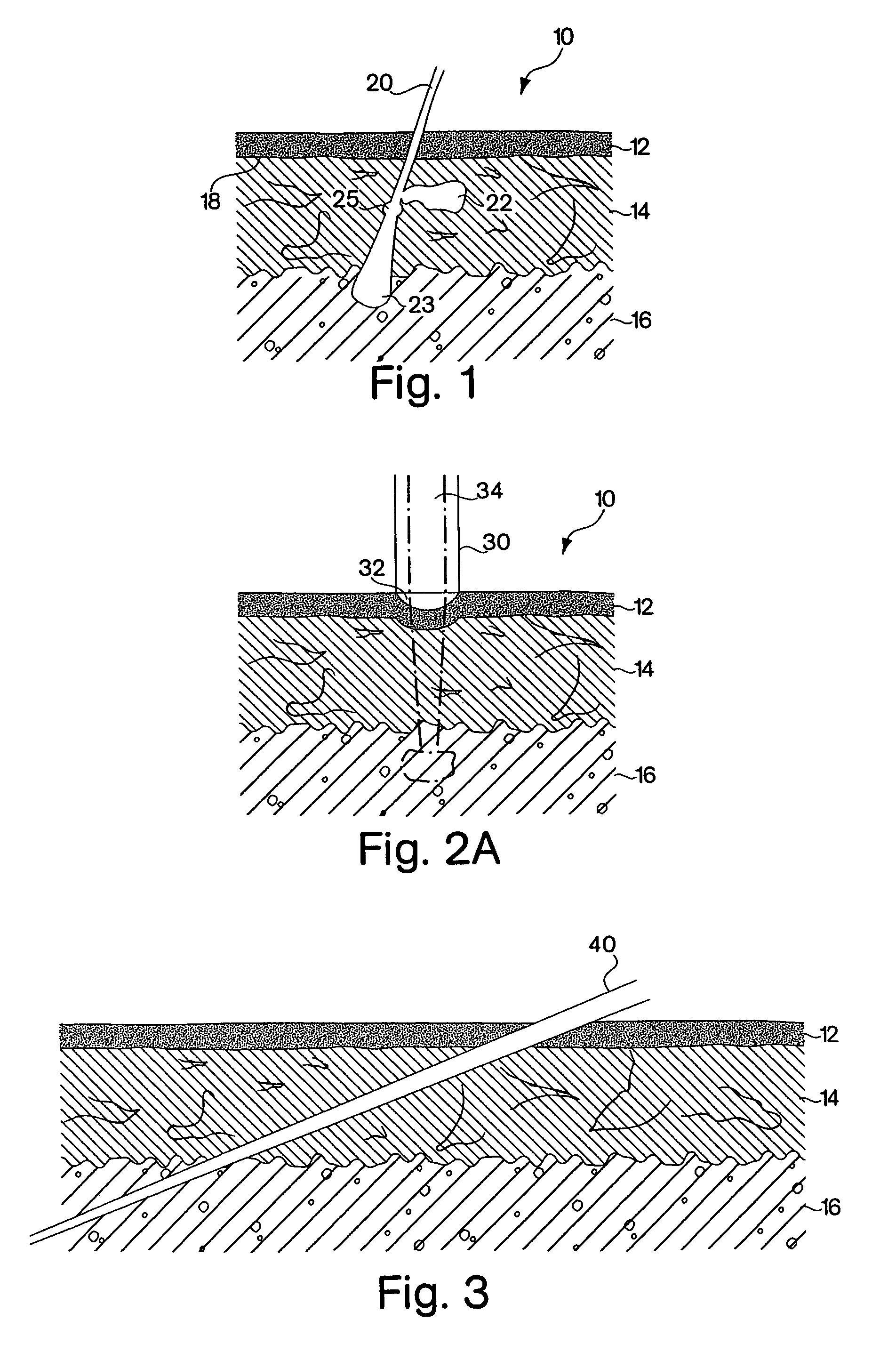

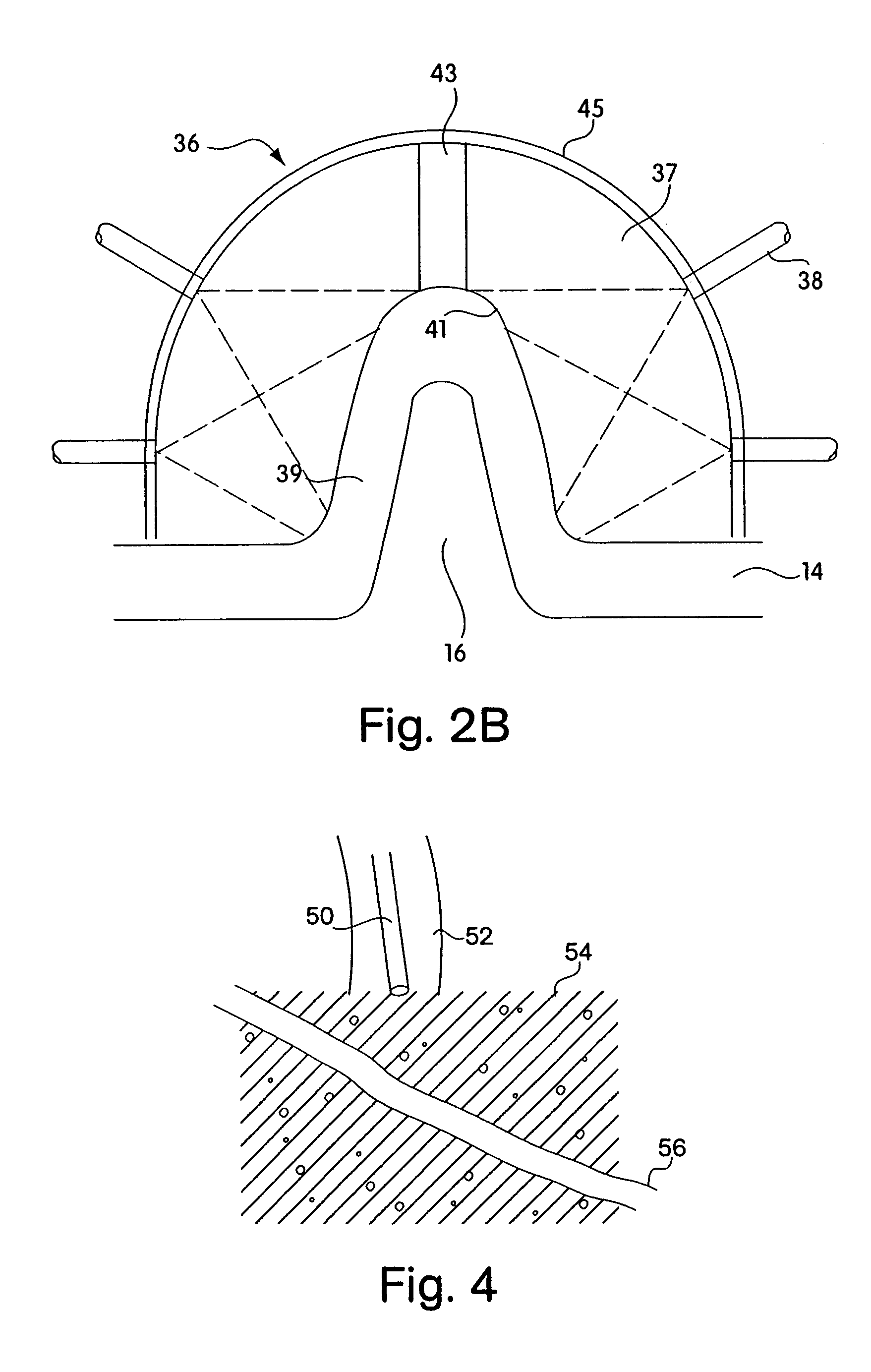

Method and apparatus for the selective targeting of lipid-rich tissues

InactiveUS7060061B2Desired treatmentSufficient durationSurgical instrument detailsSurgical pincettesHair removalLipid formation

A method and apparatus are provided for targeting lipid-rich tissue to effect a desired, the method / apparatus involving irradiating the lipid-rich tissue with energy at a wavelength preferentially absorbed by lipid cells, such wavelength being preferably in a band between 880 nm and 935 nm, 1150 nm and 1230 nm, 1690 nm to 1780 nm, or 2250 nm to 2450 nm with a fluence and duration sufficient to achieve a desired treatment. For preferred embodiments, the irradiation wavelength is between 900–930 nm, 1190–1220 nm, 1700–1730 nm, or 2280–2350 nm. The method and apparatus may for example be used to target one or more sebaceous glands for the treatment of acne or hair removal, to target subcutaneous fat for removal thereof or for targeting fat on anatomical elements for various purposes.

Owner:PALOMAR MEDICAL TECH

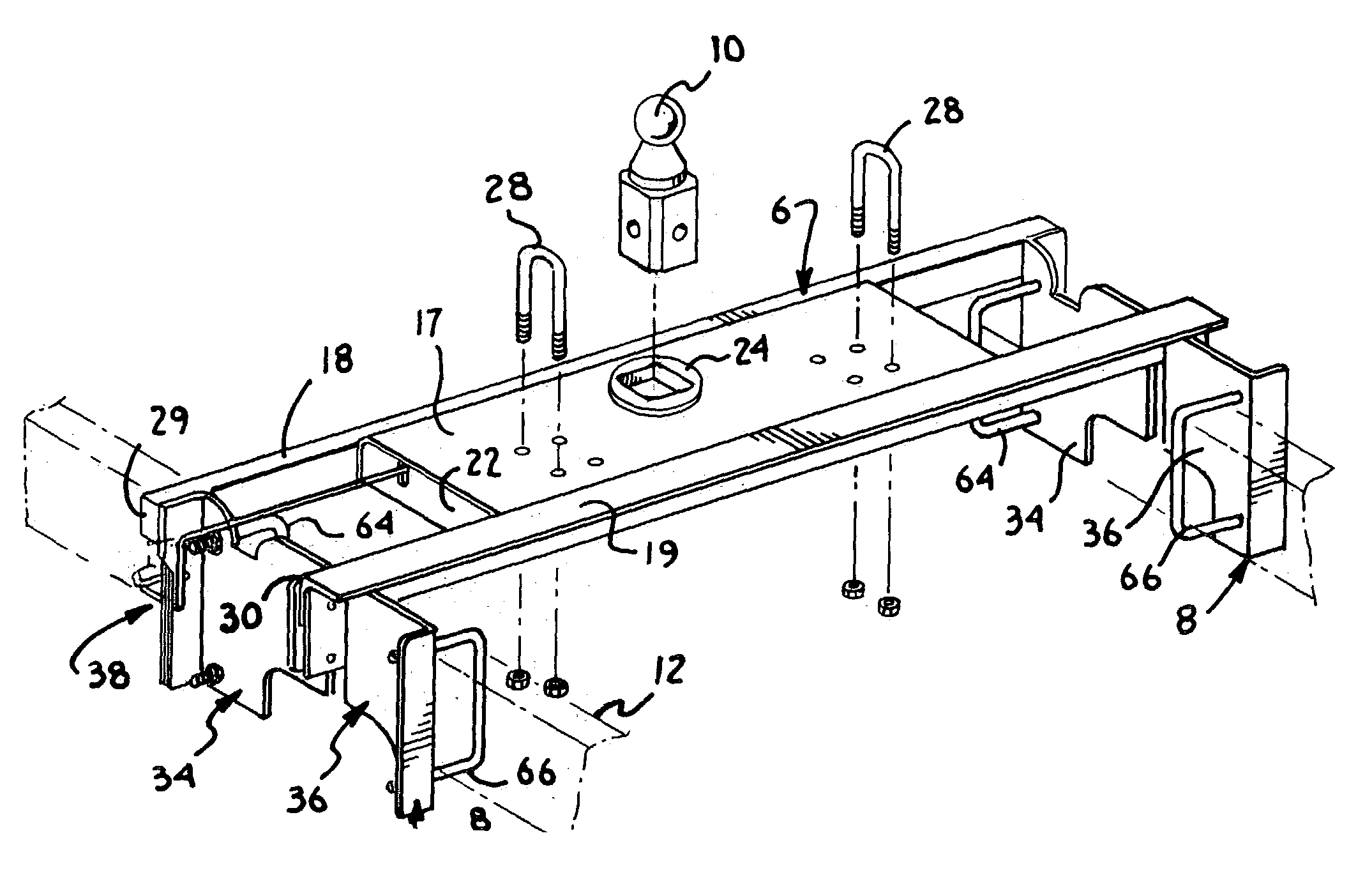

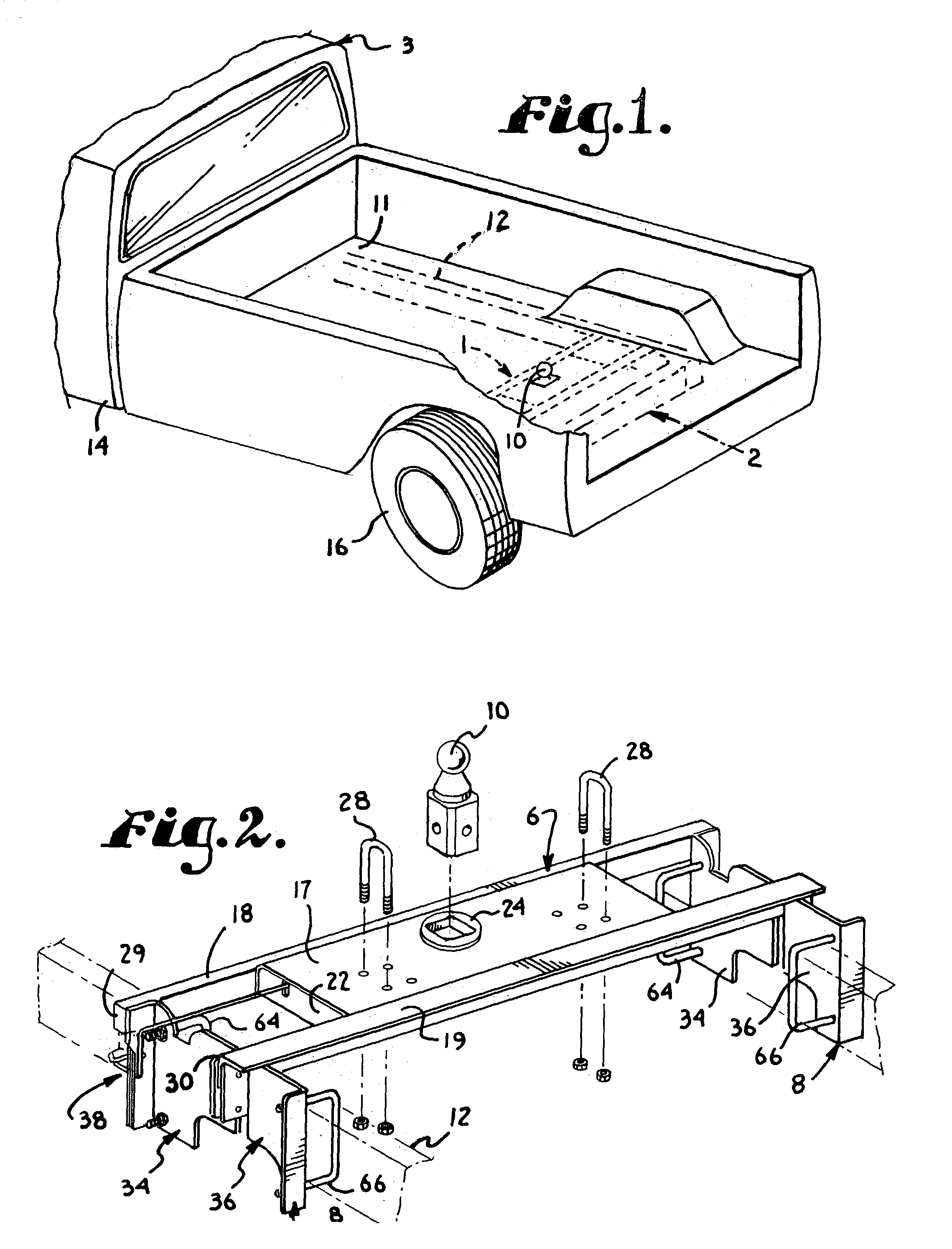

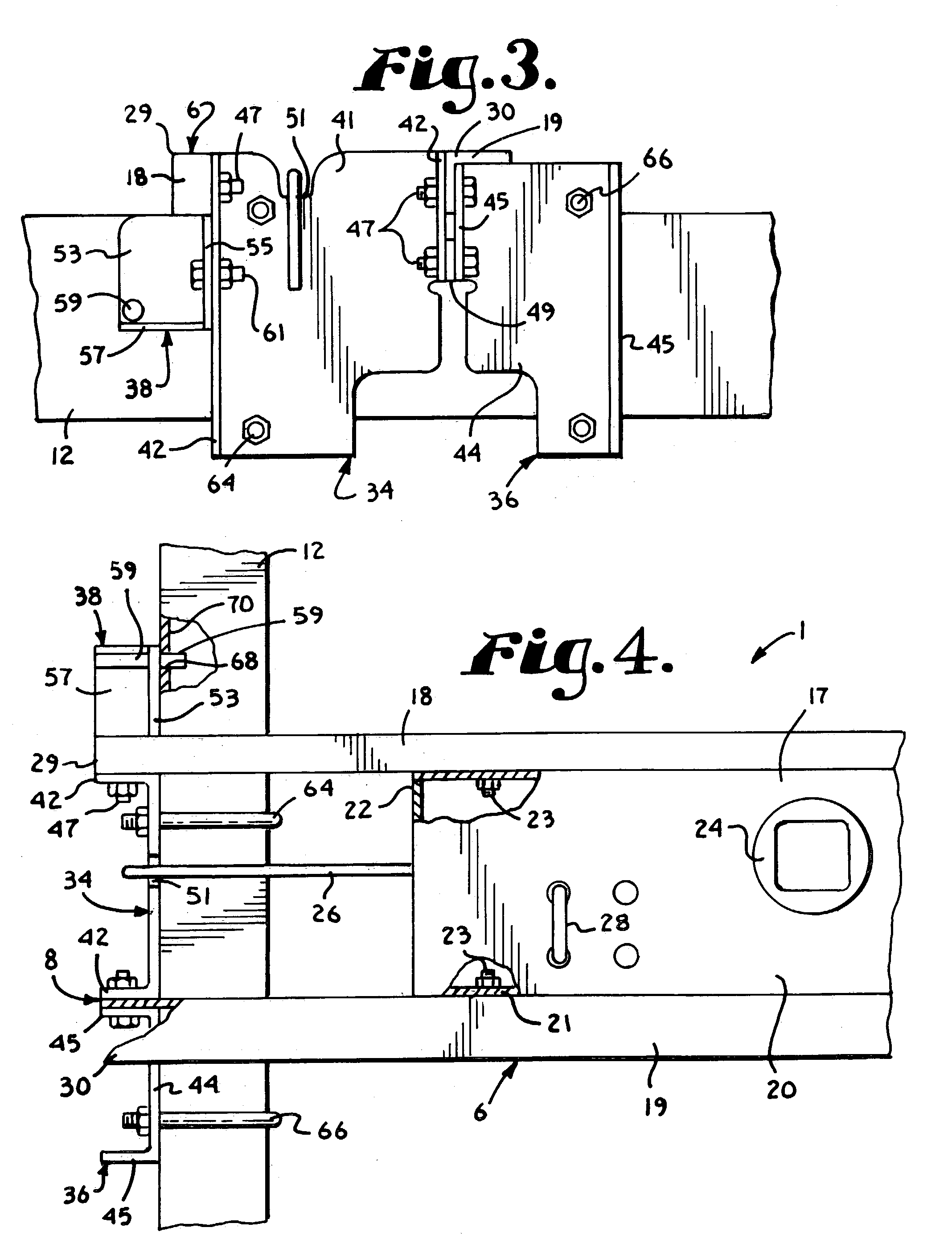

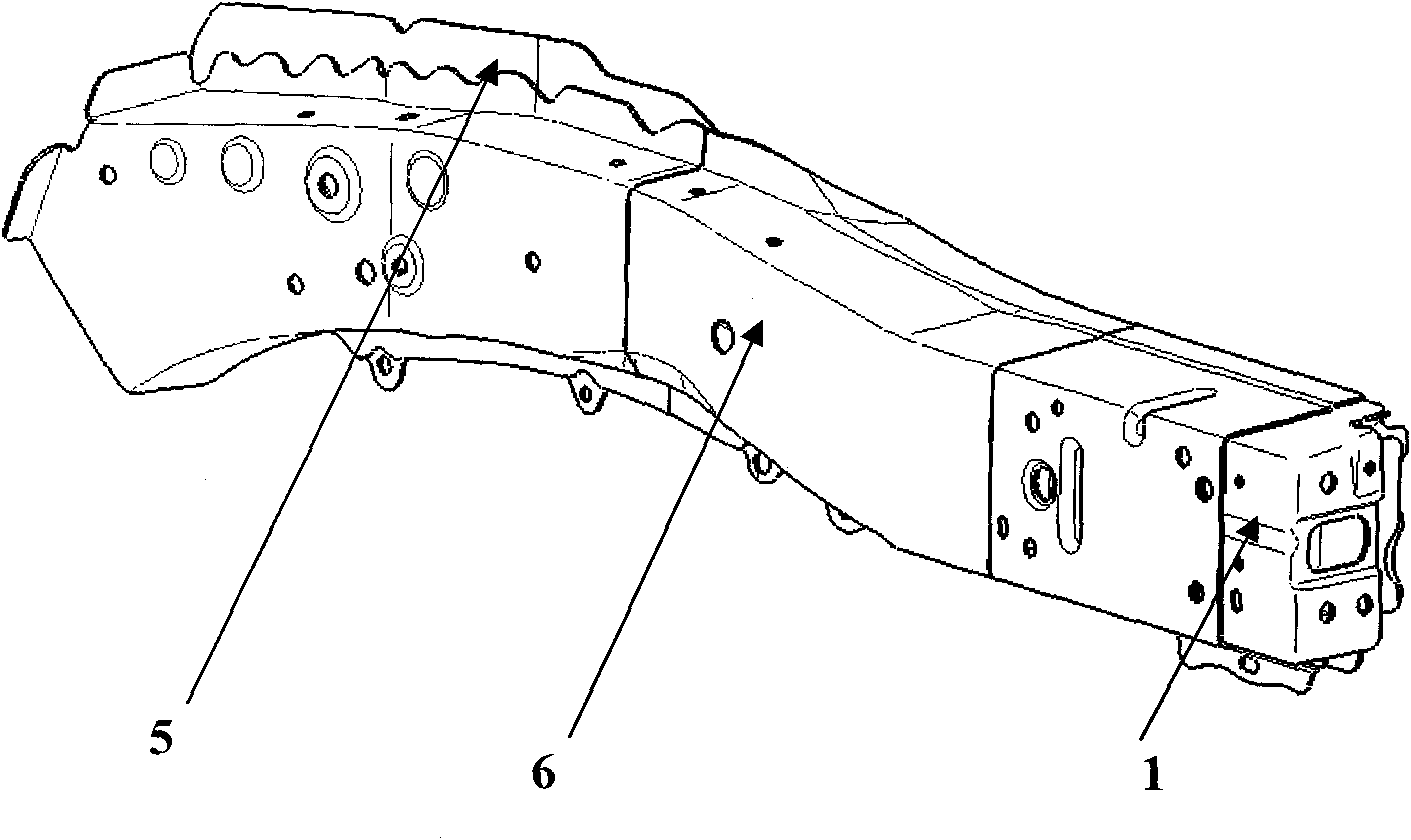

System for mounting hitches to hydroformed frames

ActiveUS6969090B1Additional resistanceImprove local strengthTractor-trailer combinationsRoad vehiclesChassis

A hitch structure for connection between a pair of elongated, laterally spaced hydroformed frame members of a vehicle chassis having preformed apertures formed therein. The hitch structure comprises a hitch base adapted to receive a hitch ball member, a pair of side plates connected respectively to opposite ends of said hitch base, a pin sized, positioned, and oriented on each of the side plates to enable reception of the pin member in the preformed aperture of an associated hydroformed frame member, and a pair of clamp members on each side plate to clamp the side plate with an associated frame member at such a location as to position the pin member in alignment with the associated preformed aperture to thereby secure said hitch base in transverse relation between the frame members.

