Rear jack reinforcing structure for vehicle body

A technology for strengthening the structure and automobile body, applied in the direction of upper structure, upper structure sub-assembly, vehicle parts, etc., can solve problems such as damage, body deformation, affecting the appearance and safety performance of automobile products, and achieve local strength and welding process improvement Easy and optimized load-bearing side structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the present invention will be further described:

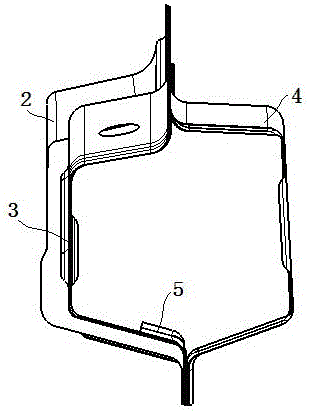

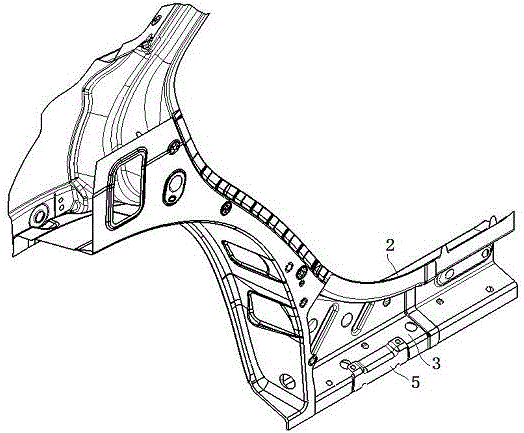

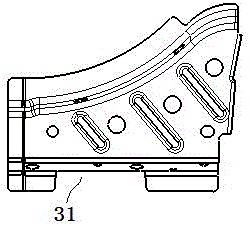

[0032] Figure 1 to Figure 5 It shows a rear jack reinforcement structure of an automobile body, including a side wall outer panel 2, a door sill rear connection plate 3 and a door sill rear section 4, and a jack reinforcement plate 5 is added between the door sill rear section 4 and the door sill rear connection plate 3, By adding the jack reinforcing plate 5, the load of the side wall outer panel 2 can be effectively shared, and the serious deformation of the side wall outer panel 2 due to a large load can be avoided when the jack is used. Car body jack supporting point 1 and jack work together. figure 2 It is a schematic diagram of the A-A section in the overall schematic diagram of the car body jack reinforcement structure. The jack reinforcement plate 5 is first welded with the door sill rear connection plate 3 and connected by spot welding. The jack reinforcing pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com