Patents

Literature

208results about How to "Avoid severe deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing atmosphere heat drying and vacuum oil frying combined dewatered fruit and vegetable crisp chip

InactiveCN1554274AAvoid severe deformationKeep shapeFood preservationFood preparationFood materialEdible mushroom

The present invention belongs to the field of fruit and vegetable food producing technology. The production process of crisp fruit and vegetable chip includes the steps of: selecting fruit, vegetable material, edible mushroom and other food material; pre-treatment including washing, peeling, slicing, scalding to kill enzyme, etc; heating to dry at normal pressure; oil frying to dewater, centrifuging to eliminate oil, seasoning and packing. Owing to the combined dewatering process of normal pressure hot drying and vacuum frying, the present invention has low oil content in crisp fruit and vegetable chip, short frying time and well maintained food shape.

Owner:JIANGNAN UNIV +1

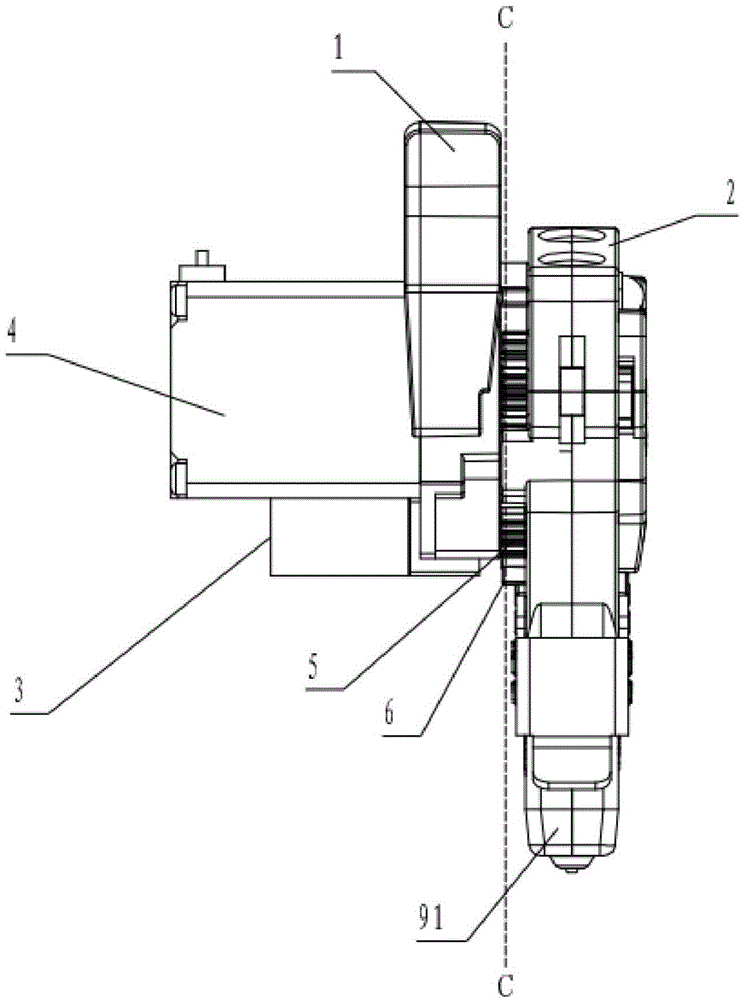

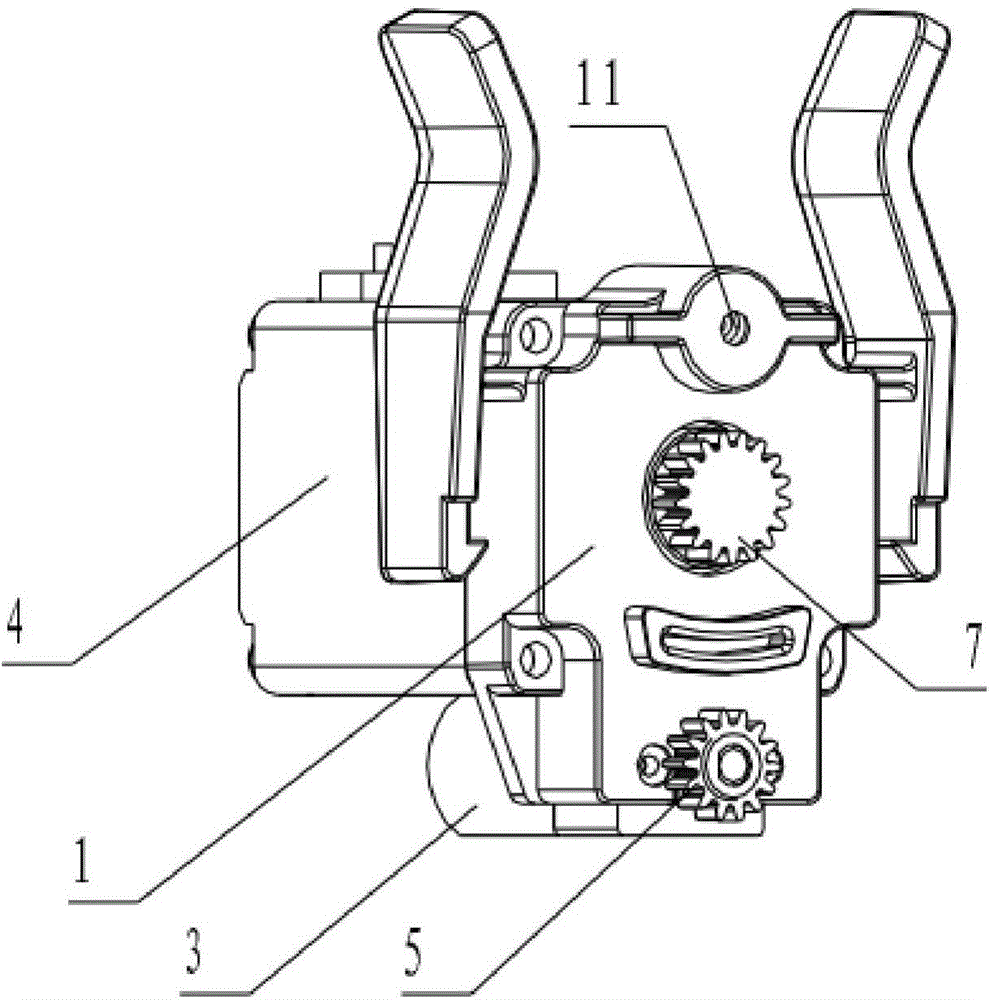

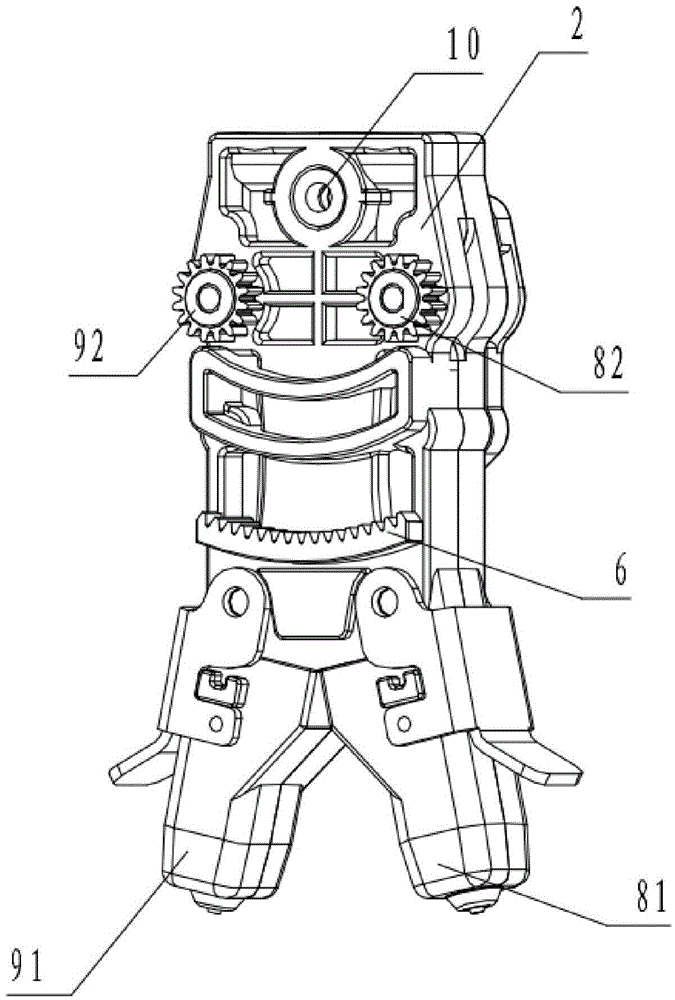

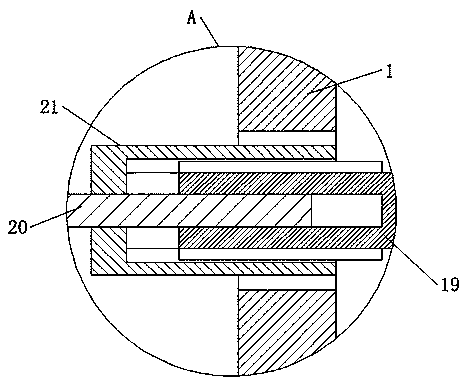

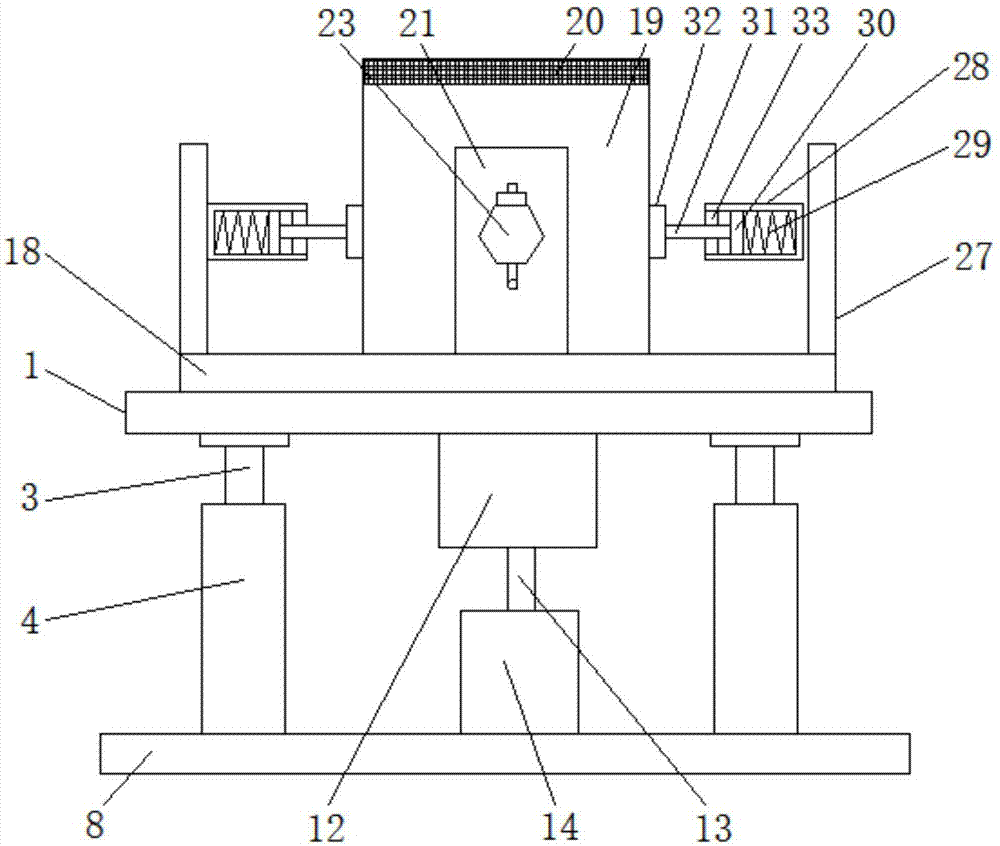

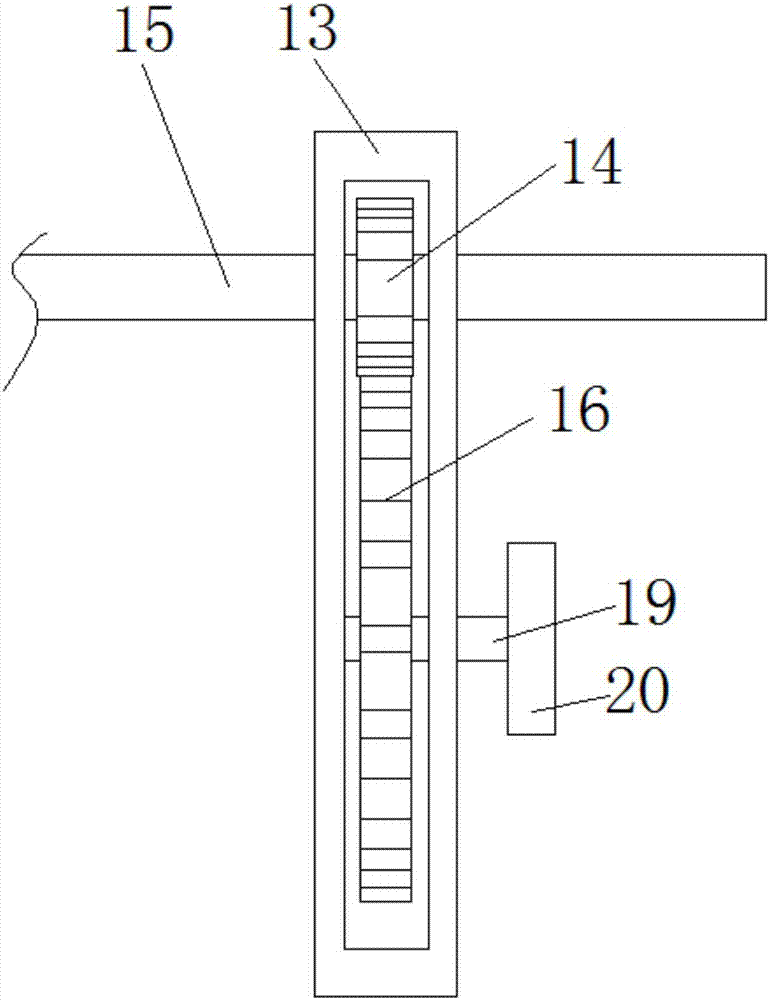

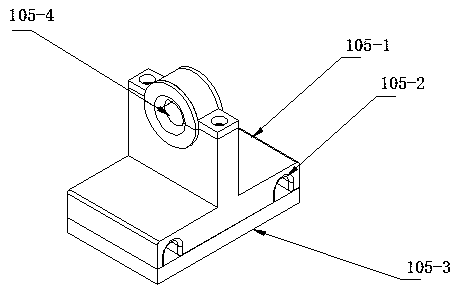

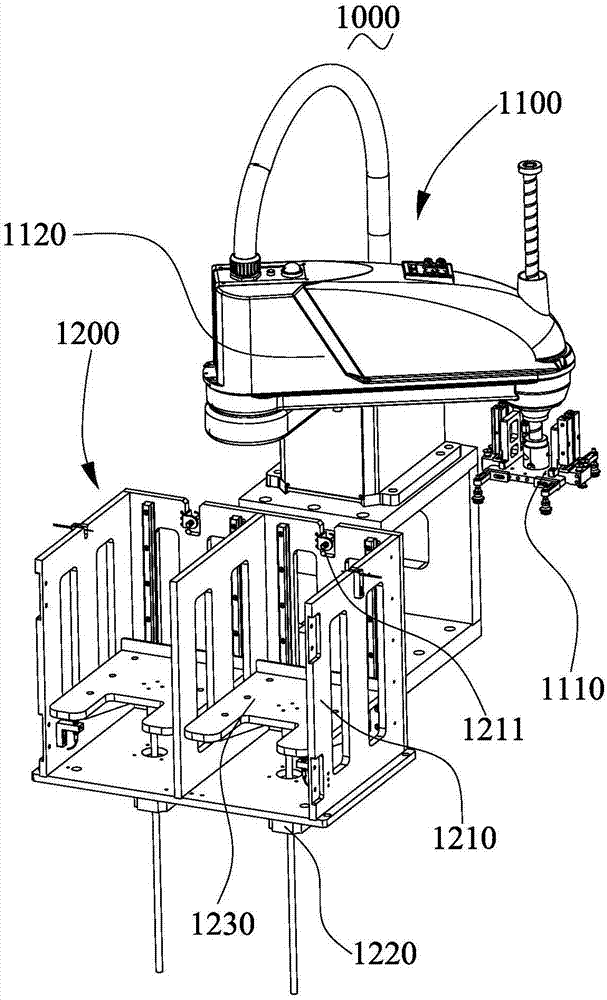

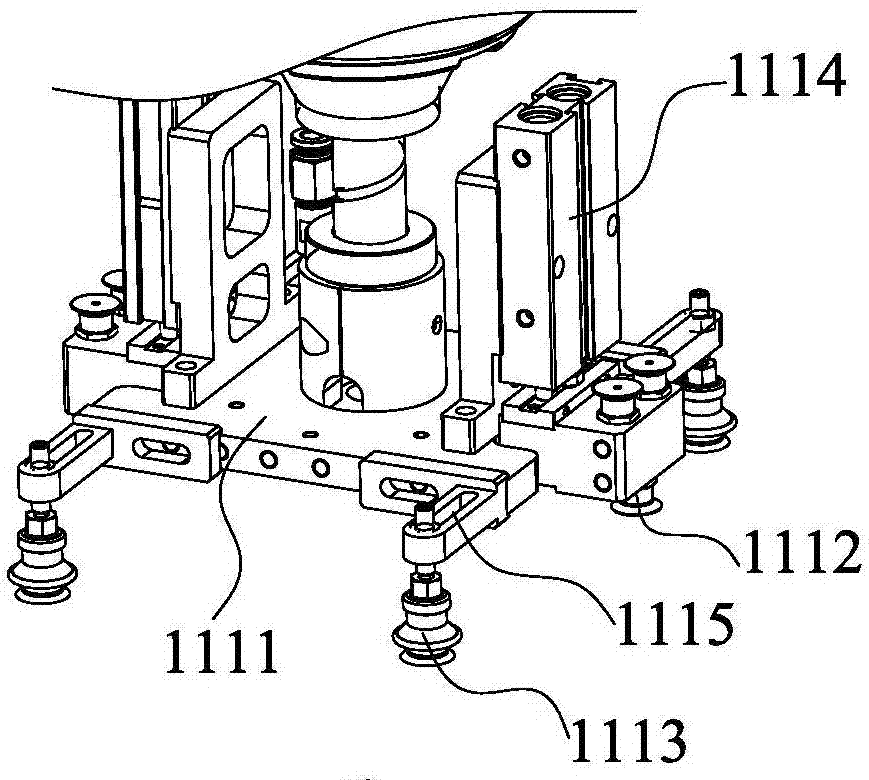

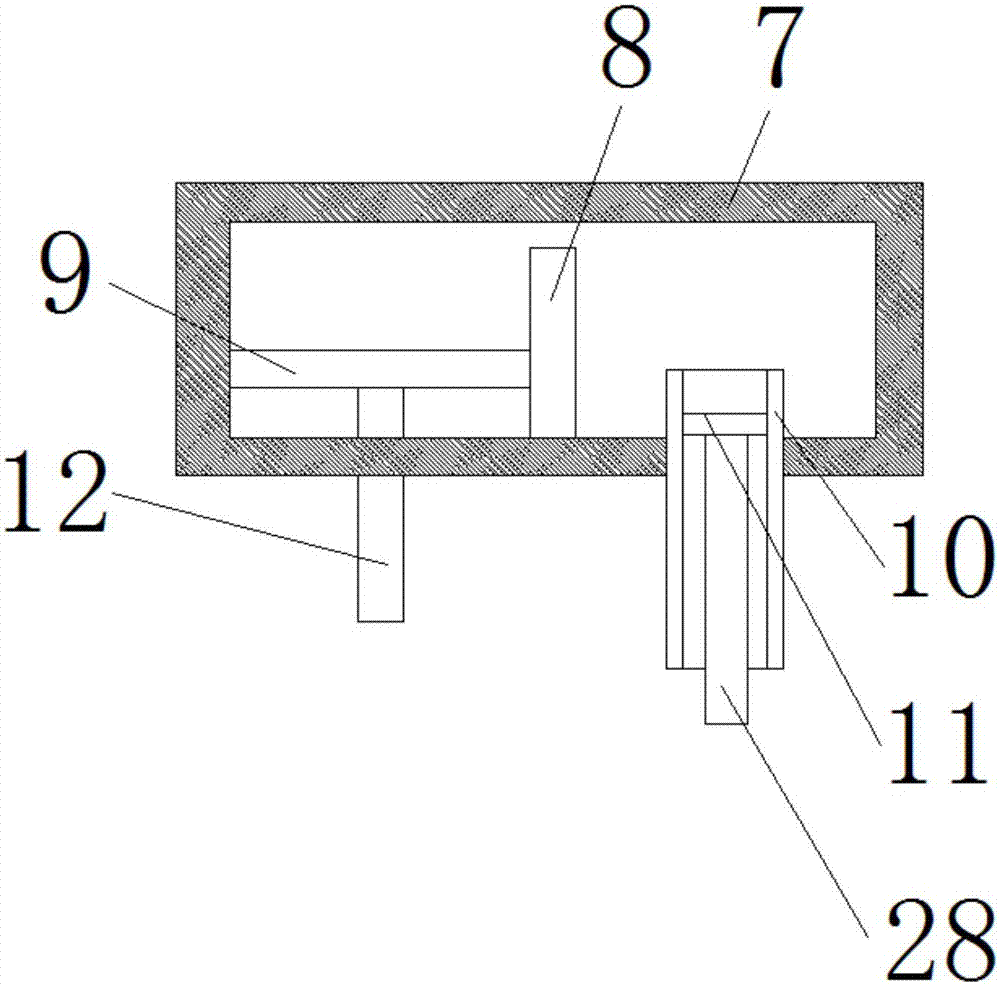

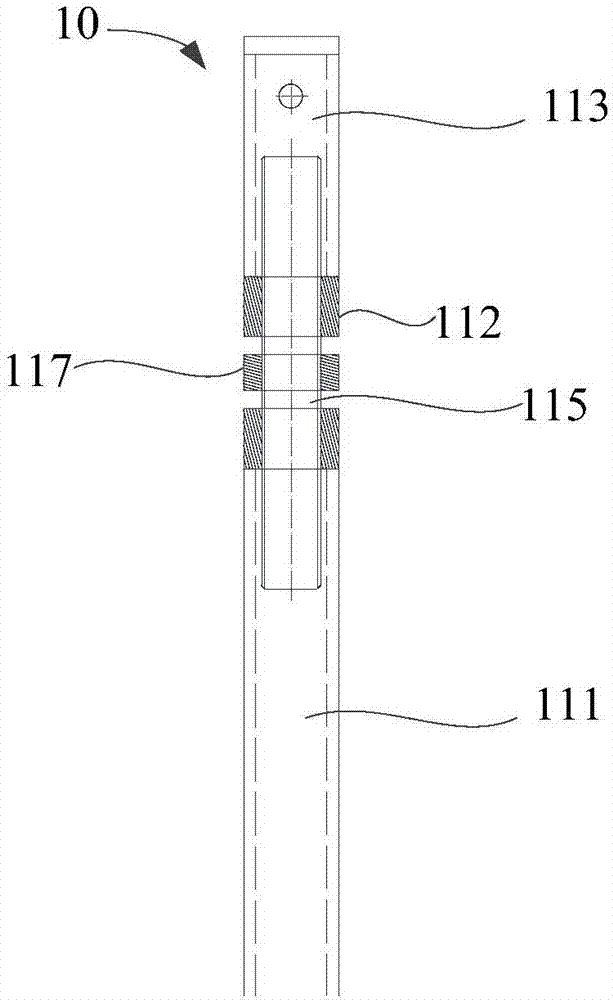

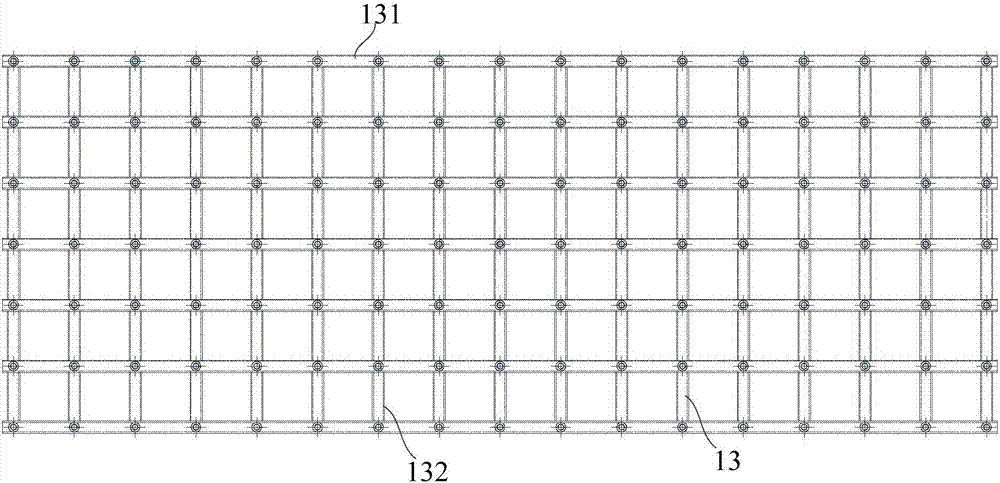

Rotary type double-nozzle switching device for 3D printing

The invention discloses a rotary type double-nozzle switching device for 3D printing. The rotary type double-nozzle switching device comprises a steering motor and a wire feeding motor which are arranged on a first bracket; a second bracket is provided with a first nozzle mounting groove, a second nozzle mounting groove, a first wire feeding gear and a second wire feeding gear which correspond to the first nozzle mounting groove and the second nozzle mounting groove, and a first driven wheel and a second driven wheel which are coaxially connected with the first wire feeding gear and the second wire feeding gear; the second bracket is rotationally arranged on the first bracket; a steering gear is connected with the steering motor in a driving manner and is engaged with an arc-shaped rack on the second bracket; under the transmission of the steering gear, the arc-shaped rack enables the second bracket to swing on the first bracket by taking the circle center of the arc-shaped rack as the circle center; a wire feeding driving wheel is in driving connection with the wire feeding motor; when the second bracket swings to the right side, the second bracket is engaged with the first driven wheel; and when the second bracket swings to the left side, the second bracket is engaged with the second driven wheel. By virtue of the rotary type double-nozzle switching device for the 3D printing, the effective printing space is effectively improved when a 3D printer adopts double nozzles, and the mutual influences between the nozzles is higher; and the practicability is high and the usability is good.