Owner:JOSEPH W WORKS

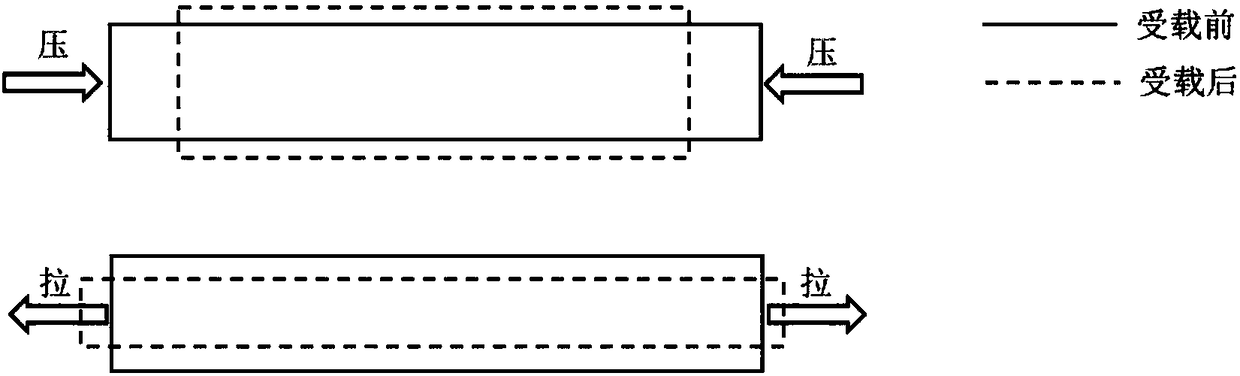

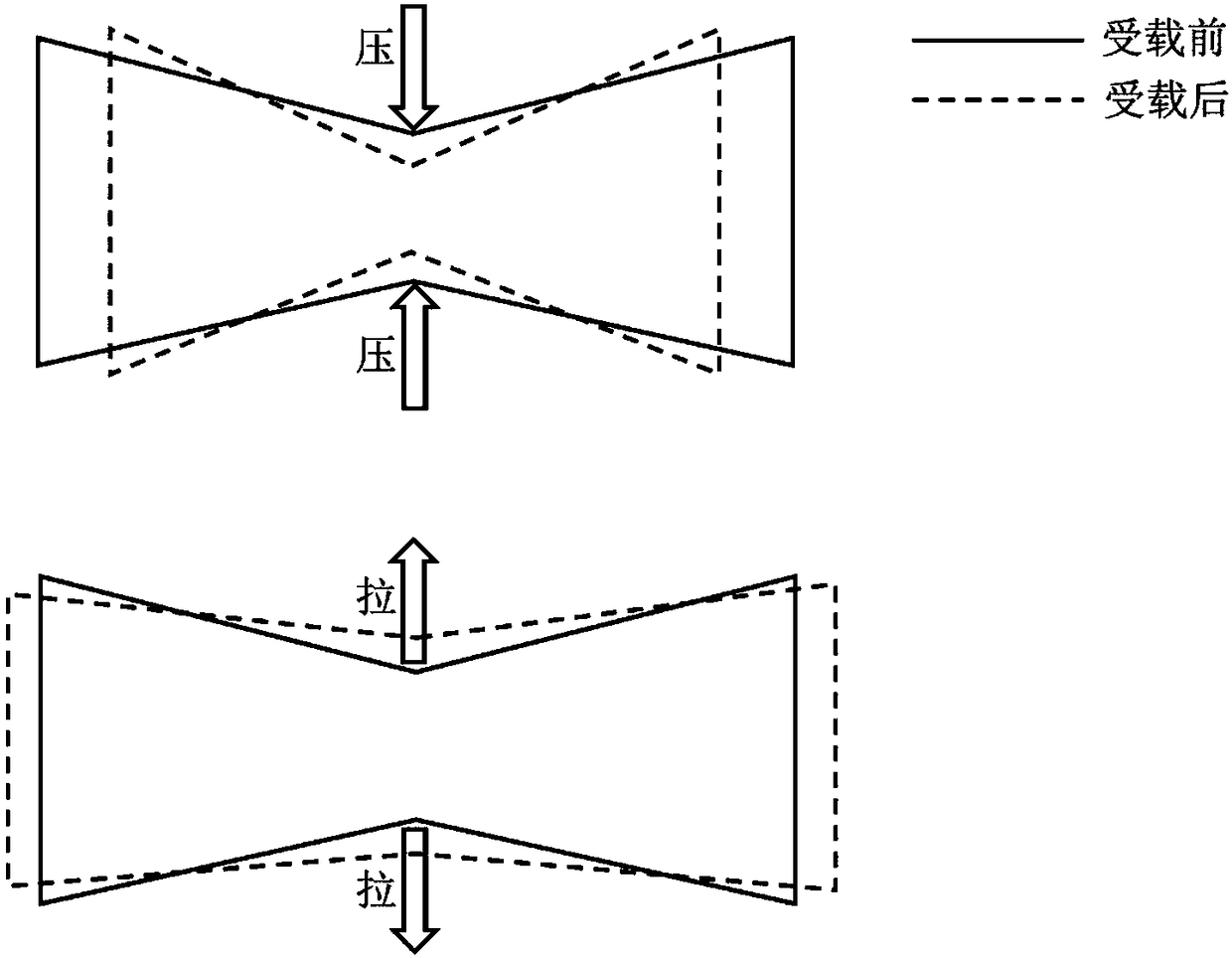

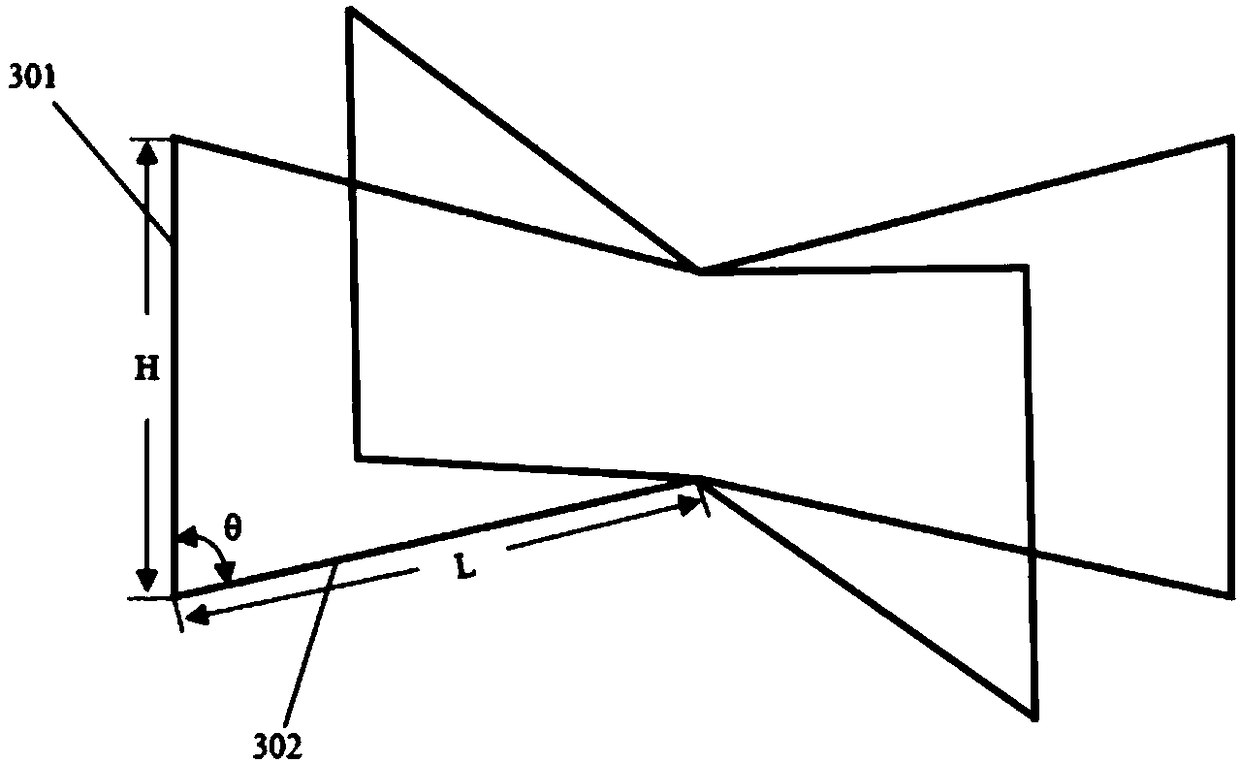

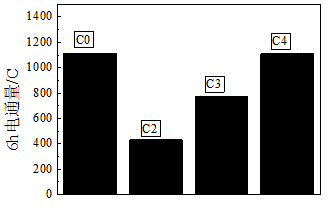

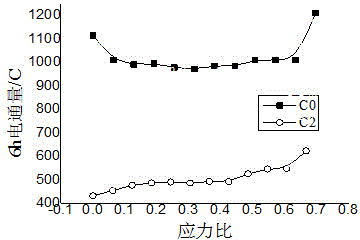

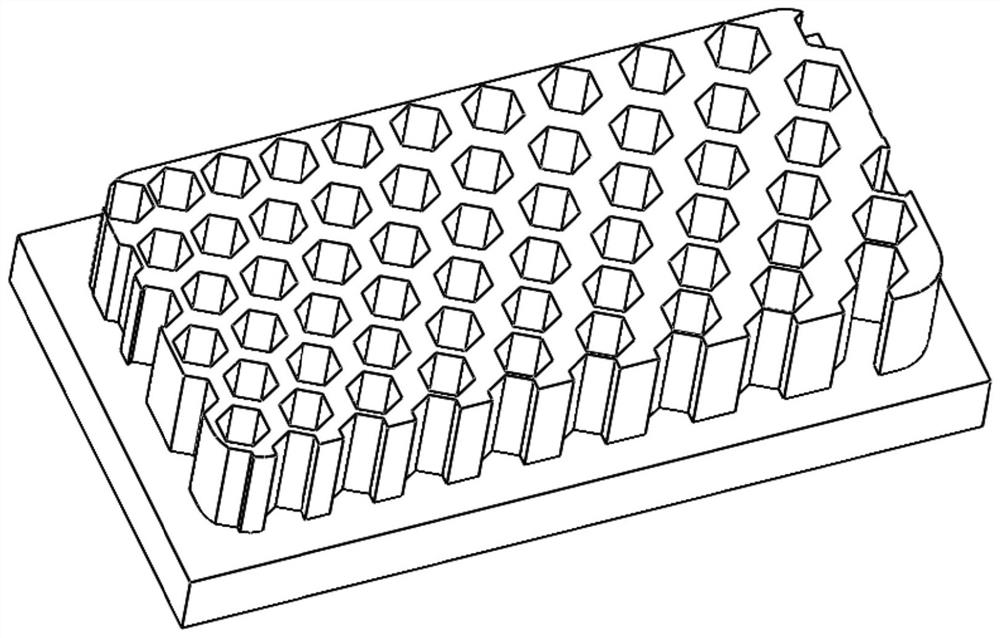

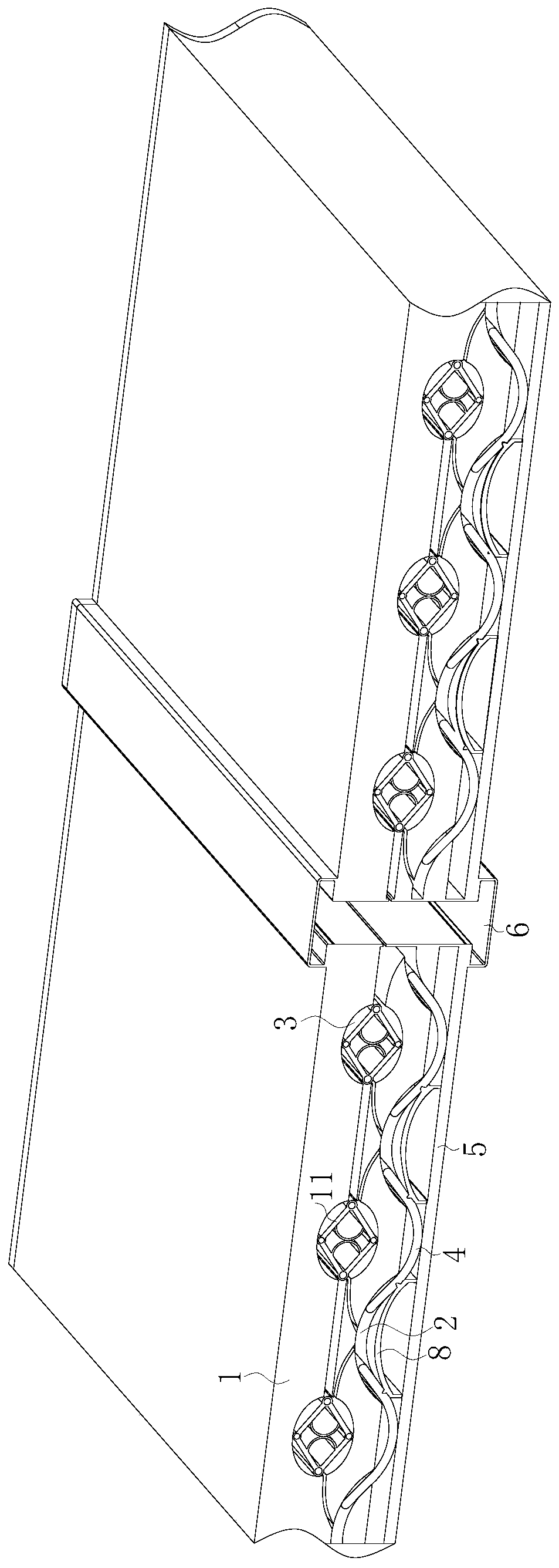

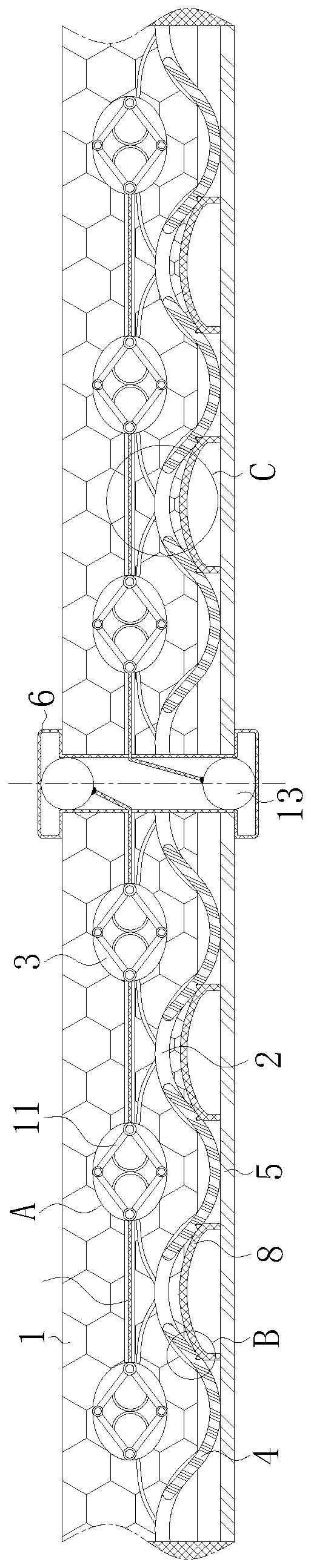

Negative poisson ratio structural component based on inner sunken hexagonal unit

PendingCN108082102AGood resilience toughness and fracture resistanceHigh strengthBumpersSustainable transportationSupporting cellElastic modulus

The invention discloses a negative poisson ratio structural component based on an inner sunken hexagonal multi-cell unit. The negative poisson ratio structural component comprises a plurality of unitcell structures, each of the unit cell structures consists of two inner sunken hexagons, the inner sunken hexagons are in a left-right symmetric dovetail shape, and every two inner sunken hexagons arearranged in an orthogonal mode and intersect at two concave angle apexes to form a complete unit cell structure; the multiple unit cell structures are connected with each other horizontally in both directions by sharing one support cell arm, and are extended in the horizontal direction to form a continuous unit layer; and a plurality of unit layers are connected with each other in the vertical direction by sharing curved ribs to form a multi-layered cross-aligned inner sunken honeycomb-shaped three-dimensional negative poisson ratio structure. According to the negative poisson ratio structural component based on the inner sunken hexagonal multi-cell unit, a significant negative poisson ratio effect is achieved, higher elastic modulus, shear modulus and storage modulus can be generated when loaded, better rebound toughness and fracture resistance are achieved and improved with the enhancement of the negative poisson ratio effect.

Owner:NANJING UNIV OF SCI & TECH

High-performance concrete admixture in use of waste ceramic powder and implementing method thereof

InactiveCN104817287AThe stability result is qualifiedImprove liquiditySolid waste managementEnvironmental resistanceFiber

The invention discloses a high-performance concrete admixture in use of waste ceramic powder and an implementing method thereof. The high-performance concrete admixture is prepared by the following steps: utilizing waste ceramics as a main material and utilizing active seed crystals and a modified enhancer as auxiliary materials; performing modified treatment and high-temperature smelting on various materials, then putting into a cement mill to mill the materials to be pre-finished products with specific area of 300-450 m2 / kg, and finally, doping mixed fibers. The high-performance concrete admixture comprises the raw materials in parts by weight: 80-100 parts of waste ceramic powder, 6-9 parts of active seed crystal, 2-6 parts of modified enhancer and 5-10 parts of mixed fibers. By adopting mixed ceramic powder, density of cement mortar is effectively increased; strength of concrete is improved and durability of concrete is remarkably improved. Energy problems are solved, and meanwhile, an environmental protection purpose is considered; the high-performance concrete admixture has remarkable technical, economic and social benefits.

Owner:EAST CHINA JIAOTONG UNIVERSITY

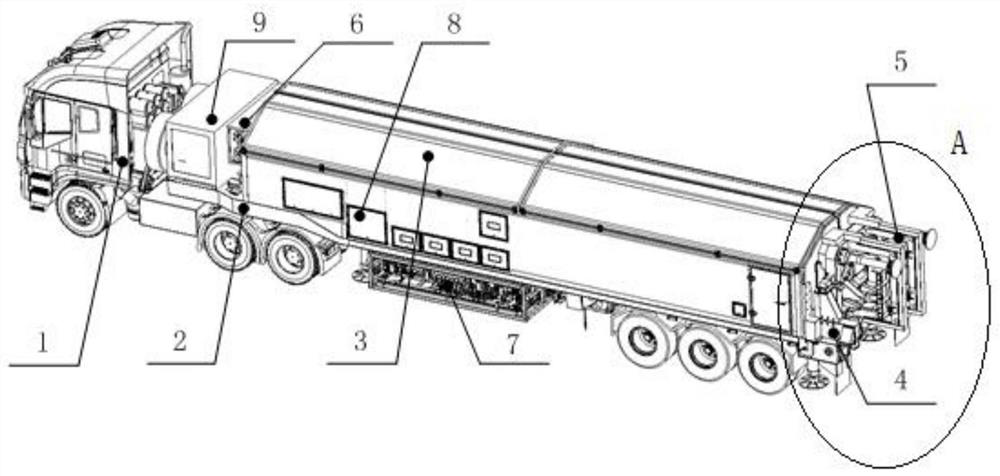

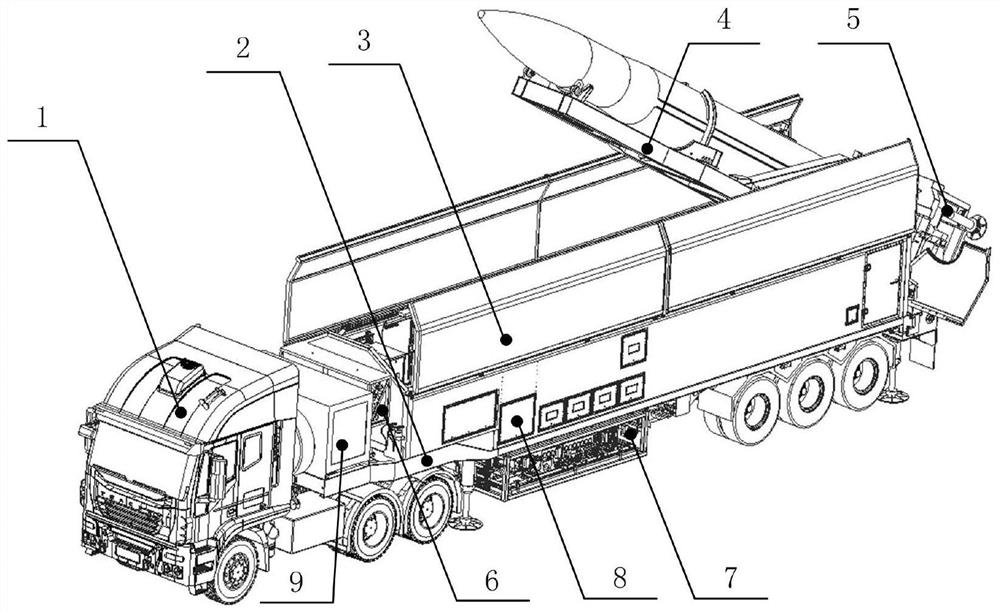

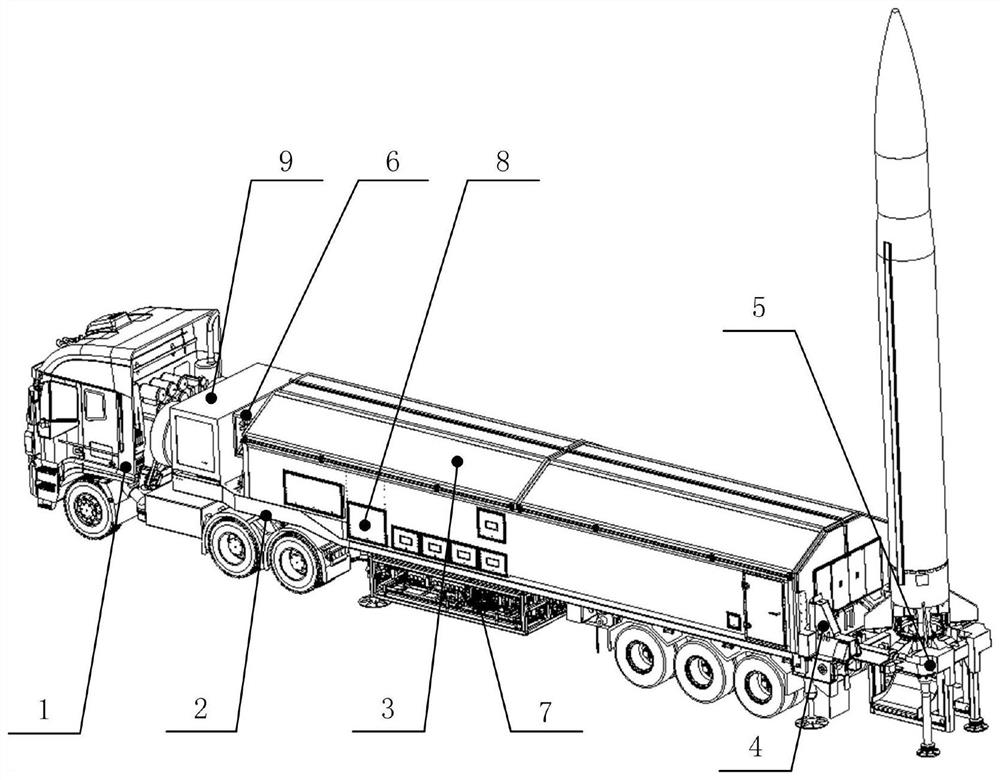

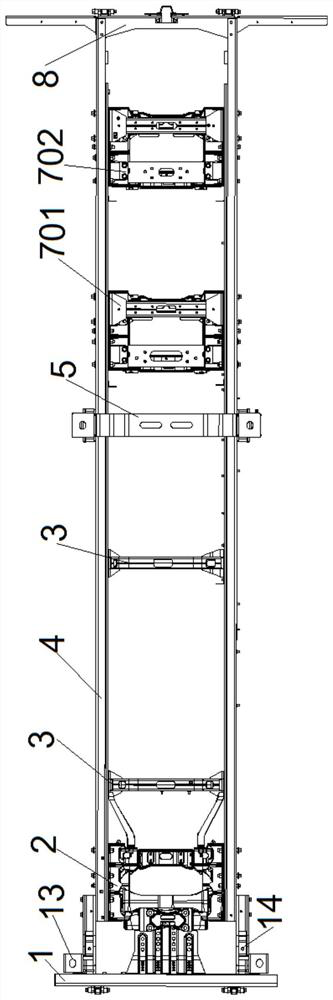

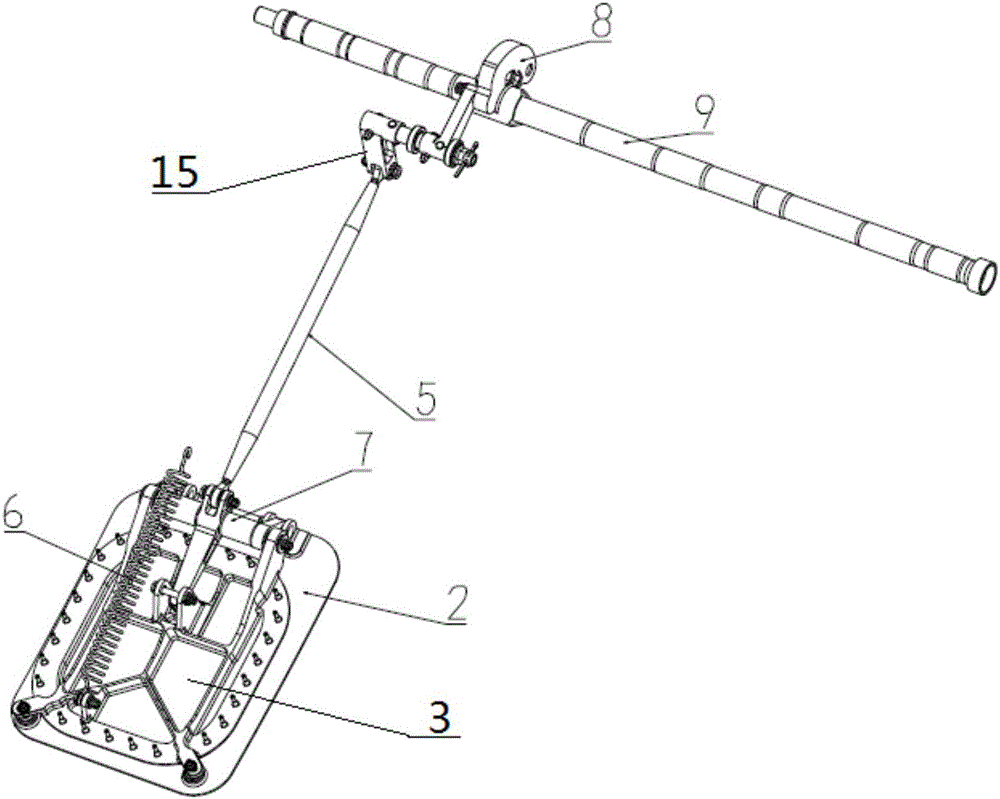

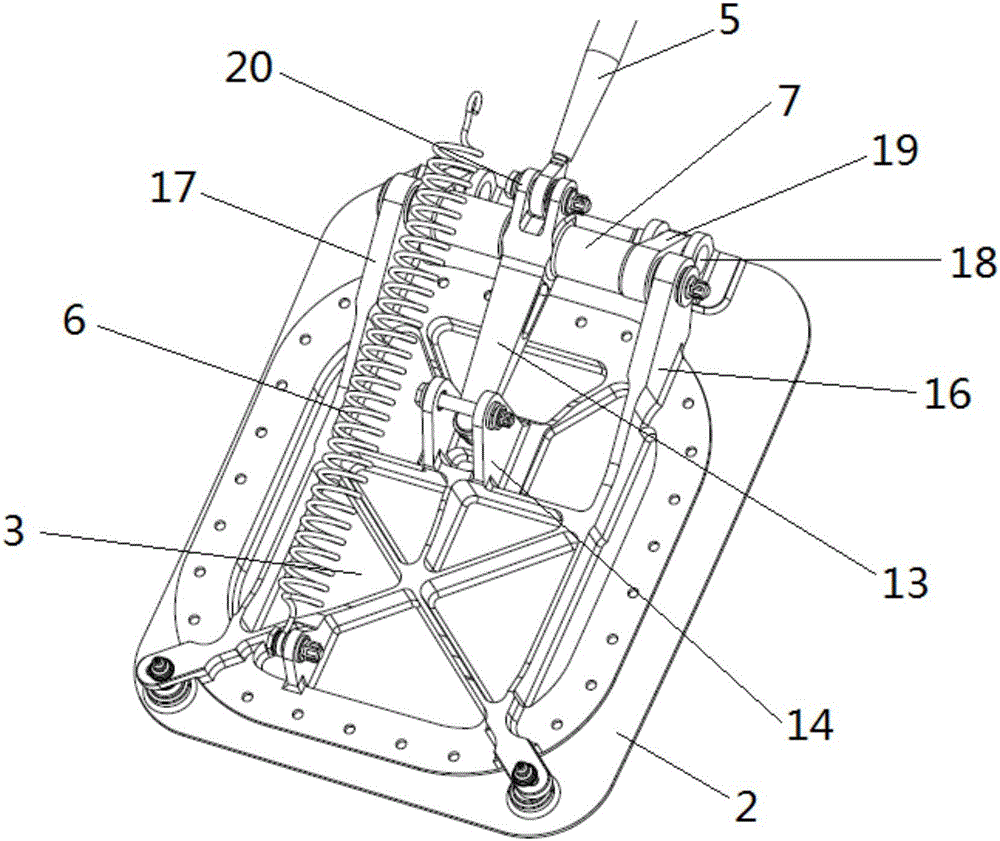

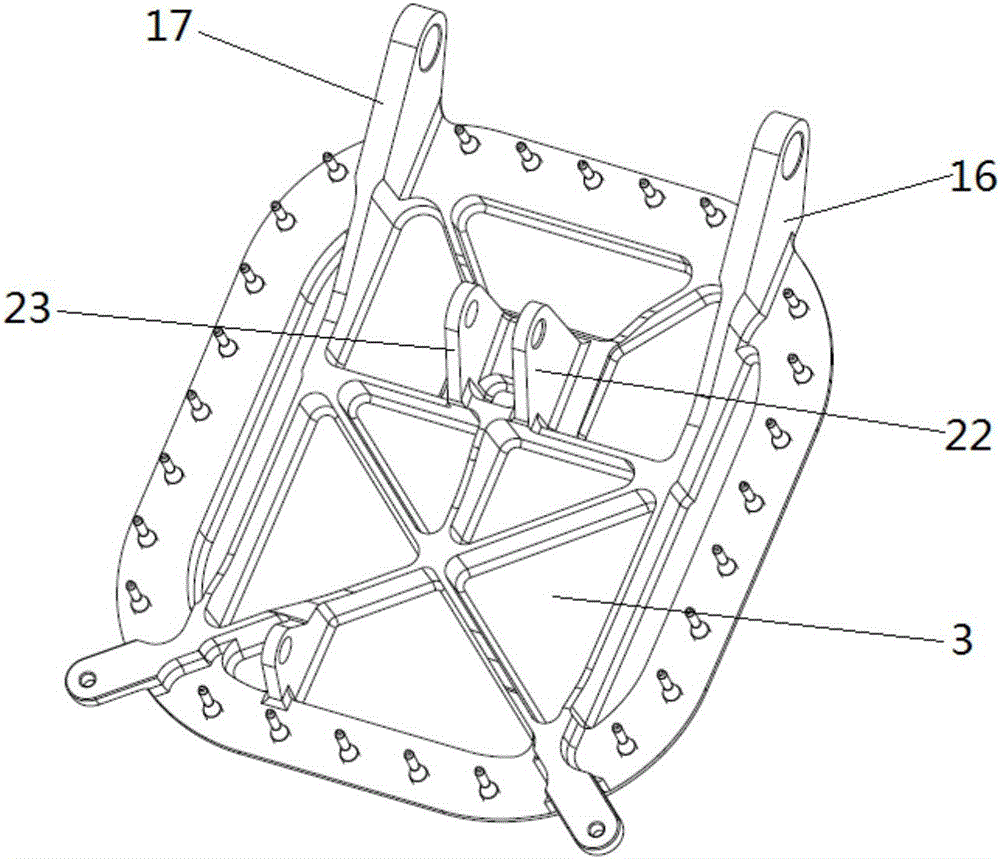

Rocket mobile launching vehicle

PendingCN111791788AShortenIncrease driving speedLaunch systemsCosmonautic partsHeat conservationRocket

The invention discloses a rocket mobile launching vehicle, which comprises a tractor, a chassis, a heat preservation cabin, an erecting system, a launching pad, temperature adjusting systems, a hydraulic system, a vehicle control system and power system wherein a traction seat is mounted on the tractor; the traction seat is connected with the chassis through a traction pin; the heat preservation cabin is fixedly mounted on the chassis; the erecting system is hinged to the rear end of the chassis; the launching pad is hinged to the rear end of the chassis; the launching pad and the erecting system are coaxial; the temperature adjusting systems are installed in front of and inside the heat preservation cabin; the hydraulic system is installed below the chassis; the vehicle control system isinstalled inside the heat preservation cabin; the operation panel is located outside the side wall of the heat preservation cabin; and the power systems are installed in the front of the chassis and inside the heat preservation cabin. The rocket mobile launching vehicle is ingenious in conception and reasonable in structural layout, the long-distance transportation time is greatly shortened, the stability in the transportation process is guaranteed, the shock absorption capacity is improved, the heat preservation cabin has good sealing performance, and meanwhile, the requirements for erectingand launching are met through the full-open design.

