High-strength valve for steam

A high-strength, valve technology, applied in valve details, valve device, valve shell structure, etc., can solve problems such as hindering the stable and long-term operation of the production system, reducing system pressure, destroying the sealing system, etc., to achieve simple and effective leakage problems, improve airtightness performance, effect of increasing corrosion resistance and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

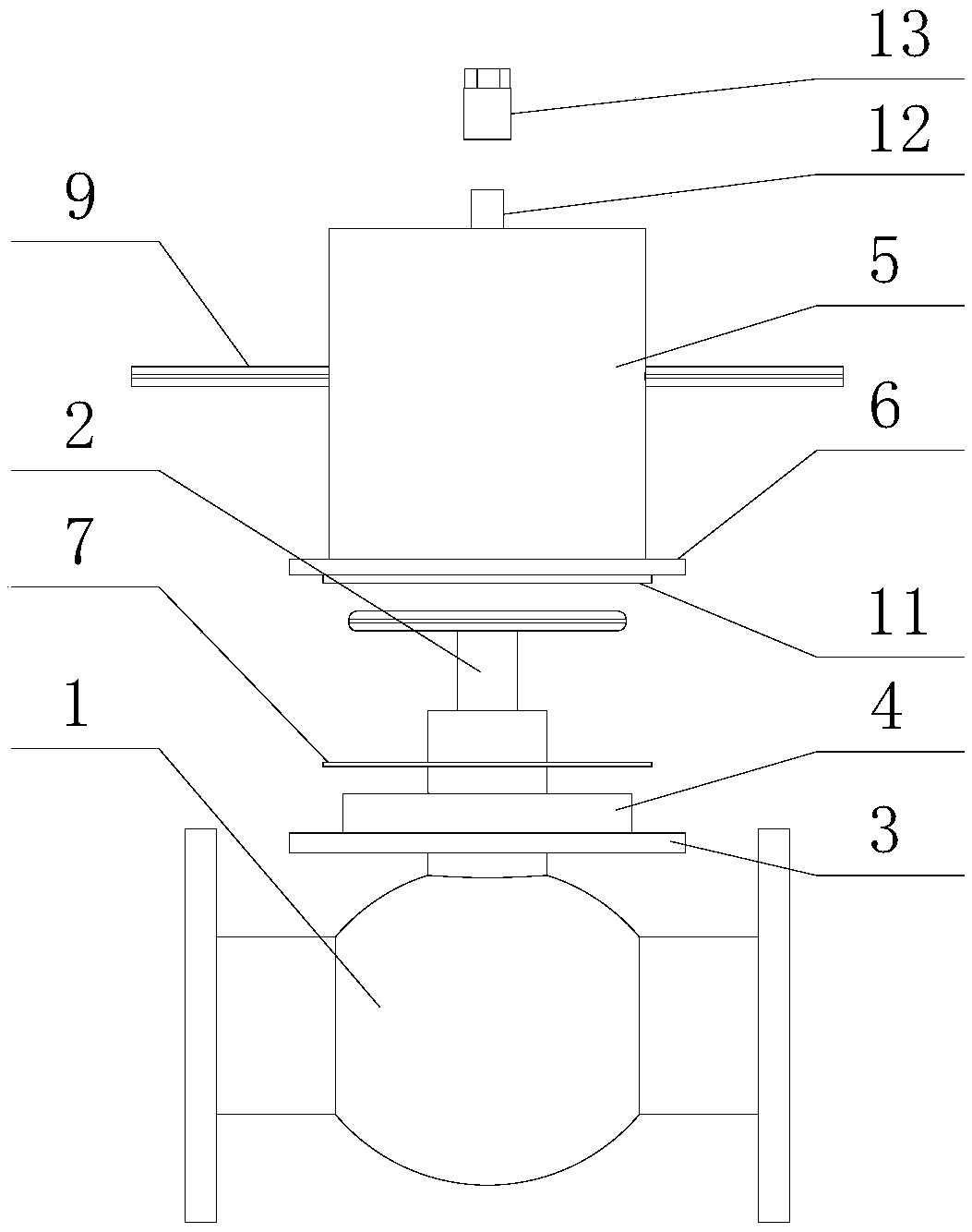

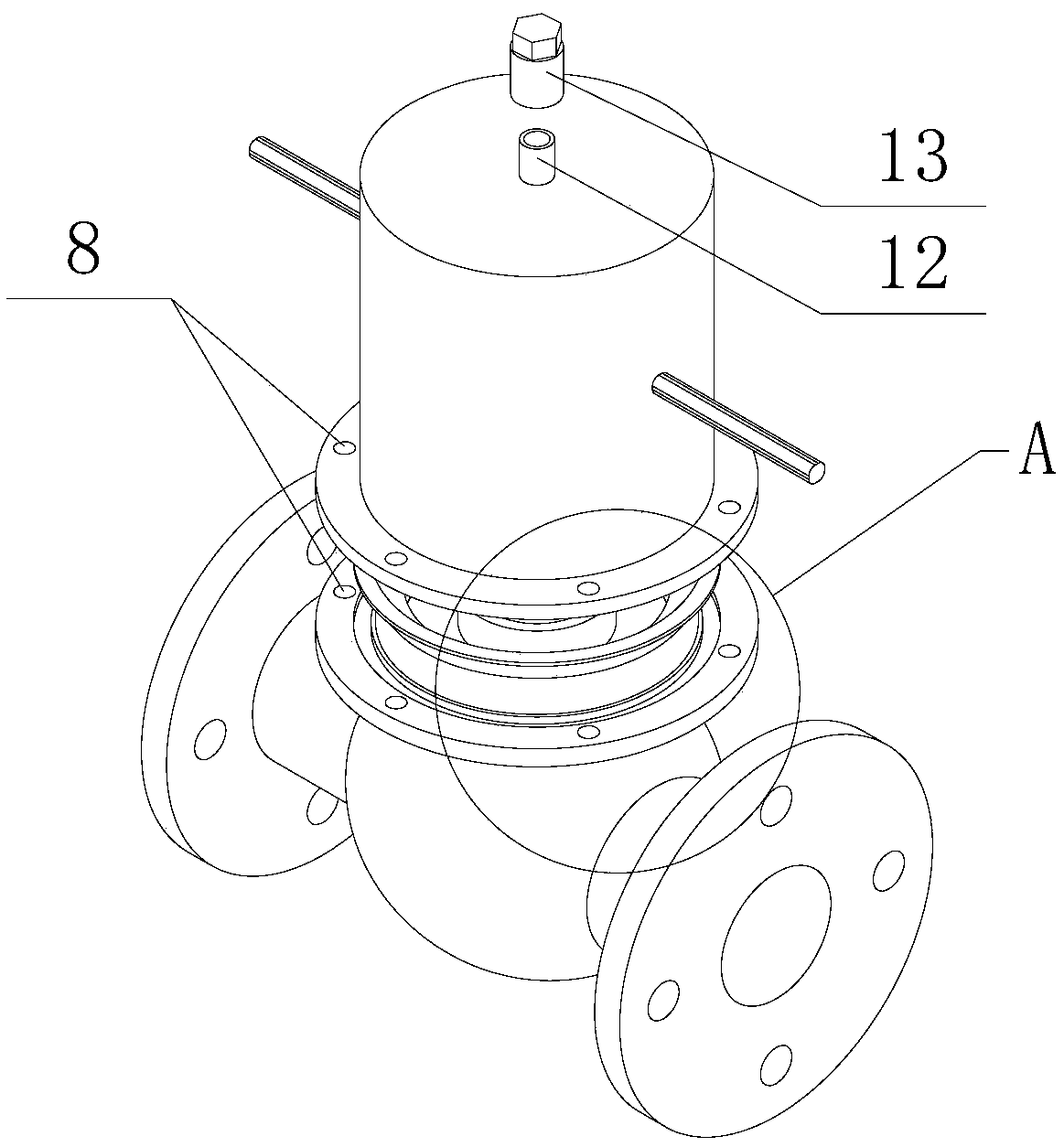

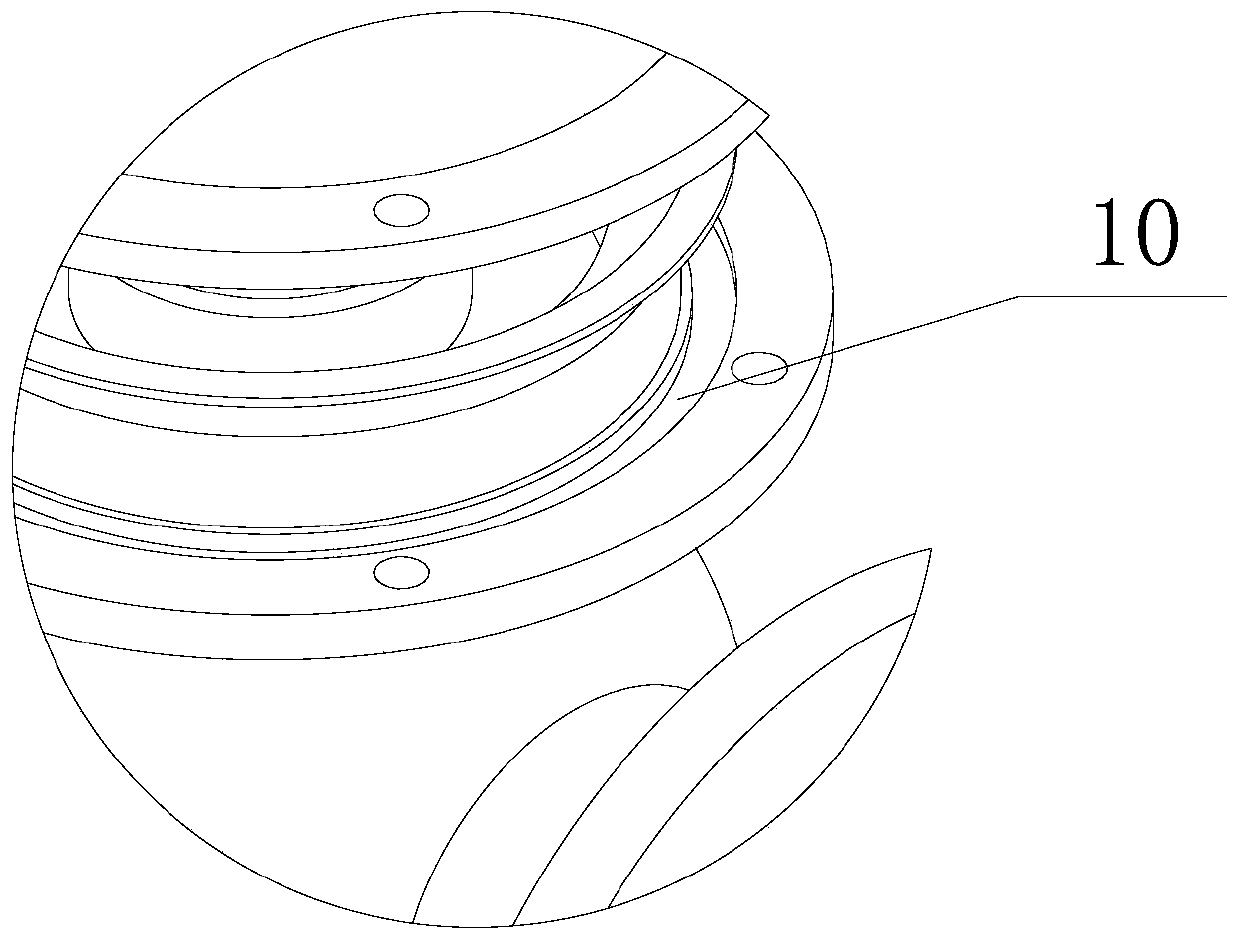

[0040] A high-strength valve for steam provided in this embodiment includes a main valve body 1, and a valve flange 2 for controlling the on-off of the main valve body 1 is provided on the upper end of the main valve body 1. A first mounting flange 3 is provided below the flange 2, a positioning boss 4 extends upward on the upper end of the first mounting flange 3, a sealing sleeve 5 is provided above the first mounting flange 3, and a sealing sleeve 5 is provided at the lower end of the sealing sleeve 5. The second mounting flange 6 matched with the first mounting flange 3 is also provided with a sealing ring 