Owner:JIANGSU HAOYU ELECTRONICS TECH

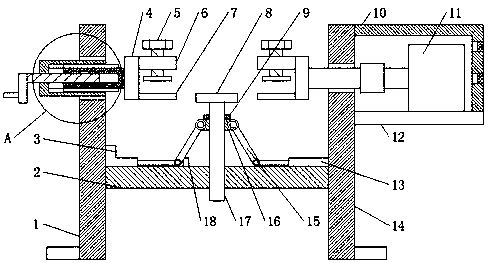

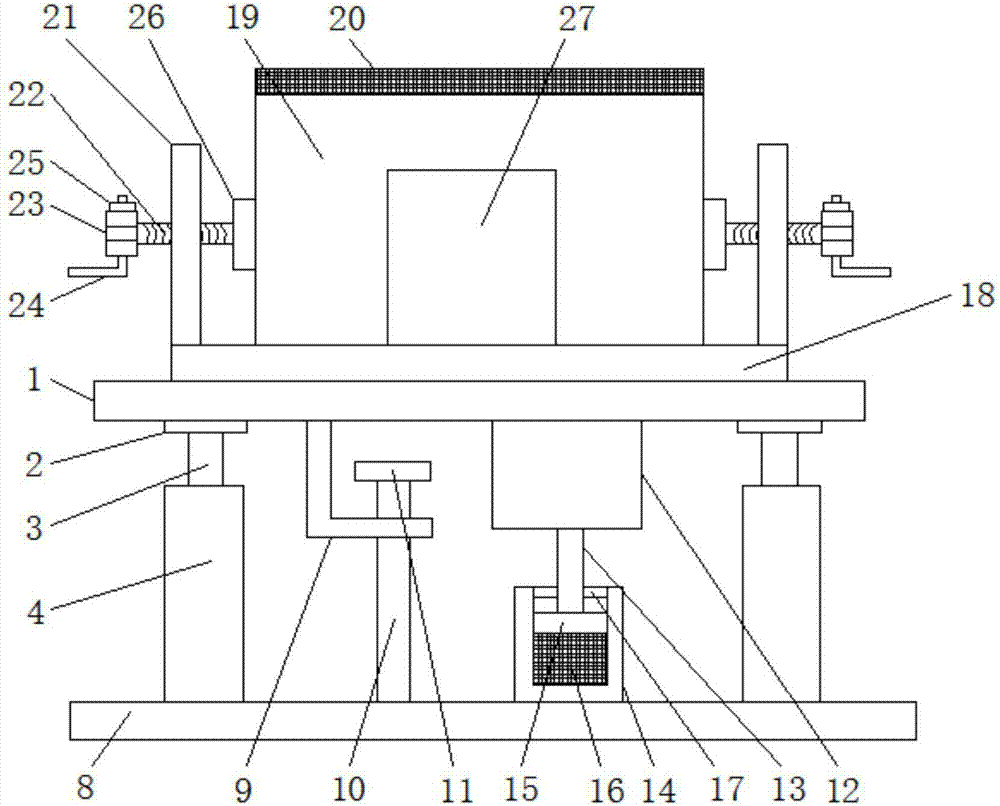

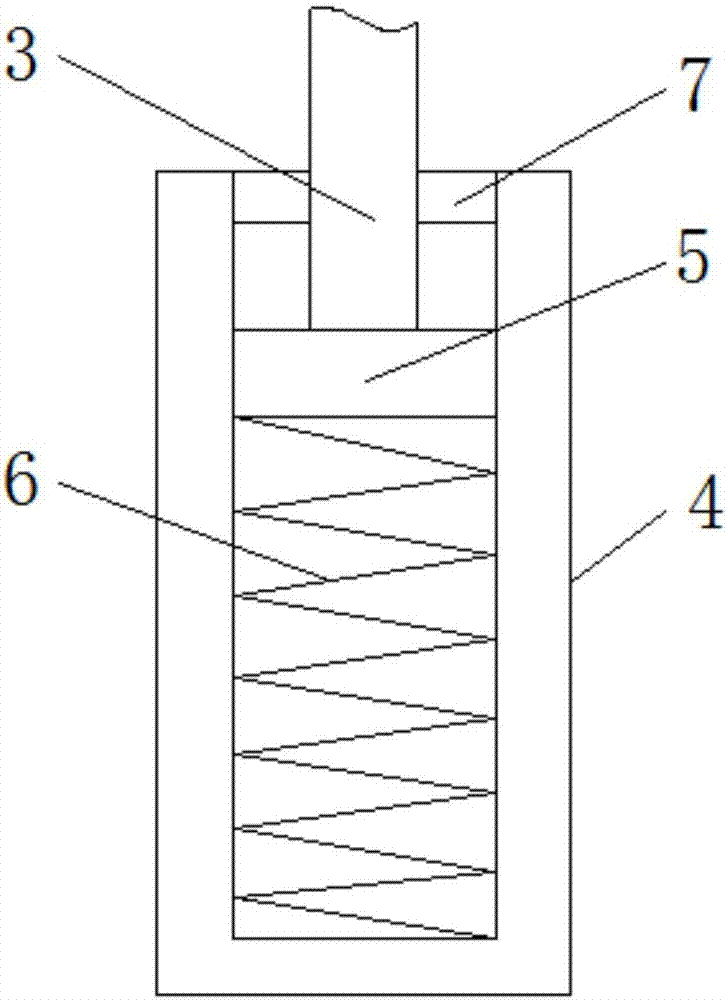

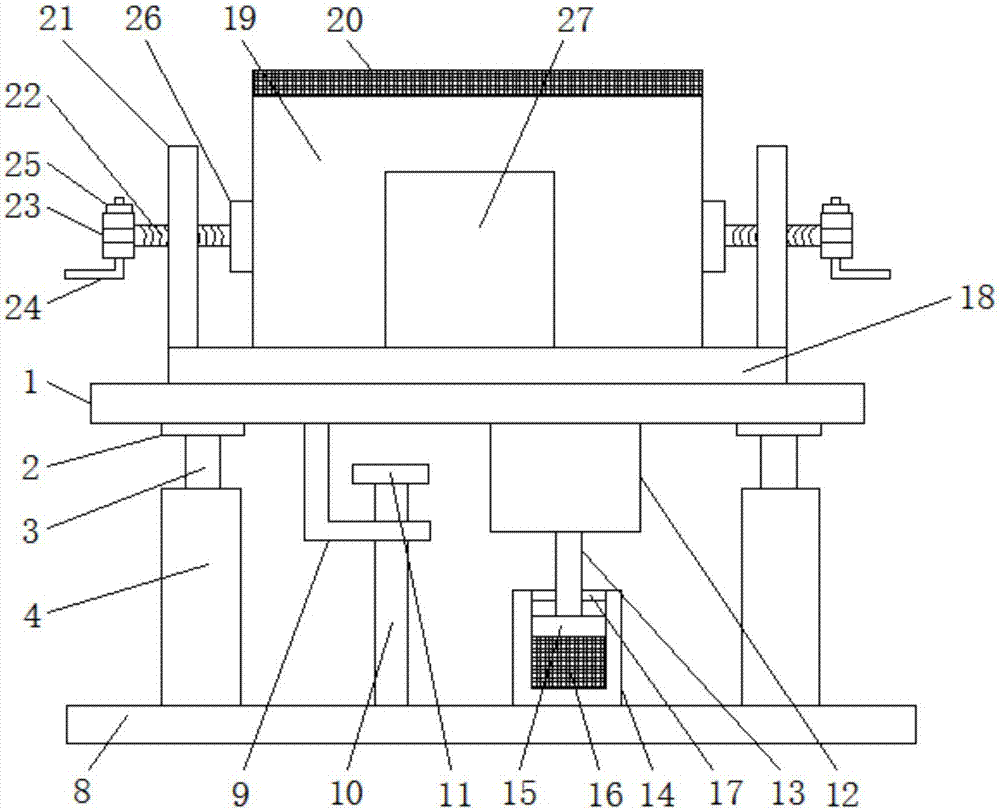

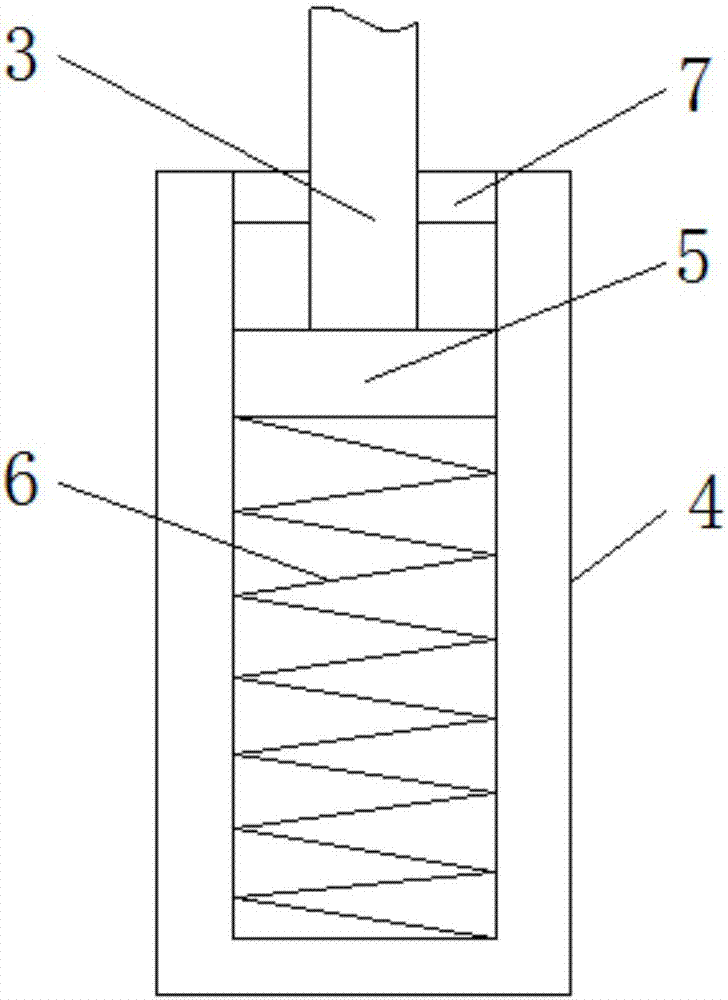

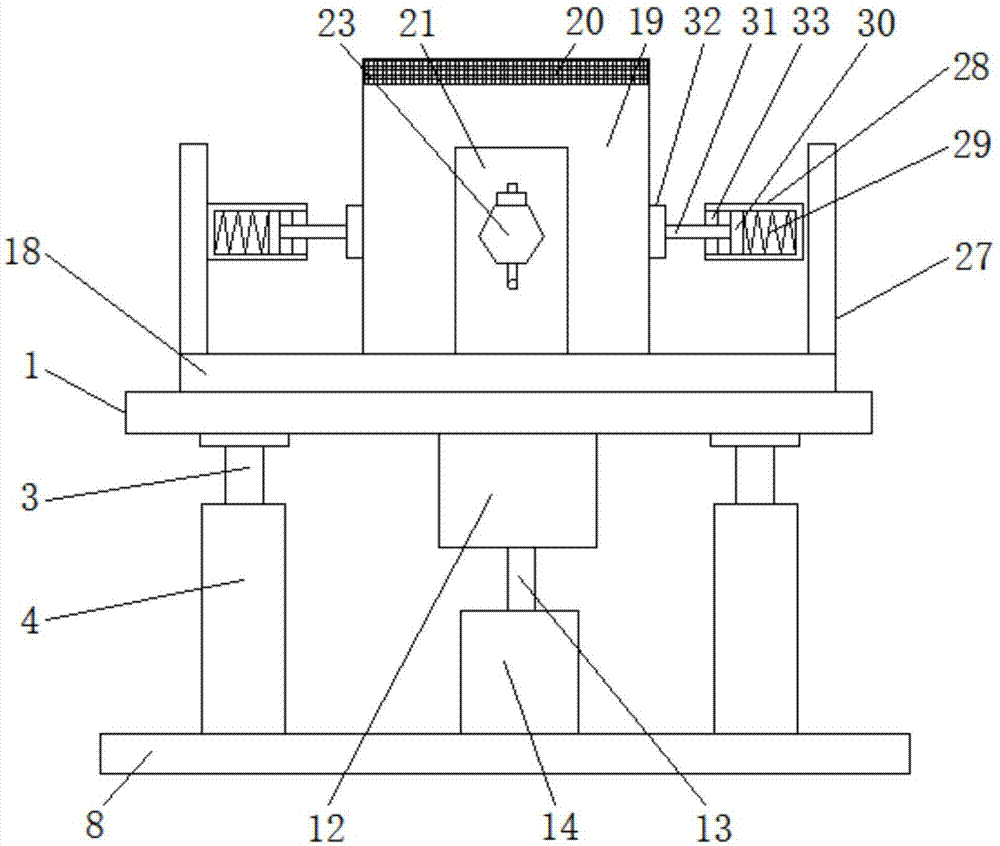

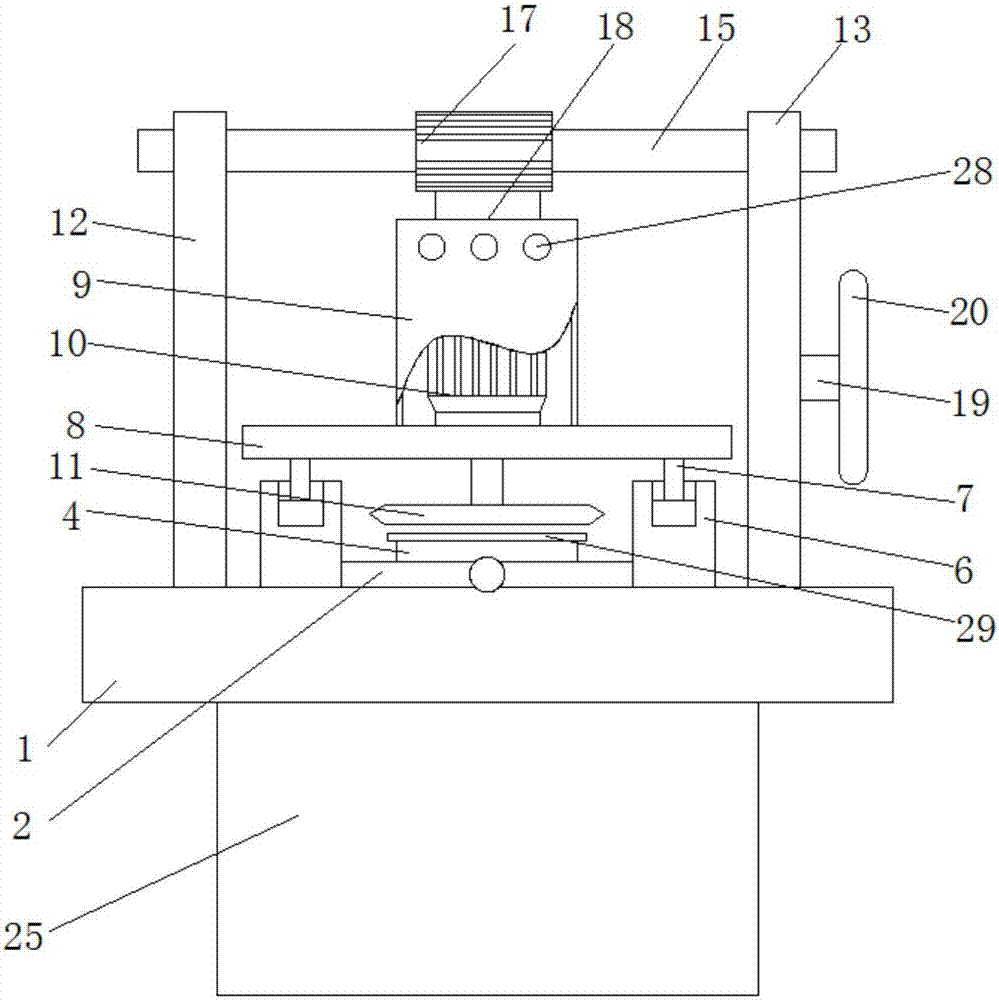

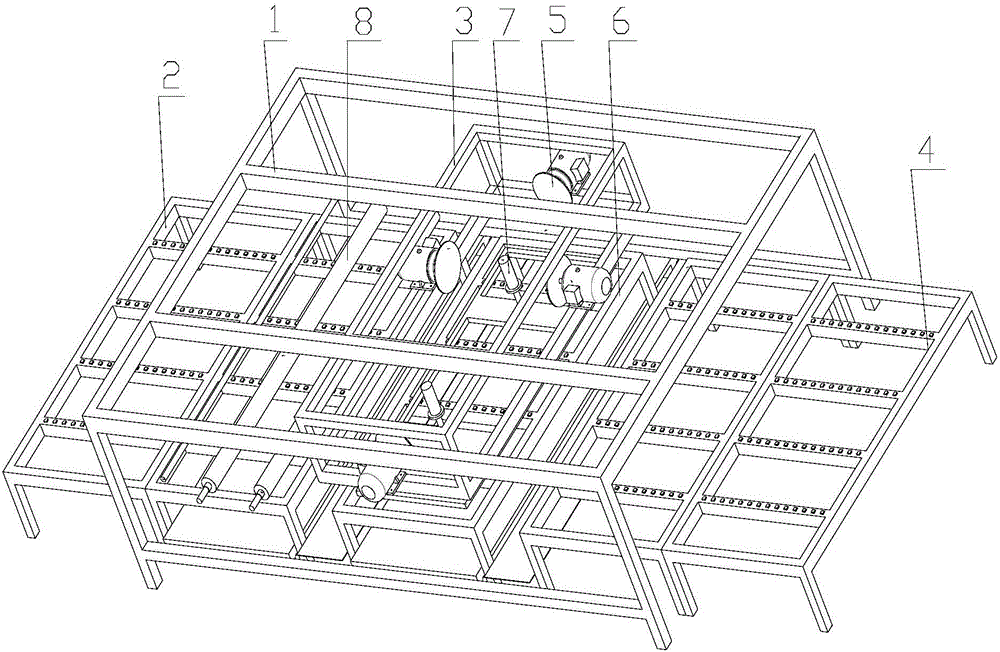

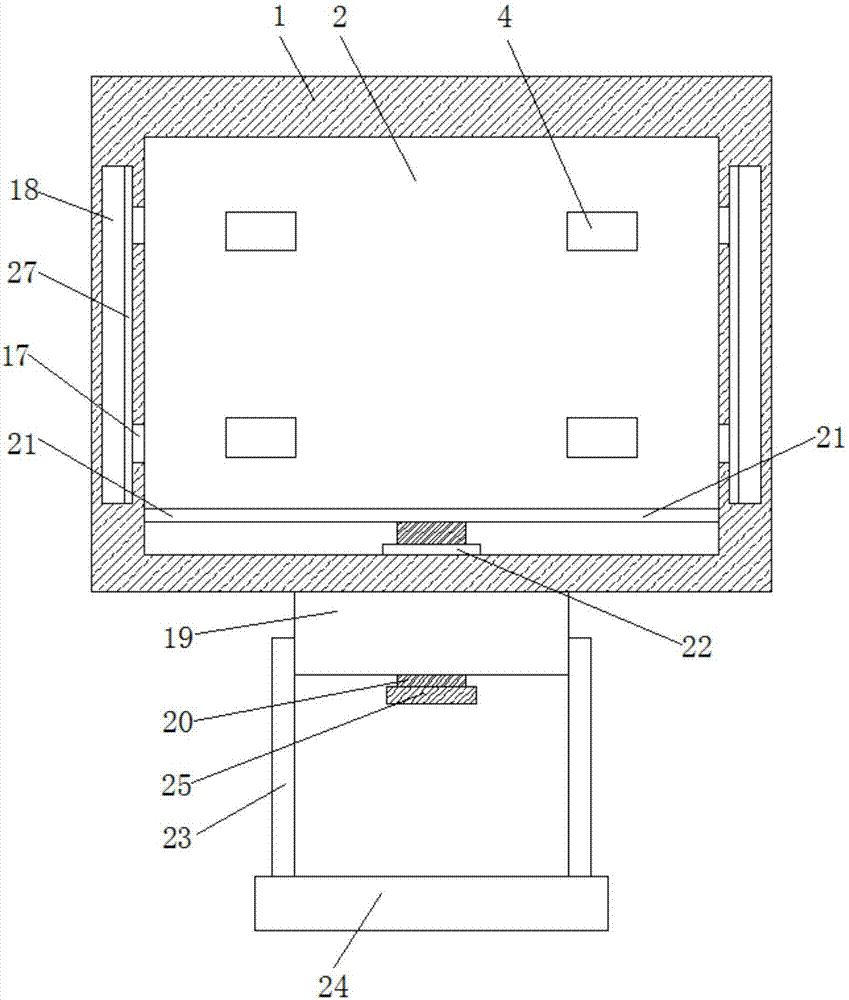

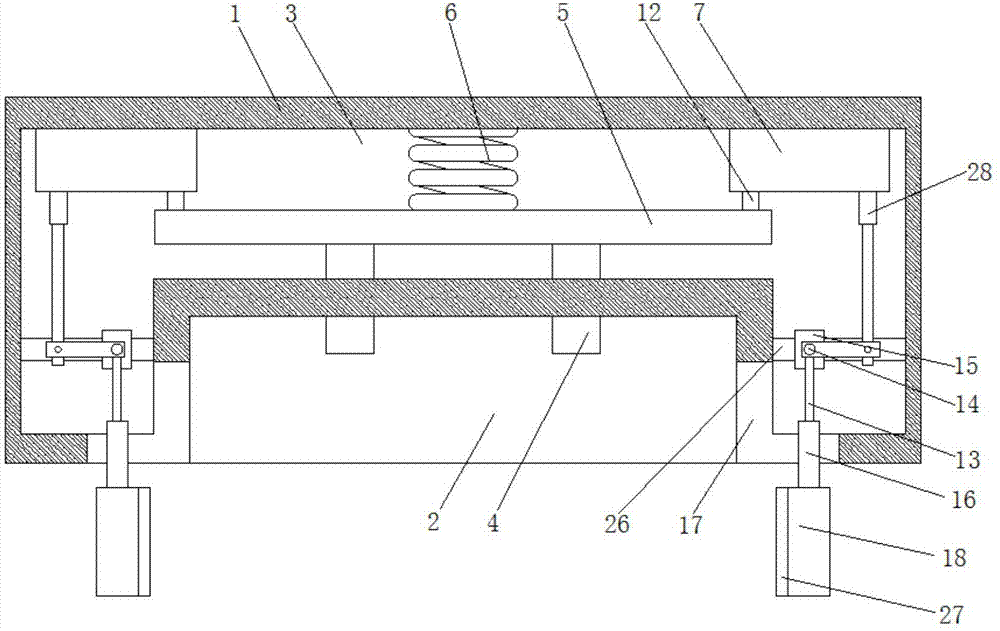

Turnover device for mechanical automatic machining

PendingCN109128921AAvoid severe deformationFlipLarge fixed membersPositioning apparatusEngineeringMachining

The invention discloses a turnover device for mechanical automatic machining. The turnover device comprises a first support plate and a second support plate, wherein the first support plate corresponds to the second support plate, corresponding through holes are respectively formed in the same high position of the first support plate and the second support plate, bearings are fixedly connected tothe inner walls of the two through holes, two symmetrical fixtures are arranged between the first support plate and the second support plate, one fixture is connected with the first support plate by virtue of an adjusting mechanism, a rotating rod is fixedly connected to the center of one side, which is far from the first support plate, of the other fixture, the rotating rod penetrates through thebearing on the second support plate and is rotatably connected with the second support plate, a mounting plate is fixedly connected to one side, which is far from the first support plate, of the second support plate, a motor is fixedly connected to the top of the mounting plate, and the tail end of an output shaft of the motor is fixedly connected with one end, which is far from the fixture, of the rotating rod by virtue of a coupling. According to the turnover device, the purpose of no deformation when a plate is milled is realized by utilizing the lifting support plates.

Owner:QUANZHOU MIAOYI AUTOMATION MACHINERY CO LTD

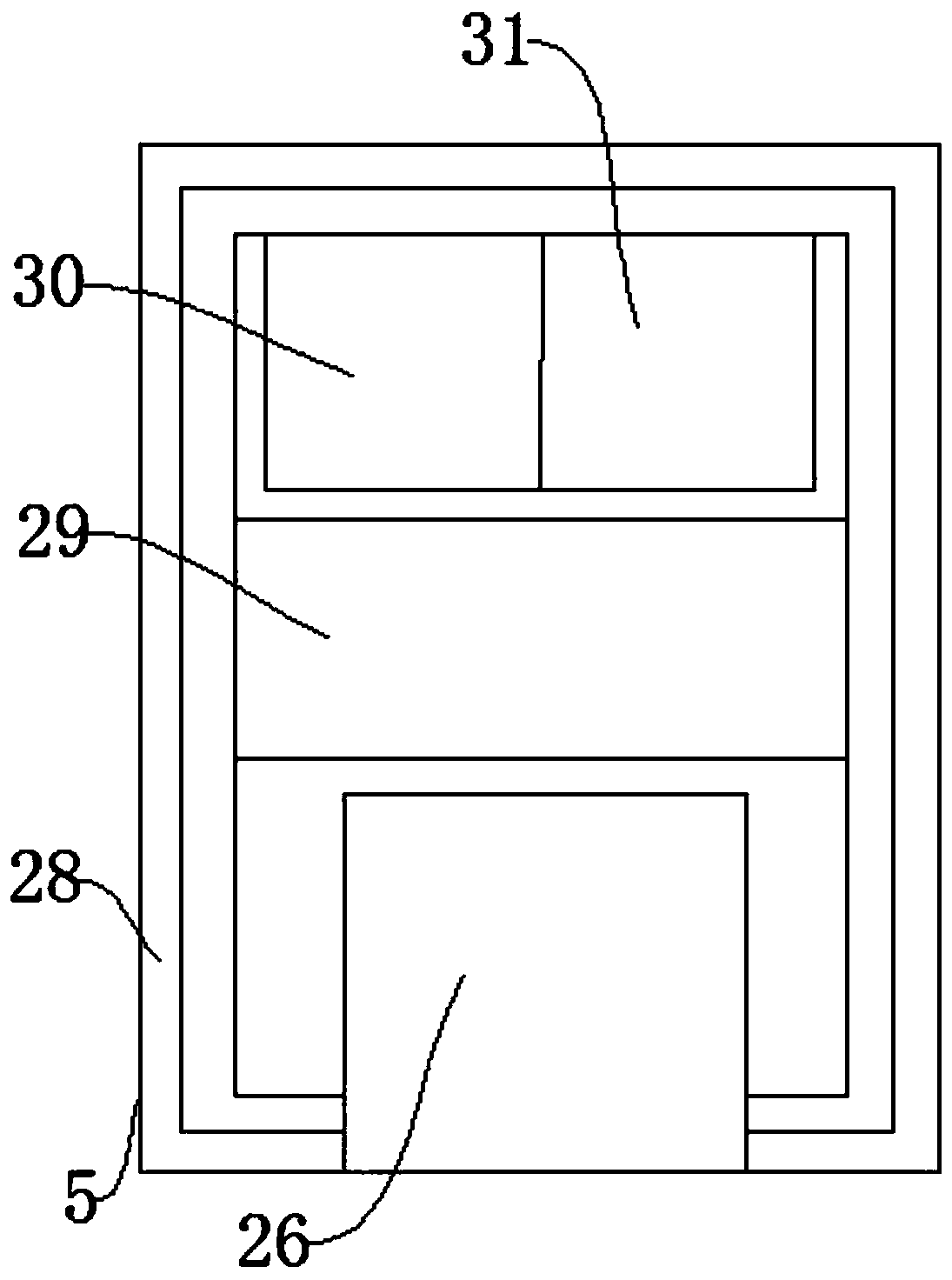

Collision-prevention electronic device control box

InactiveCN107493666ANot easy to damageAvoid damageNon-rotating vibration suppressionCasings/cabinets/drawers detailsEngineeringElectron

The invention provides an anti-collision electronic device control box, which relates to the field of electronic devices. The anti-collision electronic device control box includes a fixing plate, four corners of the bottom of the fixing plate are fixedly installed with connecting blocks, and the bottom of the connecting blocks is fixedly connected with the top of the first pressure rod. The bottom end penetrates the first shock absorber and extends to the inside of the first shock absorber and is fixedly connected with the top of the first pressing block. The anti-collision electronic device control box drives the second splint to clamp and fix the front and back of the box through the second shock absorber, and drives the first splint to clamp and fix the left and right sides of the box through the screw, so that the box is clamped and fixed. Reliably fixed, through the first shock absorber and the buffer shock absorption, the fixed plate drives the box body to move along the surface of the guide rod, so as to effectively buffer the box body and make it difficult for the box body to separate from the base. The electronic devices inside the protection box are not easily damaged, and the use cost is effectively reduced.