Owner:秦皇岛优益创联特种车辆制造有限公司 +1

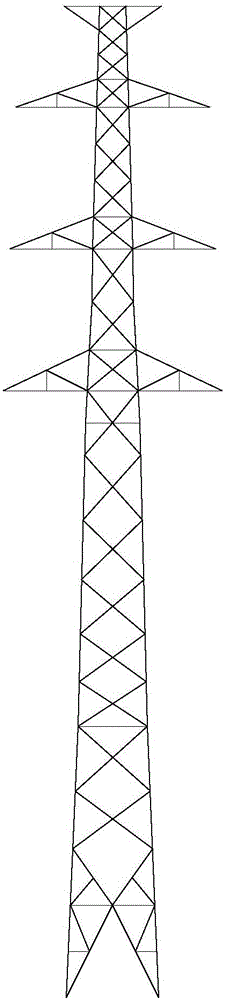

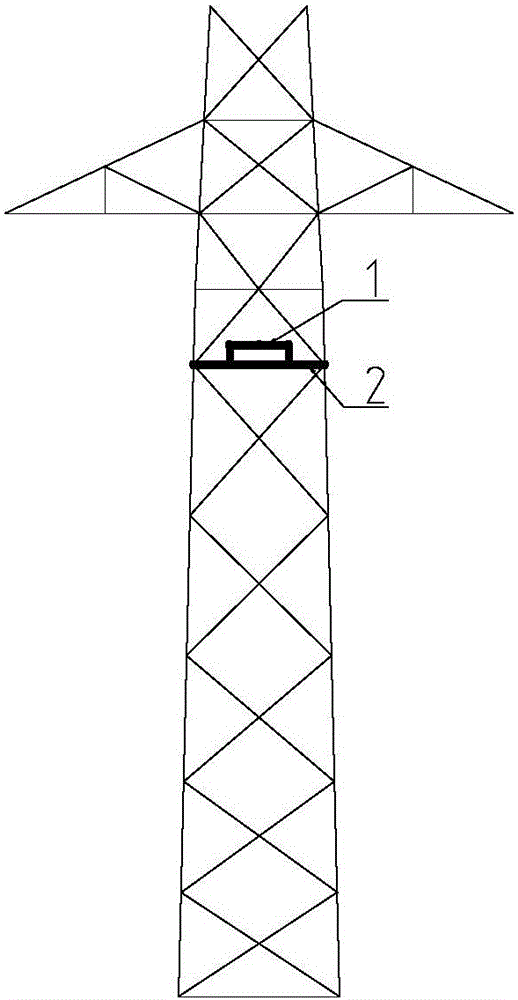

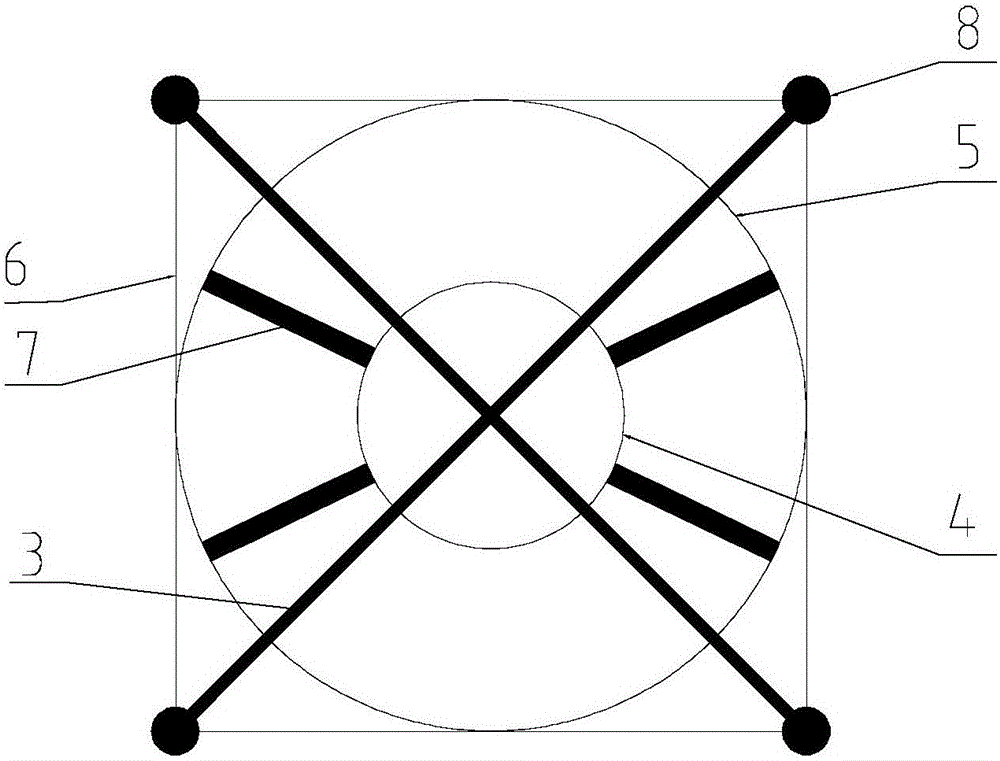

Overhead electricity transmission line tower with high wind resistance

ActiveCN104991998AReduce risk of damageReduced wind responseSpecial data processing applicationsElectricityEngineering

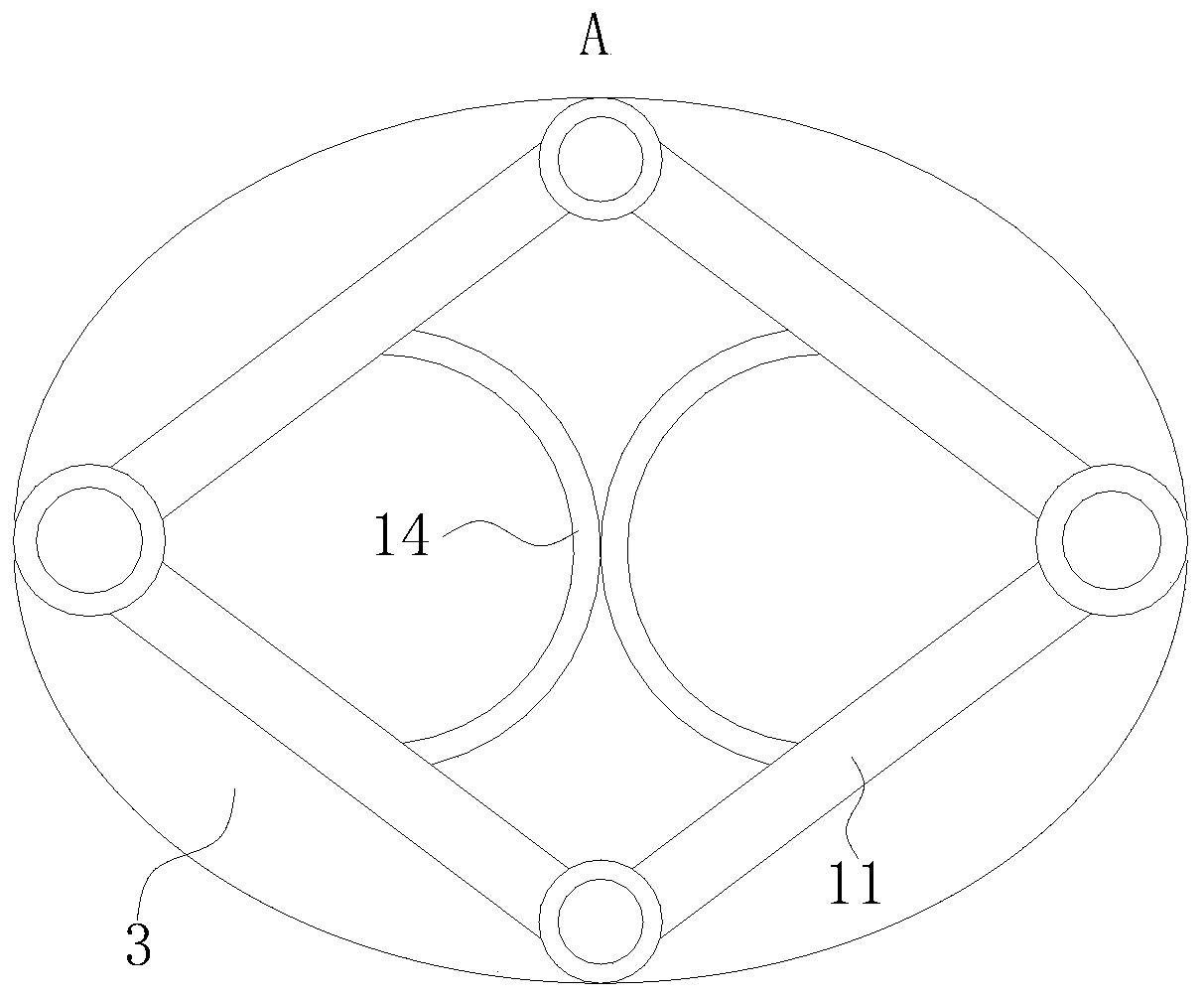

The invention provides an overhead electricity transmission line tower with high wind resistance, wherein a horizontal separation face of the line tower comprises four corner post main materials (8), wherein the four corner post main materials are equipped with four horizontal frame additional rod parts (6) which are connected into a frame shape, and the four corner post main materials are also equipped with two main supporting rods (3) which are respectively crossed and supported on the corner post main materials on opposite angles; a center round ring (4) is firmly supported on the main supporting rods in the frame shape, an incircle ring (5) is also disposed in the frame shape, contact points of the incircle ring are firmly connected with the horizontal frame additional rod parts, and the center point of the incircle ring is firmly connected to the main supporting rods; and four speed vibration-reduction damping devices (7) are disposed symmetrically between the center round ring and the incircle ring, and the included angle between a connection line of the speed vibration-reduction damping devices in opposite directions and the direction of an electricity transmission wire is less than 60 DEG. The overhead electricity transmission line tower with the high wind resistance provided by the invention integrates speed vibration reduction, tunes mass vibration reduction and increases performances of the overhead electricity transmission line tower so as to reduce risks of damages and destroy of the overhead electricity transmission line tower, is highly targeted, obtains significant effect, is constructed easily, and can be widely applied in the technical field of wind resistance of overhead electricity transmission line towers.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

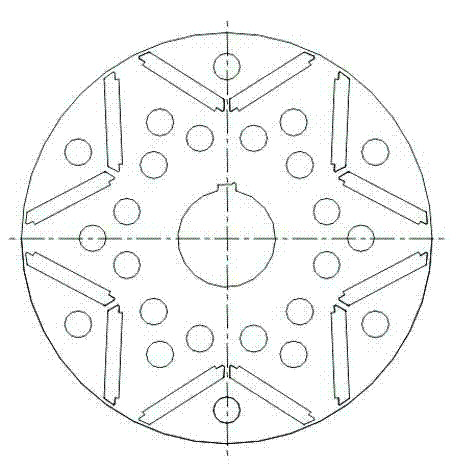

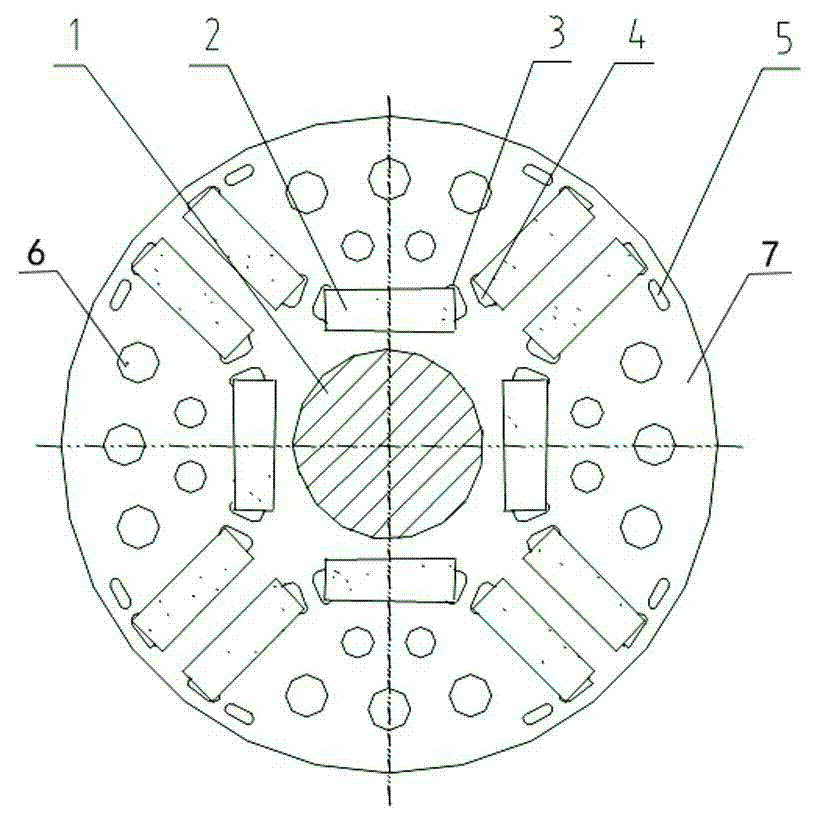

Novel rotor of permanent magnet motor

InactiveCN104767305ASpeed up the boot processImprove overload capacityMagnetic circuit rotating partsStress concentrationInterference fit

The invention relates to permanent magnet motors, in particular to rotors of the permanent magnet motors, provides a novel rotor of a permanent magnet motor and solves the problems caused by structural defects of rotors in existing permanent magnet motors. The rotor of the permanent magnet motor comprises a revolving shaft, a rotor sheet and magnetic steel, wherein the rotor sheet is fitted with the revolving shaft in a superimposed mode, magnetic steel grooves and vent holes are formed in the rotor sheet, and the magnetic steel is inserted in the magnetic steel grooves; the rotor sheet is of a U-shaped magnetic structure, namely every three magnetic steel grooves which are distributed in a U shape form a magnetic pole; two magnetism isolating bridge holes are formed below each magnetic pole, and the rotor sheet is in interference fit with the revolving shaft; the magnetic steel is in clearance fit with the rotor sheet, and gaps at the two ends of each section of the magnetic steel are sealed up with silicone rubber in a pouring mode. Fillets used for eliminating stress concentration are formed at the two ends of each magnetic steel groove. By means of the novel rotor of the permanent magnet motor, the realistic basis is provided for research and development of permanent magnet motors with higher power and higher rotating speed.

Owner:CRRC YONGJI ELECTRIC CO LTD

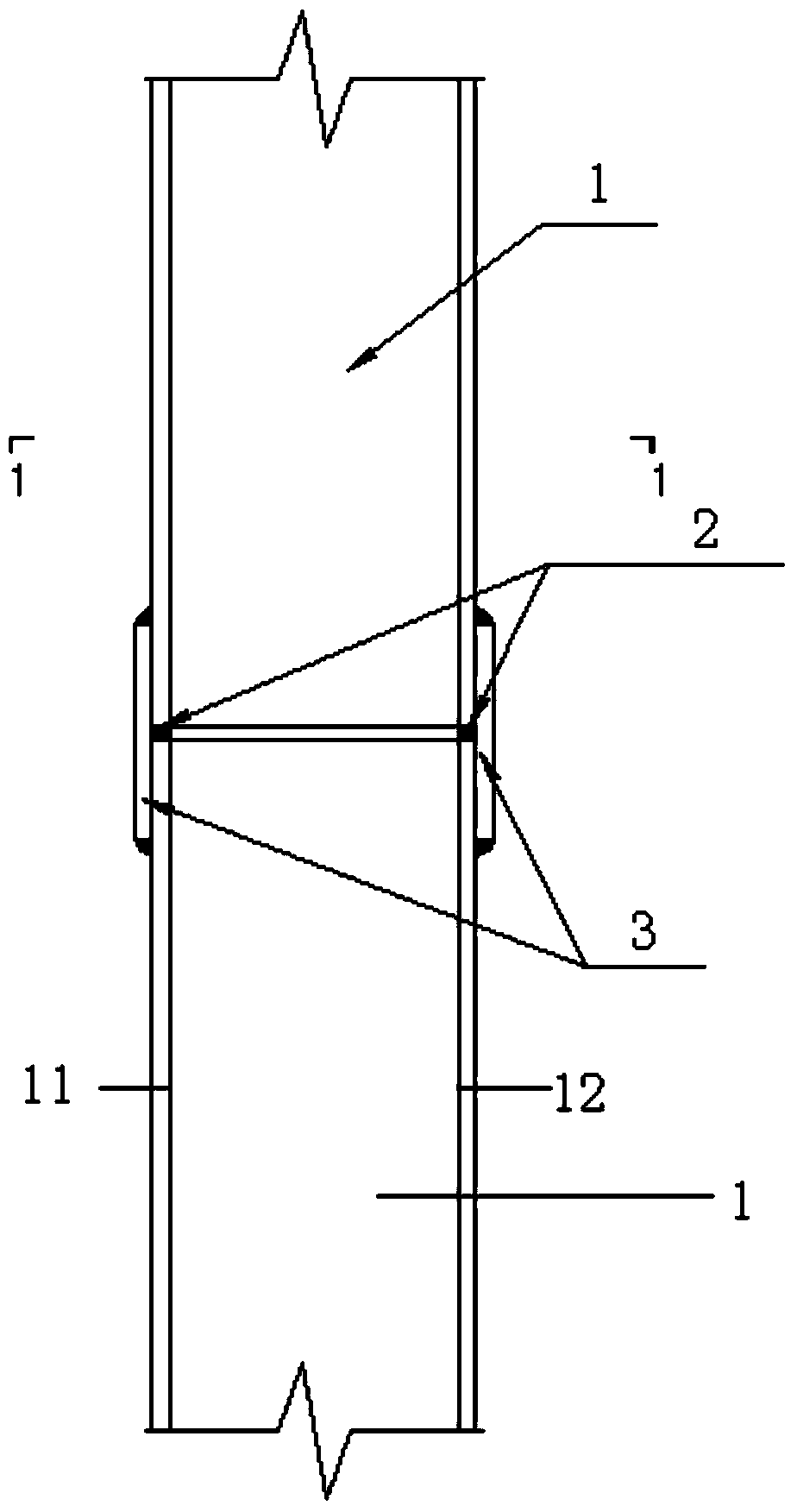

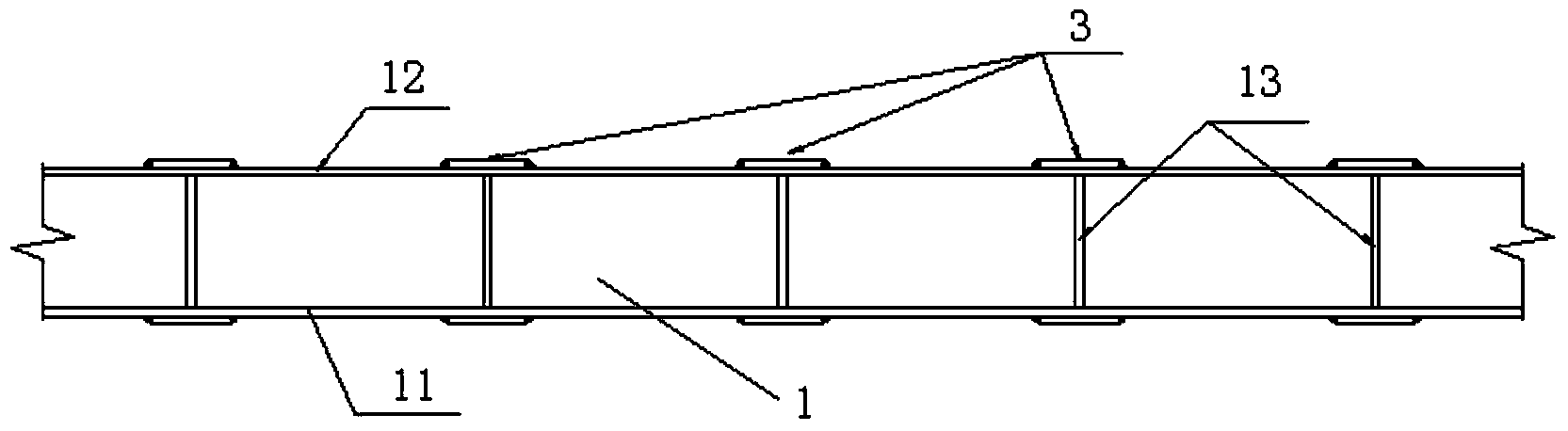

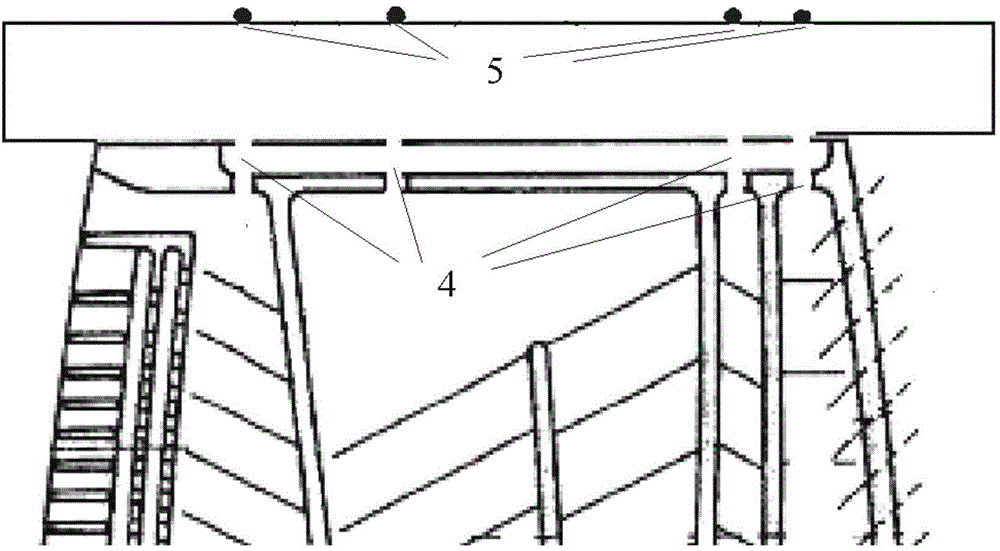

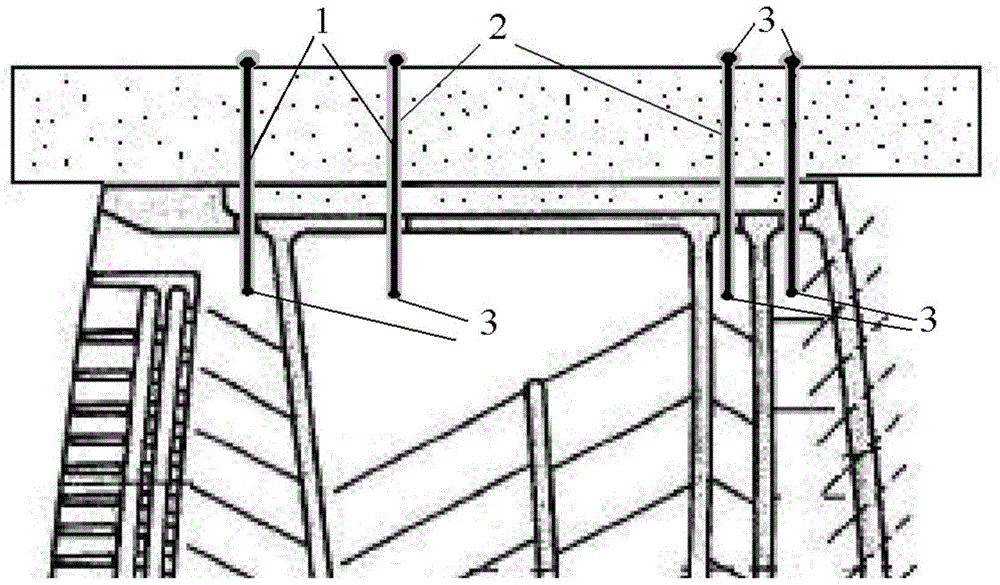

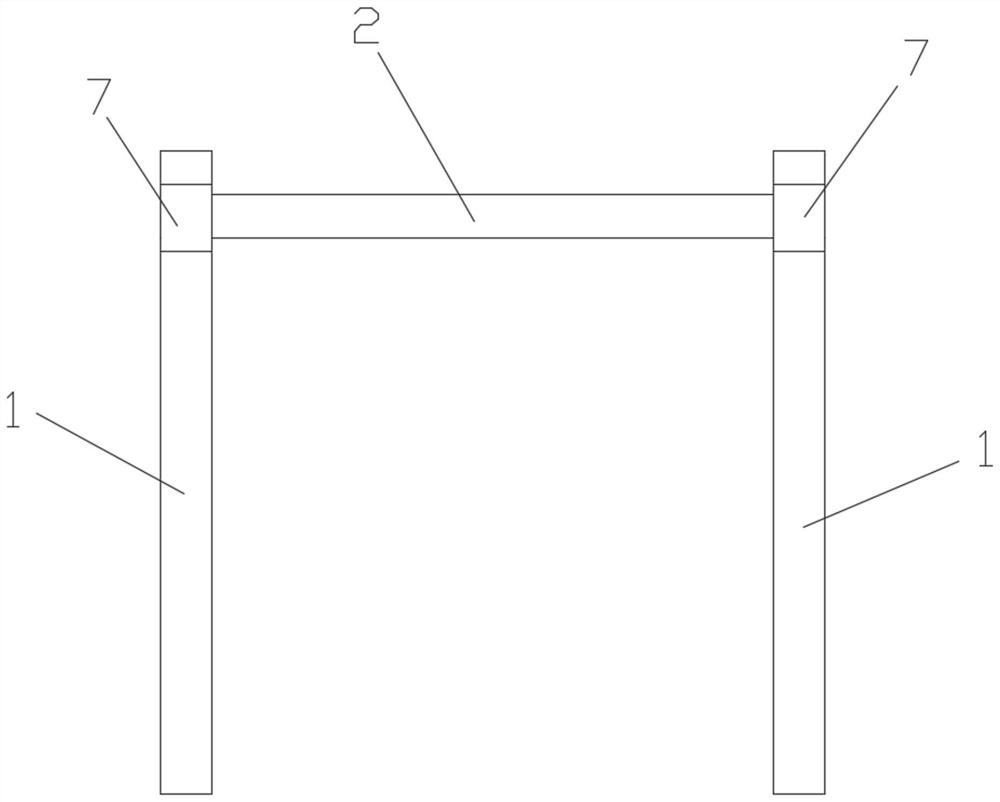

Steel tube bundle combined structure shear wall field spliced node

The invention discloses a steel tube bundle combined structure shear wall field spliced node. The steel tube bundle combined structure shear wall field spliced node is formed by splicing a plurality of steel tube bundle combined structure shear walls; each steel tube bundle combined structure shear wall comprises a left wing edge and a right wing edge which are vertically arranged and a plurality of partitions are arranged between the left wing edge and the right wing edge at intervals; each steel tube bundle combined structure shear wall is separated into a plurality of units by the left wing edge, the right wing edge and the partitions, each unit is provided with a cavity and concrete is cast in each cavity; the previous steel tube bundle combined structure shear wall is connected with the next steel tube bundle combined structure shear wall through a welding line, and two ends of the partitions are respectively welded to the welding line joints of left wing edges and right wing edges; reinforcing steel plates are arranged at the welding line joints and cover the welding line joints; two ends of the reinforcing steel plates extend respectively; one end of each reinforcing steel plate is welded to the wing edges of the previous steel tube bundle combined structure shear wall, and the other end of each reinforcing steel plate is welded to the wing edges of the next steel tube bundle combined structure shear wall. According to the steel tube bundle combined structure shear wall field spliced node, the strength of shear wall joints is improved.