7 between the first mounting flange 3 and the second mounting flange 6, and the positioning boss 4 and the inner hole of the sealing sleeve 5 Sliding fit, and the first mounting flange 3 and the second mounting flange 6 are provided with corresponding connecting holes 8, on the first mounting flange 3 there is an installation groove 10 for installing the sealing ring 7, a...

Embodiment 2

[0051] This embodiment provides a high-strength valve for steam, and the high-strength valve for steam in this embodiment has the same structure as that in Embodiment 1;

[0052] Among them, the sealing sleeve 5, the main valve body 1, and the valve flange 2 are covered with a layer of high-strength metal coating. The components of the high-strength metal coating are: carbon: 0.12%, boron: 0.26%, Chromium: 14.47%, Titanium: 0.24%, Magnesium: 2.52%, Nickel: 5.54%, Manganese: 2.53%, Niobium: 0.22%, Cobalt: 1.42%, Copper: 0.21%, Tungsten: 0.21%, Molybdenum: 0.64%, Zinc: 3.22%, Samarium: 4.63%, Neodymium: 2.24%, Promethium: 0.62%, Dysprosium: 0.21%, Thulium: 4.23%, Auxiliary: 3.42%, and the balance is iron;

[0053] The components of the additives are calculated in parts by weight: forsterite: 5 parts, cerium oxide: 12 parts, titanium dioxide: 17 parts, graphite powder: 14 parts, nickel powder: 13 parts, silicon carbide: 11 parts, ceramic powder : 7 copies;

[0054] The preparat...

Embodiment 3

[0062] This embodiment provides a high-strength valve for steam, and the high-strength valve for steam in this embodiment has the same structure as that in Embodiment 1;

[0063] Among them, the surface of the sealing sleeve 5, the main valve body 1, and the valve flange 2 is coated with a layer of high-strength metal coating, and the components of the high-strength metal coating are by mass percentage: The components of the high-strength metal coating are by mass The percentages are: Carbon: 0.15%, Boron: 0.28%, Chromium: 14.49%, Titanium: 0.53%, Magnesium: 2.55%, Nickel: 5.58%, Manganese: 2.82%, Niobium: 0.24%, Cobalt: 1.45%, Copper: 0.23%, Tungsten: 0.23%, Molybdenum: 0.68%, Zinc: 3.24%, Samarium: 4.66%, Neodymium: 2.28%, Promethium: 0.65%, Dysprosium: 0.24%, Thulium: 4.26%, Additives: 3.45%, Yu amount of iron;

[0064] The components of the additives are calculated in parts by weight: forsterite: 8 parts, cerium oxide: 14 parts, titanium dioxide: 19 parts, graphite powder: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com