Owner:石国华

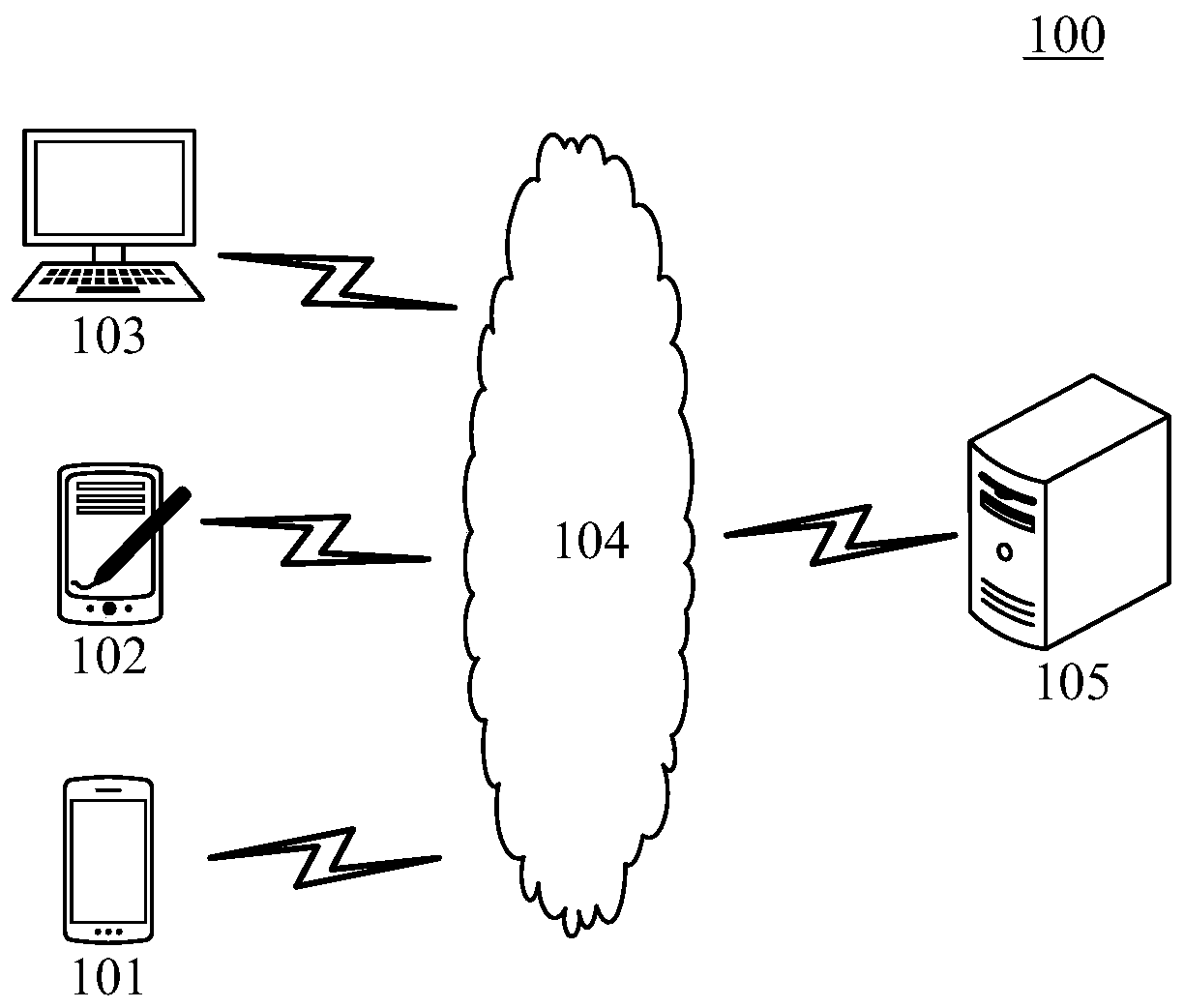

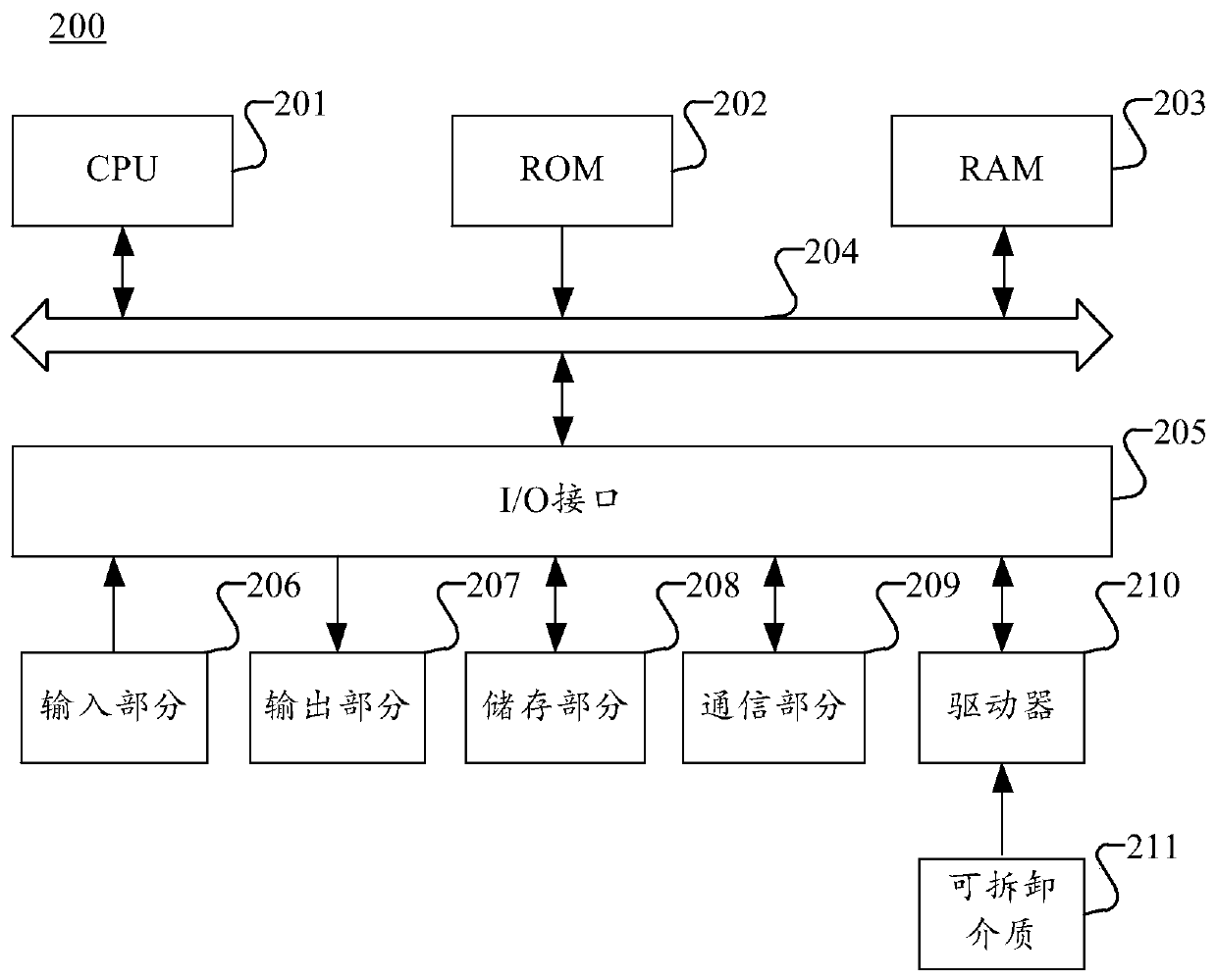

Vegetation rendering method and device, storage medium and electronic equipment

PendingCN110838162AAvoid severe deformationReal natural interaction effectDetails involving 3D image dataImage generationComputer animationMorphing

The invention provides a vegetation rendering method and device, electronic equipment and a computer readable storage medium, and relates to the technical field of computer animation. The vegetation rendering method comprises the following steps: acquiring real-time coordinates of each vertex of a target vegetation model and real-time coordinates of a central point of each surface; acquiring real-time coordinates of the virtual character; according to the real-time coordinates of the central point and the real-time coordinates of the virtual character, obtaining an offset value generated by the target vegetation model under the action of the virtual character; adding the offset value to the real-time coordinates of the vertex of the target vegetation model to obtain offset coordinates of the target vegetation model; and rendering the target vegetation model according to the offset coordinates. According to the invention, the problem of serious deformation of the vegetation in the interaction process with the virtual character can be improved, and a more natural and real vegetation rendering effect is realized.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

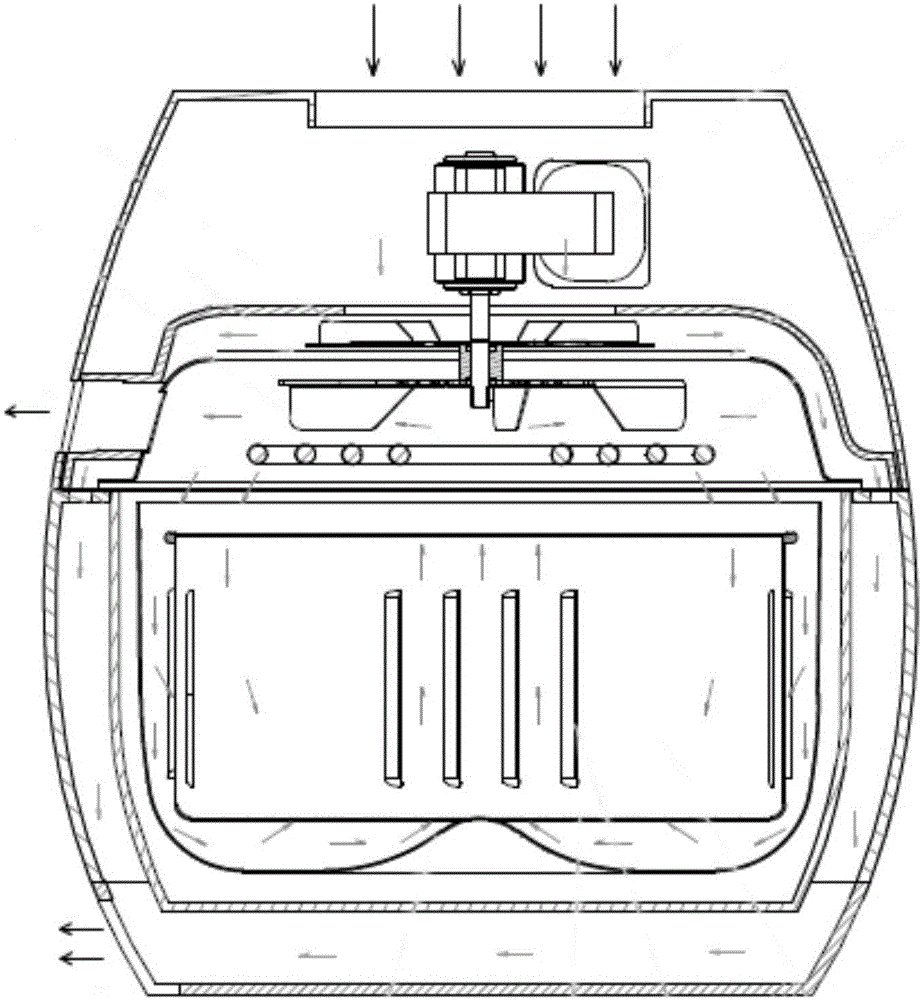

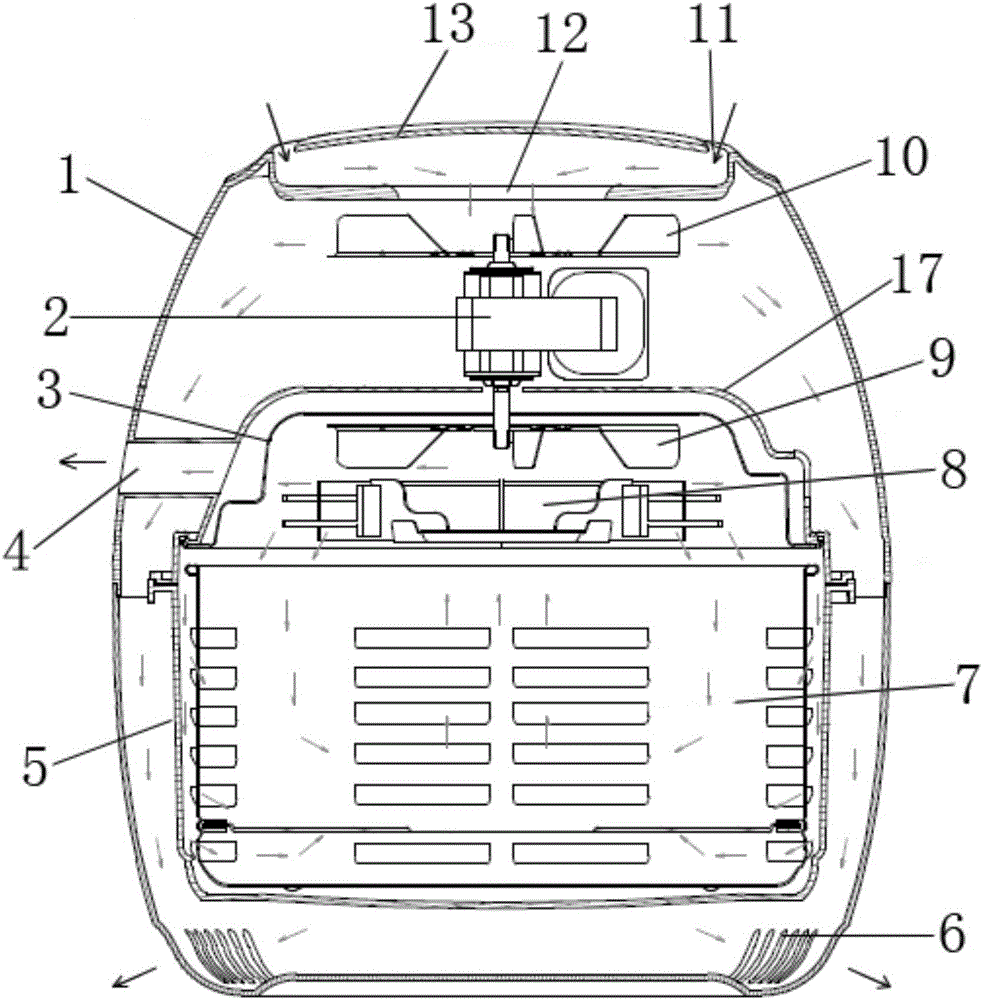

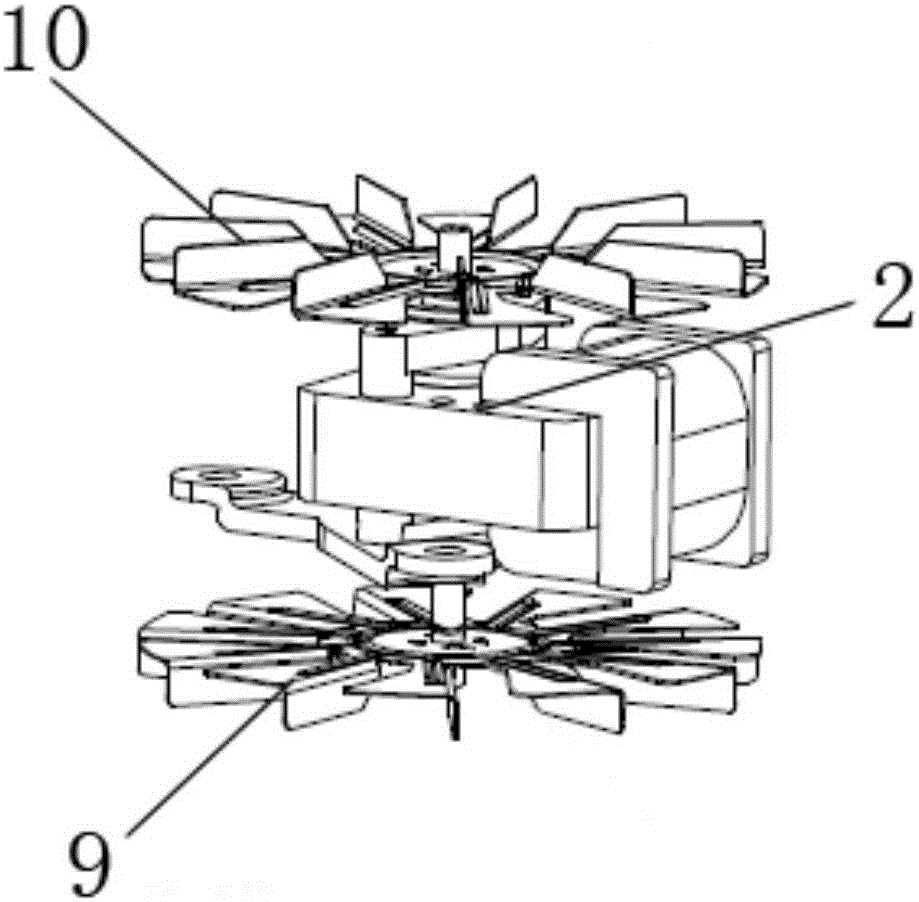

Air fryer with external cold air circulation

The invention relates to an air fryer with external cold air circulation. The air fryer comprises a shell, an upper mechanism, a lower mechanism, an airway plate, a temperature controller, a pot basket, a motor, a cold air wheel, a hot air wheel, a heating body, an air inlet and a plurality of air outlets, the cold air wheel is arranged in an interlayer between the shell and the upper mechanism in a manner of corresponding to the air inlet and is closer to the air inlet, the heating body comprises a heating element, a fixing piece, a supporting frame and a linking support, the heating element directly heats air in an exposed manner, the temperature controller is an adjustable flashing temperature controller and directly senses temperature of heated air inside, a container for containing food is a composite pot composed of the pot basket and a pot basket layer frame, and a cavity is formed at the bottom of the food. Cold air circulating quantity is increased, and heat loss of inside heating can be reduced; heating efficiency of a heating part is improved; a temperature control part is accurate in temperature sensing, so that temperature sensing delay is avoided; structure of the pot basket is simplified, so that separation of food and oil-water is facilitated, range and efficiency of heat convection are improved, and cooking efficiency is improved.

Owner:NINGBO CARELINE ELECTRIC APPLIANCE CO LTD

Machining method for deep hole reducing inner cavity

InactiveCN104001958AImprove rigidityGuaranteed accuracyBoring/drilling machinesSmall amplitudeSurface roughness

The invention relates to a machining method for a deep hole reducing inner cavity. Variable cross-section machining is carried out by the adoption of small amplitude, small cutting-in and ultrasonic frequency vibration through turning and clamping, the surface roughness of a workpiece is reduced, and the dimensional accuracy of the workpiece is improved. According to the machining method, the step of repeated cutter feeding and retreating processing for machining the complex deep hole reducing inner cavity part is changed, the machining time is effectively shortened, and the machining quality of the complex deep hole reducing inner cavity part is improved.

Owner:HARBIN DONGAN ENGINE GRP

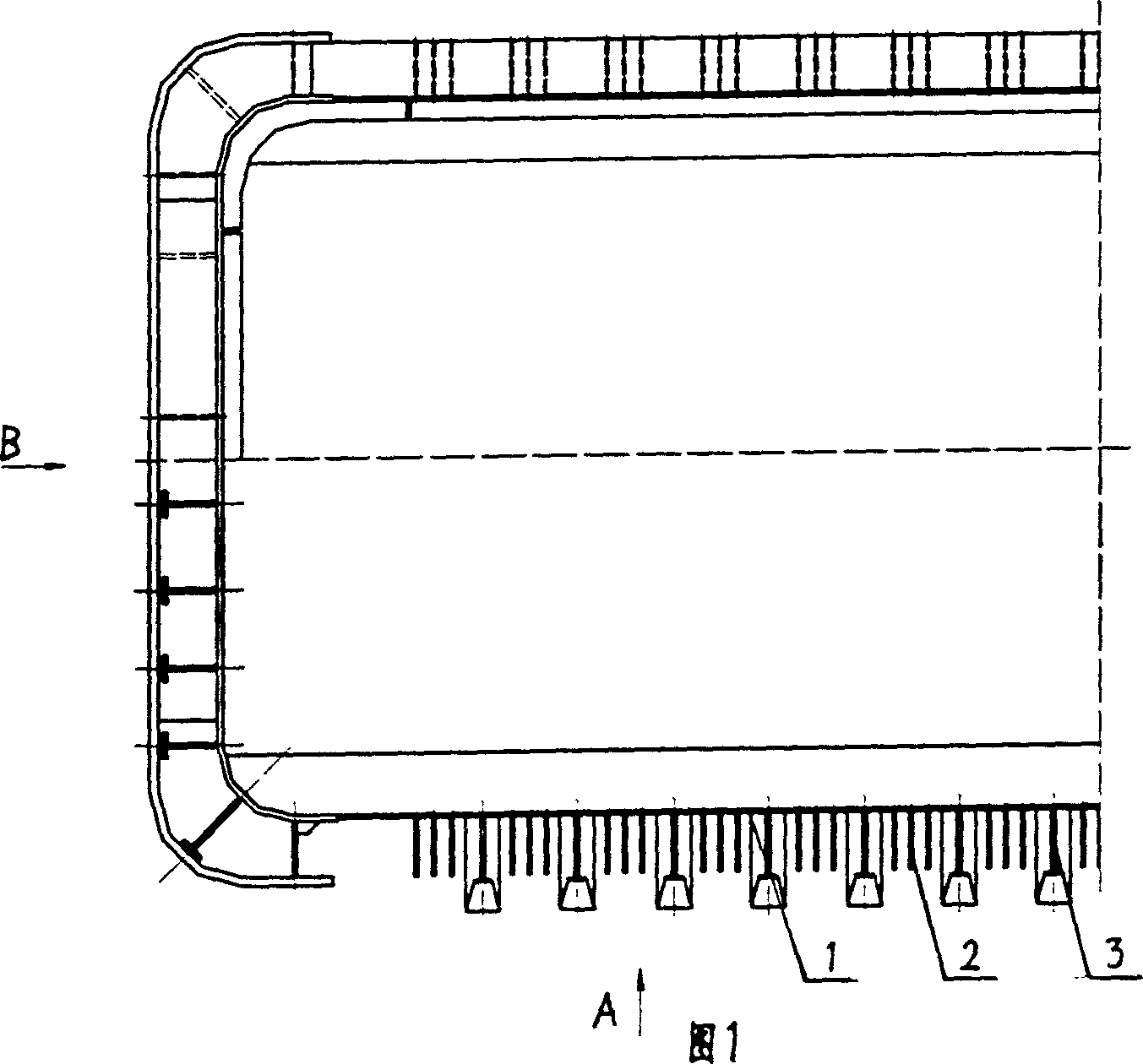

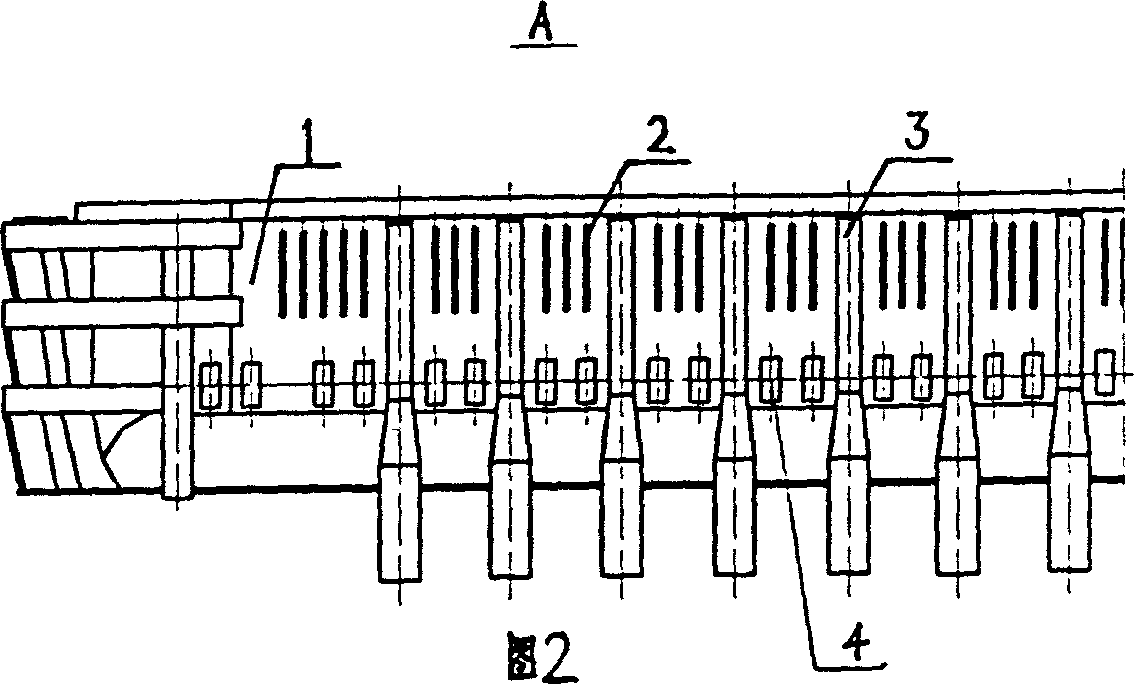

Method of enhancing heat radiation of large aluminium electrolytic bath shell

A method for improving the heat dissipation of the shell of great aluminium electrolyzer features that several heat radiating plates are welded to the external surface of said shell.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