Owner:HANGXIAO STEEL STRUCTURE

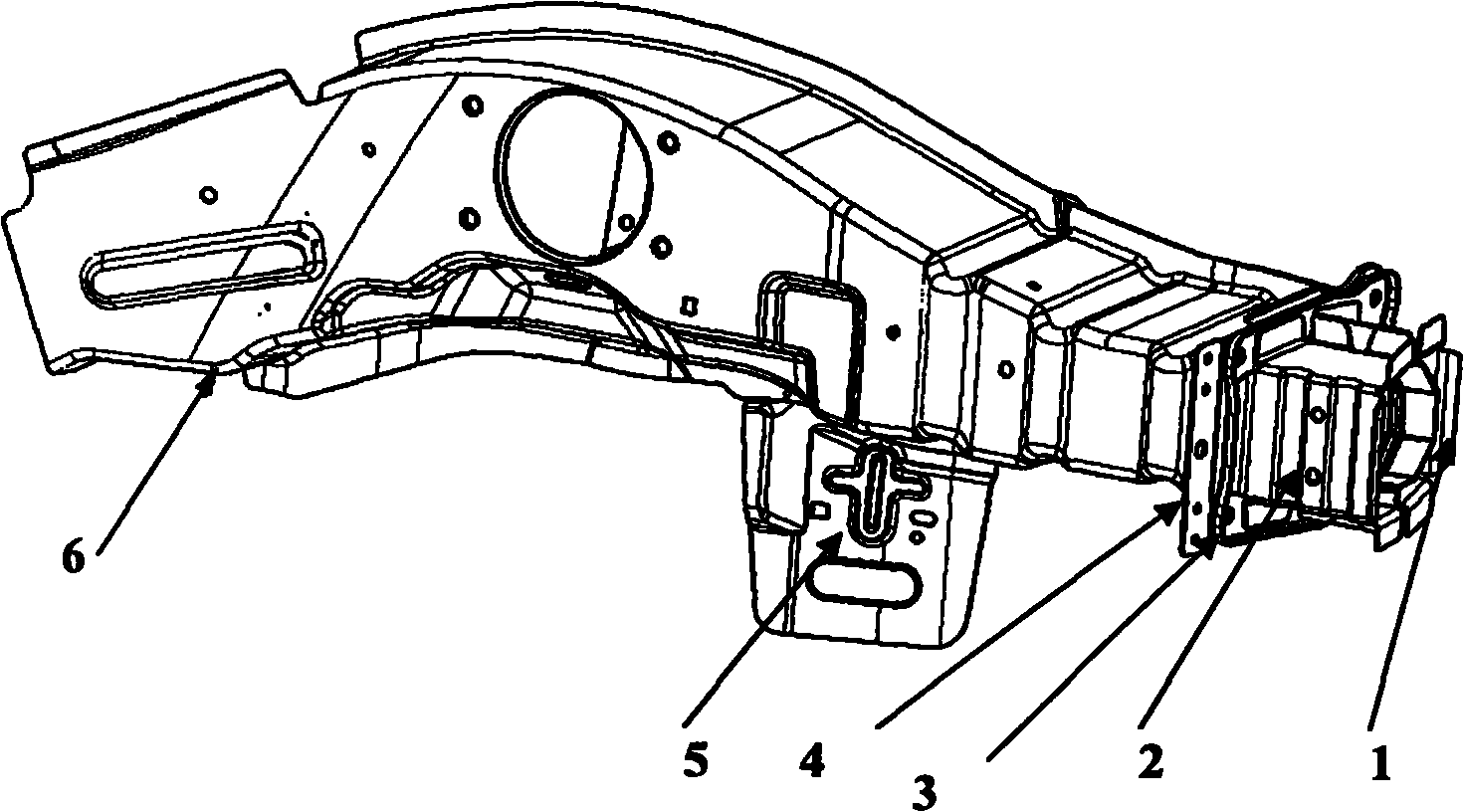

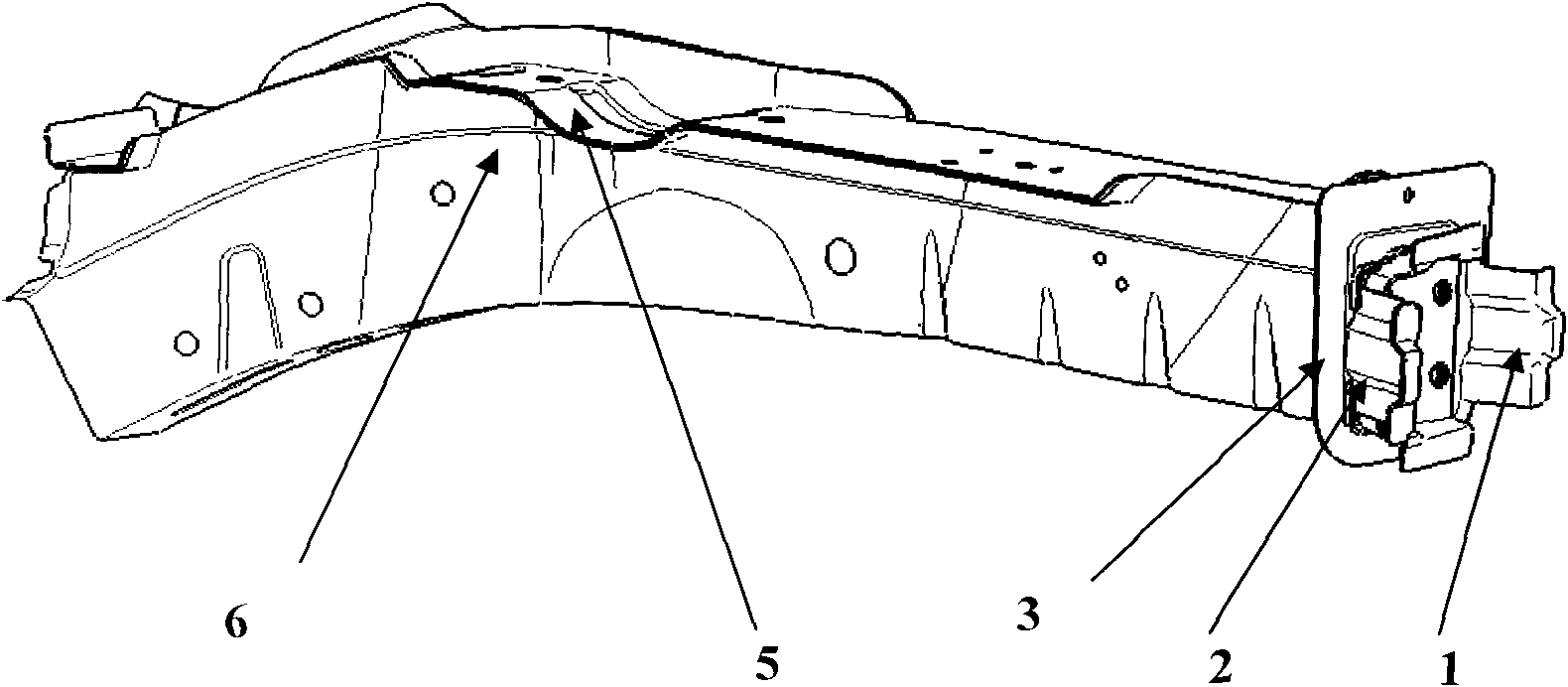

Automobile engine nacelle curb girder front part with reinforced energy absorbing structure

The invention discloses an automobile engine nacelle curb girder front part with a reinforced energy absorbing structure. The front part comprises a body, a foreplate of an external closing plate, a front lock plate, and a support of a front crush box, which is connected on the front lock plate. The invention is characterized in that one end of the front internal crush box and one end of the front external crush box are respectively connected with the support of the front crush box; the front internal crush box and the front external crush box are oppositely locked with each other and the front internal crush box is arranged inside the front external crush box; a first half reinforced cylinder and a second half reinforced cylinder are arranged inside the front internal crush box and are oppositely connected into a cylinder; and one end of the cylinder is connected with the support of the front crush box. Adopting a unique structure with the front internal crush box inside the front external crush box guarantees the complete absorption of energy during offset collision; the partitioning is reliable and punch forming is easy, thereby guaranteeing that an automobile can be successfully repaired when colliding at low speed; and the invention completely reaches the high-star score E-NCAP and C-NCAP according to the analysis of CAE.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

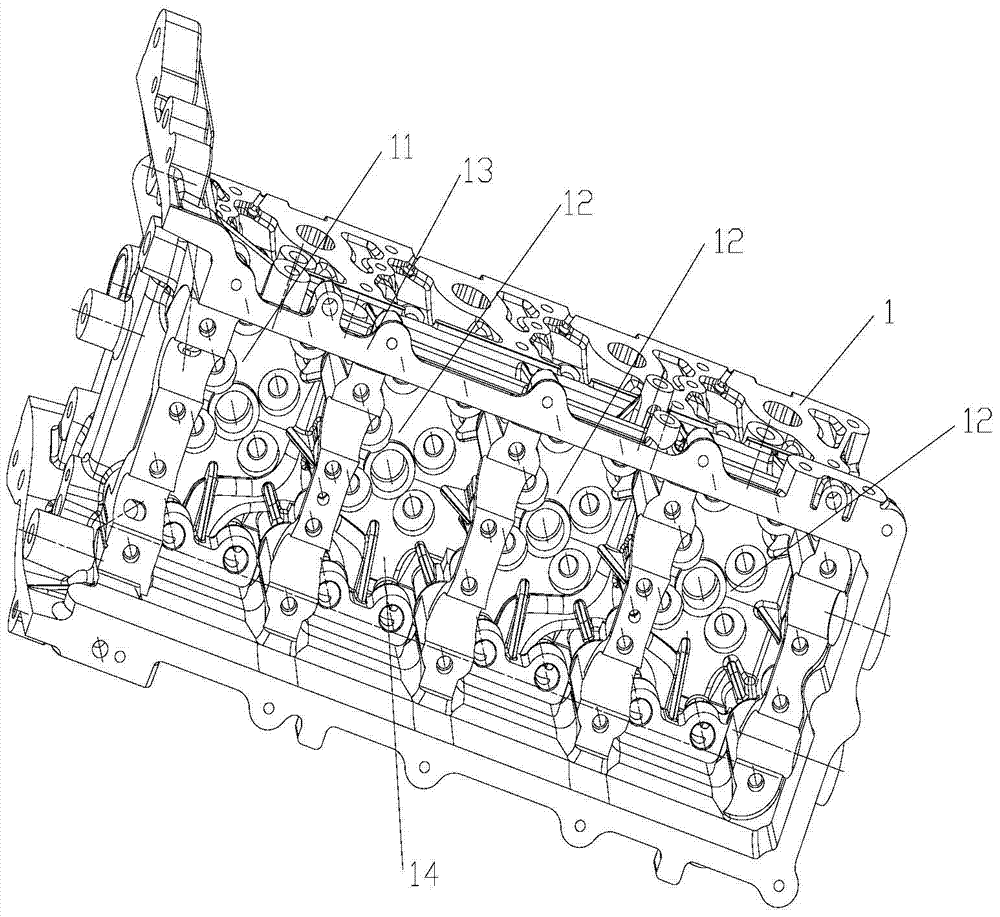

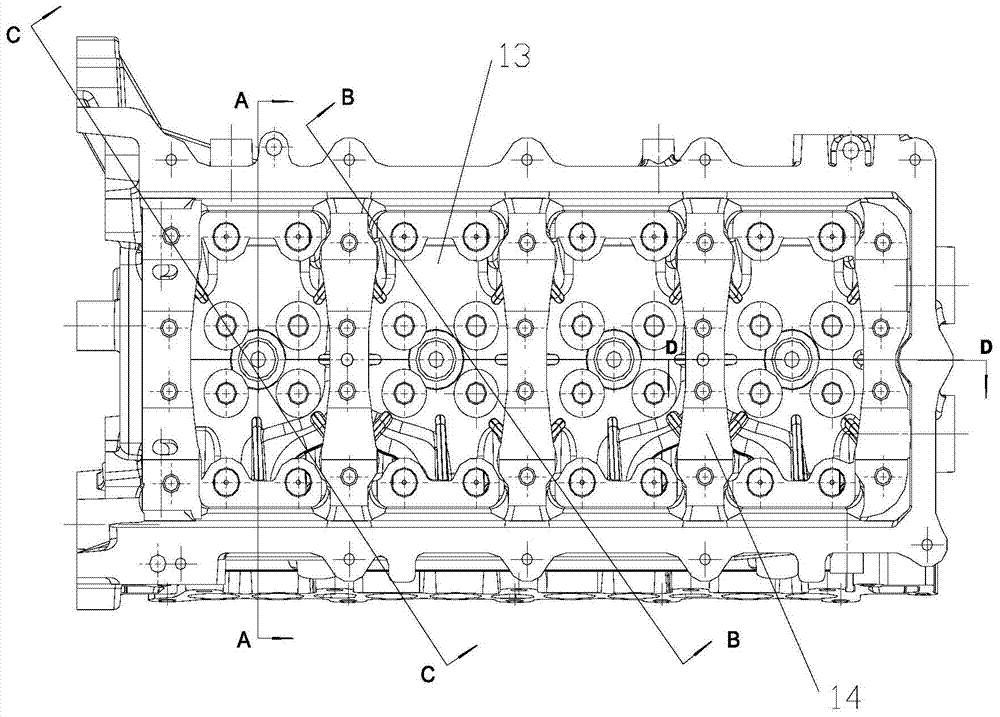

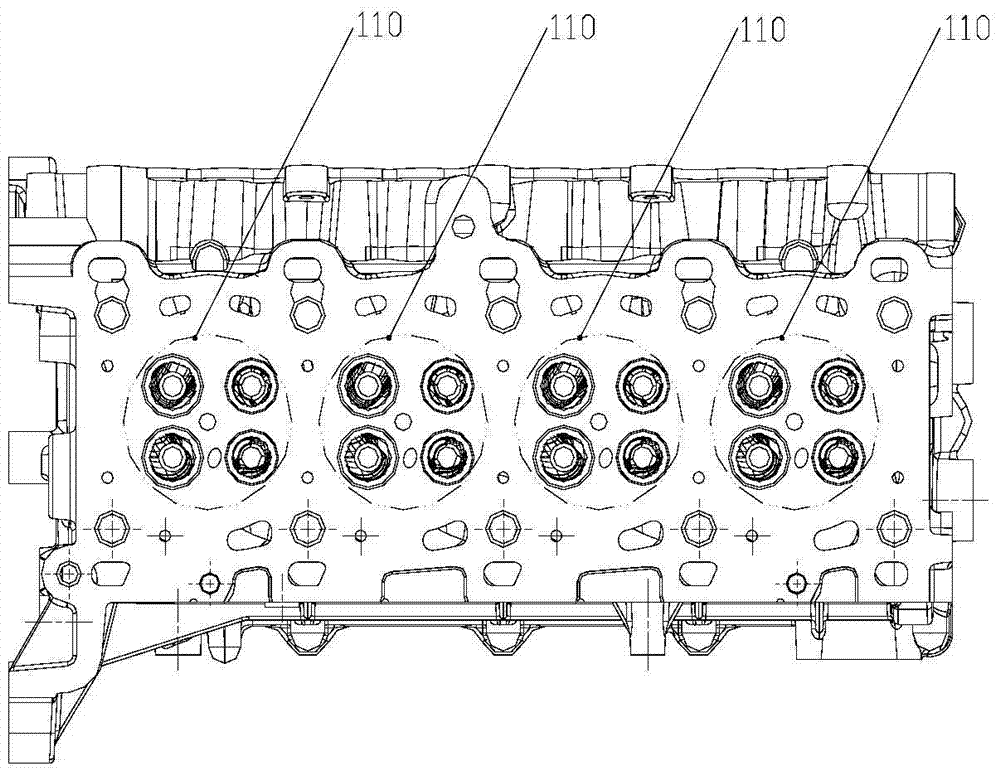

cylinder head

ActiveCN105257423BImprove local strengthSmall amount of deformationCylinder headsCylindersDesign cycleCylinder head

The invention discloses a cylinder head, the cylinder head is provided with a plurality of valve strap groups, each valve strap group is provided with a protruding side wall around the top surface, the side wall of each valve strap group is connected with the cylinder A plurality of first reinforcing ribs are arranged between the top plates of the cover. The present invention adds a plurality of reinforcing ribs on multiple positions of the cylinder head, which enhances the local strength of each part of the cylinder head, thereby forming a solid frame structure between the top plate and the bottom plate, greatly reducing the deformation of the bottom plate, Moreover, there is no need to re-design the whole, the versatility of the parts is high, the design cycle is short, the design and manufacturing costs are greatly reduced, and it is very suitable for the engine of low-cost diesel light vehicles.

Owner:GUANGXI YUCHAI MASCH CO LTD

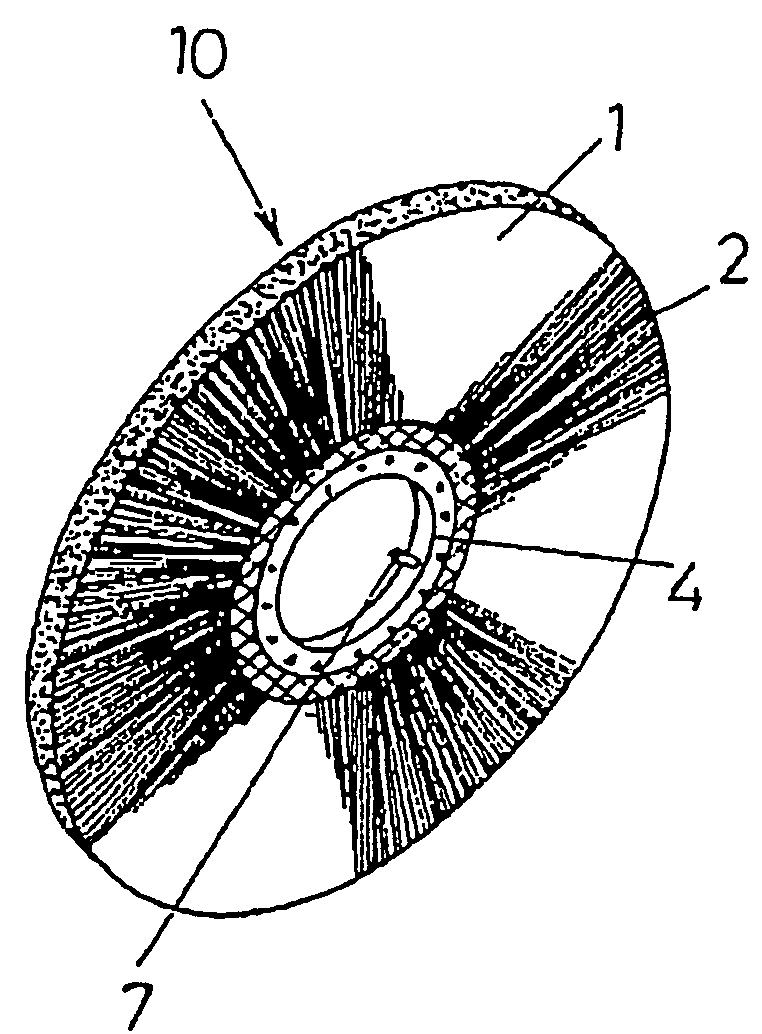

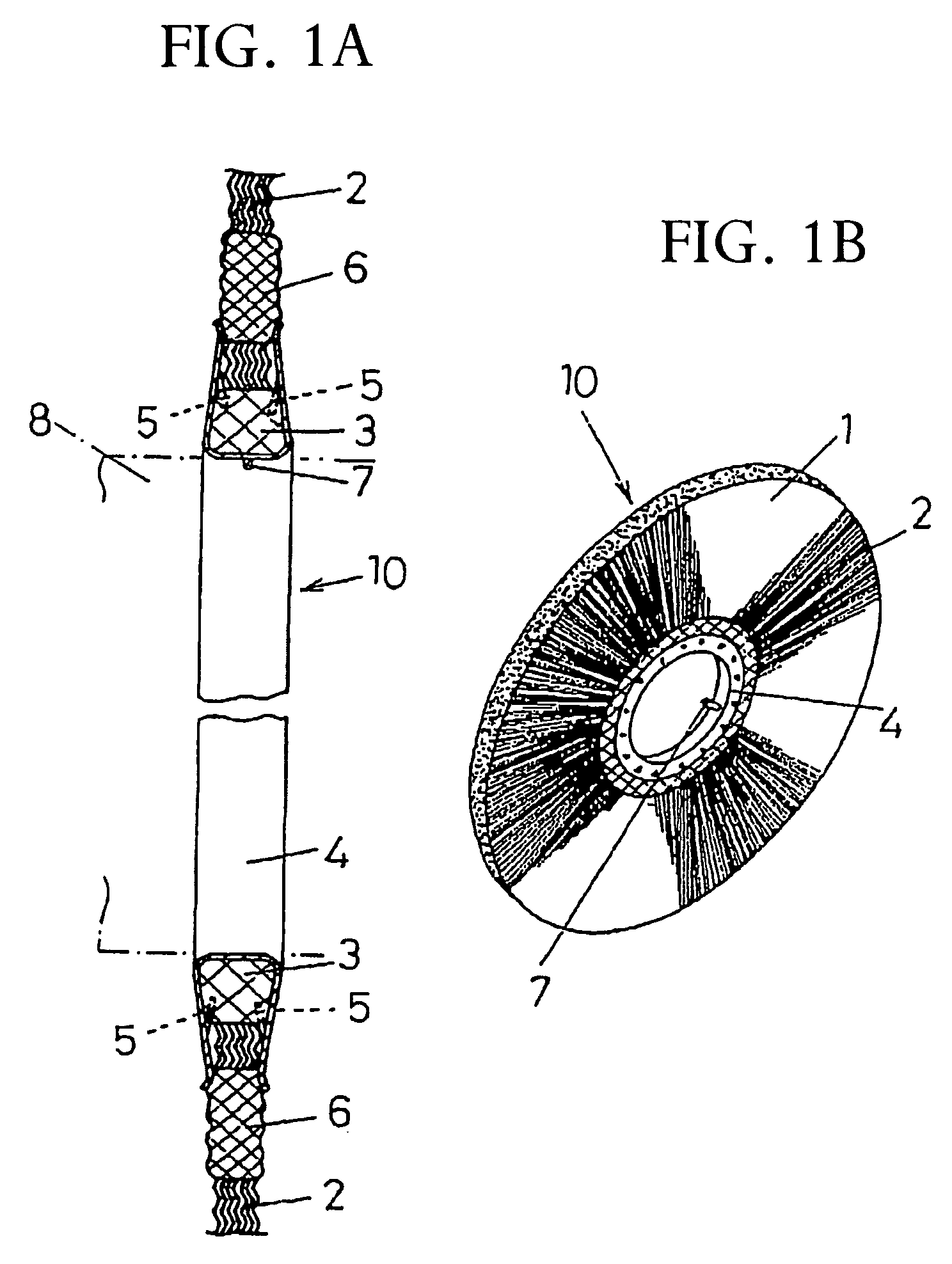

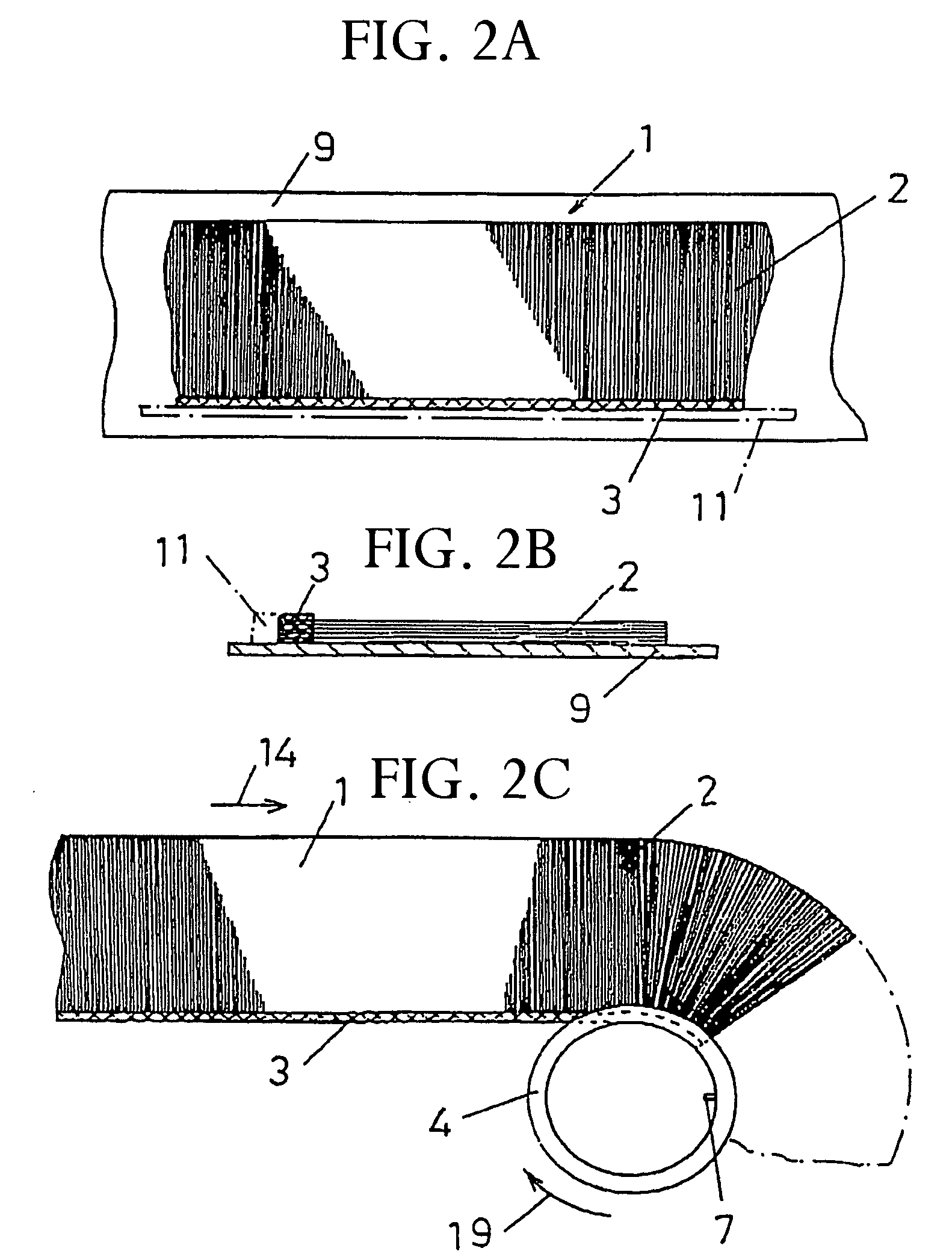

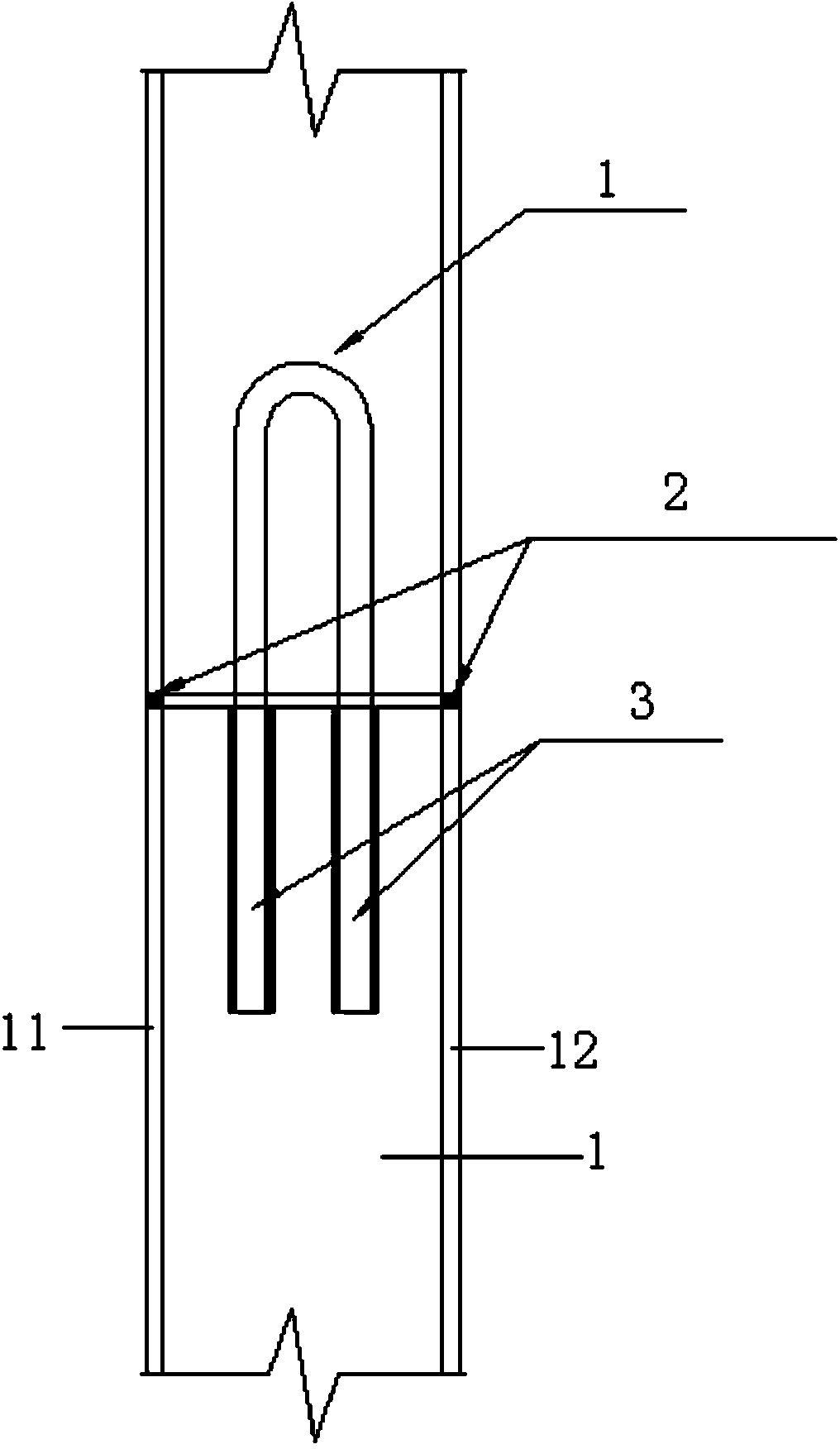

Linear or disk brush material, cylindrical brush, and method of manufacturing the linear or disk brush material

InactiveUS20090199356A1Easy to changeIncrease freedomBrush bodiesMetal rolling stand detailsEngineeringSynthetic resin

A linear or disk steel brush material for a rotary brush in which the root portions of a large number of steel brush wires are inserted and fixed into a linear or ring-like steel channel having a U-shaped cross section and an opening directed to an outer peripheral side, wherein the root portions of the steel brush wires are fixed by synthetic resin to obtain a solid portion, the solid portion is fitted into the steel channel and is then latched and fixed to a latching section projected inward from the steel channel wall, and both opening edge portions of the steel channel are curved outward.

