Clamp special for combined tension test of gate valve closing member

A technology of tension test and closing parts, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of destroying the stress structure of the gate valve, not easy to fix and stabilize, and affecting the final test results of the gate valve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

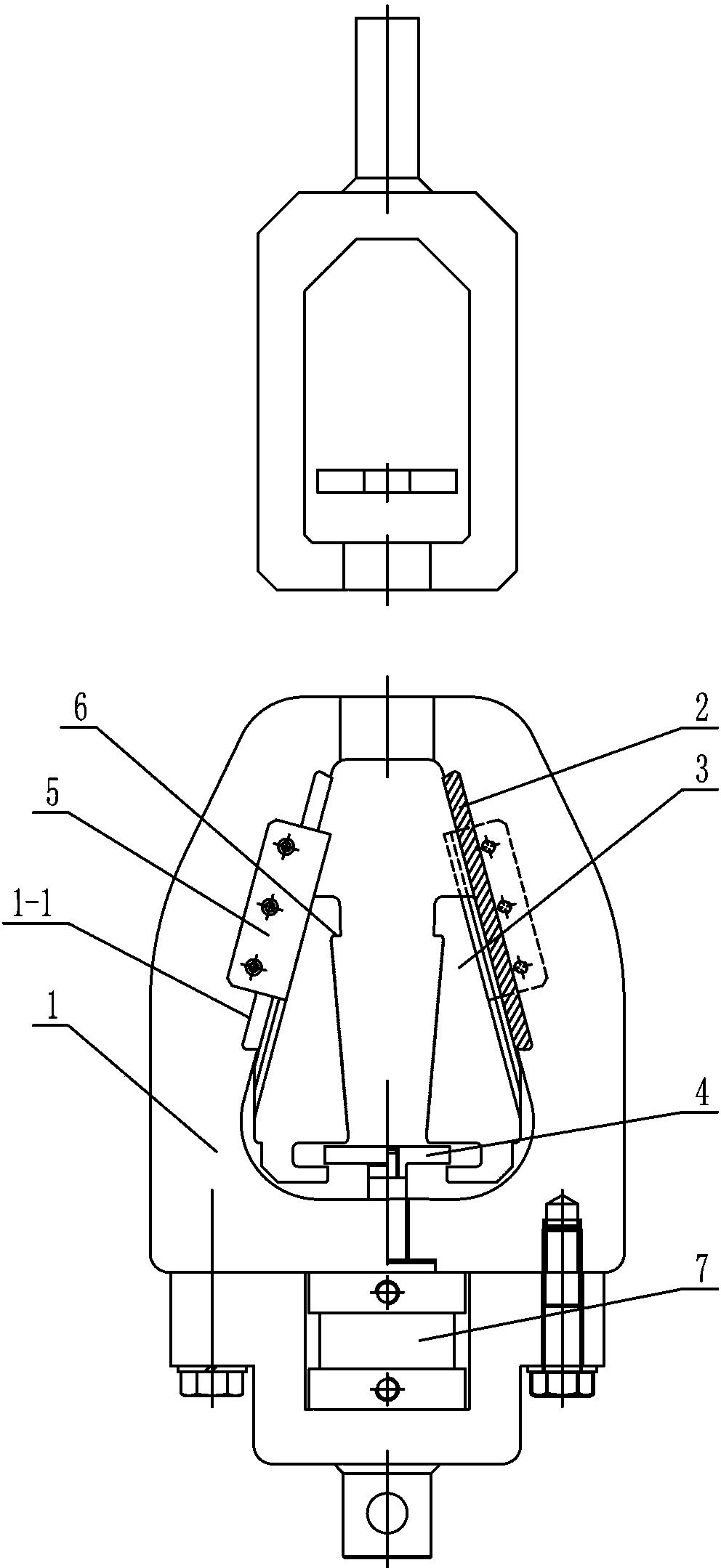

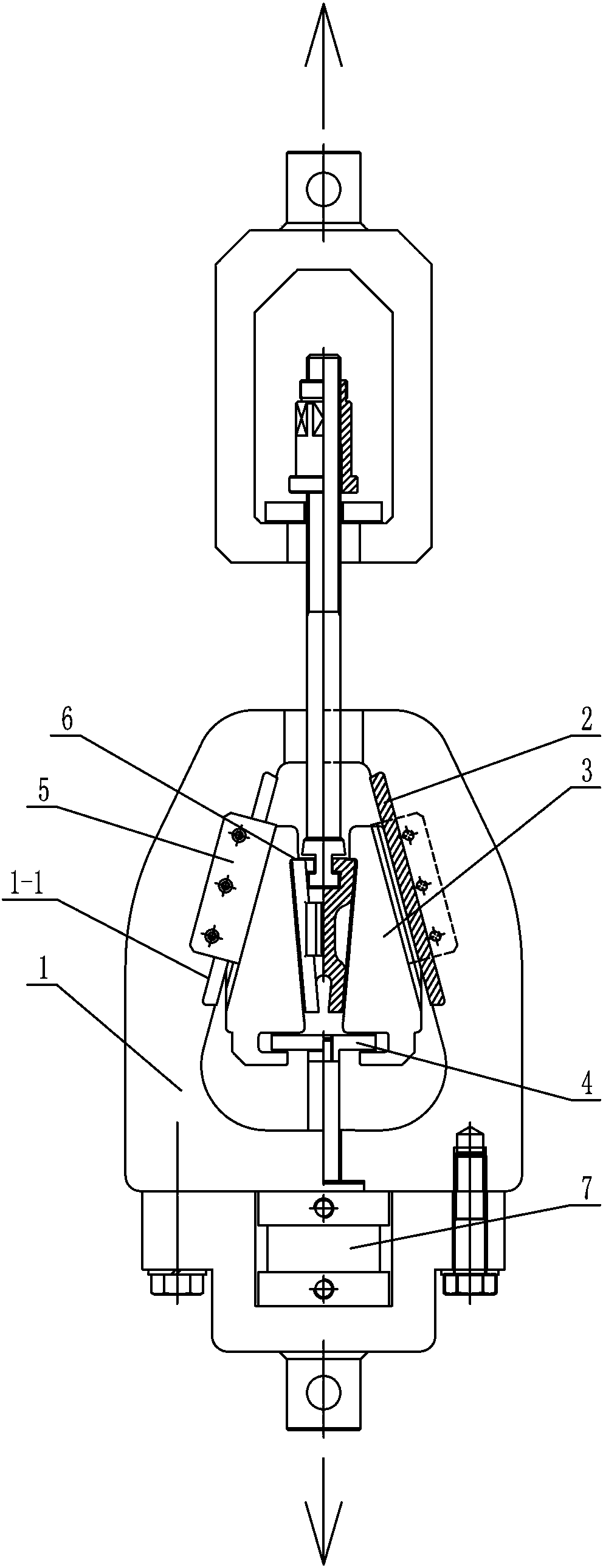

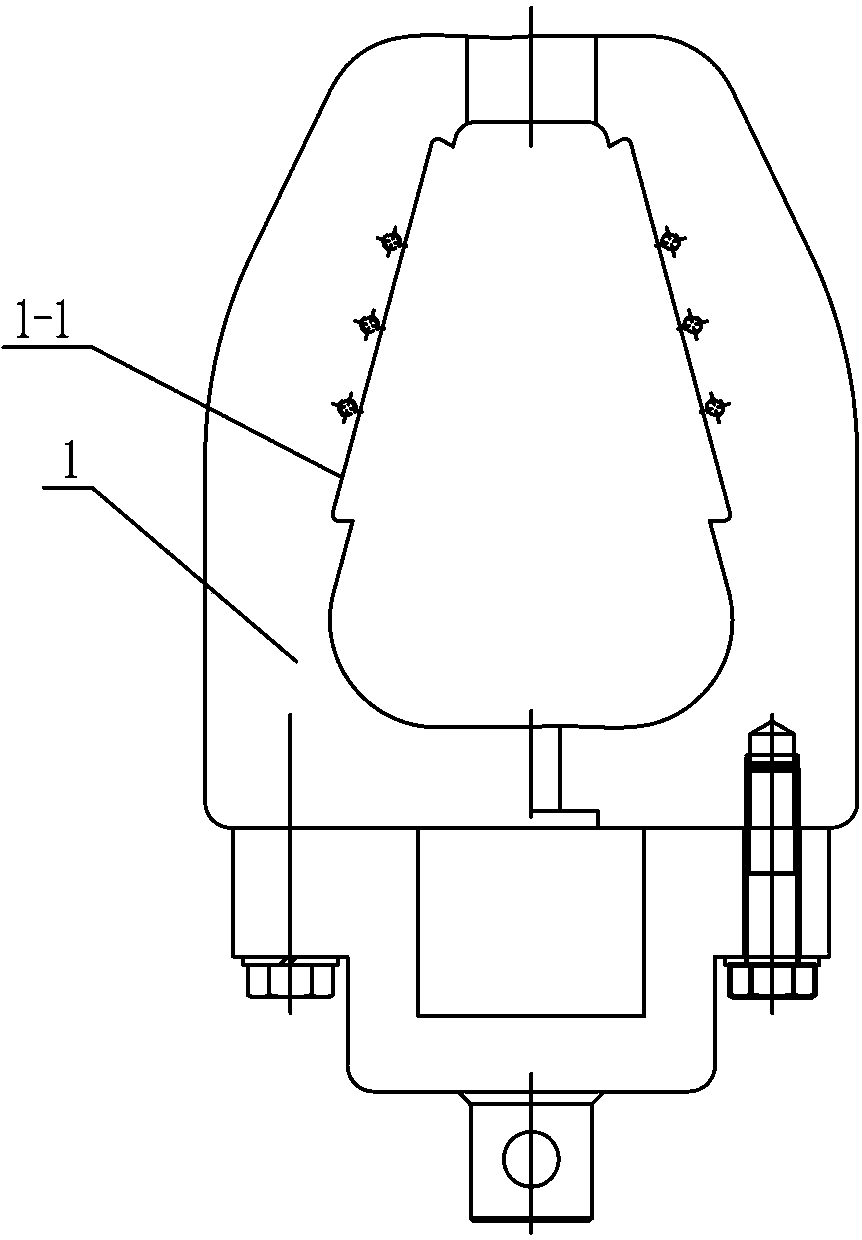

[0014] Such as figure 1 , 2 , 3, and 4, a specific embodiment of a clamp specially used for the combined tensile test of the gate valve closing member of the present invention: a clamp specially used for the combined tensile test of the gate valve closing member, including a clamp base 1, the clamp A concave bayonet 1-1 is provided on the left and right sides of the upper part of the base 1, and the two concave bayonets 1-1 are arranged symmetrically, and a cutting board is provided on the inner side of each concave bayonet 1-1 2. The cutting board 2 is embedded in the corresponding concave bayonet 1-1. The cutting board 2 is made of hard material. The inner side of the cutting board 2 is closely attached to a pressing block 3. There is a movable up and down clamp under the clamp base 1. Top plate 4, the top plate 4 that can move up and down is connected with a telescopic oil cylinder 7 provided below the clamp base 1, the top plate 4 can push the compression block 3 to move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com