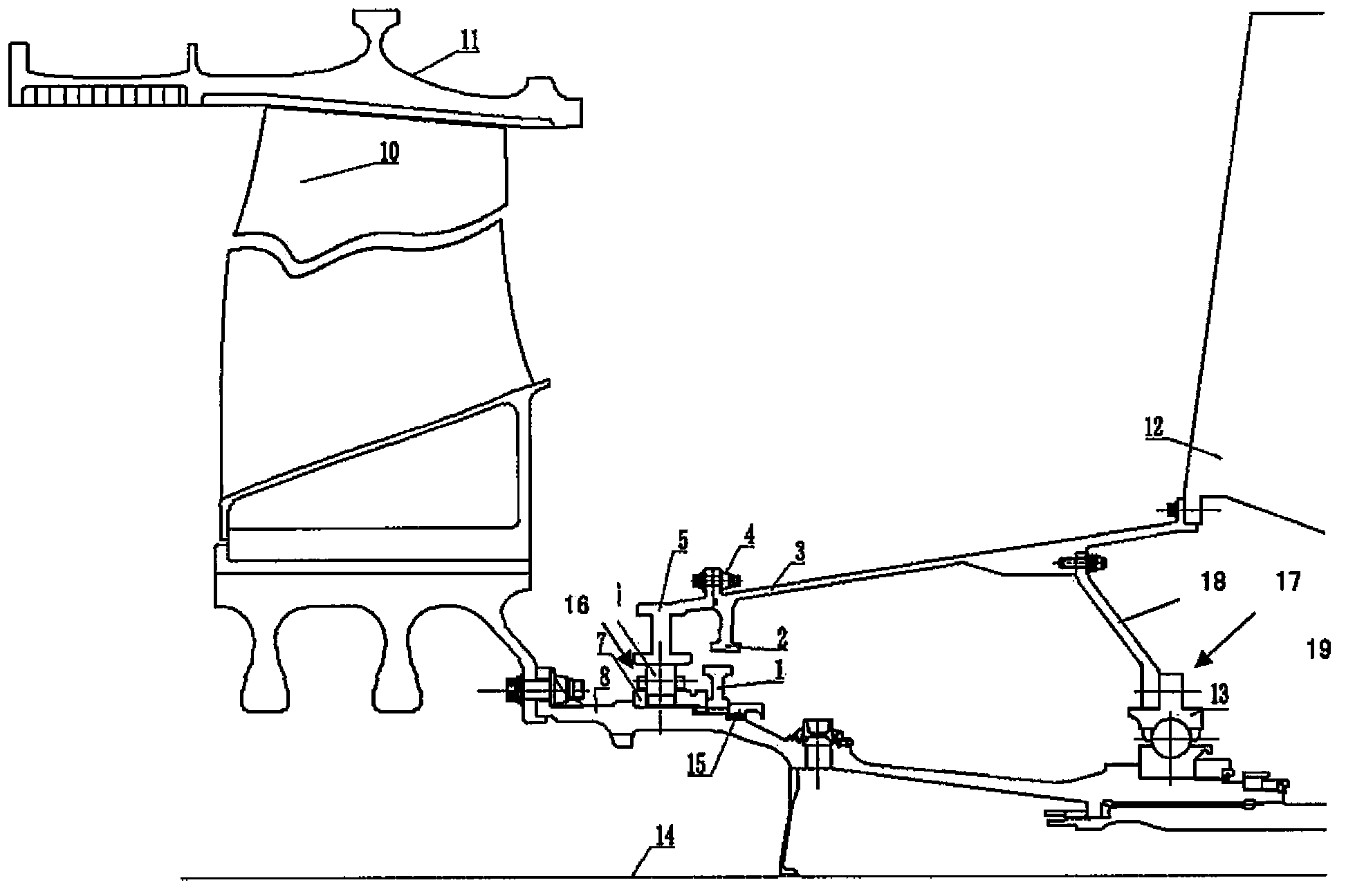

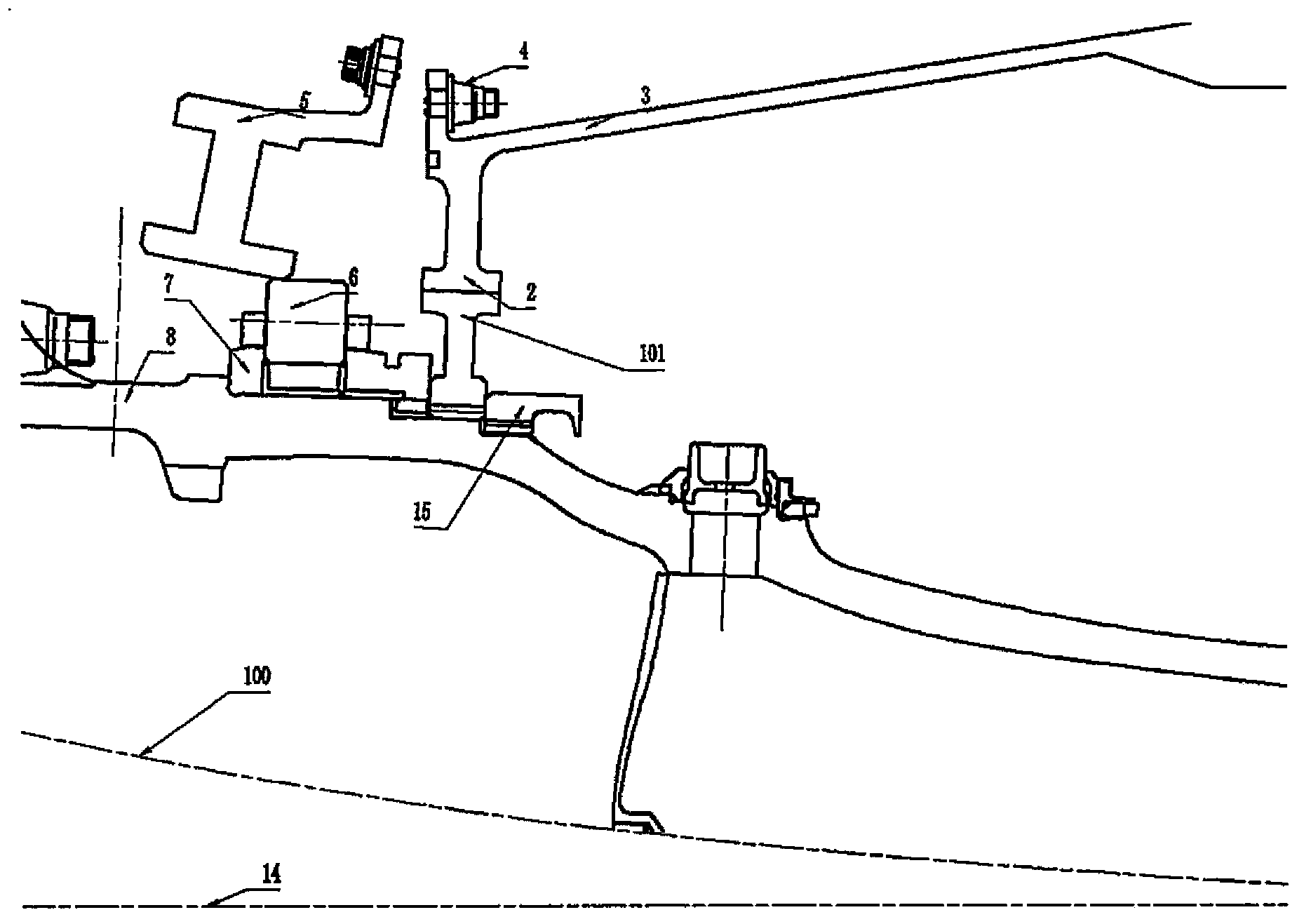

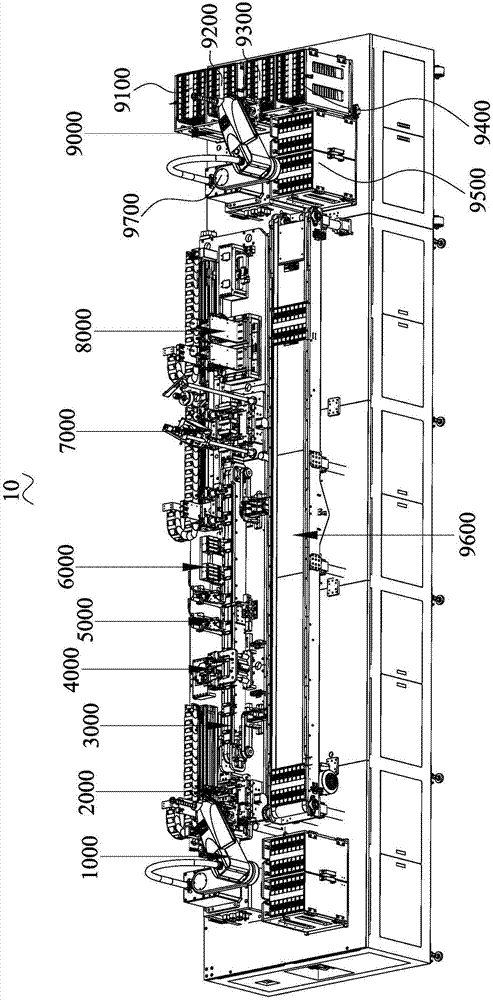

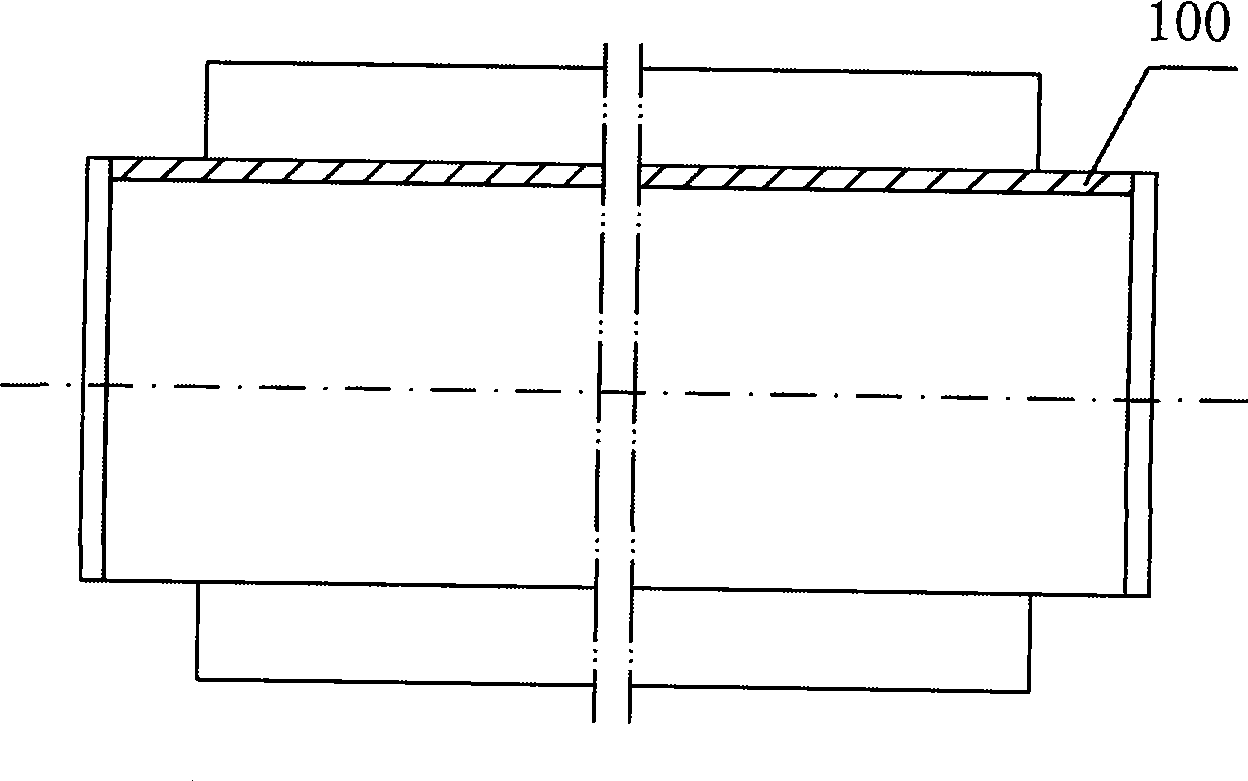

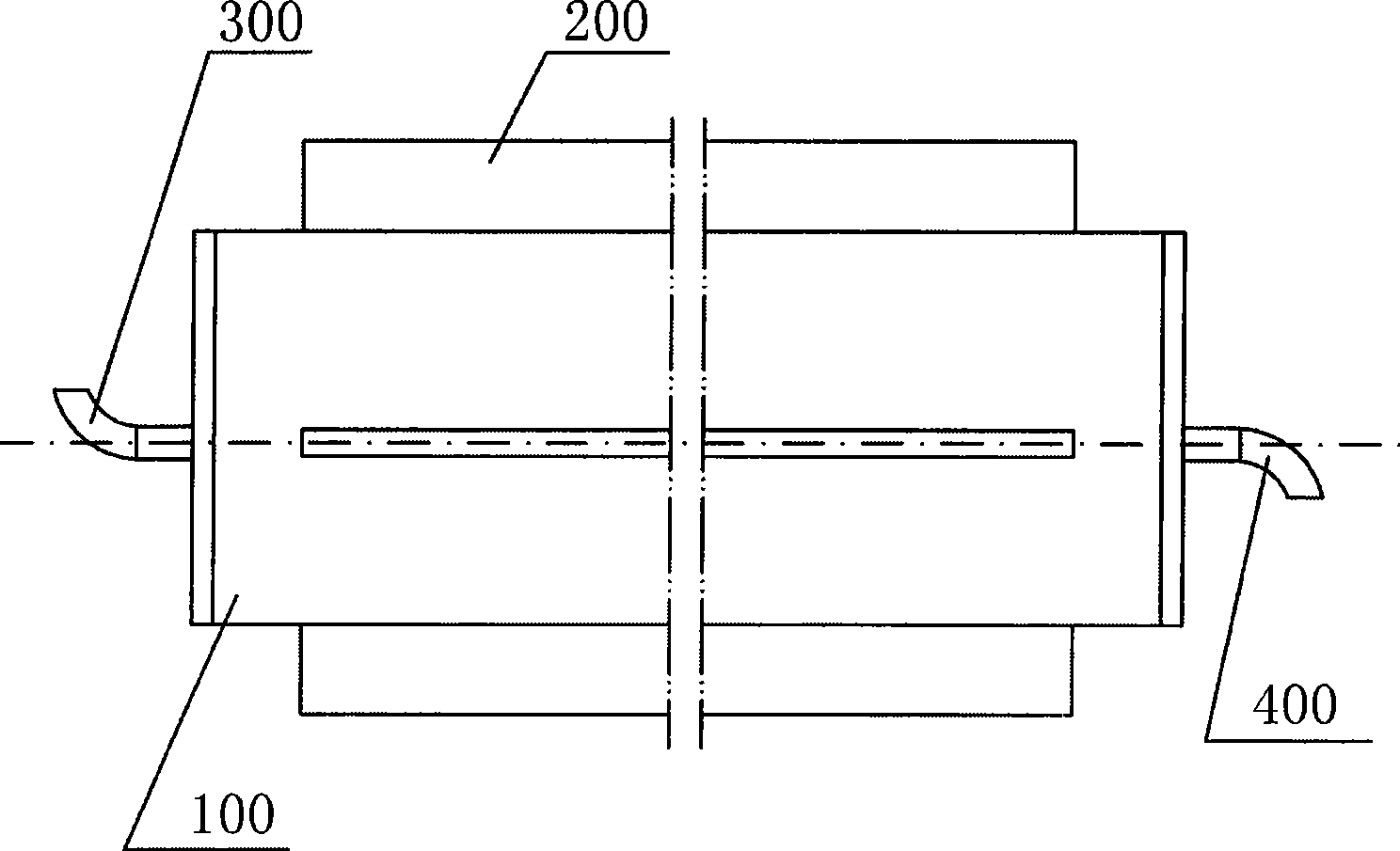

Fan failure braking device of aero-engine

ActiveCN103775212AReduce bending loadAvoid severe deformationGas turbine plantsJet propulsion plantsAviationFan blade

A fan failure braking device of an aero-engine comprises a fan shaft, a fan blade, a bearing support piece and a bearing component, wherein a rotor brake disc is arranged on the fan shaft; the fan blade is mounted on the fan shaft; one end of the bearing support piece is mounted on an aero-engine casing, the bearing support piece is provided with a stator brake disc which circumferentially surrounds the rotor brake disc and is radially spaced from the rotor brake disc; one end of the bearing component is coupled with the other end of the fan shaft, and connected with the bearing support piece by a predetermined bending moment; when the fan blade fractures, the fan shaft deflects outwards, so that when the mutation bending moment between the bearing component and the bearing support piece exceeds the predetermined bending moment, the bearing component and the bearing support piece are disconnected, and thus the rotor brake disc and the stator brake disc are jointed. when the fan blade fails and fractures, rub-impact occurs between the rotor brake disc and the stator brake disc, limits the radial displacement of bending of the fan shaft and reduces the rotational speed of the fan shaft and the FBO (Fan Blade Out) load.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Control method of collision-prevention electronic device

InactiveCN107454780AAvoid damageEasy to fixNon-rotating vibration suppressionCasings/cabinets/drawers detailsEngineeringCollision prevention

The invention provides an anti-collision electronic device control method, which relates to the field of electronic devices. The anti-collision electronic device control box includes a fixed plate, the four corners of the bottom of the fixed plate are fixedly equipped with connection blocks, the bottom of the connection block is fixedly connected with the top of the first pressure rod, and the top of the first pressure rod The bottom end passes through the first shock absorber and extends to the inside of the first shock absorber to be fixedly connected with the top of the first pressure block. The anti-collision electronic device control box drives the second splint to clamp and fix the front and back of the box body through the second shock absorber, and drives the first splint to clamp and fix the left and right sides of the box body through the screw rod, so that the box body Reliably fixed, through the buffering and shock absorption of the first shock absorber and the buffer, the fixed plate drives the box body to move along the surface of the guide rod, thereby effectively cushioning the box body and making it difficult for the box body to detach from the base, thereby The electronic devices inside the protective box are not easily damaged, which effectively reduces the cost of use.

Owner:石国华

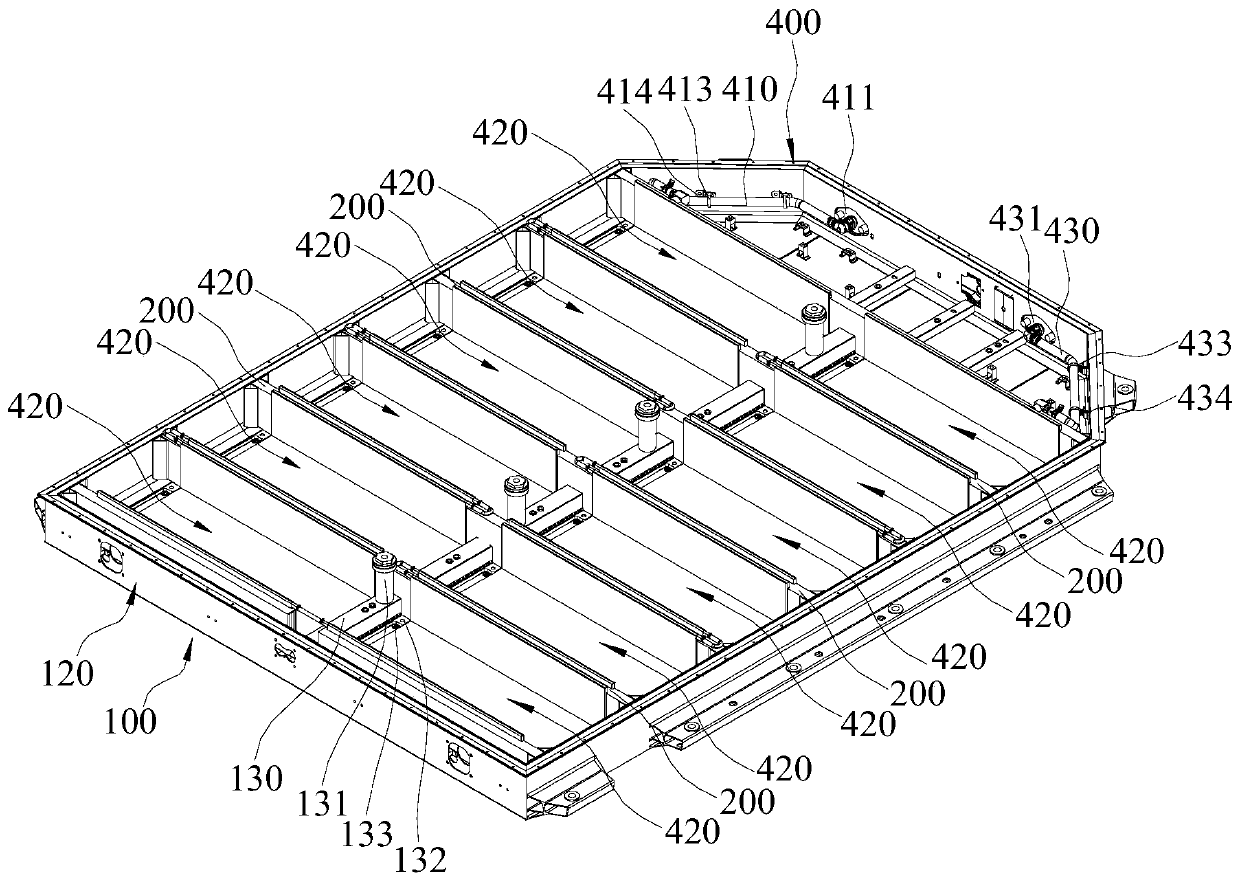

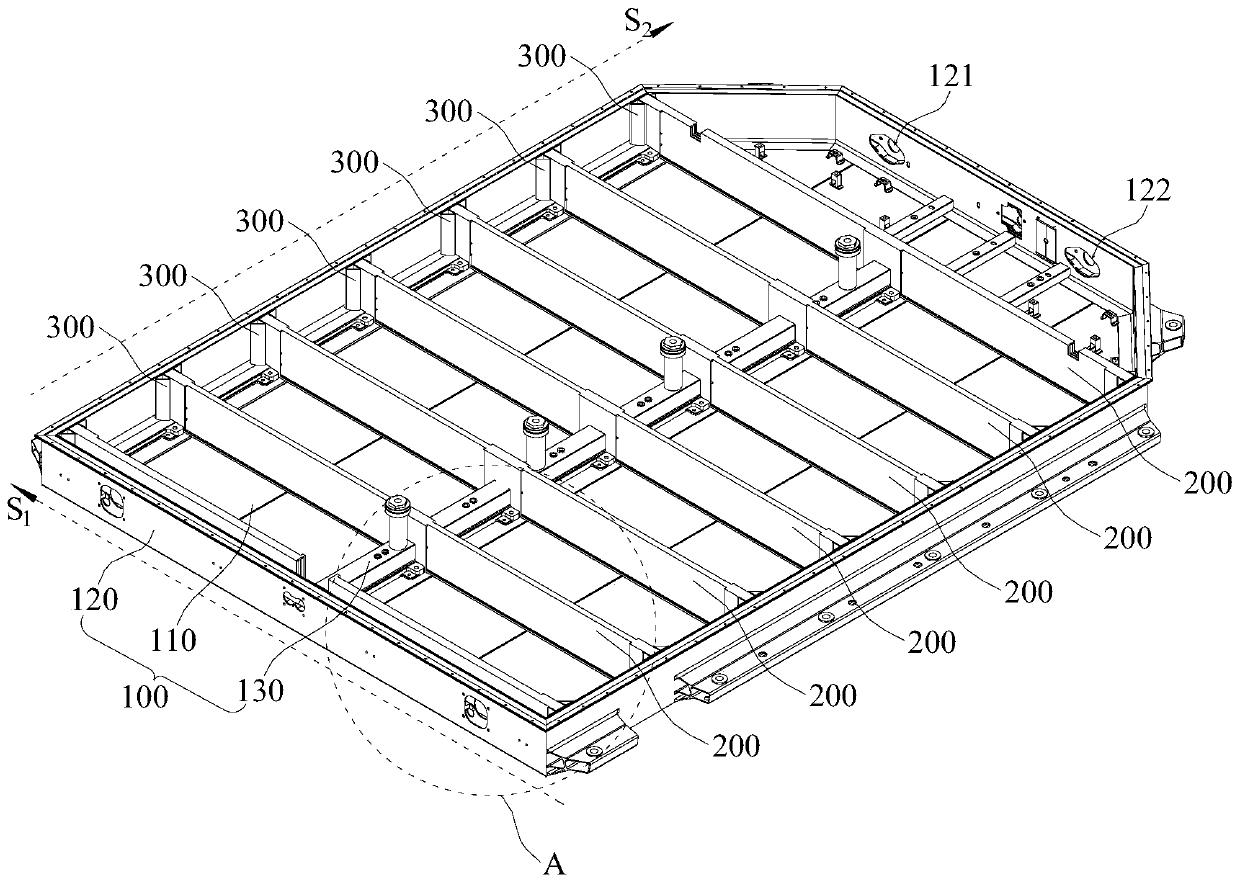

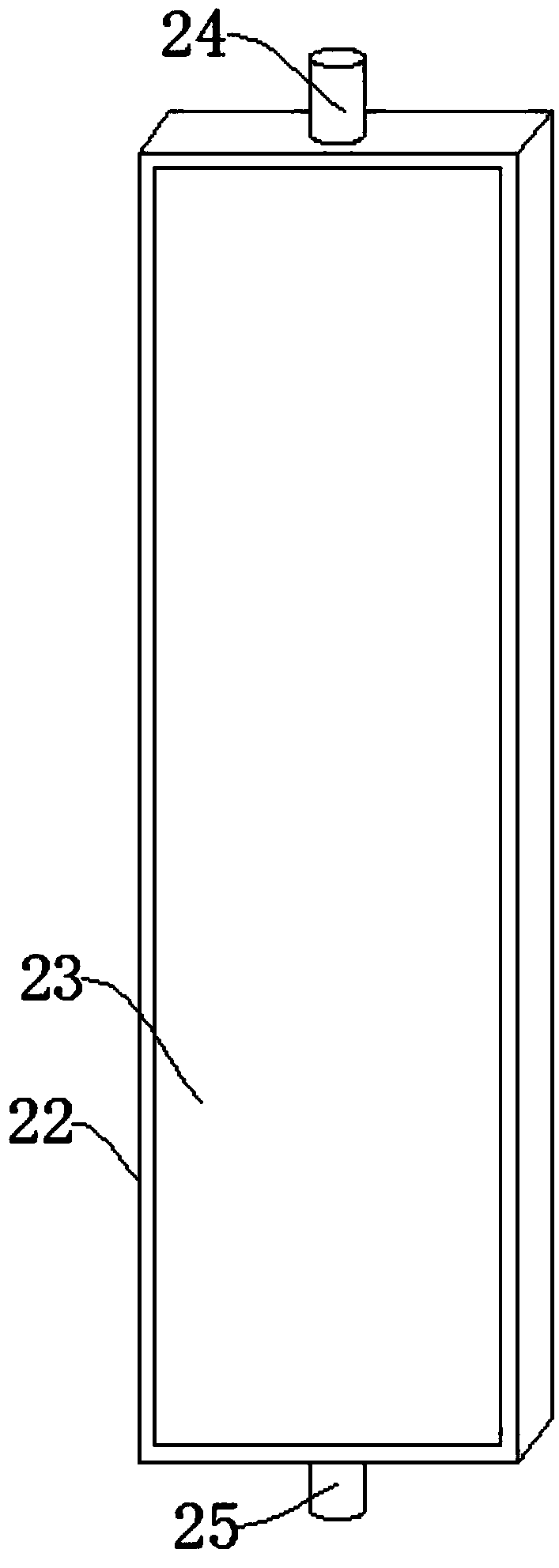

Battery shell and battery system

PendingCN110571378AAvoid short circuitImprove the forceCell component detailsBatteriesStress distributionEngineering

The invention discloses a battery shell and a battery system. A cover body covers a shell, so that battery packs are located in a sealed space, and primary protection is provided for battery packs. When the shell is impacted, a large amount of impact force can act on the side wall of the shell, and two ends of each reinforcing beam abut against the inner wall of the shell respectively, so that thestructural strength of the side wall of the shell is effectively enhanced, and therefore, the side wall of the shell is prevented from being seriously deformed due to the impact force; the impact force applied to the shell can be transferred and concentrated on the reinforcing beams, so that the impact force is transferred, and therefore, stress distribution on the shell is improved, and the structural integrity and good air tightness of the shell are ensured, the battery packs are always in a safe and stable environment, and the short circuit and even fire and explosion accidents of the battery packs due to the air tightness failure or piercing of the shell are avoided.

Owner:GAC AION NEW ENERGY AUTOMOBILE CO LTD

Water-based flexographic printing ink for cigarette tipping paper printing and preparation method thereof

ActiveCN106928771AImprove antibacterial propertiesTroubleshoot MigrationInksFreeze thawingDispersion stability

The invention discloses a water-based flexographic printing ink for cigarette tipping paper printing and a preparation method thereof. The water-based flexographic printing ink is composed of a modified acrylic emulsion, pigment and filler, a wetting dispersant, a transfer printing agent, a defoaming agent, deionized water, and a cosolvent. The modified acrylic emulsion is a novel acrylic emulsion formed by copolymerization of an imported high quality emulsifier, acrylate and special functional monomers, and has the advantages of fantastic calcium ion stability, dilution stability, mechanical stability and freeze-thaw stability, and small pollution to the environment. The water-based flexographic printing ink for tipping paper printing provided by the invention is non-toxic and tasteless, has quick drying speed and good dispersion stability, the printing product is free of deformation and edge curling, and has bright color and excellent antibacterial properties. The printing product has few residual monomer and low odor, is green and environment-friendly, the printing ink can be used cooperatively with a flexographic press, the printing speed can reach 250-300m / min, and the machine speed is doubled than the traditional intagliotipping paper printing press, thus greatly improving the production efficiency, and saving the production cost.

Owner:JIANGSU TANGCAI PRINTING INK SCI TECH CO LTD

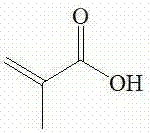

Method for preparing micro-nano-channels based on liquid-gas equilibrium polymer nano-channels self-building mechanism

InactiveCN102621805AImprove uniformityAvoid severe deformationDecorative surface effectsNanotechnologyPolymeric surfaceMicro nano

The invention discloses a method for preparing micro-nano-channels based on a liquid-gas equilibrium polymer nano-channels self-building mechanism. The method comprises the following steps of: first, preparing a nano grating structure of SU-8 photoresist by using a grating template and a nano-imprint lithography technology; then, spin-coating a layer of release agent on the grating structure of the SU-8 photoresist; and finally, coating a layer of SU-8 photoresist on the grating structure of the SU-8 photoresist coated with the release agent by a slit type extrusion gluing way, wherein the micro-nano-channels are formed by a coated SU-8 photoresist layer which is balanced with the air pressure trapped in a grating under the action of surface tension, and the preparation of a micro-nano flow control system is finished. According to the method, high pressure and high temperature are not needed, so that deformation and damage of a polymer grating structure are avoided; processing successrate is improved; and by the method, the sizes of the micro-nano-channels can be controlled by adjusting the surface tension of a polymer.

Owner:HEFEI UNIV OF TECH

Electric-induction foot cutter capable of cutting feet in bulk

InactiveCN107377827AEasy to installQuick and stable installationTransformers/inductances coils/windings/connectionsInductorEngineering

The invention discloses a cutting machine for inductive elements capable of cutting legs in batches, which comprises a base, a placing platform is fixedly installed on the top of the base, a placing groove is opened on the top of the placing platform, a fixing plate is placed inside the placing groove, and a fixing plate is placed inside the fixing plate. There are blind holes on the top, and the top of the base and both sides of the placing table are fixedly installed with slide rails, the top of the slide rails is slidably installed with support rods, the top of the support rods is fixedly connected with the bottom of the top plate, and the top of the top plate is fixedly installed There is an electric box, and the inside of the electric box is fixedly equipped with a motor. In the present invention, by setting the cooperation between the driving wheel and the driven wheel, when the driving wheel rotates, it will drive the driven wheel to rotate, and when the driven wheel rotates, it will drive the rotating rod to rotate, so that the gear rod and the rack are matched, so that the motor The chassis is moved to batch cut the inductance components on one line, which saves time and effort by cutting corners in batches.