Owner:AOKI SWEEPER

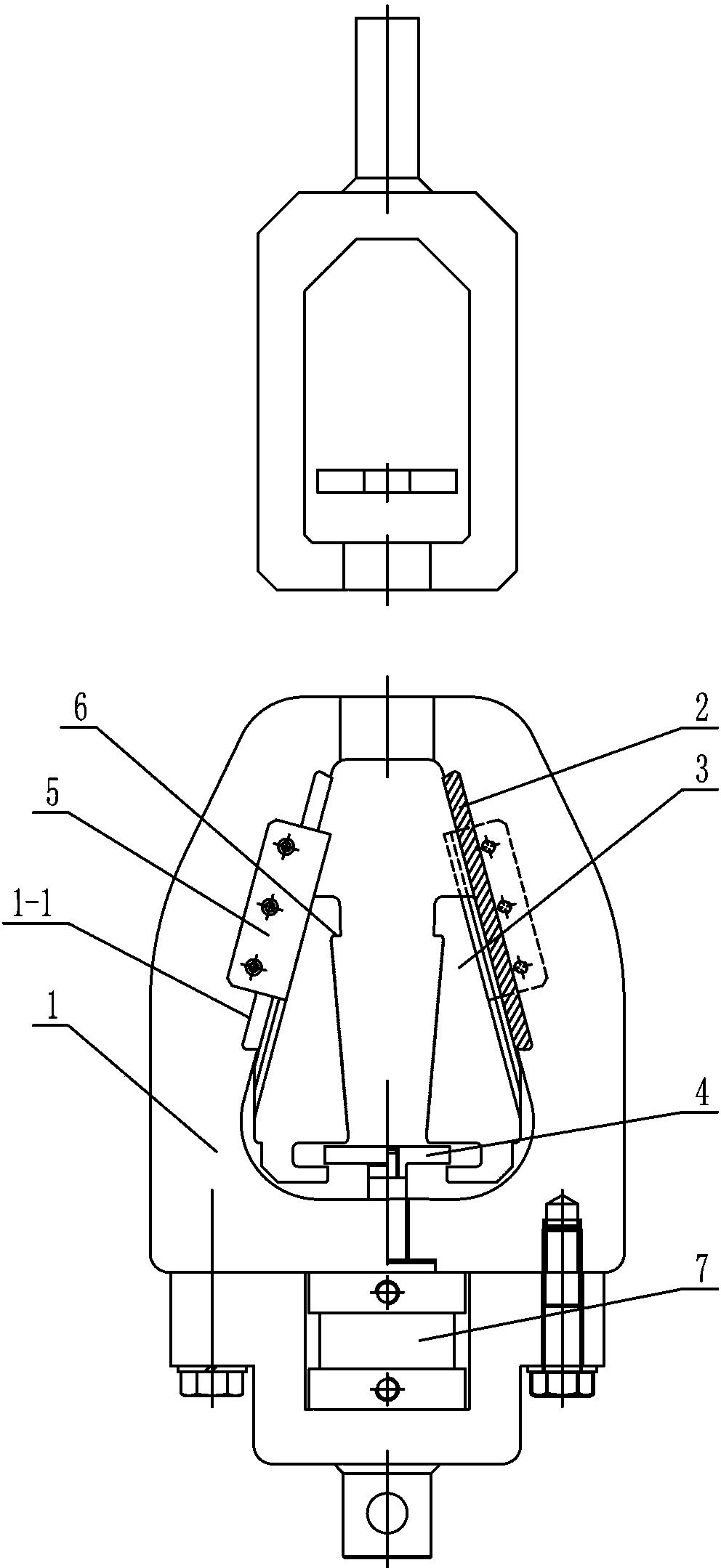

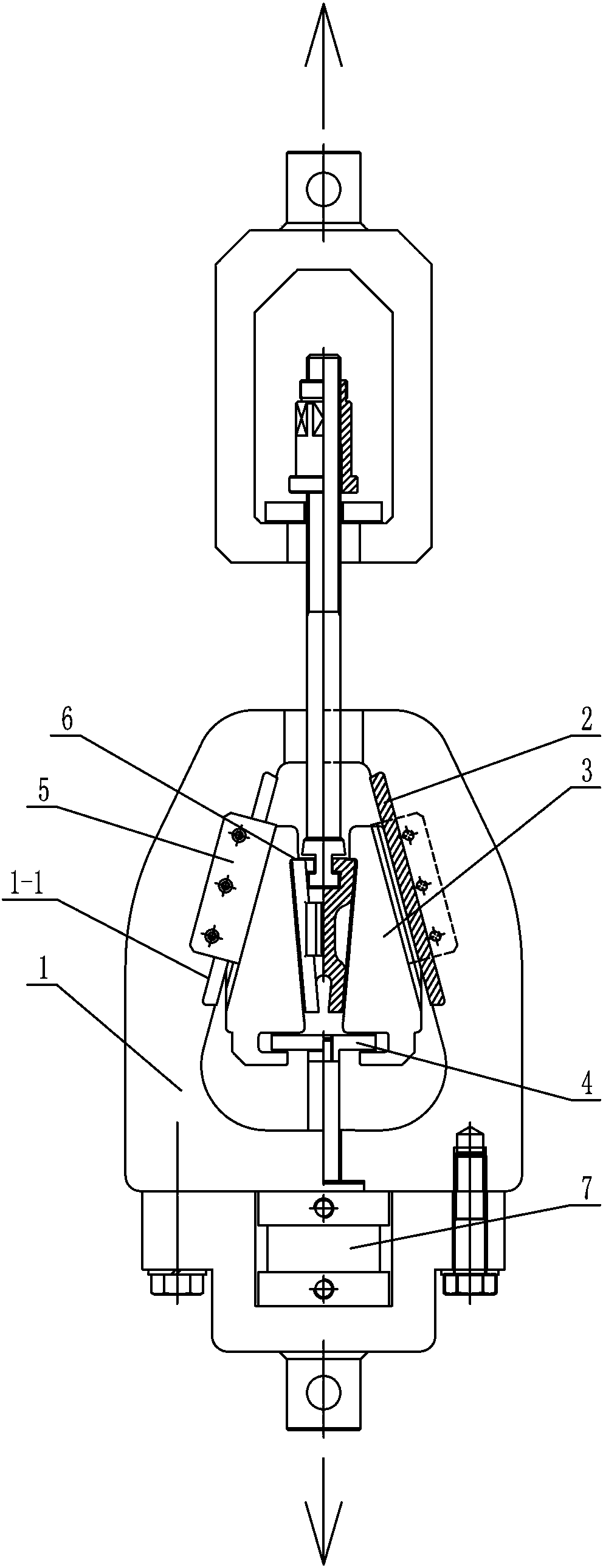

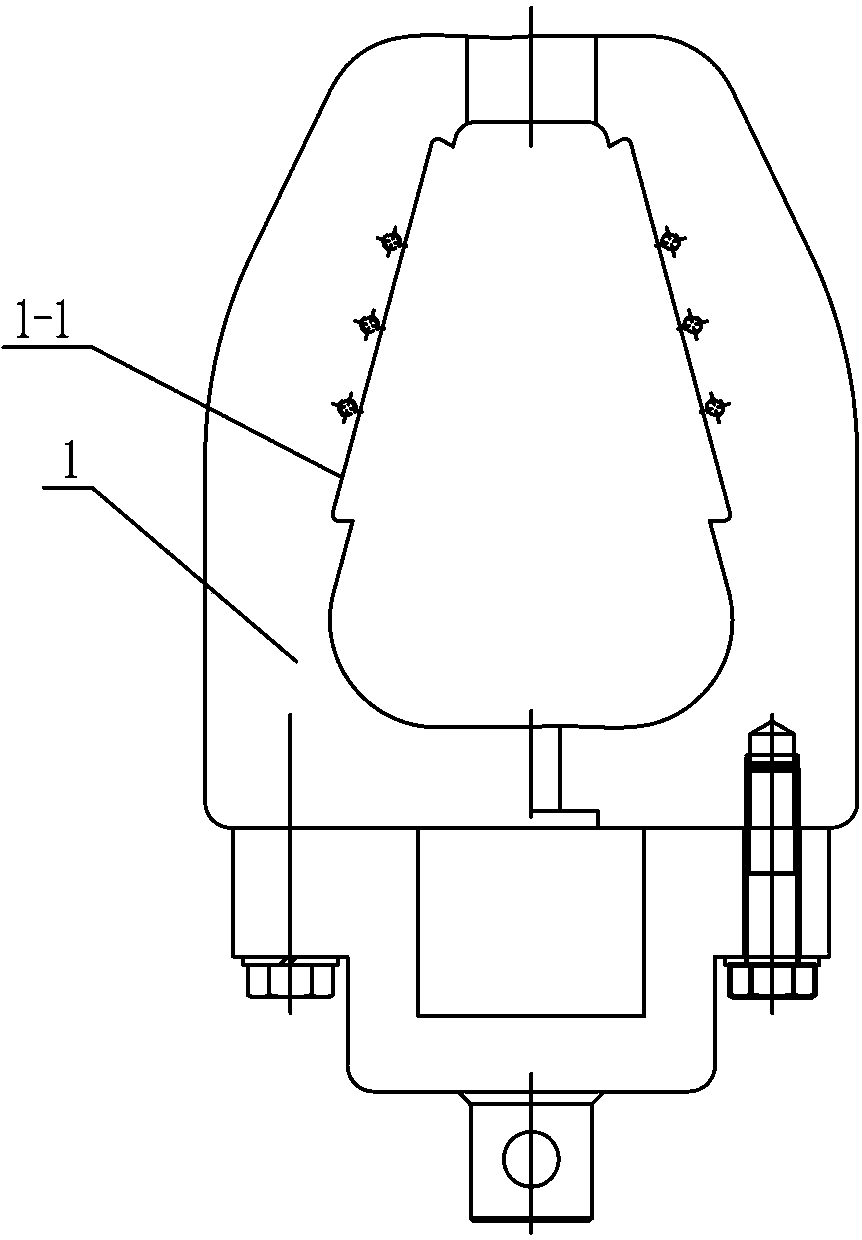

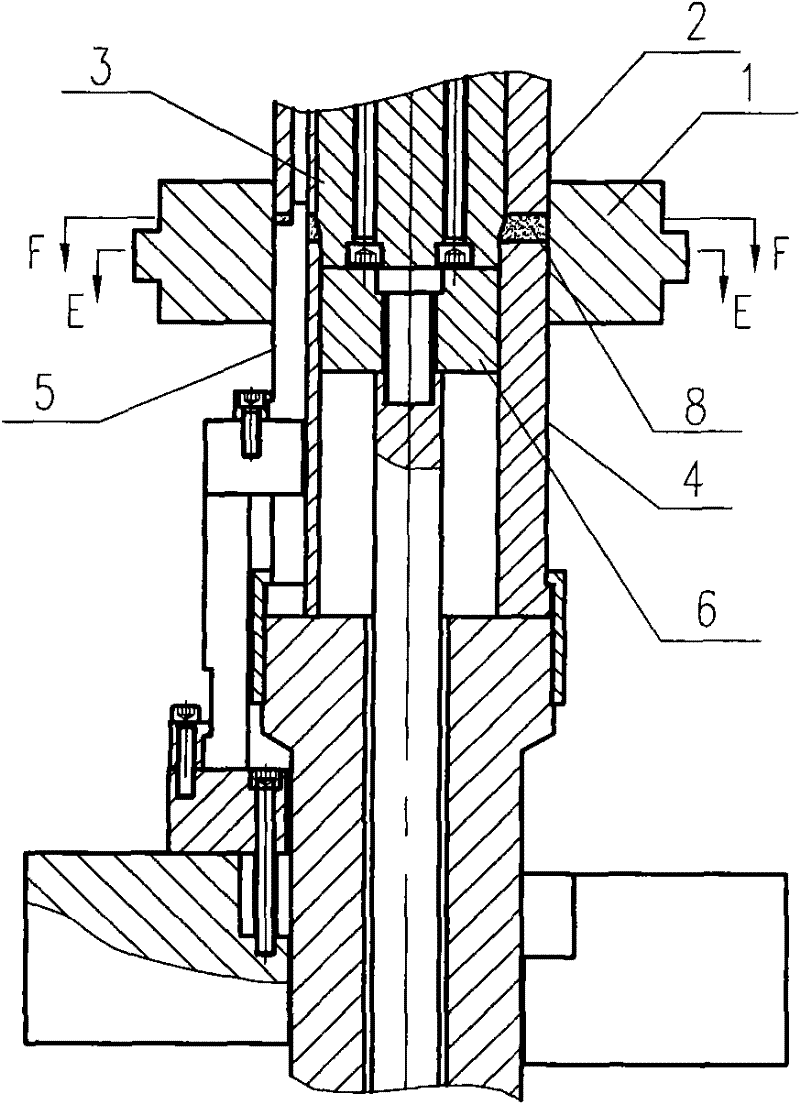

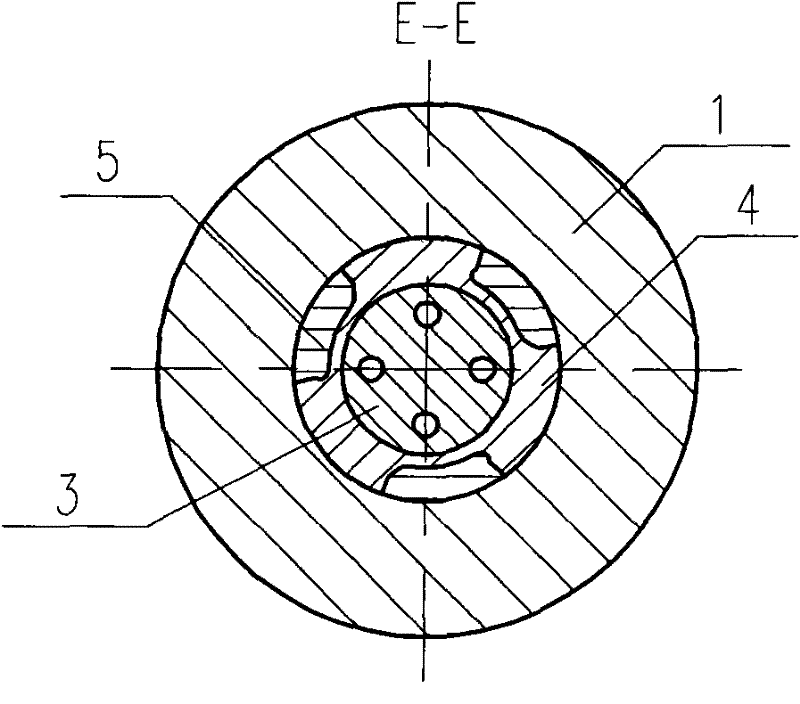

Clamp special for combined tension test of gate valve closing member

The invention discloses a clamp special for a combined tension test of a gate valve closing member. The clamp comprises a clamp base, wherein a concave bayonet is formed in each of the left side and the right side of the upper part of the clamp base, a cutting board is arranged at the inner side of each concave bayonet, the inner side of each cutting board is clung to a pressing piece, a top plate capable of moving up and down is arranged below the clamp base, the top plate is capable of pushing the pressing piece to move upwards, a surface at the inner side of each cutting board and matched with the pressing piece is an inclined surface, the pressing piece supports against the inclined surface and is capable of aslant sliding along the inclined surface, the inclined surfaces at the inner sides of the two cutting boards form a splayed sliding surface, the two pressing pieces are capable of aslant sliding up and down along the splayed sliding surface, fixing boards are arranged at the front side and the rear side of each concave bayonet, the two fixing boards located on the same concave bayonet are used for clamping the front side and the rear side of the pressing piece, the mutually opposite inner side surfaces of the two pressing pieces are reversed inclined surfaces, the two reversed inclined surfaces are of an inverted splayed structure, and convex anti-skidding bosses are arranged on the upper parts of the reversed inclined surfaces of the pressing pieces.

Owner:QUALITY INSPECTING CENT OF PUMP & VALVE PROD OF ZHEJIANG PROVINCE

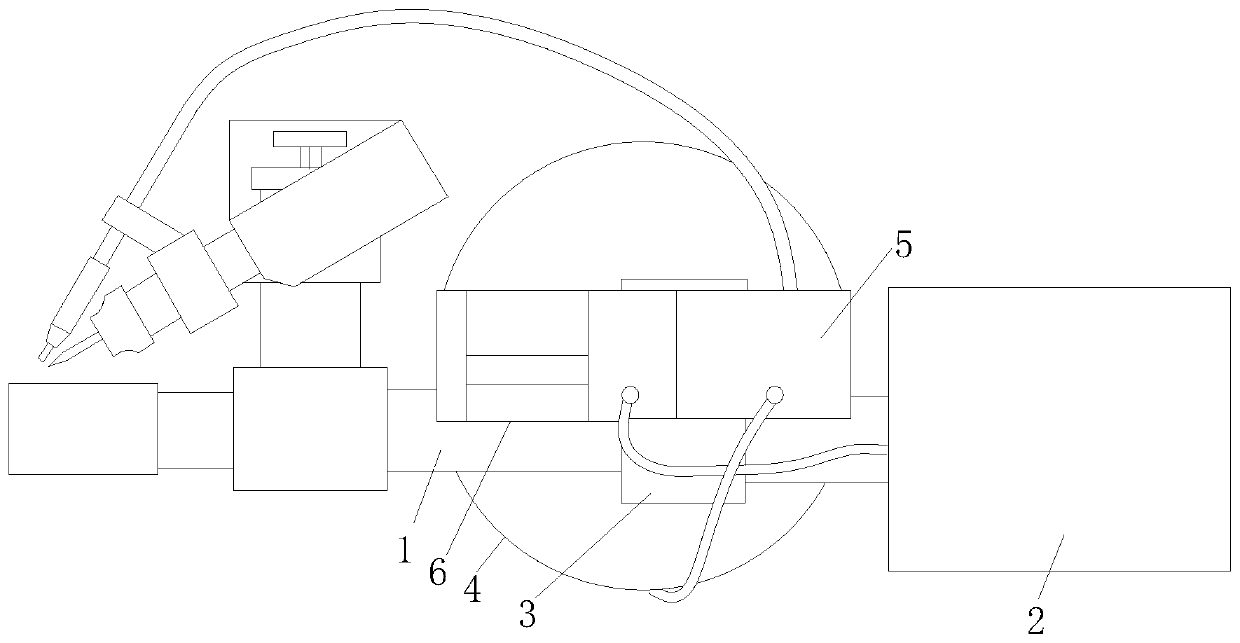

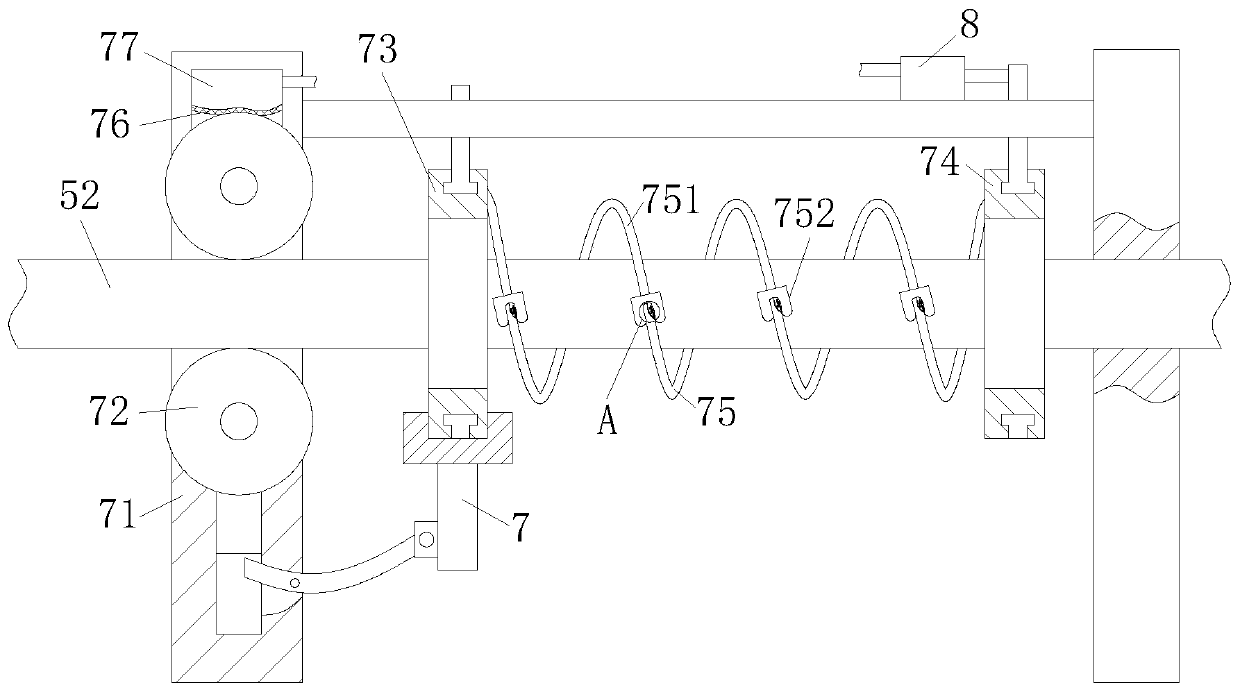

Argon arc welding machine

ActiveCN110052688AImprove rust removal effectChange spacingWelding accessoriesEngineeringArc welding

The invention belongs to the technical field of welding equipment and particularly relates to an argon arc welding machine. The argon arc welding machine comprises a rotating shaft, a machine box, a counter weight, a wire conveying disc, a wire pressing body and a wire conveying motor; the end face of one end of the rotating shaft is provided with a positioning head; the other end of the rotatingshaft is rotationally inserted into the machine box; the counter weight is arranged on the rotating shaft in a sleeving manner; the wire conveying disc is rotationally installed on the counter weight;the wire conveying disc is used for winding a welding wire; the wire pressing body comprises two wire guide wheels which are both arranged on the counter weight; the right end of the welding wire iswound on the wire conveying disc, and the other end of the welding wire passes through a clearance between the two wire guide wheels; the wire conveying motor is used for driving the two wire guide wheels to rotate; and a derusting module is positioned on the counter weight and is used for cleaning and derusting the surface of the welding wire. The argon arc welding machine provided by the invention is simple in structure and convenient to operate and is used for cleaning a rusted welding wire by cooperation of a friction wheel and a derusting spring which are arranged in the derusting module,thereby preventing occurrence of welding quality reduction caused by rusting of the welding wire.

Owner:东莞市佳凌焊割设备有限公司

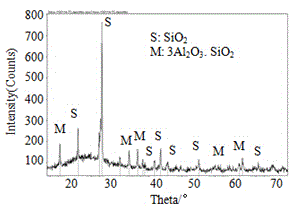

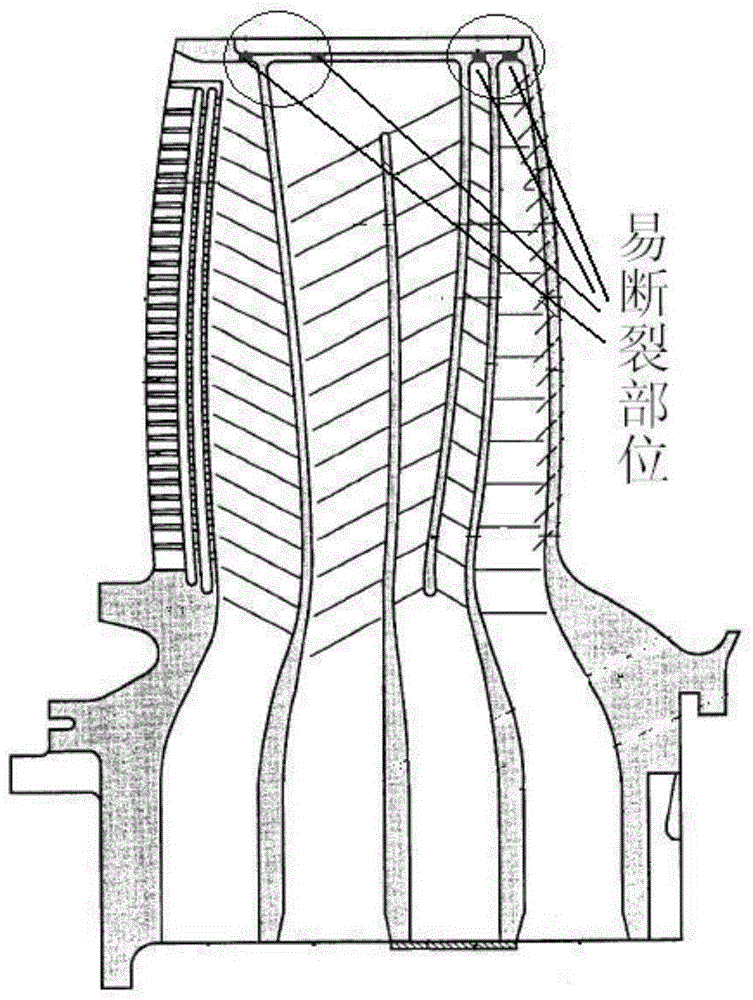

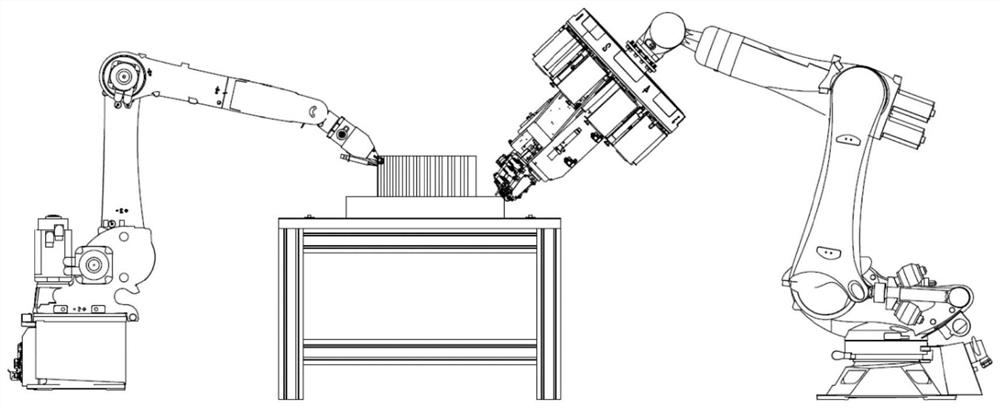

Production method of composite ceramic core for single crystal hollow blade of complex structure

ActiveCN104647586AImprove pass rateImprove local strengthCeramic shaping apparatusHollow coreWire segment

The invention provides a production method of a composite ceramic core for a single crystal hollow blade of a complex structure. The specific production process of the production method includes that a molybdenum wire is cut into a segment, the treatment is performed on two ends of the molybdenum wire segment to form a ball head at each end of the molybdenum wire, and the shape size of each ball head is larger than the diameter of the molybdenum wire; a ceramic layer is deposited on the surface of the integral molybdenum wire segment and the molybdenum wire segment after the ceramic deposition is placed into a position of a ceramic core die to be fixed, wherein the ceramic core is easy to fracture at the position; a ceramic core biscuit is produced by an injection forming method and the ceramic core is obtained after being sintered. According to the production method of the composite ceramic core for the single crystal hollow blade of the complex structure, thin layer of silicon dioxide or aluminum oxide wraps the surface of the molybdenum wire to enhance the local strength of the ceramic core, the molybdenum wire position in the core is fixed through the ball head which is arranged at each end of the molybdenum wire, and accordingly the fracture of the fine position of the ceramic core is avoided, the qualification rate of the single crystal blade is improved, and the requirement for the high qualification rate of the production of the single crystal turbine blade of the complex inner chamber structure is met.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

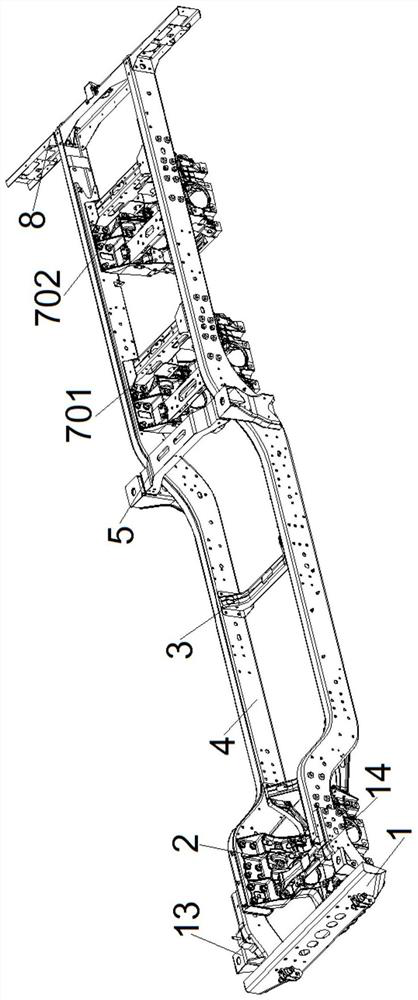

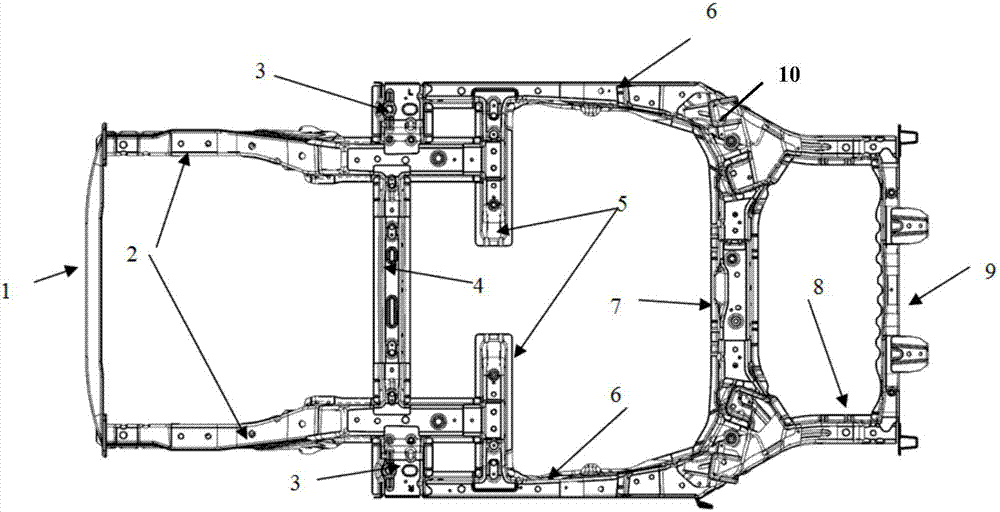

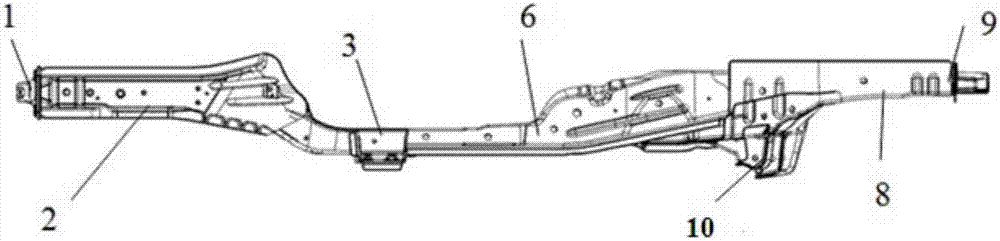

Multi-axle off-road vehicle frame structure with variable axle distance

InactiveCN112429082AIncrease layout spaceOptimize layoutUnderstructuresVehicle frameSuspension (vehicle)

The invention discloses a multi-axle off-road vehicle frame structure with a variable axle distance. The multi-axle off-road vehicle frame structure comprises a front bumper, a vehicle body front suspension beam, a front axle structure, a cross beam, longitudinal beams, a vehicle body rear suspension beam, a container supporting structure, a middle axle structure, a rear axle structure and a rearbumper. The two longitudinal beams are oppositely arranged in the left-right direction of a vehicle body and comprise the left longitudinal beam and the right longitudinal beam; each longitudinal beamis a box beam formed by tailor-welding two first channel beams along the left-right direction of the vehicle body; an engine mounting hole, a transmission mounting hole and a suspension mounting holeare formed in each longitudinal beam; each longitudinal beam comprises a vehicle front section, a vehicle middle section and a vehicle rear section which are integrally formed; each vehicle front section and each vehicle rear section are higher than the corresponding vehicle middle section, so that the longitudinal beams are arranged in the front-back direction of the vehicle body with two high ends and a low middle. According to the invention, the distance between the vehicle body front suspension and the vehicle body rear suspension can be adjusted to meet the requirements of vehicle bodieswith different lengths; and the distance among the front axle structure, the middle axle structure and the rear axle structure can be adjusted to adapt to different chassis arrangements and the performance requirements of the whole vehicle.