Owner:石国华

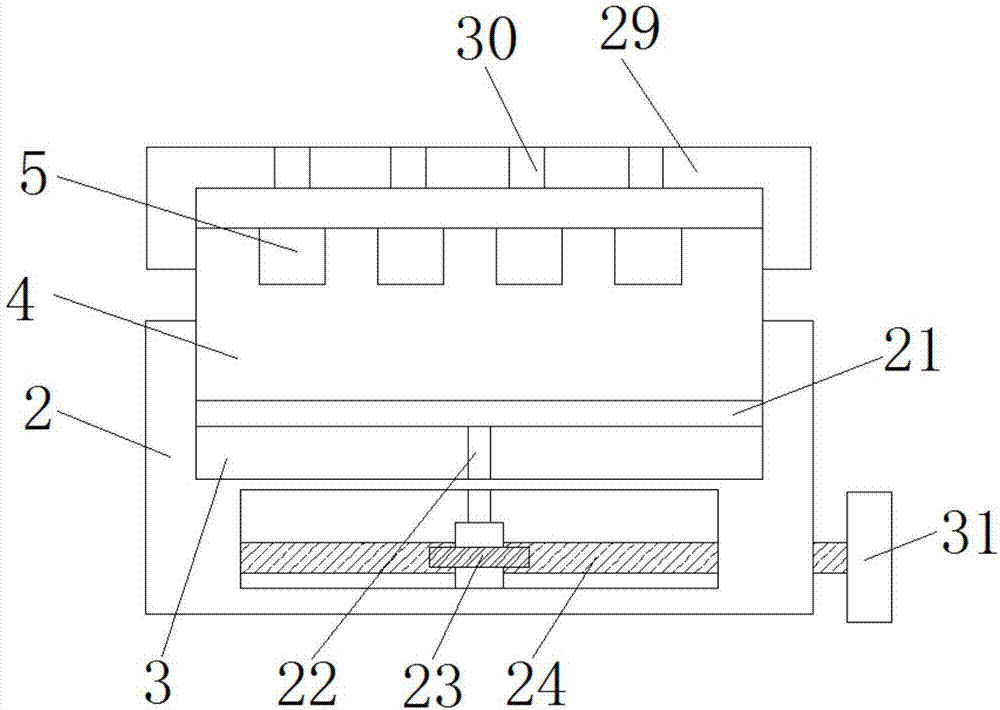

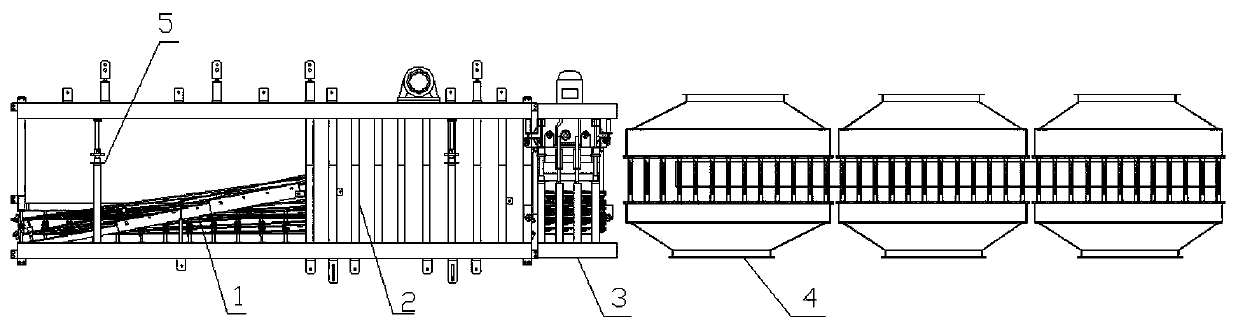

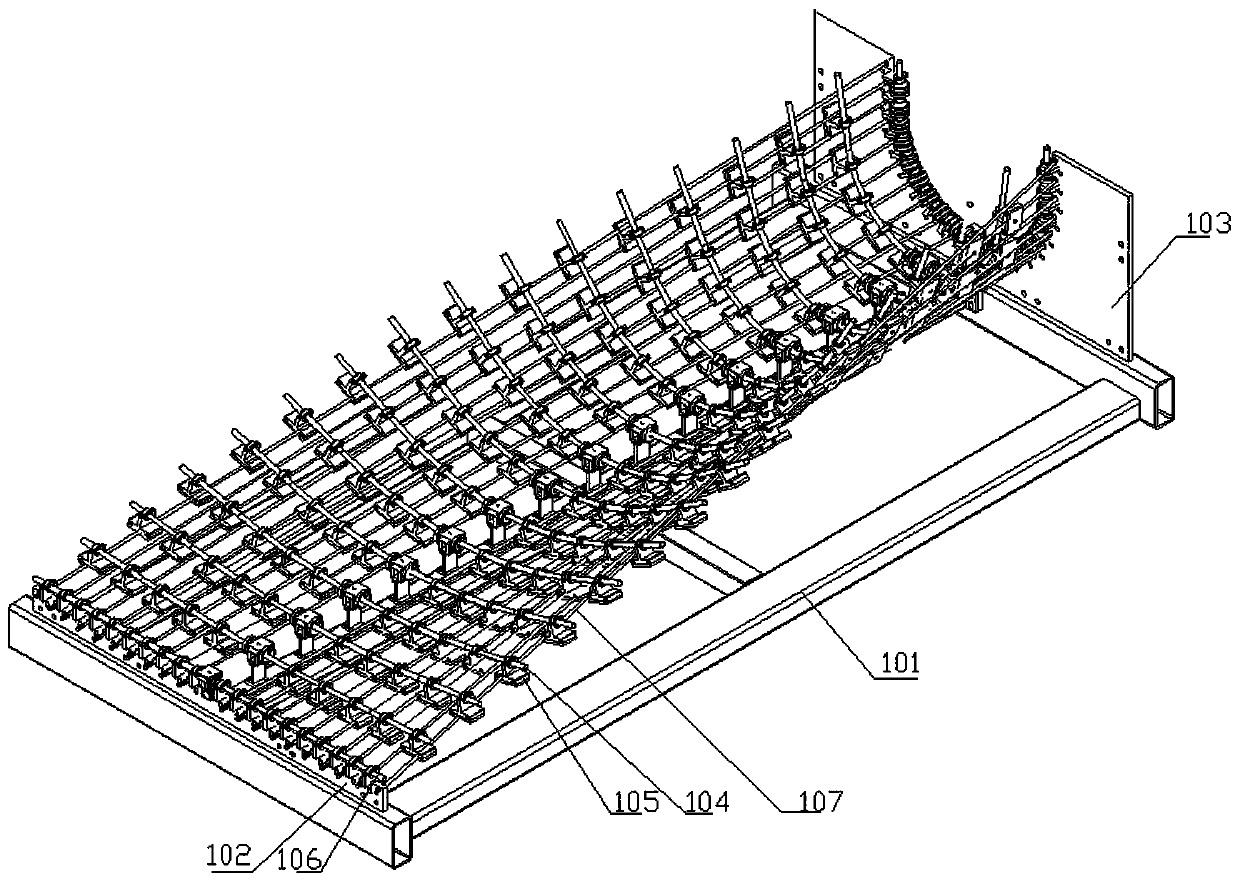

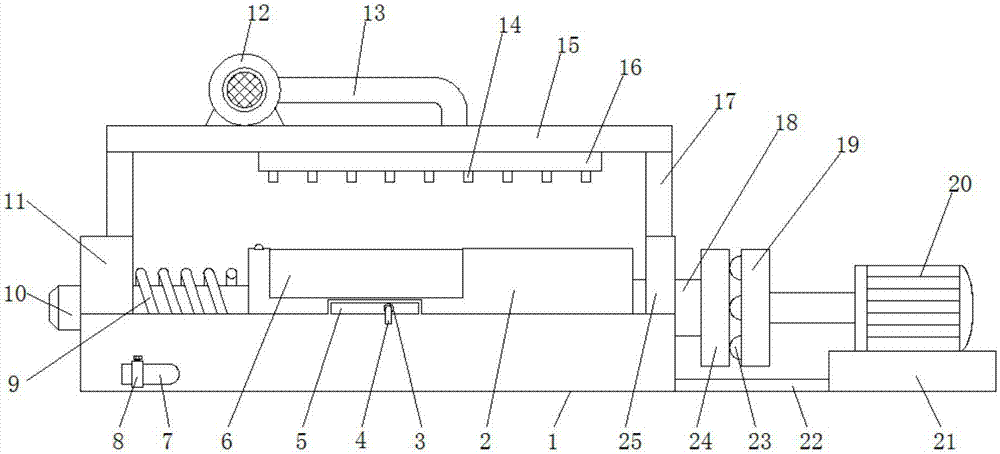

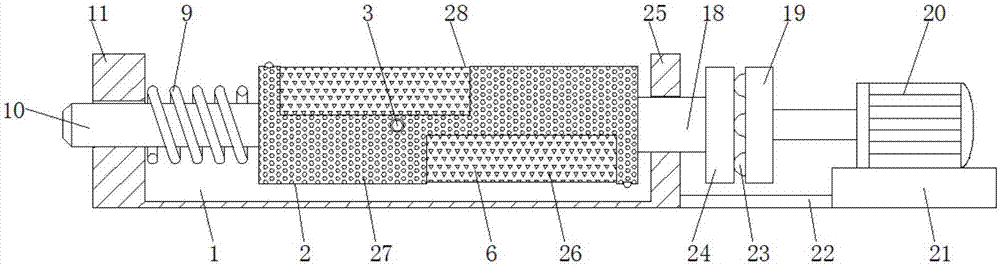

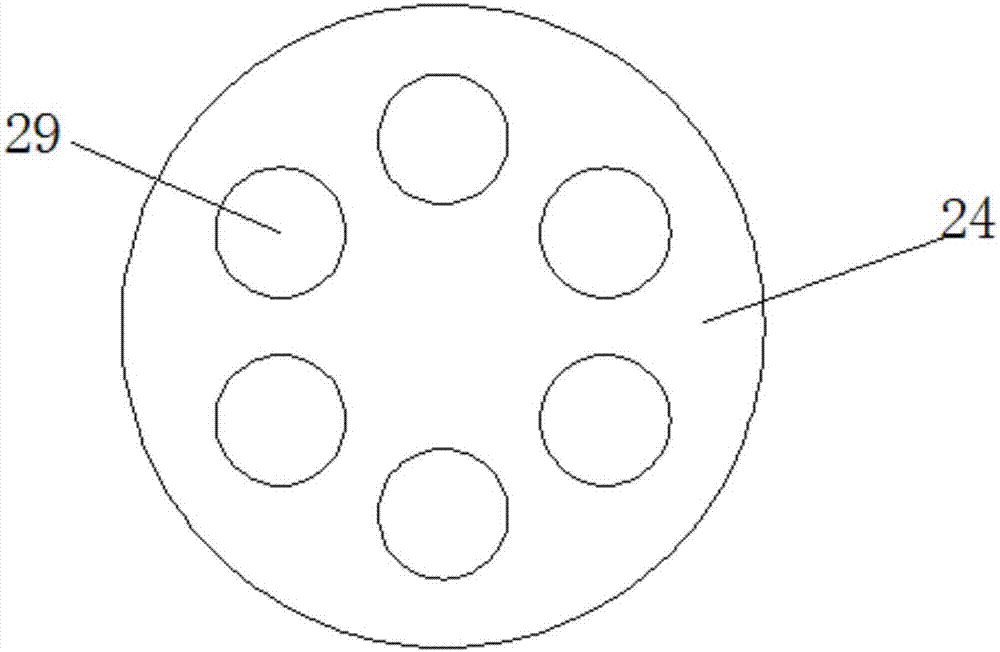

Flexible shaft toughening equipment and flexible shaft toughening forming method for bent glass

ActiveCN110498594AAvoid severe deformationQuality improvementGlass reforming apparatusGlass tempering apparatusEngineeringToughening

The invention discloses flexible shaft toughening equipment and flexible shaft toughening forming method for bent glass. The equipment comprises a transition section, a forming section and a toughening section, the transition section comprises a plurality of tensioned flexible cables and transition roller ways installed on the flexible cables, the flexible cables and the transition roller ways form a forming net, and in the process that heated glass passes through the forming net, the glass is gradually formed; the forming section is provided with a plurality of upper forming arc plates and aplurality of lower forming arc plates, the upper forming arc plates and the lower forming arc plates are respectively provided with forming roller ways or a plurality of rotatable forming roller wheels, and a forming channel is formed between the forming roller way or the plurality of forming roller wheels on the upper forming arc plates and the forming roller way or the plurality of forming roller wheels on the lower forming arc plates; and the equipment can also comprise a shape stabilizing section to correct the shape of the curved glass. By utilizing the equipment provided by the invention, the curved glass meeting the requirements is obtained after the glass is subjected to a gradual change stage, a forming stage and a shape stabilizing stage, and toughening is performed, so that theprecision and quality of the curved glass are improved.

Owner:LUOYANG LANDGLASS TECH CO LTD

Plate cutting apparatus

InactiveCN105751172AAvoid severe deformationGuaranteed cutting accuracyWork benchesTelescopic cylinderDimensional precision

The invention discloses a plate cutting apparatus, comprising a basic support, a cutting rack, a feeding platform, a discharging platform, a cutting unit mount and a plurality of cutting units; wherein all the cutting rack, the feeding platform, the discharging platform and the cutting unit mount are fixed on the basic support; a plurality of descending telescopic cylinders are discretely distributed at the top of the basic support; a plurality of ascending telescopic cylinders are discretely distributed on the cutting rack; the ascending telescopic cylinders and the descending telescopic cylinders are in one-to-one correspondence and are used for clamping the top and bottom of a plate, respectively; the multiple cutting units are mounted on the cutting unit mount to cut the plate. The plate cutting apparatus can be used to solve the problem that an existing plate cutting apparatus has low dimensional precision of produced plates.

Owner:WENDENG LANDAO ARCHITECTURAL ENG CO LTD

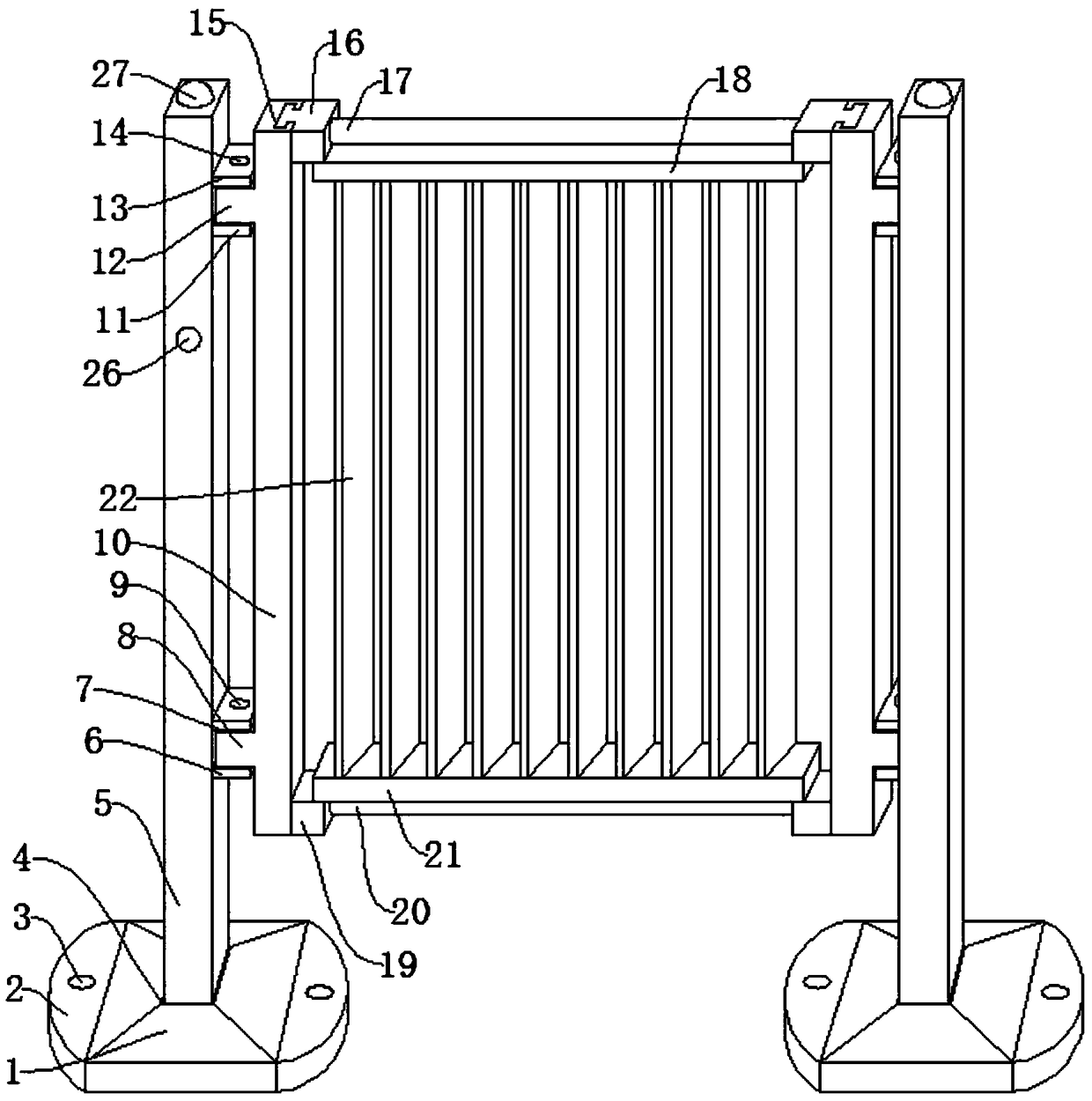

Workpiece thickness detection system and electrical core OCV test equipment thereof

The invention discloses a workpiece thickness detection system and battery cell OCV test equipment. Among them, the workpiece thickness detection system includes: a workpiece thickness measurement placement platform, a workpiece thickness measurement drive unit, a workpiece thickness measurement lifting frame, a workpiece thickness measurement lower platen, a lower platen pressure adjustment structure, and a workpiece thickness measuring device. The workpiece thickness measuring lower platen is movable on the workpiece thickness measuring elevating frame; the workpiece thickness measuring drive part drives the workpiece thickness measuring elevating frame, and the workpiece thickness measuring device is used to identify the distance between the workpiece thickness measuring platform and the workpiece thickness measuring lower platen; The pressure regulating structure of the pressing plate is connected with the lower pressing plate of the workpiece thickness measurement, and the pressure adjusting structure of the lower pressing plate is used for providing an adjustable pulling force opposite to the direction of gravity of the lower pressing plate of the workpiece thickness measuring. The workpiece thickness detection system of the present invention can adaptively adjust the downforce of the pressing plate for different types of workpieces, prevent the workpiece from being seriously deformed due to excessive extrusion force, and can accurately measure the actual thickness of the workpiece.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

Safety guard railing for road and bridge

ActiveCN109505241AGuaranteed to see clearlyBlock lightsBridge structural detailsRoadway safety arrangementsTraffic accidentEngineering

The invention discloses a safety guard railing for roads and bridges. The safety guard railing comprises a fixed seat, a fixed plate and a bolt hole. The safety guard railing has the beneficial effects that through the arrangement of a light barrier, a first rotating rod, a second rotating rod and a reflective coating, the device can effectively block the light from vehicles in the opposite direction, it is ensured that the driver can see the road information clearly, and the occurrence of traffic accidents is avoided; through the arrangement of a first lower transverse plate and a second lower transverse plate, a lower rotating shaft, a first upper transverse plate, a second upper transverse plate, an upper rotating shaft, a first fixed pin, a second fixed pin, a vertical plate, a first strong spring and a second strong spring, the car impact is flexibly buffered by the device, severe deformation of car is avoided, and the damage to the personnel in the vehicle is reduced, through thearrangement of a gravity sensor, a controller, a solar panel, a signal transmitter and a warning light, the warning light can be lighted up and give warning and the information of the fallen guard railing is sent to remote monitoring personnel for timely maintenance when the guard railing falls down, thereby reducing the road potential safety hazard.

Owner:王娟 +2

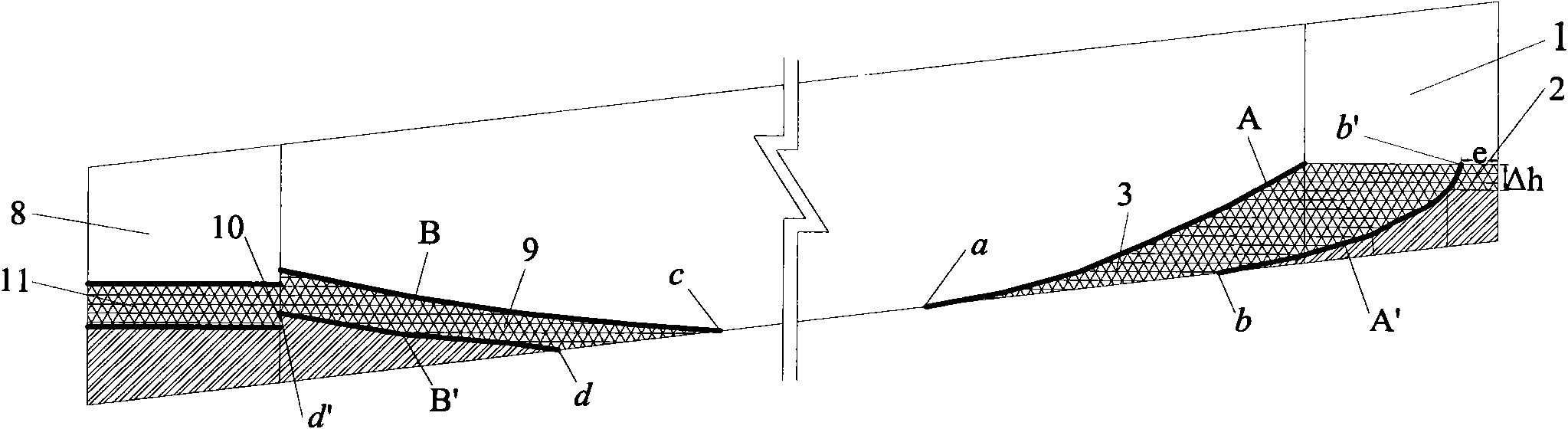

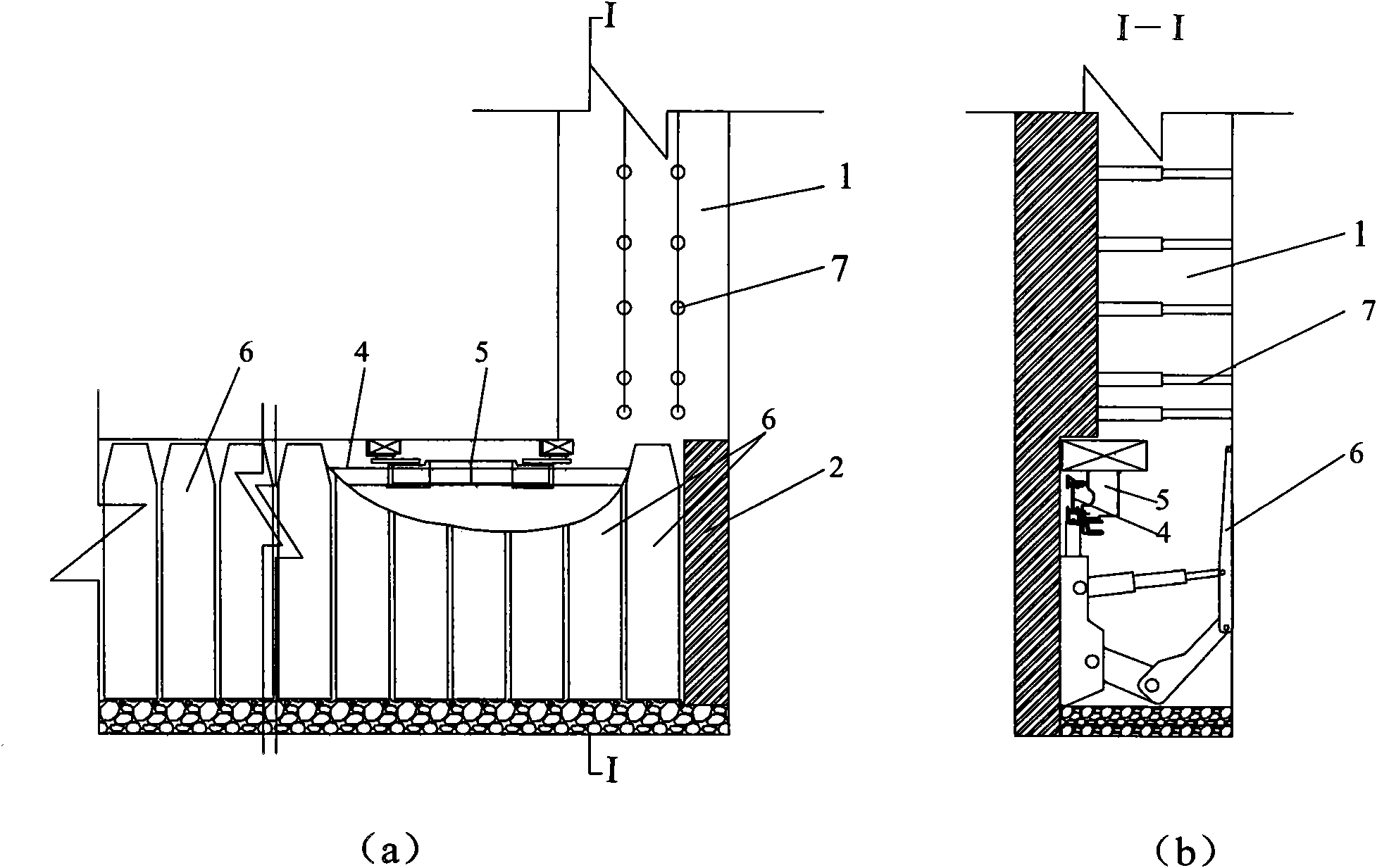

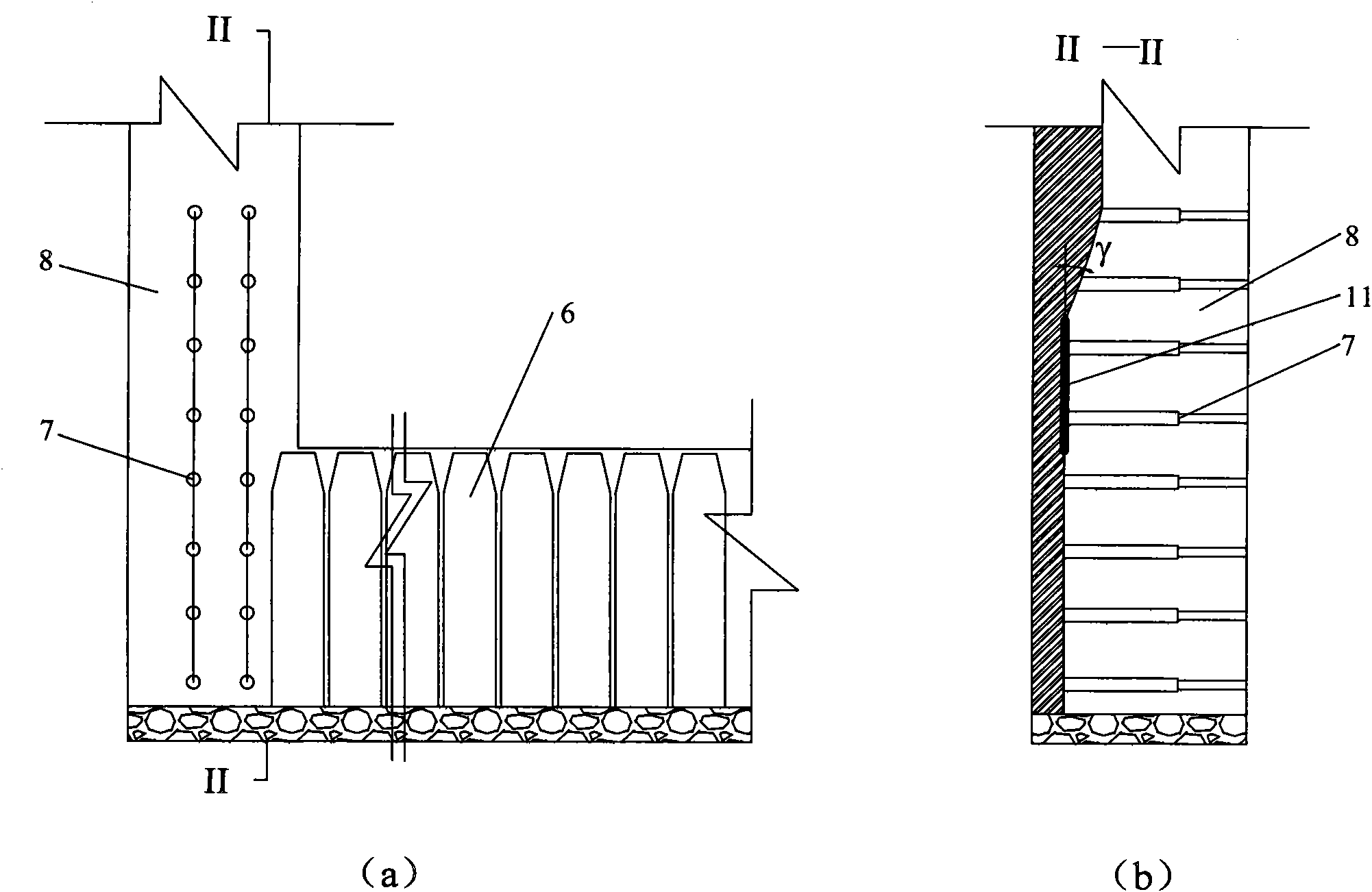

Method for recovering large mining height fully-mechanized face end part ground coal

InactiveCN101936163AEnsure safe operationReduce in quantityUnderground miningSurface miningEngineeringBuilding construction

The invention discloses a method for recovering large mining height fully-mechanized face end part ground coal. The method comprises the following steps of: setting up 2 to 3 groups of supports on one side close to a working face in a return air drift of a large mining height fully-mechanized face; according to the daily advancement degree, performing manual advancing bottoming on the ground coal along the advancing direction of the working face in a transport drift of the large mining height fully-mechanized face, wherein the bottoming length is 4 to 6 meters, the bottoming height is 1 to 1.5 meters, and the bottoming gradient gamma is less than 10 degree; performing ascending coal cutting from the transport drift to the return air drift or performing descending coal cutting from the return air drift to the transport shift by adopting a coal mining machine; and after finishing the coal cutting of the return air drift by the coal mining machine, manually recycling a step remained close to an external upper in the return air drift to ensure that the ground coal on the upper end part and the lower end part of the large mining height fully-mechanized face is recovered continuously during the mining on the working face. The method has a simple process, convenient construction and easy operation, improves the coal mining rate of the large mining height face by about 4 percent, reduces influences caused by the ground coal to fully-mechanized production, and has extensive practicability.

Owner:CHINA UNIV OF MINING & TECH

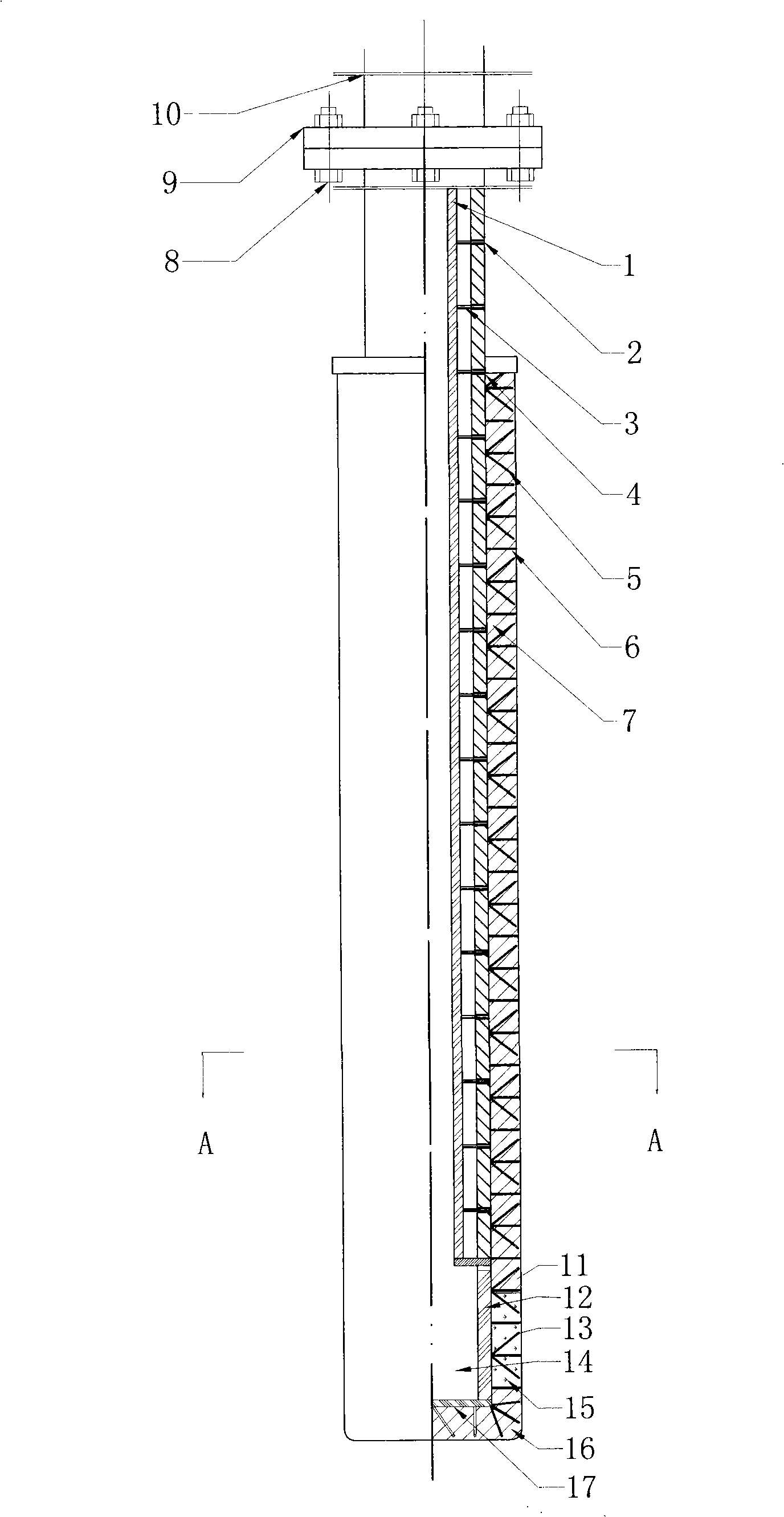

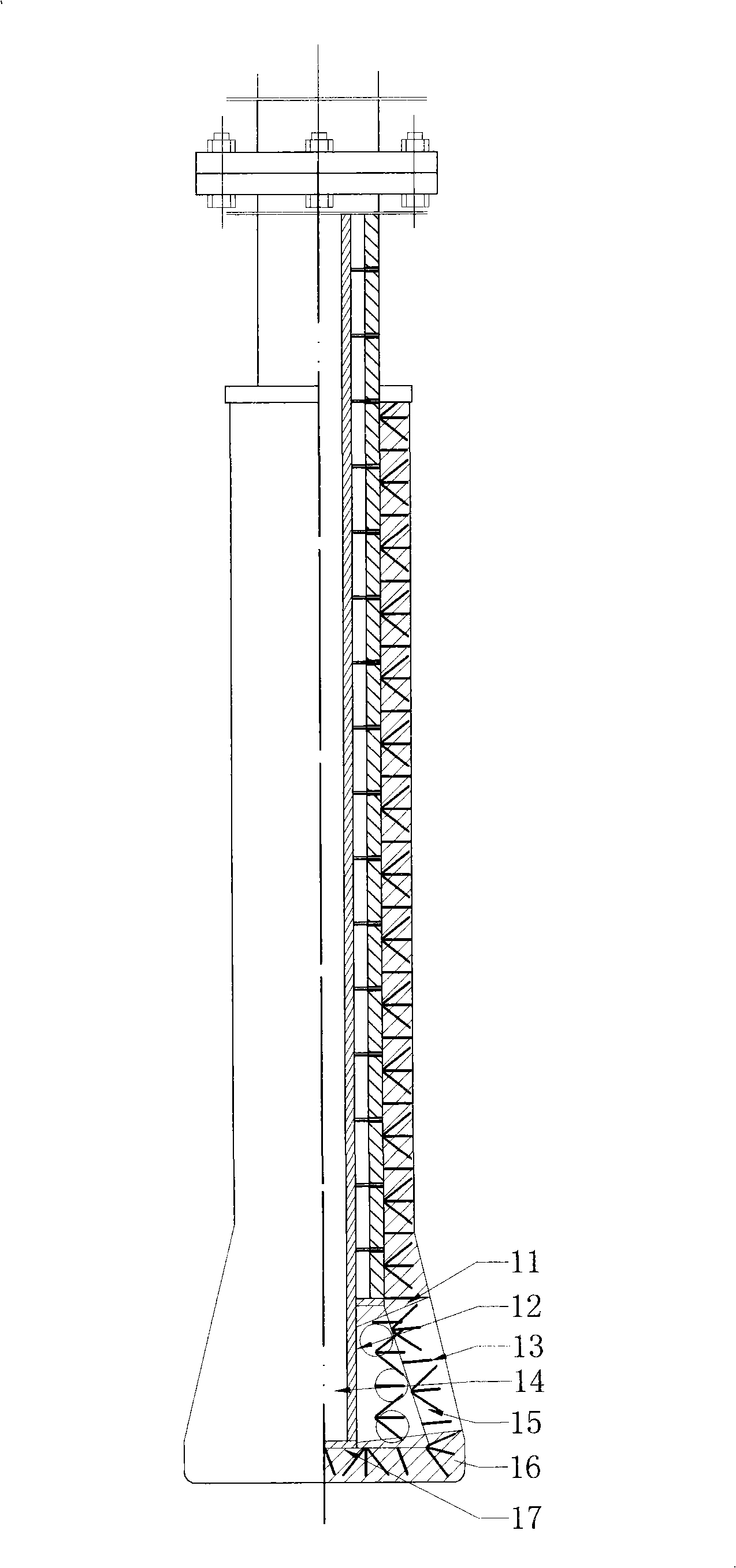

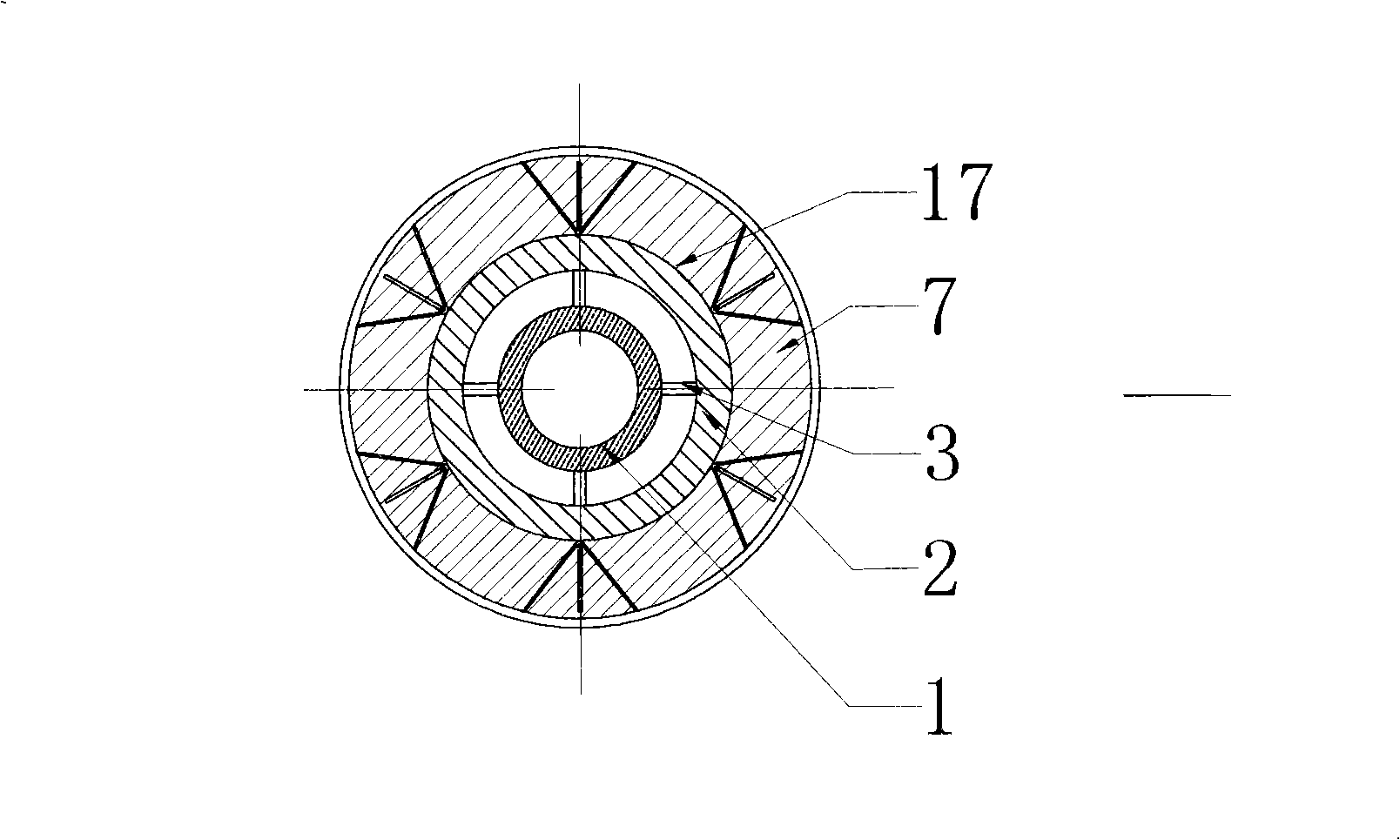

Argon-blowing spray gun for refining ladle and making method thereof

The invention discloses an argon blowing lance which includes a metal lance rod and a lance body that are connected together by a flange; the lower part of the lance body is provided with a dispersion nozzle; the lance body includes a main tube, a reinforcing tube, a plurality of bridging welding pieces, a plurality of rivet pieces and the working liner of a fire-proof material; the reinforcing tube is sheathed on the outside of the main tube; besides, a plurality of bridging welding pieces are uniformly welded between the reinforcing tube and the main tube; the rivet pieces of V shape and double V-shape are respectively and alternatively arranged in the working liner of the fire-proof material outside the reinforcing tube along the surrounding direction and the coaxial direction of the reinforcing tube; besides, the top points of the two are respectively welded with the outer surface of the reinforcing tube. The measures of the invention of sheathing the reinforcing tube and the bridging welding pieces outside the main tube of the core of the lance improve the intensity and the rigidness of the core structure of the lance; the rivet pieces of V shape and double V-shape enhance the bonding intensity between the core of the metal core of the lance and the working liner of the fire-proof casting material; the dispersion nozzle improves the blowing stirring intensity and finally achieves the goals of prolong the service life of the lance and improving the use performance of the lance.

Owner:武钢集团有限公司 +1

Vehicle-mounted mobile phone placing rack capable of being fixed firmly

InactiveCN107351779AQuick placementReduce vibration effectsVehicle componentsEngineeringMobile phone

The invention discloses a vehicle-mounted mobile phone placing rack capable of being fixed firmly. The vehicle-mounted mobile phone placing rack comprises a support plate, wherein one side of the support plate is provided with a placing groove, and the inner part of the support plate is provided with a containing cavity; an extrusion block is movably mounted at the groove bottom of the placing groove; one end of the extrusion block penetrates through the support plate and extends to the inner part of the containing cavity and is fixedly connected with one side of a pressure plate; and one side of the pressure plate is fixedly connected with one end of a spring. By arranging the placing groove, when a mobile phone is put in the placing groove, the extrusion block moves to the inner part of the containing cavity, and then the pressure plate is matched with a pressure rod to extrude a first piston, so that the first piston moves; when the first piston moves, the liquid in a hydraulic box is extruded, so that the liquid pushes a second piston and a push rod to move; when the push rod moves, a rotating rod is driven to rotate; and when the rotating rod rotates, a clamping plate is pressed on the surface of the mobile phone, thereby achieving the effects of quickly placing and clamping the mobile phone.