Owner:DONGFENG OFF ROAD VEHICLE CO LTD

Inner cone ring of heavy truck gear box synchronizer and manufacturing process thereof

The invention discloses an inner cone ring of a heavy truck gear box synchronizer and a manufacturing process thereof. The substrate is a power metallurgy material which is prepared from the following raw material components in percentage by weight: 0.5-5% of copper powder, 0.1-1.5 % of graphite powder, 0.1-1.5 % of free cutting agent, 0.2-2% of lubricating agent, 0.01-1.5% of bonding agent, and the balance of 88.5-99.09% of iron powder. The manufacturing process of the inner cone ring has the following steps: materials mixing, forming, sintering, auxiliary machinery processing, vapor treatment, and bonding. According to the invention, powder metallurgy process is adopted, and wicking treatment is carried out in the sintering process, thus the intensity at the position born greater stressof the outer cone ring blank is improved prominently, and using performances of products in the synchronizer are increased; and the process is simple and reliable, the production efficiency is high, the material utilization ratio is high, and inner cone ring products which are manufactured in bulk have the advantages of stable quality, high intensity, high manufacturing accuracy, low manufacturing cost and the like.

Owner:LAIZHOU SANWANG POWDER METALLURGY

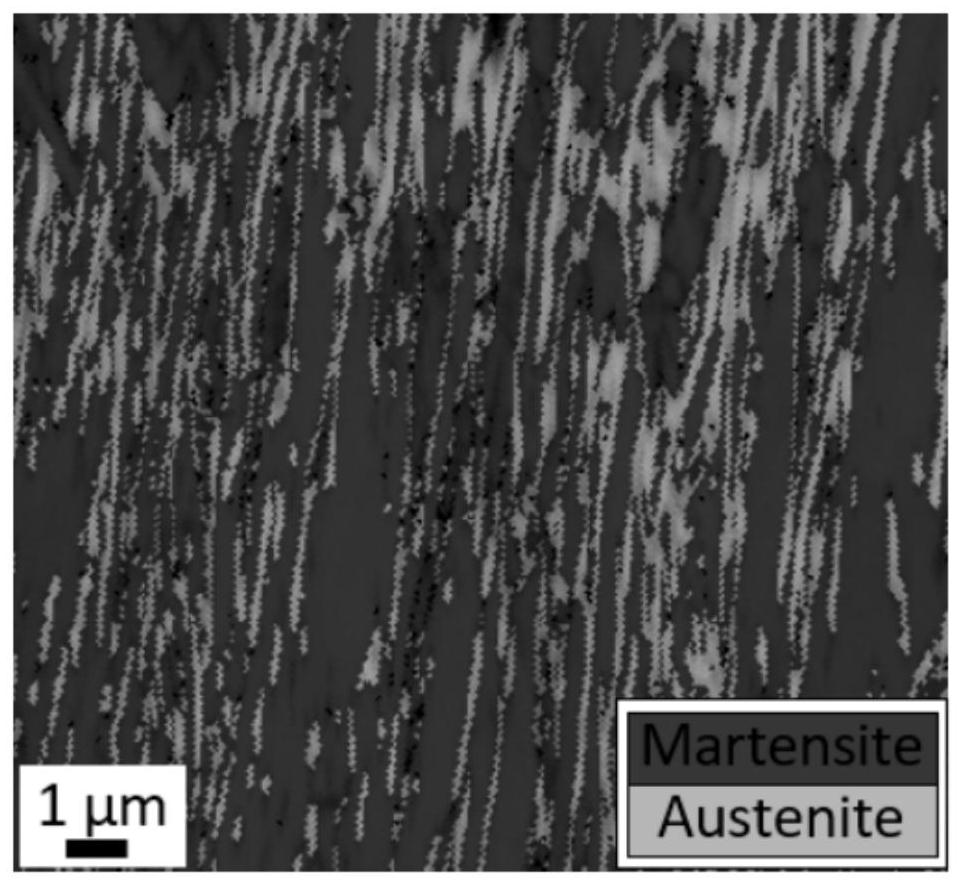

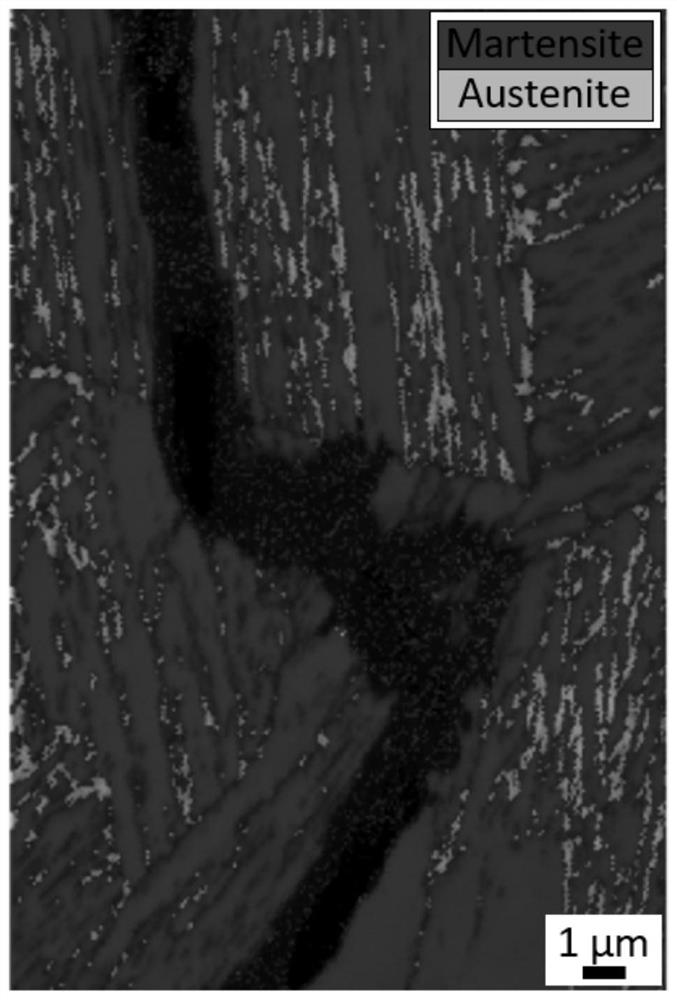

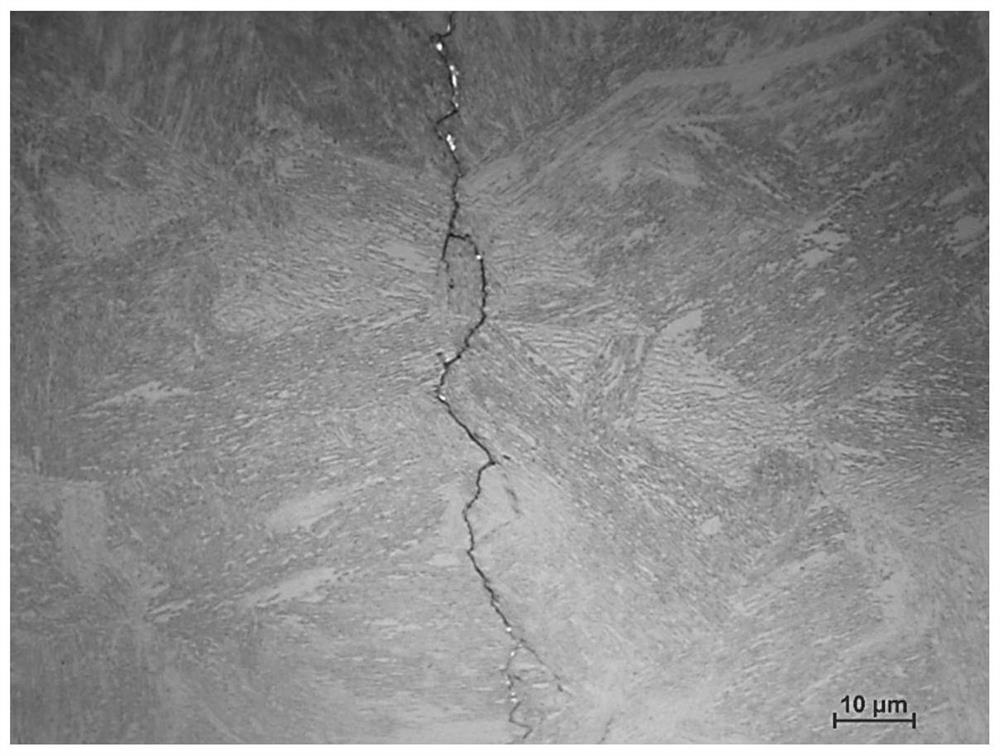

High-ductility maraging steel with excellent fatigue resistance and preparation method thereof

ActiveCN113151645AImprove ductilityExcitation closure effectFurnace typesHeat treatment furnacesIntermetallicAustenite

The invention discloses a preparation method of high-ductility maraging steel with excellent fatigue resistance. The preparation method comprises the steps of vacuum melting, forging after structure homogenization, hot rolling after structure homogenization, quenching after structure homogenization, annealing and quenching, and finally the high-ductility maraging steel with excellent fatigue resistance is obtained. According to the method of the invention, through annealing-quenching, the austenite proportion in a material is increased, the content of intermetallic compounds is regulated and controlled, and then the fatigue resistance of the material is improved. The invention also discloses the high-ductility maraging steel with the excellent fatigue resistance prepared by the method, the Vickers hardness of the material is greatly improved, the tensile strength is high, the ductility is good, the average elongation is high, and the high-ductility maraging steel has a wide application prospect.

Owner:ANSTEEL BEIJING RES INST

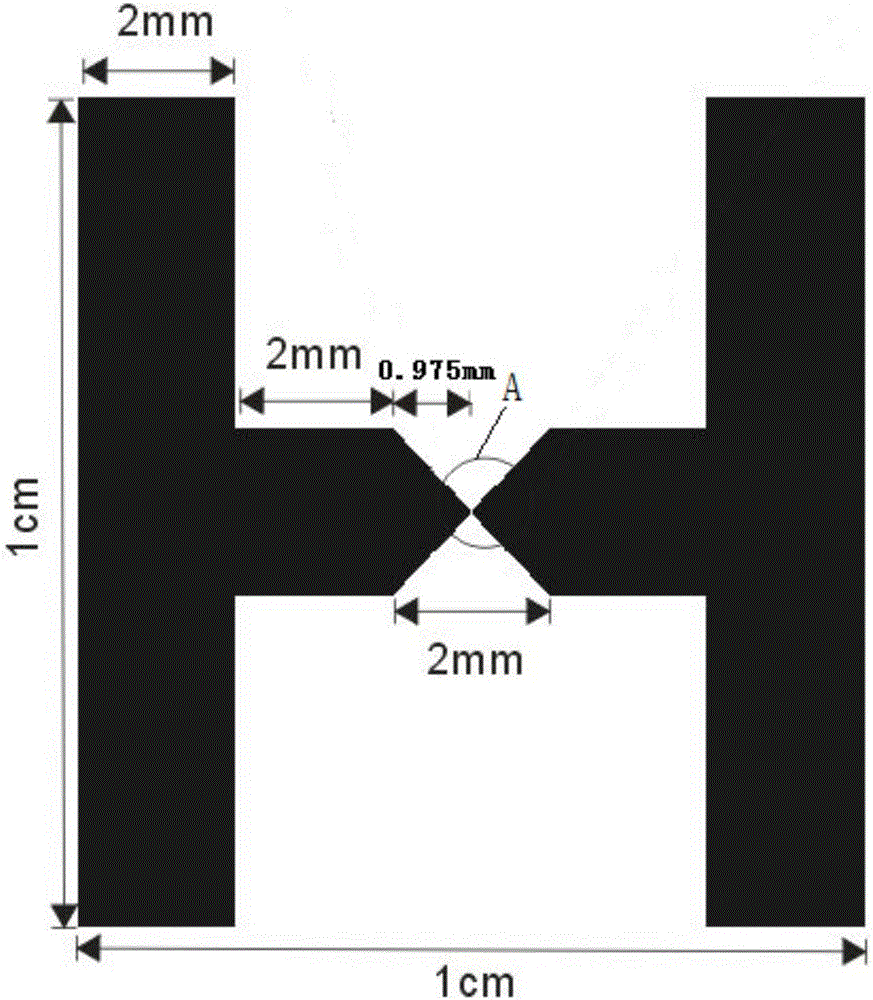

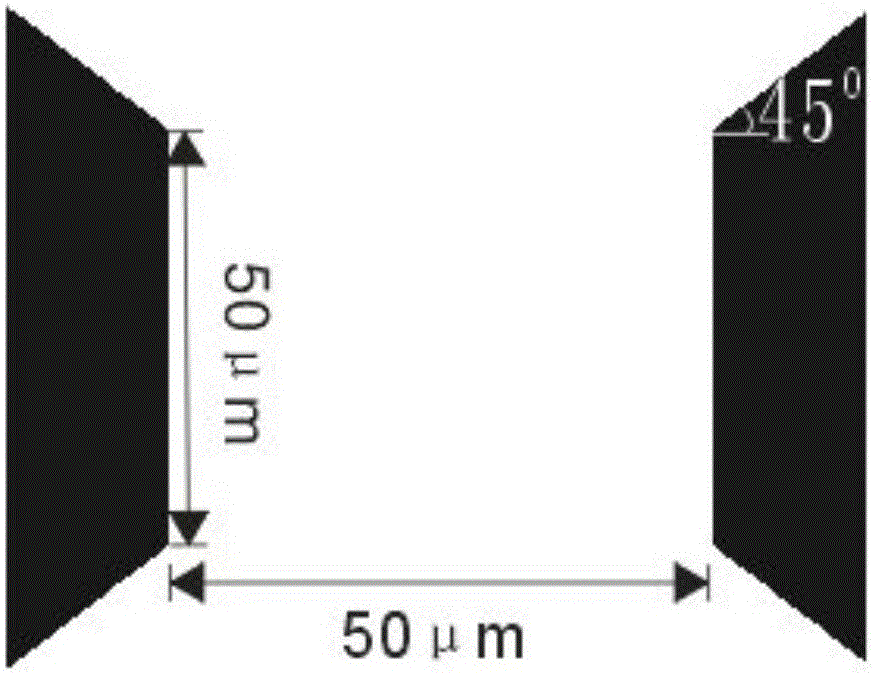

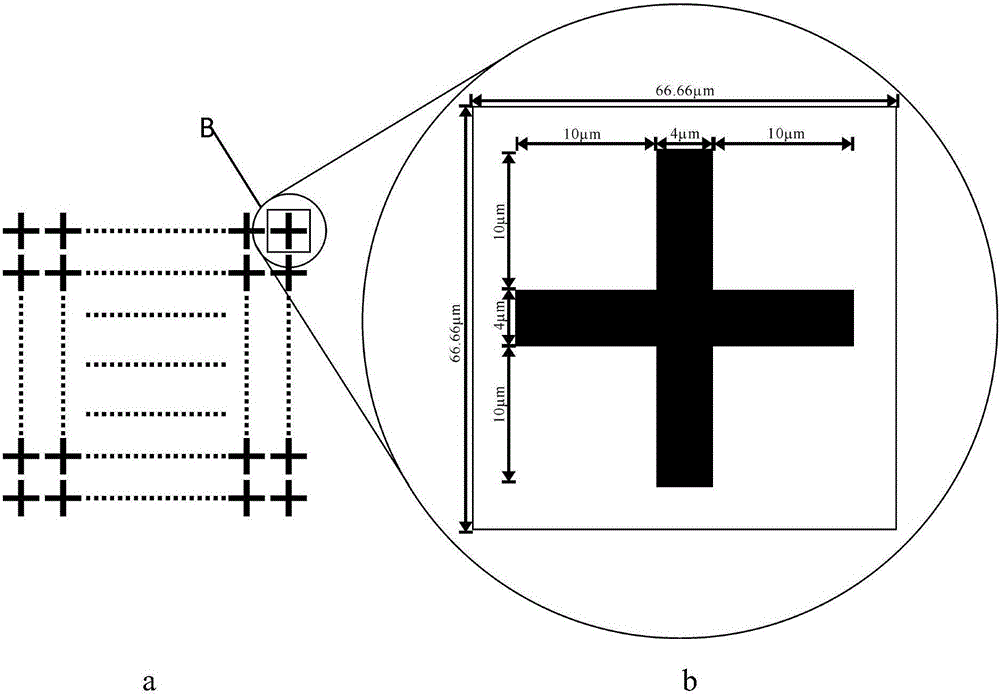

Amplitude adjustable terahertz near field excitation type molecular sensor and production method thereof

ActiveCN105923600AImprove local strengthHigh strengthTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesQ factorMetal

The invention relates to an amplitude adjustable terahertz near field excitation type molecular sensor and a production method thereof. The molecular sensor is formed by arranging a terahertz photoconductive antenna and an electromagnetic resonant cell array at two sides of a semi-insulated gallium arsenide substrate. The terahertz photoconductive antenna is composed of two T-shaped electrodes which are distributed in mirror symmetry. The horizontal axis part of each T-shaped electrode is an outer electrode. The vertical axis part is an inner electrode. The head ends of the inner electrodes are engaged with the outer electrodes. The electromagnetic resonant cell array is a periodic cross electromagnetic resonant cell array. According to the sensor and the method, the distances between the terahertz photoconductive antenna and the periodic metal resonant cells are reduced to a 3THz wavelength range; the local oscillation strength of dipoles is improved through near field enhancement; the strength of a terahertz electromagnetic resonant mode is improved; the quality factor of the resonant mode is improved; the sensitivity and spatial resolution of THz molecular detection can be improved; and the optical element layout of the whole spectrum detection system is simplified.

Owner:SHANGHAI NORMAL UNIVERSITY

Multifunctional cabin door ventilation opening device controlled through cam

ActiveCN106347627AHas a breakage safety featureImprove local strengthAircraft accessoriesFuselagesSkin openingCam

The invention discloses a multifunctional cabin door ventilation opening device controlled through a cam. The device is provided with a cover plate arranged on a cabin door skin opening, wherein a rocking arm is arranged on the cover plate; a limiting component matched with the rocking arm is arranged at the front end of the rocking arm; the rear end of the rocking arm is fixedly connected to a rotating shaft component; the rotating shaft component is mounted on a supporting lug I and a supporting lug II; a rotating shaft is arranged at one edge on the periphery of the cabin door skin opening; a rocking arm lug I and a rocking arm lug II are respectively arranged at the two ends of the rotating arm component; one end of the rocking arm lug I and one end of the rocking arm lug II are respectively articulated with the two ends of the rotating shaft component; the other end of the rocking arm lug I and the other end of the rocking arm lug II are respectively articulated with the two ends of the rotating shaft; a driving pull rod is further arranged at the rear end of the rocking arm; one end of the driving pull rod is connected with the rear end part of the rocking arm; the other end of the driving pull rod extends to the driving part of the cam. The device realizes physical pressure relief in the condition that a cabin door is not completely closed, meanwhile realizes locking in the air during flight, and provides a low-cost and high-reliability solution for civil aircrafts.

Owner:AVIC SAC COMML AIRCRAFT

Automobile front door ring, manufacturing method thereof and automobile

PendingCN112208643AImprove toughnessReduce stress concentrationSuperstructure subunitsAutomotive engineeringManufacturing engineering

The invention discloses an automobile front door ring which comprises an automobile A column comprising an A column upper section and an A column lower section, and the A column upper section is provided with a first soft area used for being welded to a roof cross beam; the automobile front door ring also comprises an automobile B column which comprises a B column upper section and a B column lower section; a front threshold, wherein the front and rear ends of the front threshold are respectively fixed with the rear side of the lower part of the column A lower section and the front side of thelower part of the column B lower section; and a rear threshold which is fixed with the rear side of the B column lower section; the A column upper section except the first soft area, the A column lower section, the B column upper section, the front threshold and the rear threshold are all hard areas, and the B column lower section is a second soft area. The invention further discloses a manufacturing method of the automobile front door ring and an automobile comprising the automobile front door ring. According to the automobile front door ring, the manufacturing method of the automobile frontdoor ring and the automobile, the automobile A column and the automobile roof cross beam are not prone to cracking, the front door ring is good in buffering performance and capable of contracting toabsorb energy in the collision process, the deformation of the front door ring can be controlled, the heads of a driver and passengers can be protected, and the safety is good.

Owner:上海齐斯哈登工程技术有限公司

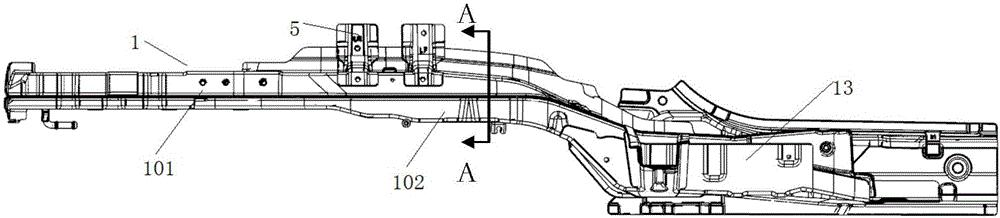

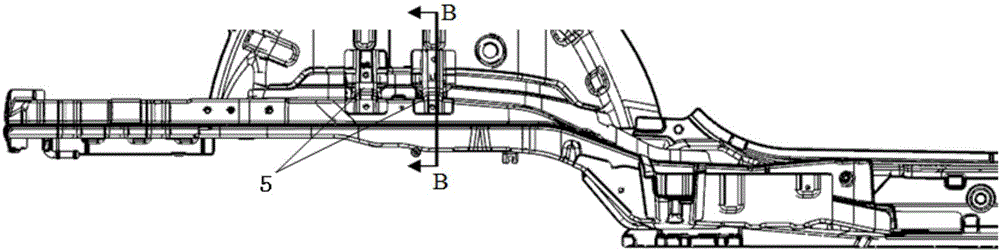

Automobile rear girder assembly and automobile rear lower automobile body structure

ActiveCN106494511AIncrease stiffnessImprove carrying capacityInternal combustion piston enginesMonocoque constructionsFuel tankExhaust pipe

The invention provides an automobile rear girder assembly and an automobile rear lower automobile body structure and belongs to the field of automobile part structures. The automobile rear girder assembly comprises a rear girder and a rear girder inner plate which are fixedly connected, the rear girder and the rear girder inner plate form a hollow cavity, the rear girder comprises a rear girder front in lap joint with a third automobile cross beam and a rear girder rear in lap joint with a rear floor, and the height between the girder rear and the ground is larger than the height between the rear girder front and the ground. The automobile rear girder assembly and the automobile rear lower automobile body structure have the advantages that the rear girder rear is lifted up, a space is spared to arrange an oil tank oil injection pipe and an exhaust pipe barrel, the space is utilized maximumly while the strength, rigidity and fuel system safety requirements in case of riding automobile rear collision are met, the rear girder inner plate is added above the rear girder, the rear girder inner plate and the rear girder form the large sealed cavity, the bearing capacity of the whole automobile is improved, and a larger acting force can be borne when the automobile is subjected to collision.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

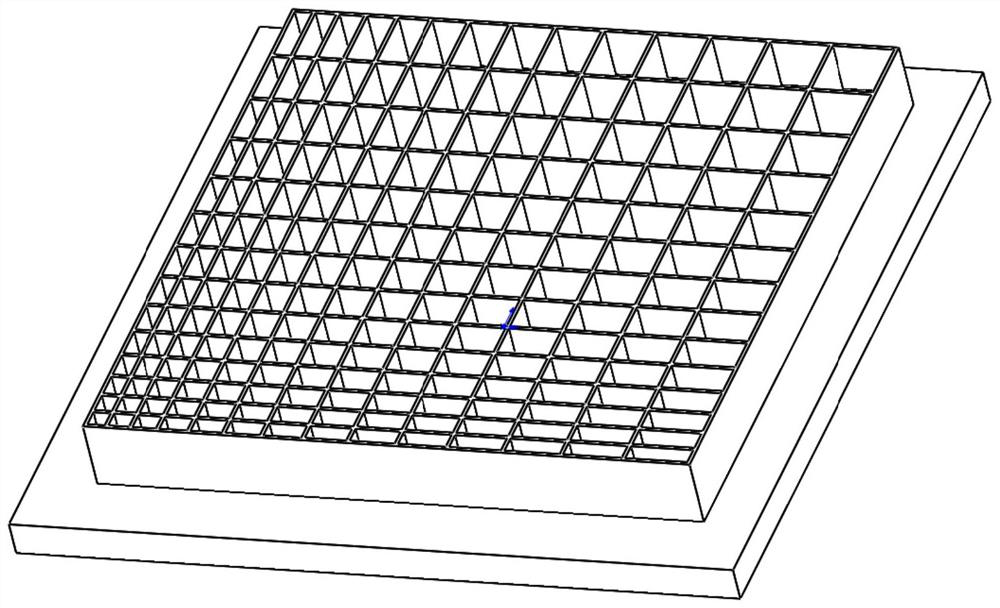

Variable-rigidity sandwich composite material structure based on 3D printing and forming method thereof

InactiveCN112549670AIncrease profitImprove mechanical propertiesLaminationLamination apparatusFiberManufacturing technology

The invention discloses a variable-rigidity sandwich composite material structure based on 3D printing and a forming method thereof, and belongs to the technical field of composite material structuredesign and manufacturing. Variable stiffness sandwich structure design is achieved by changing the wall thickness, the distribution uniformity and the geometrical shape of a core material in the sandwich structure. According to the forming method, firstly, a three-dimensional digital model of the sandwich structure is established, the stress distribution condition of the loaded part is analyzed according to working conditions, the thickness and density distribution of the core material is optimized, and then the integrated preparation of the sandwich structure is realized by utilizing a continuous fiber additive manufacturing process. According to the variable-rigidity sandwich structure designed by the invention, the rigidity and strength of the structure on the normal cross sections of different areas are different according to different working conditions, the designability of the sandwich composite material structure is expanded, and a new design thought is provided for lightweightdesign of the sandwich structure. Meanwhile, the manufacturing method provided by the invention can realize integrated forming of the complex variable-rigidity sandwich composite material structure,and the part manufacturing efficiency and quality are improved.