Owner:石国华

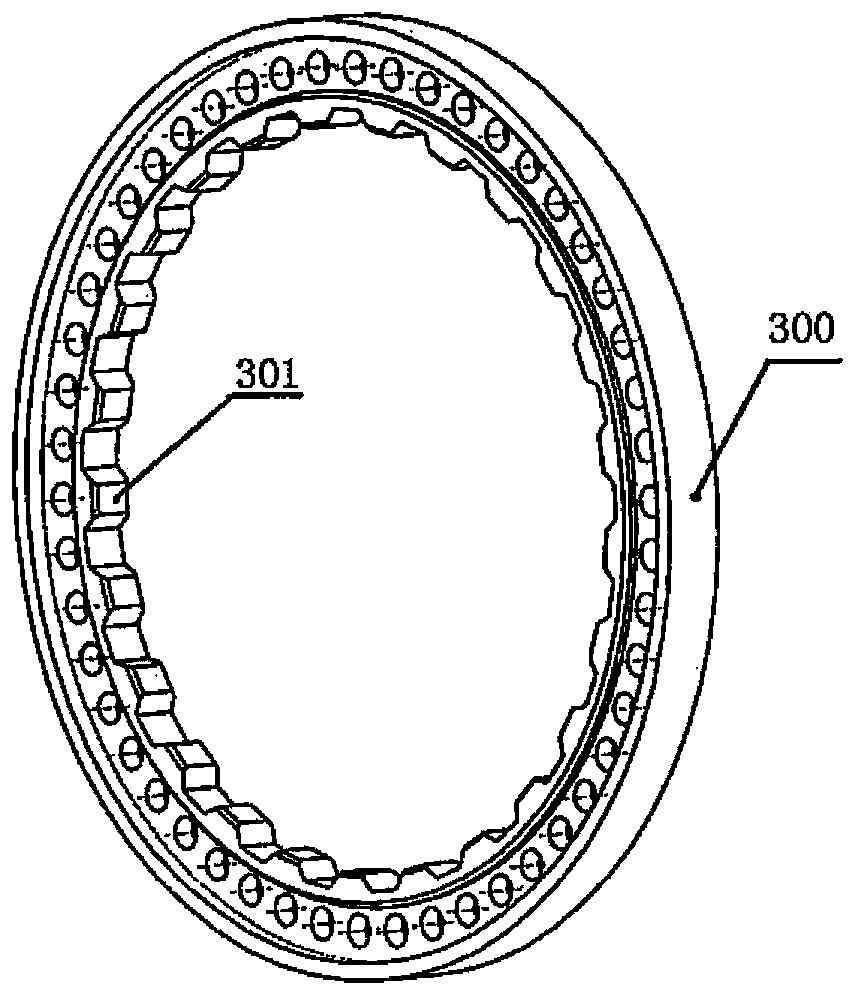

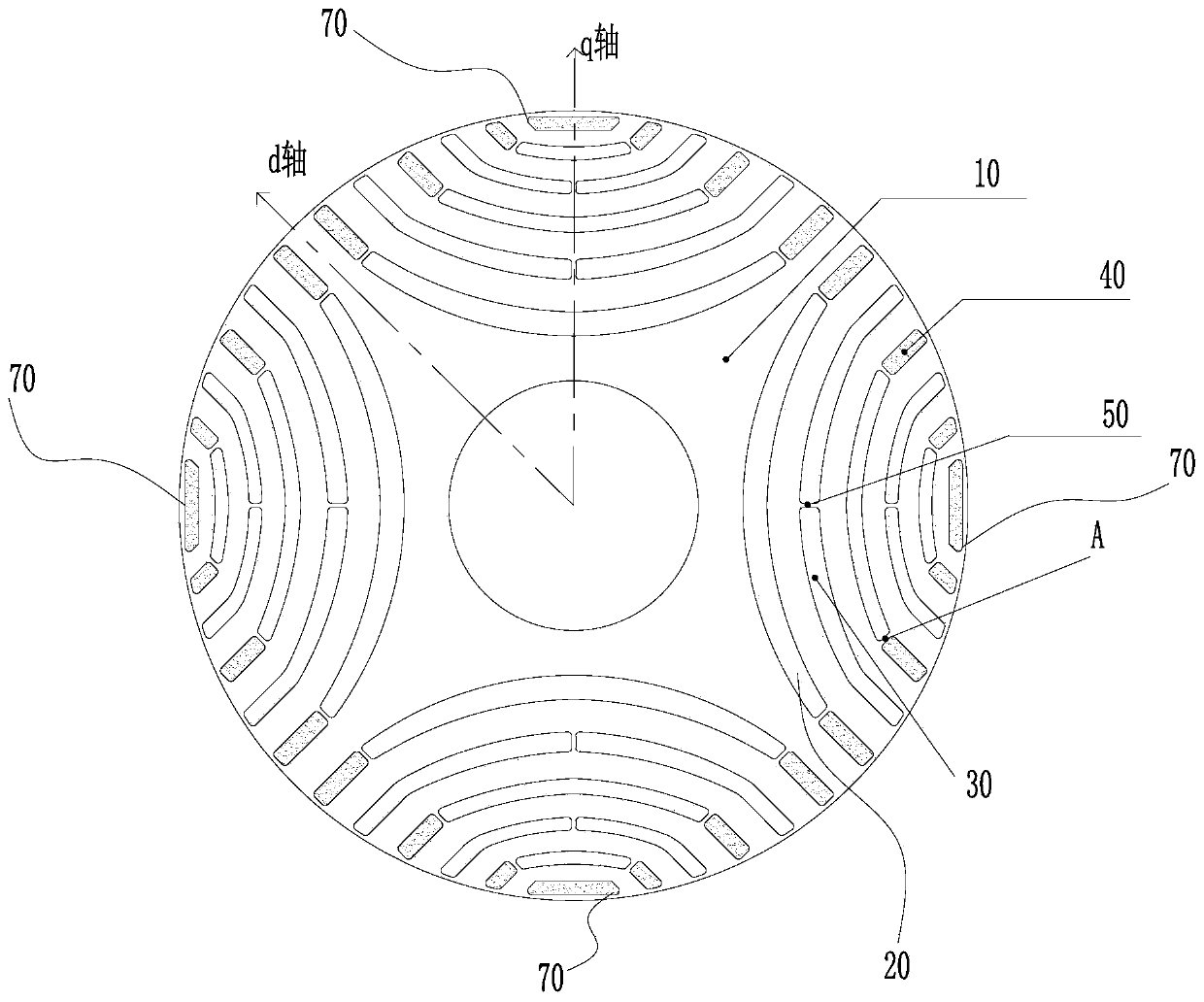

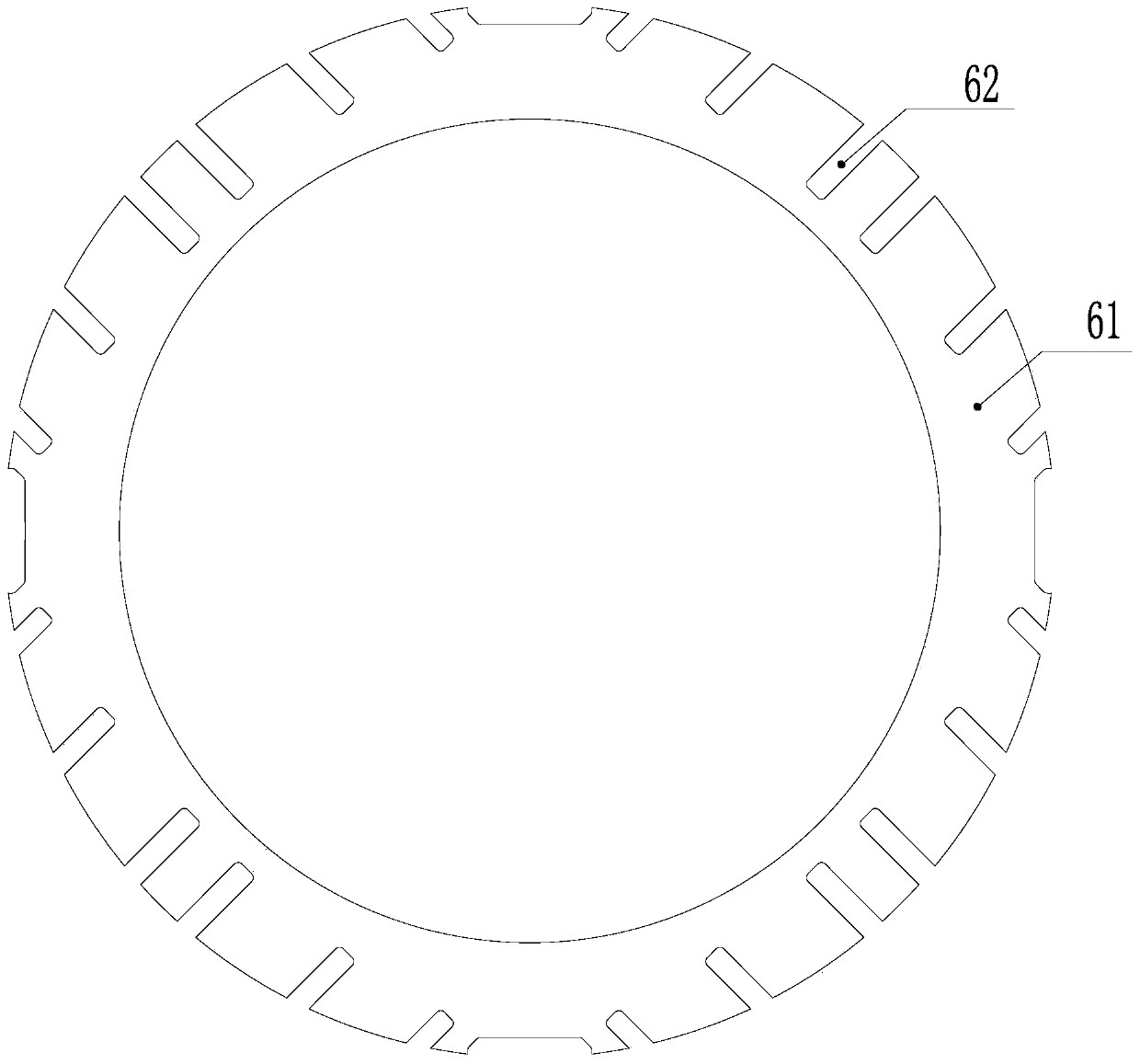

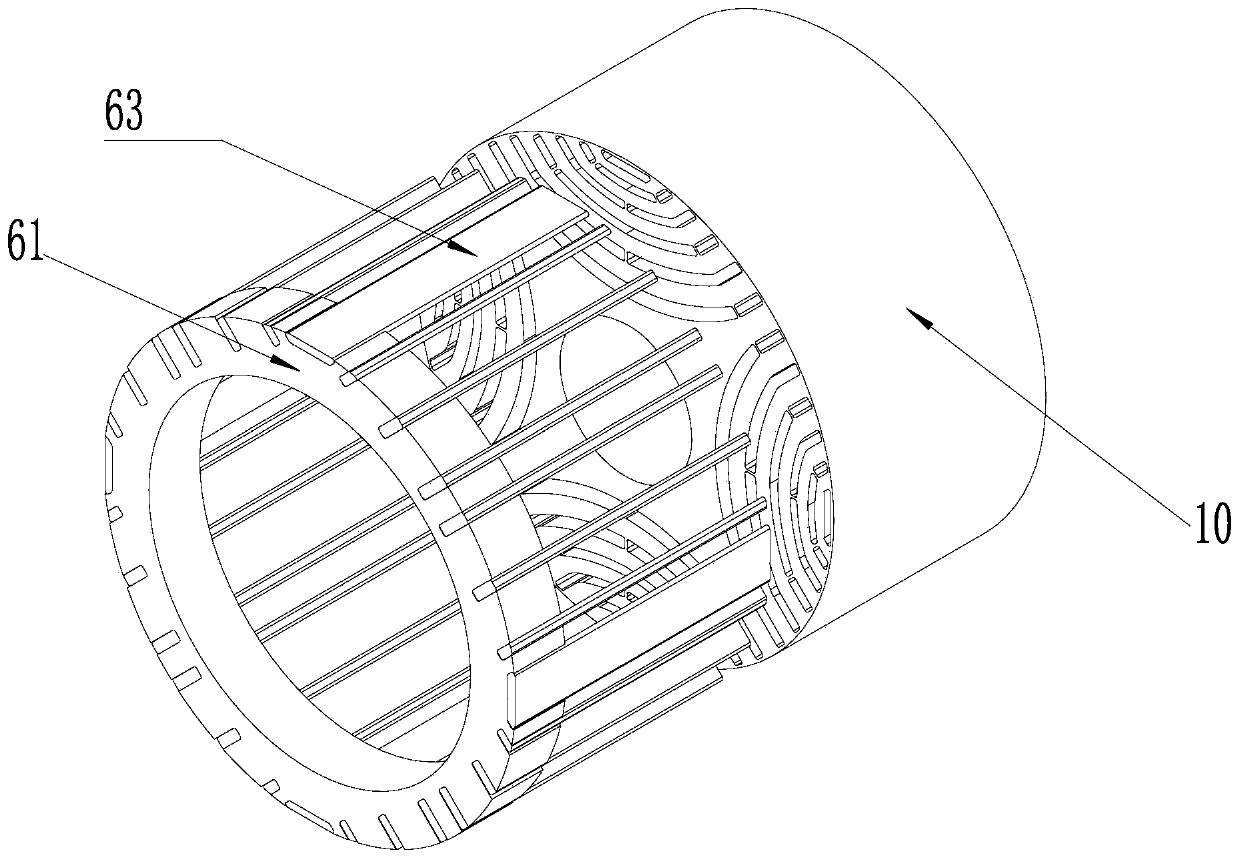

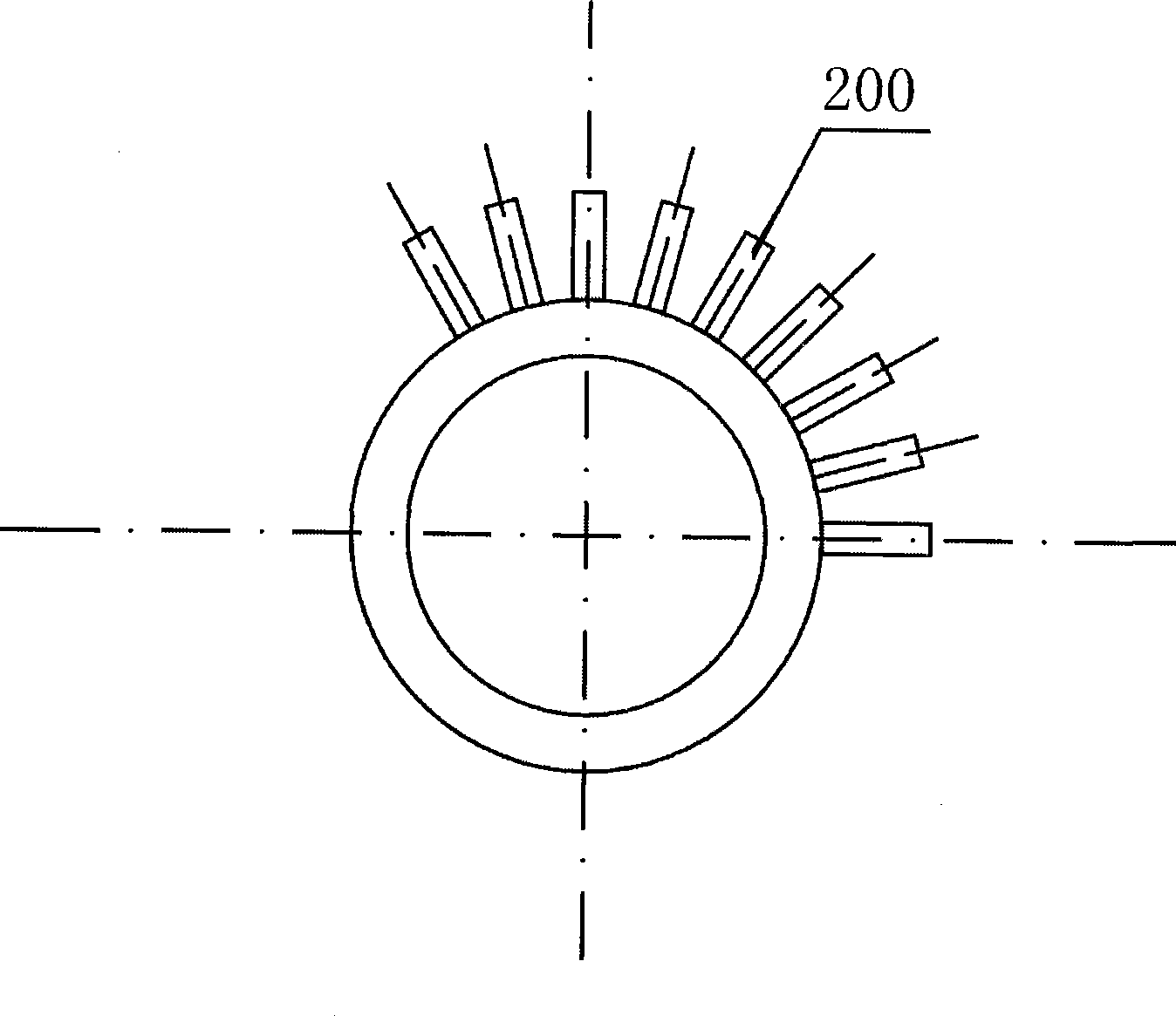

Synchronous reluctance motor rotor structure, motor and compressor

ActiveCN110138115AImprove efficiencyReduce manufacturing costMagnetic circuit rotating partsManufacturing cage rotorsSynchronous reluctance motorPhysics

The invention provides a synchronous reluctance motor rotor structure, a motor and a compressor. The synchronous reluctance motor rotor structure comprises a rotor core, first type slit grooves and second type slit grooves are set in the rotor core, the first type slit grooves and the second type slit grooves are alternately arranged in the q axis direction of the rotor core, wherein two ends of each of the first type slit grooves are provided with two filling slit grooves, and the second type slit grooves are air grooves. By setting the first type slit grooves and the second slit grooves, setting the filling slit grooves at two ends of the first type slit grooves and setting the second type slit grooves to be the air grooves, the efficiency of the motor with the rotor structure can be effectively improved, at the same time, the rotor structure can avoid the severe deformation during manufacturing, the amount of materials used for manufacturing the rotor structure can be reduced, and therefore, the production cost of the motor is effectively reduced.

Owner:GREE ELECTRIC APPLIANCES INC

Electronic component efficient fast water-saving-type washing method

InactiveCN107442504AWash thoroughlyReduce laborNon-rotating vibration suppressionDrying gas arrangementsWater savingCircular disc

The invention discloses a high-efficiency, fast, water-saving cleaning method for electronic components, comprising a water tank, the left side of the water tank is fixedly connected with a left plate, the right side of the water tank is fixedly connected with a right plate, the left plate and the right plate A vertical plate is welded on the upper surface of each vertical plate, a top plate is welded between the tops of the two vertical plates, and a gas distribution pipe is installed on the bottom surface of the top plate, and both ends of the gas distribution pipe are closed structures. The high-efficiency, fast and water-saving cleaning device for electronic components drives the second disc to rotate through the driving motor, and then uses the protrusion on the second disc to push the cleaning cylinder to the left of the driving motor. When cleaning the tank, the cleaning cylinder moves to the right under the elastic force of the return spring, and then the cleaning cylinder reciprocates in the horizontal direction, so that the electrical components placed in the cleaning cylinder are cleaned more thoroughly, which improves the cleaning efficiency and reduces the labor force of workers. labor force.

Owner:石国华

Manufacture method of multiple straight fin heat exchange tube

InactiveCN101386122ASimple manufacturing processReduce manual labor intensityTubular elementsPipingWork in process

The invention discloses a manufacturing method of a multi-straight-fin heat exchange tube, which is characterized by comprising the steps of: (1) sizing the shape of outer straight fins of a base tube; (2) welding the outer straight fins of the base tube, namely, putting a half-finished work piece on a special working rack, arranging a plug provided with a water inlet tube, a water outlet tube and a valve at two ends of the work piece, connecting the water inlet tube and the water outlet tube, inletting circulating cooling water, welding a first pair of straight fins in a two-side level and matching welding manner, turning the tube for 90 degrees after finishing the welding of the first pair of straight fins, welding a second pair of straight fins and welding other straight fins with the same method; (3) straightening the tube; (4) processing the outer appearance of the tube; (5) examining the tube. The manufacturing method of the multi-straight fin heat exchange tube has simple manufacturing technique and low labor intensity, avoids the situation of the serious deformation and twisting of the base tube and fins in the manufacturing process of the heat exchange tube and improves the quality of the multi-straight-fin heat exchange tube.

Owner:南京科臣节能设备有限公司

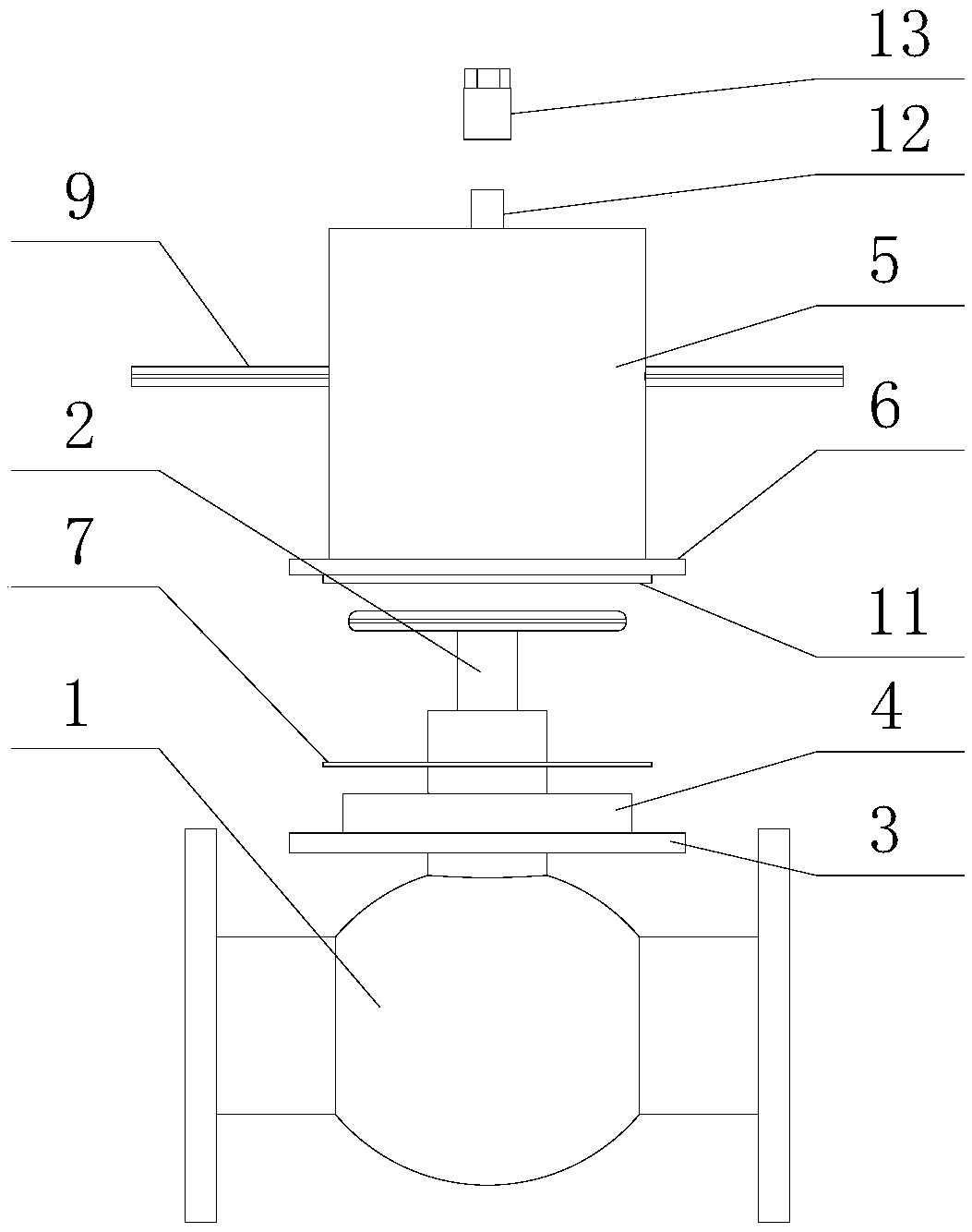

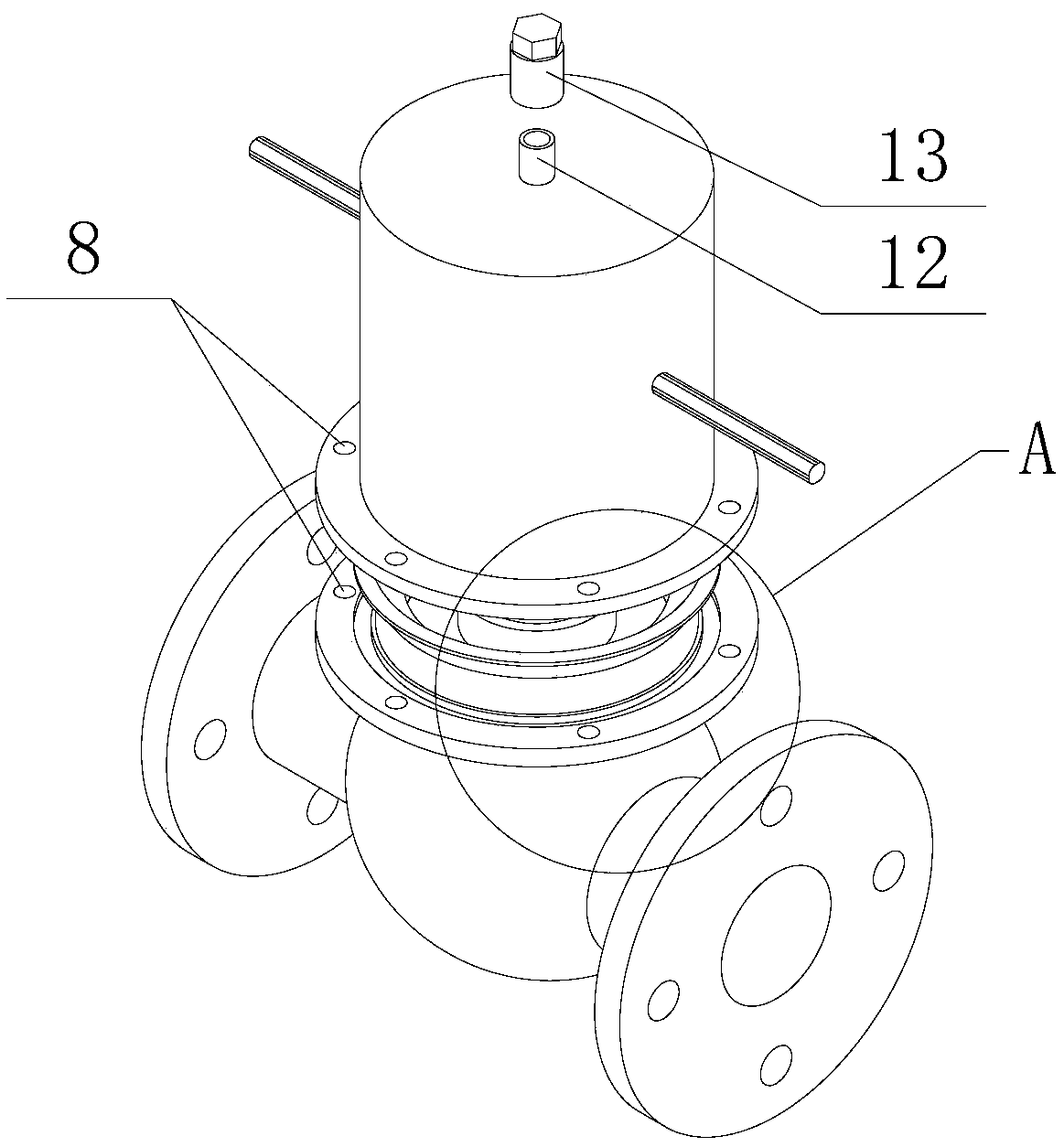

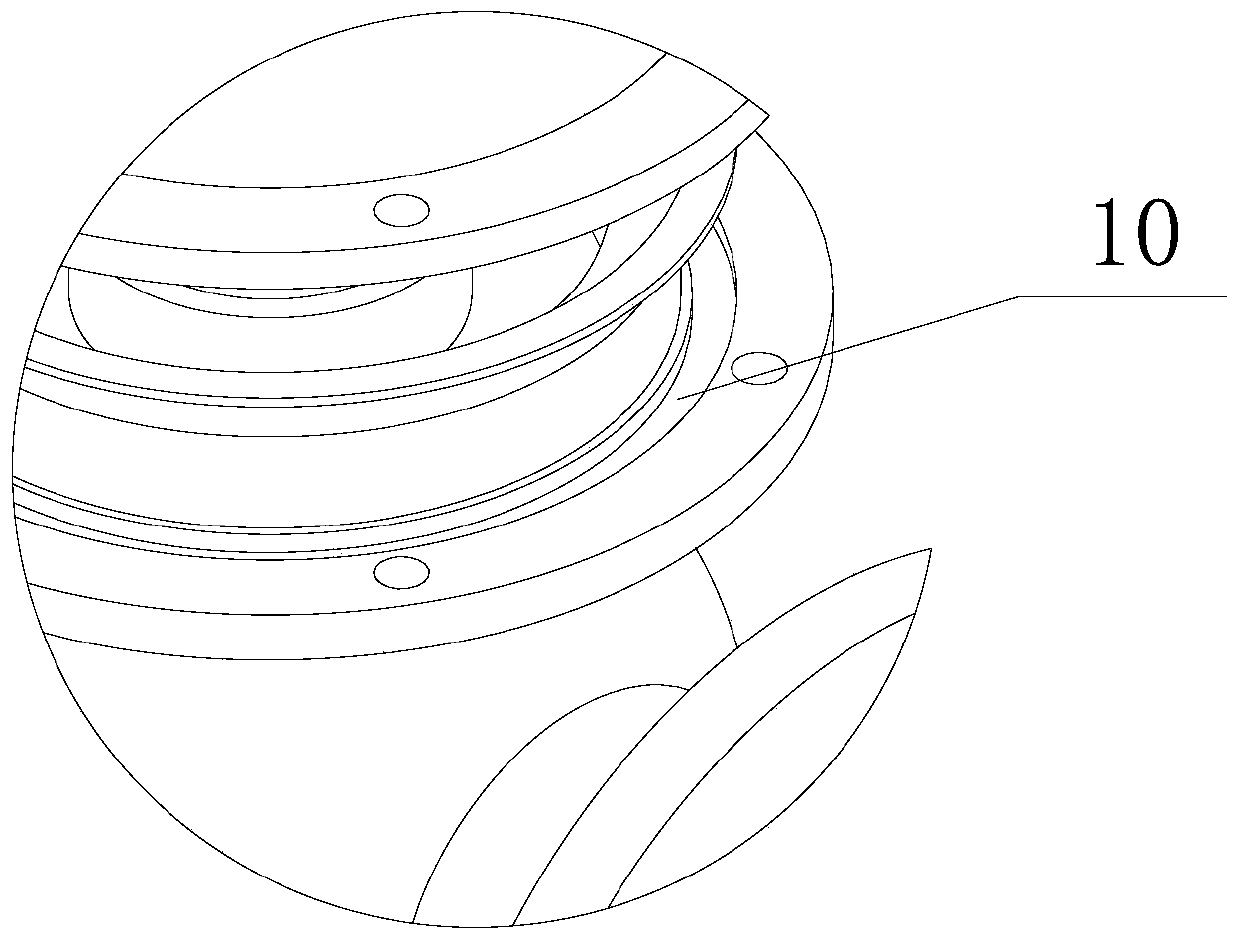

High-strength valve for steam

InactiveCN105506612APrevent leakageReduce leakageValve housingsPressure inorganic powder coatingThermodynamicsEngineering

The invention discloses a high-strength valve for steam. The high-strength valve comprises a main valve body, and the upper end of the main valve body is provided with a valve flange used for controlling connection and disconnection of the main valve body; the portion, located under the valve flange, of the main valve body is provided with a first installing flange, the upper end face of the first installing flange is provided with a positioning boss in an upwards extending mode, a seal sleeve is arranged over the first installing flange, the lower end of the sealing sleeve is provided with a second installing flange matched with the first installing flange, and a seal ring is arranged between the first installing flange and the second installing flange; the positioning boss is slidably matched with an inner hole of the seal sleeve, the first installing flange and the second installing flange are both provided with corresponding connecting holes, and the first installing flange is provided with an installing groove used for installing the seal ring. According to the high-strength valve for the steam, the structure is simple, the cost is low, the safety and reliability are achieved, the service life is long, stopping is not needed for replacing, only a secondary seal structure needs to be utilized to seal the overall valve again, therefore, the production persistence and stability are facilitated, and the production efficiency is improved.

Owner:YANCHENG FAIR TRUEMARK VALVES

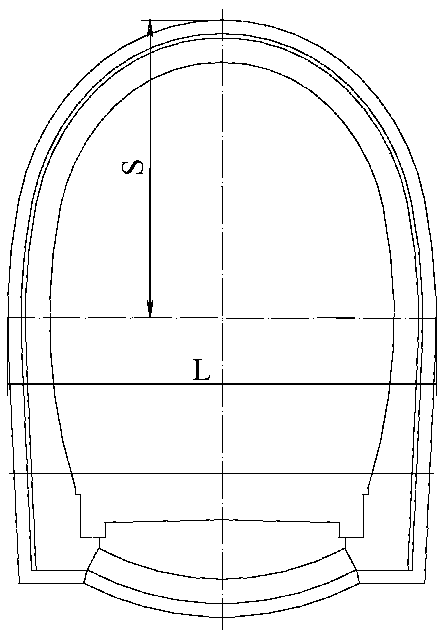

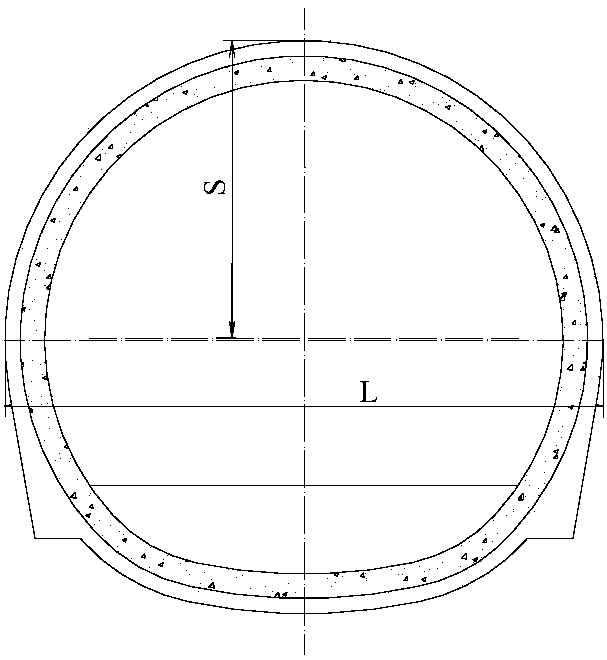

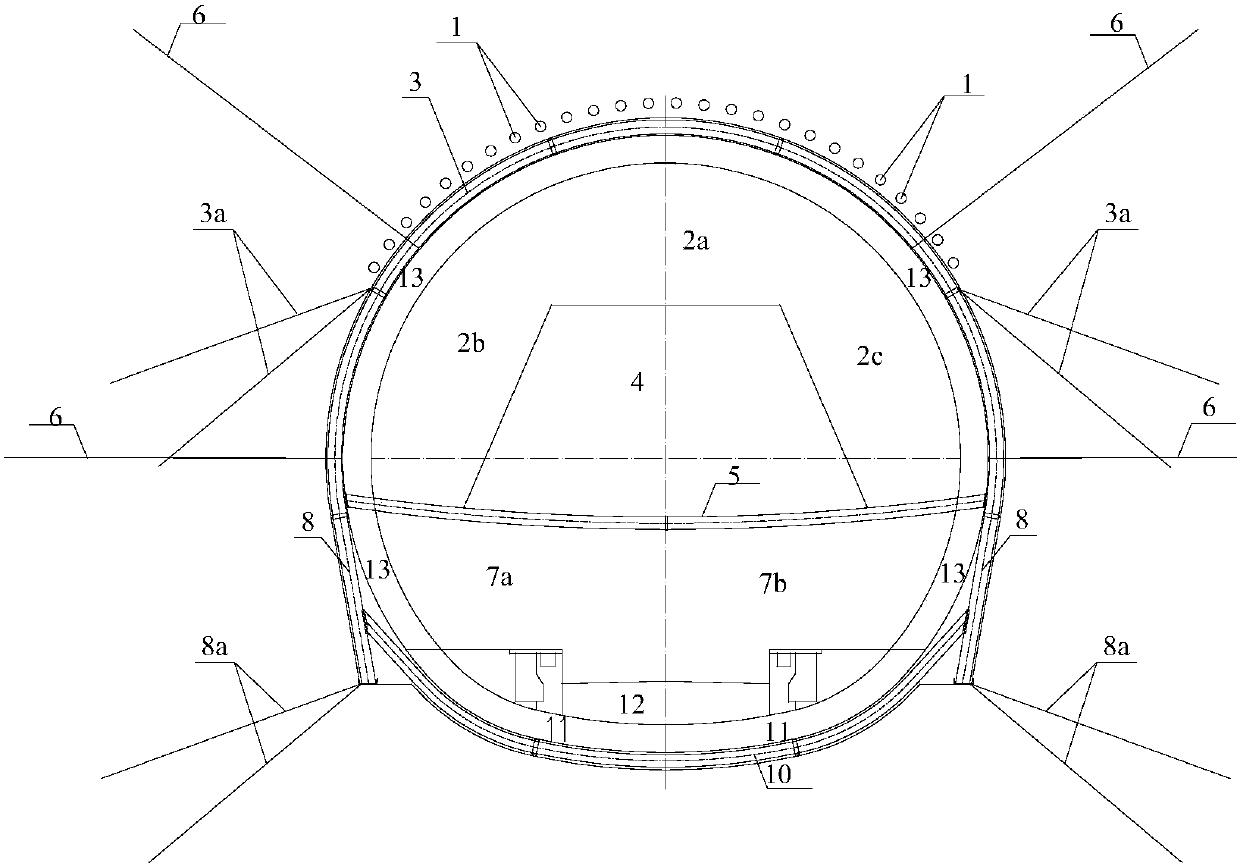

Red bed sand shale tunnel large deformation section construction method

InactiveCN110295925AImprove the forceReduce the risk of landslidesUnderground chambersTunnel liningLarge deformationClerestory

The invention discloses a red bed sand shale tunnel large deformation section construction method to effectively avoid large deformation and collapse during the construction period, lower the construction period delaying risk and improve the construction efficiency. According to the monitoring measurement condition and the deformation condition of the constructed section, the large deformation section is tested, the reserved deformation is enlarged, and the support parameter is adjusted to reinforce preliminary bracing; the rise span ratio of an excavated section is adjusted according to crownsettlement, horizontal displacement and inverted arch deformation condition, and the excavated section of the large deformation section is determined; the rise span ratio is adjusted to be about 0.5;when the horizontal displacement value is larger, the crown settlement value is smaller relative to the horizontal displacement value and inverted arch deformation is not generated, the excavated section of the large deformation section is determined to be semi-circular; and when the crown settlement value, horizontal displacement value and inverted arch deformation upheaval value are larger, theexcavated section of the large deformation section is determined to be circular.

Owner:中铁二院(成都)建设发展有限责任公司

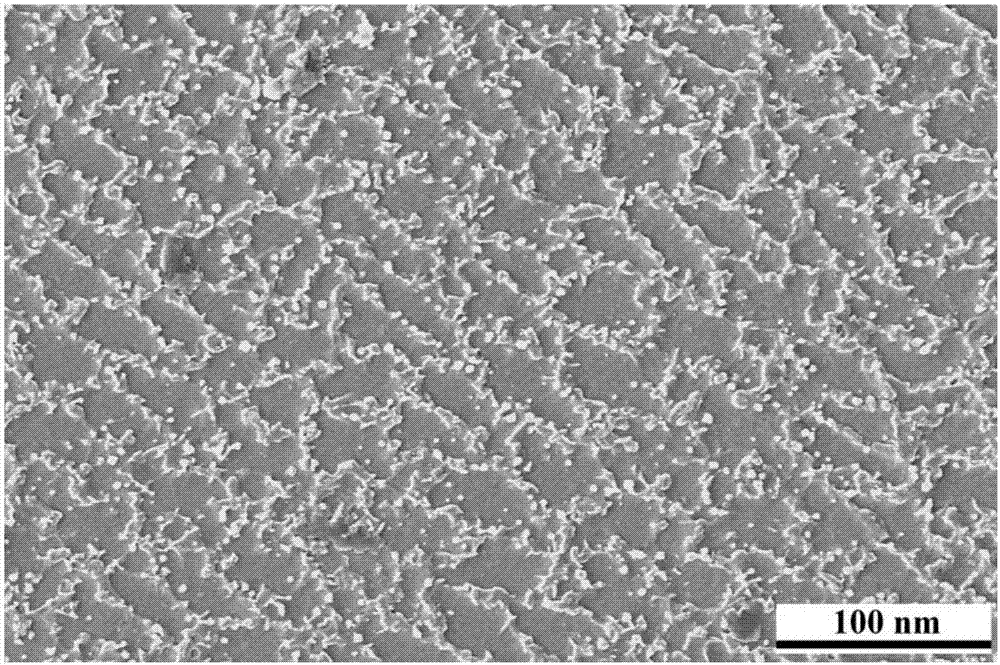

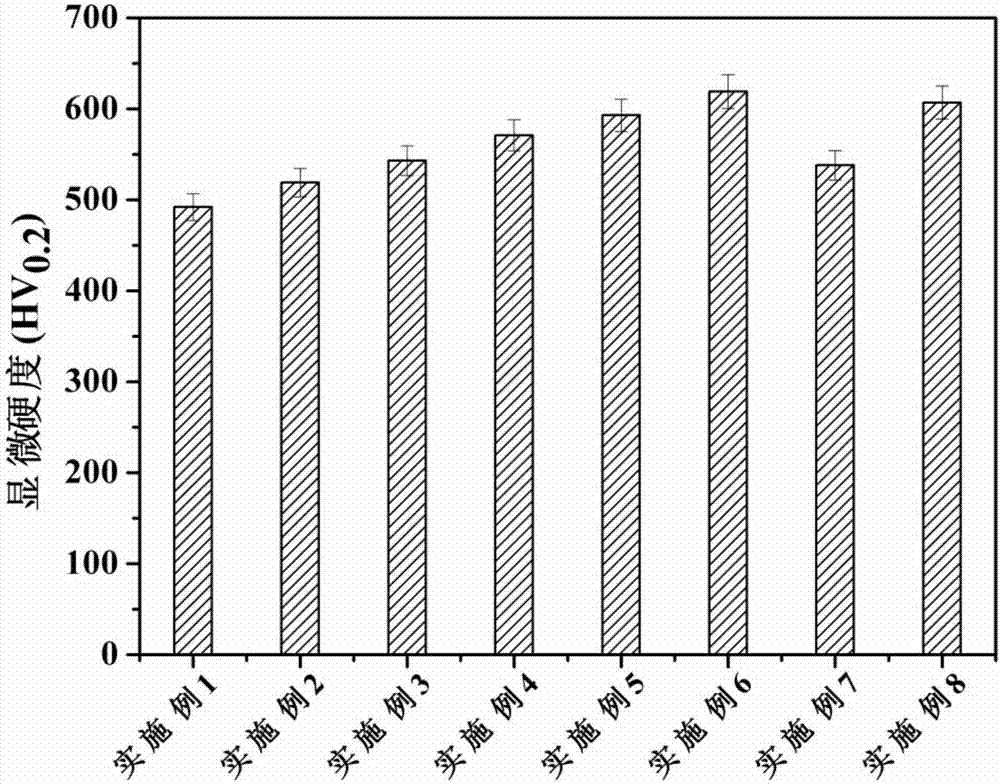

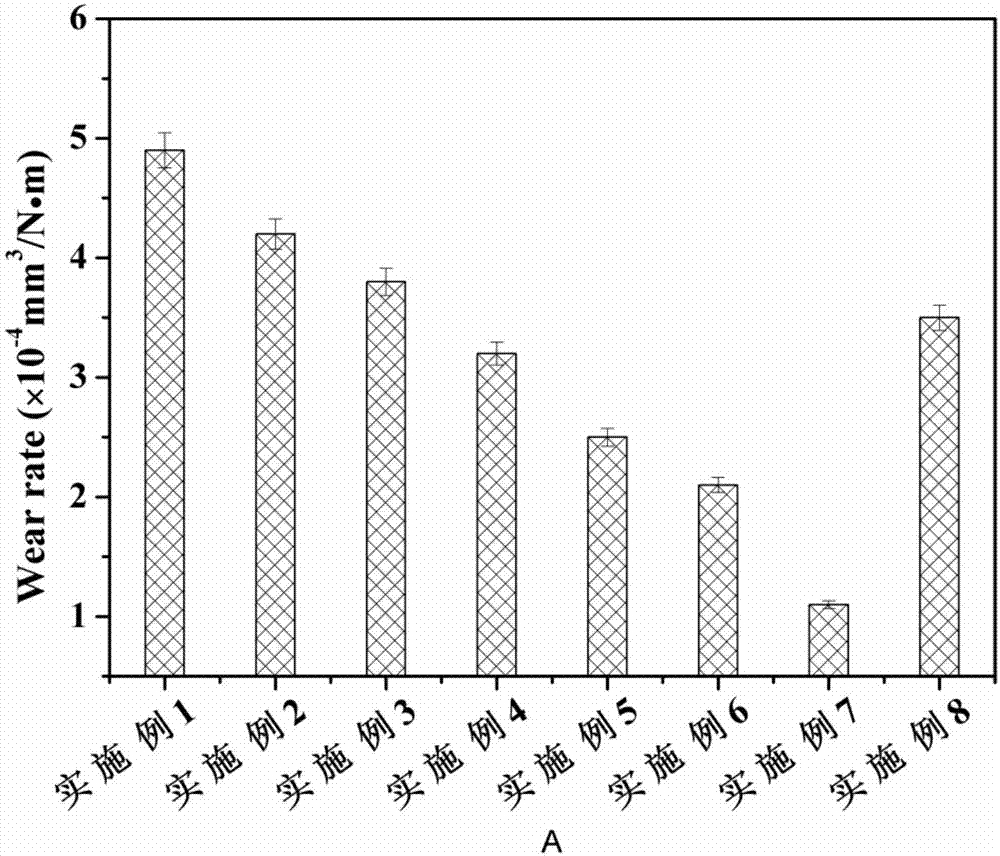

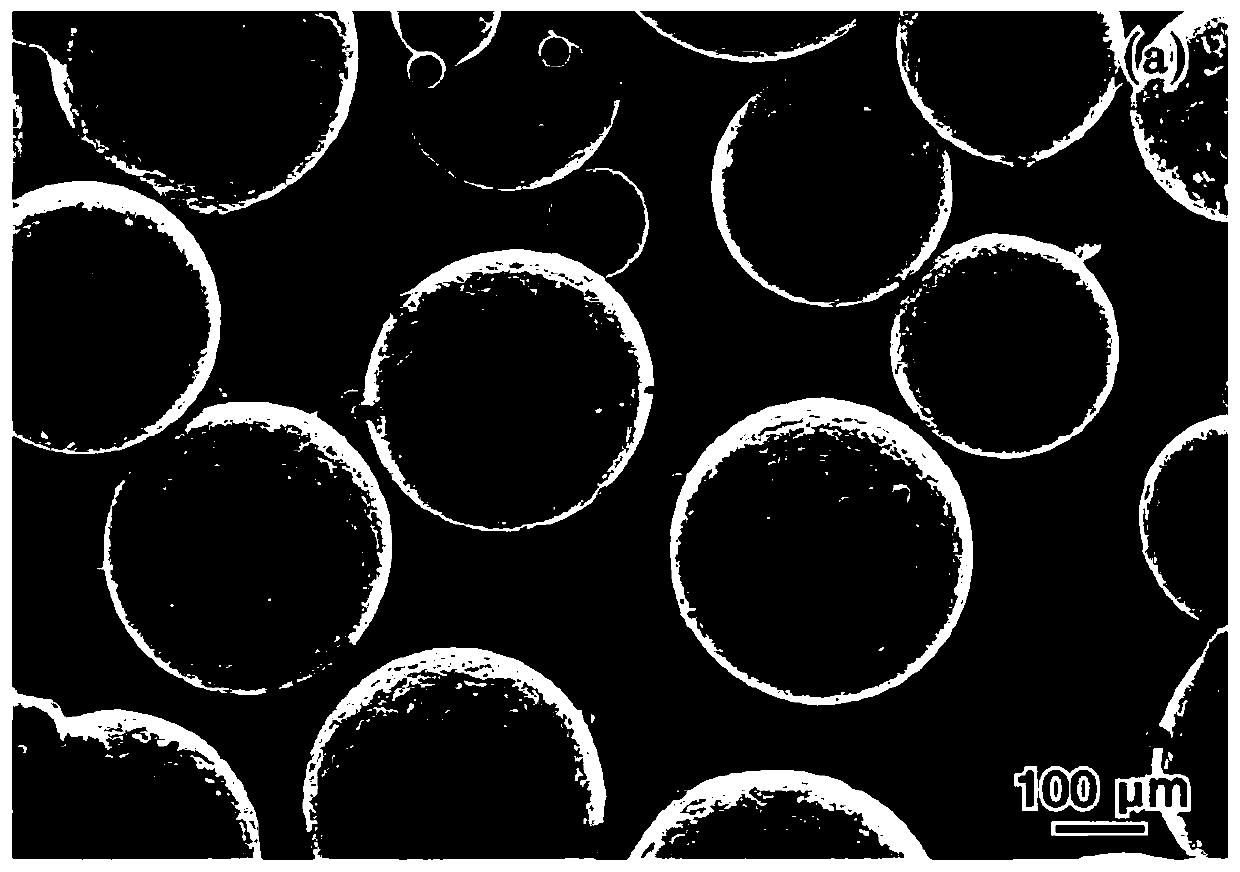

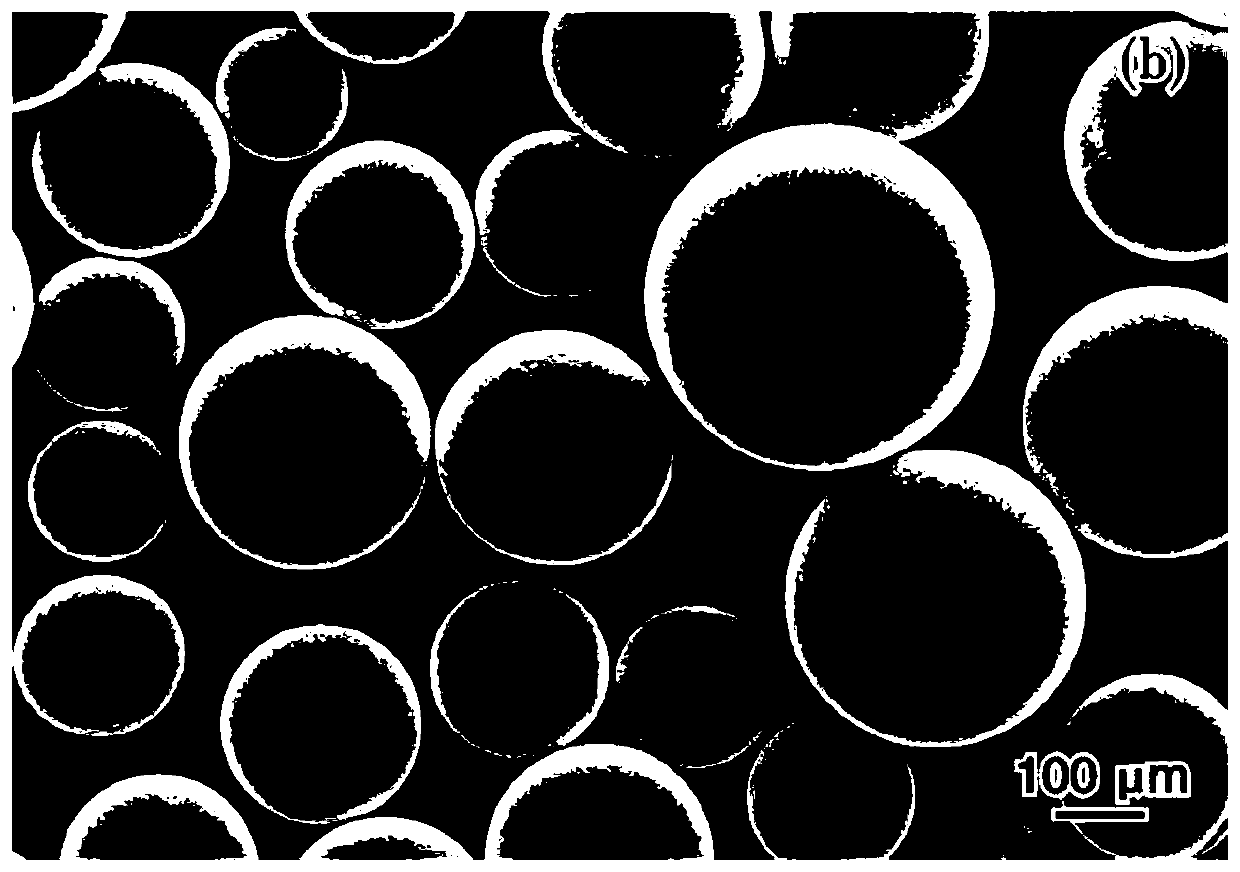

Dual-phase in-situ nano-enhanced ti-based composite material and preparing method thereof

ActiveCN108004426AImprove organizationHigh strengthAdditive manufacturing apparatusIncreasing energy efficiencyTitanium matrix compositesManufacturing technology

The invention discloses a dual-phase in-situ nano-enhanced ti-based composite material and a preparing method thereof. The preparing method is based on titanium / aluminum and titanium / silicon in-situ reaction characteristics, a laser selective fusion manufacturing technology is used, through the high energy laser beam high temperature inducing effect, titanium / aluminum and titanium / silicon chemicalaction is promoted, and in-situ reaction of Ti3Al and Ti5Si3 nano-enhanced phases is achieved; through technological condition optimization, the flow characteristic of the microcell molten bath nano-enhanced phases is regulated and controlled, homodisperse of the nano-enhanced phases in a titanium alloy base is promoted, and the Ti3Al and Ti5Si3 dual-phase nano ceramic in-situ scattered reinforced titanium matrix composite material is further obtained. According to the preparation method, the process method is simple, the cost is low, the good ceramic / titanium alloy metallurgical bonding interface is better formed, and the wettability of the ceramic / titanium alloy interface is obviously strengthened; and meanwhile, the dual nano-enhanced phases evenly dispersed into the titanium alloy base can effectively improve the comprehensive performance of the ti-based composite material.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

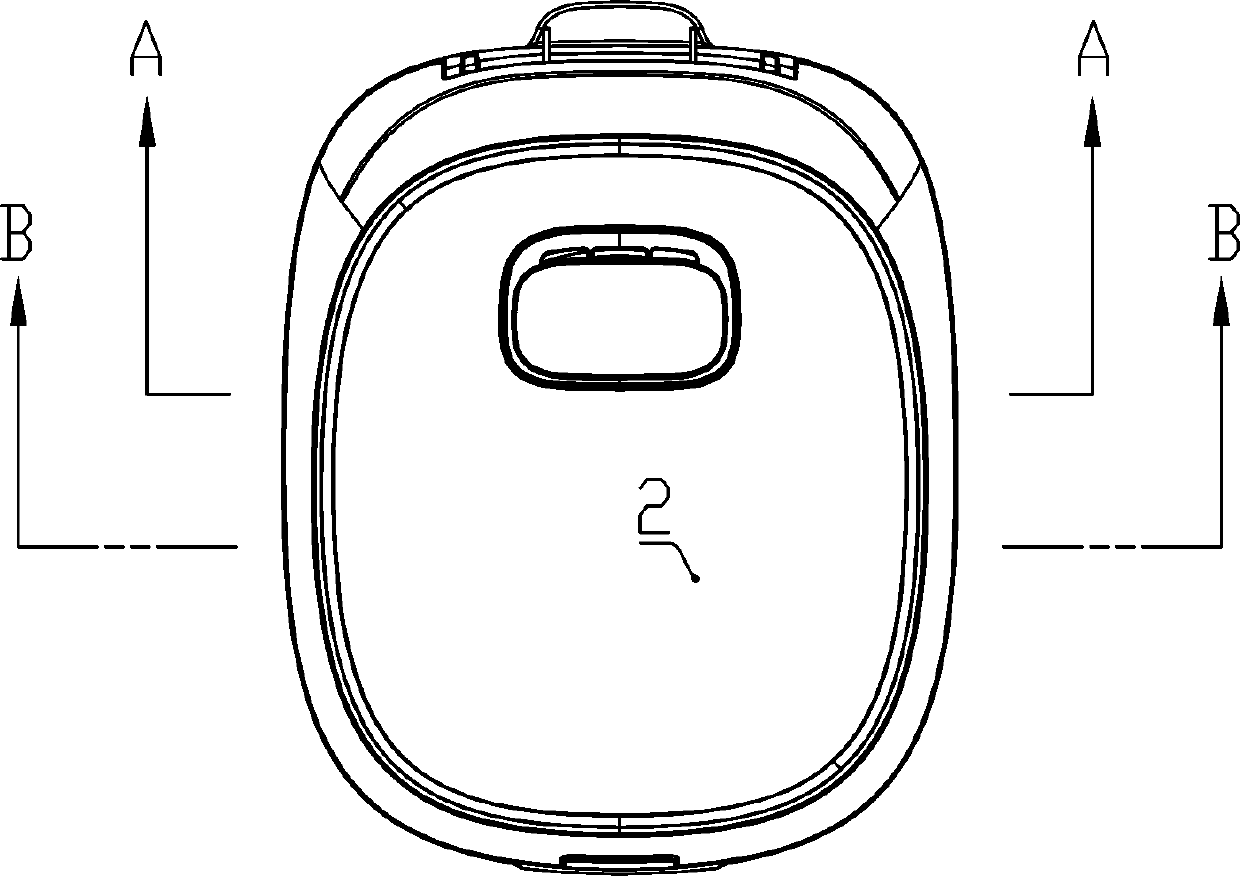

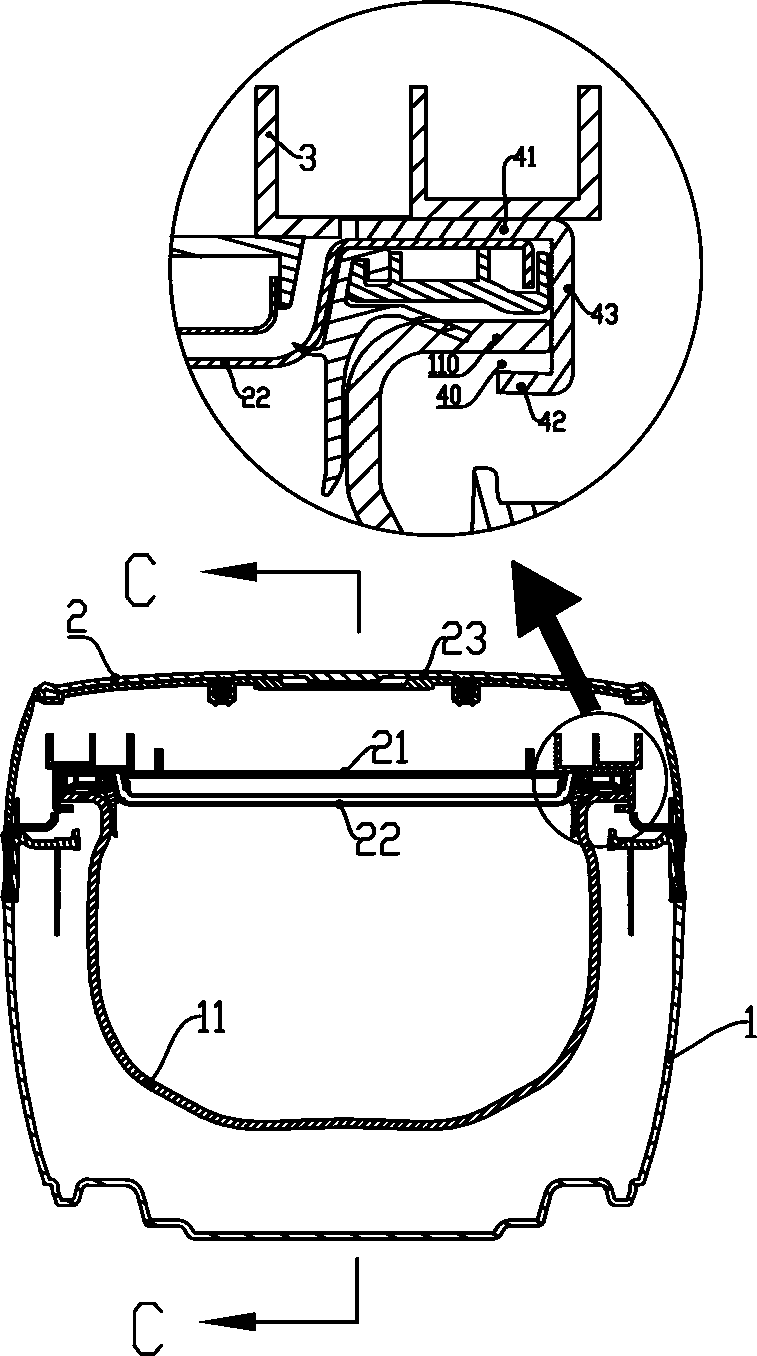

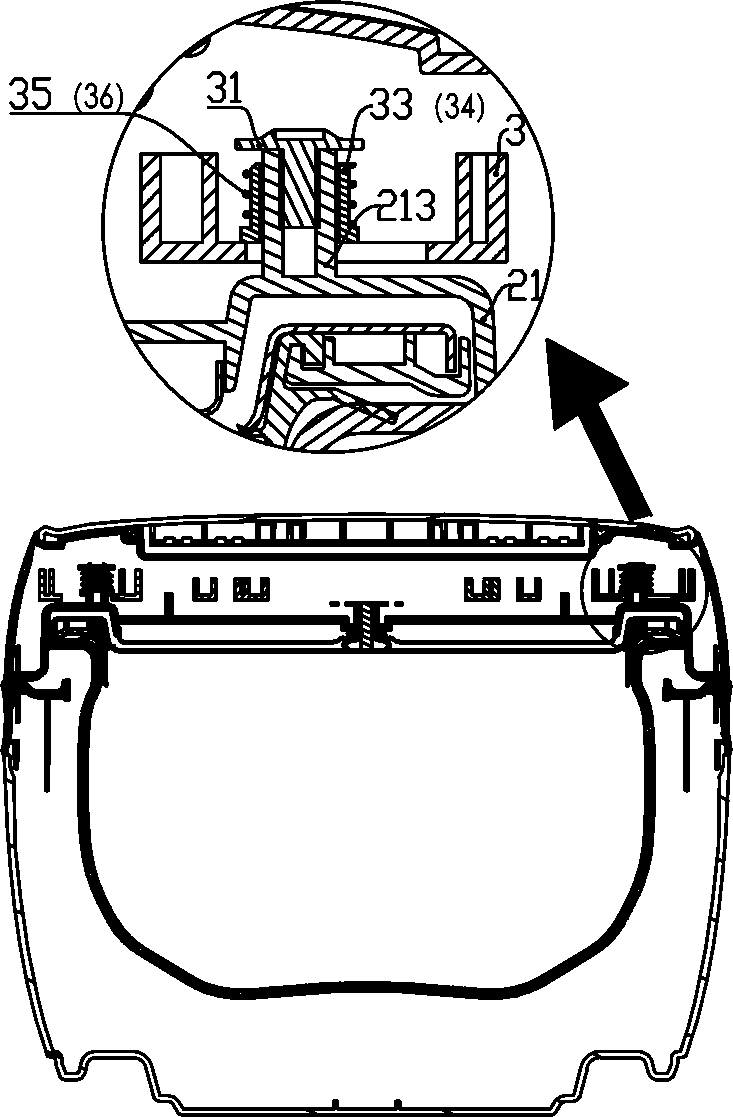

Cooking utensil with pushing mechanism

PendingCN110269507AFlexible adjustmentImprove operational stabilityPressure-cookersLocking mechanismEngineering

The invention discloses a cooking utensil with a pushing mechanism. The cooking utensil comprises a pot base, an inner pot placed on the pot base, and a pot cover hinged to the rear end of the pot base in a turnover mode; the inner pot is provided with a rigid pot edge protruding outwards; the pot cover comprises an outer cover and a rigid component mounted below the outer cover, and the pot cover is used for covering a pot opening of the inner pot on the basis of a cover closing action; the cooking utensil is characterized in that a locking mechanism is arranged on the outer cover and comprises one or more pairs of supporting frames slidably arranged on the outer cover; each supporting frame is provided with one or more rigid clamping devices with clamping openings; and the rigid clamping devices are used for being able to at least clamp the rigid component and the rigid pot edge of the inner pot through the clamping openings when the supporting frames drive the rigid clamping devices to move in the center direction of the outer cover, and also used for being able to release the rigid pot edge of the inner pot when the supporting frames drive the rigid clamping devices to move in the outer-side direction of the outer cover.

Owner:拓浦精工智能制造(邵阳)有限公司

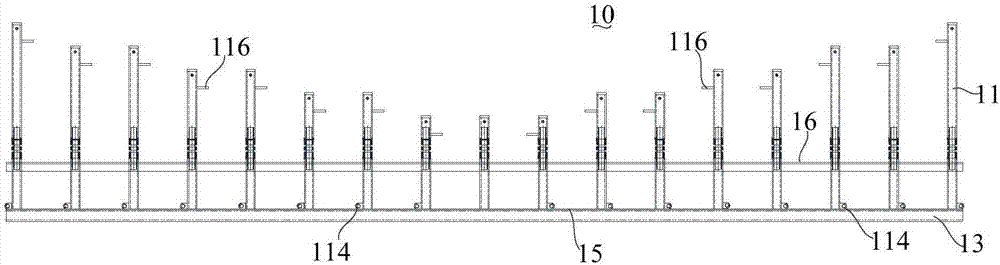

Machining tooling and method for curved panel

The invention provides a machining tooling and method for a curved panel. The machining tooling for the curved panel comprises a plurality of vertical columns used for supporting the curved panel. Themultiple vertical columns are distributed at intervals in parallel. Each vertical column comprises a bottom pipe, a top pipe opposite to the upper part and the lower part of the bottom pipe and a lead screw arranged between the bottom pipe and the top pipe. The top ends of the top pipes are used for being fixedly connected with the curved panel. The two ends of each lead screw are connected withthe corresponding bottom pipe and the corresponding top pipe in a threaded mode correspondingly. The middle of each lead screw is provided with a holding part. The lead screws are rotated through theholding parts, and the distance from each bottom pipe to the corresponding top pipe is adjusted. The end faces of the top ends of the multiple vertical columns form a curved surface, and the degree ofcurve of the curved surface is consistent with the designed degree of curve of the curved panel. The degree of curve of the curved panel is corrected according to the end faces of the top ends of thevertical columns so that the curved panel can be fixed to the machining tooling. Therefore, when the curved panel is machined again, the large deformation quantity of the curved panel cannot occur, the stability of the shape of the curved panel is ensured, and segment and folding assembly of the curved panel are facilitated.

Owner:HAIYANG CIMC RAFFLES OFFSHORE +1

Recovery processing method for waste Ti or Ti alloy powder in additive manufacturing

The invention relates to a recovery processing method for waste Ti or Ti alloy powder in additive manufacturing. Under inert gas shielding and an indoor temperature condition of 10-20 DEG C, the wasteTi or Ti alloy powder is processed by the steps that (1) sodium amalgam is added into the waste Ti or Ti alloy powder in additive manufacturing, so a mixed sizing agent is obtained; (2) the mixed sizing agent obtained at the step (1) is mixed, so the mixed sizing agent can reach a fluidized state; (3) an inert gas is fed into the mixed sizing agent in the fluidized state, shear friction is motivated to generate the Ti or Ti alloy powder and evaporation of sodium amalgam in the sizing agent is accelerated through convection effects between bubbles generated in the mixed sizing agent and the sizing agent, so solid Ti or Ti alloy powder is obtained through separation; and (4) the Ti or Ti alloy powder obtained at the step (3) is cleaned and dried, so the Ti or Ti alloy powder which can be reused in additive manufacturing is obtained.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com