Owner:XI AN JIAOTONG UNIV

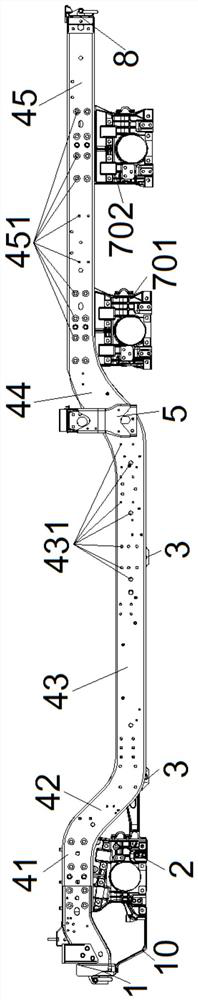

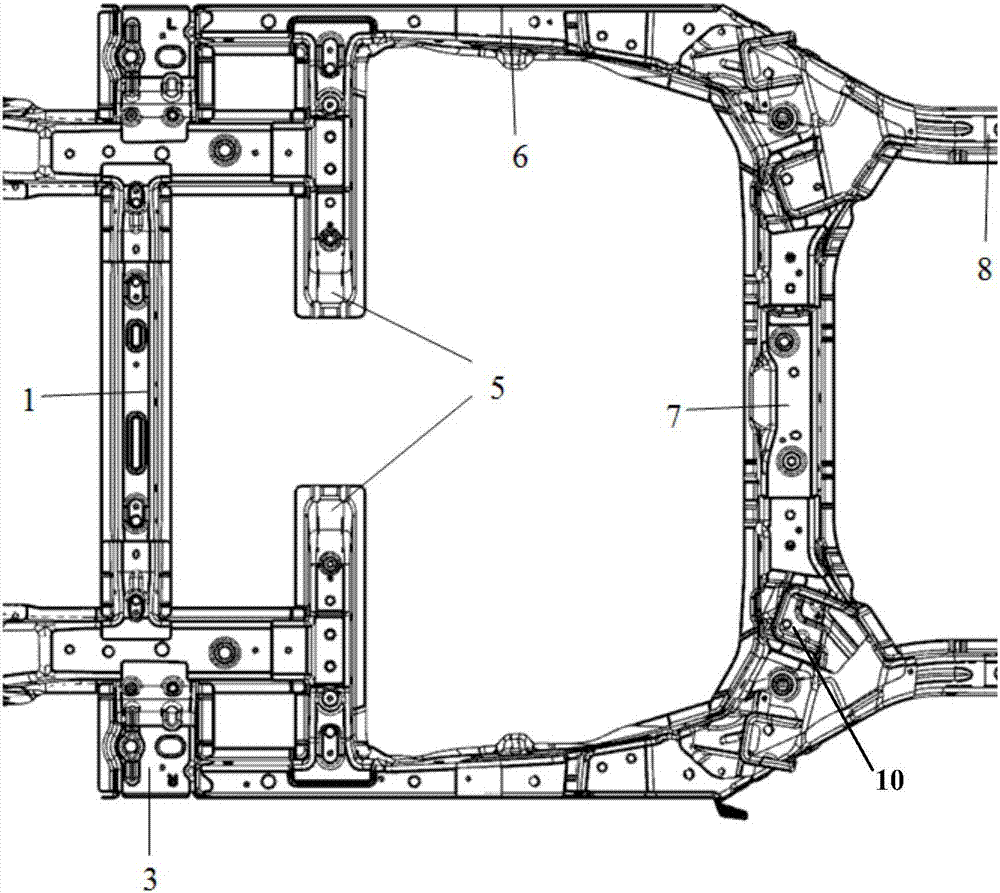

Force transmission vehicle frame

ActiveCN107416030AGuaranteed StrengthImprove local strengthUnderstructuresVehicular energy storageVehicle frameEngineering

The invention discloses a force transmission vehicle frame comprising a front cross beam, a rear cross beam, extending pieces, a first cross beam, a rear floor cross beam, two second cross beams, two front large beams, two rear large beam strengthening plates and two rear large beams. The two front large beams are parallelly arranged; one ends of the two front large beams are fixedly connected with the left end and the right end of the front cross beam correspondingly, and the other ends of the two front large beams are perpendicularly and fixedly connected with the two second cross beams correspondingly; the first cross beam is arranged between the front cross beam and the second cross beams; the two ends of the first cross beam are perpendicularly and fixedly connected with the two front large beams correspondingly; the two rear large beam strengthening plates are arranged on the two rear large beams correspondingly; one ends of the two rear large beams are connected with the two rear large beams strengthening plates through the extending pieces, and the other ends of the two rear large beams are perpendicularly connected with the rear cross beam; and the two ends of the rear floor cross beam are perpendicular to the middles of the two rear large beams correspondingly. Transmitting of force of a bearing vehicle type frame is optimized, collision energy can be well transmitted and dispersed horizontally, and good transmitting is achieved under the condition that the front large beams and the rear large beams cannot be connected in a butting mode.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Crack-resistant gypsum board

ActiveCN110258993AImprove local strengthReduce the amount of bendingCovering/liningsGypsumMaterials science

The invention belongs to the technical field of building decorative materials, and particularly relates to a crack-resistant gypsum board. The crack-resistant gypsum board includes base plates, wherein uniformly distributed arc-shaped grooves are formed in the faces, facing the outer sides, of the base plates, and uniformly distributed cavities are formed in the base plates; arc-shaped plates corresponding to the arc-shaped grooves are connected between adjacent arc-shaped grooves in an inserted mode; the arc-shaped plates are used for strengthening the strength of the base plates; and baffles are arranged on the sides, away from the base plates, of the arc-shaped plates in a covering mode; I-shaped airbags are connected between the adjacent base plates; and the outer surfaces of the airbags are bonded to the end surfaces of the baffles, and the airbags are used for closely connecting the adjacent two base plates while pressing the baffles. According to the crack-resistant gypsum board, the arc-shaped grooves are formed in the sides, facing the outside sides, of the base plates, then the arc-shaped plates are connected into the arc-shaped grooves in an inserted mode to enable the adjacent arc-shaped grooves to be connected one another through the arc-shaped plates, when the base plates are integrally pre-bent, the corresponding support can be carried out to reduce the bending amplitude of the base plates, and thus the crack resistance of the base plates is enhanced, and the service life of the base plates is prolonged.

Owner:SHANDONG BAIER BUILDING MATERIAL CO LTD

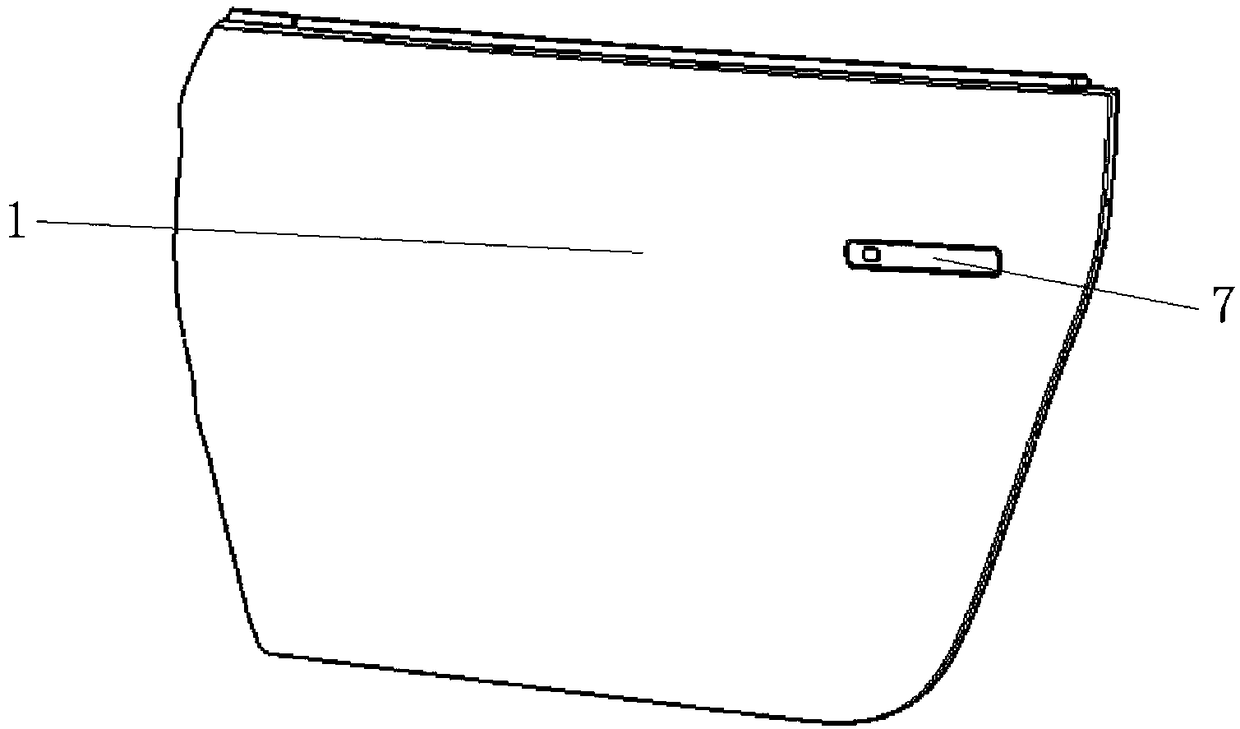

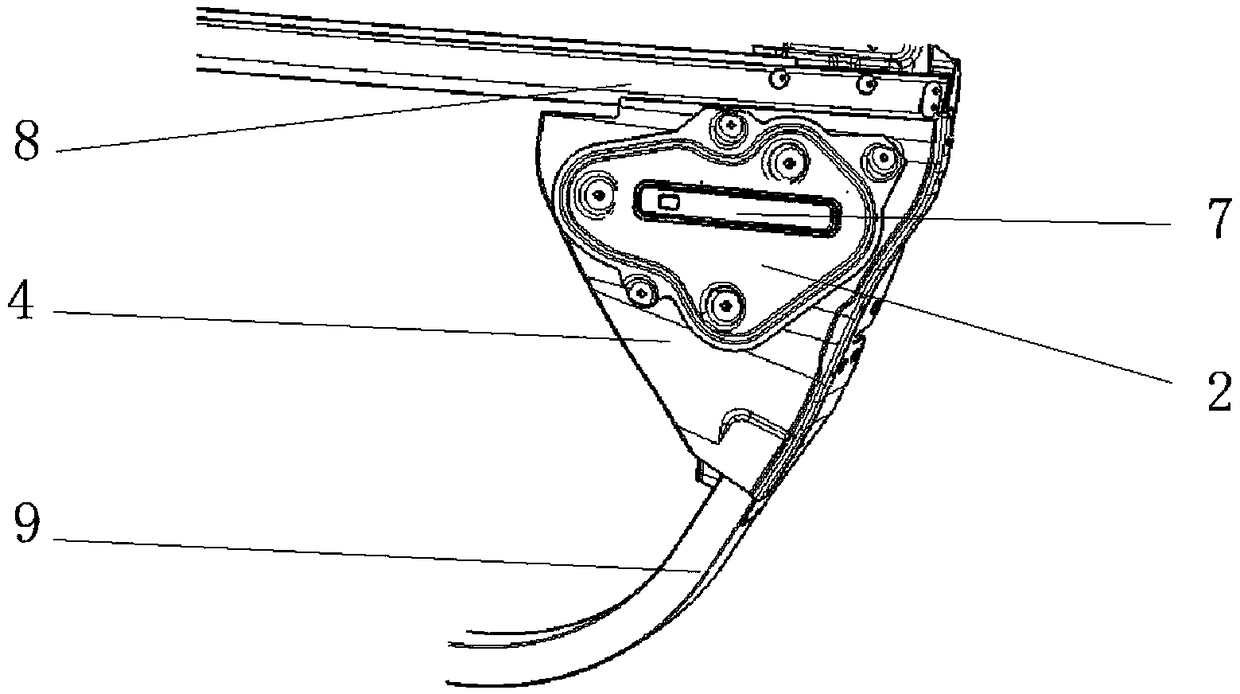

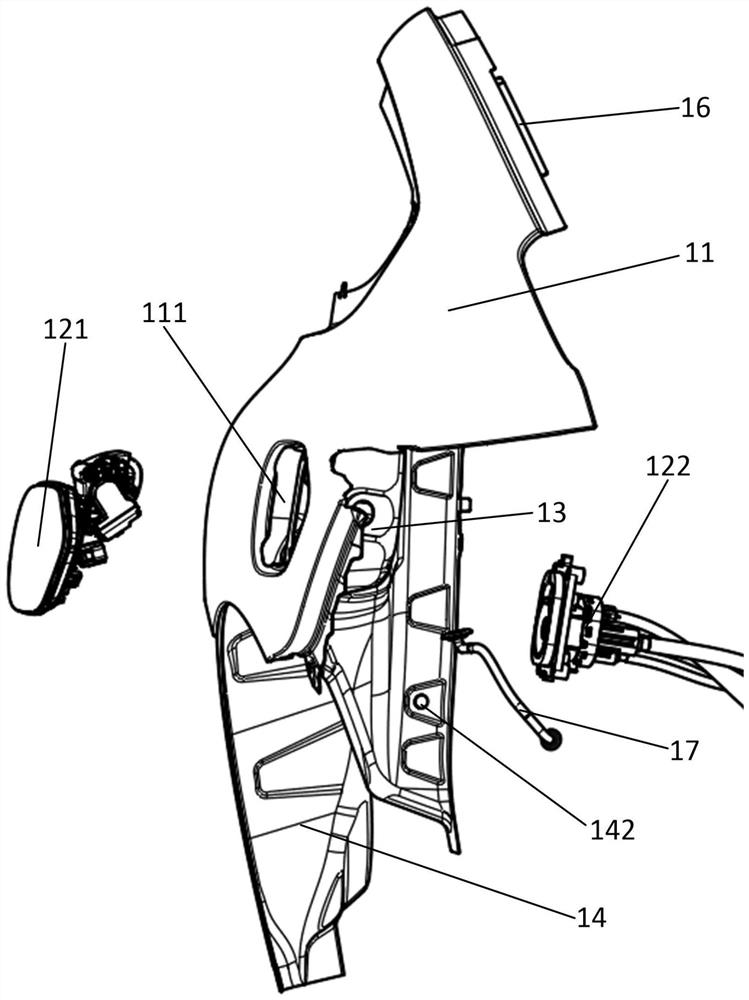

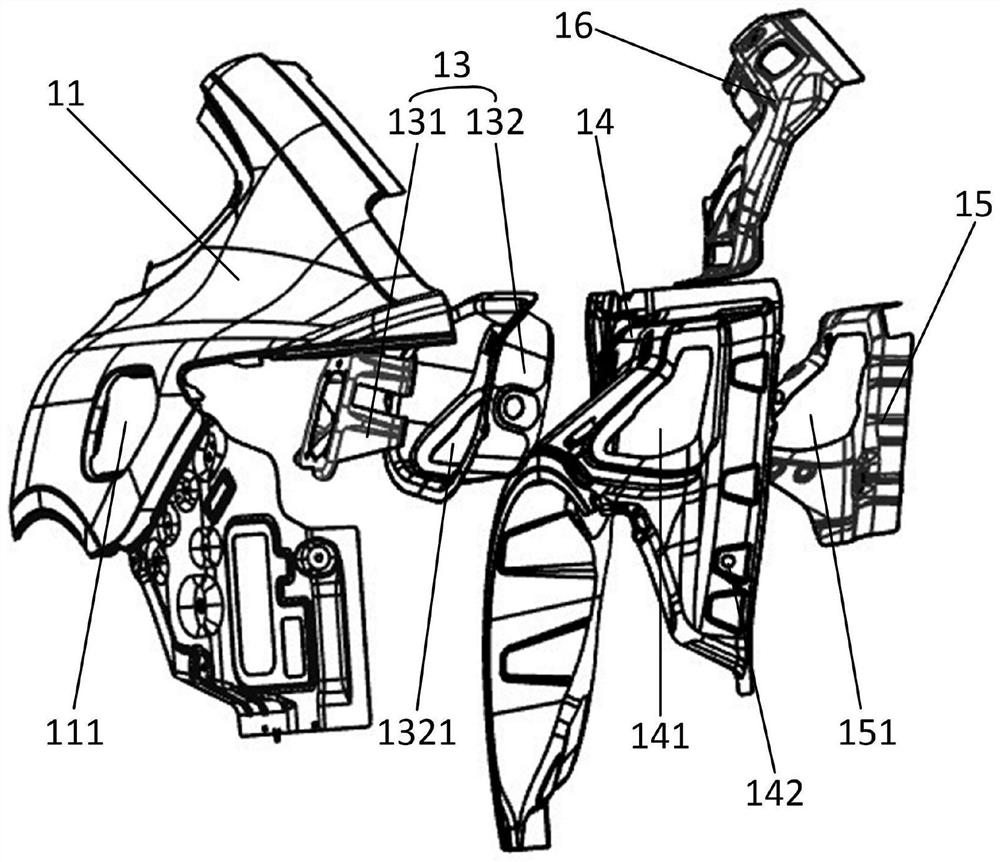

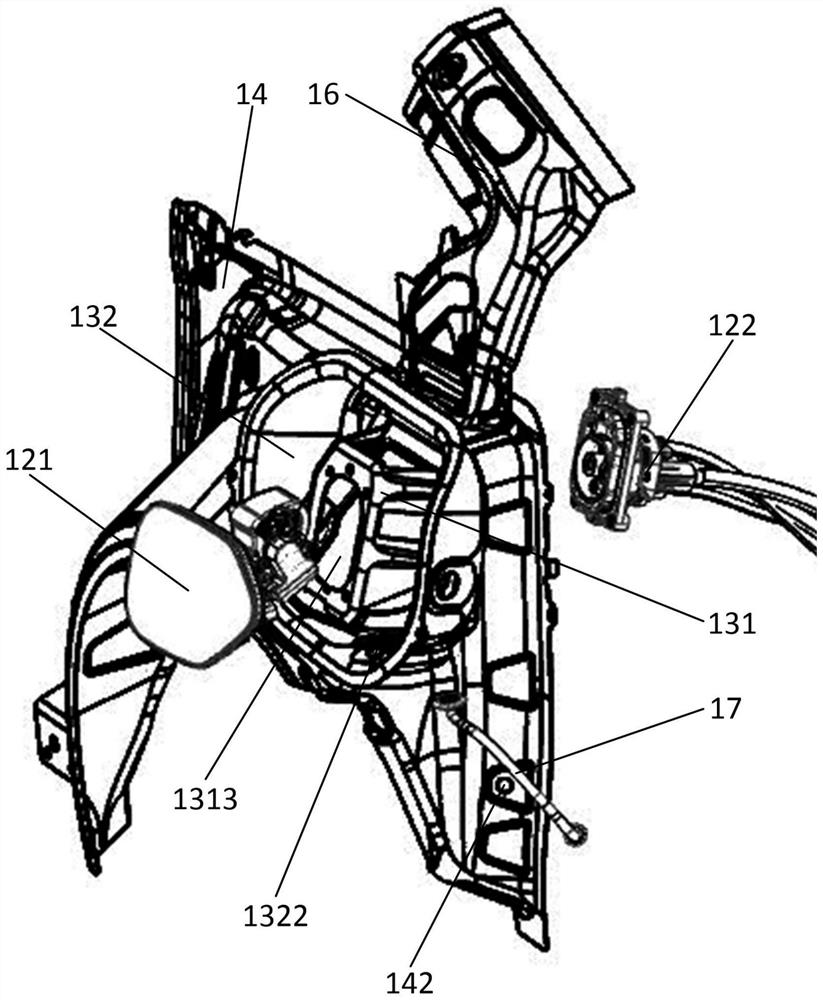

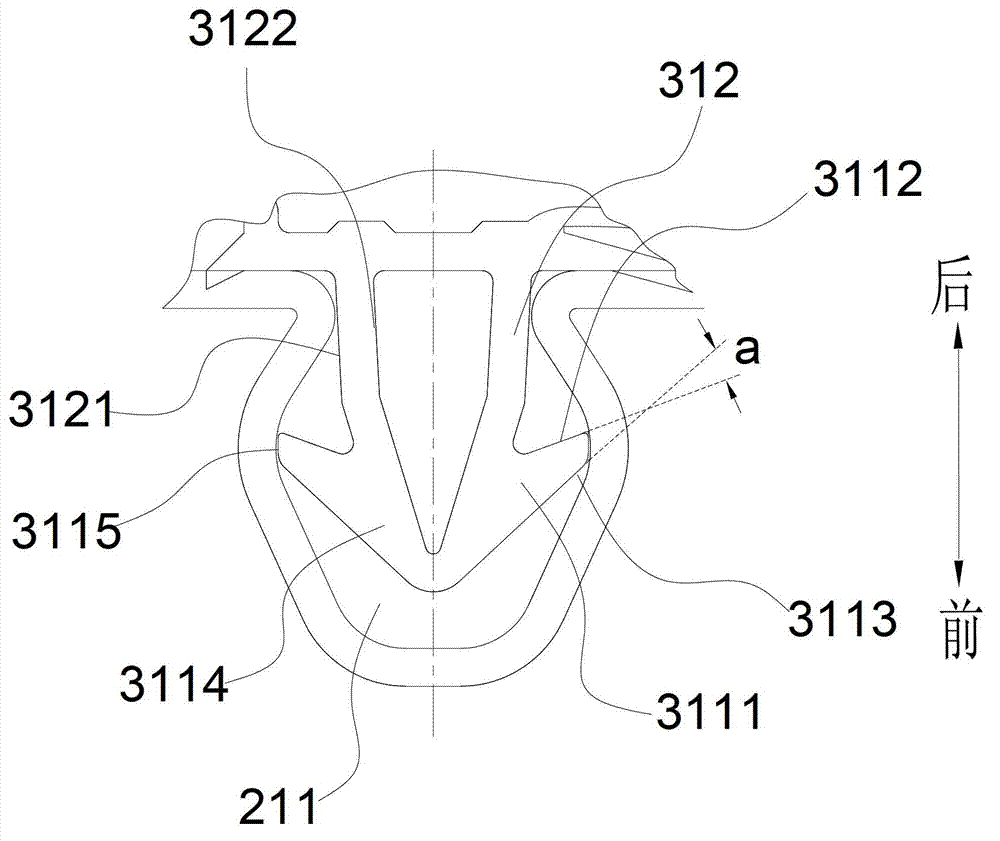

Hidden type external opening handle installation structure

The invention relates to a hidden type external opening handle installation structure which comprises an automobile door outer plate made of plastic, a handle installation plate, a supporting frame and a hidden type external opening handle. A first handle passing hole is formed in the automobile door outer plate. The handle installation plate is connected to the inner side of the automobile door outer plate in a sticking manner, and a second handle passing hole corresponding to the first handle passing hole is formed in the handle installation plate. The supporting frame is fixed in an automobile door, and the supporting frame and the handle installation plate are fixedly connected. The hidden type external opening handle is fixed to the handle installation plate, and a handle of the hidden type external opening handle penetrates the second handle passing hole and stretches into the first handle passing hole. By means of the hidden type external opening handle installation structure, and the problem that an installation support of an existing hidden type handle is likely to be loosened or disengaged in the long-term use process is effectively solved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

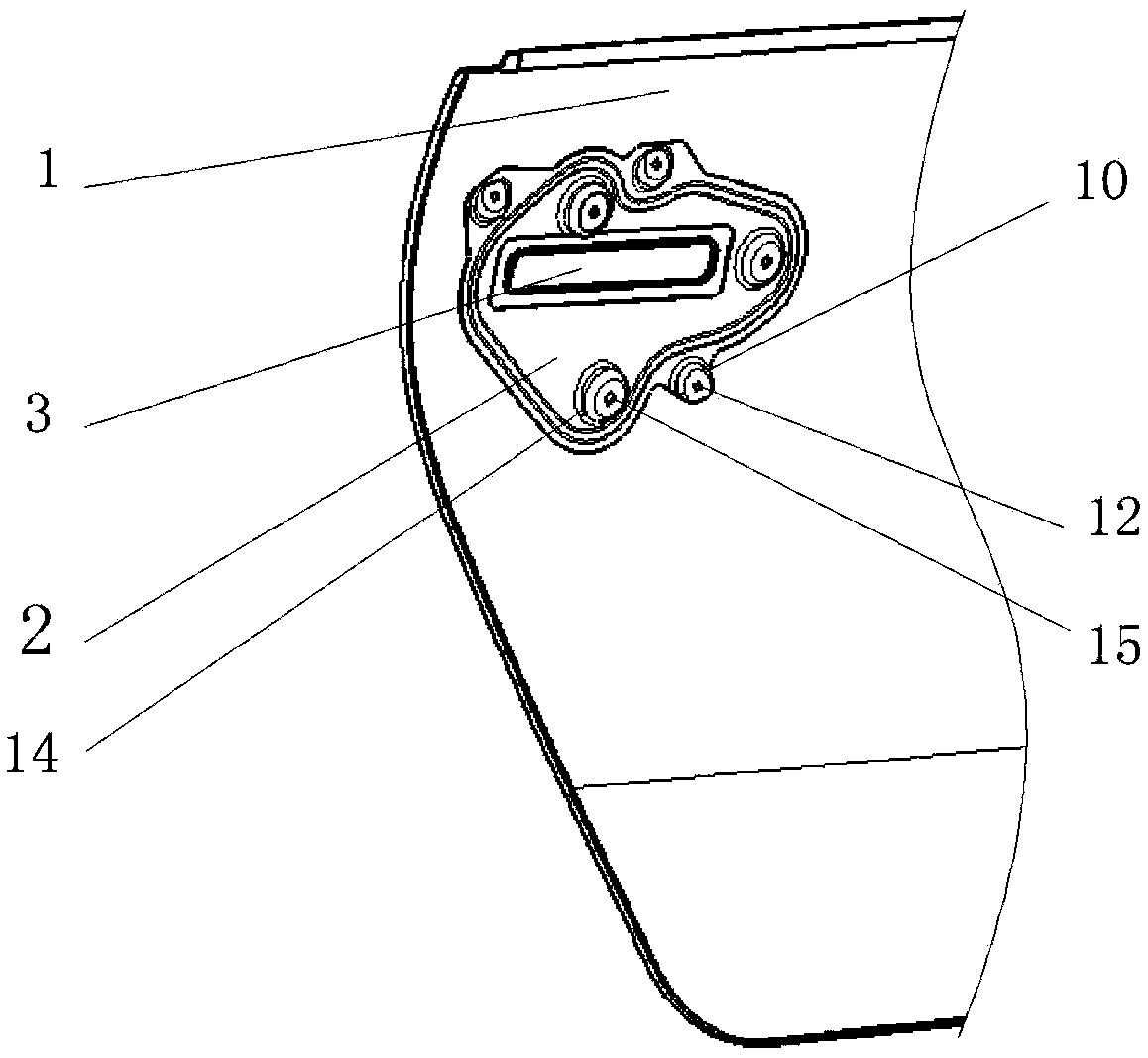

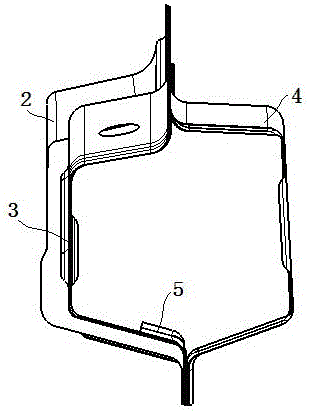

Vehicle charging port mounting assembly and vehicle

PendingCN113002336AIncrease stiffnessMeet shallow mouth designCharging stationsElectric propulsion mountingStructural engineeringMechanical engineering

The invention belongs to the technical field of vehicle charging, and particularly provides a vehicle charging port mounting assembly and a vehicle. The invention aims to solve the problem that an existing charging port assembly is poor in mounting structure design and cannot well meet use requirements. Therefore, the vehicle charging port installation assembly comprises a side wall outer plate, a charging port assembly, a charging port installation assembly, a rear wheel cover outer plate and a rear wheel cover outer plate reinforcing plate; the charging port installation assembly comprises an installation support and a containing supporting component with a containing cavity, and the installation support is arranged in the containing cavity and fixedly connected with the containing supporting component; the containing and supporting component is arranged between the side wall outer plate and the rear wheel cover outer plate, the charging port assembly and the containing and supporting component are jointly fixed through the mounting support, and therefore the durability and the NVH characteristic of the partial area are effectively improved, and the design requirement for dry-wet separation can be effectively met through the containing and supporting component; the local strength of the area can be improved through the rear wheel cover outer plate reinforcing plate, and then multiple requirements are effectively met.

Owner:NIO TECH ANHUI CO LTD

Steel tube bundle composite structure shear wall field splice node

The invention discloses a steel tube bundle composite structure shear wall field splice node which is formed by splicing multiple steel tube bundle composite structure shear walls, wherein each steel tube bundle composite structure shear wall comprises a left flange and a right flange which are arranged in the vertical direction, and multiple baffles are arranged at intervals between each left flange and the corresponding right flange; each steel tube bundle composite structure shear wall is divided into multiple units by the left flange, the right flange and the baffles, each unit is provided with a cavity, and concretes are cast in the cavities; the upper steel tube bundle composite structure shear wall and the lower steel tube bundle composite structure shear wall are connected by virtue of welding seams; two ends of each baffle are respectively welded at welding seam joints of the corresponding left flange and the corresponding right flange; the baffles are provided with anchor bars; the anchor bars penetrates through the baffles of the upper and lower steel tube bundle composite structure shear walls; the anchor bars are parallel to the left and right flanges of the steel tube bundle composite structure shear walls. According to the steel tube bundle composite structure shear wall field splice node, the shear wall joint strength is enhanced.

Owner:HANGXIAO STEEL STRUCTURE

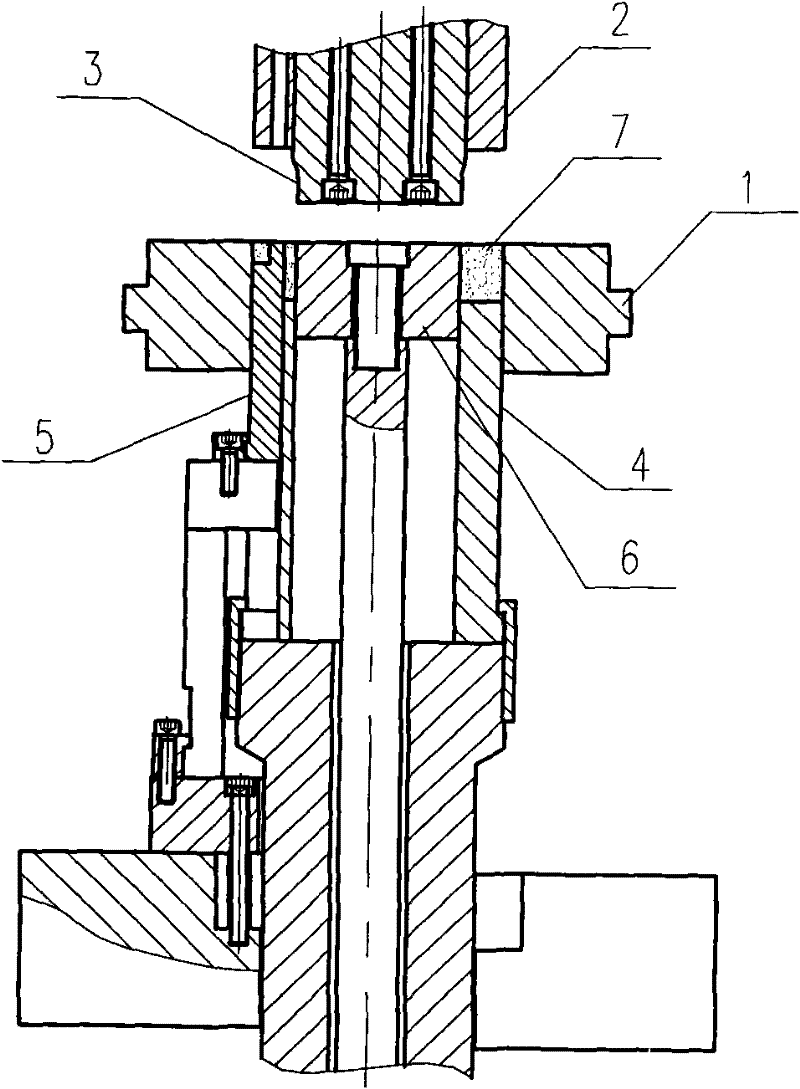

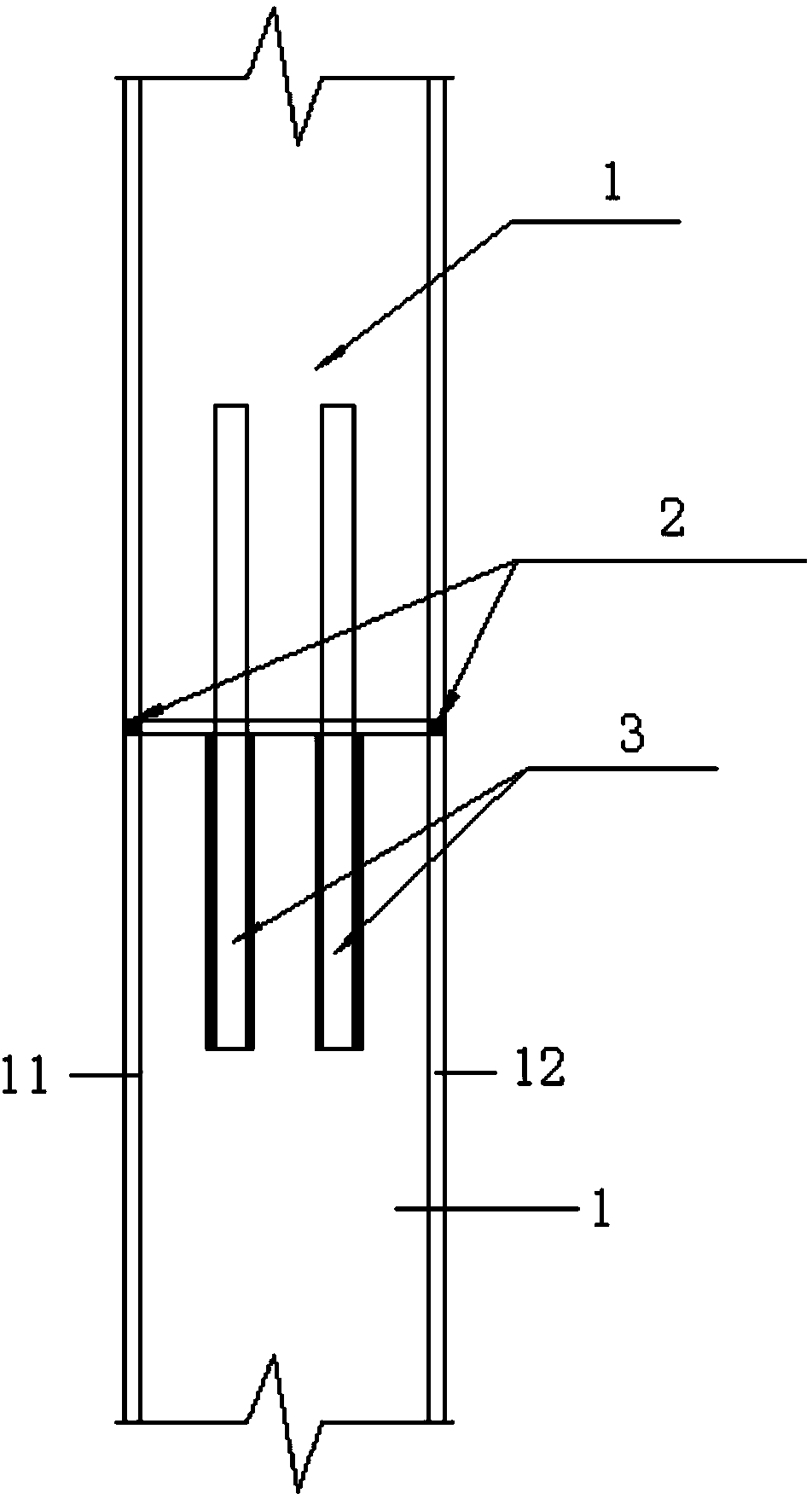

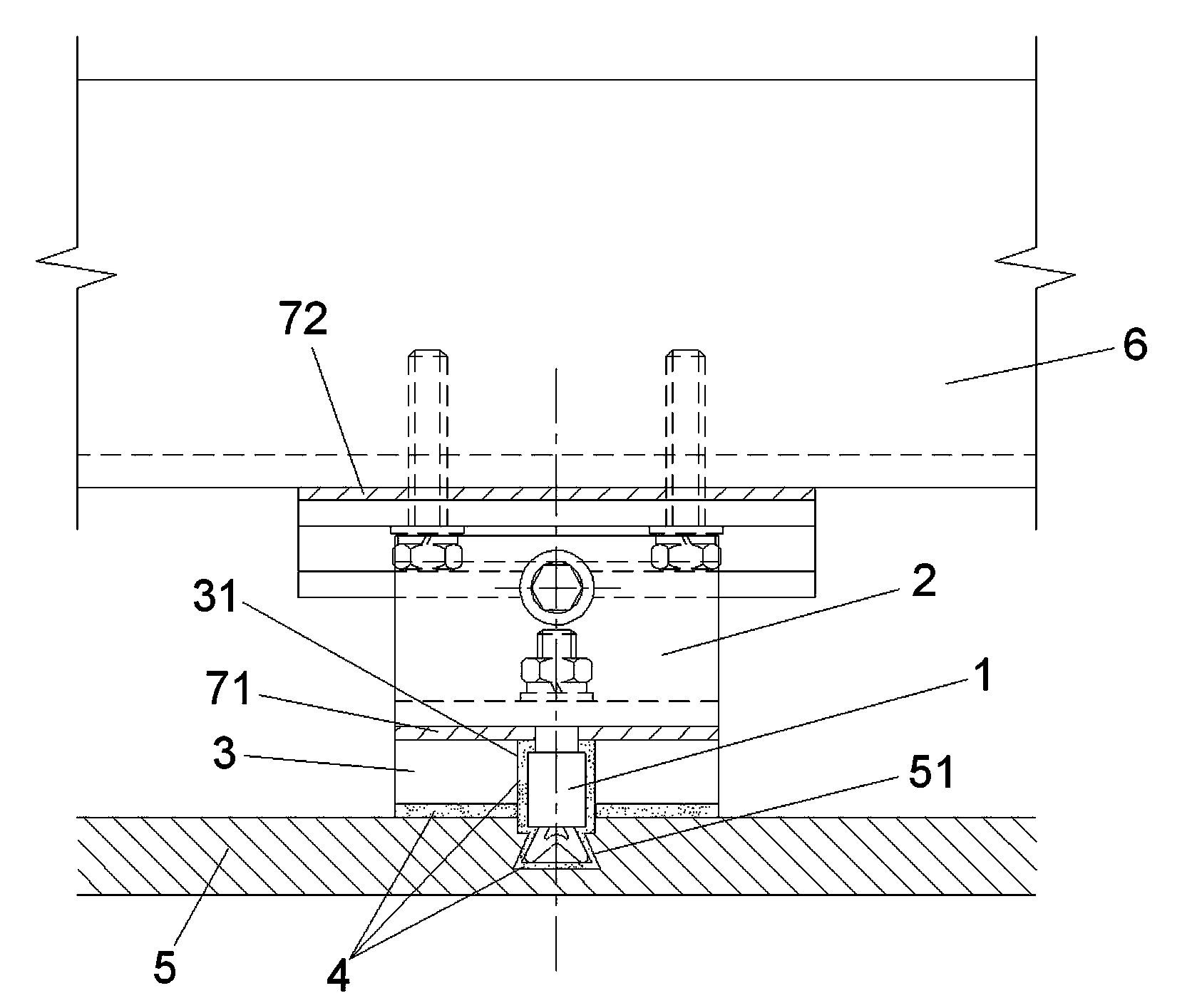

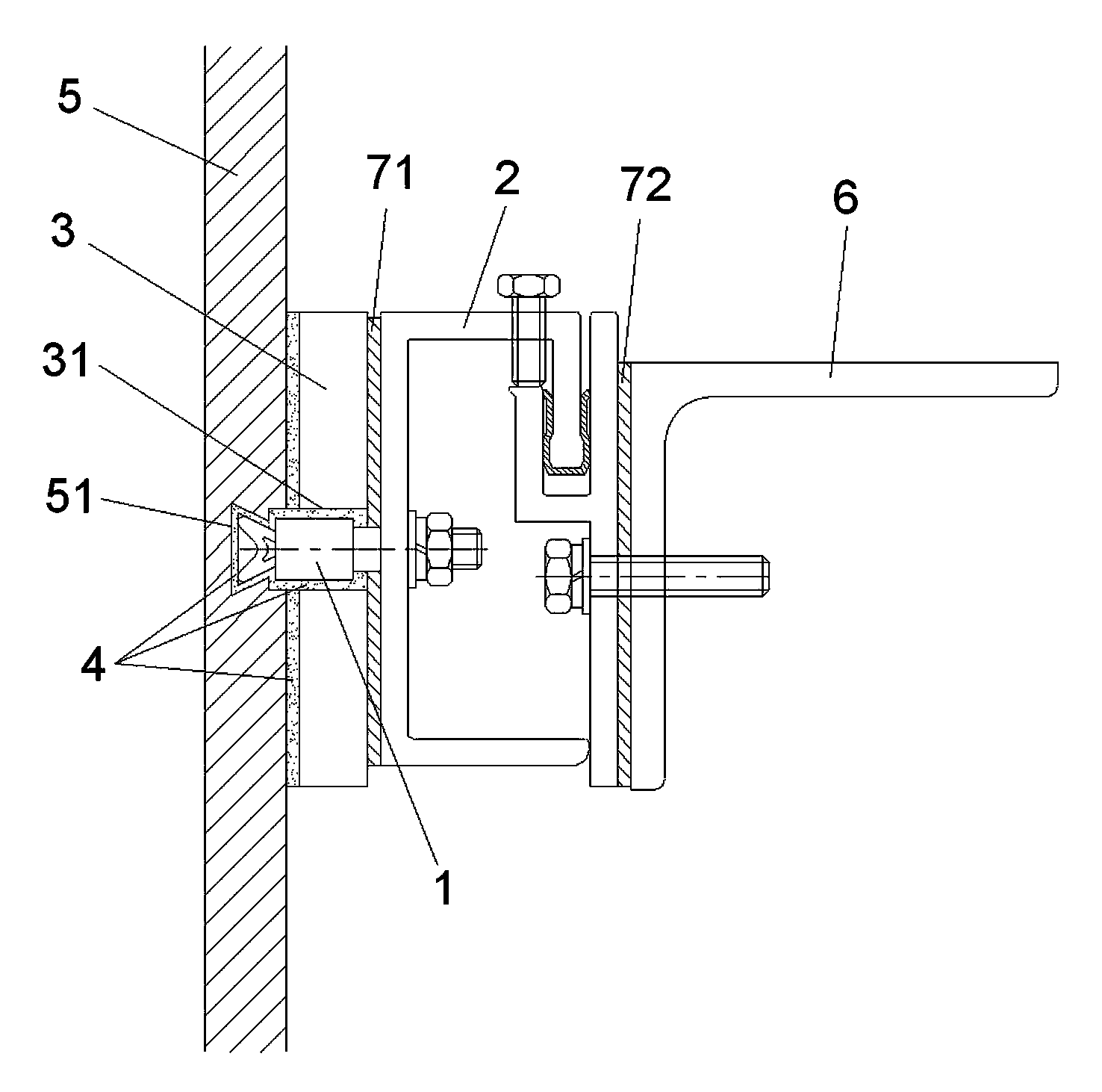

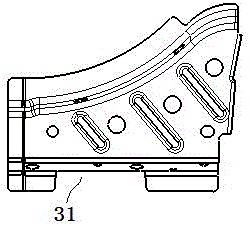

Connecting structure and connecting method for acrylic board curtain walls

A connecting structure for acrylic board curtain walls comprises a back bolt (1), a hanger (2), and a back plate (3). The back bolt (1) is mounted in an inner mounting hole (51) of an acrylic panel. The hanger (2) is connected with the back bolt (1). The back plate (3) is disposed between the inner face of the acrylic panel (5) and the hanger (2). The back plate (3) is provided with a through hole (31). The back bolt (1) passes through the through hole (31) so as to connect the acrylic panel (5), the back plate (3) and the hanger (2) together. Space between the back plate (3) and the acrylic panel is filled with adhesive (4). The invention further discloses a connecting method for acrylic board curtain walls. The connecting structure and the connecting method have the advantages that the acrylic board curtain wall can be fixed to curtain wall keels reliably and the problem of poor connection strength can be avoided.

Owner:SHENZHEN FANGDA BUILDING TECH GRP

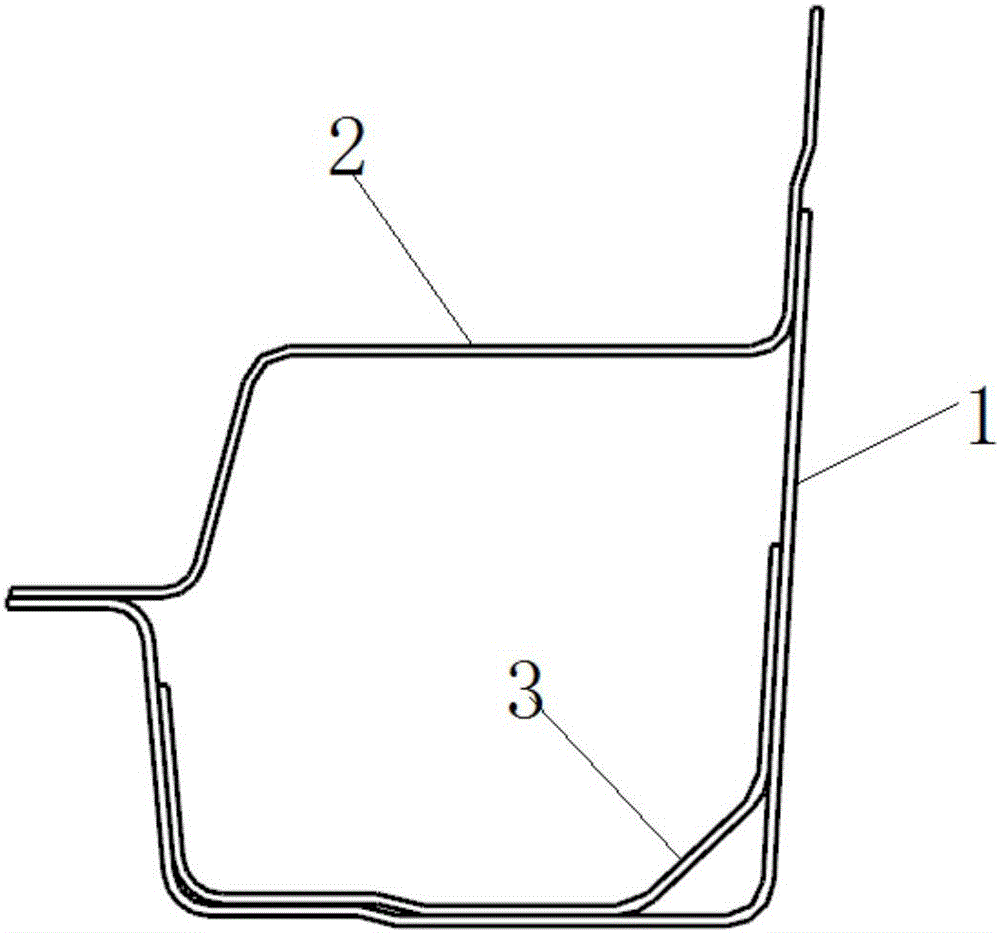

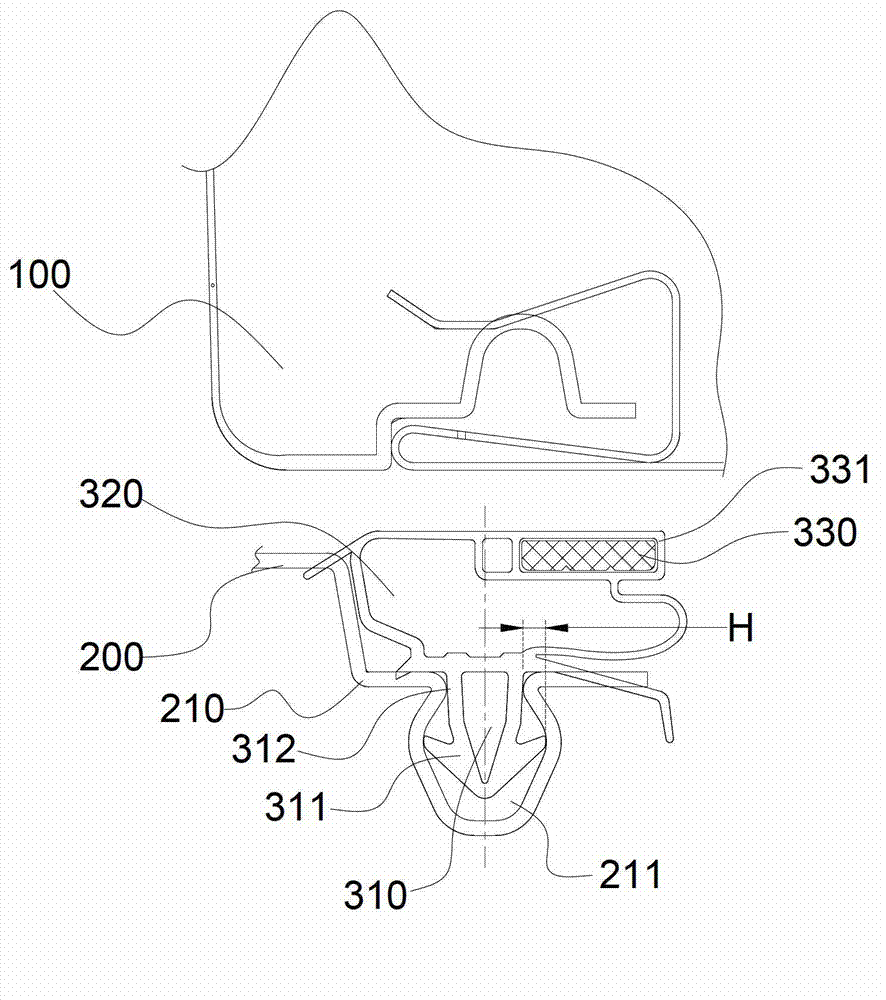

Refrigerator and door seal thereof

InactiveCN102927751ASimple structureEasy to processDomestic cooling apparatusLighting and heating apparatusEngineeringFront edge

The invention provides a refrigerator and a door seal thereof. The door seal comprises a heat insulation gas bag and an installation part, wherein the inside of the installation part is hollow, and the installation part is connected with the heat insulation gasbag; the installation part comprises a connecting part, of which one end is connected with the heat insulation gasbag, and a clamping part, which is connected with the other end of the connecting part; and the clamping part comprises a pair of clamps which are arranged along the center line of the installation part in a mirror image and back-to-back manner, the clamps backward tilt and extend, an included angle is formed between the rear edge and the front edge of each clamp, and the minimum distance from the rear edge to the front edge is greater than zero. Therefore, according to the door seal provided by the embodiment of the invention, through the structure improvement on the clamping part, not only is the integral strength of the clamping part improved, but also the local strength of the end parts of the clamps are improved, and the clamping force of the clamping part is further improved to adapt to the requirements of doors of large-volume refrigerators on clamping force of the door seal. In addition, the door seal provided by the embodiment of the invention is simple in structure, and convenient to process and manufacture.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

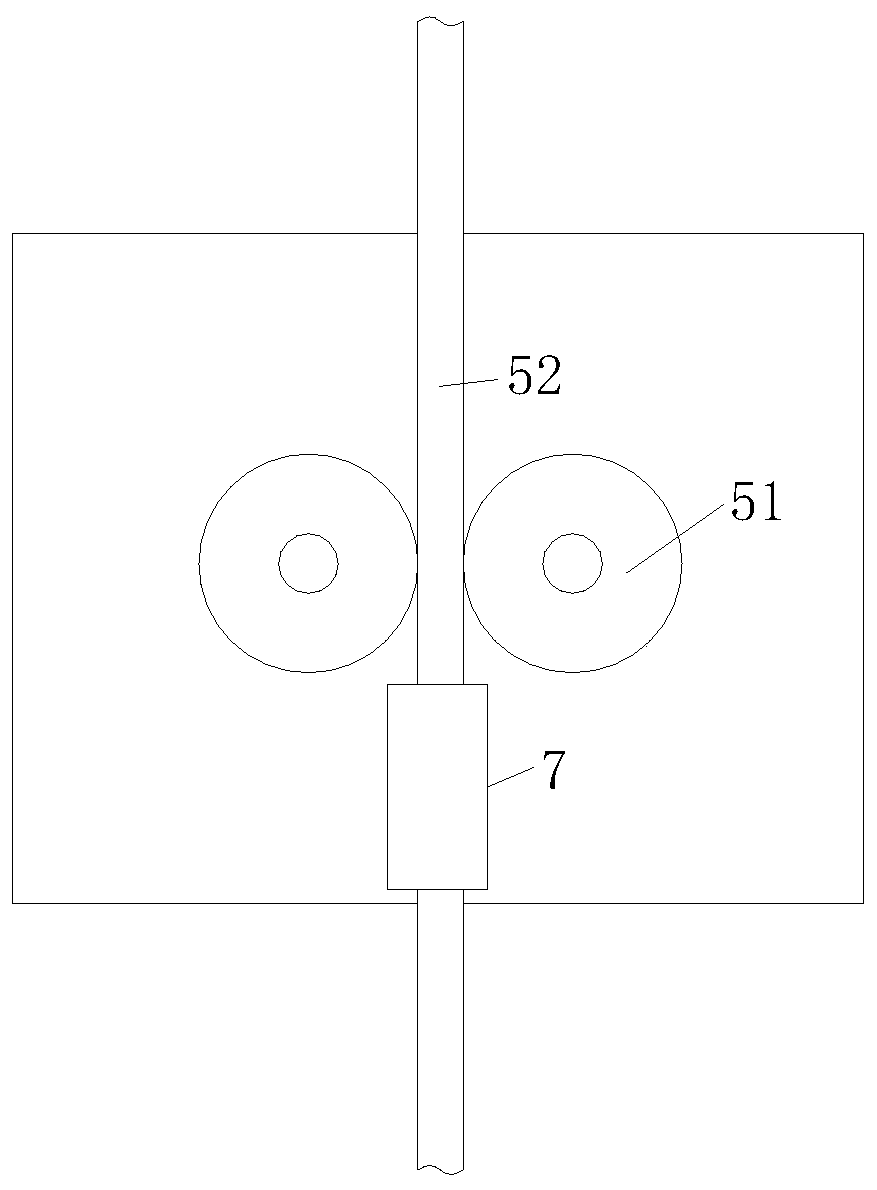

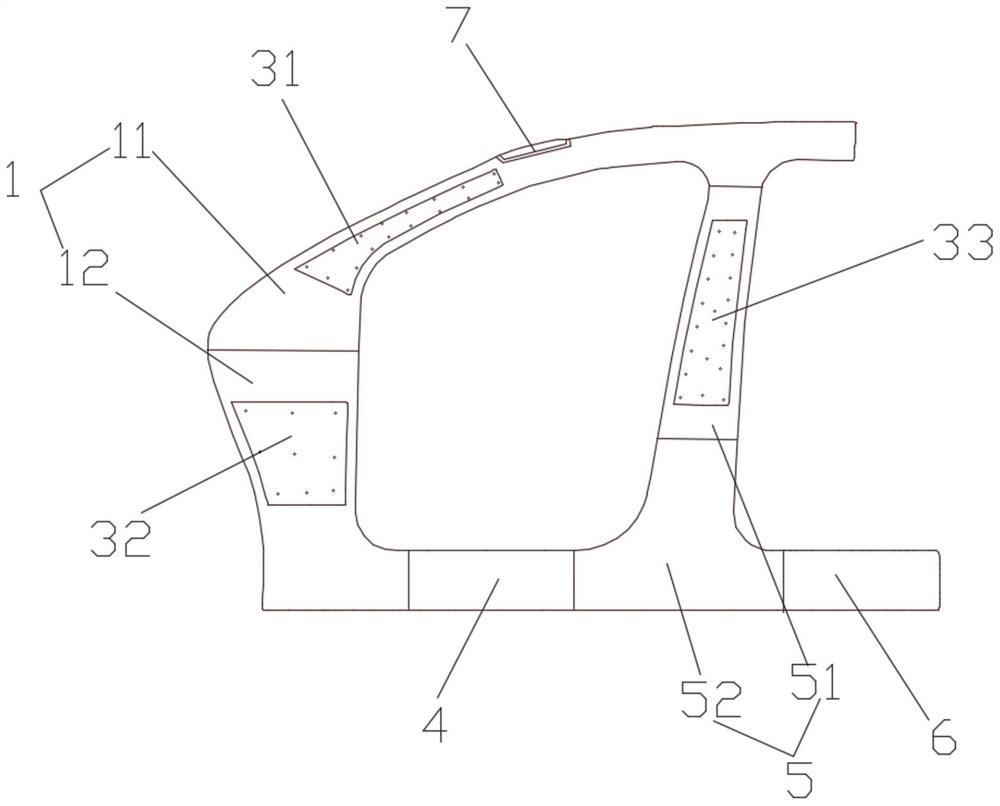

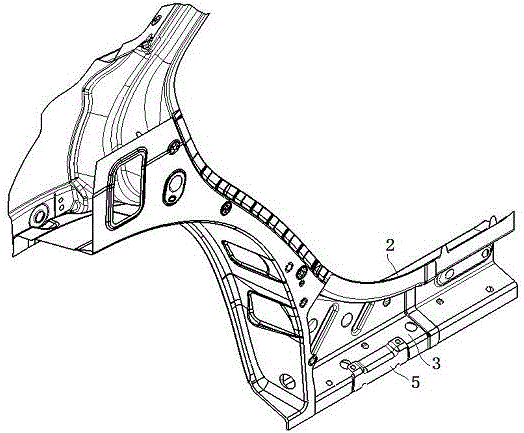

Rear jack reinforcing structure for vehicle body

ActiveCN105905166ASimple structural designPayload sharingSuperstructure subunitsEngineeringSupport point

The invention relates to a rear jack reinforcing structure for a vehicle body. The reinforcing structure comprises a side wall outer plate (2), a threshold rear connecting plate (3) and a threshold rear segment (4). A jack reinforcing plate (5) is arranged between the threshold rear segment (4) and the threshold rear connecting plate (3); the jack reinforcing plate (5) is of an L-shaped structure; two locating holes (51) are formed in one side of the L-shaped structure; a concave type surface (52) is formed between the two locating holes (51); two double-layer welding spots are arranged on the concave type surface (52), to connect the threshold rear connecting plate (3) with the jack reinforcing plate (5), and four welding spots are arranged on the other side of the L-shaped structure, to connect the side wall outer plate (2), the jack reinforcing plate (5) and the threshold rear segment (4); a U-shaped notch (31) is formed in the welding face, corresponding to the jack reinforcing plate (5), of the threshold rear connecting plate (3); the welding edge, at a vehicle body jack supporting point (1), of the side wall outer plate (2) is shortened upwards than the welding edge of other positions in the height direction.

Owner:CHERY AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com